Response to Sensor-Based Fertigation of Nagpur Mandarin (Citrus reticulata Blanco) in Vertisol of Central India

Abstract

1. Introduction

2. Materials and Methods

2.1. Site Description, Meteorological Data, Cultivation Practices and Experimental Design

2.2. Fertigation Scheduling

2.3. Irrigation Water Quality and Soil Properties

2.4. Irrigation Setup for Sensor-Based (IoT) Fertigation

2.5. Observations of Key Growth Parameters

2.6. Fruit Yield and Fruit Analysis

2.7. Determination of Leaf and Fruit Nutrient Composition

2.7.1. Sample Collection and Preparation

2.7.2. Digestion and Analysis

2.8. Statistical Analysis

3. Results and Discussion

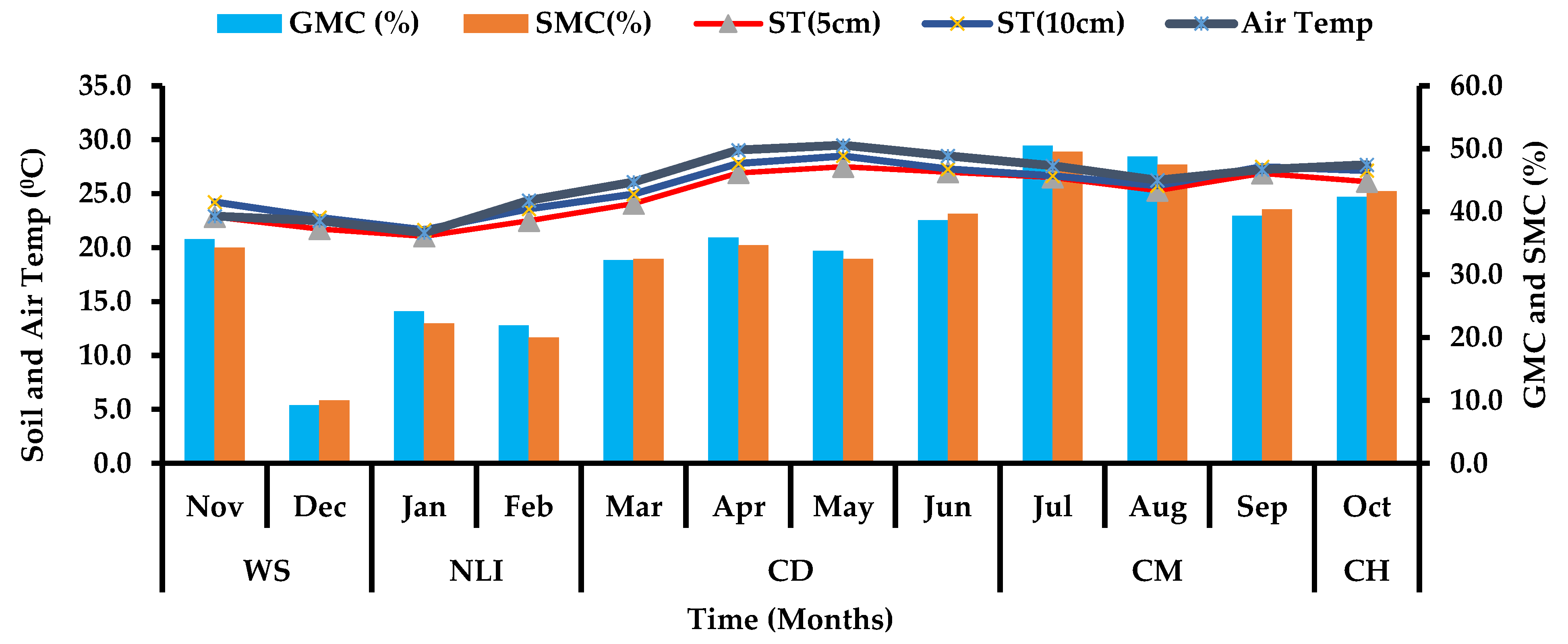

3.1. Dynamics of Crop Phenology and Distribution of Soil Moisture

3.2. Plant Growth Characteristics in Response to Fertigation Scheduling

3.3. Sensor-Based (IoT) Fertigation and Fruit Quality Parameters

3.4. Effect of Sensor-Based Ferigation Scheduling Treatments on Yield Attributes and WP

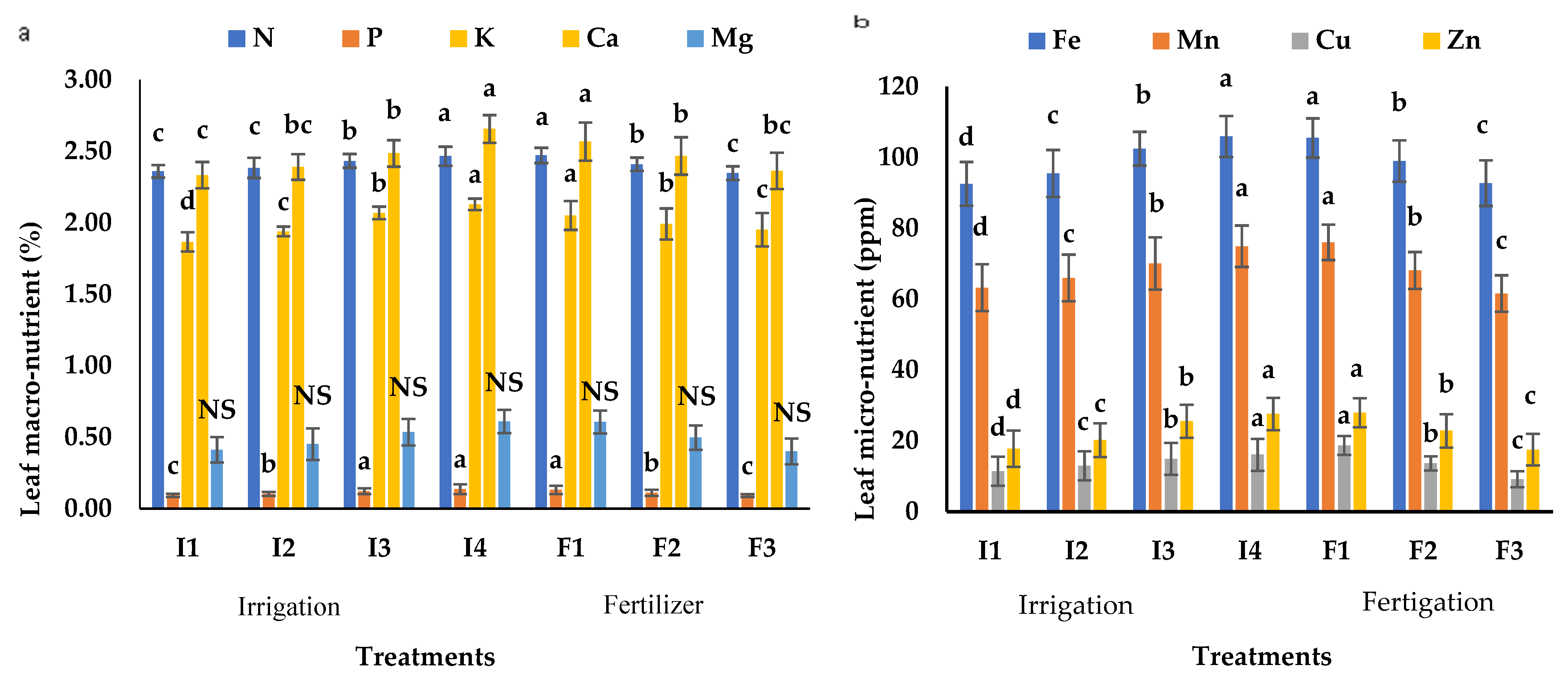

3.5. Response of Sensor-Based (IoT) Fertigation on Leaf Nutrient Composition

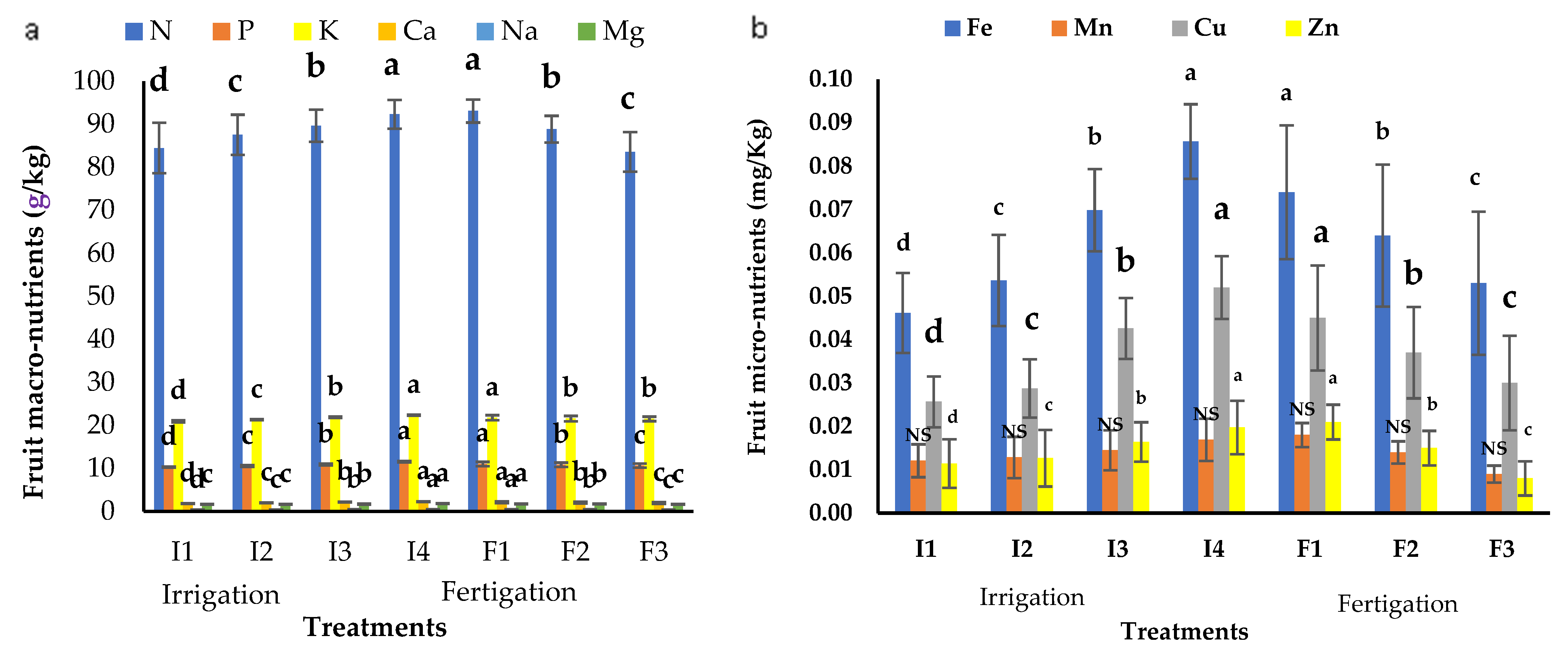

3.6. Sensor-Based Fertigation Scheduling Treatments and Fruit Nutrient Composition

3.7. Sensor-Based Fertigation Scheduling Treatments and Distribution of Fruit Size

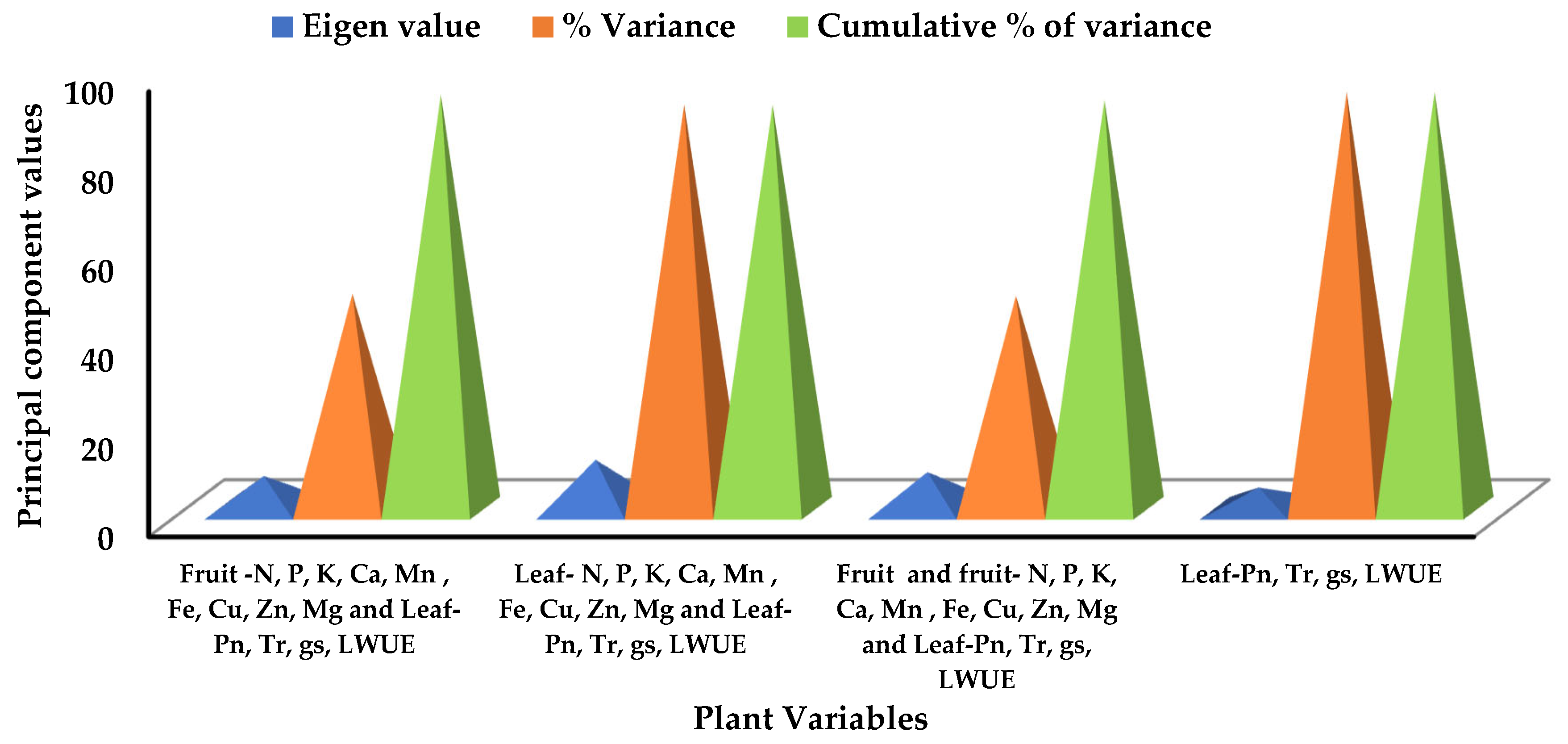

3.8. Correlation Between Fruit Yield and Other Plant-Based Variables

3.9. Improvements in WUE and NUE

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Huchche, A.; Srivastava, A.; Ram, L.; Singh, S. Statistical Basis of Production Sustainability of Citrus Orchards. Trop. Agric. Trinidad 2013, 90, 217–222. [Google Scholar]

- Kourgialas, N.N.; Karatzas, G.P. A Modeling Approach for Agricultural Water Management in Citrus Orchards: Cost-Effective Irrigation Scheduling and Agrochemical Transport Simulation. Environ. Monit. Assess. 2015, 187, 462. [Google Scholar] [CrossRef] [PubMed]

- Indian Council of Agricultural Research—Central Citrus Research Institute (ICAR—CCRI). Vision—2050; Indian Council of Agricultural Research: New Dehli, India, 2015; p. 40. [Google Scholar]

- Kumar, D.; Bhattacharyya, S.; Ghosh, D. Assessing the Export Potential of Nagpur Mandarin: The Promising Citrus Fruit of Central India. Curr. Sci. 2023, 124, 782–784. [Google Scholar]

- Government of India NHB (National Horticulture Board). Ministry of Agricultural and Farmer Welfare; Government of India NHB (National Horticulture Board): New Delhi, India, 2020. [Google Scholar]

- Shirgure, P. Micro-Irrigation Systems, Automation and Fertigation in Citrus. Sci. J. Rev. 2012, 1, 156–169. [Google Scholar]

- Carr, M.K.V. The Water Relations and Irrigation Requirements of Citrus (Citrus SPP.): A Review. Exp. Agric. 2012, 48, 347–377. [Google Scholar] [CrossRef]

- Ladaniya, M.; Marathe, R.A.; Murkute, A.; Huchche, A.; Das, A.; George, A.; Kolwadkar, J. Response of Nagpur Mandarin (Citrus Reticulata Blanco) to High Density Planting Systems. Sci. Rep. 2021, 11, 10845. [Google Scholar] [CrossRef]

- Anonymous Indian Horticulture Database; National Horticulture Board: New Delhi, India, 2019.

- Kumar, S.; Kumawat, P.; Choudhary, K. Irrigation Scheduling and Fertigation in Citrus Fruit Crops. Chem. Sci. Rev. Lett. 2020, 9, 418–420. [Google Scholar]

- Panigrahi, P.; Srivastava, A. Water and Nutrient Management Effects on Water Use and Yield of Drip-Irrigated Citrus in Vertisol under a Sub-Humid Region. J. Integr. Agric. 2017, 16, 1184–1194. [Google Scholar] [CrossRef]

- Srivastava, A.K.; Singh, S. Citrus Decline: Soil Fertility and Plant Nutrition. J. Plant Nutr. 2009, 32, 197–245. [Google Scholar] [CrossRef]

- Srivastava, A.K. Nutrient Management in Nagpur Mandarin: Frontier Developments. Sci. J. Agric. 2013, 2. [Google Scholar]

- Ayyappan, S. NRCC Vision—2030; National Centre for Citrus Research: Nagpur, India, 2011. [Google Scholar]

- Panigrahi, P.; Sharma, R.K.; Hasan, M.; Parihar, S. Deficit Irrigation Scheduling and Yield Prediction of ‘Kinnow’ Mandarin (Citrus Reticulate Blanco) in a Semiarid Region. Agric. Water Manag. 2014, 140, 48–60. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, J.; Li, L.; Zhang, Y.; Yang, G. Monitoring Citrus Soil Moisture and Nutrients Using an IoT Based System. Sensors 2017, 17, 447. [Google Scholar] [CrossRef]

- Allen, R.G.; Pereira, L.S.; Raes, D.; Smith, M. Crop Evapotranspiration, Guideline for Computing Crop Water Requirements. Irrig. Drain. 1998, 56, D05109. [Google Scholar]

- Boopathy, S.; Premkumar, P.; Ramkumar, N.; Govindaraju, P.K.P. Implementation of Automatic Fertigation System by Measuring the Plant Parameters. Int. J. Eng. Res. Technol. 2014, 3. [Google Scholar]

- Ghadge, K.M.; Ghadge, H.K.; Seeman, V. Fertigation System to Conserve Water and Fertilizers Using Wireless Sensor Network. Int. J. Eng. Res. Comput. Sci. Eng. 2018, 5, 20–25. [Google Scholar]

- Visconti, P.; De Fazio, R.; Primiceri, P.; Cafagna, D.; Strazzella, S.; Giannoccaro, N.I. A Solar-Powered Fertigation System Based on Low-Cost Wireless Sensor Network Remotely Controlled by Farmer for Irrigation Cycles and Crops Growth Optimization. Int. J. Electron. Telecommun. 2020, 66, 59–68. [Google Scholar] [CrossRef]

- Basterrechea, D.A.; Parra, L.; Botella-Campos, M.; Lloret, J.; Mauri, P.V. New Sensor Based on Magnetic Fields for Monitoring the Concentration of Organic Fertilisers in Fertigation Systems. Appl. Sci. 2020, 10, 7222. [Google Scholar] [CrossRef]

- Domínguez-Niño, J.M.; Oliver-Manera, J.; Girona, J.; Casadesús, J. Differential Irrigation Scheduling by an Automated Algorithm of Water Balance Tuned by Capacitance-Type Soil Moisture Sensors. Agric. Water Manag. 2020, 228, 105880. [Google Scholar] [CrossRef]

- Adla, S.; Rai, N.K.; Karumanchi, S.H.; Tripathi, S.; Disse, M.; Pande, S. Laboratory Calibration and Performance Evaluation of Low-Cost Capacitive and Very Low-Cost Resistive Soil Moisture Sensors. Sensors 2020, 20, 363. [Google Scholar] [CrossRef]

- Vories, E.; Sudduth, K. Determining Sensor-Based Field Capacity for Irrigation Scheduling. Agric. Water Manag. 2021, 250, 106860. [Google Scholar] [CrossRef]

- Boman, B.J.; Smith, S.; Tullos, B. Control and Automation in Citrus Microirrigation Systems; University of Florida: Gainesville, FL, USA, 2006. [Google Scholar]

- Panigrahi, P.; Raychaudhuri, S.; Thakur, A.; Nayak, A.K.; Sahu, P.; Ambast, S.K. Automatic Drip Irrigation Scheduling Effects on Yield and Water Productivity of Banana. Sci. Hortic. 2019, 257, 108677. [Google Scholar] [CrossRef]

- Cardenas-Laichaca, B. Sensor Based Automation of Irrigation of Bermuda Grass. Ph.D. Thesis, University of Florida, Gainesville, FL, USA, 2006. [Google Scholar]

- Vij, A.; Singh, V.; Jain, A.; Bajaj, S.; Bassi, A.; Sharma, A. IoT and Machine Learning Approaches for Automation of Farm Irrigation System. Procedia Comput. Sci. 2020, 167, 1250–1257. [Google Scholar] [CrossRef]

- Li, D.; Hendricks Franssen, H.-J.; Han, X.; Jiménez-Bello, M.A.; Martínez Alzamora, F.; Vereecken, H. Evaluation of an Operational Real-Time Irrigation Scheduling Scheme for Drip Irrigated Citrus Fields in Picassent, Spain. Agric. Water Manag. 2018, 208, 465–477. [Google Scholar] [CrossRef]

- Swamy, K.D.; Rajesh, G.; Jaya Krishna Pooja, M.; Rama Krishna, A. Micro-controller Based Drip Irrigation System. Int. J. Emerg. Sci. Eng. 2013, 1, 1–4. [Google Scholar]

- Rajakumar, D.; Ramah, K.; Rathika, S.; Thiyagarajan, G. Automation in Micro-Irrigatio. Sci. Tech Entrep. 2008, 1–8. [Google Scholar]

- Shirgure, P. Citrus Fertigation—A Technology of Water and Fertilizers Saving. Sci. J. Crop Sci. 2013, 2, 56–66. [Google Scholar]

- Hendre, P.; Ranpise, S.; Pawar, P. Effect of Different Irrigation and Fertigation Levels on Fruit Quality Parameters in Sweet Orange (Citrus sinensis L. Osbeck) Cv. Phule Mosambi PD Hendre, SA Ranpise and PS Pawar. J. Pharmacogn. Phytochem. 2020, 9, 503–507. [Google Scholar]

- Srivastava, A.K.; Shirgure, P.S.; Singh, S. Differential Fertigation Response of Nagpur Mandarin (Citrus Reticulata Blanco) on an Alkaline Inceptisol under the Sub-Humid Tropical Climate of Central India. Trop. Agric. 2003, 80, 97–104. [Google Scholar]

- Pawar, P.S.; Dalal, D.K.; Bhite, D.R. Identification of Critical Stages of Water Requirement in Acid Lime (Citrus Aurantifolia Swingle) under Westyern Maharashtra Cv. Phule Sharbati. Pharma Innov. J. 2020, 9, 104–107. [Google Scholar]

- IUSS Working Group WRB. World Reference Based for Soil Resources, International Soil Classification System for Naming Soils and Creating Legends for Soil Maps, 4th ed.; International Union of Soil Sciences (IUSS): Vienna, Austria, 2022. [Google Scholar]

- Meshram, D.T.; Gorantiwar, S.D.; Singh, N.V.; Babu, K.D. Response of Micro-Irrigation Systems on growth, yield and WUE of Pomegranate (Punica granatum L.) in Semi-Arid Regions of India. Sci. Horti. 2019, 246, 686–692. [Google Scholar] [CrossRef]

- Ayars, J.E.; Johnsons, R.S.; Phene, C.J.; Trout, T.J.; Clark, D.A.; Mead, R.M. Water use by drip irrigated late season Peaches. Irr. Sci. 2003, 22, 187–194. [Google Scholar] [CrossRef]

- Srivastavaa, A.K.; Malhotra, S.K. Nutrient use efficiency in perennial fruit crop—A review. J. Plant Nutri. 2017, 40, 1928–1953. [Google Scholar] [CrossRef]

- Obreza, T.A. Young “Hamlin” Orange Tree Fertilizer Response in Southwest Florida. Proc. Fla. State Hort. Soc. 1990, 103, 12–16. [Google Scholar]

- Panigrahi, P. Integrated irrigation and drainage management foor citrus orchards in Vertisols. Irri. Drain. 2014, 63, 621–627. [Google Scholar] [CrossRef]

- Pérez-Pérez, J.; Romero, P.; Navarro, J.; Botía, P. Response of Sweet Orange Cv ‘Lane Late’ to Deficit-Irrigation Strategy in Two Rootstocks. II: Flowering, Fruit Growth, Yield and Fruit Quality. Irrig. Sci. 2008, 26, 519–529. [Google Scholar] [CrossRef]

- Ranganna, S. Hand Book of Analysis and Quality Control for Fruits and Vegetable Products, 7th ed.; Tata McGraw Hill Book Co.: New Delhi, India, 2001; pp. 594–625. [Google Scholar]

- Yiling, J.; Shuozhen, Z.; Haitao, J.; Yuwen, W.; Yamin, J.; Hua, Z.; Hua, Z.; Yuying, J.; Wenqiang, L.; Li-Song, C.; et al. Fruit quality assessment based on mineral elements and juice properties in nine citrus cultivar. Front Plants Sci. 2023, 14, 1280495. [Google Scholar] [CrossRef]

- Srivastava, A.; Kohli, R.; Huchche, A. Relationship of Leaf K and Forms of Soil K at Different Growth Stages of Nagpur Mandarin. J. Indian Soc. Soil Sci. 1998, 46, 245–248. [Google Scholar]

- Bhargava, B.S. Leaf Analysis for Nutrient Diagnosis, Recommendation and Management in Fruits Crops. J. Indian Soc. Soil Sci. 2002, 50, 352–373. [Google Scholar]

- Association of Official Analytical Chemists (AOAC). Official Method of Analysis, 16th ed.; Williams S: San Francisco, CA, USA, 1995. [Google Scholar]

- Panigrahi, P.; Srivastava, A.K.; Huchche, A.D. Effect of drip irrigation regimes and basin irrigation on Nagpur mandarin agronomical, physiological performance. Agric. Water Manag. 2012, 104, 79–88. [Google Scholar] [CrossRef]

- Mittelbach, H.; Lehnar, I.; Seneviratne, S.I. Comparison of four soil moisture sensor type under firld condition in Switzerland. J. Hydrol. 2012, 430, 39–49. [Google Scholar] [CrossRef]

- Verma, S.; Pahuja, R. Recalibration and performance comparison of soil moisture sensors using regression and neural network characteristics model. Mater. Today Proceeding 2021, 45, 4852–4861. [Google Scholar] [CrossRef]

- Abdelmoneim, A.A.; Al Kalaany, C.M.; Khadra, R.; Derardja, B.; Dragonetti, G. Calibration of Low-Cost Capaci tive Soil Moisture Sensors for Irrigation Management Applications. Sensors 2025, 25, 343. [Google Scholar] [CrossRef] [PubMed]

- Chen, F.; Cui, N.; Jiang, S.; Li, H.; Wang, Y.; Gong, D.; Hu, X.; Zhao, L.; Liu, C.; Qiu, R. Effects of water deficit at different growth stages under drip irrigation on fruit quality of citrus in humid areas of South China. Agric. Water Manag. 2022, 262, 107407. [Google Scholar] [CrossRef]

- Dzikiti, S.; Verreynne, S.J.; Stuckens, J.; Strever, A.; Verstraeten, W.W.; Swennen, R.; Theron, K.I.; Coppin, P. Seasonal variation in canopy reflectance and its application to determine the water status and water use by citrus trees in the Western Cape, South Africa. Agric. Fore. Eco. 2011, 151, 1035–1044. [Google Scholar] [CrossRef]

| Stages/Treatments | NLI (Flowering /Fruiting) | Crop Development (Marble Stone Size and Fruit Development) | Maturity | Harvesting |

|---|---|---|---|---|

| Main treatments (Irrigation) | ||||

| I1 | 100% * ETNM | 100% * ETNM | 100% * ETNM | 100% * ETNM |

| I2 | 15% * VMC | 25% * VMC | 35% * VMC | 45% * VMC |

| I3 | 20% * VMC | 30% * VMC | 40% * VMC | 40% * VMC |

| I4 | 25% * VMC | 35% * VMC | 45% * VMC | 35% * VMC |

| Sub-treatments (Fertilizer) | ||||

| F1 | N, P, K, B | N, P, K, Fe, Mn, Zn | K, Fe, Mn, Zn | P, K, Zn |

| F2 | N, P, K | N, P, K, Fe, Mn | Fe, Mn, Zn, B | P, Zn |

| F3 | N, K, B | N, P, K, Fe, Zn | K, Fe, Mn | P, K |

| Formulas | Notations | References |

|---|---|---|

| ETNM—water requirement (Ld−1t−1); ETr—reference crop evapotranspiration (mm); Kc—crop coefficient (fraction); WA—wetted area (fraction); A—area occupied by each tree (m2); IE—irrigation efficiency of the drip irrigation system (fraction). | [37] | |

| IT—irrigation time (hr); WR—water requirement (Ld−1t−1); DC—dripper discharge capacity (Lhr−1). | [37] | |

| ETr —reference crop evapotranspiration (mmday−1); G—soil heat flux density (MJm−2 day−1); Rn—net radiation (MJm−2 day−1); T—mean daily air temperature (°C); γ—psychometric constant (kPa°C−1); ∆—slope of saturation vapor pressure function (kPa°C−1); es—saturation vapor pressure at air temperature T (kPa); ea—actual vapor pressure at dew-point temperature, (kPa); u2—average daily wind speed at the 2 m height (msec−1). | [17] | |

| spacing | A—area occupied by each tree (m2); P—plant-to-plant (m) spacing; RR—row-to-row spacing (m). | [37] |

| SA—shaded area (m2); A—area occupied by each tree (m2). | [37] | |

| Kc—crop coefficient; x—percentage of shaded area (%) | [38] | |

| —volumetric water content (%); n—number of layers to depth of the effective root zone; ΔSi—thickness of each layer (mm); θ1 and θ2—volumetric content of the first and second date of sampling (m3 m−3); Re—effective rainfall (mm); Wd—drainage from the root sample (mm). | [11] | |

| NUE—nutrient-use efficiency (%); FYU—fruit yield in untreated plot (kgha−1); FYT—fruit yield in treated plot (kgha−1) | [39] | |

| WP—water productivity (kgha−1); Y—yield (kgtree−1); WR—water requirement of Nagpur mandarin (Ld−1t−1). | [11] |

| Treatments | Plant Height (m) | Stem Dia. (m) | Canopy Spread(m) | Canopy Area (m2) | Canopy Volume (m3) | RLWC (%) | |

|---|---|---|---|---|---|---|---|

| N-S | E-W | ||||||

| Irrigation | |||||||

| I1 | 4.09 ± 0.21 c | 0.52 ± 0.052 d | 3.94 ± 0.15 d | 4.17 ± 0.15 d | 4.05 ± 0.14 d | 35.28 ± 4.12 d | 85.27 ± 5.31 d |

| I2 | 4.32 ± 0.32 b | 0.55 ± 0.050 c | 4.18 ± 0.09 c | 4.29 ± 0.11 c | 4.24 ± 0.10 c | 40.70 ± 4.72 c | 87.68 ± 4.61 c |

| I3 | 4.43 ± 0.26 b | 0.60 ± 0.039 b | 4.30 ± 0.07 b | 4.37 ± 0.06 b | 4.34 ± 0.06 b | 43.68 ± 3.74 b | 90.26 ± 4.52 b |

| I4 | 4.56 ± 0.13 a | 0.63 ± 0.036 a | 4.48 ± 0.08 a | 4.53 ± 0.07 a | 4.50 ± 0.08 a | 48.12 ± 2.63 a | 92.44 ± 4.81 a |

| Fertilization | |||||||

| F1 | 4.59 ± 0.19 a | 0.62 ± 0.044 a | 4.32 ± 0.16 a | 4.44 ± 0.12 a | 4.38 ± 0.13 a | 46.30 ± 4.38 a | 93.89 ± 3.04 a |

| F2 | 4.36 ± 0.18 b | 0.57 ± 0.047 b | 4.22 ± 0.23 b | 4.34 ± 0.13 b | 4.27 ± 0.17 b | 42.06 ± 4.95 b | 89.24 ± 3.39 b |

| F3 | 4.08 ± 0.24 c | 0.53 ± 0.057 c | 4.13 ± 0.24 c | 4.24 ± 0.19 c | 4.18 ± 0.21 c | 37.70 ± 5.80 c | 83.61 ± 3.72 c |

| Treatments | Juice Content (%) | TSS (°Brix) | Acidity (%) | TSS: Acid Ratio | Fruit Dia. (mm) | No. of Seg. Fruit−1 |

|---|---|---|---|---|---|---|

| Irrigation | ||||||

| I1 | 35.18 ± 4.19 c | 9.52 ± 0.62 d | 0.81 ± 0.07 a | 11.87 ± 1.77 d | 66.82 ± 5.19 c | 10.41 ± 0.47 a |

| I2 | 36.89 ± 4.04 c | 9.97 ± 0.15 c | 0.80 ± 0.11 a | 12.56 ± 2.09 c | 68.71 ± 6.10 bc | 10.50 ± 0.52 a |

| I3 | 39.98 ± 5.32 b | 10.34 ± 0.14 b | 0.73 ± 0.08 b | 14.31 ± 1.79 b | 70.04 ± 6.85 b | 10.58 ± 0.51 a |

| I4 | 42.66 ± 4.88 a | 10.61 ± 0.17 a | 0.66 ± 0.06 c | 16.32 ± 1.64 a | 73.65 ± 6.28 a | 10.67 ± 0.86 a |

| Fertilization | ||||||

| F1 | 43.72 ± 3.84 a | 10.38 ± 0.30 a | 0.66 ± 0.05 c | 15.89 ± 1.70 a | 76.44 ± 3.76 a | 11.00 ± 0.63 a |

| F2 | 38.27 ± 4.02 b | 10.13 ± 0.44 b | 0.76 ± 0.09 b | 13.44 ± 2.15 b | 69.87 ± 3.21 b | 10.53 ± 0.46 b |

| F3 | 34.04 ± 2.88 c | 9.81 ± 0.64 c | 0.83 ± 0.08 a | 11.96 ± 1.82 c | 63.10 ± 3.30 c | 10.09 ± 0.27 c |

| Treatments | Nos. of Fruits Tree−1 | Fruit Weight (gm) | Yield (kgtree−1) | WU (m3) | WP (kgm−3) | NUE (%) |

|---|---|---|---|---|---|---|

| Irrigation | ||||||

| I1 | 611.00 ± 24.89 d | 158.43 ± 7.92 d | 96.98 ± 8.71 d | 32.50± | 2.98 ± 0.26 d | Control |

| I2 | 674.83 ± 28.41 c | 163.29 ± 7.80 c | 110.40 ± 9.86 c | 22.19± | 4.98 ± 0.44 c | 87.84 ± 0.25 |

| I3 | 769.75 ± 22.05 b | 171.87 ± 8.67 b | 132.47 ± 10.43 b | 24.30± | 5.45 ± 0.43 b | 73.20 ± 0.48 |

| I4 | 839.00 ± 22.25 a | 178.92 ± 8.18 a | 150.28 ± 10.72 a | 26.50± | 5.67 ± 0.40 a | 64.53 ± 0.73 |

| Fertilization | ||||||

| F1 | 750.75 ± 88.64 a | 176.79 ± 8.71 a | 133.43 ± 22.14 a | 23.30± | 5.69 ± 0.38 a | 87.84 ± 0.27 |

| F2 | 722.81 ± 91.08 b | 168.70 ± 8.66 b | 122.65 ± 21.53 b | 23.30± | 5.22 ± 0.39 b | 79.07 ± 0.45 |

| F3 | 697.37 ± 92.17 c | 158.91 ± 8.44 c | 110.52 ± 20.40 c | 23.30± | 4.74 ± 0.40 c | 87.77 ± 0.71 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meshram, D.; Srivastava, A.K.; Utkhede, A.; Pangul, C.; Ziogas, V. Response to Sensor-Based Fertigation of Nagpur Mandarin (Citrus reticulata Blanco) in Vertisol of Central India. Horticulturae 2025, 11, 508. https://doi.org/10.3390/horticulturae11050508

Meshram D, Srivastava AK, Utkhede A, Pangul C, Ziogas V. Response to Sensor-Based Fertigation of Nagpur Mandarin (Citrus reticulata Blanco) in Vertisol of Central India. Horticulturae. 2025; 11(5):508. https://doi.org/10.3390/horticulturae11050508

Chicago/Turabian StyleMeshram, Deodas, Anoop Kumar Srivastava, Akshay Utkhede, Chetan Pangul, and Vasileios Ziogas. 2025. "Response to Sensor-Based Fertigation of Nagpur Mandarin (Citrus reticulata Blanco) in Vertisol of Central India" Horticulturae 11, no. 5: 508. https://doi.org/10.3390/horticulturae11050508

APA StyleMeshram, D., Srivastava, A. K., Utkhede, A., Pangul, C., & Ziogas, V. (2025). Response to Sensor-Based Fertigation of Nagpur Mandarin (Citrus reticulata Blanco) in Vertisol of Central India. Horticulturae, 11(5), 508. https://doi.org/10.3390/horticulturae11050508