Impact of Different Shading Conditions on Processing Tomato Yield and Quality Under Organic Agrivoltaic Systems

Abstract

1. Introduction

2. Materials and Methods

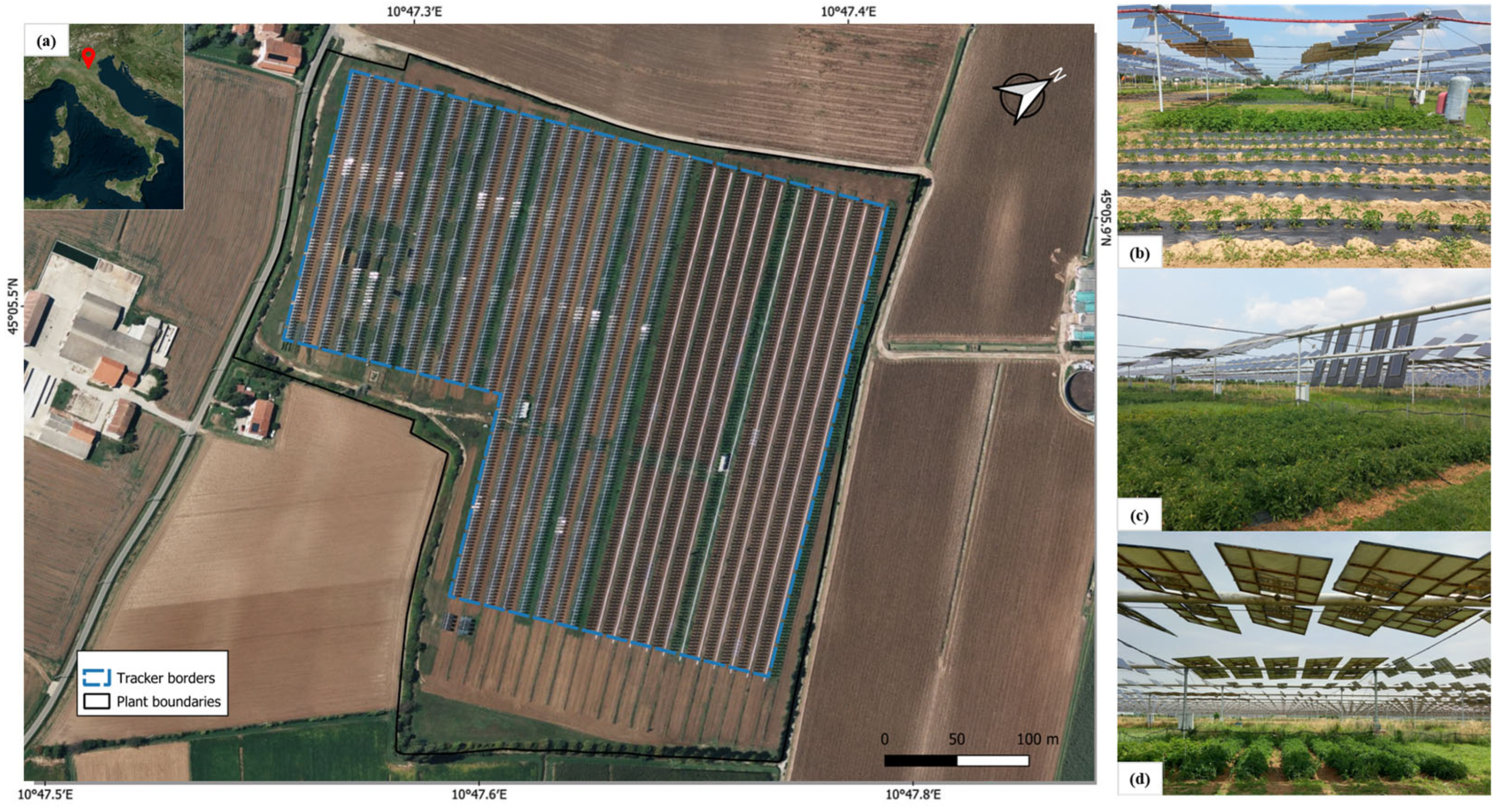

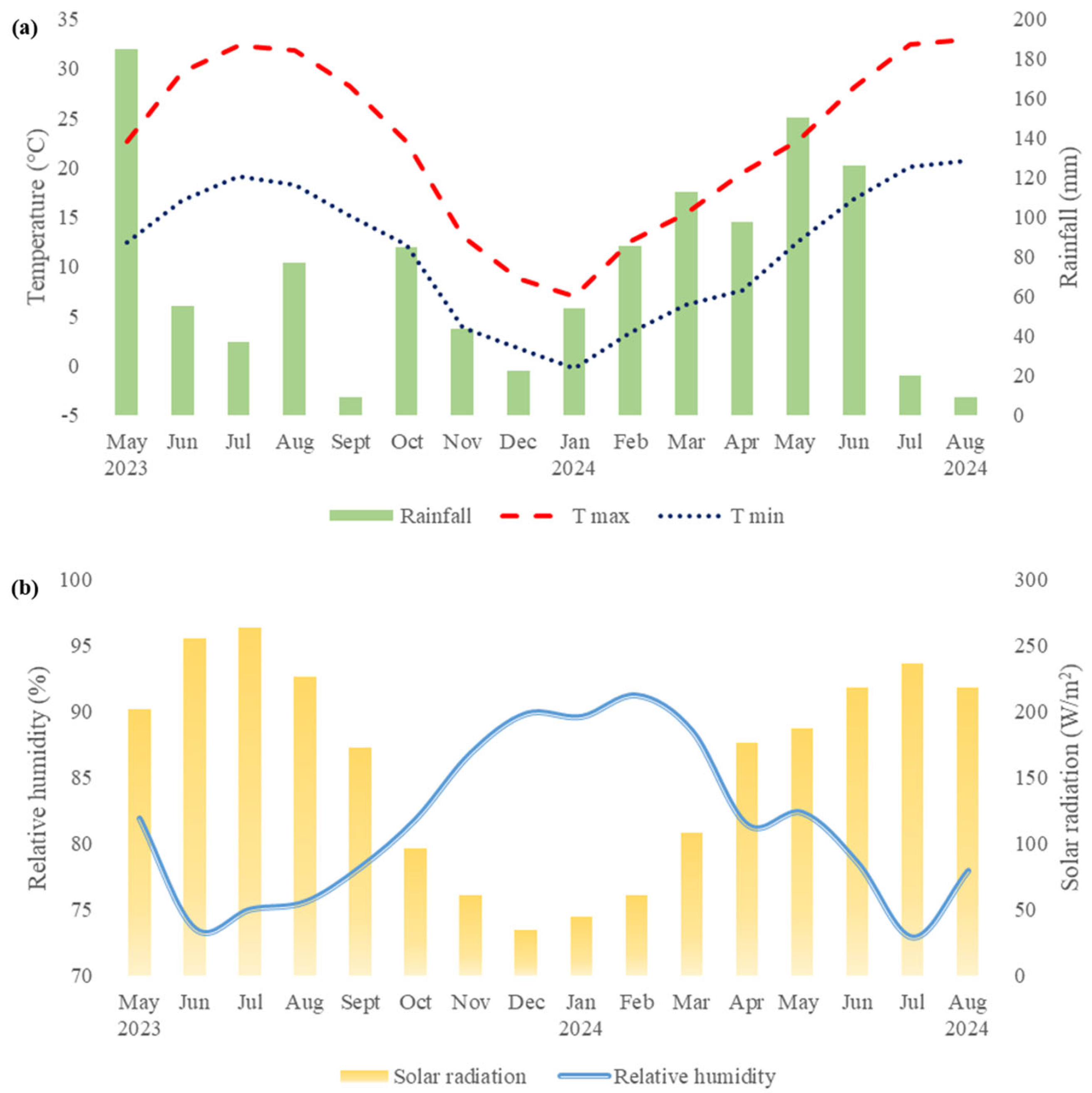

2.1. Study Area

2.2. Growth Condition and Experimental Design

2.3. Ecophysiological Parameters and Tomato Yield and Quality

2.3.1. Soil Parameters

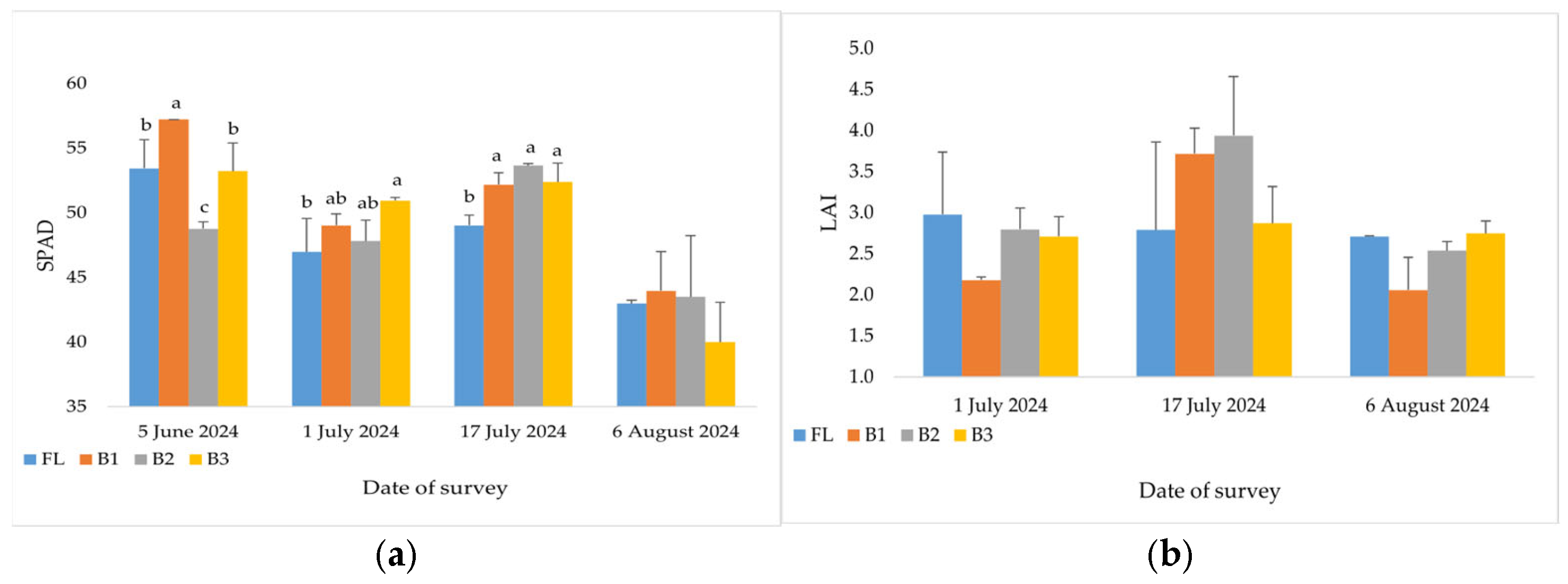

2.3.2. Plant Physiological Parameters

2.3.3. Biomass Production

2.3.4. Tomato Yield and Fruit Quality Parameters

2.4. Statistical Analysis

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Campana, P.E.; Stridh, B.; Amaducci, S.; Colauzzi, M. Optimisation of vertically mounted agrivoltaic systems. J. Clean. Prod. 2021, 325, 129091. [Google Scholar] [CrossRef]

- Johansson, D.J.A.; Azar, C.A. Scenario based analysis of land competition between food and bioenergy production in the US. Clim. Change 2007, 82, 267–329. [Google Scholar] [CrossRef]

- Nonhebel, S. Renewable energy and food supply: Will there be enough land? Renew. Sustain. Energy Rev. 2005, 9, 191–201. [Google Scholar] [CrossRef]

- Saleem, M. Possibility of utilizing agriculture biomass as a renewable and sustainable future energy source. Heliyon 2022, 8, e08905. [Google Scholar] [CrossRef]

- Foley, J.A.; Ramankutty, N.; Brauman, K.A.; Cassidy, E.S.; Gerber, J.S.; Johnston, M.; Mueller, N.D.; O’Connell, C.; Ray, D.K.; West, P.C.; et al. Solutions for a cultivated planet. Nature 2011, 478, 337–342. [Google Scholar] [CrossRef] [PubMed]

- Adeh, E.H.; Selker, J.S.; Higgins, C.W. Remarkable agrivoltaic influence on soil moisture, micrometeorology and water-use efficiency. PLoS ONE 2018, 13, e0203256. [Google Scholar] [CrossRef]

- Semeraro, T.; Scarano, A.; Curci, L.M.; Leggieri, A.; Lenucci, M.; Basset, A.; Santino, A.; Piro, G.; De Caroli, M. Shading effects in agrivoltaic systems can make the difference in boosting food security in climate change. Appl. Energy 2024, 358, 122565. [Google Scholar] [CrossRef]

- Busch, C.; Wydra, K. Life cycle assessment of an agrivoltaic system with conventional potato production. J. Renew. Sustain. Energy 2023, 15, 043501. [Google Scholar] [CrossRef]

- Weselek, A.; Bauerle, A.; Hartung, J.; Zikeli, S.; Lewandowski, I.; Högy, P. Agrivoltaic system impacts on microclimate and yield of different crops within an organic crop rotation in a temperate climate. Agron. Sustain. Dev. 2021, 41, 64. [Google Scholar] [CrossRef]

- Marrou, H.; Dufour, L.; Wery, J. How does a shelter of solar panels influence water flows in a soil–crop system? Eur. J. Agron. 2013, 50, 38–51. [Google Scholar] [CrossRef]

- AL-agele, H.A.; Proctor, K.; Murthy, G.; Higgins, C. A Case Study of Tomato (Solanum lycopersicon var. Legend) Production and Water Productivity in Agrivoltaic Systems. Sustainability 2021, 13, 2850. [Google Scholar] [CrossRef]

- Scarano, A.; Semeraro, T.; Calisi, A.; Aretano, R.; Rotolo, C.; Lenucci, M.S.; Santino, A.; Piro, G.; De Caroli, M. Effects of the Agrivoltaic System on Crop Production: The Case of Tomato (Solanum lycopersicum L.). Appl. Sci. 2024, 14, 3095. [Google Scholar] [CrossRef]

- Dupraz, C. Assessment of the ground coverage ratio of agrivoltaic systems as a proxy for potential crop productivity. Agrofor. Syst. 2024, 98, 2679–2696. [Google Scholar] [CrossRef]

- Laub, M.; Pataczek, L.; Feuerbacher, A.; Zikeli, S.; Hogy, P. Contrasting yield responses at varying levels of shade suggest different suitability of crops for dual land-use systems: A meta-analysis. Agron. Sustain. Dev. 2022, 42, 13. [Google Scholar] [CrossRef]

- World Processing Tomato Council (WPTC) WPTC Crop Update. Available online: https://www.tomatonews.com/en/wptc-crop-update-as-of-9-june-2024_2_2339.html (accessed on 10 January 2025).

- Cammarano, D.; Jamshidi, S.; Hoogenboom, G.; Ruane, A.C.; Niyogi, D.; Ronga, D. Processing Tomato Production Is Expected to Decrease by 2050 Due to the Projected Increase in Temperature. Nat. Food 2022, 3, 437–444. [Google Scholar] [CrossRef]

- Weselek, A.; Ehmann, A.; Zikeli, S.; Lewandowski, I.; Schindele, S.; Högy, P. Agrophotovoltaic systems: Applications, challenges, and opportunities. A review. Agron. Sustain. Dev. 2019, 39, 35. [Google Scholar] [CrossRef]

- El-Gizawy, A.M.; Abdallah, M.M.F.; Gomaa, H.M.; Mohamed, S.S. Effect of different shading levels on tomato plants. 2. Yield and fruit quality. Acta Hortic. 1993, 323, 349–354. [Google Scholar] [CrossRef]

- Nangare, D.D.; Singh, J.; Meena, V.S.; Bhushan, B.; Bhatnagar, P.R. Effect of green shade nets on yield and quality of tomato (Lycopersicon esculentum Mill) in semi-arid region of Punjab. Asian J. Adv. Basic. Appl. Sci. 2015, 1, 1–8. [Google Scholar]

- Peel, M.C.; Finlayson, B.L.; McMahon, T.A. Updated world map of the Köppen-Geiger climate classification. Hydrol. Earth Syst. Sci. 2007, 11, 1633–1644. [Google Scholar] [CrossRef]

- Ministero delle Politiche Agricole e Forestali (MIPAF). Approvazione dei “Metodi Ufficiali di Analisi Chimica del Suolo”. Decreto Ministeriale 13-09-99, Gazzetta Ufficiale Serie Generale n.248 del 21-10-1999, Supplemento Ordinario n. 185. 1999. Available online: http://www.gazzettaufficiale.it/eli/id/1999/10/21/099A8497/sg (accessed on 20 February 2025).

- Ronga, D.; Zaccardelli, M.; Lovelli, S.; Perrone, D.; Francia, E.; Milc, J.; Ulrici, A.; Pecchioni, N. Biomass production and dry matter partitioning of processing tomato under organic vs conventional cropping systems in a Mediterranean environment. Sci. Hortic. 2017, 224, 163–170. [Google Scholar] [CrossRef]

- Ronga, D.; Caradonia, F.; Vitti, A.; Francia, E. Agronomic Comparisons of Heirloom and Modern Processing Tomato Genotypes Cultivated in Organic and Conventional Farming Systems. Agronomy 2021, 11, 349. [Google Scholar] [CrossRef]

- Wickham, H.; Averick, M.; Bryan, J.; Chang, W.; McGowan, L.D.; François, R.; Grolemund, G.; Hayes, A.; Henry, L.; Hester, J.; et al. Welcome to the Tidyverse. J. Open Source Softw. 2019, 4, 1686. [Google Scholar] [CrossRef]

- Graves, S.; Piepho, H.-P.; Selzer, L. multcompView: Visualizations of Paired Comparisons. 2024. Available online: https://cran.r-project.org/web/packages/multcompView/index.html (accessed on 18 February 2025).

- Parkinson, S.; Hunt, J. Agrovoltaic systems: A dual approach to energy and food production. Environ. Sci. Technol. Lett. 2020, 7, 525–531. [Google Scholar] [CrossRef]

- Bellone, Y.; Croci, M.; Impollonia, G.; Zad, A.N.; Colauzzi, M.; Campana, P.E.; Amaducci, S. Simulation-Based Decision Support for Agrivoltaic Systems. Appl. Energy 2024, 369, 123490. [Google Scholar] [CrossRef]

- Dong, C.; Fu, Y.; Liu, G.; Liu, H. Low light intensity effects on the growth, photosynthetic characteristics, antioxidant capacity, yield and quality of wheat (Triticum aestivum L.) at different growth stages in BLSS. Adv. Space Res. 2014, 53, 1557–1566. [Google Scholar] [CrossRef]

- Marenco, R.; Reis, A.C.S. Shading as an environmental factor affecting the growth of Ischaemum rugosum. Rev. Bras. Fisiol. Veg. 1998, 10, 107–112. [Google Scholar]

- Reis, L.C.; Scalon, S.P.; Foresti, A.C.; Dresch, D.M.; Santos, C.C.; Lima, V.T. How does shading mitigates the water deficit in young Hymenaea courbaril L. plants? Front. Plant Sci. 2023, 14, 1235234. [Google Scholar] [CrossRef]

- Dev, R.; Singh, J.P.; Singh, T.; Dayal, D. Effect of shade levels on growth, and biomass production of cactus (Opuntiaficus-india (L.) Mill.). Int. J. Curr. Microbiol. Appl. Sci. 2018, 7, 3145–3153. [Google Scholar]

- Weselek, A.; Bauerle, A.; Zikeli, S.; Lewandowski, I.; Högy, P. Effects on crop development, yields and chemical composition of celeriac (Apium graveolens L. var. Rapaceum) cultivated underneath an agrivoltaic system. Agronomy 2021, 11, 733. [Google Scholar] [CrossRef]

- Ronga, D.; Lovelli, S.; Zaccardelli, M.; Perrone, D.; Ulrici, A.; Francia, E.; Pecchioni, N. Physiological responses of processing tomato in organic and conventional Mediterranean cropping systems. Sci. Hortic. 2015, 190, 161–172. [Google Scholar] [CrossRef]

- Maity, R.; Sudhakar, K.; Abdul Razak, A.; Karthick, A.; Barbulescu, D. Agrivoltaic: A strategic assessment using SWOT and TOWS matrix. Energies 2023, 16, 3313. [Google Scholar] [CrossRef]

- Zainali, S.; Lu, S.M.; Stridh, B.; Avelin, A.; Amaducci, S.; Colauzzi, M.; Campana, P.E. Direct and diffuse shading factors modelling for the most representative agrivoltaic system layouts. Appl. Energy 2023, 339, 120981. [Google Scholar] [CrossRef]

- Chauhan, P.M.; Kumar, S.; Patel, B.N.; Saravaiya, S.; Patel, N.B. Agrovoltaic: A novel technology for doubling the income of farmers. In Technologies and Sustainability of Protected Cultivation for Hi-Valued Vegetable Crops; Navsari Agricultural University: Gujarat, India, 2018; p. 215. Available online: https://www.researchgate.net/publication/326016018 (accessed on 18 February 2025).

- Ronga, D.; Biazzi, E.; Parati, K.; Carminati, D.; Carminati, E.; Tava, A. Microalgal Biostimulants and Biofertilisers in Crop Productions. Agronomy 2019, 9, 192. [Google Scholar] [CrossRef]

- Ureña-Sánchez, R.; Callejón-Ferre, Á.J.; Pérez-Alonso, J.; Carreño-Ortega, Á. Greenhouse tomato production with electricity generation by roof-mounted flexible solar panels. Sci. Agric. 2012, 69, 233–239. [Google Scholar] [CrossRef]

- Pataczek, L.; Weselek, A.; Otte, P.P.; Högy, P.; Lewandowski, I. Agrivoltaics mitigate drought effects in winter wheat. Physiol. Plant. 2023, 175, e14081. [Google Scholar] [CrossRef]

- Dinesh, H.; Pearce, J.M. The potential of agrivoltaic systems. Renew. Sustain. Energy Rev. 2016, 54, 299–308. [Google Scholar] [CrossRef]

| Treatments | FL | A1 | A2 | |||

|---|---|---|---|---|---|---|

| EC (dS m−1) | 0.04 | 0.04 | 0.03 | |||

| VWC (%) | 10.70 | b | 11.10 | b | 18.95 | a |

| Soil Temperature (°C) | 35.35 | 36.27 | 34.43 | |||

| Canopy Temperature (°C) | 30.24 | a | 30.78 | a | 28.65 | b |

| LFW (g plant−1) | 406.40 | a | 203.70 | b | 325.50 | ab |

| LDW (g plant−1) | 73.63 | a | 53.18 | b | 71.16 | a |

| SFW (g plant−1) | 244.10 | a | 115.50 | b | 191.00 | a |

| SDW (g plant−1) | 43.92 | a | 27.50 | b | 35.67 | ab |

| FFW (g plant−1) | 1334.50 | a | 659.00 | b | 677.60 | b |

| FDW (g plant−1) | 95.16 | a | 66.33 | b | 55.80 | b |

| RFW (g plant−1) | 165.70 | a | 68.70 | b | 97.00 | b |

| RDW (g plant−1) | 62.32 | a | 35.41 | b | 31.00 | b |

| Treatments | FL | A1 | A2 | |||

|---|---|---|---|---|---|---|

| EC (dS m−1) | 0.11 | a | 0.09 | b | 0.08 | b |

| VWC (%) | 17.31 | 21.65 | 17.90 | |||

| Soil Temperature (°C) | 33.41 | 34.80 | 34.77 | |||

| Canopy Temperature (°C) | 40.24 | a | 41.21 | a | 38.56 | b |

| LFW (g plant−1) | 245.10 | b | 366.80 | ab | 411.10 | a |

| LDW (g plant−1) | 74.04 | 71.30 | 75.13 | |||

| SFW (g plant−1) | 222.80 | a | 191.60 | ab | 232.60 | a |

| SDW (g plant−1) | 37.80 | 36.80 | 37.13 | |||

| FFW (g plant−1) | 2232.00 | a | 1121.00 | b | 1571.00 | b |

| FDW (g plant−1) | 131.30 | a | 71.80 | b | 87.63 | b |

| RFW (g plant−1) | 130.10 | ab | 146.10 | a | 144.10 | a |

| RDW (g plant−1) | 39.98 | ab | 56.63 | a | 55.63 | a |

| Treatments | FL | A1 | A2 | |||

|---|---|---|---|---|---|---|

| LFW (g plant−1) | 457.60 | a | 192.70 | b | 280.20 | b |

| LDW (g plant−1) | 119.08 | a | 43.49 | c | 63.35 | b |

| SFW (g plant−1) | 455.80 | a | 217.70 | b | 304.40 | b |

| SDW (g plant−1) | 76.79 | a | 40.93 | b | 44.82 | b |

| FFW (g plant−1) | 1571.00 | a | 1052.00 | b | 1395.00 | a |

| FDW (g plant−1) | 66.87 | a | 55.35 | ab | 70.97 | a |

| RFW (g plant−1) | 133.78 | a | 60.11 | b | 62.07 | b |

| RDW (g plant−1) | 43.30 | a | 25.93 | b | 27.10 | b |

| Average fruit weight (g plant−1) | 77.31 | a | 66.93 | b | 77.96 | a |

| Marketable yield (g plant−1) | 1531.97 | a | 1054.75 | b | 1433.00 | a |

| Total yield | 2083.00 | a | 1245.00 | c | 1572.00 | b |

| Marketable fruits (number plant−1) | 18.16 | a | 13.78 | b | 17.33 | a |

| Unripe fruits (g plant−1) | 370.80 | a | 176.90 | b | 127.10 | b |

| NAE (g g−1) | 940.50 | a | 647.90 | b | 880.30 | a |

| FWP (g m−3) | 6440.00 | a | 4436.00 | c | 6027.00 | a |

| Rotten fruits (number plant−1) | 7.33 | a | 1.89 | b | 5.11 | a |

| Fruit affected by BER (number plant−1) | 5.83 | a | 5.22 | a | 0.78 | b |

| Sunburnt fruits (number plant−1) | 0.67 | a | 0.00 | b | 0.22 | ab |

| Equatorial diameter (mm) | 40.94 | 40.99 | 42.09 | |||

| Polar diameter (mm) | 80.00 | ab | 80.94 | a | 75.49 | b |

| Pulp thickness (mm) | 11.23 | 10.14 | 10.41 | |||

| L | 35.39 | a | 33.70 | b | 33.42 | b |

| a | 20.08 | a | 21.39 | a | 18.40 | b |

| b | 19.98 | 19.42 | 18.95 | |||

| pH | 4.52 | a | 4.40 | b | 4.35 | b |

| °Brix | 5.39 | a | 5.67 | a | 4.97 | b |

| Treatments | FL | B1 | B2 | B3 | ||||

|---|---|---|---|---|---|---|---|---|

| EC (dS m−1) | 0.14 | a | 0.09 | b | 0.03 | c | 0.07 | b |

| VWC (%) | 10.24 | 12.73 | 11.10 | 9.44 | ||||

| Soil Temperature (°C) | 44.88 | a | 41.90 | c | 43.37 | b | 42.53 | bc |

| Canopy Temperature (°C) | 34.73 | a | 35.78 | a | 31.83 | b | 31.36 | b |

| LFW (g plant−1) | 421.90 | a | 367.50 | ab | 368.50 | ab | 336.50 | b |

| LDW (g plant−1) | 104.48 | a | 60.00 | b | 56.75 | b | 53.00 | b |

| SFW (g plant−1) | 327.10 | a | 274.00 | b | 228.70 | c | 232.90 | c |

| SDW (g plant−1) | 82.98 | a | 40.00 | b | 32.50 | c | 33.80 | bc |

| FFW (g plant−1) | 680.50 | c | 1355.60 | a | 1052.10 | b | 616.20 | c |

| FDW (g plant−1) | 72.95 | a | 49.51 | ab | 60.40 | a | 28.00 | b |

| RFW (g plant−1) | 153.10 | a | 104.40 | b | 126.20 | b | 77.00 | c |

| RDW (g plant−1) | 95.65 | a | 55.67 | b | 53.50 | b | 39.00 | c |

| Treatments | FL | B1 | B2 | B3 | ||||

|---|---|---|---|---|---|---|---|---|

| EC (dS m−1) | 0.29 | 0.21 | 0.22 | 0.22 | ||||

| VWC (%) | 36.03 | 35.63 | 35.96 | 37.50 | ||||

| Soil Temperature (°C) | 35.16 | a | 35.00 | a | 34.22 | b | 34.25 | b |

| Canopy Temperature (°C) | 40.40 | a | 40.46 | a | 38.70 | b | 38.35 | b |

| LFW (g plant−1) | 532.70 | b | 409.60 | c | 709.20 | a | 344.4 | c |

| LDW (g plant−1) | 88.60 | b | 73.64 | c | 119.10 | a | 55.00 | d |

| SFW (g plant−1) | 442.40 | ab | 339.50 | bc | 484.30 | a | 275.10 | c |

| SDW (g plant−1) | 78.26 | ab | 64.13 | b | 83.20 | a | 42.00 | c |

| FFW (g plant−1) | 2356.00 | b | 2293.00 | b | 3619.00 | a | 1969.00 | b |

| FDW (g plant−1) | 170.00 | b | 157.30 | b | 251.60 | a | 139.40 | b |

| RFW (g plant−1) | 120.10 | b | 158.30 | a | 79.60 | c | 95.00 | c |

| RDW (g plant−1) | 53.60 | b | 86.05 | a | 40.35 | b | 52.00 | b |

| Treatments | FL | B1 | B2 | B3 | ||||

|---|---|---|---|---|---|---|---|---|

| LFW (g plant−1) | 515.60 | b | 347.30 | c | 705.40 | a | 408.20 | bc |

| LDW (g plant−1) | 81.60 | b | 86.50 | b | 137.60 | a | 94.60 | b |

| SFW (g plant−1) | 441.50 | a | 301.00 | b | 495.00 | a | 298.80 | b |

| SDW (g plant−1) | 77.64 | b | 80.53 | b | 102.25 | a | 82.50 | b |

| FFW (g plant−1) | 1902.00 | c | 2698.00 | b | 3551.00 | a | 2680.00 | b |

| FDW (g plant−1) | 206.00 | 179.90 | 236.70 | 186.20 | ||||

| RFW (g plant−1) | 58.03 | b | 69.52 | b | 124.77 | a | 68.75 | b |

| RDW (g plant−1) | 32.50 | b | 21.03 | bc | 45.33 | a | 19.00 | c |

| Average fruit weight (g plant−1) | 64.29 | b | 85.69 | a | 83.24 | a | 85.20 | a |

| Marketable yield (g plant−1) | 1657.00 | c | 2562.00 | b | 2992.00 | a | 2408.00 | b |

| Total yield (g plant−1) | 2157.40 | c | 2977.80 | b | 3778.10 | a | 2850.60 | b |

| Marketable fruits (g plant−1) | 26.01 | c | 34.48 | ab | 40.33 | a | 30.00 | bc |

| NAE (g g−1) | 203.60 | c | 314.70 | b | 369.60 | a | 308.40 | b |

| FWP (g m−3) | 6972.00 | c | 10,778.00 | b | 12,659.00 | a | 10,561.00 | b |

| Unripe fruits | 500.40 | b | 415.80 | b | 786.10 | a | 442.60 | b |

| Rotten fruits (number plant−1) | 3.50 | a | 0.67 | bc | 2.00 | b | 0.33 | c |

| Fruit affected by BER (number plant−1) | 2.51 | 2.01 | 3.67 | 4.50 | ||||

| Equatorial diameter (mm) | 44.20 | b | 49.51 | a | 48.32 | ab | 48.75 | a |

| Polar diameter (mm) | 67.75 | a | 65.44 | ab | 65.08 | ab | 62.99 | b |

| Pulp thickness (mm) | 6.57 | a | 6.94 | a | 5.07 | b | 7.40 | a |

| L | 41.55 | b | 44.72 | a | 43.43 | a | 43.34 | a |

| a | 23.29 | a | 21.17 | b | 20.31 | b | 21.13 | b |

| b | 20.24 | a | 19.05 | ab | 17.50 | b | 18.21 | ab |

| pH | 4.32 | b | 4.38 | ab | 4.35 | b | 4.47 | a |

| °Brix | 5.17 | 5.10 | 5.27 | 5.17 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dal Prà, A.; Dainelli, R.; Santoni, M.; Lanini, G.M.; Di Serio, A.; Zanotti, D.; Greco, A.; Ronga, D. Impact of Different Shading Conditions on Processing Tomato Yield and Quality Under Organic Agrivoltaic Systems. Horticulturae 2025, 11, 319. https://doi.org/10.3390/horticulturae11030319

Dal Prà A, Dainelli R, Santoni M, Lanini GM, Di Serio A, Zanotti D, Greco A, Ronga D. Impact of Different Shading Conditions on Processing Tomato Yield and Quality Under Organic Agrivoltaic Systems. Horticulturae. 2025; 11(3):319. https://doi.org/10.3390/horticulturae11030319

Chicago/Turabian StyleDal Prà, Aldo, Riccardo Dainelli, Margherita Santoni, Giuseppe Mario Lanini, Annamaria Di Serio, Davide Zanotti, Antonino Greco, and Domenico Ronga. 2025. "Impact of Different Shading Conditions on Processing Tomato Yield and Quality Under Organic Agrivoltaic Systems" Horticulturae 11, no. 3: 319. https://doi.org/10.3390/horticulturae11030319

APA StyleDal Prà, A., Dainelli, R., Santoni, M., Lanini, G. M., Di Serio, A., Zanotti, D., Greco, A., & Ronga, D. (2025). Impact of Different Shading Conditions on Processing Tomato Yield and Quality Under Organic Agrivoltaic Systems. Horticulturae, 11(3), 319. https://doi.org/10.3390/horticulturae11030319