Harnessing the Synergy Between Edible Coatings and Non-Thermal Technologies for Improved Food Quality and Sustainable Preservation

Abstract

1. Introduction

- Examines how non-thermal treatments affect the adhesion, integrity, and functional performance of edible coatings when applied to fresh produce;

- Evaluates the synergistic (or antagonistic) effects of combined approaches on microbial stability, quality retention, and shelf-life extension;

- Identifies technological, mechanistic, and practical limitations that hinder their broader commercial adoption.

2. Methodology

2.1. Literature Search Strategy

2.2. Inclusion and Exclusion Criteria

- Focused on the application or synergistic use of edible coatings and non-thermal technologies in food preservation.

- Reported quantitative or qualitative outcomes related to food quality, shelf-life, microbial stability, or physicochemical properties.

- Were peer-reviewed journal articles or book chapters written in English.

- Investigated only thermal preservation methods without a non-thermal counterpart.

- Were conference abstracts, patents, or non-peer-reviewed materials.

- Lacked sufficient methodological or experimental detail for evaluation.

- Focused on non-horticultural products.

2.3. Study Selection and Data Extraction

- Type of edible coating or biopolymer material used.

- Non-thermal technology applied (e.g., ultrasound, plasma, irradiation).

- Horticultural product type, hurdle approach, and target foodborne threat.

2.4. Data Analysis and Synthesis

3. Functionality of Edible Coatings

4. Non-Thermal Technologies in Food Preservation and Their Potential Combinations with Edible Coatings

4.1. High-Pressure Processing (HPP)

4.1.1. Theory

4.1.2. Combination with Edible Coating

4.2. Ultrasound

4.2.1. Theory

4.2.2. Combination with Edible Coatings

4.3. Irradiation (Non-Ionizing and Ionizing Radiation) Techniques

4.3.1. Theory

4.3.2. Combination with Edible Coating

4.4. Photodynamic Inactivation (PDI)

4.4.1. Theory

4.4.2. Combination with Edible Coatings

4.5. Cold Plasma Treatment (CPT)

4.5.1. Theory

4.5.2. Combination with Edible Coatings

5. Passive Packaging Strategy

5.1. Theory

5.2. Combination of MAP with Edible Coatings

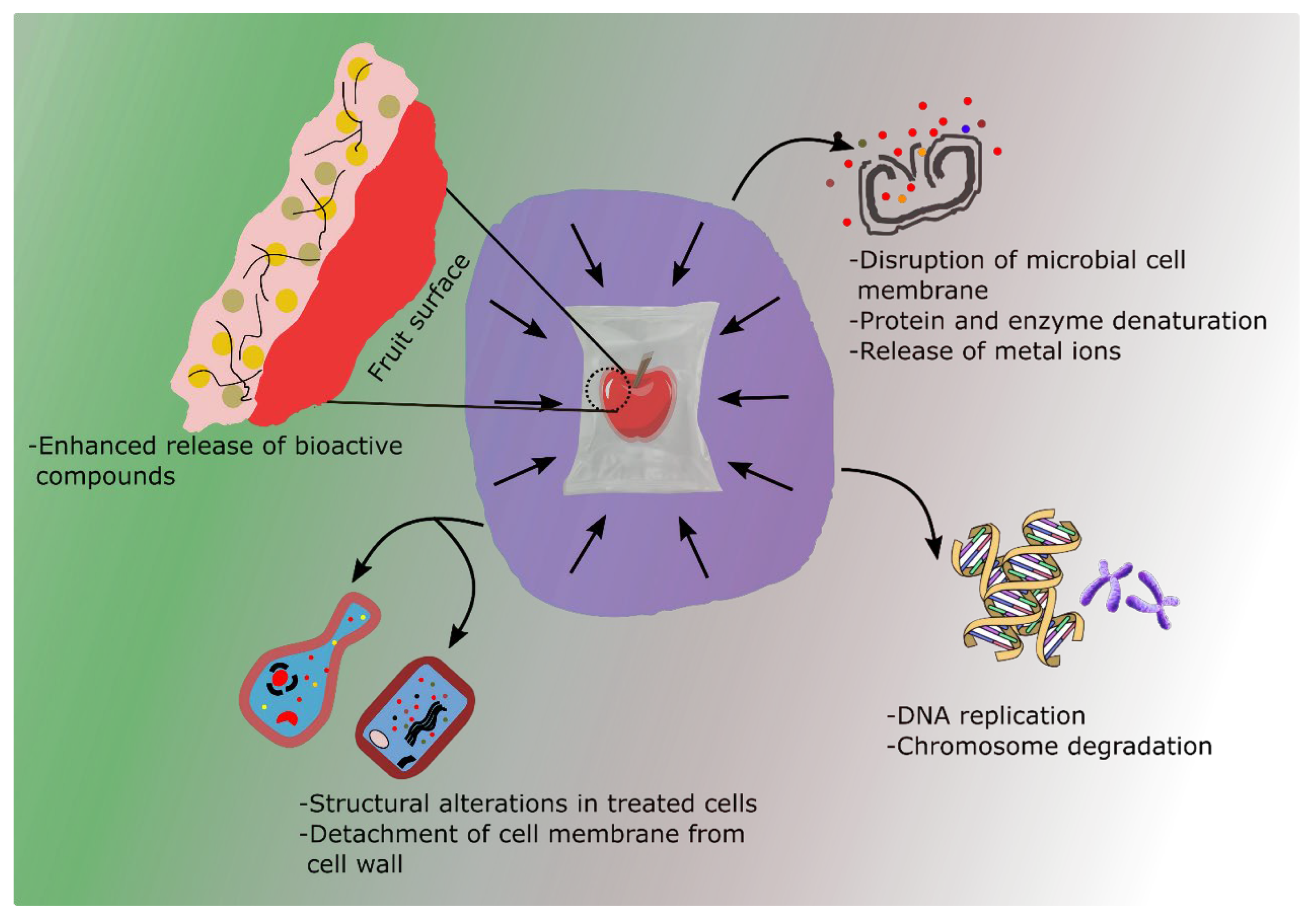

6. Possible Mechanisms Through Which Edible Coatings and Selected Hurdles Induce Microbial Decontamination

6.1. Moisture Control and Reduced Water Activity

6.2. Limited Oxygen Availability

6.3. Stress and Loss of Cell Integrity

6.4. Homeostasis

7. Practical Challenges and Implications for Future Development

8. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chandra, R.D.; Prihastyanti, M.N.U.; Lukitasari, D.M. Effects of pH, High Pressure Processing, and Ultraviolet Light on Carotenoids, Chlorophylls, and Anthocyanins of Fresh Fruit and Vegetable Juices. eFood 2021, 2, 113–124. [Google Scholar] [CrossRef]

- Piepiórka-Stepuk, J.; Wojtasik-Kalinowska, I.; Sterczyńska, M.; Mierzejewska, S.; Stachnik, M.; Jakubowski, M. The effect of heat treatment on bioactive compounds and color of selected pumpkin cultivars. LWT 2023, 175, 114469. [Google Scholar] [CrossRef]

- Valdés, A.; Burgos, N.; Jiménez, A.; Garrigós, M.C. Natural Pectin Polysaccharides as Edible Coatings. Coatings 2015, 5, 865–886. [Google Scholar] [CrossRef]

- Ammar, E.E.; Zou, X.; Ghosh, S.; Onyeaka, H.; Elmasry, S.A.; Alkeay, A.M.; AL-Farga, A.; Rady, H.A.; EL-Shershaby, N.A.; Sallam, A.S. Fresh Futures: Cutting-Edge Eco-Friendly Coating Techniques for Fruits. J. Food Process. Preserv. 2025, 2025, 5201632. [Google Scholar] [CrossRef]

- Khan, A.A.; Cui, F.-J.; Ullah, M.W.; Qayum, A.; Khalifa, I.; Bacha, S.A.S.; Ying, Z.-Z.; Khan, I.; Zeb, U.; Alarfaj, A.A.; et al. Fabrication and characterization of bioactive curdlan and sodium alginate films for enhancing the shelf life of Volvariella volvacea. Food Biosci. 2024, 62, 105137. [Google Scholar] [CrossRef]

- Huang, X.; Zhao, W.; Li, Z.; Zhang, N.; Wang, S.; Shi, J.; Zhai, X.; Zhang, J.; Shen, T. Preparation of a Dual-Functional Active Film Based on Bilayer Hydrogel and Red Cabbage Anthocyanin for Maintaining and Monitoring Pork Freshness. Foods 2023, 12, 4520. [Google Scholar] [CrossRef]

- Alawode, R.; Olaniyi, A.; Olaniyi, M. An overview of thermal and non-thermal food processing and preservation methods. In Proceedings of the e-Proceedings of the Faculty of Agriculture International Conference, Awka, Nigeria, 12–14 March 2024; pp. 409–415. [Google Scholar]

- Moreira, M.R.; Álvarez, M.V.; Martín-Belloso, O.; Soliva-Fortuny, R. Effects of pulsed light treatments and pectin edible coatings on the quality of fresh-cut apples: A hurdle technology approach. J. Sci. Food Agric. 2017, 97, 261–268. [Google Scholar] [CrossRef]

- Salehi, F.; Amiri, M.; Ghazvineh, S. Effect of ultrasound combined with edible coating based on guar gum on the physicochemical quality and texture of fried zucchini slices. J. Food Sci. 2025, 90, e17608. [Google Scholar] [CrossRef]

- Nasrin, T.A.A.; Arfin, M.S.; Rahman, M.A.; Molla, M.M.; Sabuz, A.A.; Matin, M.A. Influence of novel coconut oil and beeswax edible coating and MAP on postharvest shelf life and quality attributes of lemon at low temperature. Meas. Food 2023, 10, 100084. [Google Scholar] [CrossRef]

- Miazaki, J.B.; dos Santos, A.R.; de Freitas, C.F.; Stafussa, A.P.; Mikcha, J.M.G.; Bergamasco, R.d.C.; Tonon, L.A.C.; Madrona, G.S.; Caetano, W.; da Silva, L.H.; et al. Edible coatings and application of photodynamics in ricotta cheese preservation. LWT 2022, 165, 113697. [Google Scholar] [CrossRef]

- Abdipour, M.; Sadat Malekhossini, P.; Hosseinifarahi, M.; Radi, M. Integration of UV irradiation and chitosan coating: A powerful treatment for maintaining the postharvest quality of sweet cherry fruit. Sci. Hortic. 2020, 264, 109197. [Google Scholar] [CrossRef]

- Abad, J.; Valencia-Chamorro, S.; Castro, A.; Vasco, C. Studying the effect of combining two nonconventional treatments, gamma irradiation and the application of an edible coating, on the postharvest quality of tamarillo (Solanum betaceum Cav.) fruits. Food Control 2017, 72, 319–323. [Google Scholar] [CrossRef]

- Iqbal, M.W.; Riaz, T.; Yasmin, I.; Leghari, A.A.; Amin, S.; Bilal, M.; Qi, X. Chitosan-based materials as edible coating of cheese: A review. Starch Stärke 2021, 73, 2100088. [Google Scholar] [CrossRef]

- Tahir, H.E.; Xiaobo, Z.; Mahunu, G.K.; Arslan, M.; Abdalhai, M.; Zhihua, L. Recent developments in gum edible coating applications for fruits and vegetables preservation: A review. Carbohydr. Polym. 2019, 224, 115141. [Google Scholar] [CrossRef] [PubMed]

- Saberi Riseh, R.; Vatankhah, M.; Hassanisaadi, M.; Kennedy, J.F. Chitosan-based nanocomposites as coatings and packaging materials for the postharvest improvement of agricultural product: A review. Carbohydr. Polym. 2023, 309, 120666. [Google Scholar] [CrossRef]

- Shen, C.; Chen, W.; Li, C.; Aziz, T.; Cui, H.; Lin, L. Topical advances of edible coating based on the nanoemulsions encapsulated with plant essential oils for foodborne pathogen control. Food Control 2023, 145, 109419. [Google Scholar] [CrossRef]

- Lopez-Polo, J.; Monasterio, A.; Cantero-López, P.; Osorio, F.A. Combining edible coatings technology and nanoencapsulation for food application: A brief review with an emphasis on nanoliposomes. Food Res. Int. 2021, 145, 110402. [Google Scholar] [CrossRef]

- Pirozzi, A.; Pataro, G.; Donsì, F.; Ferrari, G. Edible Coating and Pulsed Light to Increase the Shelf Life of Food Products. Food Eng. Rev. 2021, 13, 544–569. [Google Scholar] [CrossRef]

- Wu, D.; Zhang, M.; Xu, B.; Guo, Z. Fresh-cut orange preservation based on nano-zinc oxide combined with pressurized argon treatment. LWT 2021, 135, 110036. [Google Scholar] [CrossRef]

- Beikzadeh, S.; Ghorbani, M.; Shahbazi, N.; Izadi, F.; Pilevar, Z.; Mortazavian, A.M. The Effects of Novel Thermal and Nonthermal Technologies on the Properties of Edible Food Packaging. Food Eng. Rev. 2020, 12, 333–345. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef] [PubMed]

- Taghipour, L.; Assar, P. Nano-packaging technology for conserving the quality of fruits and vegetables. In Sustainable Postharvest Technologies for Fruits and Vegetables; CRC Press: Boca Raton, FL, USA, 2024; pp. 227–243. [Google Scholar]

- Meena, N.K.; Vinod, B.R.; Menaka, M.; Gunjan, P.; Kumar, B.; Chandana, M.R. Sustainable technologies prospects and potential applications in postharvest storage of fruits and vegetables. In Sustainable Postharvest Technologies for Fruits and Vegetables; CRC Press: Boca Raton, FL, USA, 2024; pp. 42–62. [Google Scholar]

- Moghadas, H.C.; Smith, J.S.; Tahergorabi, R. Recent Advances in the Application of Edible Coatings for Shelf-Life Extension of Strawberries: A Review. Food Bioprocess Technol. 2025, 18, 1079–1103. [Google Scholar] [CrossRef]

- Alvarado, M.C.; Bulfa, A.D., Jr. Applications of Nanocellulose in Postharvest Horticulture: Recent Advances and Perspectives. Food Bioeng. 2025, 4, 383–403. [Google Scholar] [CrossRef]

- Mariño-Cortegoso, S.; Lestido-Cardama, A.; Sendón, R.; Rodríguez Bernaldo de Quirós, A.; Barbosa-Pereira, L. The State of the Art and Innovations in Active and Edible Coatings and Films for Functional Food Applications. Polymers 2025, 17, 2472. [Google Scholar] [CrossRef]

- Gao, Q.; Wang, Y.; Li, Y.; Hou, J.; Liang, Y.; Zhang, Z. Investigation of the formation of furfural compounds in apple products treated with pasteurization and high pressure processing. Food Res. Int. 2024, 190, 114546. [Google Scholar] [CrossRef]

- Yusufu, D.; Bingham, M.; Mills, A. Novel Colour-Based, Prototype Indicator for Use in High-Pressure Processing (HPP). Chemosensors 2021, 9, 164. [Google Scholar] [CrossRef]

- Aganovic, K.; Hertel, C.; Vogel, R.F.; Johne, R.; Schlüter, O.; Schwarzenbolz, U.; Jäger, H.; Holzhauser, T.; Bergmair, J.; Roth, A. Aspects of high hydrostatic pressure food processing: Perspectives on technology and food safety. Compr. Rev. Food Sci. Food Saf. 2021, 20, 3225–3266. [Google Scholar] [CrossRef]

- González-Angulo, M.; Serment-Moreno, V.; Clemente-García, L.; Tonello, C.; Jaime, I.; Rovira, J. Assessing the pressure resistance of Escherichia coli O157:H7, Listeria monocytogenes and Salmonella enterica to high pressure processing (HPP) in citric acid model solutions for process validation. Food Res. Int. 2021, 140, 110091. [Google Scholar] [CrossRef]

- Evert-Arriagada, K.; Trujillo, A.J.; Amador-Espejo, G.G.; Hernández-Herrero, M.M. High pressure processing effect on different Listeria spp. in a commercial starter-free fresh cheese. Food Microbiol. 2018, 76, 481–486. [Google Scholar] [CrossRef]

- Tomasula, P.M.; Renye, J.A.; Van Hekken, D.L.; Tunick, M.H.; Kwoczak, R.; Toht, M.; Leggett, L.N.; Luchansky, J.B.; Porto-Fett, A.C.S.; Phillips, J.G. Effect of high-pressure processing on reduction of Listeria monocytogenes in packaged Queso Fresco. J. Dairy Sci. 2014, 97, 1281–1295. [Google Scholar] [CrossRef]

- Silva, F.V.M. Pasteurization of Food and Beverages by High Pressure Processing (HPP) at Room Temperature: Inactivation of Staphylococcus aureus, Escherichia coli, Listeria monocytogenes, Salmonella, and Other Microbial Pathogens. Appl. Sci. 2023, 13, 1193. [Google Scholar] [CrossRef]

- Bruschi, C.; Komora, N.; Castro, S.M.; Saraiva, J.; Ferreira, V.B.; Teixeira, P. High hydrostatic pressure effects on Listeria monocytogenes and L. innocua: Evidence for variability in inactivation behaviour and in resistance to pediocin bacHA-6111-2. Food Microbiol. 2017, 64, 226–231. [Google Scholar] [CrossRef] [PubMed]

- Wiśniewski, P.; Chajęcka-Wierzchowska, W.; Zadernowska, A. Impact of High-Pressure Processing (HPP) on Listeria monocytogenes—An Overview of Challenges and Responses. Foods 2024, 13, 14. [Google Scholar] [CrossRef]

- Rosario, D.K.; Rodrigues, B.L.; Bernardes, P.C.; Conte-Junior, C.A. Principles and applications of non-thermal technologies and alternative chemical compounds in meat and fish. Crit. Rev. Food Sci. Nutr. 2021, 61, 1163–1183. [Google Scholar] [CrossRef]

- Bambace, M.F.; del Rosario Moreira, M.; Sánchez-Moreno, C.; De Ancos, B. Effects of combined application of high-pressure processing and active coatings on phenolic compounds and microbiological and physicochemical quality of apple cubes. J. Sci. Food Agric. 2021, 101, 4256–4265. [Google Scholar] [CrossRef]

- Sehrawat, R.; Kaur, B.P.; Nema, P.K.; Tewari, S.; Kumar, L. Microbial inactivation by high pressure processing: Principle, mechanism and factors responsible. Food Sci. Biotechnol. 2021, 30, 19–35. [Google Scholar] [CrossRef]

- Vatankhah, H.; Ramaswamy, H.S. High pressure impregnation (HPI) of apple cubes: Effect of pressure variables and carrier medium. Food Res. Int. 2019, 116, 320–328. [Google Scholar] [CrossRef]

- Donsì, F.; Marchese, E.; Maresca, P.; Pataro, G.; Vu, K.D.; Salmieri, S.; Lacroix, M.; Ferrari, G. Green beans preservation by combination of a modified chitosan based-coating containing nanoemulsion of mandarin essential oil with high pressure or pulsed light processing. Postharvest Biol. Technol. 2015, 106, 21–32. [Google Scholar] [CrossRef]

- Fan, K.; Wu, J.; Chen, L. Ultrasound and its combined application in the improvement of microbial and physicochemical quality of fruits and vegetables: A review. Ultrason. Sonochem 2021, 80, 105838. [Google Scholar] [CrossRef]

- Hua, C.; Wang, Y.; Fan, X.; Zhang, A.; Chen, L.; Zhang, L.; Ma, H.; Lv, W.; Zhou, C. Effects and decontamination mechanism of ultrasonic combined bubbling-assisted peroxyacetic acid washing on lotus root. J. Food Sci. 2025, 90, e70083. [Google Scholar] [CrossRef]

- Huang, J.; Fu, Q.; Shao, X.; Li, Y. Ultrasonic strategies for mitigating microbial adhesion and biofilm formation on medical surfaces: A mini review. Front. Microbiol. 2025, 16, 1558035. [Google Scholar] [CrossRef] [PubMed]

- Prempeh, N.Y.A.; Nunekpeku, X.; Murugesan, A.; Li, H. Ultrasound in the Food Industry: Mechanisms and Applications for Non-Invasive Texture and Quality Analysis. Foods 2025, 14, 2057. [Google Scholar] [CrossRef] [PubMed]

- Kumar, N.; Upadhyay, A.; Shukla, S. Effects of Essential Oils and Ultrasonic Treatments on Properties of Edible Coatings and Their Application on Citrus Fruits. Starch Stärke 2024, 76, 2300104. [Google Scholar] [CrossRef]

- Muñoz-Labrador, A.; Moreno, R.; Villamiel, M.; Montilla, A. Preparation of citrus pectin gels by power ultrasound and its application as an edible coating in strawberries. J. Sci. Food Agric. 2018, 98, 4866–4875. [Google Scholar] [CrossRef]

- Lan, W.; Li, S.; Shama, S.; Zhao, Y.; Sameen, D.E.; He, L.; Liu, Y. Investigation of Ultrasonic Treatment on Physicochemical, Structural and Morphological Properties of Sodium Alginate/AgNPs/Apple Polyphenol Films and Its Preservation Effect on Strawberry. Polymers 2020, 12, 2096. [Google Scholar] [CrossRef]

- EFSA Panel on Food Contact Materials, Enzymes and Processing Aids (CEP); Lambré, C.; Barat Baviera, J.M.; Bolognesi, C.; Chesson, A.; Cocconcelli, P.S.; Crebelli, R.; Gott, D.M.; Grob, K.; Lampi, E.; et al. Safety assessment of the substance silver nanoparticles for use in food contact materials. EFSA J. 2021, 19, e06790. [Google Scholar] [CrossRef]

- Nicolae-Maranciuc, A.; Chicea, D. Polymeric Systems as Hydrogels and Membranes Containing Silver Nanoparticles for Biomedical and Food Applications: Recent Approaches and Perspectives. Gels 2025, 11, 699. [Google Scholar] [CrossRef]

- Kambhampati, V.; Kotra, S.R. Effect of edible chitosan coating on combined ultrasound and NaOCl treated kiwi fruits during refrigerated storage. Int. Food Res. J. 2018, 25, 101–108. [Google Scholar]

- Nowacka, M.; Dadan, M.; Tylewicz, U. Current Applications of Ultrasound in Fruit and Vegetables Osmotic Dehydration Processes. Appl. Sci. 2021, 11, 1269. [Google Scholar] [CrossRef]

- Mathe, S.; Monyela, N.F.; Belay, Z.A.; van Breda, V.M.; Caleb, O.J. Effects of sodium alginate coating and cold plasma treatment on biochemical changes, microbial load, and microstructure of ‘Granny Smith’ apples during storage. Technol. Hortic. 2025, 5, e001. [Google Scholar] [CrossRef]

- Obadi, M.; Li, Y.; Xu, B. Recent advances in extending the shelf life of fresh wet noodles: Influencing factors and preservation technologies. J. Food Sci. 2023, 88, 3626–3648. [Google Scholar] [CrossRef]

- Bisht, B.; Bhatnagar, P.; Gururani, P.; Kumar, V.; Tomar, M.S.; Sinhmar, R.; Rathi, N.; Kumar, S. Food irradiation: Effect of ionizing and non-ionizing radiations on preservation of fruits and vegetables—A review. Trends Food Sci. Technol. 2021, 114, 372–385. [Google Scholar] [CrossRef]

- Chiesa, L.M.; Di Cesare, F.; Mosconi, G.; Pavlovic, R.; Campaniello, M.; Tomaiuolo, M.; Mangiacotti, M.; Chiaravalle, E.; Panseri, S. Lipidomics profile of irradiated ground meat to support food safety. Food Chem. 2022, 375, 131700. [Google Scholar] [CrossRef] [PubMed]

- Pathak, B.; Omre, P.; Bisht, B.; Saini, D. Effect of thermal and non-thermal processing methods on food allergens. Progress. Res. Int. J. 2018, 13, 314–319. [Google Scholar]

- Joshua Ajibola, O. An overview of irradiation as a food preservation technique. Nov. Res. Microbiol. J. 2020, 4, 779–789. [Google Scholar] [CrossRef]

- Park, S.Y.; Jung, S.-J.; Ha, S.-D. Synergistic effects of combined X-ray and aqueous chlorine dioxide treatments against Salmonella Typhimurium biofilm on quail egg shells. LWT 2018, 92, 54–60. [Google Scholar] [CrossRef]

- Aaliya, B.; Valiyapeediyekkal Sunooj, K.; Navaf, M.; Parambil Akhila, P.; Sudheesh, C.; Ahmad Mir, S.; Sabu, S.; Sasidharan, A.; Theingi Hlaing, M.; George, J. Recent trends in bacterial decontamination of food products by hurdle technology: A synergistic approach using thermal and non-thermal processing techniques. Food Res. Int. 2021, 147, 110514. [Google Scholar] [CrossRef]

- Pan, M.; Yang, J.; Liu, K.; Xie, X.; Hong, L.; Wang, S.; Wang, S. Irradiation technology: An effective and promising strategy for eliminating food allergens. Food Res. Int. 2021, 148, 110578. [Google Scholar] [CrossRef]

- Mao, H.; Liu, Y.; Han, L.; Sheng, B.; Ma, G.; Li, Y. X-ray computerized tomography for characterization of pick-up destruction and pick-up parameter optimization of tomato root lumps. Span. J. Agric. Res. 2019, 17, e0202. [Google Scholar] [CrossRef]

- IARC Working Group on the Evaluation of Carcinogenic Risks to Humans. Solar and ultraviolet radiation. In Radiation; International Agency for Research on Cancer: Lyon, France, 2012. [Google Scholar]

- Khezerlou, A.; Zolfaghari, H.; Forghani, S.; Abedi-Firoozjah, R.; Alizadeh Sani, M.; Negahdari, B.; Jalalvand, M.; Ehsani, A.; McClements, D.J. Combining Non-Thermal Processing Techniques with Edible Coating Materials: An Innovative Approach to Food Preservation. Coatings 2023, 13, 830. [Google Scholar] [CrossRef]

- Wang, J.; Chen, J.; Sun, Y.; He, J.; Zhou, C.; Xia, Q.; Dang, Y.; Pan, D.; Du, L. Ultraviolet-radiation technology for preservation of meat and meat products: Recent advances and future trends. Food Control 2023, 148, 109684. [Google Scholar] [CrossRef]

- Lin, M.G.; Lasekan, O.; Saari, N.; Khairunniza-Bejo, S. The Effect of the Application of Edible Coatings on or before Ultraviolet Treatment on Postharvested Longan Fruits. J. Food Qual. 2017, 2017, 5454263. [Google Scholar] [CrossRef]

- Yu, L.; Zong, Y.; Han, Y.; Zhang, X.; Zhu, Y.; Oyom, W.; Gong, D.; Prusky, D.; Bi, Y. Both chitosan and chitooligosaccharide treatments accelerate wound healing of pear fruit by activating phenylpropanoid metabolism. Int. J. Biol. Macromol. 2022, 205, 483–490. [Google Scholar] [CrossRef] [PubMed]

- Zambrano-Zaragoza, M.L.; Quintanar-Guerrero, D.; González-Reza, R.M.; Cornejo-Villegas, M.A.; Leyva-Gómez, G.; Urbán-Morlán, Z. Effects of UV-C and Edible Nano-Coating as a Combined Strategy to Preserve Fresh-Cut Cucumber. Polymers 2021, 13, 3705. [Google Scholar] [CrossRef]

- John, D.; Ramaswamy, H.S. Pulsed light technology to enhance food safety and quality: A mini-review. Curr. Opin. Food Sci. 2018, 23, 70–79. [Google Scholar] [CrossRef]

- Chakraborty, S.; Parab, P.V. Pulsed light treatment of table grape juice: Influence of matrix pH on microbial and enzyme inactivation kinetics. Food Biosci. 2023, 53, 102662. [Google Scholar] [CrossRef]

- Wang, B.; Mahoney, N.E.; Khir, R.; Wu, B.; Zhou, C.; Pan, Z.; Ma, H. Degradation kinetics of aflatoxin B1 and B2 in solid medium by using pulsed light irradiation. J. Sci. Food Agric. 2018, 98, 5220–5224. [Google Scholar] [CrossRef]

- Kramer, B.; Muranyi, P. Effect of pulsed light on structural and physiological properties of Listeria innocua and Escherichia coli. J. Appl. Microbiol. 2014, 116, 596–611. [Google Scholar] [CrossRef]

- Fracari, P.R.; Massia, A.G.; Laroque, D.A.; Santos, B.A.d.; Cichoski, A.J.; Carciofi, B.A.M.; Campagnol, P.C.B. Pulsed Light Treatment Effect on Color, Oxidative Stability, and Listeria monocytogenes Population of Sliced Mortadella. Foods 2024, 13, 2976. [Google Scholar] [CrossRef]

- John, D.; Ramaswamy, H.S. Comparison of pulsed light inactivation kinetics and modeling of Escherichia coli (ATCC-29055), Clostridium sporogenes (ATCC-7955) and Geobacillus stearothermophilus (ATCC-10149). Curr. Res. Food Sci. 2020, 3, 82–91. [Google Scholar] [CrossRef]

- Liu, X. Pulsed Light Inactivation of Salmonella on the Surface of Almonds and Whole Black Peppercorn. Master’s Thesis, University of Delaware, Newark, DE, USA, 2019; pp. 1–13. [Google Scholar]

- Zhang, J.; Zhou, G.; Ji, S.; Zou, L.; Liang, J.; Walayat, N.; Chen, J.; Lyu, F.; Ding, Y. Effect of pulse light on the quality of refrigerated (4 °C) large yellow croaker (Pseudosciaena crocea). LWT 2022, 167, 113855. [Google Scholar] [CrossRef]

- Wang, B.; Wei, W.; Zhang, Y.; Xu, H.; Ma, H. Decontamination and quality assessment of freshly squeezed grape juice under spiral continuous flow-through pulsed light (SCFPL) treatment. J. Food Process. Preserv. 2022, 46, e16186. [Google Scholar] [CrossRef]

- Zhang, J.; Yagoub, A.E.G.A.; Sun, Y.; Mujumdar, A.S.; Ma, H.; Wahia, H.; Zhou, C. Intensive pulsed light pretreatment combined with controlled temperature and humidity for convection drying to reduce browning and improve quality of dried shiitake mushrooms. J. Sci. Food Agric. 2021, 101, 5608–5617. [Google Scholar] [CrossRef] [PubMed]

- Pedrós-Garrido, S.; Condón-Abanto, S.; Clemente, I.; Beltrán, J.A.; Lyng, J.G.; Bolton, D.; Brunton, N.; Whyte, P. Efficacy of ultraviolet light (UV-C) and pulsed light (PL) for the microbiological decontamination of raw salmon (Salmo salar) and food contact surface materials. Innov. Food Sci. Emerg. Technol. 2018, 50, 124–131. [Google Scholar] [CrossRef]

- Luksiene, Z.; Buchovec, I. Impact of chlorophyllin-chitosan coating and visible light on the microbial contamination, shelf life, nutritional and visual quality of strawberries. Innov. Food Sci. Emerg. Technol. 2019, 52, 463–472. [Google Scholar] [CrossRef]

- Koh, P.C.; Noranizan, M.A.; Karim, R.; Nur Hanani, Z.A.; Yusof, N.L. Cell wall composition of alginate coated and pulsed light treated fresh-cut cantaloupes (Cucumis melo L. Var. Reticulatus Cv. Glamour) during chilled storage. J. Food Sci. Technol. 2020, 57, 2206–2221. [Google Scholar] [CrossRef]

- Indiarto, R.; Pratama, A.W.; Sari, T.I.; Theodora, H.C. Food irradiation technology: A review of the uses and their capabilities. Int. J. Eng. Trends Technol. 2020, 68, 91–98. [Google Scholar] [CrossRef]

- Jeong, M.-A.; Jeong, R.-D. Applications of ionizing radiation for the control of postharvest diseases in fresh produce: Recent advances. Plant Pathol. 2018, 67, 18–29. [Google Scholar] [CrossRef]

- Ben-Fadhel, Y.; Saltaji, S.; Khlifi, M.A.; Salmieri, S.; Dang Vu, K.; Lacroix, M. Active edible coating and γ-irradiation as cold combined treatments to assure the safety of broccoli florets (Brassica oleracea L.). Int. J. Food Microbiol. 2017, 241, 30–38. [Google Scholar] [CrossRef]

- Severino, R.; Ferrari, G.; Vu, K.D.; Donsì, F.; Salmieri, S.; Lacroix, M. Antimicrobial effects of modified chitosan based coating containing nanoemulsion of essential oils, modified atmosphere packaging and gamma irradiation against Escherichia coli O157:H7 and Salmonella Typhimurium on green beans. Food Control 2015, 50, 215–222. [Google Scholar] [CrossRef]

- Tawema, P.; Han, J.; Vu, K.D.; Salmieri, S.; Lacroix, M. Antimicrobial effects of combined UV-C or gamma radiation with natural antimicrobial formulations against Listeria monocytogenes, Escherichia coli O157: H7, and total yeasts/molds in fresh cut cauliflower. LWT Food Sci. Technol. 2016, 65, 451–456. [Google Scholar] [CrossRef]

- Klausen, M.; Ucuncu, M.; Bradley, M. Design of Photosensitizing Agents for Targeted Antimicrobial Photodynamic Therapy. Molecules 2020, 25, 5239. [Google Scholar] [CrossRef] [PubMed]

- Zhu, S.; Song, Y.; Pei, J.; Xue, F.; Cui, X.; Xiong, X.; Li, C. The application of photodynamic inactivation to microorganisms in food. Food Chem. X 2021, 12, 100150. [Google Scholar] [CrossRef]

- Ghate, V.S.; Zhou, W.; Yuk, H.-G. Perspectives and Trends in the Application of Photodynamic Inactivation for Microbiological Food Safety. Compr. Rev. Food Sci. Food Saf. 2019, 18, 402–424. [Google Scholar] [CrossRef]

- do Prado-Silva, L.; Brancini, G.T.P.; Braga, G.Ú.L.; Liao, X.; Ding, T.; Sant’Ana, A.S. Antimicrobial photodynamic treatment (aPDT) as an innovative technology to control spoilage and pathogenic microorganisms in agri-food products: An updated review. Food Control 2022, 132, 108527. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, M.; Xu, B.; Mujumdar, A.S.; Guo, Z. Light-emitting diodes (below 700 nm): Improving the preservation of fresh foods during postharvest handling, storage, and transportation. Compr. Rev. Food Sci. Food Saf. 2022, 21, 106–126. [Google Scholar] [CrossRef]

- Alves, E.; Faustino, M.A.F.; Neves, M.G.P.M.S.; Cunha, Â.; Nadais, H.; Almeida, A. Potential applications of porphyrins in photodynamic inactivation beyond the medical scope. J. Photochem. Photobiol. C Photochem. Rev. 2015, 22, 34–57. [Google Scholar] [CrossRef]

- Wang, D.; Kyere, E.; Ahmed Sadiq, F. New Trends in Photodynamic Inactivation (PDI) Combating Biofilms in the Food Industry—A Review. Foods 2021, 10, 2587. [Google Scholar] [CrossRef]

- Chen, L.; Zhao, Y.; Wu, W.; Zeng, Q.; Wang, J.J. New trends in the development of photodynamic inactivation against planktonic microorganisms and their biofilms in food system. Compr. Rev. Food Sci. Food Saf. 2023, 22, 3814–3846. [Google Scholar] [CrossRef]

- Alves, E.; Faustino, M.A.; Neves, M.G.; Cunha, A.; Tome, J.; Almeida, A. An insight on bacterial cellular targets of photodynamic inactivation. Future Med. Chem. 2014, 6, 141–164. [Google Scholar] [CrossRef]

- Buchovec, I.; Lukseviciute, V.; Marsalka, A.; Reklaitis, I.; Luksiene, Z. Effective photosensitization-based inactivation of Gram (−) food pathogens and molds using the chlorophyllin—Chitosan complex: Towards photoactive edible coatings to preserve strawberries. Photochem. Photobiol. Sci. 2016, 15, 506–516. [Google Scholar] [CrossRef] [PubMed]

- Jiang, C.; Scholle, F.; Jin, F.; Wei, Q.; Wang, Q.; Ghiladi, R.A. Chlorophyllin as a photosensitizer in photodynamic antimicrobial materials. Cellulose 2024, 31, 2475–2491. [Google Scholar] [CrossRef]

- Fu, B.; Zhang, L.; Zhao, P.; Gong, W.; Luo, L.; Li, B.; Yue, X.; Wang, J.; Chen, Y. Bandgap-level engineered photodynamic antibacterial film with boosting ROS production for long-term fruit preservation. Food Packag. Shelf Life 2024, 46, 101366. [Google Scholar] [CrossRef]

- Al-Asmari, F.; Mereddy, R.; Sultanbawa, Y. The effect of photosensitization mediated by curcumin on storage life of fresh date (Phoenix dactylifera L.) fruit. Food Control 2018, 93, 305–309. [Google Scholar] [CrossRef]

- Du, T.; Li, X.; Wang, S.; Su, Z.; Sun, H.; Wang, J.; Zhang, W. Phytochemicals-based edible coating for photodynamic preservation of fresh-cut apples. Food Res. Int. 2023, 163, 112293. [Google Scholar] [CrossRef]

- Li, H.; Jiang, Y.; Yang, J.; Pang, R.; Chen, Y.; Mo, L.; Jiang, Q.; Qin, Z. Preparation of curcumin-chitosan composite film with high antioxidant and antibacterial capacity: Improving the solubility of curcumin by encapsulation of biopolymers. Food Hydrocolloids 2023, 145, 109150. [Google Scholar] [CrossRef]

- Zhu, Y.; Li, C.; Cui, H.; Lin, L. Feasibility of cold plasma for the control of biofilms in food industry. Trends Food Sci. Technol. 2020, 99, 142–151. [Google Scholar] [CrossRef]

- Misra, N.N.; Yadav, B.; Roopesh, M.S.; Jo, C. Cold Plasma for Effective Fungal and Mycotoxin Control in Foods: Mechanisms, Inactivation Effects, and Applications. Compr. Rev. Food Sci. Food Saf. 2019, 18, 106–120. [Google Scholar] [CrossRef]

- Mei, D.; Zhu, X.; Wu, C.; Ashford, B.; Williams, P.T.; Tu, X. Plasma-photocatalytic conversion of CO2 at low temperatures: Understanding the synergistic effect of plasma-catalysis. Appl. Catal. B Environ. 2016, 182, 525–532. [Google Scholar] [CrossRef]

- Farber, R.; Dabush-Busheri, I.; Chaniel, G.; Rozenfeld, S.; Bormashenko, E.; Multanen, V.; Cahan, R. Biofilm grown on wood waste pretreated with cold low-pressure nitrogen plasma: Utilization for toluene remediation. Int. Biodeterior. Biodegrad. 2019, 139, 62–69. [Google Scholar] [CrossRef]

- Sharma, S.; Singh, R.k. Cold plasma treatment of dairy proteins in relation to functionality enhancement. Trends Food Sci. Technol. 2020, 102, 30–36. [Google Scholar] [CrossRef]

- Lin, L.; Liao, X.; Cui, H. Cold plasma treated thyme essential oil/silk fibroin nanofibers against Salmonella Typhimurium in poultry meat. Food Packag. Shelf Life 2019, 21, 100337. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, J.; Zhang, Y.; Hu, H.; Luo, S.; Zhang, L.; Zhou, H.; Li, P. Effects of in-package atmospheric cold plasma treatment on the qualitative, metabolic and microbial stability of fresh-cut pears. J. Sci. Food Agric. 2021, 101, 4473–4480. [Google Scholar] [CrossRef] [PubMed]

- Shen, C.; Chen, W.; Li, C.; Cui, H.; Lin, L. The effects of cold plasma (CP) treatment on the inactivation of yam peroxidase and characteristics of yam slices. J. Food Eng. 2023, 359, 111693. [Google Scholar] [CrossRef]

- Wei, W.; Yang, S.; Yang, F.; Hu, X.; Wang, Y.; Guo, W.; Yang, B.; Xiao, X.; Zhu, L. Cold Plasma Controls Nitrite Hazards by Modulating Microbial Communities in Pickled Radish. Foods 2023, 12, 2550. [Google Scholar] [CrossRef]

- Pinela, J.; Ferreira, I.C. Nonthermal physical technologies to decontaminate and extend the shelf-life of fruits and vegetables: Trends aiming at quality and safety. Crit. Rev. Food Sci. Nutr. 2017, 57, 2095–2111. [Google Scholar] [CrossRef]

- Qiu, L.; Zhang, M.; Tang, J.; Adhikari, B.; Cao, P. Innovative technologies for producing and preserving intermediate moisture foods: A review. Food Res. Int. 2019, 116, 90–102. [Google Scholar] [CrossRef]

- Han, L.; Patil, S.; Boehm, D.; Milosavljević, V.; Cullen, P.J.; Bourke, P. Mechanisms of Inactivation by High-Voltage Atmospheric Cold Plasma Differ for Escherichia coli and Staphylococcus aureus. Appl. Env. Microbiol. 2016, 82, 450–458. [Google Scholar] [CrossRef]

- Umair, M.; Sultana, T.; Xun, S.; Jabbar, S.; Riaz Rajoka, M.S.; Albahi, A.; Abid, M.; Ranjha, M.M.A.N.; El-Seedi, H.R.; Xie, F. Advances in the application of functional nanomaterial and cold plasma for the fresh-keeping active packaging of meat. Food Sci. Nutr. 2023, 11, 5753–5772. [Google Scholar] [CrossRef]

- Zhou, C.; Hu, Y.; Zhou, Y.; Yu, H.; Li, B.; Yang, W.; Zhai, X.; Wang, X.; Liu, J.; Wang, J.; et al. Air and argon cold plasma effects on lipolytic enzymes inactivation, physicochemical properties and volatile profiles of lightly-milled rice. Food Chem. 2024, 445, 138699. [Google Scholar] [CrossRef]

- Zhou, C.; Zhou, Y.; Tang, Q.; Sun, Y.; Ji, F.; Wu, J.; Yu, H.; Liu, T.; Yang, W.; Liu, S.; et al. Impact of argon dielectric barrier discharge cold plasma on the physicochemical and cooking properties of lightly-milled rice. Innov. Food Sci. Emerg. Technol. 2024, 92, 103580. [Google Scholar] [CrossRef]

- Obadi, M.; Guo, Q.; Sun, J.; Xu, B. Recent developments in the application of physical processing techniques for controlling browning in fresh wet noodles: A review. J. Cereal Sci. 2024, 118, 103951. [Google Scholar] [CrossRef]

- Odeyemi, O.A.; Alegbeleye, O.O.; Strateva, M.; Stratev, D. Understanding spoilage microbial community and spoilage mechanisms in foods of animal origin. Compr. Rev. Food Sci. Food Saf. 2020, 19, 311–331. [Google Scholar] [CrossRef] [PubMed]

- Cullen, P.J.; Lalor, J.; Scally, L.; Boehm, D.; Milosavljević, V.; Bourke, P.; Keener, K. Translation of plasma technology from the lab to the food industry. Plasma Process. Polym. 2018, 15, 1700085. [Google Scholar] [CrossRef]

- Laroque, D.A.; Seó, S.T.; Valencia, G.A.; Laurindo, J.B.; Carciofi, B.A.M. Cold plasma in food processing: Design, mechanisms, and application. J. Food Eng. 2022, 312, 110748. [Google Scholar] [CrossRef]

- Romani, V.P.; Olsen, B.; Pinto Collares, M.; Meireles Oliveira, J.R.; Prentice, C.; Martins, V.G. Cold plasma and carnauba wax as strategies to produce improved bi-layer films for sustainable food packaging. Food Hydrocoll. 2020, 108, 106087. [Google Scholar] [CrossRef]

- Jeon, Y.J.; Myung, G.E.; Min, S.C. In-package cold plasma treatment enhances the antimicrobial efficacy of malic acid-incorporated whey protein edible coating against Salmonella and Listeria monocytogenes in steamed fish paste. Food Packag. Shelf Life 2022, 33, 100905. [Google Scholar] [CrossRef]

- Jeon, Y.J.; Lee, H.; Min, S.C. Effects of in-package atmospheric dielectric barrier discharge cold plasma treatment on the antimicrobial efficacy of whey protein isolate-based edible films that incorporate malic acid against Salmonella in chicken breast processed meat. Innov. Food Sci. Emerg. Technol. 2023, 85, 103339. [Google Scholar] [CrossRef]

- Azeredo, H.M.C.; Waldron, K.W. Crosslinking in polysaccharide and protein films and coatings for food contact—A review. Trends Food Sci. Technol. 2016, 52, 109–122. [Google Scholar] [CrossRef]

- Wang, D.; Lv, R.; Ma, X.; Zou, M.; Wang, W.; Yan, L.; Ding, T.; Ye, X.; Liu, D. Lysozyme immobilization on the calcium alginate film under sonication: Development of an antimicrobial film. Food Hydrocoll. 2018, 83, 1–8. [Google Scholar] [CrossRef]

- Agarwal, S.; Hoque, M.; Bandara, N.; Pal, K.; Sarkar, P. Synthesis and characterization of tamarind kernel powder-based antimicrobial edible films loaded with geraniol. Food Packag. Shelf Life 2020, 26, 100562. [Google Scholar] [CrossRef]

- Heidemann, H.M.; Dotto, M.E.R.; Laurindo, J.B.; Carciofi, B.A.M.; Costa, C. Cold plasma treatment to improve the adhesion of cassava starch films onto PCL and PLA surface. Colloids Surf. A Physicochem. Eng. Asp. 2019, 580, 123739. [Google Scholar] [CrossRef]

- Bahrami, R.; Zibaei, R.; Hashami, Z.; Hasanvand, S.; Garavand, F.; Rouhi, M.; Jafari, S.M.; Mohammadi, R. Modification and improvement of biodegradable packaging films by cold plasma; a critical review. Crit. Rev. Food Sci. Nutr. 2022, 62, 1936–1950. [Google Scholar] [CrossRef]

- Honarvar, Z.; Farhoodi, M.; Khani, M.R.; Mohammadi, A.; Shokri, B.; Ferdowsi, R.; Shojaee-Aliabadi, S. Application of cold plasma to develop carboxymethyl cellulose-coated polypropylene films containing essential oil. Carbohydr. Polym. 2017, 176, 1–10. [Google Scholar] [CrossRef]

- Chen, G.; Dong, S.; Zhao, S.; Li, S.; Chen, Y. Improving functional properties of zein film via compositing with chitosan and cold plasma treatment. Ind. Crops Prod. 2019, 129, 318–326. [Google Scholar] [CrossRef]

- Chen, G.; Chen, Y.; Jin, N.; Li, J.; Dong, S.; Li, S.; Zhang, Z.; Chen, Y. Zein films with porous polylactic acid coatings via cold plasma pre-treatment. Ind. Crops Prod. 2020, 150, 112382. [Google Scholar] [CrossRef]

- Cui, H.; Surendhiran, D.; Li, C.; Lin, L. Biodegradable zein active film containing chitosan nanoparticle encapsulated with pomegranate peel extract for food packaging. Food Packag. Shelf Life 2020, 24, 100511. [Google Scholar] [CrossRef]

- Oh, Y.A.; Roh, S.H.; Min, S.C. Cold plasma treatments for improvement of the applicability of defatted soybean meal-based edible film in food packaging. Food Hydrocoll. 2016, 58, 150–159. [Google Scholar] [CrossRef]

- Chen, G.; Ali, F.; Dong, S.; Yin, Z.; Li, S.; Chen, Y. Preparation, characterization and functional evaluation of chitosan-based films with zein coatings produced by cold plasma. Carbohydr. Polym. 2018, 202, 39–46. [Google Scholar] [CrossRef]

- Belay, Z.A.; Nyamende, N.E.; Caleb, O.J. Impact of cold plasma-mediated treatment on coated and packaged ‘Monterey’ strawberries during cold storage. South. Afr. J. Plant Soil. 2022, 39, 302–307. [Google Scholar] [CrossRef]

- Rashvand, M.; Matera, A.; Altieri, G.; Genovese, F.; Nikzadfar, M.; Feyissa, A.H.; Di Renzo, G.C. Effect of Dielectric Barrier Discharge Cold Plasma on the Bio-nanocomposite Film and its Potential to Preserve the Quality of Strawberry under Modified Atmosphere Packaging. Food Bioprocess Technol. 2024, 17, 1247–1264. [Google Scholar] [CrossRef]

- Akhavan-Mahdavi, S.; Mirzazadeh, M.; Alam, Z.; Solaimanimehr, S. The effect of chitosan coating combined with cold plasma on the quality and safety of pistachio during storage. Food Sci. Nutr. 2023, 11, 4296–4307. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Yang, W.; Zhang, S.; Tang, J.; Shi, X.; Qin, S.; Pan, L.; Xiao, H. Enhancing the applicability of gelatin-carboxymethyl cellulose films by cold plasma modification for the preservation of fruits. LWT 2023, 178, 114612. [Google Scholar] [CrossRef]

- Ali Ghoflgar Ghasemi, M.; Hamishehkar, H.; Javadi, A.; Homayouni-Rad, A.; Jafarizadeh-Malmiri, H. Natural-based edible nanocomposite coating for beef meat packaging. Food Chem. 2024, 435, 137582. [Google Scholar] [CrossRef]

- Ghidelli, C.; Pérez-Gago, M.B. Recent advances in modified atmosphere packaging and edible coatings to maintain quality of fresh-cut fruits and vegetables. Crit. Rev. Food Sci. Nutr. 2018, 58, 662–679. [Google Scholar] [CrossRef]

- Candir, E.; Ozdemir, A.E.; Aksoy, M.C. Effects of chitosan coating and modified atmosphere packaging on postharvest quality and bioactive compounds of pomegranate fruit cv. ‘Hicaznar’. Sci. Hortic. 2018, 235, 235–243. [Google Scholar] [CrossRef]

- Porat, R.; Kosto, I.; Daus, A. Bulk storage of “Wonderful” pomegranate fruit using modified atmosphere bags. Isr. J. Plant Sci. 2016, 63, 45–50. [Google Scholar] [CrossRef]

- Olawuyi, I.F.; Park, J.J.; Lee, J.J.; Lee, W.Y. Combined effect of chitosan coating and modified atmosphere packaging on fresh-cut cucumber. Food Sci. Nutr. 2019, 7, 1043–1052. [Google Scholar] [CrossRef]

- Karagöz, Ş.; Demirdöven, A. Effect of chitosan coatings with and without Stevia rebaudiana and modified atmosphere packaging on quality of cold stored fresh-cut apples. LWT 2019, 108, 332–337. [Google Scholar] [CrossRef]

- Martiñon, M.E.; Moreira, R.G.; Castell-Perez, M.E.; Gomes, C. Development of a multilayered antimicrobial edible coating for shelf-life extension of fresh-cut cantaloupe (Cucumis melo L.) stored at 4 °C. LWT Food Sci. Technol. 2014, 56, 341–350. [Google Scholar] [CrossRef]

- Fan, K.; Zhang, M.; Fan, D.; Jiang, F. Effect of carbon dots with chitosan coating on microorganisms and storage quality of modified-atmosphere-packaged fresh-cut cucumber. J. Sci. Food Agric. 2019, 99, 6032–6041. [Google Scholar] [CrossRef] [PubMed]

- Fan, K.; Zhang, M.; Guo, C.; Dan, W.; Devahastin, S. Laser-Induced Microporous Modified Atmosphere Packaging and Chitosan Carbon-Dot Coating as a Novel Combined Preservation Method for Fresh-Cut Cucumber. Food Bioprocess Technol. 2021, 14, 968–983. [Google Scholar] [CrossRef]

- Di Millo, B.; Martínez-Blay, V.; Pérez-Gago, M.B.; Argente-Sanchis, M.; Grimal, A.; Baraldi, E.; Palou, L. Antifungal Hydroxypropyl Methylcellulose (HPMC)-Lipid Composite Edible Coatings and Modified Atmosphere Packaging (MAP) to Reduce Postharvest Decay and Improve Storability of ‘Mollar De Elche’ Pomegranates. Coatings 2021, 11, 308. [Google Scholar] [CrossRef]

- Moreira, M.R.; Tomadoni, B.; Martín-Belloso, O.; Soliva-Fortuny, R. Preservation of fresh-cut apple quality attributes by pulsed light in combination with gellan gum-based prebiotic edible coatings. LWT Food Sci. Technol. 2015, 64, 1130–1137. [Google Scholar] [CrossRef]

- Salinas-Roca, B.; Soliva-Fortuny, R.; Welti-Chanes, J.; Martín-Belloso, O. Combined effect of pulsed light, edible coating and malic acid dipping to improve fresh-cut mango safety and quality. Food Control 2016, 66, 190–197. [Google Scholar] [CrossRef]

- El-Dein, A.E.; Khozemy, E.E.; Farag, S.A.; Abd El-Hamed, N.; Dosoukey, I.M. Effect of edible co-polymers coatings using γ-irradiation on Hyani date fruit behavior during marketing. Int. J. Biol. Macromol. 2018, 117, 851–857. [Google Scholar] [CrossRef]

- Babu, I.; Yasmin, Z.; Kanwal, R.; Asghar, M.; Tahira, R. Application of γ-irradiation and chitosan skin coating for extension of storage life in mango fruit. J. Agric. Res. 2019, 57, 45–49. [Google Scholar]

- Maherani, B.; Harich, M.; Salmieri, S.; Lacroix, M. Antibacterial properties of combined non-thermal treatments based on bioactive edible coating, ozonation, and gamma irradiation on ready-to-eat frozen green peppers: Evaluation of their freshness and sensory qualities. Eur. Food Res. Technol. 2019, 245, 1095–1111. [Google Scholar] [CrossRef]

- Park, M.-J.; Kim, J.-H.; Oh, S.-W. Inactivation of Salmonella Typhimurium and Escherichia coli O157:H7 on black pepper powder using UV-C, UV-A and TiO2 coating. Food Sci. Biotechnol. 2020, 29, 283–291. [Google Scholar] [CrossRef]

- Ben-Fadhel, Y.; Cingolani, M.C.; Li, L.; Chazot, G.; Salmieri, S.; Horak, C.; Lacroix, M. Effect of γ-irradiation and the use of combined treatments with edible bioactive coating on carrot preservation. Food Packag. Shelf Life 2021, 28, 100635. [Google Scholar] [CrossRef]

- Bal, E. Storage life extension of cherry tomato by alginate-based edible coating in combination with UV-C treatment. J. Hortic. Postharvest Res. 2021, 4, 453–466. [Google Scholar] [CrossRef]

- Hussain, N.; Shukla, S.S.; Dubey, A.D.; Gautam, S.; Tripathi, J. Control of post-harvest storage losses in water chestnut (Trapa bispinosa Roxburg) fruits by natural functional herbal coating and gamma radiation processing. J. Food Sci. Technol. 2022, 59, 2842–2854. [Google Scholar] [CrossRef] [PubMed]

- Mohamed, T.M.; Attia, M.S.; El-Sayyad, G.S.; Fathy, R.M.; El-Batal, A.I. Gamma radiation crosslinking of PVA/myrrh resin thin film for improving the post-harvest time of lemon fruits. RSC Adv. 2022, 12, 5619–5628. [Google Scholar] [CrossRef]

- Elbarbary, A.M.; Khozemy, E.E.; El-Dein, A.E.; El-Sawy, N.M. Radiation Synthesis of Edible Coating Films of Nanocurcumin Based on Carboxymethyl Chitosan/Polyvinyl Alcohol to Extend the Shelf Life of Sweet Orange “Valencia”. J. Polym. Environ. 2023, 31, 3783–3802. [Google Scholar] [CrossRef]

- Amaral, R.D.A.; Achaerandio, I.; Benedetti, B.C.; Pujolà, M. The influence of edible coatings, blanching and ultrasound treatments on quality attributes and shelf-life of vacuum packaged potato strips. LWT Food Sci. Technol. 2017, 85, 449–455. [Google Scholar] [CrossRef]

- Salehi, F.; Ghazvineh, S.; Inanloodoghouz, M. Effects of edible coatings and ultrasonic pretreatment on the phenolic content, antioxidant potential, drying rate, and rehydration ratio of sweet cherry. Ultrason. Sonochemistry 2023, 99, 106565. [Google Scholar] [CrossRef]

- Salehi, F.; Ghazvineh, S.; Amiri, M. Effect of basil seed gum coating and ultrasound pretreatment on frying time, oil uptake, hardness, color indexes, and sensory properties of potato slices. Ultrason. Sonochemistry 2024, 110, 107035. [Google Scholar] [CrossRef]

- Pérez, D.A.; Gómez, J.M.; Castellanos, D.A. Combined modified atmosphere packaging and guar gum edible coatings to preserve blackberry (Rubus glaucus Benth). Food Sci. Technol. Int. 2021, 27, 353–365. [Google Scholar] [CrossRef]

- Bai, X.; Dag, D.; Jung, J.; Zhao, Y. Investigation of antioxidant edible coating and modified atmosphere packaging for enhancing storability of hazelnut kernels. J. Agric. Food Res. 2024, 17, 101246. [Google Scholar] [CrossRef]

- Ghidelli, C.; Mateos, M.; Rojas-Argudo, C.; Pérez-Gago, M.B. Novel approaches to control browning of fresh-cut artichoke: Effect of a soy protein-based coating and modified atmosphere packaging. Postharvest Biol. Technol. 2015, 99, 105–113. [Google Scholar] [CrossRef]

- Barikloo, H.; Ahmadi, E. Shelf life extension of strawberry by temperatures conditioning, chitosan coating, modified atmosphere, and clay and silica nanocomposite packaging. Sci. Hortic. 2018, 240, 496–508. [Google Scholar] [CrossRef]

- Song, W.-J.; Kang, D.-H. Influence of water activity on inactivation of Escherichia coli O157:H7, Salmonella Typhimurium and Listeria monocytogenes in peanut butter by microwave heating. Food Microbiol. 2016, 60, 104–111. [Google Scholar] [CrossRef] [PubMed]

- Tapia, M.S.; Alzamora, S.M.; Chirife, J. Effects of Water Activity (a w) on Microbial Stability as a Hurdle in Food Preservation. In Water Activity in Foods; John Wiley & Sons: Hoboken, NJ, USA, 2020; pp. 323–355. [Google Scholar]

- López-Malo, A.; Alzamora, S.M. Water Activity and Microorganism Control: Past and Future. In Water Stress in Biological, Chemical, Pharmaceutical and Food Systems; Gutiérrez-López, G.F., Alamilla-Beltrán, L., del Pilar Buera, M., Welti-Chanes, J., Parada-Arias, E., Barbosa-Cánovas, G.V., Eds.; Springer: New York, NY, USA, 2015; pp. 245–262. [Google Scholar]

- Caleb, O.J.; Mahajan, P.V.; Al-Said, F.A.; Opara, U.L. Modified Atmosphere Packaging Technology of Fresh and Fresh-cut Produce and the Microbial Consequences-A Review. Food Bioproc. Tech. 2013, 6, 303–329. [Google Scholar] [CrossRef]

- Miteluț, A.C.; Popa, E.E.; Drăghici, M.C.; Popescu, P.A.; Popa, V.I.; Bujor, O.C.; Ion, V.A.; Popa, M.E. Latest Developments in Edible Coatings on Minimally Processed Fruits and Vegetables: A Review. Foods 2021, 10, 2821. [Google Scholar] [CrossRef]

- Islam, M.Z.; Saha, T.; Monalisa, K.; Hoque, M.M. Effect of starch edible coating on drying characteristics and antioxidant properties of papaya. J. Food Meas. Charact. 2019, 13, 2951–2960. [Google Scholar] [CrossRef]

- Beyza, H.; Fatma, K.; Hecer, C. Edible films and coatings: A good idea from past to future technology. J. Food Technol. 2018, 5, 28–33. [Google Scholar]

- Liao, X.; Xing, Y.; Fan, X.; Qiu, Y.; Xu, Q.; Liu, X. Effect of Composite Edible Coatings Combined with Modified Atmosphere Packaging on the Storage Quality and Microbiological Properties of Fresh-Cut Pineapple. Foods 2023, 12, 1344. [Google Scholar] [CrossRef]

- Kumar, N.; Daniloski, D.; D’cunha, N.M.; Naumovski, N.; Petkoska, A.T. Pomegranate peel extract–A natural bioactive addition to novel active edible packaging. Food Res. Int. 2022, 156, 111378. [Google Scholar] [CrossRef]

- Vahedikia, N.; Garavand, F.; Tajeddin, B.; Cacciotti, I.; Jafari, S.M.; Omidi, T.; Zahedi, Z. Biodegradable zein film composites reinforced with chitosan nanoparticles and cinnamon essential oil: Physical, mechanical, structural and antimicrobial attributes. Colloids Surf. B Biointerfaces 2019, 177, 25–32. [Google Scholar] [CrossRef]

- Majidi, H.J.; Babaei, A.; Bafrani, Z.A.; Shahrampour, D.; Zabihi, E.; Jafari, S.M. Investigating the best strategy to diminish the toxicity and enhance the antibacterial activity of graphene oxide by chitosan addition. Carbohydr. Polym. 2019, 225, 115220. [Google Scholar] [CrossRef]

- Li, T.; Chen, J.; Duan, X.; Wu, X.; Liao, X. Combined antimicrobial effect of high pressure processing and ethyl lauroyl arginate (LAE)-containing films and its application in coconut water preservation. Food Control 2024, 155, 110039. [Google Scholar] [CrossRef]

- Abera, G. Review on high-pressure processing of foods. Cogent Food Agric. 2019, 5, 1568725. [Google Scholar] [CrossRef]

- Tsironi, T.; Houhoula, D.; Taoukis, P. Hurdle technology for fish preservation. Aquac. Fish. 2020, 5, 65–71. [Google Scholar] [CrossRef]

- Mahmoud, M.Z.; Fagiry, M.A.; Davidson, R.; Abdelbasset, W.K. The benefits, drawbacks, and potential future challenges of the most commonly used ultrasound-based hurdle combinations technologies in food preservation. J. Radiat. Res. Appl. Sci. 2022, 15, 206–212. [Google Scholar] [CrossRef]

- Sharma, P.; Shehin, V.; Kaur, N.; Vyas, P. Application of edible coatings on fresh and minimally processed vegetables: A review. Int. J. Veg. Sci. 2019, 25, 295–314. [Google Scholar] [CrossRef]

- Khanzadi, S.; Keykhosravy, K.; Hashemi, M.; Azizzadeh, M. Alginate coarse/nanoemulsions containing Zataria multiflora Boiss essential oil as edible coatings and the impact on microbial quality of trout fillet. Aquac. Res. 2020, 51, 873–881. [Google Scholar] [CrossRef]

- Nair, M.S.; Tomar, M.; Punia, S.; Kukula-Koch, W.; Kumar, M. Enhancing the functionality of chitosan-and alginate-based active edible coatings/films for the preservation of fruits and vegetables: A review. Int. J. Biol. Macromol. 2020, 164, 304–320. [Google Scholar] [CrossRef]

- Kumar, N.; Prasad, J.; Yadav, A.; Upadhyay, A.; Shukla, S.; Petkoska, A.T.; Suri, S.; Gniewosz, M.; Kieliszek, M. Recent Trends in Edible Packaging for Food Applications—Perspective for the Future. Food Eng. Rev. 2023, 15, 718–747. [Google Scholar] [CrossRef]

- Mohamed, S.A.A.; El-Sakhawy, M.; El-Sakhawy, M.A.-M. Polysaccharides, Protein and Lipid -Based Natural Edible Films in Food Packaging: A Review. Carbohydr. Polym. 2020, 238, 116178. [Google Scholar] [CrossRef]

- Zhang, S.; Kuang, Y.; Xu, P.; Chen, X.; Bi, Y.; Peng, D.; Li, J. Applications of Prolamin-Based Edible Coatings in Food Preservation: A Review. Molecules 2023, 28, 7800. [Google Scholar] [CrossRef]

- Xu, W.; Wu, C. The impact of pulsed light on decontamination, quality, and bacterial attachment of fresh raspberries. Food Microbiol. 2016, 57, 135–143. [Google Scholar] [CrossRef]

- Oliveira, F.A.d.; Neto, O.C.; Santos, L.M.R.d.; Ferreira, E.H.R.; Rosenthal, A. Effect of high pressure on fish meat quality—A review. Trends Food Sci. Technol. 2017, 66, 1–19. [Google Scholar] [CrossRef]

| Non-Thermal Techniques | Fresh Produce | Hurdle Approach (Functional Ingredients or Experimental Conditions) | Target Foodborne-Threat | Findings After Hurdle Treatment | References |

|---|---|---|---|---|---|

| Irradiation | Fresh-cut apple (Malus domestica) | PL (30 pulses/s, 0.3 ms, 0.4 J/cm2, λ = 180–1100 nm) + gellan gum (calcium chloride, ascorbic acid) | Mesophilic aerobic, psychrophilic and yeast and mold | • Ensured the preservation of the antioxidant value of fresh-cut apples. | Moreira et al. [149] |

| Fresh-cut mango (Mangifera indica L.) | PL (20 pulses/s, 0.4 J·cm−2/pulse), alginate coating (ALC) (2%), or malic acid (MA) (2%) | L. innocua | Results show that MA-PL and PL-ALC-MA treatments additively reduced L. innocua counts by 4.5 and 3.9 logs, respectively. | [150] | |

| Broccoli florets (Brassica oleracea L.) | γ-irradiation (0.4 and 0.8 kGy) + Alginate (essential oils, organic acid salts and natamycin) | E. coli, L. monocytogenes, S. Typhimurium and Aspergillus niger | • 0.8 kGy and edible coating combination reduced A. niger to 2.3 and 2.0 log conidia/g on day 0 and 1 and then it decreased to under the detectable level during the whole of storage at 4 °C. | Ben-Fadhel, Saltaji, Khlifi, Salmieri, Dang Vu, and Lacroix [84] | |

| Date (Phoenix dactylifera L.) | γ-irradiation (5 and 20 kGy) + CHS (Poly vinyl alcohol and tannic acids) | Saccharomyces cerevisiae and Acinetobacter baumannii and E. coli | • Coated dates recorded higher values of acceptability after four-weeks marketing period. | El-Dein et al. [151] | |

| Mango (Mangifera indica L.) | γ-irradiation (350 kGy) + CHS | N/A | • Mangoes coated with irradiated chitosan recorded minimum weight loss. • Maximum firmness. • Increased total soluble solids. | Babu et al. [152] | |

| Pre-cut green peppers (Capsicum annuum, L.) | γ-irradiation (0.5 kGy) + Antibacterial coating (lemongrass essential oil, citrus extract, fermented dextrose Prolong 2, and concentrated cranberry juice) | L. innocua, E. coli and S. enterica | • Irradiated • The combination of ozonation, coating, and irradiation inhibits L. innocua, E. coli, and S. enterica. | Maherani et al. [153] | |

| Black pepper powder (Piper nigrum) | UVC and UVA | S. Typhimurium and E. coli O157:H7 | • Coatings significantly increased the inactivation effects of UVA and UVC against S. Typhimurium and E. coli O157:H7. | Park et al. [154] | |

| Carrot (Daucus carota) | γ-irradiation (32 kGy) + calcium caseinate coating (Ca-Cas) (citrus extract, cranberry juice, and essential oils) | Mesophilic flora (TMF) counts and yeasts and mold | • Combination of edible coating with irradiation did not affect the weight loss, firmness, or color difference between carrots throughout storage. | Ben-Fadhel et al. [155] | |

| Cherry tomato (Solanum lycopersicum L.) | UVC + Alginate | N/A | • Alginate coating combined with UVC inhibited weight loss with more efficiency throughout the storage period. | Bal [156] | |

| Water chestnut (Trapa bispinosa Roxburg) | γ-irradiation (0.25–1.0 kGy) + aloe-vera gel | N/A | • The most effective combination treatments such as 50% Aloe vera gel + 0.75 kGy achieved the best results in terms of reduction in weight loss, percentage age damage, and insect infestations, without sacrificing the quality of stored water chestnuts. | Hussain et al. [157] | |

| Lemon (Citrus limon) | γ-irradiation (1.0 kGy) + Resin | Penicillium digitatum | • Reduced green mold disease symptoms caused by P. digitatum and disease severity in lemon fruits. | Mohamed et al. [158] | |

| Sweet Orange (Citrus sinensis (L.) Osb.) | γ-irradiation (5, 10, 15, 20, and 25 kGy) + Carboxymethyl Chitosan/Polyvinyl Alcohol | B. Subtilis (ATCC 6633), S. aureus, E. coli, A. niger, Candida albicans | • The antimicrobial activity of the coating materials had good sensitivity for both Gram-positive and negative bacteria and showed an excellent inhibitory zone ranging from 24 to 27 mm. | Elbarbary et al. [159] | |

| Ultrasound (US) | Potatoes (Solanum tuberosum L. cv Asterix) | Sonicating (40 kHz, 5 min), 20 g L−1 alginate, 20 g L−1 citric acid | Enterobacteriaceae, coliforms and mesophilic bacteria | The study found that the combination of ultrasound and citric acid 20 g L−1 was effective in reducing the counts of total coliforms, Enterobacteriaceae, and aerobic bacteria in vacuum-packaged potato strips. | [160] |

| Strawberry (Fragaria ananassa) | Sonicating (20 kHz and 400 W for 30 min), Pectin solutions were prepared (1%, 3%, 5% and 8%, w/v) | N/A | US treatments give rise to pectin gels that can improve the quality of strawberries over their lifetime. | [47] | |

| Sweet cherries (Prunus avium) | Sonicating (40 kHz and 150 W for 3 min), 0.2% concentration gums solutions (xanthan, guar, and wild sage seed) | N/A | The effective moisture diffusivity (Deff) values were lower for the coated sweet cherries compared to the uncoated ones. The guar gum coating had the lowest Deff at 1.39 × 10−9 m2/s. | [161] | |

| Potato (Solanum tuberosum L.) | Sonicating (40 kHz and 75 and 150 W for 5 min), basil seed gum (BSG) (0.5%, w/v) | N/A | Edible coating with BSG and high-intensity ultrasonic pretreatment (150 W) significantly decreased the oil uptake of the fried potato slices. | [162] | |

| Modified atmosphere packaging (MAP) | Blackberry (Rubus glaucus Benth) | Guar gum (sorbitol, glycerol, canola oil and Tween 80) + MAP (perforated PET packages) | N/A | • The combination of edible coating and a MAP system significantly delayed the deterioration rate of blackberry fruits, increasing their shelf life up to 13 days for the coating of 0.3% guar gum and perforated PET clamshells and 12 days for the guar gum at 0.3% and PET clamshells with PLA films from only 6 days for uncoated fruits in perforated PET. | Pérez et al. [163] |

| Hazelnuts (Corylus avellana) | Methylcellulose and chitosan + MAP (100% N2 at 35 °C) | N/A | Effective reduction in lipid oxidation in hazelnut kernels. | [164] | |

| Artichoke (Cynara cardunculus var. scolymus L.) | Soy protein isolate and Beeswax (L-cysteine) + MAP | N/A | Combination of the coating and MAP did not increase the shelf life of artichoke slices but did assist in sustaining the product’s antioxidant capacity. | Ghidelli et al. [165] | |

| Green beans (Phaseolus vulgaris) | CHS (Nanoemulsion) + MAP (60% O2, 30% CO2, and 10% N2) | E. coli and S. Typhimurium | When antimicrobial coating, gamma irradiation, and MAP were all used together, the number of microorganisms was reduced to undetectable amounts for the entire storage period for E. coli and from day 7 until the end of the storage period for S. Typhimurium. | Severino, Ferrari, Vu, Donsì, Salmieri, and Lacroix [85] | |

| Cucumber (Cucumis sativus L.) | CHS (0%, 1%, and 2% chitosan concentration) + MAP (nitrogen, oxygen and argon) | N/A | • Combined treatment-maintained quality, microbial safety, and extended the shelf life of fresh-cut cucumber. | Candir, Ozdemir, and Aksoy [141] | |

| Strawberry (Fragaria ananassa) | Chitosan/nanocomposite + MAP (10% O2, 15% CO2, and 75% N2) | N/A | • Nanocomposite film with chitosan coating under MAP conditions maintained the qualitative and mechanical properties of strawberries and improved the shelf life. | Barikloo and Ahmadi [166] | |

| Cold plasma treatment | Pistachio (Pistacia vera) | CHS + CPT | Aflatoxins B1 and B2 and yeast | • 1.5% chitosan and cold plasma treatment for 120 s could significantly reduce the amount of mold and yeast after 120 days of storage. | Akhavan-Mahdavi et al. [137] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tian, X.; Dong, H.; Fang, Q.; Zhang, X.; Dai, C.; Aheto, J.H. Harnessing the Synergy Between Edible Coatings and Non-Thermal Technologies for Improved Food Quality and Sustainable Preservation. Horticulturae 2025, 11, 1466. https://doi.org/10.3390/horticulturae11121466

Tian X, Dong H, Fang Q, Zhang X, Dai C, Aheto JH. Harnessing the Synergy Between Edible Coatings and Non-Thermal Technologies for Improved Food Quality and Sustainable Preservation. Horticulturae. 2025; 11(12):1466. https://doi.org/10.3390/horticulturae11121466

Chicago/Turabian StyleTian, Xiaoyu, Hui Dong, Qin Fang, Xiaorui Zhang, Chunxia Dai, and Joshua Harrington Aheto. 2025. "Harnessing the Synergy Between Edible Coatings and Non-Thermal Technologies for Improved Food Quality and Sustainable Preservation" Horticulturae 11, no. 12: 1466. https://doi.org/10.3390/horticulturae11121466

APA StyleTian, X., Dong, H., Fang, Q., Zhang, X., Dai, C., & Aheto, J. H. (2025). Harnessing the Synergy Between Edible Coatings and Non-Thermal Technologies for Improved Food Quality and Sustainable Preservation. Horticulturae, 11(12), 1466. https://doi.org/10.3390/horticulturae11121466