Abstract

Kitchen waste has been confirmed as an appropriate substrate for anaerobic digestion, although means of alleviating the difficulties and time-consuming nature of the start-up phase need to be further explored. Based on the mechanism of anaerobic digestion, we discuss the factors influencing the anaerobic start-up phase of kitchen waste. By controlling the temperature, pH, organic loading rate, inoculation ratio and other parameters, the high activity of methane-producing archaea and other bacteria can be intensified, thereby increasing the biogas yield. Furthermore, we introduce the methods of substrate pretreatment, operating condition optimization and conductive material addition. Finally, we put forward future perspectives and research gaps related to accelerating the start-up phase of anaerobic bioreactors utilized for kitchen waste biodegradation.

1. Introduction

The amount of kitchen waste (KW) originating from households, food processing and the catering industry is increasing annually. According to the China Statistical Yearbook from 2020, the amount of municipal solid waste production in China has been increasing at a steady growth rate of 5~6% continuously. Specifically, KW accounts for 30~50% of municipal solid waste, and the quantity is about 72.44~127.40 million tons in China [1]. KW has the characteristics of a high organic content and moisture content, which gives it tremendous potential in terms of resource utilization. However, if handled improperly, it can contribute to unsatisfactory odors and air pollution and threaten public health [2]. Traditional KW disposal strategies involve sanitary landfill, incineration, livestock feeding and aerobic composting. Sanitary landfill technology is convenient to operate, although it poses a huge threat to the environment, such as secondary pollution caused by the generation of foul odors, landfill leachate and groundwater pollution [3]. Furthermore, incineration technology converts organic matters into energies by means of high temperatures to kill parasites and pathogens. Nevertheless, it also produces a large number of acidic and toxic gases, such as dioxin [4]. On the other hand, though KW aerobic composting technology can transform KW into humus and improve soil nutrients and fertility, it occupies a large floor space and has an enormous environmental footprint and high life-cycle cost.

As a cost-effective and eco-friendly technique, anaerobic digestion (AD) has been widely applied for municipal solid waste treatment, such as KW [5]. KW is considered an appropriate substrate for anaerobic microbes because it has the characteristic of a high organic content, moisture content, salinity and oil content [6]. Compared to conventional substrates for anaerobic microorganisms, KW shows higher biogas conversion efficiency theoretically (94.8%) [7]. Moreover, AD contributes to clean energy production, such as methane, which can be recognized as a succedaneum of fossil energy. Nevertheless, the start-up phase of anaerobic reactors for KW biodegradation is considered an untoward and time-consuming process. Specifically, the large molecular organic matter in KW accounts for 30~70% of the total organic matter in the dry base, which mainly includes fats, grease, oil, etc. They will result in sludge flotation and washout aligned with sludge acidification during the hydrolysis process. On the other hand, functional microbes such as methane-production archaea (MPA) need to survive under strict anaerobic conditions. In addition, they not only have a low growth rate and long generation time but also show sensibility to the pH, temperature, volatile fatty acid, ammonia nitrogen and other environmental factors, which poses a great challenge to starting KW anaerobic bioreactors.

So far, some researchers have explored strategies to accelerate the start-up phase. Traditionally, the anaerobic bioreactor for KW biodegradation should be maintained at a low organic loading rate (OLR) initially, and then the OLR can gradually increase according to the bioreactor’s performance. Wu et al. discovered that adding other substrates, such as leachate sludge, can enhance the stability of the AD system and start-up rate [8]. In addition, Lim et al. proposed that the additive biochar can be applied to expedite the start-up phase of thermophilic AD bioreactors to dispose KW. The results revealed that the total methane production can increase by up to 18% in a bioreactor with biochar [9]. Broadly speaking, the addition of biochar can promote direct interspecific electron transfer (DIET) between diverse microbial species and promote the stability of the start-up process. In addition, multiple strategies have been proved to shorten the start-up time. However, there is a lack of systematic research about the strategy for accelerating the start-up phase of AD reactors for KW biodegradation.

The aim of this paper is to elucidate different strategies that can be adopted during the KW AD start-up phase for the sake of reducing the original start-up duration as well as obtaining better substrate digestibility and more methane production. Firstly, different factors affecting the start-up phase are analyzed, and subsequently, the targeted strategy is put forward. Eventually, future challenges and prospects concerning accelerating the start-up phase in KW anaerobic bioreactors are clarified. In a word, this paper summarizes the methods to accelerate the start-up phase in anaerobic KW bioreactors according to previous studies, which can be utilized as guidance for similar studies in the future.

2. Factors Affecting Anaerobic Digestion Start-Up

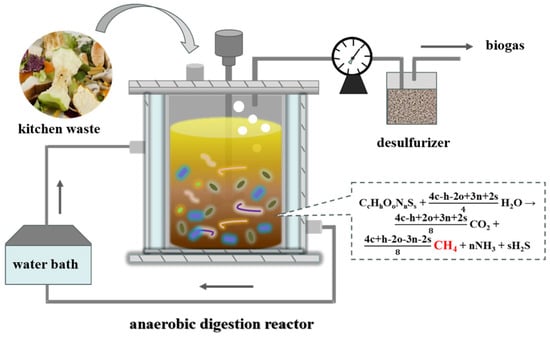

The start-up phase of AD is the process of cultivation and domestication of the anaerobic sludge. During this process, anaerobic microorganisms have difficulty maintaining equilibrium in the face of load shocks. Therefore, initiating KW AD bioreactors inevitably consumes a significant amount of time. Figure 1 demonstrates one of the typical bioreactors used for KW biodegradation.

Figure 1.

Typical bioreactor used for the start-up phase of anaerobic digestion of kitchen waste.

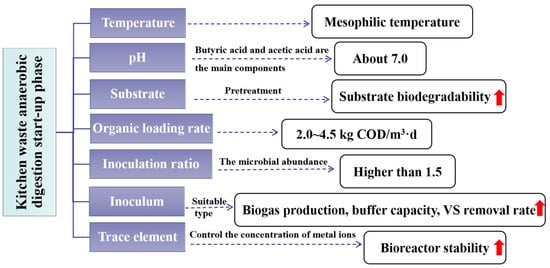

Due to the high environmental sensitivity of MPA, appropriate environmental parameters need to be controlled during the AD of KW in order to ensure that MPA work with high vital activity. Figure 2 presents the factors influencing the start-up phase of KW AD systems.

Figure 2.

Factors influencing the start-up phase of anaerobic digestion of kitchen waste.

2.1. Temperature

In general, temperature can affect the vital activity of microorganisms. Specifically, It can affect enzyme and coenzyme activity, which is responsible for methane production, hydrolytic fermentation and digestive quality [10]. On the other hand, AD bioreactors can start and operate at disparate temperatures, such as psychrophilic (below 20 °C), mesophilic (25~40 °C) and thermophilic conditions (45~60 °C) [11]. However, bioreactors usually perform under mesophilic and thermophilic conditions. Previous studies have confirmed that acetic acid is the predominant volatile fatty acid (VFA) in thermophilic bioreactors utilized for the dry AD process (cultivated by a substrate with over 15% total solid contents), while butyric acid is the primary one in mesophilic bioreactors. Moreover, thermophilic digestion has been proved to be more feasible for facing anti-unbalance performance, especially during the start-up phase of the dry AD process [12]. Similarly, Dinh Duc et al.’s study reached a similar conclusion that thermophilic digestion is more stable and faster than mesophilic digestion in the process of dry semi-continuous AD for KW disposal [13].

However, with regard to the AD of wet KW (with less than 15% total solid contents), the implications of mesophilic and thermophilic properties on the start-up phase are contradictory. More studies have shown that AD performance is more stable under mesophilic conditions, while thermophilic systems are more susceptible to the disturbance and inhibition of ammonia nitrogen and lipids [14]. Generally, the utilization efficiency of VFAs in mesophilic reactors was 83~92%, and that in thermophilic reactors was 79~84%, indicating that a high temperature deteriorates VFA accumulation. Under mesophilic conditions, the methane content immediately remains stable [15]. In addition, the biodegradation rate of propionic acid, which is conducive to the stable operation of the start-up phase under mesophilic conditions, is faster than that under thermophilic conditions, thus reducing the inhibitory effect of propionic acid on MPA [16]. In addition, under mesophilic conditions, the acetate-utilizing and hydrogen-utilizing MPA abundance, such as Methanosaeta and Methanospirillum, surpass that in thermophilic conditions [17]. However, other studies hold the adverse opinion that thermophilic conditions theoretically promote the metabolic rate and substrate supply of MPA, as well as accelerate the methanogenesis process compared with mesophilic conditions [18].

In short, different species of MPA have diverse adaptability to temperature and can only function under specific growth temperatures. If the temperature is inappropriate, the AD start-up phase can contribute to failure due to the inactivation of the predominant functional microbes. Therefore, the anaerobic bioreactor should be maintained at a constant temperature to ensure the stability of microbial abundance.

2.2. pH and Substrate

Anaerobic microbial vital activity and substance metabolism are closely related to the system’s pH value. Hence, the transformation of the pH directly influences the AD start-up duration. Based on previous research, in the lipid-rich waste hydrolysis and acidification process, a pH change can contribute to dramatic changes in microbial abundance and metabolic pathways. The pH value plays a significant role in hydrolytic acidification bioreactors [19].

The distribution of VFA components in KW hydrolytic acidification products is basically consistent with the results reported by Horiuchi [20]. Under acidic and neutral conditions, butyric acid is the main component of VFAs, while acetic acid is the main one under alkaline conditions. Therefore, the amount of lactic acid and propionic acid is low and butyric acid and acetic acid are the main components of VFAs when the pH value is around 7, which is more favorable to the start-up and operation of the methanogenesis process than other pH conditions.

On the other hand, KW, as the single AD substrate, has the negative characteristics of a low reaction efficiency and system stability because KW is unfavorable to hydrolysis and fermentation microorganisms due to its high solid content. Therefore, the duration of AD for KW biodegradation is determined by the KW particle size, substrate concentration and morphology. Generally speaking, the smaller the particle size is, the faster the start-up phase is.

For example, Yiwen Xu et al. investigate the effect of ultrasound, microwave and alkali-thermal pretreatment of KW on AD performance. The pretreatment contributes to the formation of small particles that elevate the performance of hydrolysis and acidification, which could accelerate the start-up phase of AD reactors. Specifically, the biodegradable organic matter in KW is decomposed and utilized within a short period of time, which not only promotes the methane production rate but also increases the performance of the AD reactor [21].

2.3. Organic Loading Rate

The OLR and sludge loading rate during the start-up phase are important parameters to control the seed sludge characteristic for KW disposal. By regulating the loading rates appropriately, superior sludge granulation and high COD removal efficiency can be obtained. If the OLR is higher than the microbial tolerance scope, the bioreactor can collapse due to acid accumulation. On the other hand, the biogas production and methane yield rate can descend under low OLR conditions.

Specifically, Ghangrekar et al. observe that the OLR should be maintained within the range of 2.0~4.5 kg COD/m3·d and the sludge loading rate should be controlled at 0.1~0.25 kg COD/kg VSS·d to obtain seed sludge with superior characteristics during the start-up phase of AD reactors [22]. Furthermore, Song et al. discover that as the OLR decreases, the duration of the KW acidogenesis stage can be slackened, while the concentration of VFAs in the effluent diminishes. When the OLR of an AD system is 7 g VS/L·d, the maximum VFA concentration can reach 11,000 mg/L and the acidification degree of KW decreases from 32% to 8% [23]. In addition, the alkalinity is consumed in the AD reactor and the total suspended solid concentration (TSS) in the effluent decreases accordingly when the dilution rate declines.

In addition, Meng et al. find that the start-up phase of AD to dispose of lipid-rich FW depends on the OLR. When the reactor operates at an OLR of 2 g COD/L·d, the performance of the start-up phase is advantageous. On the other hand, when the OLR is higher than 8 g COD/L·d, the system becomes unstable. Therefore, excess lipids need to be removed before conducting the AD process, which is conducive to the start-up and operation of anaerobic bioreactors [24].

2.4. Inoculum and Inoculation Ratio

According to the previous literature, the inoculation source shows significant influence on the start-up stage of anaerobic digestion [25,26]. Specifically, the inoculum plays a vital role in providing an initial microbial population in the anaerobic process. The biodegradation rate and lag time of organic waste depends on the abundance of microorganisms [27].

Lignin and cellulose in KW are substances that are tough to biodegrade by microorganisms. Therefore, the addition of an inoculum from other sources can provide more MPA to facilitate their biodegradation. The complementary inoculum determines whether the anaerobic reactor has sufficient buffering capacity and ultimately affects the anaerobic digestion start-up phase [28]. In addition, a good source of inoculum can improve the KW biodegrading efficiency, shorten the lag time and maintain the stability of the AD bioreactor [29].

In general, a suitable inoculum is an important factor in the successful start-up of AD. Suwat compares the performance of cattle manure with municipal solid waste (MSW) as a thermophilic inoculum. The thermophilic flora in cattle manure do not rapidly degrade acetic acid, whereas acetic acid degradation is evident in the reactor inoculated with MSW and the start-up phase is rapid [30].

On the other hand, the ratio of the sludge VS to the fermentation substrate VS (inoculation ratio) can affect the start-up performance of KW AD systems. Specifically, the quantity of effective components in the seed sludge should be taken into consideration on account of the fact that the content of volatile solid (VS) in the sludge is an important index reflecting the microbial abundance.

For example, Zheng et al. compare the effects of 0.36 and 0.90 inoculation ratios on the AD start-up phase for dry KW disposal. The results indicate that acidification appears during the start-up phase in the two groups. When the inoculation ratio is 0.36, the bioreactor cannot produce biogas normally, while the system’s pH gradually increases and returns to normal when the inoculation ratio is 0.90 [31]. According to further research, when the ratio is lower than 1.5, the AD system is maintained at the acidification stage, which leads to the KW AD system’s failure to start. Meanwhile, with an increase in the inoculation ratio, the AD system can start smoothly, and methane production can significantly elevate as well [32].

2.5. Trace Elements

Generally, the start-up duration of AD is influenced by the pH, temperature, alkalinity, metal elements and many other factors. Specifically, different concentrations of metal elements inevitably have different effects on functional microbes and then affect the start-up phase of AD for KW degradation.

Common light metal ions in anaerobic reactors include Na+, K+, Mg2+, Ca2+, and Al3+ derived from the decomposition of organic matter and addition of pH regulators [33]. These metals are essential nutrients for microbial vital activity and growth. However, excessive concentrations of light metals can impede the growth of microorganisms and cause poisoning, which can affect the stable operation of anaerobic reactors [34]. For example, the optimal Ca2+ concentration for MPA growth is 200 mg/L, while a strong inhibition concentration is more than 8000 mg/L [35]. In addition, the acclimated anaerobic microorganisms can withstand concentrations of 2500 mg/L Al3+ and 7200 mg/L Mg2+ without changing the growth rate [36,37]. Furthermore, when the concentration of Na+ is 100~200 mg/L, it is beneficial to the growth of anaerobic microorganisms [38].

The typical heavy metal ions in AD reactors contain Cr3+, Fe3+, Co2+, Cu2+, Zn2+, Cd2+ and Ni2+ [39]. Heavy metals exhibit limited biodegradability, which can interact strongly with anaerobic microbes and enzymes to make them inactive [40]. Furthermore, the heavy metals’ promotion or inhibition degree in the AD process depends on their concentrations. Microscopically, acidogenesis bacteria exhibit higher tolerance to heavy metal toxicity than MPA [41]. For example, Zhang explores the influence of trace elements on methane production in the AD of KW and discovers that when the concentrations of Fe3+, Co2+ and Ni2+ are 100 mg/L, 1 mg/L and 5 mg/L, respectively, the maximum methane yield is 504 mg/L·VS, which indicates an increase of 35% compared with the bioreactor without trace elements [42].

In addition, according to previous studies on the functions of heavy metals under anaerobic conditions, Ni has been proved to produce a synergy function in Ni–Cu, Ni–Mo–Co and Ni–Hg systems. Otherwise, Ni presents an antagonism function in Ni–Cd and Ni–Zn systems [43]. Furthermore, Ni contributes to the toxicity reduction of other heavy metals, such as Cd and Cu [44]. Guo studies the effect of adding Ni foam on methane production. As a result, compared with the control group without adding Ni foam, the addition of 2.45 g/L of Ni foam to the AD system increases the maximum methane production rate by 27.4% and shortens the peak production time by 33% [45].

In a word, according to the discussion above, a feasible environmental index of the start-up phase of a KW AD system has been presented in Figure 1. Specifically, at the given range of diverse indicators, the start-up of the AD bioreactor for KW biodegradation can obtain maximum acceleration and access optimal operating conditions.

3. Methods to Accelerate the Start-Up Phase

In the past few years, more and more attention has been paid to accelerating the start-up process of AD bioreactors, especially under the overload condition and pressure operation. Specifically, various efforts have been made to accelerate the start-up phase, and the environment parameters deserve exploration in depth and systematical summary. Based on previous research, we define a ‘rapid start-up phase’ as the following concepts [30]:

- A short lag time before methane production.

- A significant methane production rate (>0.2 L/L/d) after the lag time.

- The presence of acetate-utilizing or hydrogen-utilizing MPA.

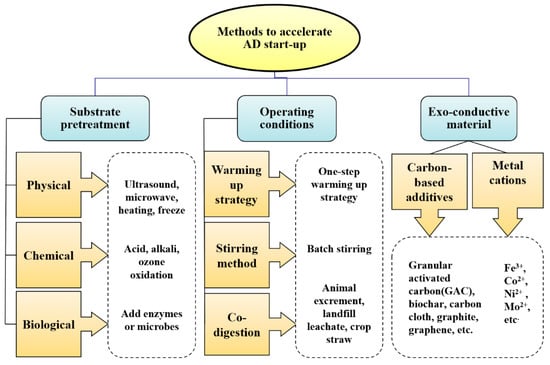

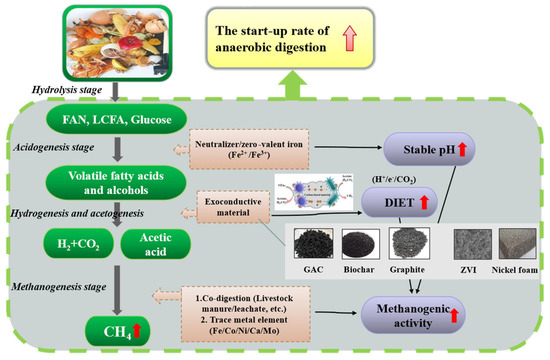

Optimization of the operating conditions, such as the temperature, stirring mode and single digestion or co-digestion, is an effective scheme in initiating the AD start-up phase. Moreover, thermal pretreatment, ultrasonic pretreatment and chemical pretreatment have been used to pretreat FW to accelerate the AD start-up phase. In the aspect of bioaugmentation, the acclimated microbial species can be regarded as the dominant species promoting the AD start-up phase by adding carbon sources to regulate microbial catabolism and anabolism. Figure 3 shows the methods used to accelerate the start-up phase of the anaerobic digestion of KW.

Figure 3.

Methods used to accelerate the start-up phase of anaerobic digestion of KW.

3.1. Substrate Pretreatment

Due to the inherent composition and characteristics of KW, the overall biogas conversion efficiency is low due to the long hydrolysis duration. The application of pretreatment methods can effectively accelerate the hydrolysis process of organic waste to increase the system soluble COD and thus increase biogas production [46,47].

According to Ariunbaatar et al.’s research, hydrolysis is the rate-limiting step for lipidic-rich waste biodegradation due to toxic by-products such as long-chain fatty acids (LCFAs) and undesirable VFA formation, while the methanogenesis process can be limited [48]. Furthermore, the substrate biodegradability and hydrolysis rates determine the yield of biogas [49]. Therefore, the application of pretreatment methods can facilitate the production of biogas, such as overcoming the hydrolytic solubilization and biodegradation of lignin and hemicellulose, and thus accelerate the AD start-up phase [50]. Generally, the main objectives of the application of pretreatment are:

- (i)

- to improve surface performance for the sake of achieving better microbial interaction reaction efficiency;

- (ii)

- to reduce/remove toxic and harmful compounds that are detrimental to the process;

- (iii)

- to improve the kinetics of the rate of hydrolysis of proteins and lipids;

- (iv)

- to treat KW prior to the AD process to reduce the loss of organic carbon during storage/transport [51,52,53,54].

3.1.1. Single Pretreatment

Generally speaking, pretreatment is an effective way to improve the performance of the AD process, which can shorten the start-up duration. The common single pretreatment methods include physical pretreatment, chemical pretreatment and biological pretreatment [55]. Table 1 shows various pretreatment methods used to accelerate the start-up phase of AD.

The physical properties of the substrate have a significant influence on the start-up rate of the AD process. Therefore, physical pretreatment can be applied to split large insoluble substances, decrease the size of the KW, and destroy cells and gel clusters to increase the contact area to promote the rate and efficiency of hydrolysis [56,57]. Generally, physical pretreatment technology mainly includes mechanical shredding, ultrasound, microwave, high pressure, heating, freezing and other methods.

Specifically, it has been reported that the substrate particle size has a significant effect on the methanogenesis process, especially on the function of acetate-utilizing and hydrogen-utilizing MPA [58]. According to previous reports, Izumi et al. reduce the particle size of KW from 0.843 mm to 0.391 mm by crushing it, and the methane production increases by 28% [59]. Gianico et al. propose a new biorefinery platform with integrated thermal pretreatment and solid-liquid separation units to smash KW for further AD processing [60]. In addition, thermal pretreatment effectively extracts a portion of the macromolecular organic matter into the liquid phase and promotes acid-producing fermentation. Parra-Orobio et al. thermally pretreat KW and show a 50% reduction in lignin and a 34% increase in hemicellulose as well as a higher methane yield than the untreated substrate [61].

On the other hand, chemical pretreatment can increase the conversion of polysaccharides into fermentable and available sugars [62]. It can be used to accelerate the KW hydrolysis process by means of several technologies, such as acid, alkali and ozone oxidation, which is more conducive to organic matter utilization by microorganisms in AD systems [63]. Among all the chemical pretreatment technologies, acid pretreatment can effectively dissolve carbohydrates, while alkali pretreatment can effectively dissolve proteins and lignin as well as promote lipid saponification to speed up the start-up phase.

However, chemical pretreatment has certain limitations. Specifically, the chemicals used for acid pretreatment are corrosive (such as sulfuric acid and hydrochloric acid), meaning they can destroy the stable conditions in AD bioreactors. In addition, though alkali pretreatment consumes a long reaction time, salt formation is considered to be the main disadvantage. Furthermore, other pretreatment methods (such as ozone and hydrogen peroxide) are not suitable for KW pretreatment.

In general, biological pretreatment has the merits of being characterized by low energy consumption and mild conditions [64]. Biological pretreatment is carried out by enzymes’ addition or microbes’ addition to enrich microbial abundance. Direct enzymatic addition of KW by a-amylase and glucoamylase has been applied to hydrolyze substrates and thus increase the release of fermentable organic compounds for microbial growth and vital movement [65,66]. However, the low bioavailability of amylase is a key issue during this process. In addition, most enzyme production is complicated, which will limit its widespread adoption, and the high cost of enzymes contributes to the low economic benefits [67,68].

Table 1.

Summary of substrate pretreatments used to accelerate the start-up phase of AD.

Table 1.

Summary of substrate pretreatments used to accelerate the start-up phase of AD.

| Pretreatment Type | Pretreatment Conditions | Temperature | pH | Treatment Effect | Start-Up Time (d) | Reference |

|---|---|---|---|---|---|---|

| Freeze/thaw | Freeze for 24 h; thaw 12 h; the duration is 0.5 to 30 min | −20 °C/25 °C | 7.2 | Methane production increased by 6.7%; batch operation time is reduced by 42%; hydrogen production rate increased by 127% | 8 | [69] |

| Hydrothermal | 6.2 bar | 160 °C | 7.3~7.6 | Methane production is increased by 5–10% | 10 | [70] |

| Hydrothermal | 140 °C for 60 min | 140 °C | 7.96 | Methane yield increased by 27.78% | 11 | [71] |

| Ultrasonic | Sonication time is 24 min/d; HRT is 2 d; 20 kHz | 37 °C | 6.9~7.2 | The removal rate of VS was 67%; Methane production rate increased by 100% | 15 | [72] |

| Ultrasonic | 250 W for 40 min; 50 d | 37 °C | 6.9~7.4 | Cumulative gas production increased by 42.6%; methane content increased to 58.8%; biodegradation rate increased to 73.5%. | 10 | [73] |

| Microwave | 3.9 and 1.9/min; 175 °C for 1 min | 33 ± 2 °C | - | Average gas production increased by 16% | 30 | [74] |

| Aeration | 37.5 mL O2/LR-d; 4 day; 5 L/h for 24 h | 35 °C | 5.2~7.0 | Cumulative methane production increased by 21%; methane production increased by 45.6% | 25 | [75] |

| Acid/alkali | 4 mol/L NaOH/HCl; pH (2–13) | 35 °C | - | The hydrogen production rate of the acid pretreatment and alkali pretreatment increased by 21% and 480%, respectively | - | [76] |

| Alkali | 121 °C for 15 min; 4 mol/L NaOH/HCl | 35 ± 1 °C | 7.5 | The hydrogen production rate increased by 266% when the pH was 13 | 20 | [77] |

| Bio-enzyme | 45 °C for 24 h; 6 days at 30 °C | 60 °C | 4.0~4.5 | The rate of methane production increased by 350%; VS removal rate was 80.5% | 24 | [78] |

3.1.2. Combined Pretreatment

Combined pretreatment involves the combination of two or more pretreatment methods to optimize the pretreatment effect and improve the AD bioreactor performance. Specifically, Cheng et al. effectively degrade 87.56% of triglyceride through the AD process by means of hydrothermal pretreatment aligned with alkali pretreatment and immensely reduce the accumulation of undegraded lipids. After the pretreatment, the methane yield increases from 32.60 mL CH4/g VS/d to 51.22 mL CH4/g VS/d and the energy conversion efficiency increases from 48.05% to 66.21% [79].

Moreover, Hafid et al. combine physicochemical pretreatment with enzymatic digestion in order to elevate the yield of glucose in KW. The results show that the combination of acid pretreatment and the enzymatic hydrolysis method can produce relatively high levels of glucose for anaerobic microorganisms compared to acid pretreatment alone at high temperatures [80]. Kakar et al. investigate the effect of combined chemical and hydrothermal pretreatment on the AD process of thickened sludge and KW. The combination of free nitrous acid and hydrothermal pretreatment results in the highest methane yield of 275 mL CH4/g COD [81].

The above-mentioned combined pretreatment technology shows a preferable effect on KW anaerobic biodegradation. It has a wider range of applications than the single pretreatment method and deserves more attention.

3.2. Type of Inoculum

The source of the inoculum is an important factor that determines the initial microbial activity directly. The microbial abundance brought about by the inoculum determines the biodegradation rate, lag time and substrate degradation rate during the start-up phase [82,83]. Therefore, we can transform the types of inoculations to improve the activity of microbes for KW degradation so as to achieve the purpose of a rapid start-up.

Currently, researchers have compared the performances of AD using different sludge inoculants or mixed sludge at different temperatures, especially the effect of the reaction during the start-up phase.

Under thermophilic conditions, Lim and Wang investigate the effects of two different sludges (wastewater treatment plant-digested sludge and KW anaerobically digested sludge) on the performance of the AD start-up of KW. The results show that the dominant MPA is Methanosarcina in the KW sludge, which is able to utilize both acetate and H2/CO2, and it can accommodate environmental changes during the start-up phase [84]. Furthermore, Elbeshbishy et al. come to the same conclusion [85]. Meanwhile, compared with cow manure, which contains inappropriate MPA to biodegrade acetate, municipal solid waste shows greater potential to produce methane during the thermophilic AD start-up phase for KW biodegradation [30].

Wilkins et al. utilize UASB sludge from different bioreactors, including UASB and a mesophilic anaerobic digester, as inoculums to investigate the digestive performance by dosing them with different substrates. The results demonstrate butyric acid reaches the highest concentration (7.9 mM) in the sludge from the anaerobic digester and contains moderate concentrations of acetic and propionic acid. In contrast, VFA is less accumulated in the thermophilic reactor, which inoculates the sludge from UASB so that it can enhance the FW biodegradability preferably [86].

It has also been shown that mixed sludge can be recognized as an inoculum because it shows superior results in the early stages of AD. When thickened waste activated sludge (TWAS) is mixed with anaerobic sludge (AnS) as the KW AD inoculum, the alkalinity can neutralize the acidity and the pH value remains stable throughout the experiment. In addition, the addition of TWAS significantly alters the initial bacterial community diversity and enriches the abundance of MPA to accelerate the conversion of hydrolysis products into methane [87]. In contrast, the inoculation of KW fermentation with anaerobic activated sludge alone accelerates the biodegradation of carbohydrates and contributes to the instability in the early stages of the reaction [88]. Therefore, complete and efficient AD systems can be assembled from different inoculums and consist of different kinds of microbial communities that together perform similar functions [86].

3.3. Optimization of Operating Conditions

3.3.1. Warming-Up Strategy

Recently, the initiation process from mesophilic to thermophilic condition has been considered by researchers. Warming-up strategies are particularly important for AD systems and microbial growth. To cultivate thermophilic sludge with eminent characteristics, researchers often take advantage of two strategies to convert mesophilic sludge, including raising the temperature directly or gradually.

As MPA are extremely sensitive to temperature, a majority of thermophilic digesters operate using a stepwise heating strategy to take the edge off the effect of temperature on the microbial abundance, especially MPA [89]. This approach is beneficial to cut down VFA accumulation, although it requires a longer start-up time. Some researchers have pointed out that the one-step warming strategy produces more VFA under stable thermophilic conditions, although this strategy achieves similar methane production compared to gradual warming [90,91]. Moreover, Shin et al. find that the one-step warming strategy can increase the VS removal efficiency by 34% due to the ample total archaea abundance of thermophilic bacteria [92].

In order to further determine the impacts of different warming-up methods on the start-up phase of thermophilic reactors, Lim et al. convert mesophilic bacteria into thermophilic bacteria through these two strategies (gradual warming and one-step warming). The results indicate that the one-step warming strategy generates a more successful start of the thermophilic AD system than gradual warming. Therefore, the one-step warming strategy can not only shorten the transition time and lag stage but also conduct rapid colonization of thermophilic bacteria to establish metabolic communities [84].

3.3.2. Stirring Method

In the start-up phase of an AD bioreactor, the stirring strategy in the reactor should be taken into consideration because it is an indispensable operating condition. According to previous studies, the significance of stirring in AD includes dispersing the substrate and increasing the contact area with microorganisms, heating the sludge uniformly in the reactor and reducing the formation of scum and sediment [93].

Nevertheless, some researchers recommend not stirring heavily in the start-up phase. Specifically, if the stirring intensity is too high, it will cause reactor acidification because the agitating vane can destroy the microbial structure [94]. Meanwhile, it has been reported that intense stirring in the reactor inhibits propionate degradation and thus leads to propionate accumulation [95]. According to the past literature, the accumulation of propionate brings about an imbalance between acid production and acid consumption, which inhibits the growth and reproduction of MPA [96]. Normally, acid accumulation in mesophilic conditions results in a low buffer capacity and low pH and thus contributes to the low methane production rate [97].

In practice, intermittent stirring is a relatively better stirring strategy. Additionally, in the AD start-up phase for KW biodegradation, a small amount of water can be added into the bioreactor to promote the KW viscosity reduction and intermittent stirring can be jointly used to meet the requirement of adequate mixing of the substrate.

3.3.3. Co-Digestion

During the AD process, if KW is utilized as the single substrate, the hydrolytic acidification process is carried out dominantly by lactic acid fermentation without any hinderance [98]. Generally, the accumulation of propionate in VFAs is not conducive to meeting the utilizing requirements of MPA, which will ultimately bring about the failure of the AD start-up phase [99].

Recently, researchers tend to combine different biomass as another substrate for co-digestion during the KW AD process, and they compare the bioreactor’s performance with single FW digestion. Specifically, an anaerobic co-digestion system of KW has better performance, stability and cushioning ability, which optimizes the initial conditions in the start-up phase [100]. Table 2 presents a summary of the co-digestion of KW and other substrates. At present, the typical substrates for co-digestion contain animal excrement, residual sludge, landfill leachate and crop straw.

Many researchers attach great importance to the combined AD system of KW and livestock waste. The anaerobic co-digestion improves the stability of the anaerobic start-up stage, alleviates the inhibition of the high ammonia and sulfide concentration, and produces more stable biogas production due to the improved buffer capacity. Xing et al. find that the methane yield and KW hydrolysis rate increase by adding a small amount of cow manure (CM) to the AD bioreactor. In addition, stable high-speed co-digestion can successfully start when the ratio of KW/CM and initial pH are controlled at 2.5 and 7.65, respectively, without VFA accumulation [101]. In addition, Zhang et al. investigate the kinetics and gas production rates of combined KW and CM and discover that co-digestion can speed up the reaction process, especially during the start-up phase [102].

Furthermore, Yuan compares the start-up phase of a co-digestion system with KW and sewage sludge under the inoculation process and non-inoculation process. The results indicate that the co-digestion system can be maintained at a stable operation condition from the thirteenth day, while the system without sewage sludge fails to start up. Specifically, in the bioreactor inoculated with sewage sludge, the average daily methane yield is 32.8 L/d and the pH value is in the range of 7.07~7.27, while the reactor without adding sewage sludge only produces 0.4 L/d methane and the pH value is less than 6.50, which poses the risk of sludge acidification [103].

Moreover, landfill leachate can be introduced into KW digestion systems to increase the total ammonia nitrogen and form a buffer system with VFAs to maintain a delicate biochemical balance between the acetogenic bacteria and MPA. Therefore, a series of single-phase batch mesophilic anaerobic digestions are carried out by Liao et al. at 41.8 g VS/L KW [100]. VFA accumulation is inhibited due to the existence of landfill leachate and thus it is conducive to the stable start-up of AD.

Table 2.

Summary of the co-digestion of KW and other substrates.

Table 2.

Summary of the co-digestion of KW and other substrates.

| Co-Digestible Mass Ratio | Operation Mode | Temperature (°C) | pH | Maximum Methane Yield (mL CH4/g VS) | Start-Up Duration (d) | Reference |

|---|---|---|---|---|---|---|

| Sewage sludge: KW = 1:1 | Batch assay | 35 ± 1 | 7.07~7.27 | 251 | 12 | [103] |

| Cow manure: KW = 1:2.5 | Semi-continuous | 39 | 7.63~7.67 | 441 | 13 | [100] |

| Chicken manure: KW = 1:1 | Semicontinuous | 55 | - | 136 | - | [104] |

| KW: Yard waste: Waste activated sludge = 0.8:1.7:0.5 | Semi-continuous | 35 | 6.74~6.98 | 149 | 28 | [105] |

| Maize straw silage: KW = 1:9 | Semi-continuous | 35 | 7.25~7.55 | 613 | 30 | [106] |

| Livestock manure: KW = 3:1 | Batch assay | 37 | 6.50~7.00 | 250 | 18 | [107] |

| Excess sludge: KW = 1:4 | Continuous | 35 | 7.17~7.77 | 274 | 12 | [108] |

| Sewage sludge: KW = 1:1 | Semi-continuous | 37 ± 1 | 7.00~7.50 | 402 | 6 | [109] |

| Cattle manure: KW = 1:3 | Batch assay | 35 ± 1 | 7.20~7.30 | 233 | 7 | [110] |

| Wastewater sludge: KW = 1:1 | Semi-continuous | 35 ± 1 | 6.00~7.00 | - | 10 | [111] |

3.4. Exo-Conductive Material

3.4.1. Mechanisms of Electron Transfer

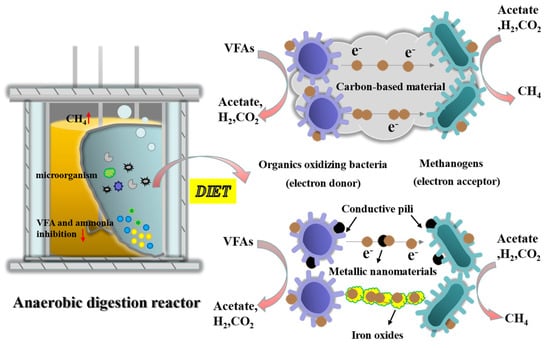

The methanogenesis process is an endothermic reaction process, although MPA cannot metabolize by themselves, so they need to cooperate with other microorganisms. Therefore, there is nutritional dependence between MPA and other bacteria, which is called microbial intermigration. Generally, microbial flocs exist widely among MPA and other bacteria [112,113]. The whole process requires a variety of microbes working together to degrade complex organic matter into small compounds, such as acetate and CO2, and then to convert the small compounds into methane. The mode of extracellular electron transfer between acetogenesis bacteria and MPA is called direct interspecific electron transfer (DIET) [114]. The flow of energy and substance between microorganisms is realized by DIET, and it is the main driving force of methanogenesis.

MPA have three electron-accepting ways to convert acetic acid and CO2 into methane, including interspecific H2 transfer, formic acid transfer and DIET [115]. Specifically, interspecific H2 transfer means that H2 is recognized as an electron carrier between acetogenesis bacteria and MPA. As a direct electron acceptor, H2 can pass through the bacterial phospholipid membrane and complete the energy and material transfer between different bacteria in the methanogenesis process [116]. In the same way, formic acid can play a role as an electron transfer carrier to conduct interspecific formic acid transfer. However, the concentrations of hydrogen and formic acid are low in the methanogenesis process, so interspecific H2 transfer and formic acid transfer are not predominant electron-accepting ways.

In addition, previous studies have shown that some bacteria can transfer electrons directly to MPA instead of traditional interspecific hydrogen or formic acid transfer. Direct electron transfer between bacteria is thermodynamically more efficient when it comes to accelerating the rate of the methanogenesis process without the involvement of diffused electron carriers [117,118]. Meanwhile, conductive materials can play a role as a bridge between acetogenesis bacteria and MPA to replace the conductive pili or cytochrome in DIET, which is a more effective way to enhance the electron transfer [115,119]. Figure 4 shows the mechanism of external materials promoting DIET.

Figure 4.

Mechanism of external conductive materials promoting DIET.

3.4.2. Carbon-Based Additives

Carbon-based additives have been widely applied to promote methane production via DIET. They have the merits of a large specific surface area, good conductivity, high adsorption capacity and high stability. Therefore, they are ideal substances to be added to enhance the methanogenesis process during AD. These additives contain granular activated carbon (GAC), powdered activated carbon, biochar, carbon cloth, graphite, graphene and other carbon-based materials.

For example, Johnravindar et al. take advantage of activated carbon to explore the effect of carbon-based additives on the anaerobic co-digestion of waste-activated sludge (WAS) and KW. The results indicate that adding activated carbon can increase methane production by 45%. The SEM analysis indicates that GAC can form biofilms to enrich hydrolase and acetogenesis enzyme activity. Therefore, it can promote the electron transfer efficiency of the methanogenesis process [120].

Furthermore, Lim et al. explore biochar’s impacts on AD for KW biodegradation and methane production during the start-up phase. Compared with the bioreactor without added biochar, the bioreactor with the addition of biochar increases the total methane production rate by 18%, and the addition of 5 g/L biochar is the most favorable for the start-up of the KW AD process [9]. Moreover, Li et al. study the effect of combining ethanol-based fermentation pretreatment with biochar on the anaerobic co-digestion of KW and WAS. The results indicate that the abundance of microorganisms, especially MPA, further aggrandizes due to the presence of biochar. Meanwhile, methane production is boosted by about 44% and the total VS of effluent vastly decreases compared with the bioreactor without biochar. The methane production efficiency in the reactor with the addition of biochar reaches up to 241.6 mL/g COD, which is 30% higher than that without biochar [121].

3.4.3. Metal Cations

Trace elements such as Fe, Co, Mo, and Ni are not only essential nutrients for microbial cell growth but also necessary for the synthesis of key coenzymes related to the methanogenesis process [105]. Specifically, the methanogenesis process requires a lot of carbon sources and energy to maintain the symbiotic environment between the bacteria and MPA. Therefore, if metal cations exist in the anaerobic environment, microorganisms will preferentially apply these substances to mediate the direct electron transfer between microbial species [122]. In addition, the addition of trace metal elements can restore the instability of the KW AD bioreactor caused by the accumulation of propionic acid [123].

For example, iron is the most important element among the various trace metal elements. It can serve as an electron acceptor or donor to participate in the redox reaction of methanogenesis. Based on previous studies, Chen et al. explore the effect of sulfide trace zero-valent iron (S-mZVI) on the anaerobic co-digestion of WAS and KW during the start-up phase, which indicates that S-mZVI can promote the direct interspecific electron transfer and increase the methane yield to 264.78 mL/g VS [124]. In addition, Wei et al. add zero-valent iron (Fe0) into a semi-continuous mesophilic AD reactor because Fe0 could promote the conversion of propionate into acetate and thus increase methane production during the start-up phase [125]. Moreover, adding iron oxide can not only improve the methane production of KW but also shorten the lag phase of the biogas production time [126].

Apart from Fe, the addition of Co, Ni and other trace metals can also significantly affect the process of methanogenesis. Song et al. find that 0.25~2.00 mg/(L·d) Co can effectively promote the production of biogas, and the best effect can be obtained under 0.50 mg/(L·d) Co [127]. Furthermore, Guo et al. discover that adding 2.45 g/L FN to the AD reactor strengthens the maximum methane production rate by 27.4% and reduces the peak production time by 33% compared with the control group [45].

Most attention has been paid to the addition of several trace metal elements into anaerobic bioreactors for KW disposal because the composition of KW varies greatly with time and space. When the pH value is 7, adding 50 mg/L Fe3+ and 30 mg/L Cu2+ to the anaerobic reactor at the same time can reduce the amount of lactic acid production in the AD process [128]. On the other hand, when the concentrations of Fe3+, Co2+, Ni2+ and Mo2+ are 15 mg/L, 2 mg/L, 0.5 mg/L and 6.0 mg/L, respectively, in the combined digestion bioreactor of KW and residual sludge at the same time, the reactor shows the best performance in terms of digestion efficiency and the pH value is stably maintained at 7.0~7.2 [129].

With the continuous breakthroughs of DIET research, the utilization of conductive materials to strengthen the DIET process in AD systems for KW biodegradation has obtained more and more attention. Specifically, the effects of the addition of Fe, Ni, Co and other trace metal elements have been widely studied to maintain the stability and performance of AD bioreactors. In summary, Table 3 presents the impacts of external conductive materials on the AD start-up phase.

Table 3.

Impacts of external conductive materials on the AD start-up phase.

3.5. Combination of Methods

Previous studies have shown that changing multiple factors can achieve a better priming effect embodied in improved methane production and maintained system stability. Figure 5 shows the effects of additives on different processes of the AD start-up phase.

Figure 5.

Effects of additives on different processes of the AD start-up phase.

For example, Chen et al. find that the main methanogenic metabolic pathway can convert from “acetic acid decomposition to methane production” into “cotrophic acetic acid oxidation and hydrogenated nutrition to methane production” through the joint addition of Fe and carbon during the start-up phase, which can ensure the subsequent efficient and stable operation of the thermophilic digestion of KW [139]. In addition, Zhang et al. combine activated charcoal with appropriate mixing strategies to suppress the negative influence of OLR augmentation on the thermophilic AD process. When the bioreactor operates at a moderate mixing strength, alternating the current addition can promote microbial enrichment to accelerate the AD start-up stage and maintain the system stability [104].

On the other hand, Ma et al. explore the promotion of methanogenic activity and start-up efficiency by adding powdered activated carbon (PAC) on the basis of the anaerobic co-digestion of KW. The microbial community analysis indicates that the addition of PAC can effectively improve bacterial abundance, such as Firmicutes, Bacteroidota, Clostridiaceae, Ruminococcaceae and Syntrophobacteraceae, as well as MPA, including Methanosaeta. Thus, they can promote DIET between species to improve the methanogenesis efficiency [140].

4. Conclusions

This paper investigates the principle of accelerating the start-up of AD for KW biodegradation. We propose several opinions according to the above-mentioned content.

- (1)

- In general, a KW AD system starts faster and more stably under the following parameters: under mesophilic conditions, pH is controlled around 7.0, OLR ranges from 2.0 to 4.5 kg COD/m3·d and the inoculation ratio is higher than 1.5. In addition, the metal ion concentration should be strictly controlled to maintain the stability of the bioreactor.

- (2)

- On the other hand, utilizing KW as the only substrate for long-term AD reactor operation may generate a slow start-up, so it can be considered to add livestock manure or residual sludge for co-digestion, or to add exogenous conductive materials to enhance the DIET and microbial methanogenic activity to accelerate the start-up phase.

5. Prospects and Challenges

Through the above-mentioned, we have explored diverse methods to accelerate the start-up phase of KW anaerobic bioreactors. Therefore, we propose the directions of future efforts and challenges in relation to KW anaerobic bioreactors.

- (1)

- A dry AD reactor for FW biodegradation has been shown to exhibit better performance under thermophilic conditions. However, the optimal start-up temperature for wet AD has not been concluded yet, which needs further studies.

- (2)

- The addition of multiple metal elements can reduce the lag time of the AD start-up phase. Yet, it is unconclusive to the effect of co-precipitation and adsorption between different metals on DIET.

- (3)

- The AD process of KW can be affected by diverse factors, and a variety of methods are derived to accelerate the start-up phase of the reaction. Nevertheless, which method is the most efficient and economical remains to be explored.

Author Contributions

Conceptualization, Y.-J.Y. and Y.H.; methodology, Y.-J.Y. and T.K.; software, X.L. and C.-S.L.; validation, G.-Y.Z.; investigation, X.L.; data curation, T.K. and G.-Y.Z.; writing—original draft preparation, Y.-J.Y.; writing—review and editing, G.-Y.Z. and Y.H.; visualization, C.-S.L.; supervision, T.K. and Y.H. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the NSFC (National Natural Science Foundation of China) (No. 52170037).

Acknowledgments

The authors gratefully acknowledge the financial support from the NSFC.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Wang, H.; Xu, J.; Sheng, L. Study on the comprehensive utilization of city kitchen waste as a resource in China. Energy 2019, 173, 263–277. [Google Scholar] [CrossRef]

- Halloran, A.; Clement, J.; Kornum, N.; Bucatariu, C.; Magid, J. Addressing food waste reduction in Denmark. Food Policy 2014, 49, 294–301. [Google Scholar] [CrossRef]

- Ul Saqib, N.; Sharma, H.B.; Baroutian, S.; Dubey, B.; Sarmah, A.K. Valorisation of food waste via hydrothermal carbonisation and techno-economic feasibility assessment. Sci. Total Environ. 2019, 690, 261–276. [Google Scholar] [CrossRef] [PubMed]

- Sharma, P.; Gaur, V.K.; Kim, S.-H.; Pandey, A. Microbial strategies for bio-transforming food waste into resources. Bioresour. Technol. 2020, 299, 122580. [Google Scholar] [CrossRef] [PubMed]

- Liu, N.; Jiang, J. Effects of activated carbon on the in-situ control of odorous gases emitted from anaerobic digestion of food waste and the microbial community response. Environ. Technol. Innov. 2021, 21, 101170. [Google Scholar] [CrossRef]

- Girotto, F.; Alibardi, L.; Cossu, R. Food waste generation and industrial uses: A review. Waste Manag. 2015, 45, 32–41. [Google Scholar] [CrossRef]

- Jeganathan, J.; Nakhla, G.; Bassi, A. Long-term performance of high-rate anaerobic reactors for the treatment of oily wastewater. Environ. Sci. Technol. 2006, 40, 6466–6472. [Google Scholar] [CrossRef]

- Wu, B.; Wang, X.; Deng, Y.Y.; He, X.L.; Li, Z.W.; Li, Q.; Qin, H.; Chen, J.T.; He, M.X.; Zhang, M. Adaption of microbial community during the start-up stage of a thermophilic anaerobic digester treating food waste. Biosci. Biotechnol. Biochem. 2016, 80, 2025–2032. [Google Scholar] [CrossRef]

- Lim, E.Y.; Tian, H.L.; Chen, Y.Y.; Ni, K.W.; Zhang, J.X.; Tong, Y.W. Methanogenic pathway and microbial succession during start-up and stabilization of thermophilic food waste anaerobic digestion with biochar. Bioresour. Technol. 2020, 314, 123751. [Google Scholar] [CrossRef]

- Coelho, N.M.G.; Droste, R.L.; Kennedy, K.J. Evaluation of continuous mesophilic, thermophilic and temperature phased anaerobic digestion of microwaved activated sludge. Water Res. 2011, 45, 2822–2834. [Google Scholar] [CrossRef]

- Chiu, S.L.H.; Lo, I.M.C. Reviewing the anaerobic digestion and co-digestion process of food waste from the perspectives on biogas production performance and environmental impacts. Environ. Sci. Pollut. Res. 2016, 23, 24435–24450. [Google Scholar] [CrossRef] [PubMed]

- Lu, S.-g.; Imai, T.; Ukita, M.; Sekine, M. Start-up performances of dry anaerobic mesophilic and thermophilic digestions of organic solid wastes. J. Environ. Sci. 2007, 19, 416–420. [Google Scholar] [CrossRef] [PubMed]

- Dinh Duc, N.; Chang, S.W.; Cha, J.H.; Jeong, S.Y.; Yoon, Y.S.; Lee, S.J.; Minh Chi, T.; Ngo, H.H. Dry semi-continuous anaerobic digestion of food waste in the mesophilic and thermophilic modes: New aspects of sustainable management and energy recovery in South Korea. Energy Convers. Manag. 2017, 135, 445–452. [Google Scholar] [CrossRef]

- Jang, H.M.; Ha, J.H.; Kim, M.-S.; Kim, J.-O.; Kim, Y.M.; Park, J.M. Effect of increased load of high-strength food wastewater in thermophilic and mesophilic anaerobic co-digestion of waste activated sludge on bacterial community structure. Water Res. 2016, 99, 140–148. [Google Scholar] [CrossRef]

- Jang, H.M.; Ha, J.H.; Kim, M.-S.; Kim, J.-O.; Kim, Y.M.; Park, J.M. Evaluating the impact of Iron Oxide nanoparticles (IO-NPs) and IO-NPs doped granular activated carbon on the anaerobic digestion of food waste at mesophilic and thermophilic temperature. J. Environ. Chem. Eng. 2022, 10, 107388. [Google Scholar] [CrossRef]

- Kim, M.; Speece, R.E. Waste Activated Sludge for Start-up Seed of Thermophilic Anaerobic Digestion. J. Korean Soc. Water Environ. 2005, 21, 490–495. [Google Scholar]

- Li, X.; Yang, Y.; Lu, C.-S.; Kobayashi, T.; Kong, Z.; Hu, Y. Oleate Impacts on Acetoclastic and Hydrogenotrophic Methanogenesis under Mesophilic and Thermophilic Conditions. Int. J. Environ. Res. Public Health 2023, 20, 3423. [Google Scholar] [CrossRef]

- Avery, G.B.; Shannon, R.D.; White, J.R.; Martens, C.S.; Alperin, M.J. Controls on methane production in a tidal freshwater estuary and a peatland: Methane production via acetate fermentation and CO2 reduction. Biogeochemistry 2003, 62, 19–37. [Google Scholar] [CrossRef]

- Yu, H.Q.; Fang, H.H.P. Acidogenesis of gelatin-rich wastewater in an upflow anaerobic reactor: Influence of pH and temperature. Water Res. 2003, 37, 55–66. [Google Scholar] [CrossRef]

- Horiuchi, J.I.; Shimizu, T.; Tada, K.; Kanno, T.; Kobayashi, M. Selective production of organic acids in anaerobic acid reactor by pH control. Bioresour. Technol. 2002, 82, 209–213. [Google Scholar] [CrossRef]

- Xu, Y.; Jiang, J.; Liu, N.; Yang, M.; Meng, Y. Effects of pretreatments on anaerobic co-digestion of kitchen waste and other organic wastes. J. Tsinghua Univ. Sci. Technol. 2019, 59, 558–566. [Google Scholar]

- Ghangrekar, M.M.; Asolekar, S.R.; Joshi, S.G. Characteristics of sludge developed under different loading conditions during UASB reactor start-up and granulation. Water Res. 2005, 39, 1123–1133. [Google Scholar] [CrossRef]

- Song, Y.-C.; Sik, S.H.; Chae, S.-R.; Oh, S.-E. Effects of Organic Loading Rate and Dilution Rate on Acidogenesis of Food Wastes. J. Korean Soc. Waste Manag. 2002, 19, 722–729. [Google Scholar]

- Meng, Y.; Shen, F.; Yuan, H.; Zou, D.; Liu, Y.; Zhu, B.; Chufo, A.; Jaffar, M.; Li, X. Start-up and operation strategies on the liquefied food waste anaerobic digestion and a full-scale case application. Bioprocess Biosyst. Eng. 2014, 37, 2333–2341. [Google Scholar] [CrossRef]

- Moset, V.; Al-zohairi, N.; Moller, H.B. The impact of inoculum source, inoculum to substrate ratio and sample preservation on methane potential from different substrates. Biomass Bioenergy 2015, 83, 474–482. [Google Scholar] [CrossRef]

- Moestedt, J.; Westerholm, M.; Isaksson, S.; Schnurer, A. Inoculum Source Determines Acetate and Lactate Production during Anaerobic Digestion of Sewage Sludge and Food Waste. Bioengineering 2020, 7, 3. [Google Scholar] [CrossRef] [PubMed]

- Rajput, A.A.; Sheikh, Z. Effect of inoculum type and organic loading on biogas production of sunflower meal and wheat straw. Sustain. Environ. Res. 2019, 29, 4. [Google Scholar] [CrossRef]

- Córdoba, V.; Fernández, M.; Santalla, E. The effect of different inoculums on anaerobic digestion of swine wastewater. J. Environ. Chem. Eng. 2016, 4, 115–122. [Google Scholar] [CrossRef]

- Quintero, M.; Castro, L.; Ortiz, C.; Guzman, C.; Escalante, H. Enhancement of starting up anaerobic digestion of lignocellulosic substrate: Fique’s bagasse as an example. Bioresour. Technol. 2012, 108, 8–13. [Google Scholar] [CrossRef] [PubMed]

- Suwannoppadol, S.; Ho, G.; Cord-Ruwisch, R. Rapid start-up of thermophilic anaerobic digestion with the turf fraction of MSW as inoculum. Bioresour. Technol. 2011, 102, 7762–7767. [Google Scholar] [CrossRef]

- Zheng, X.; Li, B.; Li, Y.; Chen, L. Effect of different inoculation ratios on start-up performances of dry anaerobic digestions for kitchen waste. Chin. J. Environ. Eng. 2014, 8, 1157–1162. [Google Scholar]

- Zheng, X.; Li, B.; Guo, D.; Fu, X.; Chen, L. Start-up performance and methane production efficiency on anaerobic digestion for kitchen waste. Environ. Eng. 2018, 36, 128–132. [Google Scholar]

- Bozym, M.; Florczak, I.; Zdanowska, P.; Wojdalski, J.; Klimkiewicz, M. An analysis of metal concentrations in food wastes for biogas production. Renew. Energy 2015, 77, 467–472. [Google Scholar] [CrossRef]

- Soto, M.; Mendez, R.; Lema, J.M. Methanogenic and non-methanogenic activity tests—Theoretical basis and experimental set-up. Water Res. 1993, 27, 1361–1376. [Google Scholar] [CrossRef]

- Huang, J.; Pinder, K.L. Effects of calcium on development of anaerobic acidogenic biofilms. Biotechnol. Bioeng. 1995, 45, 212–218. [Google Scholar] [CrossRef] [PubMed]

- Jacksonmoss, C.A.; Duncan, J.R. The effect of aluminum on anaerobic-digestion. Biotechnol. Lett. 1991, 13, 143–148. [Google Scholar] [CrossRef]

- Schmidt, J.E.; Ahring, B.K. Effects of magnesium on thermophilic acetate-degrading granules in upflow anaerobic sludge blanket (uasb) reactors. Enzym. Microb. Technol. 1993, 15, 304–310. [Google Scholar] [CrossRef]

- Yuan, H.; Wen, J.; Xing, B.; Han, Y.; Cao, S.; Zhang, K.; Wang, X. Inhibition effects of sodium salinity on the high-rate mesophilic anaerobic codigestion of food waste with waste activated sludge. Acta Sci. Circumstantiae 2020, 40, 3331–3340. [Google Scholar]

- Jin, P.K.; Bhattacharya, S.K.; Williams, C.J.; Zhang, H.N. Effects of sulfide addition on copper inhibition in methanogenic systems. Water Res. 1998, 32, 977–988. [Google Scholar] [CrossRef]

- Liu, S.-H.; Zeng, G.-M.; Niu, Q.-Y.; Liu, Y.; Zhou, L.; Jiang, L.-H.; Tan, X.-f.; Xu, P.; Zhang, C.; Cheng, M. Bioremediation mechanisms of combined pollution of PAHs and heavy metals by bacteria and fungi: A mini review. Bioresour. Technol. 2017, 224, 25–33. [Google Scholar] [CrossRef]

- Mudhoo, A.; Kumar, S. Effects of heavy metals as stress factors on anaerobic digestion processes and biogas production from biomass. Int. J. Environ. Sci. Technol. 2013, 10, 1383–1398. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, L.; Li, A. Enhanced anaerobic digestion of food waste by trace metal elements supplementation and reduced metals dosage by green chelating agent S, S -EDDS via improving metals bioavailability. Water Res. 2015, 84, 266–277. [Google Scholar] [CrossRef] [PubMed]

- Babich, H.; Stotzky, G. Toxicity of nickel to microbes—Environmental aspects. Adv. Appl. Microbiol. 1983, 29, 195–265. [Google Scholar] [CrossRef]

- Zhao, J.; Bello, M.O.; Meng, Y.; Prosser, J.I. Selective inhibition of ammonia oxidising archaea by simvastatin stimulates growth of ammonia oxidising bacteria. Soil Biol. Biochem. 2020, 141, 107673. [Google Scholar] [CrossRef]

- Guo, X.; Sun, C.; Lin, R.; Xia, A.; Huang, Y.; Zhu, X. Effects of foam nickel supplementation on anaerobic digestion: Direct interspecies electron transfer. J. Hazard. Mater. 2020, 399, 122830. [Google Scholar] [CrossRef] [PubMed]

- Quiroga, G.; Castrillon, L.; Fernandez-Nava, Y.; Maranon, E.; Negral, L. Effect of ultrasound pre-treatment in the anaerobic co-digestion of cattle manure with food waste and sludge. Bioresour. Technol. 2014, 154, 74–79. [Google Scholar] [CrossRef]

- Deepanraj, B.; Sivasubramanian, V.; Jayaraj, S. Effect of substrate pretreatment on biogas production through anaerobic digestion of food waste. Int. J. Hydrogen Energy 2017, 42, 26522–26528. [Google Scholar] [CrossRef]

- Ariunbaatar, J.; Panico, A.; Esposito, G.; Pirozzi, F.; Lens, P.N.L. Pretreatment methods to enhance anaerobic digestion of organic solid waste. Appl. Energy 2014, 123, 143–156. [Google Scholar] [CrossRef]

- Carlsson, M.; Lagerkvist, A.; Morgan-Sagastume, F. The effects of substrate pre-treatment on anaerobic digestion systems: A review. Waste Manag. 2012, 32, 1634–1650. [Google Scholar] [CrossRef]

- Rafique, R.; Poulsen, T.G.; Nizami, A.-S.; Asam, Z.-u.-Z.; Murphy, J.D.; Kiely, G. Effect of thermal, chemical and thermo-chemical pre-treatments to enhance methane production. Energy 2010, 35, 4556–4561. [Google Scholar] [CrossRef]

- Kurian, J.K.; Nair, G.R.; Hussain, A.; Raghavan, G.S.V. Feedstocks, logistics and pre-treatment processes for sustainable lignocellulosic biorefineries: A comprehensive review. Renew. Sustain. Energy Rev. 2013, 25, 205–219. [Google Scholar] [CrossRef]

- Monlau, F.; Sambusiti, C.; Barakat, A.; Guo, X.M.; Latrille, E.; Trably, E.; Steyer, J.-P.; Carrere, H. Predictive Models of Biohydrogen and Biomethane Production Based on the Compositional and Structural Features of Lignocellulosic Materials. Environ. Sci. Technol. 2012, 46, 12217–12225. [Google Scholar] [CrossRef]

- Szlachta, J.; Prask, H.; Fugol, M.; Luberanski, A. Effect of Mechanical Pre-Treatment of the Agricultural Substrates on Yield of Biogas and Kinetics of Anaerobic Digestion. Sustainability 2018, 10, 3669. [Google Scholar] [CrossRef]

- Fisgativa, H.; Tremier, A.; Dabert, P. Characterizing the variability of food waste quality: A need for efficient valorisation through anaerobic digestion. Waste Manag. 2016, 50, 264–274. [Google Scholar] [CrossRef]

- Zhang, C.; Su, H.; Baeyens, J.; Tan, T. Reviewing the anaerobic digestion of food waste for biogas production. Renew. Sustain. Energy Rev. 2014, 38, 383–392. [Google Scholar] [CrossRef]

- Kim, J.K.; Oh, B.R.; Chun, Y.N.; Kim, S.W. Effects of temperature and hydraulic retention time on anaerobic digestion of food waste. J. Biosci. Bioeng. 2006, 102, 328–332. [Google Scholar] [CrossRef]

- Jia, S.; Zhang, D.; Zhao, J.; Yu, S. Research on different pre-treatment methods for improving anaerobic digestion of primary/excess sludge of biogas production. Chem. Ind. Eng. Prog. 2013, 32, 193–198. [Google Scholar]

- Obulisamy, P.K.; Chakraborty, D.; Selvam, A.; Wong, J.W.C. Anaerobic co-digestion of food waste and chemically enhanced primary-treated sludge under mesophilic and thermophilic conditions. Environ. Technol. 2016, 37, 3200–3207. [Google Scholar] [CrossRef]

- Izumi, K.; Okishio, Y.-k.; Nagao, N.; Niwa, C.; Yamamoto, S.; Toda, T. Effects of particle size on anaerobic digestion of food waste. Int. Biodeterior. Biodegrad. 2010, 64, 601–608. [Google Scholar] [CrossRef]

- Gianico, A.; Gallipoli, A.; Gazzola, G.; Pastore, C.; Tonanzi, B.; Braguglia, C.M. A novel cascade biorefinery approach to transform food waste into valuable chemicals and biogas through thermal pretreatment integration. Bioresour. Technol. 2021, 338, 125517. [Google Scholar] [CrossRef]

- Parra-Orobio, B.A.; Giron-Bol, L.M.; Gomez-Munoz, D.F.; Marmolejo-Rebellon, L.F.; Torres-Lozada, P. Thermal pre-treatment as a tool for energy recovery from food waste through anaerobic digestion. Effect on kinetic and physicochemical characteristics of the substrate. Environ. Technol. Innov. 2021, 21, 101262. [Google Scholar] [CrossRef]

- Qin, L.; Liu, Z.-H.; Li, B.-Z.; Dale, B.E.; Yuan, Y.-J. Mass balance and transformation of corn stover by pretreatment with different dilute organic acids. Bioresour. Technol. 2012, 112, 319–326. [Google Scholar] [CrossRef]

- Ma, J.; Duong, T.H.; Smits, M.; Verstraete, W.; Carballa, M. Enhanced biomethanation of kitchen waste by different pre-treatments. Bioresour. Technol. 2011, 102, 592–599. [Google Scholar] [CrossRef] [PubMed]

- Shrestha, S.; Fonoll, X.; Khanal, S.K.; Raskin, L. Biological strategies for enhanced hydrolysis of lignocellulosic biomass during anaerobic digestion: Current status and future perspectives. Bioresour. Technol. 2017, 245, 1245–1257. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Han, W.; Xu, X.; Chen, L.; Tang, J.; Hou, P. Ethanol production from waste pizza by enzymatic hydrolysis and fermentation. Biochem. Eng. J. 2020, 156, 107528. [Google Scholar] [CrossRef]

- Moon, H.C.; Song, I.S.; Kim, J.C.; Shirai, Y.; Lee, D.H.; Kim, J.K.; Chung, S.O.; Kim, D.H.; Oh, K.K. Enzymatic hydrolysis of food waste and ethanol fermentation. Int. J. Energy Res. 2009, 33, 164–172. [Google Scholar] [CrossRef]

- Duvernay, W.H.; Chinn, M.S.; Yencho, G.C. Hydrolysis and fermentation of sweetpotatoes for production of fermentable sugars and ethanol. Ind. Crops Prod. 2013, 42, 527–537. [Google Scholar] [CrossRef]

- Vavouraki, A.I.; Volioti, V.; Kornaros, M.E. Optimization of thermo-chemical pretreatment and enzymatic hydrolysis of kitchen wastes. Waste Manag. 2014, 34, 167–173. [Google Scholar] [CrossRef]

- Stabnikova, O.; Liu, X.Y.; Wang, J.Y. Digestion of frozen/thawed food waste in the hybrid anaerobic solid-liquid system. Waste Manag. 2008, 28, 1654–1659. [Google Scholar] [CrossRef]

- Tampio, E.; Ervasti, S.; Paavola, T.; Heaven, S.; Banks, C.; Rintala, J. Anaerobic digestion of autoclaved and untreated food waste. Waste Manag. 2014, 34, 370–377. [Google Scholar] [CrossRef]

- Ding, L.; Yang, M.; Areeprasert, C.; Cheng, X.; Chen, X.; Wang, F.; Yu, G. Analysis of micro-particle effect and methanogenic potential of food waste model compounds by hydrothermal pretreatment. Fuel 2023, 331, 125686. [Google Scholar] [CrossRef]

- Elbeshbishy, E.; Nakhla, G. Comparative study of the effect of ultrasonication on the anaerobic biodegradability of food waste in single and two-stage systems. Bioresour. Technol. 2011, 102, 6449–6457. [Google Scholar] [CrossRef]

- Feng, L.; Li, R. Efficiency of anaerobic digestion of kitchen waste by low intensity ultrasound pretreatment. Chin. J. Environ. Eng. 2012, 6, 3280–3286. [Google Scholar]

- Marin, J.; Kennedy, K.J.; Eskicioglu, C. Effect of microwave irradiation on anaerobic degradability of model kitchen waste. Waste Manag. 2010, 30, 1772–1779. [Google Scholar] [CrossRef]

- Lim, J.W.; Wang, J.-Y. Enhanced hydrolysis and methane yield by applying microaeration pretreatment to the anaerobic co-digestion of brown water and food waste. Waste Manag. 2013, 33, 813–819. [Google Scholar] [CrossRef]

- Zhao, M.X.; Yan, Q.; Ruan, W.Q.; Miao, H.F.; Ren, H.Y.; Xu, Y. Enhancement of substrate solubilization and hydrogen production from kitchen wastes by pH pretreatment. Environ. Technol. 2011, 32, 119–125. [Google Scholar] [CrossRef]

- Zhao, M.X.; Yan, Q.; Ruan, W.Q.; Xu, Y. Enhancement of hydrogen production from kitchen wastes by alkaline pretreatment. J. Saf. Environ. 2009, 9, 88–91. [Google Scholar]

- Kiran, E.U.; Liu, Y. Bioethanol production from mixed food waste by an effective enzymatic pretreatment. Fuel 2015, 159, 463–469. [Google Scholar] [CrossRef]

- Cheng, J.; Yue, L.; Hua, J.; Dong, H.; Zhou, J.; Li, Y.-Y. Hydrothermal alkali pretreatment contributes to fermentative methane production of a typical lipid from food waste through co-production of hydrogen with methane. Bioresour. Technol. 2020, 306, 123164. [Google Scholar] [CrossRef]

- Hafid, H.S.; Rahman, N.A.A.; Shah, U.K.M.; Baharudin, A.S. Enhanced fermentable sugar production from kitchen waste using various pretreatments. J. Environ. Manag. 2015, 156, 290–298. [Google Scholar] [CrossRef]

- laqa Kakar, F.; Purohit, N.; Okoye, F.; Liss, S.N.; Elbeshbishy, E. Combined hydrothermal and free nitrous acid, alkali and acid pretreatment for biomethane recovery from municipal sludge. Waste Manag. 2021, 131, 376–385. [Google Scholar] [CrossRef] [PubMed]

- Simkins, S.; Alexander, M. Models for mineralization kinetics with the variables of substrate concentration and population-density. Appl. Environ. Microbiol. 1984, 47, 1299–1306. [Google Scholar] [CrossRef] [PubMed]

- Chudoba, P.; Capdeville, B.; Chudoba, J. Explanation of biological meaning of the s0/x0 ratio in batch cultivation. Water Sci. Technol. 1992, 26, 743–751. [Google Scholar] [CrossRef]

- Lim, J.W.; Wong, S.W.K.; Dai, Y.; Tong, Y.W. Effect of seed sludge source and start-up strategy on the performance and microbial communities of thermophilic anaerobic digestion of food waste. Energy 2020, 203, 117922. [Google Scholar] [CrossRef]

- Elbeshbishy, E.; Nakhla, G.; Hafez, H. Biochemical methane potential (BMP) of food waste and primary sludge: Influence of inoculum pre-incubation and inoculum source. Bioresour. Technol. 2012, 110, 18–25. [Google Scholar] [CrossRef]

- Wilkins, D.; Rao, S.; Lu, X.; Lee, P.K.H. Effects of sludge inoculum and organic feedstock on active microbial communities and methane yield during anaerobic digestion. Front. Microbiol. 2015, 6, 1114. [Google Scholar] [CrossRef]

- Ding, H.; Barlaz, M.A.; de los Reyes Iii, F.L.; Call, D.F. Influence of Inoculum Type on Volatile Fatty Acid and Methane Production in Short-Term Anaerobic Food Waste Digestion Tests. ACS Sustain. Chem. Eng. 2022, 10, 17071–17080. [Google Scholar] [CrossRef]

- Wang, K.; Yin, J.; Shen, D.; Li, N. Anaerobic digestion of food waste for volatile fatty acids (VFAs) production with different types of inoculum: Effect of pH. Bioresour. Technol. 2014, 161, 395–401. [Google Scholar] [CrossRef]

- Tian, Z.; Zhang, Y.; Li, Y.; Chi, Y.; Yang, M. Rapid establishment of thermophilic anaerobic microbial community during the one-step startup of thermophilic anaerobic digestion from a mesophilic digester. Water Res. 2015, 69, 9–19. [Google Scholar] [CrossRef]

- Palatsi, J.; Gimenez-Lorang, A.; Ferrer, I.; Flotats, X. Start-up strategies of thermophilic anaerobic digestion of sewage sludge. Water Sci. Technol. 2009, 59, 1777–1784. [Google Scholar] [CrossRef]

- Xu, R.; Yang, Z.-H.; Wang, Q.-P.; Bai, Y.; Liu, J.-B.; Zheng, Y.; Zhang, Y.-R.; Xiong, W.-P.; Ahmad, K.; Fan, C.-Z. Rapid startup of thermophilic anaerobic digester to remove tetracycline and sulfonamides resistance genes from sewage sludge. Sci. Total Environ. 2018, 612, 788–798. [Google Scholar] [CrossRef] [PubMed]

- Shin, J.; Jang, H.M.; Shin, S.G.; Kim, Y.M. Thermophilic anaerobic digestion: Effect of start-up strategies on performance and microbial community. Sci. Total Environ. 2019, 687, 87–95. [Google Scholar] [CrossRef] [PubMed]

- Kobayashi, T.; Wu, Y.P.; Xu, K.Q.; Li, Y.Y. Effect of Mixing Driven by Siphon Flow: Parallel Experiments Using the Anaerobic Reactors with Different Mixing Modes. Energies 2013, 6, 4207–4222. [Google Scholar] [CrossRef]

- Kariyama, I.D.; Zhai, X.; Wu, B. Influence of mixing on anaerobic digestion efficiency in stirred tank digesters: A review. Water Res. 2018, 143, 503–517. [Google Scholar] [CrossRef] [PubMed]

- Liu, G.; Li, Y.; Wang, J.; Sheng, H.; Li, Q.; Zeng, Y.; Song, R. A comparative experimental study of the anaerobic treatment of food wastes using an anaerobic digester with a polyamide stirring rake or a stainless-steel stirring rake. J. Environ. Manag. 2018, 218, 435–441. [Google Scholar] [CrossRef] [PubMed]

- Zhao, J.; Zhang, B.; Cai, W. Research Progress on Propionic Acid Accumulation and Control in Anaerobic Digestion System. China Water Wastewater 2005, 21, 25–27. [Google Scholar]

- Srisowmeya, G.; Chakravarthy, M.; Devi, G.N. Critical considerations in two-stage anaerobic digestion of food waste—A review. Renew. Sustain. Energy Rev. 2020, 119, 109587. [Google Scholar] [CrossRef]

- Wang, Q.; Yamabe, K.; Narita, J.; Morishita, M.; Ohsumi, Y.; Kusano, K.; Shirai, Y.; Ogawa, H.I. Suppression of growth of putrefactive and food poisoning bacteria by lactic acid fermentation of kitchen waste. Process Biochem. 2001, 37, 351–357. [Google Scholar] [CrossRef]

- Zhang, B.; Shi, H.; Zhang, L.; Cai, W. The influence of pH on hydrolysis and acidogenesis of kitchen wastes in two-phase anaerobic digestion. Acta Sci. Circumstantiae 2005, 25, 665–669. [Google Scholar] [CrossRef]

- Xing, B.-S.; Cao, S.; Han, Y.; Wen, J.; Zhang, K.; Wang, X.C. Stable and high-rate anaerobic co-digestion of food waste and cow manure: Optimisation of start-up conditions. Bioresour. Technol. 2020, 307, 123195. [Google Scholar] [CrossRef]

- Liao, X.; Zhu, S.; Zhong, D.; Zhu, J.; Liao, L. Anaerobic co-digestion of food waste and landfill leachate in single-phase batch reactors. Waste Manag. 2014, 34, 2278–2284. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Xiao, G.; Peng, L.; Su, H.; Tan, T. The anaerobic co-digestion of food waste and cattle manure. Bioresour. Technol. 2013, 129, 170–176. [Google Scholar] [CrossRef] [PubMed]

- Yuan, Y. Start-up strategy of co-digestion system of sewage sludge and food waste. Environ. Eng. 2018, 36, 137–140. [Google Scholar]

- Zhang, J.; Qi, Q.; Mao, L.; He, Y.; Loh, K.-C.; Tong, Y.W. Mixing strategies? Activated carbon nexus: Rapid start-up of thermophilic anaerobic digestion with the mesophilic anaerobic sludge as inoculum. Bioresour. Technol. 2020, 310, 123401. [Google Scholar] [CrossRef]

- Lee, E.; Bittencourt, P.; Casimir, L.; Jimenez, E.; Wang, M.; Zhang, Q.; Ergas, S.J. Biogas production from high solids anaerobic co-digestion of food waste, yard waste and waste activated sludge. Waste Manag. 2019, 95, 432–439. [Google Scholar] [CrossRef]

- Yong, Z.H.; Dong, Y.L.; Zhang, X.; Tan, T.W. Anaerobic co-digestion of food waste and straw for biogas production. Renew. Energy 2015, 78, 527–530. [Google Scholar] [CrossRef]

- Sun, Y.; Liu, Q.; Jiang, Y.; Che, Z.; Zhang, H.; Wang, X.; Cao, Y.; Kou, W. Analysis of microorganism at starting stage of anaerobic fermentation of vegetable waste and restaurant garbage. Chin. J. Environ. Eng. 2014, 8, 310–316. [Google Scholar]

- Chang, C.; Ming, L.; Mu, Y.; Hua, Z.; Li, X.; Zhang, D. Synergistic effect of kitchen waste and sludge anaerobic fermentation for methane production. China Environ. Sci. 2022, 42, 1259–1266. [Google Scholar]

- Varsha, S.S.V.; Soomro, A.F.; Baig, Z.T.; Vuppaladadiyam, A.K.; Murugavelh, S.; Antunes, E. Methane production from anaerobic mono- and co-digestion of kitchen waste and sewage sludge: Synergy study on cumulative methane production and biodegradability. Biomass Convers. Biorefin. 2022, 12, 3911–3919. [Google Scholar] [CrossRef]

- Li, R.; Chen, S.; Li, X. Anaerobic Co-digestion of Kitchen Waste and Cattle Manure for Methane Production. Energy Sources Part A Recovery Util. Environ. Eff. 2009, 31, 1848–1856. [Google Scholar] [CrossRef]

- Antony, D.; Murugavelh, S. Anaerobic co-digestion of kitchen waste and wastewater sludge: Biogas-based power generation. Biofuels 2018, 9, 157–162. [Google Scholar] [CrossRef]

- Schink, B. Energetics of syntrophic cooperation in methanogenic degradation. Microbiol. Mol. Biol. Rev. 1997, 61, 262–280. [Google Scholar] [CrossRef]

- Morris, B.E.L.; Henneberger, R.; Huber, H.; Moissl-Eichinger, C. Microbial syntrophy: Interaction for the common good. Fems Microbiol. Rev. 2013, 37, 384–406. [Google Scholar] [CrossRef]

- Shen, L.; Zhao, Q.; Wu, X.; Li, X.; Li, Q.; Wang, Y. Interspecies electron transfer in syntrophic methanogenic consortia: From cultures to bioreactors. Renew. Sustain. Energy Rev. 2016, 54, 1358–1367. [Google Scholar] [CrossRef]

- Li, J.; Zhang, B.; Liu, Q.; Han, Y. Research progress on enhancement of methane production through direct interspecific electron transfer by conductive materials. Acta Microbiol. Sin. 2021, 61, 1507–1524. [Google Scholar]

- Stams, A.J.M. Metabolic interactions between anaerobic-bacteria in methanogenic environments. Antonie Leeuwenhoek Int. J. Gen. Mol. Microbiol. 1994, 66, 271–294. [Google Scholar] [CrossRef]

- Cheng, Q.; Call, D.F. Hardwiring microbes via direct interspecies electron transfer: Mechanisms and applications. Environ. Sci. Process. Impacts 2016, 18, 968–980. [Google Scholar] [CrossRef]

- Rotaru, A.-E.; Shrestha, P.M.; Liu, F.; Markovaite, B.; Chen, S.; Nevin, K.P.; Lovley, D.R. Direct Interspecies Electron Transfer between Geobacter metallireducens and Methanosarcina barkeri. Appl. Environ. Microbiol. 2014, 80, 4599–4605. [Google Scholar] [CrossRef]

- Achinas, S.; Achinas, V.; Euverink, G.J.W. A Technological Overview of Biogas Production from Biowaste. Engineering 2017, 3, 299–307. [Google Scholar] [CrossRef]

- Johnravindar, D.; Liang, B.; Fu, R.; Luo, G.; Meruvu, H.; Yang, S.; Yuan, B.; Fei, Q. Supplementing granular activated carbon for enhanced methane production in anaerobic co-digestion of post-consumer substrates. Biomass Bioenergy 2020, 136, 105543. [Google Scholar] [CrossRef]

- Li, Y.; Liu, M.; Che, X.; Li, C.; Liang, D.; Zhou, H.; Liu, L.; Zhao, Z.; Zhang, Y. Biochar stimulates growth of novel species capable of direct interspecies electron transfer in anaerobic digestion via ethanol-type fermentation. Environ. Res. 2020, 189, 109983. [Google Scholar] [CrossRef] [PubMed]