Impact of Commercial Inactive Yeast Derivatives on Antiradical Properties, Volatile and Sensorial Profiles of Grašac Wines

Abstract

1. Introduction

2. Materials and Methods

2.1. Wine Production

2.2. Total Free -SH Groups Determination

2.3. Total Polyphenols Determination

2.4. Antioxidative Activity of Wine (DPPH Assay, Antiradical Activity)

2.5. Volatile Compound Analysis (HS-SPME-GC-MS)

2.6. Sensory Analysis

2.7. Statistical Analysis

3. Results and Discussion

3.1. Standard Oenological Parameters

3.2. Polyphenols and Total Free Sulphydryl Groups (-SH) Content

3.3. Volatile Compounds

| Compound | OTL, mg/L | Time | C | IYD Treatment * | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| NO20 | NO40 | OL20 | OL40 | OW20 | OW40 | OE20 | OE40 | ||||

| 3-Methyl-1-butanol | 30.00 [41] | 3 | 28.32 ** | 24.13 | 33.64 | 40.48 | 37.44 | 39.97 | 39.74 | 37.84 | 39.80 |

| 6 | 23.1 | 22.30 | 12.59 | 13.70 | 18.59 | 13.85 | 29.28 | 37.82 | 39.82 | ||

| 2-Methyl-1-propanol | 30.00 [42] | 3 | 15.68 | 6.08 | 11.33 | 14.20 | 8.15 | 9.80 | 15.00 | 8.99 | 14.95 |

| 6 | 19.21 | 5.22 | 18.55 | 19.87 | 14.31 | 10.28 | 18.69 | 8.69 | 16.39 | ||

| n-Hexanol | 8.000 [42] | 3 | 4.52 | 5.51 | 5.88 | 6.49 | 6.98 | 5.16 | 6.02 | 5.97 | 4.96 |

| 6 | 4.1 | 5.25 | 5.71 | 6.32 | 6.11 | 4.99 | 5.88 | 5.11 | 4.83 | ||

| Phenyl ethyl alcohol | 14.000 [42] | 3 | 15.21 | 14.54 | 18.68 | 16.26 | 22.95 | 24.53 | 22.35 | 13.13 | 19.39 |

| 6 | 15.55 | 19.30 | 26.26 | 22.73 | 23.72 | 38.94 | 35.00 | 20.81 | 25.10 | ||

| Total alcohols | 3 | 63.73 | 50.26 | 69.53 | 77.43 | 75.52 | 79.46 | 84.11 | 65.93 | 79.1 | |

| 6 | 61.96 | 52.07 | 63.11 | 62.62 | 62.73 | 68.06 | 88.85 | 70.43 | 86.14 | ||

| Ethyl acetate | 7.500 [42] | 3 | 17.98 | 16.73 | 28.55 | 17.31 | 19.67 | 18.58 | 21.60 | 19.81 | 20.73 |

| 6 | 12.02 | 14.25 | 18.30 | 21.79 | 16.59 | 19.39 | 14.11 | 20.63 | 16.25 | ||

| Ethyl hexanoate | 0.005 [42] | 3 | 1.109 | 1.195 | 1.208 | 1.131 | 1.384 | 1.697 | 1.394 | 1.061 | 1.235 |

| 6 | 1.85 | 1.518 | 3.249 | 4.408 | 3.451 | 1.96454 | 1.451 | 1.343 | 1.576 | ||

| Ethyl octanoate | 0.002 [42] | 3 | 3.21 | 4.374 | 4.879 | 4.649 | 4.026 | 4.046 | 4.714 | 4.283 | 4.755 |

| 6 | tr | 3.671 | 2.861 | 2.572 | 3.688 | 3.355 | 3.015 | 3.190 | 3.854 | ||

| Methyl octanoate | 0.017 [41] | 3 | tr | tr | 1.67 | 3.06 | 2.86 | 2.02 | 3.30 | 3.80 | 3.26 |

| 6 | tr *** | tr | 1.11 | 2.89 | 2.53 | 1.86 | 3.05 | 3.68 | 3.18 | ||

| Ethyl decanoate | 0.200 [42] | 3 | 7.53 | 5.66 | 6.20 | 6.75 | 6.56 | 6.97 | 6.10 | 6.38 | 6.13 |

| 6 | 6.23 | 6.72 | 6.02 | 6.15 | 6.18 | 7.08 | 6.64 | 6.96 | 6.56 | ||

| Ethyl dodecanoate | 1.500 [42] | 3 | 10.977 | 6.028 | 5.406 | 6.041 | 4.080 | 6.164 | 6.640 | 5.115 | 4.010 |

| 6 | 9.88 | 4.033 | 4.053 | 4.857 | 3.796 | 4.646 | 3.420 | 3.556 | 3.047 | ||

| 3-Methyl-1-butanol-acetate | 0.030 [41] | 3 | 0.40 | - | 0.91 | 0.10 | 0.10 | 0.91 | 0.36 | 0.40 | 0.43 |

| 6 | 0.31 | - | 0.79 | 0.15 | 0.11 | 0.97 | 0.78 | 0.8 | 0.84 | ||

| 3-Methyl- butyl -octanoate | - | 3 | 7.18 | 4.44 | 5.38 | 5.65 | 6.08 | 5.82 | 5.53 | 5.37 | 5.74 |

| 6 | 6.98 | 5.44 | 5.51 | 4.81 | 5.01 | 6.20 | 5.34 | 5.57 | 5.49 | ||

| 3-methyl- butyl -pentanoate | - | 3 | 0.29 | 0.14 | 0.19 | 0.24 | 0.22 | 0.24 | 0.20 | 0.26 | 0.20 |

| 6 | 0.41 | 0.25 | 0.31 | 0.34 | 0.28 | 0.38 | 0.31 | 0.32 | 0.30 | ||

| Ethyl-(9)-decenoate | 0.100 [41] | 3 | 3.55 | 3.59 | 3.75 | 4.18 | 4.03 | 4.36 | 4.24 | 3.95 | 4.20 |

| 6 | 3.61 | 4.27 | 4.82 | 3.69 | 3.84 | 4.02 | 3.97 | 4.24 | 4.48 | ||

| ethyl 9-hexadecenoate | 2.000 [41] | 3 | 7.4 | tr | tr | 10.11 | 16.87 | 16.49 | 16.74 | 12.34 | 16.23 |

| 6 | 8.23 | tr | tr | 31.88 | 33.31 | 27.10 | 32.76 | 29.52 | 33.07 | ||

| 2-phenil-ethyl acetate | 0.250 [42] | 3 | 10.39 | 8.91 | 11.84 | 10.94 | 11.92 | 12.69 | 11.94 | 10.54 | 10.42 |

| 6 | 8.22 | 7.1 | 14.53 | 13.81 | 14.1 | 15.21 | 14.98 | 12.78 | 13.11 | ||

| Hexyl acetate | 0.670 [42] | 3 | - | 0.56 | 0.164 | 0.147 | 0.178 | 0.177 | tr | 0.138 | 0.158 |

| 6 | - | tr | tr | tr | tr | tr | tr | tr | tr | ||

| Total esters | 3 | 70.02 | 51.07 | 69.98 | 70.16 | 77.81 | 79.99 | 82.76 | 73.31 | 77.34 | |

| 6 | 57.74 | 47.25 | 61.55 | 97.35 | 92.88 | 92.16 | 89.83 | 92.59 | 91.76 | ||

| Octanoic acid | 0.500 [42] | 3 | 2.132 | 0.98 | 2.23 | 2.812 | 2.78 | 3.55 | 3.08 | 2.09 | 2.31 |

| 6 | 2.23 | 3.29 | 5.27 | 4.71 | 4.19 | 4.55 | 4.21 | 4.13 | 2.61 | ||

| Decanoic acid | 15.000 [42] | 3 | 1.47 | 0.49 | 1.18 | 1.70 | 1.67 | 2.31 | 2.01 | 1.67 | 1.36 |

| 6 | 1.98 | 2.29 | 3.84 | 3.823 | 3.02 | 3.02 | 3.32 | 3.12 | 1.78 | ||

| Dodecanoic acid | 10.000 [42] | 3 | 10.13 | - | - | 9.07 | 10.40 | 13.44 | 12.06 | 9.52 | 7.72 |

| 6 | 10.99 | - | - | 13.97 | 16.99 | 19.07 | 15.05 | 12.80 | 11.84 | ||

| Total acids | 3 | 13.73 | 1.47 | 3.41 | 13.58 | 14.85 | 19.3 | 17.15 | 13.28 | 11.39 | |

| 6 | 15.2 | 5.59 | 9.12 | 22.50 | 24.20 | 26.64 | 22.58 | 20.05 | 16.23 | ||

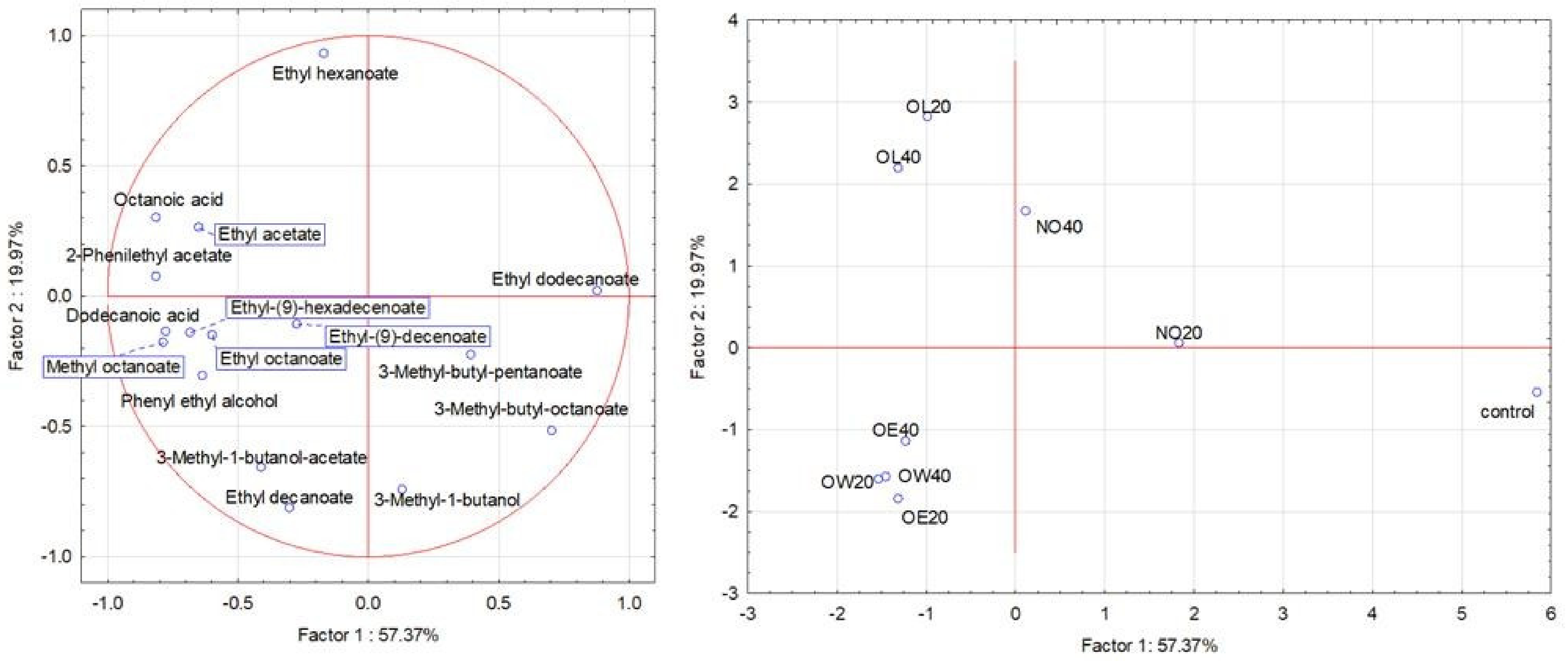

3.4. PCA Analysis

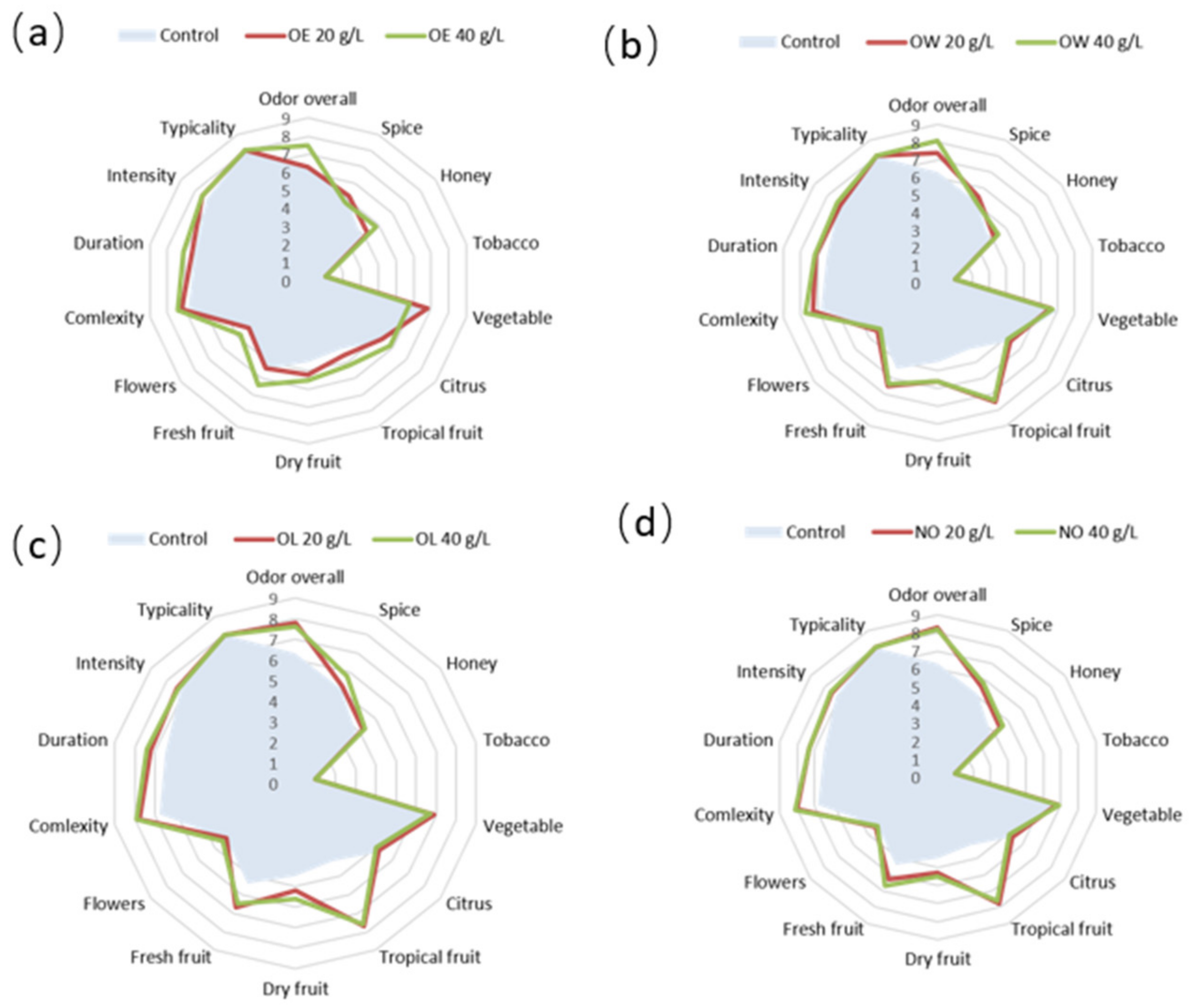

3.5. Sensory Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bisson, L.F.; Waterhouse, A.L.; Ebeler, S.E.; Walker, M.A.; Lapsley, J.T. The Present and Future of the International Wine Industry. Nature 2002, 418, 696–699. [Google Scholar] [CrossRef] [PubMed]

- Rigou, P.; Mekoue, J.; Sieczkowski, N.; Doco, T.; Vernhet, A. Impact of Industrial Yeast Derivative Products on the Modification of Wine Aroma Compounds and Sensorial Profile. A Review. Food Chem. 2021, 358, 129760. [Google Scholar] [CrossRef] [PubMed]

- Nioi, C.; Lisanti, M.T.; Meunier, F.; Redon, P.; Massot, A.; Moine, V. Antioxidant Activity of Yeast Derivatives: Evaluation of Their Application to Enhance the Oxidative Stability of White Wine. LWT 2022, 171, 114116. [Google Scholar] [CrossRef]

- Comuzzo, P.; Tat, L.; Tonizzo, A.; Battistutta, F. Yeast Derivatives (Extracts and Autolysates) in Winemaking: Release of Volatile Compounds and Effects on Wine Aroma Volatility. Food Chem. 2006, 99, 217–230. [Google Scholar] [CrossRef]

- Pérez-Magariño, S.; Martínez-Lapuente, L.; Bueno-Herrera, M.; Ortega-Heras, M.; Guadalupe, Z.; Ayestarán, B. Use of Commercial Dry Yeast Products Rich in Mannoproteins for White and Rosé Sparkling Wine Elaboration. J. Agric. Food Chem. 2015, 63, 5670–5681. [Google Scholar] [CrossRef]

- Nikolantonaki, M.; Julien, P.; Coelho, C.; Roullier-Gall, C.; Ballester, J.; Schmitt-Kopplin, P.; Gougeon, R.D. Impact of Glutathione on Wines Oxidative Stability: A Combined Sensory and Metabolomic Study. Front. Chem. 2018, 6, 182. [Google Scholar] [CrossRef]

- Ignacia Lambert-Royo, M.; Ubeda, C.; Del Barrio-Galán, R.; Sieczkowski, N.; Miquel Canals, J.; Peña-Neira, Á.; Gil i Cortiella, M. The Diversity of Effects of Yeast Derivatives during Sparkling Wine Aging. Food Chem. 2022, 390, 133174. [Google Scholar] [CrossRef]

- Gabrielli, M.; Aleixandre-Tudo, J.L.; Kilmartin, P.A.; Sieczkowski, N.; Du Toit, W.J. Additions of Glutathione or Specific Glutathione-Rich Dry Inactivated Yeast Preparation (DYP) to Sauvignon Blanc Must: Effect on Wine Chemical and Sensory Composition. SAJEV 2017, 38, 18–28. [Google Scholar] [CrossRef]

- Bahut, F.; Romanet, R.; Sieczkowski, N.; Schmitt-Kopplin, P.; Nikolantonaki, M.; Gougeon, R.D. Antioxidant Activity from Inactivated Yeast: Expanding Knowledge beyond the Glutathione-Related Oxidative Stability of Wine. Food Chem. 2020, 325, 126941. [Google Scholar] [CrossRef]

- Li, Y.; Wei, G.; Chen, J. Glutathione: A Review on Biotechnological Production. Appl. Microbiol. Biotechnol. 2004, 66, 233–242. [Google Scholar] [CrossRef]

- Manzanares, P.; Vallés, S.; Viana, F. Non-Saccharomyces Yeasts in the Winemaking Process. In Molecular Wine Microbiology; Elsevier Inc.: Amsterdam, The Netherlands, 2011; pp. 85–110. [Google Scholar] [CrossRef]

- Ivit, N.N.; Longo, R.; Kemp, B. The Effect of Non-Saccharomyces and Saccharomyces Non-Cerevisiae Yeasts on Ethanol and Glycerol Levels in Wine. Fermentation 2020, 6, 77. [Google Scholar] [CrossRef]

- Lu, Y.; Huang, D.; Lee, P.R.; Liu, S.Q. Assessment of Volatile and Non-Volatile Compounds in Durian Wines Fermented with Four Commercial Non-Saccharomyces Yeasts. J. Sci. Food Agric. 2016, 96, 1511–1521. [Google Scholar] [CrossRef] [PubMed]

- Mančić, S.; Stojanović, S.S.; Danilović, B.; Djordjević, N.; Malićanin, M.; Lazić, M.; Karabegović, I. Oenological Characterization of Native Hanseniaspora Uvarum Strains. Fermentation 2022, 8, 92. [Google Scholar] [CrossRef]

- Martin, V.; Jose Valera, M.; Medina, K.; Boido, E.; Carrau, F. Oenological Impact of the Hanseniaspora/Kloeckera Yeast Genus on Wines—A Review. Fermentation 2018, 4, 76. [Google Scholar] [CrossRef]

- Satyanarayana, T.; Kunze, G. The Fermentative and Aromatic Ability of Kloeckera and Hanseniaspora Yeasts. In Yeast Biotechnology: Diversity and Applications; Satyanarayana, T.K.G., Ed.; Springer: Dordrecht, The Netherlands, 2009; pp. 1–744. ISBN 9781402082917. [Google Scholar]

- Duarte, F.L.; Egipto, R.; Baleiras-Couto, M.M. Mixed Fermentation with Metschnikowia Pulcherrima Using Different Grape Varieties. Fermentation 2019, 5, 59. [Google Scholar] [CrossRef]

- Kieliszek, M.; Kot, A.M.; Bzducha-Wróbel, A.; BŁażejak, S.; Gientka, I.; Kurcz, A. Biotechnological Use of Candida Yeasts in the Food Industry: A Review. Fungal. Biol. Rev. 2017, 31, 185–198. [Google Scholar] [CrossRef]

- Mančić, S.; Danilović, B.; Malićanin, M.; Stojanović, S.S.; Nikolić, N.; Lazić, M.; Karabegović, I. Fermentative Potential of Native Yeast Candida Famata for Prokupac Grape Must Fermentation. Agriculture 2021, 11, 358. [Google Scholar] [CrossRef]

- Karabegović, I.; Malićanin, M.; Danilović, B.; Stanojević, J.; Stojanović, S.S.; Nikolić, N.; Lazić, M. Potential of Non-Saccharomyces Yeast for Improving the Aroma and Sensory Profile of Prokupac Red Wine. OENO One 2021, 55, 181–195. [Google Scholar] [CrossRef]

- Karabegović, I.; Malićanin, M.; Popović, N.; Stamenković Stojanović, S.; Lazić, M.; Stanojević, J.; Danilović, B. Native Non-Saccharomyces Yeasts as a Tool to Produce Distinctive and Diverse Tamjanika Grape Wines. Foods 2022, 11, 1935. [Google Scholar] [CrossRef]

- OIV. Review Document on Sensory Analysis of Wine; OIV: Paris, France, 2015. [Google Scholar]

- Kontogeoros, N.; Roussis, I.G. Total Free Sulphydryls of Several White and Red Wines. S. Afr. J. Enol. Vitic. 2014, 35, 125–127. [Google Scholar]

- Arnous, A.; Makris, D.P.; Kefalas, P. Effect of Principal Polyphenolic Components in Relation to Antioxidant Characteristics of Aged Red Wines. J. Agric. Food Chem. 2001, 49, 5736–5742. [Google Scholar] [CrossRef] [PubMed]

- Psarra, E.; Makris, D.P.; Kallithraka, S.; Kefalas, P. Evaluation of the Antiradical and Reducing Properties of Selected Greek White Wines: Correlation with Polyphenolic Composition. J. Sci. Food Agric. 2002, 82, 1014–1020. [Google Scholar] [CrossRef]

- Del Barrio-Galán, R.; Pérez-Magariño, S.; Ortega-Heras, M.; Guadalupe, Z.; Ayestarán, B. Polysaccharide Characterization of Commercial Dry Yeast Preparations and Their Effect on White and Red Wine Composition. LWT 2012, 48, 215–223. [Google Scholar] [CrossRef]

- Tzachristas, A.; Pasvanka, K.; Liouni, M.; Calokerinos, A.C.; Tataridis, P.; Proestos, C. Effect of Hippophae rhamnoides L. Leaves Treatment on the Antioxidant Capacity, Total Phenol Content and Sensory Profile of Moschofilerowines Vinified with and without Added Sulphites. Appl. Sci. 2020, 10, 3444. [Google Scholar] [CrossRef]

- Staško, A.; Brezová, V.; Mazúr, M.; Čertík, M.; Kaliňák, M.; Gescheidt, G. A Comparative Study on the Antioxidant Properties of Slovakian and Austrian Wines. LWT 2008, 41, 2126–2135. [Google Scholar] [CrossRef]

- Harbertson, J.F.; Kennedy, J.A.; Adams, D.O. Tannin in Skins and Seeds of Cabernet Sauvignon, Syrah, and Pinot Noir Berries during Ripening. Am. J. Enol. Vitic. 2002, 53, 54–59. [Google Scholar] [CrossRef]

- Mazauric, J.P.; Salmon, J.M. Interactions between Yeast Lees and Wine Polyphenols during Simulation of Wine Aging: I. Analysis of Remnant Polyphenolic Compounds in the Resulting Wines. J. Agric. Food Chem. 2005, 53, 5647–5653. [Google Scholar] [CrossRef]

- Marset-Castro, A.; López-Gallardo, Á.; López-Muñoz, H.; Sánchez-Sánchez, L.; Maya, I.; López, Ó.; Fernández-Bolaños, J.G. Phenolic Peptides as Antioxidant and Anti-Proliferative Agents. J. Mol. Clin. Med. 2018, 1, 237–248. [Google Scholar] [CrossRef]

- Romanet, R.; Gougeon, R.D.; Nikolantonaki, M. White Wine Antioxidant Metabolome: Definition and Dynamic Behavior during Aging on Lees in Oak Barrels. Antioxidants 2023, 12, 395. [Google Scholar] [CrossRef]

- Moreno-Arribas, M.V.; Polo, M.C. Wine Chemistry and Biochemistry; Springer: New York, NY, USA, 2009; ISBN 9780387741161. [Google Scholar]

- Ribéreau-Gayon, P.; Dubourdieu, D.; Donèche, B.; Lonvaud-Funel, A.; Glories, Y.; Maujean, A.; Towey, J. Handbook of Enology; John Wiley and Sons: Hoboken, NJ, USA, 2021; ISBN 978-1-119-58468-1. [Google Scholar]

- Ruipérez, V.; Rodríguez-Nogales, J.M.; Fernández-Fernández, E.; Vila-Crespo, J. Impact of β-Glucanases and Yeast Derivatives on Chemical and Sensory Composition of Long-Aged Sparkling Wines. J. Food Compost. Anal. 2022, 107, 104385. [Google Scholar] [CrossRef]

- Bautista, R.; Fernández, E.; Falqué, E. Effect of the Contact with Fermentation-Lees or Commercial-Lees on the Volatile Composition of White Wines. Eur. Food Res. Technol. 2007, 224, 405–413. [Google Scholar] [CrossRef]

- Escudero, A.; Campo, E.; Fariña, L.; Cacho, J.; Ferreira, V. Analytical Characterization of the Aroma of Five Premium Red Wines. Insights into the Role of Odor Families and the Concept of Fruitiness of Wines. J. Agric. Food Chem. 2007, 55, 4501–4510. [Google Scholar] [CrossRef] [PubMed]

- Luzzini, G.; Slaghenaufi, D.; Pasetto, F.; Ugliano, M. Influence of Grape Composition and Origin, Yeast Strain and Spontaneous Fermentation on Aroma Profile of Corvina and Corvinone Wines. LWT 2021, 143, 111120. [Google Scholar] [CrossRef]

- Malićanin, M.; Danilović, B.; Stojanović, S.S.; Cvetković, D.; Lazić, M.; Karabegović, I.; Savić, D. Pre-Fermentative Cold Maceration and Native Non-Saccharomyces Yeasts as a Tool to Enhance Aroma and Sensory Attributes of Chardonnay Wine. Horticulturae 2022, 8, 212. [Google Scholar] [CrossRef]

- Lu, Y.; Liu, Y.; Lv, J.; Ma, Y.; Guan, X. Changes in the Physicochemical Components, Polyphenol Profile, and Flavor of Persimmon Wine during Spontaneous and Inoculated Fermentation. Food Sci. Nutr. 2020, 8, 2728–2738. [Google Scholar] [CrossRef]

- Korenika, A.M.J.; Preiner, D.; Tomaz, I.; Jeromel, A. Volatile Profile Characterization of Croatian Commercial Sparkling Wines. Molecules 2020, 25, 4349. [Google Scholar] [CrossRef]

- Jiang, B.; Zhang, Z. Volatile Compounds of Young Wines from Cabernet Sauvignon, Cabernet Gernischet and Chardonnay Varieties Grown in the Loess Plateau Region of China. Molecules 2010, 15, 9184–9196. [Google Scholar] [CrossRef]

- Tsakiris, A.; Koutinas, A.A.; Psarianos, C.; Kourkoutas, Y.; Bekatorou, A. A New Process for Wine Production by Penetration of Yeast in Uncrushed Frozen Grapes. Appl. Biochem. Biotechnol. 2010, 162, 1109–1121. [Google Scholar] [CrossRef]

| IYD | Specification | Expected Results |

|---|---|---|

| Noblesse™ (Lallemand, Canada) | Specific inactivated yeast S. cerevisiae | Increase the perception of ripe fruit, contribute to a more intense structure, initial mouthfeel volume and rounded finish. It can decrease the perception of harsh, chemical and burning sensations. Can have a stimulatory effect on malolactic fermentation. |

| Optimum white™ (Lallemand, Canada) | Specific inactivated yeast S. cerevisiae with guaranteed glutathione levels | It helps protect white and rosé wines from oxidation, increases wine quality, fruitiness, freshness and longevity. |

| Oenolees™ (Lafort, USA) | Specific preparation of S. cerevisiae cell walls | The fining effect. Elevates midpalate sensations. Eliminating specific polyphenols responsible for bitterness and astringency. |

| Optilees™ (Lallemand, Canada) | Specific inactive S. cerevisiae yeast, rich in polysaccharides. | Faster maturation of the wine. The sensation of sweetness and fullness. |

| Parameter | IYD Treatment * | |||||||

|---|---|---|---|---|---|---|---|---|

| NO20 ** | NO40 | OL20 | OL40 | OW20 | OW40 | OE20 | OE40 | |

| Ethanol, % v/v | 12.43 ± 0.10 | 12.43 ± 0.08 | 12.47 ± 0.18 | 12.46 ± 0.11 | 12.47 ± 0.02 | 12.45 ± 0.12 | 12.45 ± 0.09 | 12.48 ± 0.07 |

| Total acids (as tartaric acid), g/L | 5.1 ± 0.01 | 5.1 ± 0.01 | 5.2 ± 0.02 | 5.2 ± 0.10 | 5.2 ± 0.02 | 5.2 ± 0.01 | 5.1 ± 0.03 | 5.1 ± 0.00 |

| Volatile acids (as acetic acid), g/L | 0.37 ± 0.00 | 0.37 ± 0.01 | 0.36 ± 0.03 | 0.36 ± 0.02 | 0.37 ± 0.00 | 0.37 ± 0.01 | 0.36 ± 0.01 | 0.36 ± 0.00 |

| Reducing sugar, g/L | 2.3 ± 0.02 | 2.4 ± 0.00 | 2.3 ± 0.01 | 2.4 ± 0.02 | 2.5 ± 0.00 | 2.5 ± 0.00 | 2.5 ± 0.01 | 2.3 ± 0.00 |

| Free SO2, mg/L | 6.2 ± 0.10 | 6.2 ± 0.04 | 6.6 ± 0.06 | 6.6 ± 0.02 | 6.4 ± 0.03 | 6.3 ± 0.00 | 6.0 ± 0.01 | 6.2 ± 0.00 |

| Total SO2, mg/L | 88 ± 1.0 | 91 ± 2.0 | 92 ± 0.0 | 92 ± 0.0 | 92 ± 0.0 | 92 ± 0.0 | 89 ± 0.0 | 91 ± 0.0 |

| pH | 3.32 ± 0.00 | 3.32 ± 0.00 | 3.3 ± 0.00 | 3.30 ± 0.10 | 3.29 ± 0.00 | 3.30 ± 0.00 | 3.30 ± 0.00 | 3.29 ± 0.20 |

| Glucose, g/L | 0.9 ± 0.00 | 1.0 ± 0.00 | 1.2 ± 0.00 | 1.2 ± 0.00 | 1.1 ± 0.00 | 1.4 ± 0.00 | 1.1 ± 0.00 | 1.2 ± 0.01 |

| Fructose, g/L | 0.9 ± 0.00 | 1.0 ± 0.00 | 0.9 ± 0.00 | 0.9 ± 0.01 | 1.0 ± 0.00 | 1.0 ± 0.00 | 0.9 ± 0.00 | 0.9 ± 0.00 |

| Tartaric acid, g/L | 3.7 ± 0.10 | 3.8 ± 0.03 | 3.7 ± 0.00 | 3.8 ± 0.00 | 3.7 ± 0.10 | 3.8 ± 0.05 | 3.7 ± 0.00 | 3.7 ± 0.05 |

| Citric acid, g/L | 0.21 ± 0.00 | 0.20 ± 0.00 | 0.23 ± 0.00 | 0.22 ± 0.00 | 0.23 ± 0.00 | 0.24 ± 0.00 | 0.21 ± 0.00 | 0.22 ± 0.00 |

| Malic acid, g/L | 0.6 ± 0.00 | 0.6 ± 0.00 | 0.7 ± 0.00 | 0.7 ± 0.00 | 0.8 ± 0.00 | 0.7 ± 0.00 | 0.7 ± 0.00 | 0.7 ± 0.00 |

| Lactic acid, g/L | 0.8 ± 0.00 | 0.8 ± 0.00 | 0.7 ± 0.00 | 0.7 ± 0.00 | 0.7 ± 0.00 | 0.7 ± 0.00 | 0.8 ± 0.00 | 0.7 ± 0.00 |

| Glycerol, g/L | 6.3 ± 0.10 | 6.3 ± 0.00 | 6.2 ± 0.10 | 6.3 ± 0.00 | 6.2 ± 0.00 | 6.3 ± 0.00 | 6.2 ± 0.00 | 6.2 ± 0.10 |

| Wine Treatment ** | Aging Time, Months | Polyphenols | AR | -SH Groups |

|---|---|---|---|---|

| CONTROL | 0 | 321.6 a * ± 7.63 | 0.75 ae ± 0.09 | 450.1 a ± 3.82 |

| 3 | 222.4 b ± 5.20 | 0.64 bd ± 0.02 | 376.5 b ± 5.43 | |

| 6 | 199.1 c ± 3.87 | 0.52 c ± 0.00 | 330.1 c ± 3.32 | |

| NO20 | 3 | 309.1 d ± 6.29 | 0.67 bd ± 0.01 | 473.6 d ± 2.26 |

| 6 | 320.8 a ± 2.55 | 0.62 d ± 0.05 | 416.7 eg ± 2.88 | |

| NO40 | 3 | 334.1 ae ± 6.17 | 0.77 e ± 0.04 | 488.1 d ± 3.14 |

| 6 | 343.3 ef ± 6.61 | 0.73 a ± 0.00 | 476.0 d ± 2.34 | |

| OL20 | 3 | 337.4 afgh ± 10.41 | 0.71 ab ± 0.02 | 397.5 f ± 4.12 |

| 6 | 347.4 eh ± 5.24 | 0.69 ab ± 0.01 | 345.7 c ± 3.82 | |

| OL40 | 3 | 334.1 afh ± 5.21 | 0.72 ab ± 0.01 | 395.7 f ± 6.55 |

| 6 | 359.1 fhkl ± 9.46 | 0.71 ab ± 0.01 | 373.3 b ± 4.74 | |

| OW20 | 3 | 296.6 d ± 6.52 | 0.70 ab ± 0.01 | 402.2 ef ± 4.12 |

| 6 | 326.6 afi ± 3.82 | 0.70 ab ± 0.01 | 408.5 ef ± 8.08 | |

| OW40 | 3 | 355.8 fhj ± 2.50 | 0.72 a ± 0.01 | 421.4 g ± 7.07 |

| 6 | 364.9 jkl ± 7.63 | 0.71 ab ± 0.00 | 435.6 ag ± 1.66 | |

| OE20 | 3 | 321.6 a ± 5.21 | 0.77 ae ± 0.03 | 440.7 a ± 8.21 |

| 6 | 342.4 egij ± 9.01 | 0.70 ab ± 0.02 | 438.7 a ± 4.02 | |

| OE40 | 3 | 335.8 afh ± 2.54 | 0.79 e ± 0.01 | 436.7 ag ± 8.85 |

| 6 | 374.9 l ± 5.26 | 0.75 ae ± 0.01 | 443.7 a ± 4.23 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stamenković Stojanović, S.; Mančić, S.; Cvetković, D.; Malićanin, M.; Danilović, B.; Karabegović, I. Impact of Commercial Inactive Yeast Derivatives on Antiradical Properties, Volatile and Sensorial Profiles of Grašac Wines. Fermentation 2023, 9, 494. https://doi.org/10.3390/fermentation9050494

Stamenković Stojanović S, Mančić S, Cvetković D, Malićanin M, Danilović B, Karabegović I. Impact of Commercial Inactive Yeast Derivatives on Antiradical Properties, Volatile and Sensorial Profiles of Grašac Wines. Fermentation. 2023; 9(5):494. https://doi.org/10.3390/fermentation9050494

Chicago/Turabian StyleStamenković Stojanović, Sandra, Stojan Mančić, Dragan Cvetković, Marko Malićanin, Bojana Danilović, and Ivana Karabegović. 2023. "Impact of Commercial Inactive Yeast Derivatives on Antiradical Properties, Volatile and Sensorial Profiles of Grašac Wines" Fermentation 9, no. 5: 494. https://doi.org/10.3390/fermentation9050494

APA StyleStamenković Stojanović, S., Mančić, S., Cvetković, D., Malićanin, M., Danilović, B., & Karabegović, I. (2023). Impact of Commercial Inactive Yeast Derivatives on Antiradical Properties, Volatile and Sensorial Profiles of Grašac Wines. Fermentation, 9(5), 494. https://doi.org/10.3390/fermentation9050494