Characteristics of Substrates Used for Biogas Production in Terms of Water Content

Abstract

1. Introduction

1.1. Climate Problems

1.2. Biomass Characteristics and Utilization

1.3. Water Requirements for Biomass Production

2. Characteristics of Substrates Used for Anaerobic Digestion

2.1. Types and Potential of Raw Materials Used for Biogas Production

2.2. Water Content of Substrates vs. the Environmental Effect of Their Transport

3. Feedstock Hydration and Anaerobic Digestion Technology

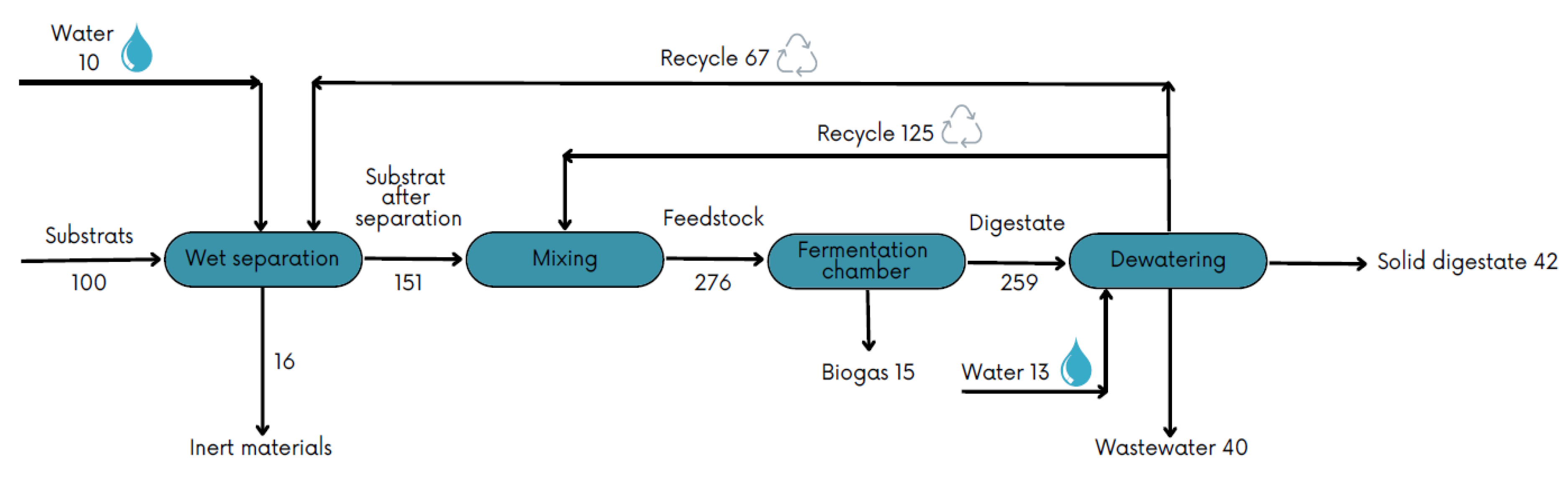

3.1. Wet Anaerobic Digestion

3.2. Dry Anaerobic Digestion

4. Substrate Pretreatment as Key to Increasing Anaerobic Digestion Process Efficiency

4.1. Chemical and Biological Pretreatment

4.2. Mechanical and Thermal Pretreatment

5. Conclusions and Directions for Further Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sanson, A.V.; Van Hoorn, J.; Burke, S.E.L. Responding to the Impacts of the Climate Crisis on Children and Youth. Child Dev. Perspect. 2019, 13, 201–207. [Google Scholar] [CrossRef]

- Lamb, W.F.; Wiedmann, T.; Pongratz, J.; Andrew, R.; Crippa, M.; Olivier, J.G.J.; Wiedenhofer, D.; Mattioli, G.; Khourdajie, A.A.; House, J.; et al. A review of trends and drivers of greenhouse gas emissions by sector from 1990 to 2018. Environ. Res. Lett. 2021, 16, 073005. [Google Scholar] [CrossRef]

- Ahmad, S.; Razzaq, S.; Rehan, M.A.; Hashmi, M.A.; Ali, S.; Amjad, M.S.; Mehmood, U. Experimental Investigation of Novel Fixed Dome Type Biogas Plant using Gas Recovery Chamber in Rural Areas of Pakistan. Int. J. Renew. Energy Res. IJRER 2019, 9, 1537–1547. [Google Scholar]

- Patinvoh, R.J.; Taherzadeh, M.J. Challenges of biogas implementation in developing countries. Curr. Opin. Environ. Sci. Health 2019, 12, 30–37. [Google Scholar] [CrossRef]

- Jarrar, L.; Ayadi, O.; Al Asfar, J. Techno-economic Aspects of Electricity Generation from a Farm Based Biogas Plant. J. Sustain. Dev. Energy Water Environ. Syst. 2020, 8, 476–492. [Google Scholar] [CrossRef]

- Adeleke, A.; Odusote, J.; Lasode, O.; Ikubanni, P.; Madhurai, M.; Paswan, D. Evaluation of thermal decomposition characteristics and kinetic parameters of melina wood. Biofuels 2022, 13, 117–123. [Google Scholar] [CrossRef]

- Ibikunle, R.A.; Titiladunayo, I.F.; Lukman, A.F.; Dahunsi, S.O.; Akeju, E.A. Municipal solid waste sampling, quantification and seasonal characterization for power evaluation: Energy potential and statistical modelling. Fuel 2020, 277, 118122. [Google Scholar] [CrossRef]

- Werghemmi, W.; Fayssal, S.A.; Mazouz, H.; Hajjaj, H.; Hajji, L. Olive and green tea leaves extract in Pleurotus ostreatus var. florida culture media: Effect on mycelial linear growth rate, diameter and growth induction index. IOP Conf. Ser. Earth Environ. Sci. 2022, 1090, 012020. [Google Scholar] [CrossRef]

- Elbagory, M.; El-Nahrawy, S.; Omara, A.E.-D.; Eid, E.M.; Bachheti, A.; Kumar, P.; Abou Fayssal, S.; Adelodun, B.; Bachheti, R.K.; Kumar, P.; et al. Sustainable Bioconversion of Wetland Plant Biomass for Pleurotus ostreatus var. florida Cultivation: Studies on Proximate and Biochemical Characterization. Agriculture 2022, 12, 2095. [Google Scholar] [CrossRef]

- Czekała, W.; Janczak, D.; Pochwatka, P.; Nowak, M.; Dach, J. Gases Emissions during Composting Process of Agri-Food Industry Waste. Appl. Sci. 2022, 12, 9245. [Google Scholar] [CrossRef]

- Jansson, A.T.; Patinvoh, R.J.; Sárvári Horváth, I.; Taherzadeh, M.J. Dry Anaerobic Digestion of Food and Paper Industry Wastes at Different Solid Contents. Fermentation 2019, 5, 40. [Google Scholar] [CrossRef]

- Adeleke, A.A.; Odusote, J.K.; Ikubanni, P.P.; Orhadahwe, T.A.; Lasode, O.A.; Ammasi, A.; Kumar, K. Ash analyses of bio-coal briquettes produced using blended binder. Sci. Rep. 2021, 11, 547. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Kumar, V.; Jia, L.; Sarsaiya, S.; Kumar, D.; Juneja, A.; Zhang, Z.; Sindhu, R.; Binod, P.; Bhatia, S.K.; et al. Biopolymer poly-hydroxyalkanoates (PHA) production from apple industrial waste residues: A review. Chemosphere 2021, 284, 131427. [Google Scholar] [CrossRef] [PubMed]

- World Energy Outlook 2020—Analysis. Available online: https://www.iea.org/reports/world-energy-outlook-2020 (accessed on 1 February 2023).

- Aberilla, J.M.; Gallego-Schmid, A.; Azapagic, A. Environmental sustainability of small-scale biomass power technologies for agricultural communities in developing countries. Renew. Energy 2019, 141, 493–506. [Google Scholar] [CrossRef]

- Anal, A.K. Quality Ingredients and Safety Concerns for Traditional Fermented Foods and Beverages from Asia: A Review. Fermentation 2019, 5, 8. [Google Scholar] [CrossRef]

- Gerbens-Leenes, W.; Vaca-Jiménez, S.; Mekonnen, M. Burning Water, Overview of the Contribution of Arjen Hoekstra to the Water Energy Nexus. Water 2020, 12, 2844. [Google Scholar] [CrossRef]

- Irfan, M.; Zhao, Z.-Y.; Panjwani, M.K.; Mangi, F.H.; Li, H.; Jan, A.; Ahmad, M.; Rehman, A. Assessing the energy dynamics of Pakistan: Prospects of biomass energy. Energy Rep. 2020, 6, 80–93. [Google Scholar] [CrossRef]

- Branco, R.H.R.; Serafim, L.S.; Xavier, A.M.R.B. Second Generation Bioethanol Production: On the Use of Pulp and Paper Industry Wastes as Feedstock. Fermentation 2019, 5, 4. [Google Scholar] [CrossRef]

- Robak, K.; Balcerek, M. Review of Second Generation Bioethanol Production from Residual Biomass. Food Technol. Biotechnol. 2018, 56, 174–187. [Google Scholar] [CrossRef]

- Chowdhury, H.; Loganathan, B. Third-generation biofuels from microalgae: A review. Curr. Opin. Green Sustain. Chem. 2019, 20, 39–44. [Google Scholar] [CrossRef]

- Nugent, N.; Rhinard, M. The ‘political’ roles of the European Commission. J. Eur. Integr. 2019, 41, 203–220. [Google Scholar] [CrossRef]

- Khan, M.U.; Lee, J.T.E.; Bashir, M.A.; Dissanayake, P.D.; Ok, Y.S.; Tong, Y.W.; Shariati, M.A.; Wu, S.; Ahring, B.K. Current status of biogas upgrading for direct biomethane use: A review. Renew. Sustain. Energy Rev. 2021, 149, 111343. [Google Scholar] [CrossRef]

- Wielgosinski, G.; Czerwińska, J. Smog Episodes in Poland. Atmosphere 2020, 11, 277. [Google Scholar] [CrossRef]

- Kozłowski, K.; Pietrzykowski, M.; Czekała, W.; Dach, J.; Kowalczyk-Juśko, A.; Jóźwiakowski, K.; Brzoski, M. Energetic and economic analysis of biogas plant with using the dairy industry waste. Energy 2019, 183, 1023–1031. [Google Scholar] [CrossRef]

- Theuerl, S.; Herrmann, C.; Heiermann, M.; Grundmann, P.; Landwehr, N.; Kreidenweis, U.; Prochnow, A. The Future Agricultural Biogas Plant in Germany: A Vision. Energies 2019, 12, 396. [Google Scholar] [CrossRef]

- Kumar, P.; Eid, E.M.; Taher, M.A.; El-Morsy, M.H.E.; Osman, H.E.M.; Al-Bakre, D.A.; Adelodun, B.; Abou Fayssal, S.; Goala, M.; Mioč, B.; et al. Biotransforming the Spent Substrate of Shiitake Mushroom (Lentinula edodes Berk.): A Synergistic Approach to Biogas Production and Tomato (Solanum lycopersicum L.) Fertilization. Horticulturae 2022, 8, 479. [Google Scholar] [CrossRef]

- Czekała, W. Digestate as a Source of Nutrients: Nitrogen and Its Fractions. Water 2022, 14, 4067. [Google Scholar] [CrossRef]

- Mathioudakis, V.; Gerbens-Leenes, P.W.; Van der Meer, T.H.; Hoekstra, A.Y. The water footprint of second-generation bioenergy: A comparison of biomass feedstocks and conversion techniques. J. Clean. Prod. 2017, 148, 571–582. [Google Scholar] [CrossRef]

- Czekała, W.; Lewicki, A.; Pochwatka, P.; Czekała, A.; Wojcieszak, D.; Jóźwiakowski, K.; Waliszewska, H. Digestate management in Polish farms as an element of the nutrient cycle. J. Clean. Prod. 2020, 242, 118454. [Google Scholar] [CrossRef]

- Mudryk, K.; Frączek, J.; Jewiarz, M.; Wróbel, M.; Dziedzic, K. Analysis of Mechanical Dewatering of Digestate. Agric. Eng. 2016, 20, 157–166. [Google Scholar] [CrossRef]

- Yuan, Z.L.; Gerbens-Leenes, P.W. Biogas feedstock potentials and related water footprints from residues in China and the European Union. Sci. Total Environ. 2021, 793, 148340. [Google Scholar] [CrossRef] [PubMed]

- Mekonnen, M.M.; Gerbens-Leenes, W. The Water Footprint of Global Food Production. Water 2020, 12, 2696. [Google Scholar] [CrossRef]

- IRENA. Renewable Energy Prospects: China, REmap 2030 Analysis; IRENA: Abu Dhabi, UAE, 2014; Available online: http://www.irena.org/remap/IRENA_REmap_China_report_2014.pdf (accessed on 10 March 2023).

- Langeveld, H.; Kalf, R.; Elbersen, H.W. Bioenergy production chain development in the Netherlands: Key factors for success. Biofuels Bioprod. Biorefining 2010, 4, 484–493. [Google Scholar] [CrossRef]

- Li, Y.; Chen, Y.; Wu, J. Enhancement of methane production in anaerobic digestion process: A review. Appl. Energy 2019, 240, 120–137. [Google Scholar] [CrossRef]

- Mikhaylov, A.; Moiseev, N.; Aleshin, K.; Burkhardt, T. Global climate change and greenhouse effect. Entrep. Sustain. Issues 2020, 7, 2897–2913. [Google Scholar] [CrossRef]

- Abbas, I.; Liu, J.; Noor, R.S.; Faheem, M.; Farhan, M.; Ameen, M.; Shaikh, S.A. Development and performance evaluation of small size household portable biogas plant for domestic use. Biomass Convers. Biorefinery 2022, 12, 3107–3119. [Google Scholar] [CrossRef]

- Ellacuriaga, M.; García-Cascallana, J.; Gómez, X. Biogas Production from Organic Wastes: Integrating Concepts of Circular Economy. Fuels 2021, 2, 144–167. [Google Scholar] [CrossRef]

- Agabo-García, C.; Pérez, M.; Rodríguez-Morgado, B.; Parrado, J.; Solera, R. Biomethane production improvement by enzymatic pre-treatments and enhancers of sewage sludge anaerobic digestion. Fuel 2019, 255, 115713. [Google Scholar] [CrossRef]

- Mao, C.; Wang, Y.; Wang, X.; Ren, G.; Yuan, L.; Feng, Y. Correlations between microbial community and C:N:P stoichiometry during the anaerobic digestion process. Energy 2019, 174, 687–695. [Google Scholar] [CrossRef]

- Kushkevych, I.; Vítězová, M.; Vítěz, T.; Kováč, J.; Kaucká, P.; Jesionek, W.; Bartoš, M.; Barton, L. A new combination of substrates: Biogas production and diversity of the methanogenic microorganisms. Open Life Sci. 2018, 13, 119–128. [Google Scholar] [CrossRef]

- Schnürer, A. Biogas Production: Microbiology and Technology. Adv. Biochem. Eng. Biotechnol. 2016, 156, 195–234. [Google Scholar] [CrossRef] [PubMed]

- McGenity, T.J.; Timmis, K.N.; Fernández, B.N. Hydrocarbon and Lipid Microbiology Protocols; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar]

- Nwokolo, N.; Mukumba, P.; Obileke, K.; Enebe, M. Waste to Energy: A Focus on the Impact of Substrate Type in Biogas Production. Processes 2020, 8, 1224. [Google Scholar] [CrossRef]

- Rasit, N.; Idris, A.; Harun, R.; Wan Ab Karim Ghani, W.A. Effects of lipid inhibition on biogas production of anaerobic digestion from oily effluents and sludges: An overview. Renew. Sustain. Energy Rev. 2015, 45, 351–358. [Google Scholar] [CrossRef]

- Rajagopal, R.; Massé, D.I.; Singh, G. A critical review on inhibition of anaerobic digestion process by excess ammonia. Bioresour. Technol. 2013, 143, 632–641. [Google Scholar] [CrossRef]

- Westerholm, M.; Moestedt, J.; Schnürer, A. Biogas production through syntrophic acetate oxidation and deliberate operating strategies for improved digester performance. Appl. Energy 2016, 179, 124–135. [Google Scholar] [CrossRef]

- Solowski, G.; Konkol, I.; Cenian, A. Production of hydrogen and methane from lignocellulose waste by fermentation. A review of chemical pre-treatment for enhancing the efficiency of the digestion process. J. Clean. Prod. 2020, 267, 121721. [Google Scholar] [CrossRef]

- Ullah Khan, I.; Hafiz Dzarfan Othman, M.; Hashim, H.; Matsuura, T.; Ismail, A.F.; Rezaei-DashtArzhandi, M.; Wan Azelee, I. Biogas as a renewable energy fuel—A review of biogas upgrading, utilization and storage. Energy Convers. Manag. 2017, 150, 277–294. [Google Scholar] [CrossRef]

- Perez-Esteban, N.; Vinardell, S.; Vidal-Antich, C.; Peña-Picola, S.; Chimenos, J.M.; Peces, M.; Dosta, J.; Astals, S. Potential of anaerobic co-fermentation in wastewater treatment plants: A review. Sci. Total Environ. 2022, 813, 152498. [Google Scholar] [CrossRef]

- Abubakar, A.M.; Yunus, M.U. Reporting Biogas Data from Various Feedstock. Int. J. Form. Sci. Curr. Future Res. Trends 2021, 11, 23–36. [Google Scholar]

- Bacenetti, J.; Lovarelli, D.; Ingrao, C.; Tricase, C.; Negri, M.; Fiala, M. Assessment of the influence of energy density and feedstock transport distance on the environmental performance of methane from maize silages. Bioresour. Technol. 2015, 193, 256–265. [Google Scholar] [CrossRef]

- Huopana, T.; Song, H.; Kolehmainen, M.; Niska, H. A regional model for sustainable biogas electricity production: A case study from a Finnish province. Appl. Energy 2013, 102, 676–686. [Google Scholar] [CrossRef]

- Bochmann, G.; Montgomery, L.F.R. 4—Storage and pre-treatment of substrates for biogas production. In The Biogas Handbook; Wellinger, A., Murphy, J., Baxter, D., Eds.; Woodhead Publishing Series in Energy; Woodhead Publishing: Cambridge, UK, 2013; pp. 85–103. ISBN 978-0-85709-498-8. [Google Scholar] [CrossRef]

- Tucki, K.; Piatkowski, P.; Wojcik, G. Selected aspects from the analysis of the agricultural biogas plants sector in Poland. Energy Mark. 2016, 122, 54–58. [Google Scholar]

- May, G.; Piekarski, W.; Kowalczyk-Juśko, A. Logistics of supplying raw material to an agricultural biogas plant. Logistics 2014. [Google Scholar]

- Jolliet, O.; Margni, M.; Charles, R.; Humbert, S.; Payet, J.; Rebitzer, G.; Rosenbaum, R. IMPACT 2002+: A New Life Cycle Impact Assessment Methodology. Int. J. Life Cycle Assess. 2003, 8, 324–330. [Google Scholar] [CrossRef]

- Muradin, M.; Foltynowicz, Z. Logistic aspects of the ecological impact indicators of an agricultural biogas plant. Logforum 2018, 14, 535–547. [Google Scholar] [CrossRef]

- Dach, J.; Pulka, J.; Janczak, D.; Lewicki, A.; Pochwatka, P.; Oniszczuk, T. Energetic Assessment of Biogas Plant Projects Based on Biowaste and Maize Silage Usage. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2020; Volume 505, p. 012029. [Google Scholar]

- Borek, K.; Romaniuk, W. Biogas Installations for Harvesting Energy and Utilization of Natural Fertilisers. Agric. Eng. 2020, 24, 1–14. [Google Scholar] [CrossRef]

- Stanbury, P.F.; Whitaker, A.; Hall, S.J. Principles of Fermentation Technology; Elsevier: Amsterdam, The Netherlands, 2013; ISBN 978-1-4832-9291-5. [Google Scholar]

- Stürmer, B. Feedstock change at biogas plants–Impact on production costs. Biomass Bioenergy 2017, 98, 228–235. [Google Scholar] [CrossRef]

- Koryś, K.A.; Latawiec, A.E.; Grotkiewicz, K.; Kuboń, M. The Review of Biomass Potential for Agricultural Biogas Production in Poland. Sustainability 2019, 11, 6515. [Google Scholar] [CrossRef]

- Nordberg, A.; Jarvis, A.; Stenberg, B.; Mathisen, B.; Svensson, B.H. Anaerobic digestion of alfalfa silage with recirculation of process liquid. Bioresour. Technol. 2007, 98, 104–111. [Google Scholar] [CrossRef]

- Adekunle, K.F.; Okolie, J.A. A Review of Biochemical Process of Anaerobic Digestion. Adv. Biosci. Biotechnol. 2015, 06, 205. [Google Scholar] [CrossRef]

- Shahriari, H.; Warith, M.; Hamoda, M.; Kennedy, K.J. Effect of leachate recirculation on mesophilic anaerobic digestion of food waste. Waste Manag. 2012, 32, 400–403. [Google Scholar] [CrossRef] [PubMed]

- Weiland, P. Biogas production: Current state and perspectives. Appl. Microbiol. Biotechnol. 2010, 85, 849–860. [Google Scholar] [CrossRef] [PubMed]

- Angelonidi, E.; Smith, S. A comparison of wet and dry anaerobic digestion processes for the treatment of municipal solid waste and food waste. Water Environ. J. 2015, 29, 549–557. [Google Scholar] [CrossRef]

- Luning, L.; van Zundert, E.H.M.; Brinkmann, A.J.F. Comparison of dry and wet digestion for solid waste. Water Sci. Technol. 2003, 48, 15–20. [Google Scholar] [CrossRef] [PubMed]

- Stolze, Y.; Zakrzewski, M.; Maus, I.; Eikmeyer, F.; Jaenicke, S.; Rottmann, N.; Siebner, C.; Pühler, A.; Schlüter, A. Comparative metagenomics of biogas-producing microbial communities from production-scale biogas plants operating under wet or dry fermentation conditions. Biotechnol. Biofuels 2015, 8, 14. [Google Scholar] [CrossRef] [PubMed]

- Czubaszek, R.; Wysocka-Czubaszek, A.; Banaszuk, P. GHG Emissions and Efficiency of Energy Generation through Anaerobic Fermentation of Wetland Biomass. Energies 2020, 13, 6497. [Google Scholar] [CrossRef]

- Abdelsalam, E.M.; Samer, M.; Amer, M.A.; Amer, B.M.A. Biogas production using dry fermentation technology through co-digestion of manure and agricultural wastes. Environ. Dev. Sustain. 2021, 23, 8746–8757. [Google Scholar] [CrossRef]

- Jha, A.K.; Li, J.; Zhang, L.; Ban, Q.; Jin, Y. Comparison between Dry and Wet Anaerobic Digestions of Cow Dung under mesophilic and thermophilic conditions. Adv. Water Resour. Prot 2013, 1, 28–38. [Google Scholar]

- Vogel, T.; Ahlhaus, M.; Barz, M. Optimization of the biogas production from grass by dry-wet fermentation. In Proceedings of the Eighth International Scientific Conference—Engineering for Rural Development, Jelgava, Latvia, 28–29 May 2009; LLU: Loma Linda, CA, USA, 2009. [Google Scholar]

- Rocamora, I.; Wagland, S.T.; Villa, R.; Simpson, E.W.; Fernández, O.; Bajón-Fernández, Y. Dry anaerobic digestion of organic waste: A review of operational parameters and their impact on process performance. Bioresour. Technol. 2020, 299, 122681. [Google Scholar] [CrossRef]

- Yu, Q.; Liu, R.; Li, K.; Ma, R. A review of crop straw pre-treatment methods for biogas production by anaerobic digestion in China. Renew. Sustain. Energy Rev. 2019, 107, 51–58. [Google Scholar] [CrossRef]

- Shapovalov, Y.; Zhadan, S.; Bochmann, G.; Salyuk, A.; Nykyforov, V. Dry Anaerobic Digestion of Chicken Manure: A Review. Appl. Sci. 2020, 10, 7825. [Google Scholar] [CrossRef]

- Rapport, J.L.; Zhang, R.; Williams, R.B.; Jenkins, B.M. Anaerobic Digestion technologies for the treatment of Municipal Solid Waste. Int. J. Environ. Waste Manag. 2012, 9, 100–122. [Google Scholar] [CrossRef]

- Mata-Alvarez, J. Biomethanization of the Organic Fraction of Municipal Solid Wastes; IWA Publishing: Barcelona, Spain, 2003. [Google Scholar]

- Kothari, R.; Pandey, A.K.; Kumar, S.; Tyagi, V.V.; Tyagi, S.K. Different aspects of dry anaerobic digestion for bio-energy: An overview. Renew. Sustain. Energy Rev. 2014, 39, 174–195. [Google Scholar] [CrossRef]

- Anukam, A.; Mohammadi, A.; Naqvi, M.; Granström, K. A Review of the Chemistry of Anaerobic Digestion: Methods of Accelerating and Optimizing Process Efficiency. Processes 2019, 7, 504. [Google Scholar] [CrossRef]

- Patinvoh, R.J.; Osadolor, O.A.; Chandolias, K.; Sárvári Horváth, I.; Taherzadeh, M.J. Innovative pre-treatment strategies for biogas production. Bioresour. Technol. 2017, 224, 13–24. [Google Scholar] [CrossRef]

- Maneein, S.; Milledge, J.J.; Nielsen, B.V.; Harvey, P.J. A Review of Seaweed pre-Treatment Methods for Enhanced Biofuel Production by Anaerobic Digestion or Fermentation. Fermentation 2018, 4, 100. [Google Scholar] [CrossRef]

- Cao, B.; Zhang, T.; Zhang, W.; Wang, D. Enhanced technology based for sewage sludge deep dewatering: A critical review. Water Res. 2021, 189, 116650. [Google Scholar] [CrossRef] [PubMed]

- Kang, Q.; Appels, L.; Tan, T.; Dewil, R. Bioethanol from Lignocellulosic Biomass: Current Findings Determine Research Priorities. Sci. World J. 2014, 2014, e298153. [Google Scholar] [CrossRef]

- Zhang, Y.-H.P. Reviving the carbohydrate economy via multi-product lignocellulose biorefineries. J. Ind. Microbiol. Biotechnol. 2008, 35, 367–375. [Google Scholar] [CrossRef]

- Patinvoh, R.J.; Feuk-Lagerstedt, E.; Lundin, M.; Sárvári Horváth, I.; Taherzadeh, M.J. Biological pre-treatment of Chicken Feather and Biogas Production from Total Broth. Appl. Biochem. Biotechnol. 2016, 180, 1401–1415. [Google Scholar] [CrossRef]

- Yoshida, S.; Hiraga, K.; Takehana, T.; Taniguchi, I.; Yamaji, H.; Maeda, Y.; Toyohara, K.; Miyamoto, K.; Kimura, Y.; Oda, K. A bacterium that degrades and assimilates poly(ethylene terephthalate). Science 2016, 351, 1196–1199. [Google Scholar] [CrossRef] [PubMed]

- Phillips, J.R.; Huhnke, R.L.; Atiyeh, H.K. Syngas Fermentation: A Microbial Conversion Process of Gaseous Substrates to Various Products. Fermentation 2017, 3, 28. [Google Scholar] [CrossRef]

- Taherzadeh, M.J.; Karimi, K. Pretreatment of Lignocellulosic Wastes to Improve Ethanol and Biogas Production: A Review. Int. J. Mol. Sci. 2008, 9, 1621–1651. [Google Scholar] [CrossRef] [PubMed]

- Brentrup, F.; Hoxha, A.; Christensen, B. Carbon Footprint Analysis of Mineral Fertilizer Production in Europe and Other World Regions. In Proceedings of the 10th International Conference on Life Cycle Assessment of Food, Dublin, Ireland, 19–21 October 2016. [Google Scholar]

- Bharathiraja, D.B.; Sudharsana, T.; Jayamuthunagai, J.; Ramanujam, P.K.; Sivasankaran, C.; Iyyappan, J. Biogas production—A review on composition, fuel properties, feed stock and principles of anaerobic digestion. Renew. Sustain. Energy Rev. 2018, 90, 570–582. [Google Scholar] [CrossRef]

- Liu, Z.-H.; Qin, L.; Jin, M.-J.; Pang, F.; Li, B.-Z.; Kang, Y.; Dale, B.E.; Yuan, Y.-J. Evaluation of storage methods for the conversion of corn stover biomass to sugars based on steam explosion pretreatment. Bioresour. Technol. 2013, 132, 5–15. [Google Scholar] [CrossRef] [PubMed]

- Rentizelas, A.; Tolis, A.; Tatsiopoulos, I. Logistics issues of biomass: The storage problem and the multi-biomass supply chain. Renew. Sustain. Energy Rev. 2009, 13, 887–894. [Google Scholar] [CrossRef]

- Ariunbaatar, J.; Panico, A.; Esposito, G.; Pirozzi, F.; Lens, P.N.L. Pre-treatment methods to enhance anaerobic digestion of organic solid waste. Appl. Energy 2014, 123, 143–156. [Google Scholar] [CrossRef]

- Wan, C.; Li, Y. Fungal pre-treatment of lignocellulosic biomass. Biotechnol. Adv. 2012, 30, 1447–1457. [Google Scholar] [CrossRef]

- Kumar, D.; Murthy, G.S. Impact of pre-treatment and downstream processing technologies on economics and energy in cellulosic ethanol production. Biotechnol. Biofuels 2011, 4, 27. [Google Scholar] [CrossRef]

- Mao, C.; Feng, Y.; Wang, X.; Ren, G. Review on research achievements of biogas from anaerobic digestion. Renew. Sustain. Energy Rev. 2015, 45, 540–555. [Google Scholar] [CrossRef]

- Li, H.; Li, C.; Liu, W.; Zou, S. Optimized alkaline pre-treatment of sludge before anaerobic digestion. Bioresour. Technol. 2012, 123, 189–194. [Google Scholar] [CrossRef] [PubMed]

- Liew, L.N.; Shi, J.; Li, Y. Enhancing the solid-state anaerobic digestion of fallen leaves through simultaneous alkaline treatment. Bioresour. Technol. 2011, 102, 8828–8834. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Cheng, J.J.; Creamer, K.S. Inhibition of anaerobic digestion process: A review. Bioresour. Technol. 2008, 99, 4044–4064. [Google Scholar] [CrossRef] [PubMed]

- Montgomery, L.; Bochmann, G. Pretreatment of Feedstock for Enhanced Biogas Production; IEA Bioenergy: Paris, France, 2014; ISBN 978-1-910154-05-2. [Google Scholar]

- Liu, D.; Liu, D.; Zeng, R.J.; Angelidaki, I. Hydrogen and methane production from household solid waste in the two-stage fermentation process. Water Res. 2006, 40, 2230–2236. [Google Scholar] [CrossRef] [PubMed]

- Zheng, Y.; Zhao, J.; Xu, F.; Li, Y. Pretreatment of lignocellulosic biomass for enhanced biogas production. Prog. Energy Combust. Sci. 2014, 42, 35–53. [Google Scholar] [CrossRef]

- Mshandete, A.; Björnsson, L.; Kivaisi, A.K.; Rubindamayugi, S.T.; Mattiasson, B. Enhancement of anaerobic batch digestion of sisal pulp waste by mesophilic aerobic pre-treatment. Water Res. 2005, 39, 1569–1575. [Google Scholar] [CrossRef]

- Nah, I.W.; Kang, Y.W.; Hwang, K.-Y.; Song, W.-K. Mechanical pre-treatment of waste activated sludge for anaerobic digestion process. Water Res. 2000, 34, 2362–2368. [Google Scholar] [CrossRef]

- Barber, W.P.F. Thermal hydrolysis for sewage treatment: A critical review. Water Res. 2016, 104, 53–71. [Google Scholar] [CrossRef]

- Menind, A.; Normak, A. Study on grinding biomass as pre-treatment for biogasification. In Agronomy Research; Estonian Agricultural University: Tartu, Estonia, 2003; p. 155. [Google Scholar]

- Skiadas, I.V.; Gavala, H.N.; Lu, J.; Ahring, B.K. Thermal pre-treatment of primary and secondary sludge at 70 degrees C prior to anaerobic digestion. Water Sci. Technol. 2005, 52, 161–166. [Google Scholar] [CrossRef]

| Pretreatment Process | Advantages | Reference |

| Chemical | decomposition of lignocellulose only solution for highly acidic substrate | [98,101,102] |

| Biological Mechanical | used as pre-acidification low temperature increasing the surface area for bacterial activity | [96,104] [94,97,105] |

| Thermal | more stable anaerobic digestion process | [94,95,107] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Czekała, W.; Nowak, M.; Bojarski, W. Characteristics of Substrates Used for Biogas Production in Terms of Water Content. Fermentation 2023, 9, 449. https://doi.org/10.3390/fermentation9050449

Czekała W, Nowak M, Bojarski W. Characteristics of Substrates Used for Biogas Production in Terms of Water Content. Fermentation. 2023; 9(5):449. https://doi.org/10.3390/fermentation9050449

Chicago/Turabian StyleCzekała, Wojciech, Mateusz Nowak, and Wiktor Bojarski. 2023. "Characteristics of Substrates Used for Biogas Production in Terms of Water Content" Fermentation 9, no. 5: 449. https://doi.org/10.3390/fermentation9050449

APA StyleCzekała, W., Nowak, M., & Bojarski, W. (2023). Characteristics of Substrates Used for Biogas Production in Terms of Water Content. Fermentation, 9(5), 449. https://doi.org/10.3390/fermentation9050449