Abstract

Gamma-aminobutyric acid (GABA) is a major inhibitory neurotransmitter in the mammalian central nervous system that has a significant beneficial effect on human health. Traditional microbial GABA synthesis requires continuous oxygen supplementation. Here, a new anaerobic platform for GABA production was established with engineered C. tyrobutyricum ATCC 25755, which is considered an ideal anaerobic microbial-cell factory for bioproduction. Glutamate decarboxylase (GAD) and Class I heat-shock proteins were screened and overexpressed, generating an excellent Ct-pMAG strain for monosodium-glutamate (MSG) tolerance and GABA production, with a GABA titer of 14.26 g/L in serum bottles with the mixed substrate of glucose and MSG. Fed-batch fermentation was carried out in a 5 L bioreactor, achieving 35.57 g/L and 122.34 g/L final titers of GABA by applying the pH-free strategy and the pH-control strategy, respectively using MSG. Finally, a two-stage strategy (growth stage and bioconversion stage) was applied using glutamate acid (L-Glu) and glucose as the substrate, obtaining a 400.32 g/L final titer of GABA with a productivity of 36.39 g/L/h. Overall, this study provides an anaerobic-fermentation platform for high-level bio-GABA production.

1. Introduction

Gamma-aminobutyric acid (GABA), a major inhibitory neurotransmitter in the mammalian central nervous system, has been reported to have hypotensive, diuretic, and sedative effects [1]. GABA is extensively dispersed in animals, plants, and microorganisms, and its benefits for human health are highly regarded [2]. In the field of food additives, Gabaron tea (>150 mg GABA/100 g), a GABA-enriched tea beverage with the ability to decrease blood pressure, was created by Japanese scientists in the 1980s and attracted widespread attention in the market [3,4]. More recently, in 2009, the Chinese Ministry of Health approved GABA for use in the production of beverages, cocoa, chocolate, candies, baked goods, and puffed foods. [3]. Due to numerous health advantages and the commercial value of GABA, there was a rapid rise in demand on the market. In the past, GABA could be synthesized chemically; however, the toxic effects of byproducts and environmental concern severely restricted its use [5,6]. It was difficult to remove and purify the product from the plant material, and the output of GABA enrichment from plants was insufficient to fulfill the market [1]. Microbial synthesis of GABA has recently received great attention due to its benefits of high specificity, environmental friendliness, cost-effectiveness, and numerous generating strains [7,8,9,10].

Glutamate decarboxylase (GAD; EC 4.1.1.15) plays a key role in GABA synthesis [11], consuming intracellular protons and converting glutamate to GABA and CO2 [12]. Recently, numerous microorganisms have been used to produce GABA. Among them, Escherichia coli, lactic-acid bacteria (LAB), and Corynebacterium glutamicum could serve as the cell-factory chassis [8,13,14,15]. Synthesizing GABA utilizing whole-cell bioconversion with E. coli as the cell biocatalyst showed great potential because of its high efficiency and simple preparation. A total of 308.26 g/L GABA with a molar yield of 99.6% from 3 mol/L L-Glu was achieved with the engineered E. coli with a modified cascade system [16]. Using E. coli, 4.8 g/L GABA was achieved from glucose with a yield of 49.2% (mol/mol glucose) by applying the metabolic-state-switching method to rewire the metabolic regulatory network [9]. LAB was a competitive GABA producer and mainly contains the genera Lactobacillus, Lactococcus, Bifidobacterium, Enterococcus, and Streptococcus [17,18,19,20,21]. Lactobacillus brevis CRL 2013 was isolated from quinoa and could produce 265 mM GABA with a molar yield of over 99% from modified MRS broth with MSG [22]. A two-stage pH-control strategy was widely applied to GABA fermentation, the parameters of which could be adjusted for bacterial growth or GABA synthesis separately [2]. The glutamate-decarboxylase system was reconstructed in Lactococcus lactis and 33.52 g/L GABA was achieved from MSG under a two-stage pH-control strategy [14]. C. glutamicum is an important industrial producer of various amino acids, including glutamic acid, which could be further developed for GABA production. A remarkable GABA concentration of 70.6 g/L was achieved using engineered C. glutamicum APLGGP from glucose through a two-stage pH-control strategy [8]. Recently, a dynamic metabolic-control method was employed in engineered C. glutamicum G7-1, resulting in 45.6 g/L of GABA production from a low-value substrate—glycerol—which exhibited great potential in biorefinery [15].

The traditional bio-based GABA synthesis process usually requires continuous oxygen supplementation for the growth of the microbes. Anaerobic-fermentation technology has advantages over aerobic fermentation, including a simple operation method, cheap operating costs, and better stability [23]. Cell number is a key factor responsible for GABA production [9]; however, anaerobic conditions interfere with the bacterial growth of these traditional aerobic GABA producers, creating obstacles to obtaining a large cell count. Currently, several attempts have been made to carry out the synthesis of GABA under anaerobic conditions, such as using Levilactobacillus brevis, Lactobacillus brevis, Bifidobacterium adolescentis, and Bifidobacterium dentium, but their GABA production (4.94–43.99 g/L) was unsatisfactory [19,24,25]. Clostridium tyrobutyricum is an anaerobic, Gram-positive, spore-forming, and non-pathogenic bacterium mainly used for short-chain fatty-acid production [26]. It is regarded as an ideal anaerobic-chassis cell and has been engineered to generate multiple chemical compounds, such as n-butanol and butyl butyrate [27,28]. This non-pathogenic strain is favored for industrial use due to environmental health and safety considerations [26,29]. Thus, in this work, a new anaerobic platform for GABA production was established with engineered C. tyrobutyricum ATCC 25755 by introducing glutamate decarboxylase since it does not have native glutamate decarboxylase. Considering the stress from the high concentration of substrate, heat-shock proteins were employed to improve strain tolerance and GABA production. Finally, pH-free, pH-control, and two-stage strategies for GABA synthesis were developed in a 5 L bioreactor.

2. Materials and Methods

2.1. Organism, Plasmids, and Culture Conditions

The sources of bacteria and plasmids used in this study are listed in Table S1. C. tyrobutyricum ATCC 25755 was preserved in our lab and anaerobically cultured in Reinforced Clostridial Medium (RCM) or Clostridial Growth Medium (CGM) at 37 °C unless otherwise mentioned [30]. RCM consists of 5 g/L glucose, 5 g/L NaCl, 10 g/L peptone, 10 g/L beef extract, 3 g/L yeast extract, 3 g/L sodium acetate, 1 g/L soluble starch, and 0.5 g/L Cysteine-HCl. CGM consists of 2 g/L yeast extract, 4 g/L peptone, 1 g/L K2HPO4·3H2O, 0.5 g/L KH2PO4, 2 g/L (NH4)2SO4, 0.1 g/L MgSO4·7H2O, 0.015 g/L FeSO4·7H2O, 0.015 g/L CaCl2·2H2O, 0.01 g/L MnSO4·H2O, 0.02 g/L CoCl2·6H2O, and 0.02 g/L ZnSO4·7H2O. E. coli CA434 was cultured in Luria–Bertani (LB) medium and employed to construct and maintain the recombinant plasmids [31]. The medium was sterilized by autoclaving for 20 min at 121 °C. OD600 was measured by a 96-well reader (Molecular Devices, San Jose, CA, USA, SpectraMax® M5).

2.2. Construction of the Engineered C. tyrobutyricum

GAD genes from E. coli, Lactococcus lactis JN001, and Lactobacillus plantarum JN002 were cloned into plasmid pMTL82151 under the control of the promoter Pcat1 to generate strains names such as pMA01, pMA02, and pMB01, respectively. The Class I HSGs genes groES and groEL were first amplified from the genomic DNA of C. tyrobutyricum ATCC 25755 and then ligated with Pcat1. Then, the fragment was inserted into pMA02 to create plasmid pMAG. Recombinant plasmids were transformed into C. tyrobutyricum to generate Ct-pMA01, Ct-pMA02, Ct-pMB01, and Ct-pMAG by conjugation as previously described (Figure S1) [29]. To be brief, cell pellets of E. coli CA434 with recombinant plasmids were collected and then mixed with C. tyrobutyricum. Then, the mixture was spread on the RCM agar plate for subculture (37 °C for 24 h), followed by screening recombinant C. tyrobutyricum on a CGM select agar plate (37 °C for 48–60 h) containing 25 µg/mL thiamphenicol and 250 µg/mL D-cycloserine.

2.3. Quantitative Real-Time PCR and Relative-Gene-Expression Analysis

As previously reported, the GTP-binding-protein gene was chosen to be the housekeeping gene [29]. Ct-pMA02 was cultured in RCM medium and MSG was added to the treatment group. At the mid-exponential-growth phase of Ct-pMA02, quantitative real-time PCRs were applied to analyze the expression of Class I HSP genes under MSG stress. Strains were treated with two concentrations of MSG (10 g/L or 40 g/L) and samples were collected after MSG treatment for RNA isolation. Samples without MSG treatment were also collected at the same time as the control. RNA extraction, cDNA preparation, and PCR were carried out as previously described [29]. Primers for quantitative real-time PCR are listed in Table S2.

2.4. GAD-Enzyme-Activity and Cell-Bound-Activity Analysis

C. tyrobutyricum were harvested by centrifugation at 12,000 rpm for 1 min. One mL of 10 OD cell pellets were collected, washed once, and resuspended in 1 mL PBS. Samples were sonicated using an ultrasonic cell crusher (SCIENTZ, Ningbo, China, SCIENTZ-IID) under sonic power of 100 W for 3 s, followed by an interval of 3 s, lasting 10 min. After sonication, the cell extracts were centrifuged at 12,000 rpm for 5 min and the supernatant was collected for the cytoplasmic-GAD-activity determination. As per the previously described method with a few modifications, the activity of the GAD enzyme was determined by measuring the amount of GABA formed at 37 °C in a 500 μL reaction mixture for 10 min, which consisted of 50 μL of cell-extract supernatant, 0.2 mol/L Na2HPO4-citrate buffer, 20 mmol/L MSG, and 0.5 mmol/L pyridoxal-5-phosphate (PLP) [32]. One unit (U) of cytoplasmic GAD activity was defined as 1 μmol GABA produced in 1 min under the above conditions. Similarly, in order to determine the cell-bound GAD activity, 0.5 mL of 10 OD cell pellets were collected, washed once by PBS, and resuspended in 500 μL reaction mixture. Cell-bound activity was determined in the same reaction system (without cell-extract supernatant) as cytoplasmic GAD activity. One unit (U/OD600) of cell-bound GAD activity was defined as 1 μmol of GABA produced in 1 min per OD cell pellets under the above conditions. The reaction mixture was centrifuged at 12,000 rpm for 5 min to collect the supernatant and GABA content was determined by Berthelot reaction [32].

2.5. MSG-Tolerance Test

To evaluate the inhibitory effect of MSG on bacterial growth, C. tyrobutyricum wild-type and engineered strains were cultured in CGM medium at 37 °C in serum bottles with different concentrations of MSG (10, 20, 30, and 40 g/L). All samples were carried out in triplicate. Samples were collected every 2 h for 36 h and OD600 was measured. The specific growth rate was calculated by analyzing the data as previously described [29].

2.6. Fermentation Experiments

The fermentation kinetics of C. tyrobutyricum were determined in serum bottles with 50 mL of CGM containing 10 g/L MSG. A total of 24 g/L glucose was added to the medium when the fermentation started. Similarly, the fermentation kinetics of C. tyrobutyricum in a 5 L bioreactor were investigated. When pH-free and pH-control strategies were applied, 1 L CGM medium was involved in the bioreactor with initial 30 g/L MSG and 60 g/L glucose. MSG was dissolved in H2O to prepare 50 mL MSG aliquot (600 g/L) and 200 mL MSG aliquot (700 g/L) as previously described [33]. When the two-stage strategies were applied, 60 g/L, 90 g/L, and 120 g/L glucose were added initially, respectively. Then, 4 mol/L L-Glu was added to generate the bioconversion. N2 was sparged into the medium to generate anaerobic conditions before inoculation. The fermentation was operated at 37 °C with a stirring speed of 150 rpm, and pH was controlled by NH3·H2O or H2SO4 solution when necessary.

The concentrations of GABA and MSG in the fermentation broth were determined by HPLC (Shimadzu, Kyoto, Japan, LC-20A) with an Agilent zorbax SB C18 column (4.6 mm × 150 mm, 5 μm). Samples were pretreated by precolumn derivatization using 1% 2,4-dinitrofluorobenzene. A binary gradient was elution-program applied with mobile phase A (0.05 mol/L sodium acetate, 1% N, N-dimethylformamide, pH 6.8) and mobile phase B (acetonitrile: H2O 1:1 by volume). The gradient-elution program was as follows: The flow rate was set to 1 mL/min; equilibration (6 min, 15% B), gradient (16 min 15–30% B, 8 min 30–100% B), cleaning (1 min, 100% B), and equilibration (3 min, 15% B). The column temperature was maintained at 40 °C. Samples were detected at UV 360 nm.

3. Results

3.1. Amino-Acid-Sequence Analysis and Enzymatic-Property Comparison of Putative GADs

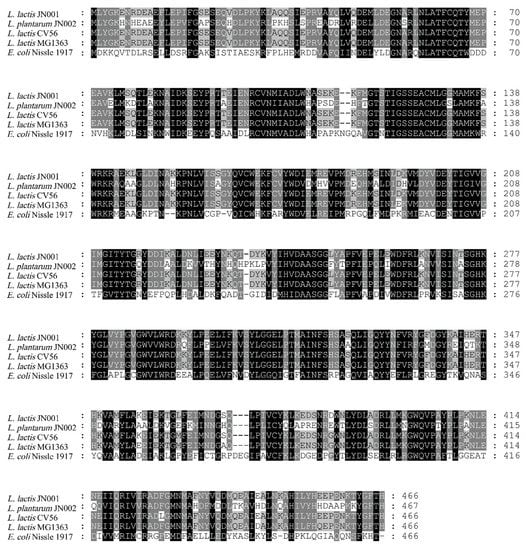

GAD is responsible for acid tolerance and GABA production in many bacteria [34]. The putative gadB gene encoding GAD was amplified from the genomic DNA of L. lactis JN001 and L. plantarum JN002, which were separated from shrimp-aquaculture water and preserved in our laboratory to generate pMA02 and pMB01. DNA sequencing suggested that lcgadB from L. lactis JN001 consisted of 1401 bases, encoding 466 amino-acid residues with a calculated molecular weight of 54.0 kDa and a pI of 5.02. LpgadB from L. plantarum JN002 consisted of 1404 bases, encoding 467 amino-acid residues with a calculated molecular weight of 53.4 kDa and a pI of 5.63. BLAST results of the protein-sequence alignment suggest that LcgadB shared 98.93%, 97.64%, and 44.92% homology with the GAD of L. lactis CV56, L. lactis MG1363, and E. coli Nissle 1917, respectively (Figure 1). As for LpgadB, it shared 68.52%, 68.52%, and 44.57% homology with the GAD of L. lactis CV56, L. lactis MG1363, and E. coli Nissle 1917, respectively.

Figure 1.

Alignment of the amino-acid sequences of selected GADs. Sequences were analyzed by MEGA6. The amino-acid sequences of GAD from L. lactis JN001 and L. plantarum JN001 were aligned with those of other GADs; L. lactis subsp. lactis CV56 (ADZ63898.1), L. lactis subsp. lactis cremoris MG1363 (CAL97772.1), and E. coli Nissle 1917 (UJL93810.1).

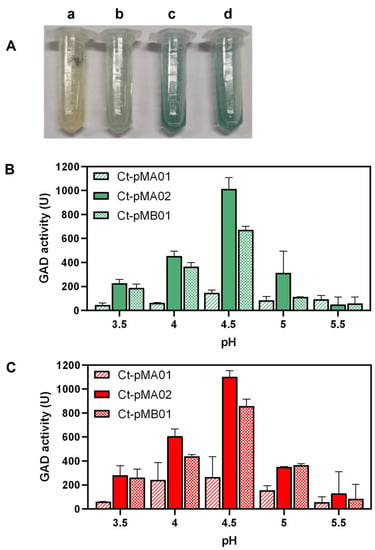

EcgadB, LcgadB, and LpgadB were cloned into C. tyrobutyricum and the engineered strains were named Ct-pMA01, Ct-pMA02, and Ct-pMB01, respectively. Cytoplasmic GAD activity was determined to investigate the enzymatic properties of different GADs, and the results suggest that wild-type C. tyrobutyricum ATCC 25755 had no glutamate-decarboxylase activity since it appeared as the color of substrate, whereas Ct-pMA02 and Ct-pMB01 turned a deeper blue than Ct-pMA01, indicating that higher GAD activity was achieved by introducing LcgadB and LpgadB (Figure 2A). GAD activity in the exponential phase and the stationary phase was determined using cell extracts of engineered strains under the pH gradient (Figure 2B,C). Overall, the GAD activity of engineered strains was higher in the stationary phase than in the exponential phase, and there was a rapid increase in GAD activity of the three engineered strains from pH 3.5 to 4.5, which then quickly dropped. The activity of Ct-pMA02 and Ct-pMB01 was the highest at pH 4.5, and Ct-pMA02 exhibited overall higher activity than Ct-pMB01.

Figure 2.

(A) The GAD activity of wild-type (a), Ct-pMA01 (b), Ct-pMA02 (c), and Ct-pMB01 (d) was determined by detecting the amount of GABA produced from MSG by the Berthelot method. (B) The GAD activity of cell extracts in the exponential phase. (C) The GAD activity of cell extracts in the stationary phase.

3.2. Production of GABA by Engineered C. tyrobutyricum

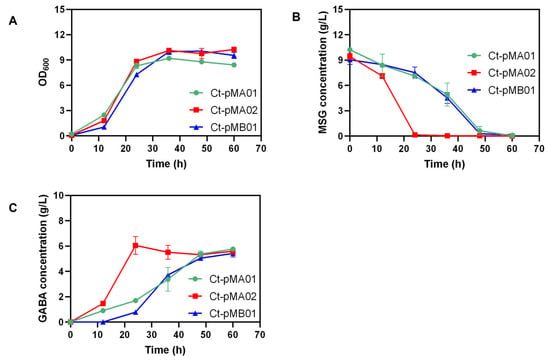

GABA production of recombinant strains was evaluated in 50 mL serum bottles (Figure 3). After 36 h of culture, a higher OD600 was achieved by Ct-pMA02 and Ct-pMB01, and MSG was rapidly consumed by Ct-pMA02 in the first 24 h with a GABA production of 6.05 g/L. Moreover, a longer fermentation period was observed for Ct-pMA01 and Ct-pMB01 to reach the highest GABA titer, which was 5.76 g/L and 5.42 g/L, respectively. A slight decrease in GABA concentration was observed during the fermentation period of Ct-pMA02 after 48 h, which might have been due to GabT, gamma-aminobutyrate aminotransferase, which is responsible for GABA degradation, and the encoding gene was found in the C. tyrobutyricum genome. Similarly, degradation of GABA was also found in a previous report on E. coli [35]. On the contrary, no significant GABA degradation was observed for Ct-pMA01 or Ct-pMB01, which might have been due to the lower productivity of GABA compared to Ct-pMA02, indicating that GABA degradation might be induced by a high productivity of GABA. Overall, Ct-pMA02 exhibited the best GABA-synthesis ability.

Figure 3.

Batch fermentation in serum bottle by Ct-pMA01, Ct-pMA02, and Ct-pMB01. (A) OD600; (B) MSG concentration; (C) GABA concentration. GABA synthesis of engineered C. tyrobutyricum strains was investigated in CGM medium containing 10 g/L MSG during 60 h of incubation at 37 °C.

3.3. Enhanced MSG Tolerance and GABA Production by Class I Heat-Shock Protein GroESL Overexpression

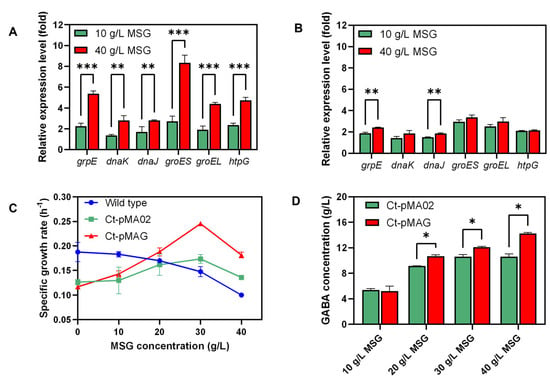

Quantitative real-time PCRs were carried out to test whether MSG stress could induce transcriptional changes of the Class I heat-shock genes (HSGs) in Ct-pMA02, and the results indicate that all six measured genes (grpE, dnaK, dnaJ, groES, groEL, and htpG) were highly overexpressed during the time course of all the MSG stress conditions tested (Figure 4A,B). The expression of grpE, dnaK, dnaJ, groES, groEL, and htpG increased by more than 1.5 times when treated with 10 g/L MSG and further increased with 40 g/L MSG, especially grpE, groES, groEL, and htpG (Figure 4A). With the prolonged treatment time, the expression of grpE, dnaK, dnaJ, groES, groEL, and htpG slowly decreased (Figure 4B). These results suggest that the expression of Class I heat-shock protein genes would be significantly up-regulated under stress from a high concentration of MSG, thus facilitating C. tyrobutyricum to respond to MSG stress. After adapting to MSG stress, the expression of these genes would gradually return to the normal level.

Figure 4.

Relative expression level of grpE, dnaK, dnaJ, groES, groEL, and htpG under different concentration of MSG in Ct-pMA02. The error bars indicate the variations of three biological replicates. (A) MSG treatment for 15 min; (B) MSG treatment for 30 min. (C) The specific growth rate of wild-type, Ct-pMA02, and Ct-pMAG in CGM medium with different MSG concentrations (0–40 g/L) was compared. (D) Final GABA production of Ct-pMA02 and Ct-pMAG in CGM medium with different MSG concentrations (10–40 g/L) at 37 °C after 72 h. Statistically significant differences (*** p < 0.001, ** p < 0.01, * p < 0.05, Student’s t-test) are indicated by asterisks.

Distinct increased expression levels for groES and groEL were observed under MSG stress, and the relative expression levels of groES and groEL were nearly 1.8 and 1.3 times higher, respectively, with the increased MSG concentration after treatment for 15 min (Figure 4A). Inspired by these facts, groES and groEL were overexpressed to test whether engineered strains could be more tolerant against MSG stress and improve GABA production. Based on the plasmid pMA02, groES and groEL were ligated to Pcat1 under lcgadB to generate plasmid pMAG, which was further transformed to C. tyrobutyricum to generate Ct-pMAG.

Specific growth rate was used to evaluate the inhibitory effect caused by MSG. Wild-type, Ct-pMA02, and Ct-pMAG strains were cultured with different concentrations of MSG in 50 mL serum bottles to examine whether overexpression of HSGs could improve tolerance to MSG. The specific growth rate of the wild-type strain decreased gradually with increased MSG concentration; however, the specific growth rate of Ct-pMA02 and Ct-pMAG increased from 0 to 30 g/L and then dropped (Figure 4C). The specific growth rates of Ct-pMAG and Ct-pMA02 were highest when 30 g/L MSG were added. Ct-pMAG exhibited a generally higher specific growth rate under the MSG gradient, indicating that the tolerance to MSG stress was improved by HSG overexpression. The final GABA titer was measured as shown in Figure 4D. As for Ct-pMAG and Ct-pMA02, GABA production was similar under 10 g/L MSG; however, a higher titer was achieved by Ct-pMAG as the MSG concentration increased from 20 to 40 g/L. The highest GABA production (14.26 g/L) was observed under 40 g/L MSG using Ct-pMAG, which was 34.53% higher than that of Ct-pMA02. These results suggest that overexpression of groESL could improve GABA production, which is consistent with a previous report on E. coli [16].

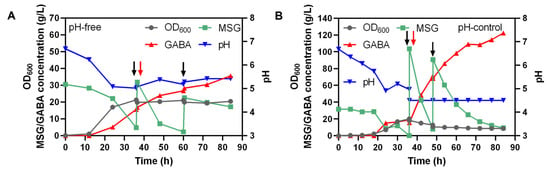

3.4. Production of GABA in Fed-Batch Fermentation

As described above, strain Ct-pMAG exhibited the highest GABA production under the given condition. Thus, Ct-pMAG was selected for GABA synthesis in a 5 L bioreactor with pH-free and pH-control strategies. During the fermentation, C. tyrobutyricum produced butyric acid and acetic acid, leading to the acidic condition [36], which drove GABA synthesis. No additional alkalis needed to be added during the fermentation since GABA production consumed MSG and protons in the broth to maintain pH. When applying the pH-free strategy, Ct-pMAG grew rapidly within 12–36 h, and the pH of the fermentation broth dropped quickly to drive the synthesis of GABA. Consumption of protons resulted in an increase in pH. The MSG-consumption rate gradually decreased after fermentation for 60–84 h, resulting in a final GABA titer of 35.57 g/L (Figure 5A).

Figure 5.

Fed-batch fermentation of Ct-pMAG in a 5 L bioreactor at 37 °C for 84 h. MSG and glucose were supplied during the period. (A) Fermentation using the pH-free strategy, with 2 times 50 mL MSG aliquot (600 g/L) added. (B) Fermentation using the pH-control strategy, with 2 times 200 mL MSG aliquot (700 g/L) added. The black arrow indicates the MSG-feeding moment and the red arrow indicates the 60 g/L glucose-feeding moment.

The pH-control strategy was applied to further improve the GABA production (Figure 5B). After the first 36 h, the fermentation process using the pH-control strategy was essentially the same as that under the pH-free strategy. Then, when the biomass peaked at 36 h, H2SO4 solution was supplied to maintain the pH at 4.5 to reach the highest GAD activity. A total of 200 mL MSG aliquot (700 g/L) was added to the bioreactor at 36 h and 48 h. After 48 h, the MSG-consumption rate and GABA synthesis steadily decreased, which might have been due to the substantial fall in biomass that was responsible for bio-transformation. At the end of the fermentation, a 122.34 g/L final titer of GABA was achieved by applying pH-control strategy, which was 3.43 times as much as that under the pH-free strategy (Figure 5A,B).

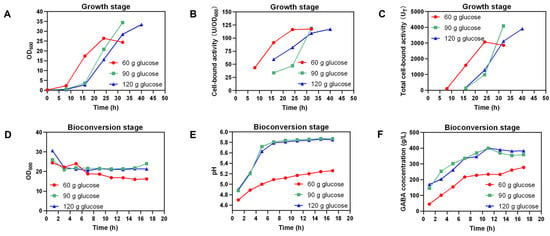

3.5. Improvement of GABA Biosynthesis by Two-Stage Strategy Using Glutamate Acid (L-Glu) as Substrate

As mentioned above, excessive soluble MSG inhibited cell growth. Although the detrimental effects of excessive MSG could have been decreased by using the fed-batch approach, continuous H2SO4 supplementation was required to achieve a high titer of GABA, which made the fermentation process more complicated. It was reported that GABA production could be further improved using L-Glu as the substrate instead of MSG [37,38]. L-Glu functioned equally as MSG during the glutamate decarboxylation. However, L-Glu was barely soluble in water (1.51 g/100 g water, 40 °C) and the pH value of the saturated water solution was about 3.2, which might have provided little inhibitory effect and ideal acidic conditions for the reaction. Thus, the supplement of L-Glu was equivalent to a substrate-sustained release process, as the solution of L-Glu was accompanied with substrate consumption by glutamate decarboxylation dynamically.

Compared to Ct-pMA02, Ct-pMAG also showed improved GABA production during the bioconversion of L-Glu (Figure S3). To further enhance GABA production in the 5 L bioreactor, a two-stage strategy was applied, including a growth stage (Figure 6A–C) and a bioconversion stage (Figure 6D–F). Totals of 60, 90, and 120 g/L glucose were supplied to examine how the carbon source would influence the cell growth and GABA synthesis. Additionally, NH3·H2O was supplied at the growth stage to maintain the pH at 6 for cell growth. The biomass of Ct-pMAG with 60 g/L glucose increased quickly after the first 16 h and peaked at 24 h, reaching an OD600 of 26.4. When 90 g/L and 120 g/L glucose were added initially, the strain grew quickly after 16 h of culture and obtained a higher OD600 than that with 60 g/L glucose at the end of the growth stage (Figure 6A). Cell-bound activity was also examined during the growth stage and the results indicate that the maximal cell-bound activity in the three groups was comparable (Figure 6B); however, the addition of 90 g/L glucose resulted in the highest total cell-bound activity (Figure 6C). At the beginning of the bioconversion stage, 588.52 g/L L-Glu was supplied in the bioreactor. Under the condition of 60 g/L glucose, 277.96 g/L GABA were produced with a productivity of 16.35 g/L/h after bioconversion for 17 h. The GABA production and productivity were improved under the condition of 90 g/L and 120 g/L glucose, which were 400.32 g/L and 36.39 g/L/h, and 400.55 g/L and 36.41 g/L/h, respectively (Table 1).

Figure 6.

Profiles of two-stage bioconversion of L-Glu into GABA by Ct-pMAG. OD600, cell-bound activity, and total cell-bound activity in the growth stage are shown in (A–C), respectively. OD600, pH, and GABA concentration in the bioconversion stage are shown in (D–F), respectively. Total cell-bound activity (UT) = OD600 × cell-bound activity.

Table 1.

Comparison of GABA production from L-Glu by Ct-pMAG under the two-stage strategy.

4. Discussion

As a major inhibitory neurotransmitter in the mammalian central nervous system, GABA has been employed in various fields. A cost-effective method of GABA biosynthesis was required to meet the growing needs in the market. C. tyrobutyricum ATCC 25755 is a non-pathogenic strain and could attain a large amount of biomass under anaerobic conditions, which is necessary in the industry application [26,29,36]. Compared to employing pure GAD enzymes, using cells as a biocatalyst to generate GABA is a promising method because of its efficiency and stability. Several studies have been conducted on metabolic engineering of GABA-producing bacteria, focusing on improving GABA-production titer and productivity, which are summarized in Table 2.

Table 2.

Summary of strategies for enhanced GABA production using wild-type and metabolically engineered strains.

GAD played a key role in the GABA synthesis; however, C. tyrobutyricum ATCC 25755 could not synthesize GABA due to a lack of native GAD. GAD from E. coli (EcgadB) is one of the most widely studied enzymes, and its crystal structure has been reported [9,40]. LcgadB was reported to have a low Km value that possesses a potentially high affinity with the substrate and high activity [18,41,42]. Recently, many studies on GAD from the application of L. plantarum (LpgadB) have been carried out due to its relative wide pH and activity [11,14]. Thus, three GADs were introduced in C. tyrobutyricum, and the GAD activity of LcgadB was the highest, followed by LpgadB. GAD expression was analyzed by SDS-PAGE, and the results show that there were deeper bands for Ct-pMA02 (LcgadB) and Ct-pMB01 (LpgadB) near the 55 kDa marker, as predicted (Figure S2). However, the expected band for Ct-pMA01 (EcgadB) was unclear, indicating a low expression level of EcgadB.

During GABA fermentation, bacteria constantly encounter stress caused by a high concentration of MSG as a substrate, which has a side effect on bacterial growth and GABA production [13]. It was reported that heat-shock proteins are multifunctional in response to extracellular stress. In Clostridium botulinum, heat-shock proteins were reported to play a significant role against pH and NaCl [43]. Butyric-acid tolerance and production were improved by overexpressing groES and groEL in C. tyrobutyricum [29]. The increased relative-expression level of groES and groEL indicate that the bacterial cells were sensitive in response to MSG stress (Figure 4A). Thus, groES and groEL were overexpressed to investigate the potential for enhanced GABA production. Compared to wild-type, the specific growth rate of Ct-pMA02 and Ct-pMAG increased over the range of 10–30 g/L and then steadily decreased. This might have been due to GABA synthesis consuming protons, creating a more alkaline environment suitable for bacterial growth [12]; however, an excessive amount of MSG (>30 g/L) inhibited the bacterial growth. Improved GABA production was observed when 20–40 g/L MSG was added using Ct-pMAG (overexpressed groES and groEL) (Figure 4D), indicating that GroESL might help strains against low pH and MSG stress to grow better under given conditions (Figure 4C). Although no significant difference was observed in cytoplasmic GAD activity between Ct-pMAG and Ct-pMA02 (Figure S4A), a higher cell-bound activity was achieved by Ct-pMAG (Figure S4B), which is consistent with previous work on Lactobacillus brevis [33].

When using the pH-free strategy in fed-batch fermentation, an excessive amount of MSG remained, which was possibly due to the low GAD activity caused by the increased pH of the fermentation broth (Figure 5A). Moreover, the final titer of GABA (34.87 g/L) did not increase with more MSG supplied (Figure S5A). Previous reports revealed that relative acidic conditions were essential for the reaction of glutamate decarboxylase [8,14]. The pH-control strategy is common in microbial GABA synthesis [2]. By applying the pH-control strategy, the pH was adjusted to 4.5 to attain the highest GAD activity to generate GABA synthesis, and increase in the GABA titer (62.59 g/L) was observed under equivalent MSG supplementation (Figure S5B). With more MSG supplied, a higher titer (122.34 g/L) and productivity (1.46 g/L/h) were achieved (Figure 5B). Many studies have revealed that L-Glu as a substrate could enhance GABA synthesis compared with MSG as a substrate [37,38]. In this study, L-Glu was also investigated as a substrate. However, during fermentation with 10 g/L L-Glu added, wild-type and engineered strains Ct-pMA01, Ct-pMA02, Ct-pMAB01, and Ct-pMAG all failed to grow (data not shown). The pH was considered to be the major obstacle since the initial pH was nearly 3.2, which was not suitable for the growth of C. tyrobutyricum. It was reported that L. brevis NCL912 could grow well in an extremely-low-pH environment and synthesize GABA, and the initial pH of the fermentation medium with L-Glu added was approximate 3.3 [38]. L-Glu inhibited the growth of C. tyrobutyricum when it was added to the medium at the beginning of the fermentation, but it could also be added once there are enough cells (as biocatalyst) to catalyze the synthesis of GABA. Using the two-stage strategy, firstly, the fermentation procedure began with the accumulation of biomass. At the bioconversion stage, a higher GABA titer (400.32 g/L) and productivity (36.39 g/L/h) were achieved under the condition of 90 g/L glucose with a competitive molar yield (97.07%) (Figure 6F).

5. Conclusions

In conclusion, this study suggested that C. tyrobutyricum could synthesize GABA by introducing GAD gene. By co-expressing Class I heat-shock genes groES and groEL, strain tolerance against MSG was improved and a higher GABA titer was achieved. In fed-batch fermentation using MSG, GABA production reached 35.57 g/L and 122.34 g/L using the pH-free strategy and pH-control strategy, respectively. To further improve GABA production, a two-stage strategy was carried out, achieving a final GABA titer of 400.32 g/L with a productivity of 36.39 g/L/h from L-Glu. Thus, our study exhibits a promising method and platform for high-level GABA production using C. tyrobutyricum.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/fermentation9050445/s1, Table S1. Primers used in this study; Table S2. Strains and plasmids used in this study [31,44]; Figure S1. Electrophoresis results of colony PCR for recombinant strains; Figure S2. SDS-PAGE of cell extracts prepared by wild-type and engineered C. tyrobutyricum strains; Figure S3. Profiles of bioconversion of L-Glu using Ct-pMA02 and Ct-pMAG; Figure S4. (A) Comparison of GAD activity between Ct-pMA02 and Ct-pMAG; Figure S5. Fed-batch fermentation of Ct-pMAG in a 5 L bioreactor at 37 °C for 84 h.

Author Contributions

Z.L.: Conceptualization, methodology, investigation, formal analysis, data curation, original draft preparation; X.G.: methodology, investigation, writing—reviewing and editing; K.D.: investigation, writing—review and editing; J.F.: investigation, writing—review and editing; T.Z.: investigation, writing—review and editing; H.F.: conceptualization, methodology, investigation, resources, writing—review and editing; J.W.: writing—review and editing, supervision, project administration, funding acquisition. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the National Natural Science Foundation of China (22178133, and 21808069).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All data generated or analyzed during this study are included in this published article and its Supplementary Materials.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Luo, H.; Liu, Z.; Xie, F.; Bilal, M.; Liu, L.; Yang, R.; Wang, Z. Microbial production of gamma-aminobutyric acid: Applications, state-of-the-art achievements, and future perspectives. Crit. Rev. Biotechnol. 2021, 41, 491–512. [Google Scholar] [CrossRef] [PubMed]

- Pannerchelvan, S.; Rios-Solis, L.; Wong, F.W.F.; Zaidan, U.H.; Wasoh, H.; Mohamed, M.S.; Tan, J.S.; Mohamad, R.; Halim, M. Strategies for improvement of gamma-aminobutyric acid (GABA) biosynthesis via lactic acid bacteria (LAB) fermentation. Food Funct. 2023. [Google Scholar] [CrossRef] [PubMed]

- Heli, Z.; Hongyu, C.; Dapeng, B.; Yee Shin, T.; Yejun, Z.; Xi, Z.; Yingying, W. Recent advances of γ-aminobutyric acid: Physiological and immunity function, enrichment, and metabolic pathway. Front. Nutr. 2022, 9, 1076223. [Google Scholar] [CrossRef] [PubMed]

- Zhao, M.; Ma, Y.; Wei, Z.-Z.; Yuan, W.-X.; Li, Y.-l.; Zhang, C.-H.; Xue, X.-T.; Zhou, H.-J. Determination and Comparison of γ-Aminobutyric Acid (GABA) Content in Pu-erh and Other Types of Chinese Tea. J. Agric. Food Chem. 2011, 59, 3641–3648. [Google Scholar] [CrossRef]

- Koubaa, M.; Delbecq, F.; Roohinejad, S.; Mallikarjunan, K. Gamma-Aminobutyric Acid. In Encyclopedia of Food Chemistry; Melton, L., Shahidi, F., Varelis, P., Eds.; Academic Press: Oxford, UK, 2019; pp. 528–534. [Google Scholar]

- Boonstra, E.; de Kleijn, R.; Colzato, L.S.; Alkemade, A.; Forstmann, B.U.; Nieuwenhuis, S. Neurotransmitters as food supplements: The effects of GABA on brain and behavior. Front. Psychol. 2015, 6, 1520. [Google Scholar] [CrossRef]

- Sarasa, S.B.; Mahendran, R.; Muthusamy, G.; Thankappan, B.; Selta, D.R.F.; Angayarkanni, J. A Brief Review on the Non-protein Amino Acid, Gamma-amino Butyric Acid (GABA): Its Production and Role in Microbes. Curr. Microbiol. 2020, 77, 534–544. [Google Scholar] [CrossRef]

- Zhang, R.; Yang, T.; Rao, Z.; Sun, H.; Xu, M.; Zhang, X.; Xu, Z.; Yang, S. Efficient one-step preparation of γ-aminobutyric acid from glucose without an exogenous cofactor by the designed Corynebacterium glutamicum. Green Chem. 2014, 16, 4190–4197. [Google Scholar] [CrossRef]

- Soma, Y.; Fujiwara, Y.; Nakagawa, T.; Tsuruno, K.; Hanai, T. Reconstruction of a metabolic regulatory network in Escherichia coli for purposeful switching from cell growth mode to production mode in direct GABA fermentation from glucose. Metab. Eng. 2017, 43, 54–63. [Google Scholar] [CrossRef]

- Lyu, C.J.; Liu, L.; Huang, J.; Zhao, W.R.; Hu, S.; Mei, L.H.; Yao, S.J. Biosynthesis of gamma-aminobutyrate by engineered Lactobacillus brevis cells immobilized in gellan gum gel beads. J. Biosci. Bioeng. 2019, 128, 123–128. [Google Scholar] [CrossRef]

- Cui, Y.; Miao, K.; Niyaphorn, S.; Qu, X. Production of Gamma-Aminobutyric Acid from Lactic Acid Bacteria: A Systematic Review. Int. J. Mol. Sci. 2020, 21, 995. [Google Scholar] [CrossRef]

- Gong, L.; Ren, C.; Xu, Y. GlnR Negatively Regulates Glutamate-Dependent Acid Resistance in Lactobacillus brevis. Appl. Environ. Microbiol. 2020, 86, e02615–e02619. [Google Scholar] [CrossRef]

- Li, H.; Qiu, T.; Gao, D.; Cao, Y. Medium optimization for production of gamma-aminobutyric acid by Lactobacillus brevis NCL912. Amino Acids 2010, 38, 1439–1445. [Google Scholar] [CrossRef]

- Lyu, C.; Yao, L.; Zhu, Q.; Mei, J.; Cao, Y.; Hu, S.; Zhao, W.; Huang, J.; Mei, L.; Yao, S.; et al. Reconstruction of the glutamate decarboxylase system in Lactococcus lactis for biosynthesis of food-grade gamma-aminobutyric acid. Appl. Microbiol. Biotechnol. 2021, 105, 4127–4140. [Google Scholar] [CrossRef]

- Wei, L.; Zhao, J.; Wang, Y.; Gao, J.; Du, M.; Zhang, Y.; Xu, N.; Du, H.; Ju, J.; Liu, Q.; et al. Engineering of Corynebacterium glutamicum for high-level gamma-aminobutyric acid production from glycerol by dynamic metabolic control. Metab. Eng. 2022, 69, 134–146. [Google Scholar] [CrossRef]

- Yang, X.; Ke, C.; Zhu, J.; Wang, Y.; Zeng, W.; Huang, J. Enhanced productivity of gamma-amino butyric acid by cascade modifications of a whole-cell biocatalyst. Appl. Microbiol. Biotechnol. 2018, 102, 3623–3633. [Google Scholar] [CrossRef]

- Gong, L.; Ren, C.; Xu, Y. Deciphering the crucial roles of transcriptional regulator GadR on gamma-aminobutyric acid production and acid resistance in Lactobacillus brevis. Microb. Cell Fact. 2019, 18, 108. [Google Scholar] [CrossRef]

- Lyu, C.-J.; Fei, J.-Y.; Yan, J.-P.; Xu, Q.-C.; Mei, J.-Q.; Yue, H.-Y.; Chen, L.-L.; Mei, L.-H.; Huang, J.; Yao, S.-J. Improvement of γ-aminobutyrate biosynthesis by genetically engineered Lactococcus lactis. Biochem. Eng. J. 2020, 157, 107525. [Google Scholar] [CrossRef]

- Altaib, H.; Kozakai, T.; Badr, Y.; Nakao, H.; El-Nouby, M.A.M.; Yanase, E.; Nomura, I.; Suzuki, T. Cell factory for gamma-aminobutyric acid (GABA) production using Bifidobacterium adolescentis. Microb. Cell Fact. 2022, 21, 33. [Google Scholar] [CrossRef]

- Lee, K.W.; Shim, J.M.; Yao, Z.; Kim, J.A.; Kim, H.J.; Kim, J.H. Characterization of a glutamate decarboxylase (GAD) from Enterococcus avium M5 isolated from Jeotgal, a Korean fermented seafood. J. Microbiol. Biotechnol. 2017, 27, 1216–1222. [Google Scholar] [CrossRef]

- Yang, S.-Y.; Lin, Q.; Lu, Z.-X.; Lü, F.-X.; Bie, X.-M.; Zou, X.-K.; Sun, L.-J. Characterization of a novel glutamate decarboxylase from Streptococcus salivarius ssp. thermophilus Y2. J. Chem. Technol. Biotechnol. 2008, 83, 855–861. [Google Scholar] [CrossRef]

- Cataldo, P.G.; Villegas, J.M.; Savoy de Giori, G.; Saavedra, L.; Hebert, E.M. Enhancement of gamma-aminobutyric acid (GABA) production by Lactobacillus brevis CRL 2013 based on carbohydrate fermentation. Int. J. Food Microbiol. 2020, 333, 108792. [Google Scholar] [CrossRef] [PubMed]

- Yazdani, S.S.; Gonzalez, R. Anaerobic fermentation of glycerol: A path to economic viability for the biofuels industry. Curr. Opin. Biotechnol. 2007, 18, 213–219. [Google Scholar] [CrossRef] [PubMed]

- Zotta, T.; Faraone, I.; Giavalisco, M.; Parente, E.; Lela, L.; Storti, L.V.; Ricciardi, A. The Production of γ-Aminobutyric Acid from Free and Immobilized Cells of Levilactobacillus brevis Cultivated in Anaerobic and Aerobic Conditions. Microorganisms 2022, 10, 2184. [Google Scholar] [CrossRef] [PubMed]

- Barrett, E.; Ross, R.P.; O’Toole, P.W.; Fitzgerald, G.F.; Stanton, C. γ-Aminobutyric acid production by culturable bacteria from the human intestine. J. Appl. Microbiol. 2012, 113, 411–417. [Google Scholar] [CrossRef] [PubMed]

- Jiang, L.; Fu, H.; Yang, H.K.; Xu, W.; Wang, J.; Yang, S.T. Butyric acid: Applications and recent advances in its bioproduction. Biotechnol. Adv. 2018, 36, 2101–2117. [Google Scholar] [CrossRef]

- Bao, T.; Feng, J.; Jiang, W.; Fu, H.; Wang, J.; Yang, S.T. Recent advances in n-butanol and butyrate production using engineered Clostridium tyrobutyricum. World J. Microbiol. Biotechnol. 2020, 36, 138. [Google Scholar] [CrossRef]

- Guo, X.; Zhang, H.; Feng, J.; Yang, L.; Luo, K.; Fu, H.; Wang, J. De novo biosynthesis of butyl butyrate in engineered Clostridium tyrobutyricum. Metab. Eng. 2023, 77, 64–75. [Google Scholar] [CrossRef]

- Suo, Y.; Luo, S.; Zhang, Y.; Liao, Z.; Wang, J. Enhanced butyric acid tolerance and production by Class I heat shock protein-overproducing Clostridium tyrobutyricum ATCC 25755. J. Ind. Microbiol. Biotechnol. 2017, 44, 1145–1156. [Google Scholar] [CrossRef]

- Jiang, L.; Wang, J.; Liang, S.; Cai, J.; Xu, Z. Control and optimization of Clostridium tyrobutyricum ATCC 25755 adhesion into fibrous matrix in a fibrous bed bioreactor. Appl. Biochem. Biotechnol. 2011, 165, 98–108. [Google Scholar] [CrossRef]

- Williams, D.R.; Young, D.I.; Young, M. Conjugative plasmid transfer from Escherichia coli to Clostridium acetobutylicum. J. Gen. Microbiol. 1990, 136, 819–826. [Google Scholar] [CrossRef]

- Liu, Q.; Cheng, H.; Ma, X.; Xu, N.; Liu, J.; Ma, Y. Expression, characterization and mutagenesis of a novel glutamate decarboxylase from Bacillus megaterium. Biotechnol. Lett. 2016, 38, 1107–1113. [Google Scholar] [CrossRef]

- Lyu, C.; Zhao, W.; Peng, C.; Hu, S.; Fang, H.; Hua, Y.; Yao, S.; Huang, J.; Mei, L. Exploring the contributions of two glutamate decarboxylase isozymes in Lactobacillus brevis to acid resistance and gamma-aminobutyric acid production. Microb. Cell Fact. 2018, 17, 180. [Google Scholar] [CrossRef]

- De Biase, D.; Pennacchietti, E. Glutamate decarboxylase-dependent acid resistance in orally acquired bacteria: Function, distribution and biomedical implications of the gadBC operon. Mol. Microbiol. 2012, 86, 770–786. [Google Scholar] [CrossRef]

- Le Vo, T.D.; Kim, T.W.; Hong, S.H. Effects of glutamate decarboxylase and gamma-aminobutyric acid (GABA) transporter on the bioconversion of GABA in engineered Escherichia coli. Bioprocess Biosyst. Eng. 2012, 35, 645–650. [Google Scholar] [CrossRef]

- Suo, Y.; Fu, H.; Ren, M.; Liao, Z.; Ma, Y.; Wang, J. Enhanced butyric acid production in Clostridium tyrobutyricum by overexpression of rate-limiting enzymes in the Embden-Meyerhof-Parnas pathway. J. Biotechnol. 2018, 272, 14–21. [Google Scholar] [CrossRef]

- Shi, X.; Chang, C.; Ma, S.; Cheng, Y.; Zhang, J.; Gao, Q. Efficient bioconversion of L-glutamate to gamma-aminobutyric acid by Lactobacillus brevis resting cells. J. Ind. Microbiol. Biotechnol. 2017, 44, 697–704. [Google Scholar] [CrossRef]

- Wang, Q.; Liu, X.; Fu, J.; Wang, S.; Chen, Y.; Chang, K.; Li, H. Substrate sustained release-based high efficacy biosynthesis of GABA by Lactobacillus brevis NCL912. Microb. Cell Fact. 2018, 17, 80. [Google Scholar] [CrossRef]

- Lyu, C.J.; Zhao, W.R.; Hu, S.; Huang, J.; Lu, T.; Jin, Z.H.; Mei, L.H.; Yao, S.J. Physiology-Oriented Engineering Strategy to Improve Gamma-Aminobutyrate Production in Lactobacillus brevis. J. Agric. Food Chem. 2017, 65, 858–866. [Google Scholar] [CrossRef]

- Capitani, G.; De Biase, D.; Aurizi, C.; Gut, H.; Bossa, F.; Grütter, M.G. Crystal structure and functional analysis of Escherichia coli glutamate decarboxylase. EMBO J. 2003, 22, 4027–4037. [Google Scholar] [CrossRef]

- Ke, C.; Yang, X.; Rao, H.; Zeng, W.; Hu, M.; Tao, Y.; Huang, J. Whole-cell conversion of l-glutamic acid into gamma-aminobutyric acid by metabolically engineered Escherichia coli. Springerplus 2016, 5, 591. [Google Scholar] [CrossRef] [PubMed]

- Nomura, M.; Nakajima, I.; Fujita, Y.; Kobayashi, M.; Kimoto, H.; Suzuki, I.; Aso, H. Lactococcus lactis contains only one glutamate decarboxylase gene. Microbiology 1999, 145, 1375–1380. [Google Scholar] [CrossRef] [PubMed]

- Selby, K.; Lindstrom, M.; Somervuo, P.; Heap, J.T.; Minton, N.P.; Korkeala, H. Important role of class I heat shock genes hrcA and dnaK in the heat shock response and the response to pH and NaCl stress of group I Clostridium botulinum strain ATCC 3502. Appl. Environ. Microbiol. 2011, 77, 2823–2830. [Google Scholar] [CrossRef] [PubMed]

- Heap, J.T.; Pennington, O.J.; Cartman, S.T.; Minton, N.P. A modular system for Clostridium shuttle plasmids. J. Microbiol. Methods 2009, 78, 79–85. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).