Microbial Electrochemical CO2 Reduction and In-Situ Biogas Upgrading at Various pH Conditions

Abstract

1. Introduction

2. Materials and Methods

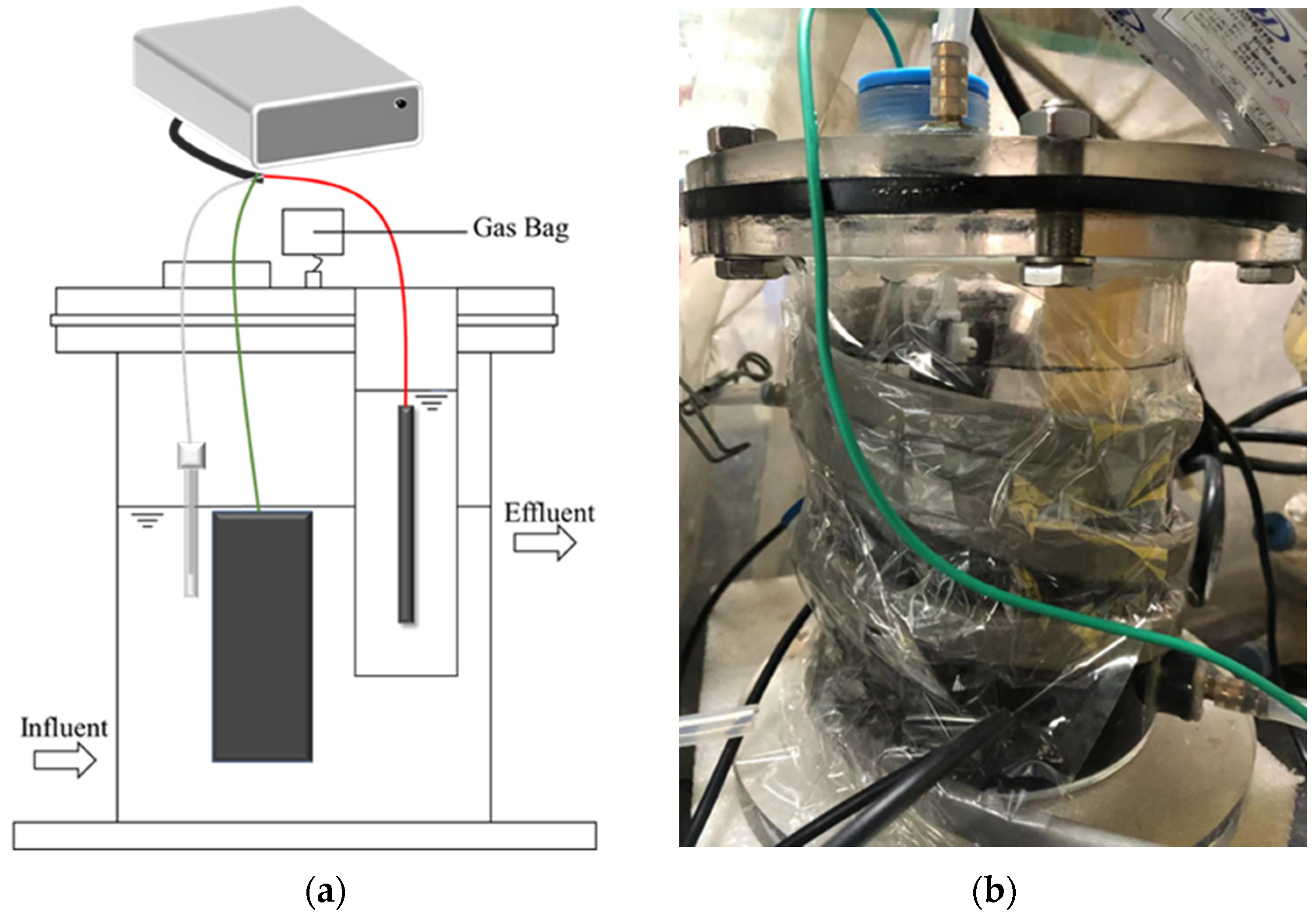

2.1. Reactor Setup and Operation

2.2. Analytical and Testing Methods

2.3. Microbial Analysis Methods

2.4. Data Processing and Statistical Analysis

3. Results

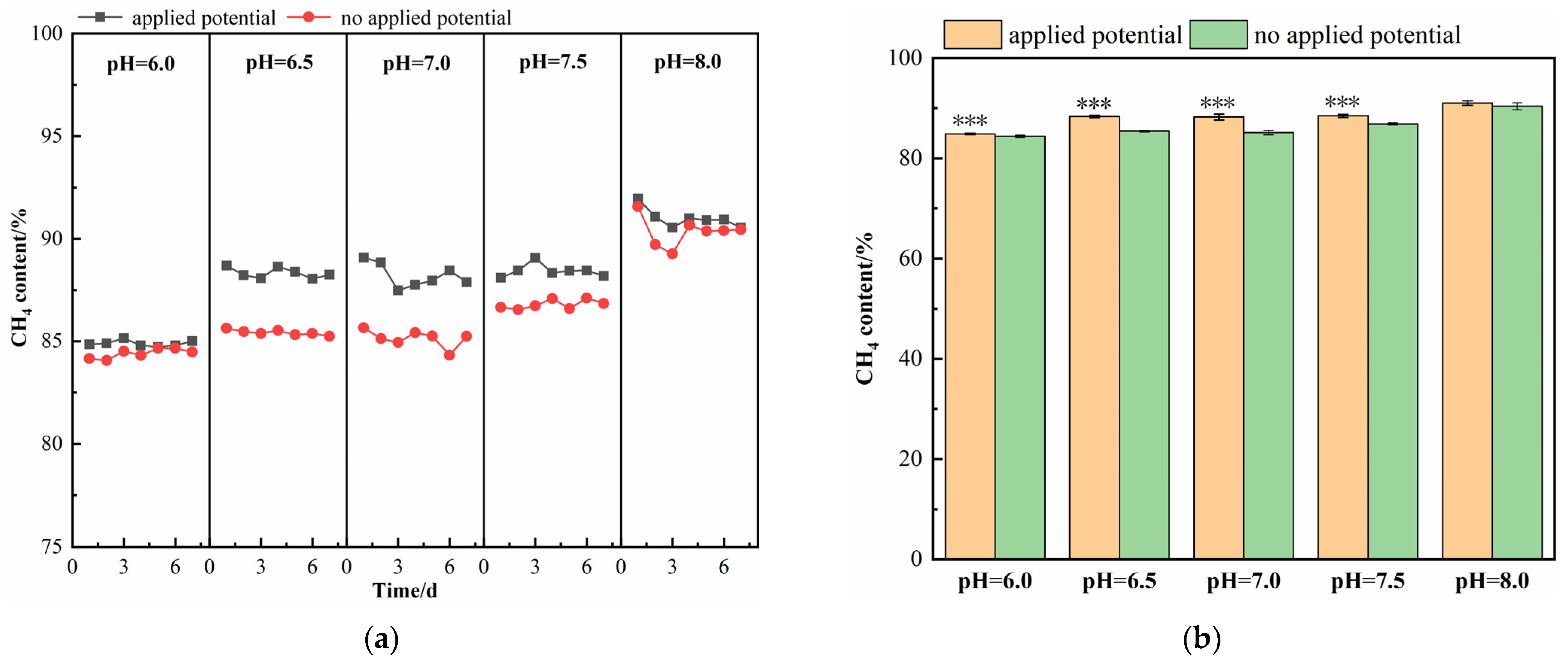

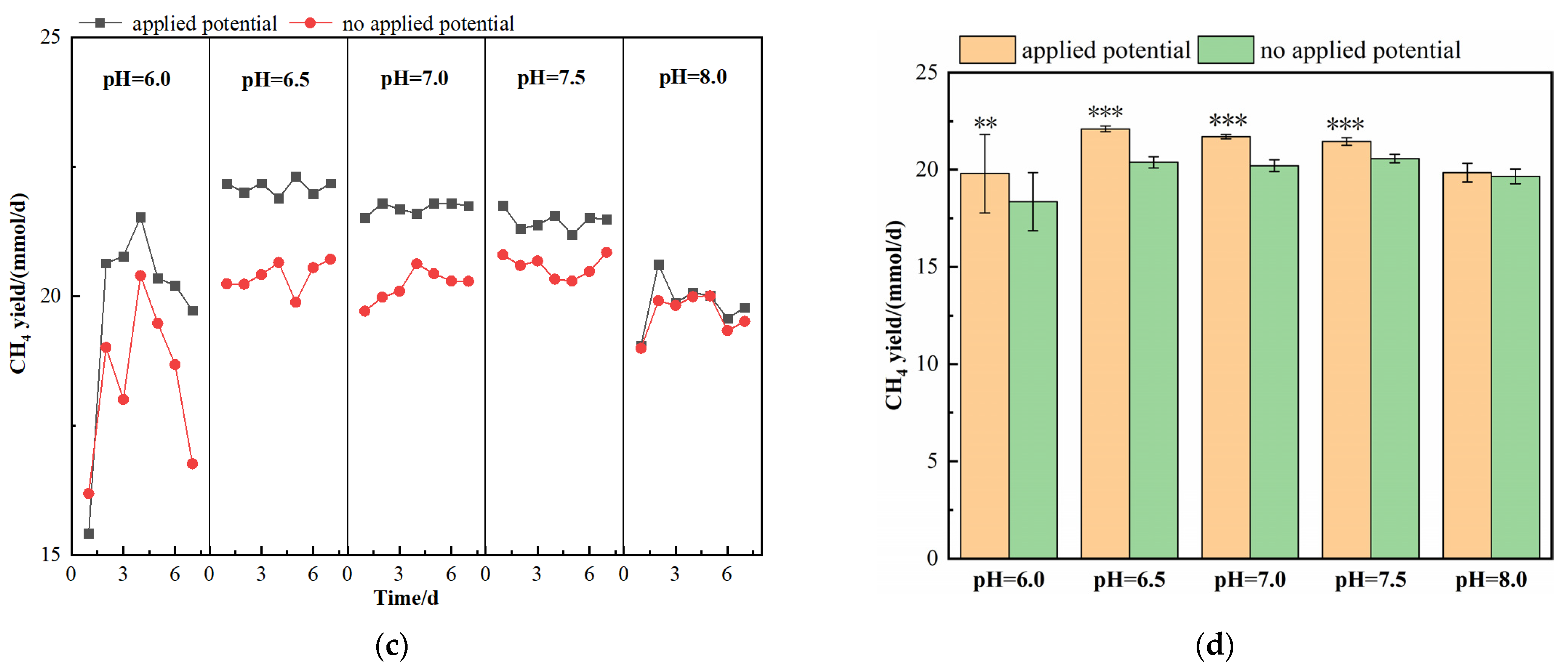

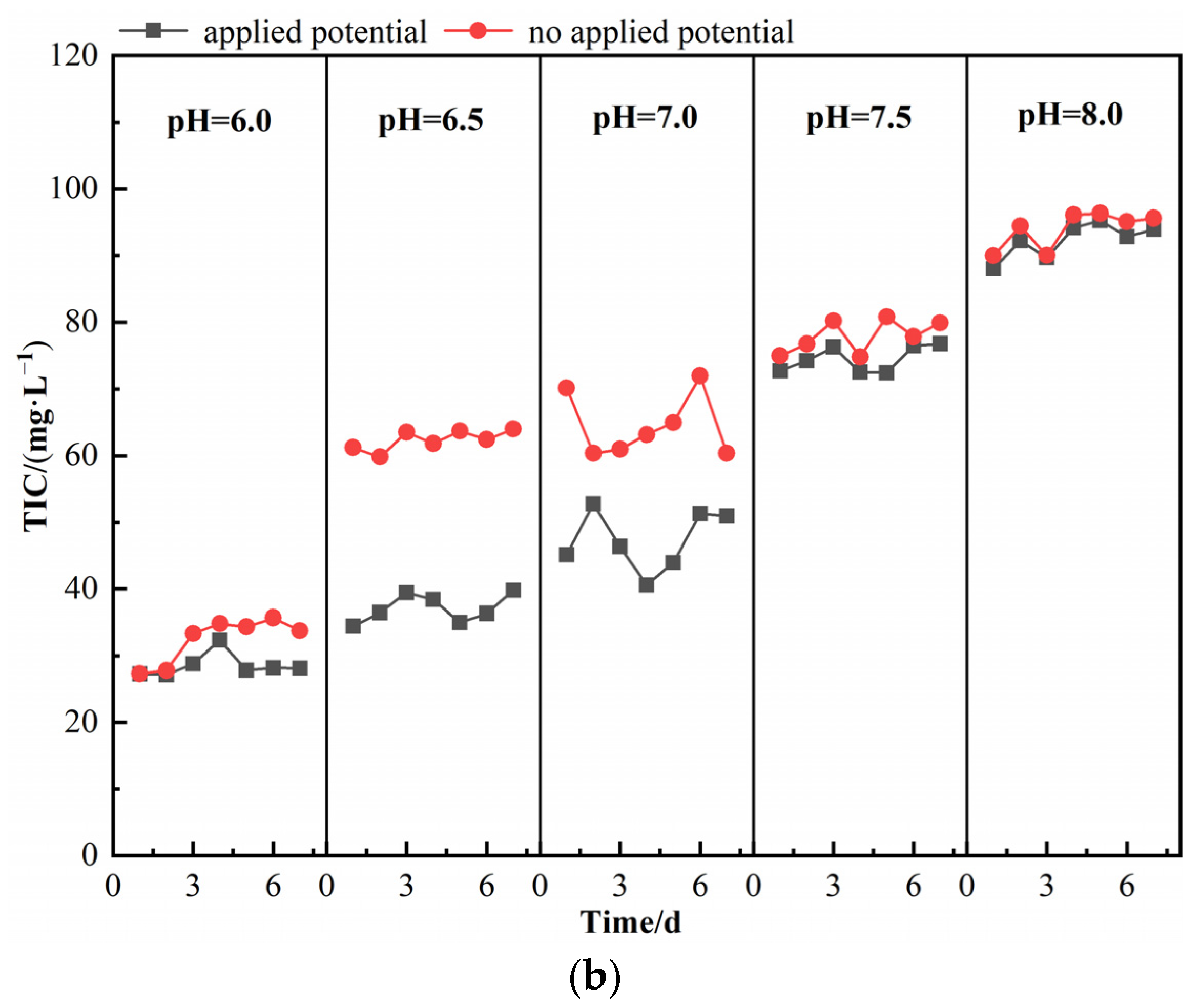

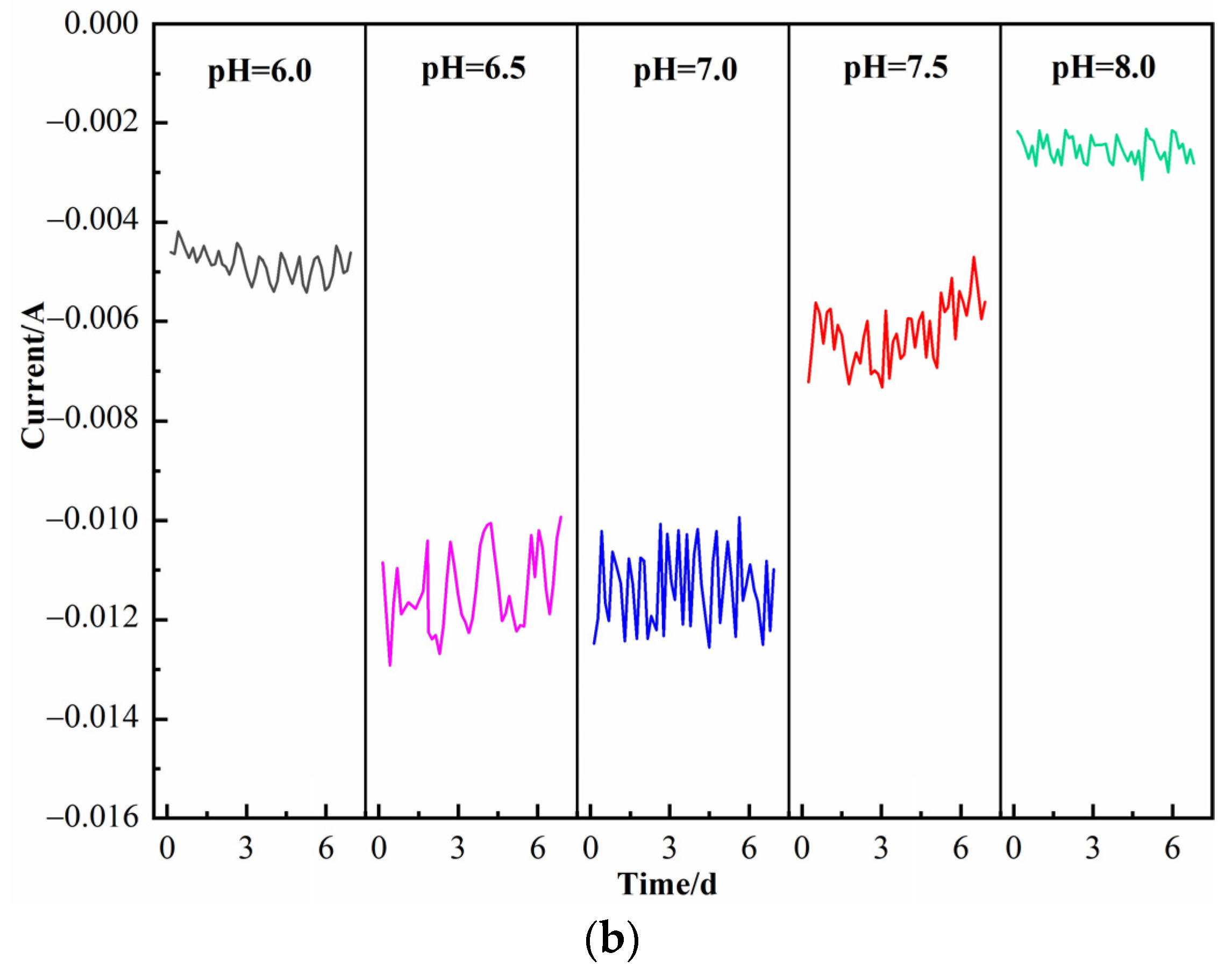

3.1. Effect of pH on the Efficiency of Biogas Upgrading

3.2. Microbial Community Structure and Morphology of Cathode under Optimal Operating Conditions

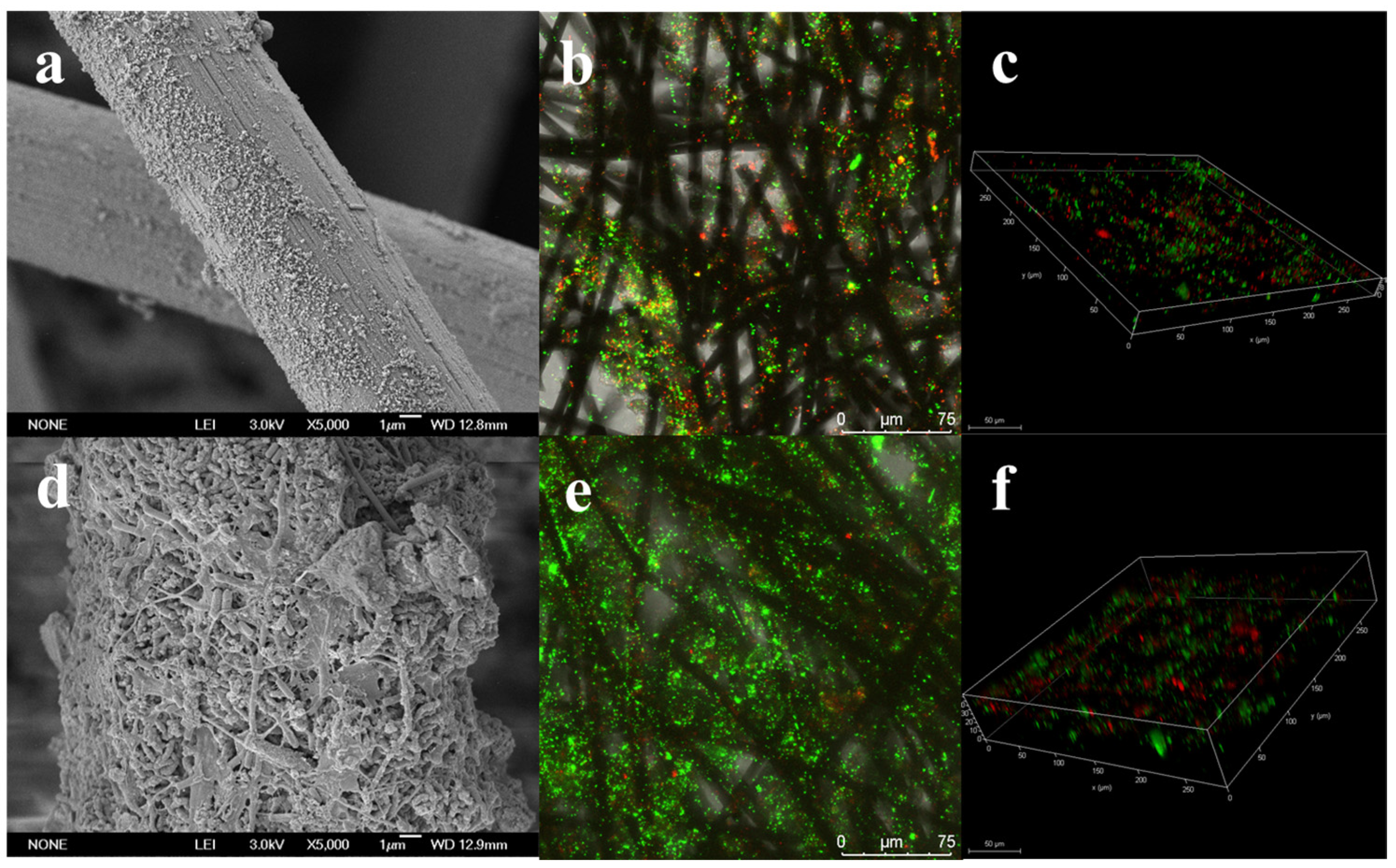

3.2.1. Biofilm Morphology of Cathode

3.2.2. Microbial Community Structure of Cathode

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- IEA-International-Energy Agency. World Energy Statistics in 2022; IEA-International-Energy Agency: Paris, France, 2022. [Google Scholar]

- Zhao, J.; Li, Y.; Dong, R. Recent progress towards in-situ biogas upgrading technologies. Sci. Total Environ. 2021, 800, 149667. [Google Scholar] [CrossRef] [PubMed]

- Piechota, G. Siloxanes in Biogas: Approaches of Sampling Procedure and GC-MS Method Determination. Molecules 2021, 26, 1953. [Google Scholar] [CrossRef] [PubMed]

- Villarim, P.; Genty, E.; Zemmouri, J.; Fourmentin, S. Deep eutectic solvents and conventional solvents as VOC absorbents for biogas upgrading: A comparative study. Chem. Eng. J. 2022, 446, 136875. [Google Scholar] [CrossRef]

- Jia, X.; Yan, H.; Wang, Z.; He, H.; Xu, Q.; Wang, H.; Yin, C.; Liu, L. Carbon dioxide fixation by Chlorella sp. USTB-01 with a fermentorhelical combined photobioreactor. Front. Environ. Sci. Eng. China 2011, 5, 402–408. [Google Scholar] [CrossRef]

- Zhong, J.; Yang, X.; Wu, Z.; Liang, B.; Huang, Y.; Zhang, T. State of the art and perspectives in heterogeneous catalysis of CO2 hydrogenation to methanol. Chem. Soc. Rev. 2020, 49, 1385–1413. [Google Scholar] [CrossRef] [PubMed]

- Kumaravel, V.; Bartlett, J.; Pillai, S.C. Photoelectrochemical Conversion of Carbon Dioxide (CO2) into Fuels and Value-Added Products. ACS Energy Lett. 2020, 5, 486–519. [Google Scholar] [CrossRef]

- Francke, R.; Schille, B.; Roemelt, M. Homogeneously Catalyzed Electroreduction of Carbon Dioxide-Methods, Mechanisms, and Catalysts. Chem. Rev. 2018, 118, 4631–4701. [Google Scholar] [CrossRef]

- Li, M.; Wang, H.; Luo, W.; Sherrell, P.C.; Chen, J.; Yang, J. Heterogeneous Single-Atom Catalysts for Electrochemical CO2 Reduction Reaction. Adv. Mater. 2020, 32, 2001848. [Google Scholar] [CrossRef]

- Zhen, G.; Zheng, S.; Lu, X.; Zhu, X.; Mei, J.; Kobayashi, T.; Xu, K.; Li, Y.; Zhao, Y. A comprehensive comparison of five different carbon-based cathode materials in CO2 electromethanogenesis: Long-term performance, cell-electrode contact behaviors and extracellular electron transfer pathways. Bioresour. Technol. 2018, 266, 382–388. [Google Scholar] [CrossRef]

- Luo, T.; Song, Q.; Han, J.; Li, Y.; Liu, L. The reduction of CO2/bicarbonate to ethanol driven by Bio-electrochemical system using reduced graphene oxide modified nickel foam. Sep. Purif. Technol. 2022, 280, 119437. [Google Scholar] [CrossRef]

- Gomez Vidales, A.; Omanovic, S.; Li, H.; Hrapovic, S.; Tartakovsky, B. Evaluation of biocathode materials for microbial electrosynthesis of methane and acetate. Bioelectrochemistry 2022, 148, 108246. [Google Scholar] [CrossRef] [PubMed]

- Pepè, S.T.; Batlle, V.P.; Colombo, B.; Scaglia, B.; Balaguer, M.D.; Colprim, J.; Puig, S.; Adani, F. Bio-electrorecycling of carbon dioxide into bioplastics. Green Chem. 2018, 20, 4058–4066. [Google Scholar] [CrossRef]

- Igliński, B.; Pietrzak, M.B.; Kiełkowska, U.; Skrzatek, M.; Kumar, G.; Piechota, G. The assessment of renewable energy in Poland on the background of the world renewable energy sector. Energy 2022, 261, 125319. [Google Scholar] [CrossRef]

- Adnan, A.I.; Ong, M.Y.; Nomanbhay, S.; Chew, K.W.; Show, P.L. Technologies for Biogas Upgrading to Biomethane: A Review. Bioengineering 2019, 6, 92. [Google Scholar] [CrossRef] [PubMed]

- Angelidaki, I.; Treu, L.; Tsapekos, P.; Luo, G.; Campanaro, S.; Wenzel, H.; Kougias, P.G. Biogas upgrading and utilization: Current status and perspectives. Biotechnol. Adv. 2018, 36, 452–466. [Google Scholar] [CrossRef]

- Xu, H.; Wang, K.; Holmes, D.E. Bioelectrochemical removal of carbon dioxide (CO2): An innovative method for biogas upgrading. Bioresour. Technol. 2014, 173, 392–398. [Google Scholar] [CrossRef]

- Wahid, R.; Mulat, D.G.; Gaby, J.C.; Horn, S.J. Effects of H2:CO2 ratio and H2 supply fluctuation on methane content and microbial community composition during in-situ biological biogas upgrading. Biotechnol. Biofuels 2019, 12, 104. [Google Scholar] [CrossRef]

- Zhao, J.; Li, Y.; Marandola, C.; Krooneman, J.; Euverink, G.J.W. Comparison of the microbial communities in anaerobic digesters treating high alkalinity synthetic wastewater at atmospheric and high-pressure (11 bar). Bioresour. Technol. 2020, 318, 124101. [Google Scholar] [CrossRef]

- Wei, W.; Guo, W.; Ngo, H.H.; Mannina, G.; Wang, D.; Chen, X.; Liu, Y.; Peng, L.; Ni, B. Enhanced high-quality biomethane production from anaerobic digestion of primary sludge by corn stover biochar. Bioresour. Technol. 2020, 306, 123159. [Google Scholar] [CrossRef]

- Cheng, S.; Xing, D.; Call, D.F.; Logan, B.E. Direct biological conversion of electrical current into methane by electromethanogenesis. Environ. Sci. Technol. 2009, 43, 3953–3958. [Google Scholar] [CrossRef]

- Logan, B.E.; Rabaey, K. Conversion of wastes into bioelectricity and chemicals by using microbial electrochemical technologies. Science 2012, 337, 686–690. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Sun, D.; Zhao, Z.; Dang, Y.; Holmes, D.E. Methanothrix enhances biogas upgrading in microbial electrolysis cell via direct electron transfer. Bioresour. Technol. 2019, 291, 121877. [Google Scholar] [CrossRef] [PubMed]

- Lin, C.; Wu, P.; Liu, Y.; Wong, J.W.C.; Yong, X.; Wu, X.; Xie, X.; Jia, H.; Zhou, J. Enhanced biogas production and biodegradation of phenanthrene in wastewater sludge treated anaerobic digestion reactors fitted with a bioelectrode system. Chem. Eng. J. 2019, 365, 1–9. [Google Scholar] [CrossRef]

- Pelaz, G.; Carrillo-Peña, D.; Morán, A.; Escapa, A. Electromethanogenesis at medium-low temperatures: Impact on performance and sources of variability. Fuel 2022, 310, 122336. [Google Scholar] [CrossRef]

- Mohanakrishna, G.; Vanbroekhoven, K.; Pant, D. Impact of dissolved carbon dioxide concentration on process parameters during its conversion to acetate through microbial electrosynthesis. React. Chem. Eng. 2018, 3, 371–378. [Google Scholar] [CrossRef]

- Gao, T.; Zhang, H.; Xu, X.; Teng, J. Mutual effects of CO2 absorption and H2-mediated electromethanogenesis triggering efficient biogas upgrading. Sci. Total Environ. 2022, 818, 151732. [Google Scholar] [CrossRef]

- Mao, C.; Feng, Y.; Wang, X.; Ren, G. Review on research achievements of biogas from anaerobic digestion. Renew. Sustain. Energy Rev. 2015, 45, 540–555. [Google Scholar] [CrossRef]

- Izadi, P.; Fontmorin, J.; Godain, A.; Yu, E.H.; Head, I.M. Parameters influencing the development of highly conductive and efficient bio-film during microbial electrosynthesis: The importance of applied potential and inorganic carbon source. NPJ Biofilms Microbiomes 2020, 6, 40. [Google Scholar] [CrossRef]

- Li, Z.; Fu, Q.; Kobayashi, H.; Xiao, S.; Li, J.; Zhang, L.; Liao, Q.; Zhu, X. Polarity reversal facilitates the development of biocathodes in microbial electrosynthesis systems for biogas production. Int. J. Hydrogen Energy 2019, 44, 26226–26236. [Google Scholar] [CrossRef]

- Jia, R.; Tao, Q.; Sun, D.; Dang, Y. Carbon cloth self-forming dynamic membrane enhances anaerobic removal of organic matter from incineration leachate via direct interspecies electron transfer. Chem. Eng. J. 2022, 445, 136732. [Google Scholar] [CrossRef]

- Li, J.; Li, Z.; Xiao, S.; Fu, Q.; Kobayashi, H.; Zhang, L.; Liao, Q.; Zhu, X. Startup cathode potentials determine electron transfer behaviours of biocathodes catalysing CO2 reduction to CH4 in microbial electrosynthesis. J. CO2 Util. 2020, 35, 169–175. [Google Scholar] [CrossRef]

- Zheng, S.; Liu, F.; Wang, B.; Zhang, Y.; Lovley, D.R. Methanobacterium capable of direct interspecies electron transfer. Environ. Sci. Technol. 2020, 54, 15347–15354. [Google Scholar] [CrossRef] [PubMed]

- LaBarge, N.; Yilmazel, Y.D.; Hong, P.; Logan, B.E. Effect of pre-acclimation of granular activated carbon on microbial electrolysis cell startup and performance. Bioelectrochemistry 2017, 113, 20–25. [Google Scholar] [CrossRef] [PubMed]

- Dridi, B.; Fardeau, M.; Ollivier, B.; Raoult, D.; Drancourt, M. Methanomassiliicoccus luminyensis gen. nov., sp. nov., a methanogenic archaeon isolated from human faeces. Int. J. Syst. Evol. Microbiol. 2012, 62, 1902–1907. [Google Scholar] [CrossRef] [PubMed]

- Huang, L.; Liu, X.; Tang, J.; Yu, L.; Zhou, S. Electrochemical evidence for direct interspecies electron transfer between Geobacter sulfurreducens and Prosthecochloris aestuarii. Bioelectrochemistry 2019, 127, 21–25. [Google Scholar] [CrossRef] [PubMed]

- Walker, D.J.F.; Nevin, K.P.; Holmes, D.E.; Rotaru, A.; Ward, J.E.; Woodard, T.L.; Zhu, J.; Ueki, T.; Nonnenmann, S.S.; McInerney, M.J.; et al. Syntrophus conductive pili demonstrate that common hydrogen-donating syntrophs can have a direct electron transfer option. ISME J. 2020, 14, 837–846. [Google Scholar] [CrossRef]

- Yin, Q.; Miao, J.; Li, B.; Wu, G. Enhancing electron transfer by ferroferric oxide during the anaerobic treatment of synthetic wastewater with mixed organic carbon. Int. Biodeterior. Biodegrad. 2017, 119, 104–110. [Google Scholar] [CrossRef]

- Wang, C.; Qiao, W.; Chen, H.; Xu, X.; Zhu, L. A short-term stimulation of ethanol enhances the effect of magnetite on anaerobic digestion. Appl. Microbiol. Biotechnol. 2019, 103, 1511–1522. [Google Scholar] [CrossRef]

- Rivalland, C.; Radouani, F.; Gonzalez-Rizzo, S.; Robert, F.; Salvin, P. Enrichment of Clostridia enhances Geobacter population and electron harvesting in a complex electroactive biofilm. Bioelectrochemistry 2022, 143, 107954. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, W.; Song, Y.; Liu, C.; Dong, H.; Li, H.; Huang, Y.; Liang, Z.; Xu, H.; Wu, H.; Li, P.; et al. Microbial Electrochemical CO2 Reduction and In-Situ Biogas Upgrading at Various pH Conditions. Fermentation 2023, 9, 444. https://doi.org/10.3390/fermentation9050444

Lu W, Song Y, Liu C, Dong H, Li H, Huang Y, Liang Z, Xu H, Wu H, Li P, et al. Microbial Electrochemical CO2 Reduction and In-Situ Biogas Upgrading at Various pH Conditions. Fermentation. 2023; 9(5):444. https://doi.org/10.3390/fermentation9050444

Chicago/Turabian StyleLu, Wenduo, Yuening Song, Chuanqi Liu, He Dong, Haoyong Li, Yinhui Huang, Zhao Liang, Haiyu Xu, Hongbin Wu, Pengsong Li, and et al. 2023. "Microbial Electrochemical CO2 Reduction and In-Situ Biogas Upgrading at Various pH Conditions" Fermentation 9, no. 5: 444. https://doi.org/10.3390/fermentation9050444

APA StyleLu, W., Song, Y., Liu, C., Dong, H., Li, H., Huang, Y., Liang, Z., Xu, H., Wu, H., Li, P., Sun, D., Xu, K., & Dang, Y. (2023). Microbial Electrochemical CO2 Reduction and In-Situ Biogas Upgrading at Various pH Conditions. Fermentation, 9(5), 444. https://doi.org/10.3390/fermentation9050444