Biomethane Production from the Mixture of Sugarcane Vinasse, Solid Waste and Spent Tea Waste: A Bayesian Approach for Hyperparameter Optimization for Gaussian Process Regression

Abstract

1. Introduction

2. Materials and Methods

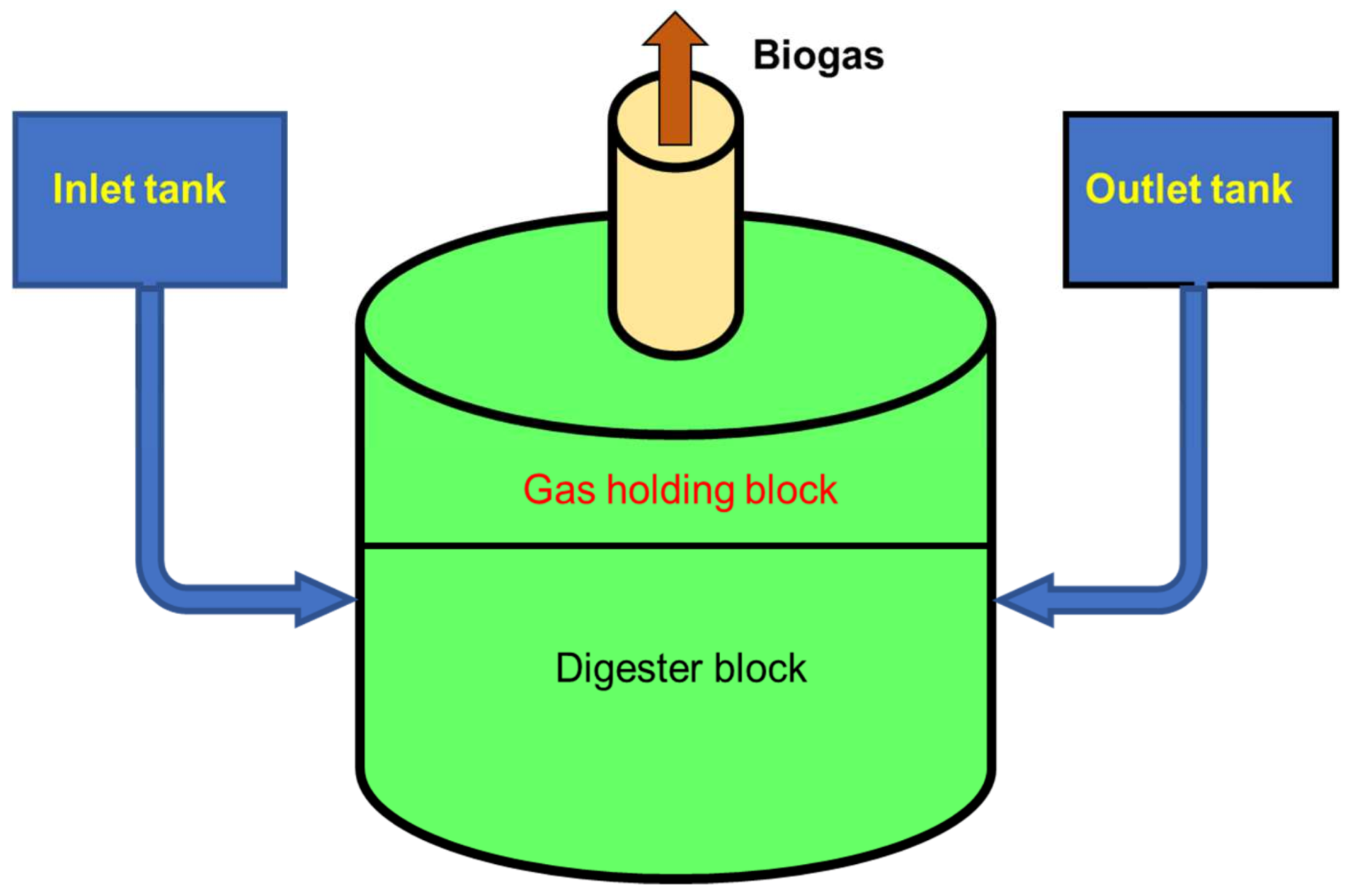

2.1. Waste Collection and Preparation of the Substrate

2.2. Soft Computing Method for Simulation Modeling

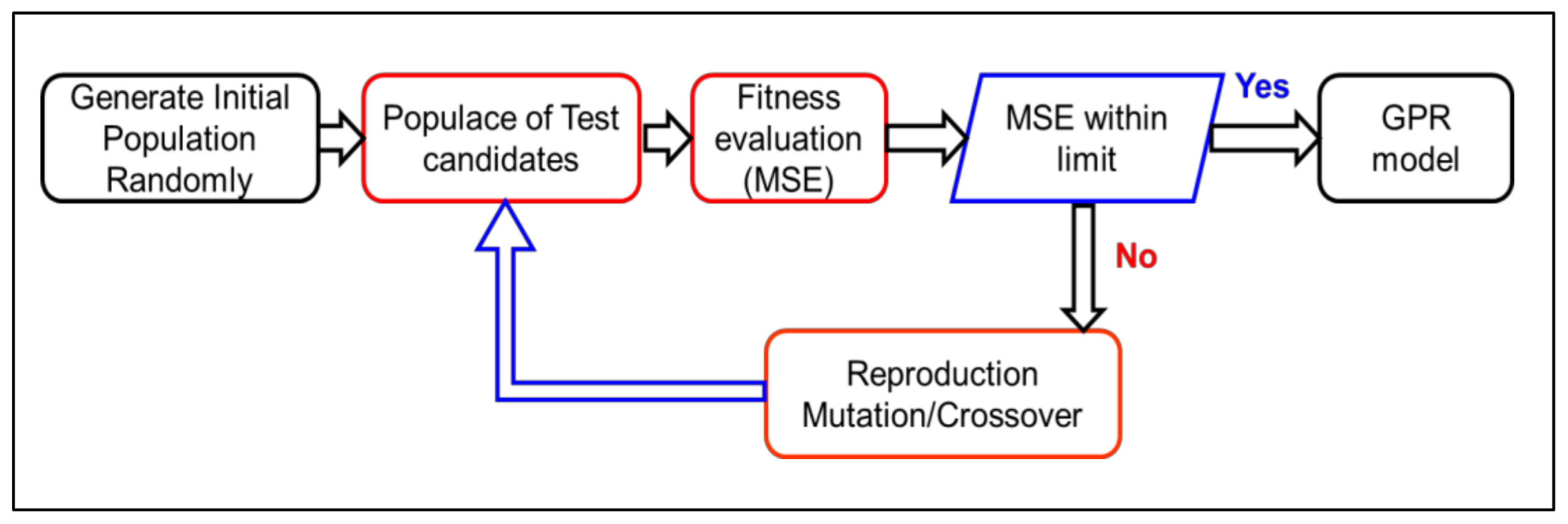

2.2.1. Gaussian Process Regression

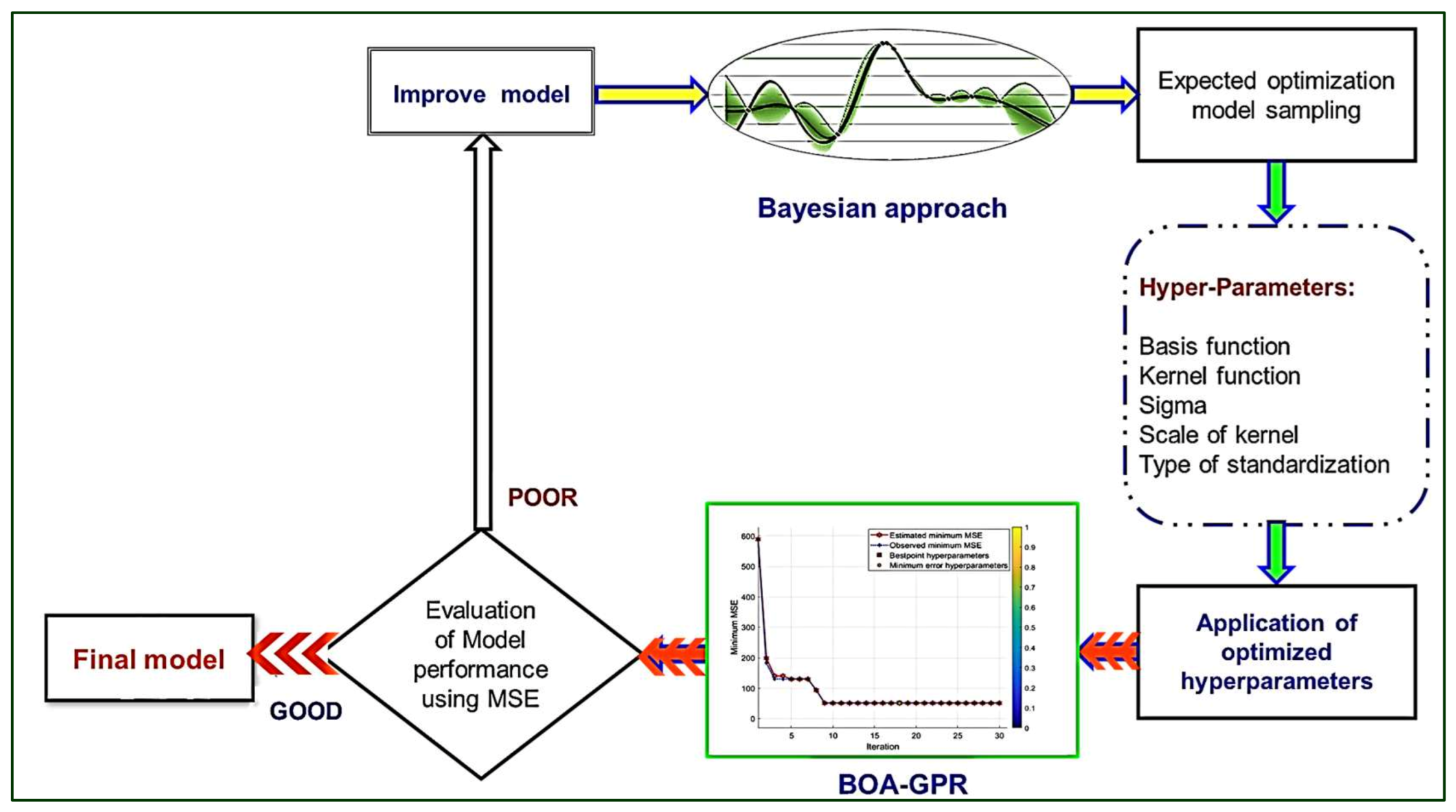

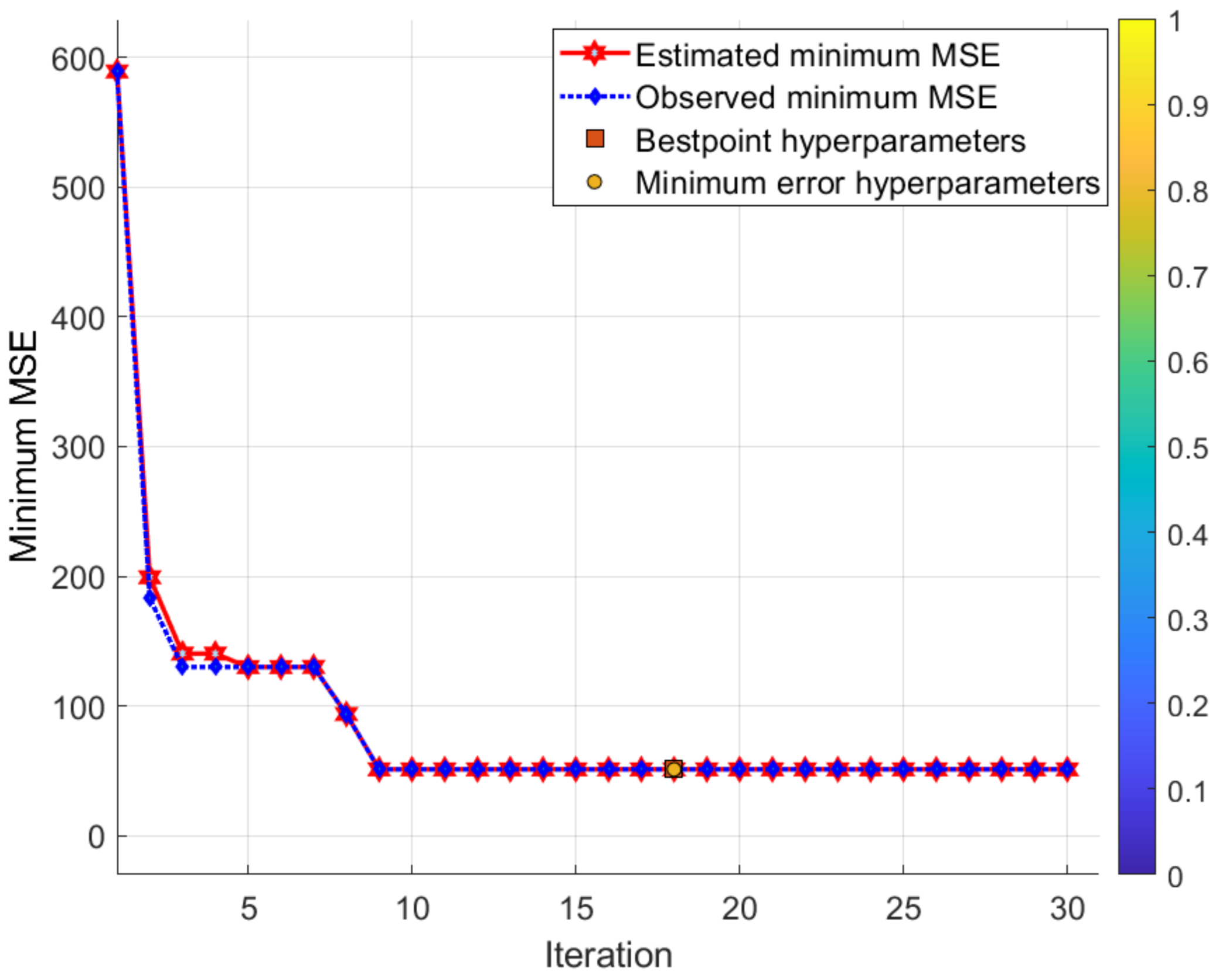

2.2.2. Bayesian Approach for the Optimization of Hyperparameters

2.2.3. Statistical Evaluation of the Prediction Model

3. Results and Discussion

3.1. Data Analysis

3.1.1. Kendall’s Rank of Correlation

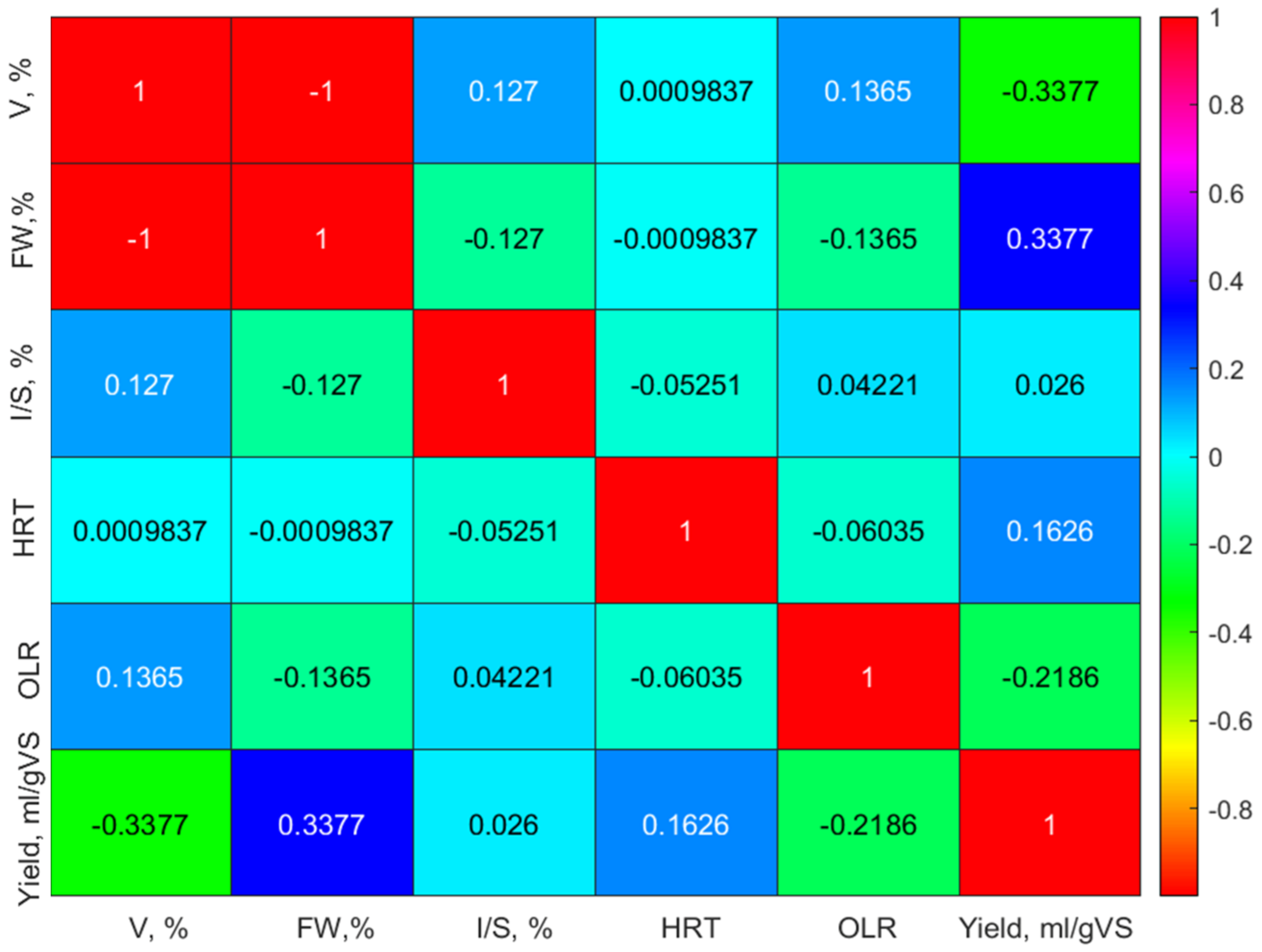

3.1.2. Pearson’s Correlation Matrix

3.2. Model Prediction of Biomethane Yield

4. Conclusions

- ○

- Fivefold cross-validation helped in the prevention of model overtraining, as the value of R2 was observed to be higher during the model test phase by 0.72%.

- ○

- The mean squared error during the model training phase was 36.243, which was reduced to 21.145 during the model test process.

- ○

- The mean absolute percentage error was observed to be only 0.1% which was reduced to 0.085% during the test phase of the model.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sharma, P.; Sharma, A.K. Statistical and Continuous Wavelet Transformation-Based Analysis of Combustion Instabilities in a Biodiesel-Fueled Compression Ignition Engine. J. Energy Resour. Technol. Trans. ASME 2022, 144, 032304. [Google Scholar] [CrossRef]

- Bora, B.J.; Dai Tran, T.; Krushna Prasad, S.; Sharma, P.; Said, Z.; Kalita, P.; Buradi, A.; Van, N.N.; Niyas, H.; Minh, T.P.; et al. Improving Combustion and Emission Characteristics of a Biogas/Biodiesel-Powered Dual-Fuel Diesel Engine through Trade-off Analysis of Operation Parameters Using Response Surface Methodology. Sustain. Energy Technol. Assess. 2022, 53, 102455. [Google Scholar] [CrossRef]

- Sharma, P.; Chhillar, A.; Said, Z.; Huang, Z.; Nguyen, V.N.; Nguyen, P.Q.P.; Nguyen, X.P. Experimental Investigations on Efficiency and Instability of Combustion Process in a Diesel Engine Fueled with Ternary Blends of Hydrogen Peroxide Additive/Biodiesel/Diesel. Energy Sources Part A Recovery Util. Environ. Eff. 2022, 44, 5929–5950. [Google Scholar] [CrossRef]

- Kapoor, R.; Ghosh, P.; Tyagi, B.; Vijay, V.K.; Vijay, V.; Thakur, I.S.; Kamyab, H.; Nguyen, D.D.; Kumar, A. Advances in Biogas Valorization and Utilization Systems: A Comprehensive Review. J. Clean Prod. 2020, 273, 123052. [Google Scholar] [CrossRef]

- Parsaee, M.; Kiani Deh Kiani, M.; Karimi, K. A Review of Biogas Production from Sugarcane Vinasse. Biomass Bioenergy 2019, 122, 117–125. [Google Scholar] [CrossRef]

- Sharma, P.; Sivaramakrishnaiah, M.; Deepanraj, B.; Saravanan, R.; Reddy, M.V. A Novel Optimization Approach for Biohydrogen Production Using Algal Biomass. Int. J. Hydrog. Energy 2022, in press. [Google Scholar] [CrossRef]

- Mona, S.; Kumar, S.S.; Kumar, V.; Parveen, K.; Saini, N.; Deepak, B.; Pugazhendhi, A. Green Technology for Sustainable Biohydrogen Production (Waste to Energy): A Review. Sci. Total Environ. 2020, 728, 138481. [Google Scholar] [CrossRef]

- Babbitt, C.W.; Neff, R.A.; Roe, B.E.; Siddiqui, S.; Chavis, C.; Trabold, T.A. Transforming Wasted Food Will Require Systemic and Sustainable Infrastructure Innovations. Curr. Opin. Env. Sustain 2022, 54, 101151. [Google Scholar] [CrossRef]

- Vizzoto, F.; Testa, F.; Iraldo, F. Strategies to Reduce Food Waste in the Foodservices Sector: A Systematic Review. Int. J. Hosp. Manag. 2021, 95, 102933. [Google Scholar] [CrossRef]

- Chen, C.; Chaudhary, A.; Mathys, A. Nutritional and Environmental Losses Embedded in Global Food Waste. Resour. Conserv. Recycl. 2020, 160, 104912. [Google Scholar] [CrossRef]

- Melikoglu, M. Reutilisation of Food Wastes for Generating Fuels and Value Added Products: A Global Review. Env. Technol. Innov. 2020, 19, 101040. [Google Scholar] [CrossRef]

- Sadhukhan, J.; Dugmore, T.I.J.; Matharu, A.; Martinez-Hernandez, E.; Aburto, J.; Rahman, P.K.S.M.; Lynch, J. Perspectives on “Game Changer” Global Challenges for Sustainable 21st Century: Plant-Based Diet, Unavoidable Food Waste Biorefining, and Circular Economy. Sustainability 2020, 12, 1976. [Google Scholar] [CrossRef]

- Kumar, K.R.; Dashora, K.; Krishnan, N.; Sanyal, S.; Chandra, H.; Dharmaraja, S.; Kumari, V. Feasibility Assessment of Renewable Energy Resources for Tea Plantation and Industry in India—A Review. Renew. Sustain. Energy Rev. 2021, 145, 111083. [Google Scholar] [CrossRef]

- Palmisano, G.O.; Bottalico, F.; Cardone, G.; Capone, R. Food Losses and Waste in the Context of Sustainable Food and Nutrition Security. Food Secur. Nutr. 2020, 235–255. [Google Scholar] [CrossRef]

- Thamagasorn, M.; Pharino, C. An Analysis of Food Waste from a Flight Catering Business for Sustainable Food Waste Management: A Case Study of Halal Food Production Process. J. Clean Prod. 2019, 228, 845–855. [Google Scholar] [CrossRef]

- Khayum, N.; Anbarasu, S.; Murugan, S. Biogas Potential from Spent Tea Waste: A Laboratory Scale Investigation of Co-Digestion with Cow Manure. Energy 2018, 165, 760–768. [Google Scholar] [CrossRef]

- de Corato, U. Agricultural Waste Recycling in Horticultural Intensive Farming Systems by On-Farm Composting and Compost-Based Tea Application Improves Soil Quality and Plant Health: A Review under the Perspective of a Circular Economy. Sci. Total Environ. 2020, 738, 139840. [Google Scholar] [CrossRef] [PubMed]

- Thamizhakaran Stanley, J.; Thanarasu, A.; Senthil Kumar, P.; Periyasamy, K.; Raghunandhakumar, S.; Periyaraman, P.; Devaraj, K.; Dhanasekaran, A.; Subramanian, S. Potential Pre-Treatment of Lignocellulosic Biomass for the Enhancement of Biomethane Production through Anaerobic Digestion—A Review. Fuel 2022, 318, 123593. [Google Scholar] [CrossRef]

- Debnath, B.; Haldar, D.; Purkait, M.K. Potential and Sustainable Utilization of Tea Waste: A Review on Present Status and Future Trends. J. Env. Chem. Eng. 2021, 9, 106179. [Google Scholar] [CrossRef]

- Negi, T.; Kumar, Y.; Sirohi, R.; Singh, S.; Tarafdar, A.; Pareek, S.; Kumar Awasthi, M.; Alok Sagar, N. Advances in Bioconversion of Spent Tea Leaves to Value-Added Products. Bioresour. Technol. 2022, 346, 126409. [Google Scholar] [CrossRef]

- Özarslan, S.; Abut, S.; Atelge, M.R.; Kaya, M.; Unalan, S. Modeling and Simulation of Co-Digestion Performance with Artificial Neural Network for Prediction of Methane Production from Tea Factory Waste with Co-Substrate of Spent Tea Waste. Fuel 2021, 306, 121715. [Google Scholar] [CrossRef]

- le Pera, A.; Sellaro, M.; Bencivenni, E.; D’Amico, F. Environmental Sustainability of an Integrate Anaerobic Digestion-Composting Treatment of Food Waste: Analysis of an Italian Plant in the Circular Bioeconomy Strategy. Waste Manag. 2022, 139, 341–351. [Google Scholar] [CrossRef]

- Mandpe, A.; Yadav, N.; Paliya, S.; Tyagi, L.; Ram Yadav, B.; Singh, L.; Kumar, S.; Kumar, R. Exploring the Synergic Effect of Fly Ash and Garbage Enzymes on Biotransformation of Organic Wastes in In-Vessel Composting System. Bioresour. Technol. 2021, 322, 124557. [Google Scholar] [CrossRef] [PubMed]

- Behera, S.; Samal, K. Sustainable Approach to Manage Solid Waste through Biochar Assisted Composting. Energy Nexus 2022, 7, 100121. [Google Scholar] [CrossRef]

- Zhou, Y.; Xiao, R.; Klammsteiner, T.; Kong, X.; Yan, B.; Mihai, F.C.; Liu, T.; Zhang, Z.; Kumar Awasthi, M. Recent Trends and Advances in Composting and Vermicomposting Technologies: A Review. Bioresour. Technol. 2022, 360, 127591. [Google Scholar] [CrossRef]

- Cabrera-Díaz, A.; Pereda-Reyes, I.; Dueñas-Moreno, J.; Véliz-Lorenzo, E.; Díaz-Marrero, M.A.; Menéndez-Gutiérrez, C.L.; Oliva-Merencio, D.; Zaiat, M. Combined Treatment of Vinasse by an Upflow Anaerobic Filter-Reactor and Ozonation Process. Braz. J. Chem. Eng. 2016, 33, 753–762. [Google Scholar] [CrossRef]

- Mahapatra, S.; Ali, M.H.; Samal, K. Assessment of Compost Maturity-Stability Indices and Recent Development of Composting Bin. Energy Nexus 2022, 6, 100062. [Google Scholar] [CrossRef]

- Ardolino, F.; Cardamone, G.F.; Parrillo, F.; Arena, U. Biogas-to-Biomethane Upgrading: A Comparative Review and Assessment in a Life Cycle Perspective. Renew. Sustain. Energy Rev. 2021, 139, 110588. [Google Scholar] [CrossRef]

- D’Adamo, I.; Ribichini, M.; Tsagarakis, K.P. Biomethane as an Energy Resource for Achieving Sustainable Production: Economic Assessments and Policy Implications. Sustain. Prod. Consum. 2023, 35, 13–27. [Google Scholar] [CrossRef]

- Khan, M.U.; Lee, J.T.E.; Bashir, M.A.; Dissanayake, P.D.; Ok, Y.S.; Tong, Y.W.; Shariati, M.A.; Wu, S.; Ahring, B.K. Current Status of Biogas Upgrading for Direct Biomethane Use: A Review. Renew. Sustain. Energy Rev. 2021, 149, 111343. [Google Scholar] [CrossRef]

- Sun, H.; Wang, E.; Li, X.; Cui, X.; Guo, J.; Dong, R. Potential Biomethane Production from Crop Residues in China: Contributions to Carbon Neutrality. Renew. Sustain. Energy Rev. 2021, 148, 111360. [Google Scholar] [CrossRef]

- Hoarau, J.; Caro, Y.; Grondin, I.; Petit, T. Sugarcane Vinasse Processing: Toward a Status Shift from Waste to Valuable Resource. A Review. J. Water Process. Eng. 2018, 24, 11–25. [Google Scholar] [CrossRef]

- Soares, J.F.; Confortin, T.C.; Todero, I.; Mayer, F.D.; Mazutti, M.A. Dark Fermentative Biohydrogen Production from Lignocellulosic Biomass: Technological Challenges and Future Prospects. Renew. Sustain. Energy Rev. 2020, 117, 109484. [Google Scholar] [CrossRef]

- Christofoletti, C.A.; Escher, J.P.; Correia, J.E.; Marinho, J.F.U.; Fontanetti, C.S. Sugarcane Vinasse: Environmental Implications of Its Use. Waste Manag. 2013, 33, 2752–2761. [Google Scholar] [CrossRef] [PubMed]

- Junior, A.D.N.F.; Etchebehere, C.; Perecin, D.; Teixeira, S.; Woods, J. Advancing Anaerobic Digestion of Sugarcane Vinasse: Current Development, Struggles and Future Trends on Production and End-Uses of Biogas in Brazil. Renew. Sustain. Energy Rev. 2022, 157, 112045. [Google Scholar] [CrossRef]

- Kim, S.R.; Ha, S.J.; Wei, N.; Oh, E.J.; Jin, Y.S. Simultaneous Co-Fermentation of Mixed Sugars: A Promising Strategy for Producing Cellulosic Ethanol. Trends Biotechnol. 2012, 30, 274–282. [Google Scholar] [CrossRef] [PubMed]

- Palmonari, A.; Cavallini, D.; Sniffen, C.J.; Fernandes, L.; Holder, P.; Fusaro, I.; Giammarco, M.; Formigoni, A.; Mammi, L.M.E. In Vitro Evaluation of Sugar Digestibility in Molasses. Ital. J. Anim. Sci. 2021, 20, 571–577. [Google Scholar] [CrossRef]

- Silva Neto, J.V.; Gallo, W.L.R. Potential Impacts of Vinasse Biogas Replacing Fossil Oil for Power Generation, Natural Gas, and Increasing Sugarcane Energy in Brazil. Renew. Sustain. Energy Rev. 2021, 135, 110281. [Google Scholar] [CrossRef]

- Hu, B.; Rodrigues Reis, C.E. Vinasse from Sugarcane Ethanol Production: Better Treatment or Better Utilization? Front. Energy Res. 2017, 5. [Google Scholar] [CrossRef]

- Ascher, S.; Watson, I.; You, S. Machine Learning Methods for Modelling the Gasification and Pyrolysis of Biomass and Waste. Renew. Sustain. Energy Rev. 2022, 155, 111902. [Google Scholar] [CrossRef]

- Hosseinzadeh, A.; Zhou, J.L.; Altaee, A.; Li, D. Machine Learning Modeling and Analysis of Biohydrogen Production from Wastewater by Dark Fermentation Process. Bioresour. Technol. 2022, 343, 126111. [Google Scholar] [CrossRef]

- Sharma, P.; Sahoo, B.B.; Said, Z.; Hadiyanto, H.; Nguyen, X.P.; Nižetić, S.; Huang, Z.; Hoang, A.T.; Li, C. Application of Machine Learning and Box-Behnken Design in Optimizing Engine Characteristics Operated with a Dual-Fuel Mode of Algal Biodiesel and Waste-Derived Biogas. Int. J. Hydrog. Energy 2022. [Google Scholar] [CrossRef]

- Muthudineshkumar, R.; Anand, R. Anaerobic Digestion of Various Feedstocks for Second-Generation Biofuel Production. In Advances in Eco-Fuels for a Sustainable Environment; Elsevier: Amsterdam, The Netherlands, 2019; pp. 157–185. [Google Scholar]

- Boyle, P. Gaussian Processes for Regression and Optimisation. 2007. Available online: http://researcharchive.vuw.ac.nz/handle/10063/421 (accessed on 11 December 2022).

- Calandra, R.; Peters, J.; Rasmussen, C.E.; Deisenroth, M.P. Manifold Gaussian Processes for Regression. In Proceedings of the 2016 International Joint Conference on Neural Networks (IJCNN), Vancouver, BC, Canada, 24–29 July 2016; pp. 3338–3345. [Google Scholar] [CrossRef]

- Kopsiaftis, G.; Protopapadakis, E.; Voulodimos, A.; Doulamis, N.; Mantoglou, A. Gaussian Process Regression Tuned by Bayesian Optimization for Seawater Intrusion Prediction. Comput. Intell. Neurosci. 2019, 2019, 2859429. [Google Scholar] [CrossRef] [PubMed]

- Schulz, E.; Speekenbrink, M.; Krause, A. A Tutorial on Gaussian Process Regression: Modelling, Exploring, and Exploiting Functions. J. Math. Psychol. 2018, 85, 1–16. [Google Scholar] [CrossRef]

- Zhang, Y.; Xu, X. Fe-Based Superconducting Transition Temperature Modeling through Gaussian Process Regression. J. Low. Temp. Phys. 2021, 202, 205–218. [Google Scholar] [CrossRef]

- Li, X.; Wang, Z.; Yan, J. Prognostic Health Condition for Lithium Battery Using the Partial Incremental Capacity and Gaussian Process Regression. J. Power. Sources 2019, 421, 56–67. [Google Scholar] [CrossRef]

- Ly, H.B.; Nguyen, T.A.; Pham, B.T. Investigation on Factors Affecting Early Strength of High-Performance Concrete by Gaussian Process Regression. PLoS One 2022, 17, e0262930. [Google Scholar] [CrossRef]

- Xue, Y.; Liu, Y.; Ji, C.; Xue, G.; Huang, S. System Identification of Ship Dynamic Model Based on Gaussian Process Regression with Input Noise. Ocean Eng. 2020, 216, 107862. [Google Scholar] [CrossRef]

- Elbeltagi, A.; Azad, N.; Arshad, A.; Mohammed, S.; Mokhtar, A.; Pande, C.; Etedali, H.R.; Bhat, S.A.; Islam, A.R.M.T.; Deng, J. Applications of Gaussian Process Regression for Predicting Blue Water Footprint: Case Study in Ad Daqahliyah, Egypt. Agric. Water Manag. 2021, 255, 107052. [Google Scholar] [CrossRef]

- Shi, X.; Jiang, D.; Qian, W.; Liang, Y. Application of the Gaussian Process Regression Method Based on a Combined Kernel Function in Engine Performance Prediction. ACS Omega 2022, 7, 41732–41743. [Google Scholar] [CrossRef]

- Pang, X.; Liu, X.; Jia, J.; Wen, J.; Shi, Y.; Zeng, J.; Zhao, Z. A Lithium-Ion Battery Remaining Useful Life Prediction Method Based on the Incremental Capacity Analysis and Gaussian Process Regression. Microelectron. Reliab. 2021, 127, 114405. [Google Scholar] [CrossRef]

- Saleh, E.; Tarawneh, A.; Naser, M.Z.; Abedi, M.; Almasabha, G. You Only Design Once (YODO): Gaussian Process-Batch Bayesian Optimization Framework for Mixture Design of Ultra High Performance Concrete. Constr. Build. Mater. 2022, 330, 127270. [Google Scholar] [CrossRef]

- Adun, H.; Wole-Osho, I.; Okonkwo, E.C.; Ruwa, T.; Agwa, T.; Onochie, K.; Ukwu, H.; Bamisile, O.; Dagbasi, M. Estimation of Thermophysical Property of Hybrid Nanofluids for Solar Thermal Applications: Implementation of Novel Optimizable Gaussian Process Regression (O-GPR) Approach for Viscosity Prediction. Neural Comput. Appl. 2022, 34, 11233–11254. [Google Scholar] [CrossRef]

- Zhou, Y.; Liu, Y.; Wang, D.; De, G.; Li, Y.; Liu, X.; Wang, Y. A Novel Combined Multi-Task Learning and Gaussian Process Regression Model for the Prediction of Multi-Timescale and Multi-Component of Solar Radiation. J. Clean Prod. 2021, 284, 124710. [Google Scholar] [CrossRef]

- Gibbs, M.N. Bayesian Gaussian Processes for Regression and Classification. Ph.D. Thesis, University of Cambridge, Cambridge, UK, 1997; p. 134. [Google Scholar]

- Greenhill, S.; Rana, S.; Gupta, S.; Vellanki, P.; Venkatesh, S. Bayesian Optimization for Adaptive Experimental Design: A Review. IEEE Access 2020, 8, 13937–13948. [Google Scholar] [CrossRef]

- Becerra, M.; Goos, P. Bayesian I-Optimal Designs for Choice Experiments with Mixtures. Chemom. Intell. Lab. Syst. 2021, 217, 104395. [Google Scholar] [CrossRef]

- Cheng, K.; Lu, Z. Active Learning Bayesian Support Vector Regression Model for Global Approximation. Inf. Sci. 2021, 544, 549–563. [Google Scholar] [CrossRef]

- Wang, J.; Li, C.; Xu, G.; Li, Y.; Kareem, A. Efficient Structural Reliability Analysis Based on Adaptive Bayesian Support Vector Regression. Comput. Methods Appl. Mech. Eng. 2021, 387, 114172. [Google Scholar] [CrossRef]

- Wu, J.; Chen, X.Y.; Zhang, H.; Xiong, L.D.; Lei, H.; Deng, S.H. Hyperparameter Optimization for Machine Learning Models Based on Bayesian Optimization. J. Electron. Sci. Technol. 2019, 17, 26–40. [Google Scholar] [CrossRef]

- Said, Z.; Sharma, P.; Elavarasan, R.M.; Tiwari, A.K.; Rathod, M.K. Exploring the Specific Heat Capacity of Water-Based Hybrid Nanofluids for Solar Energy Applications: A Comparative Evaluation of Modern Ensemble Machine Learning Techniques. J. Energy Storage 2022, 54, 105230. [Google Scholar] [CrossRef]

- Sharma, P.; Chhillar, A.; Said, Z.; Memon, S. Exploring the Exhaust Emission and Efficiency of Algal Biodiesel Powered Compression Ignition Engine: Application of Box–Behnken and Desirability Based Multi-Objective Response Surface Methodology. Energies 2021, 14, 5968. [Google Scholar] [CrossRef]

- Xu, W.; Lai, H.; Dai, J.; Zhou, Y. Spectrum Sensing for Cognitive Radio Based on Kendall’s Tau in the Presence of Non-Gaussian Impulsive Noise. Digit. Signal Process. 2022, 123, 103443. [Google Scholar] [CrossRef]

| Property | Sugarcane Vinasse | Spent Tea Waste | Food Waste |

|---|---|---|---|

| COD | 31.5, g/L | 21.05 | 32.5, g/L |

| pH | 4 | 6.7 | 5.45 |

| Total N | 0.56, g/L N | -- | -- |

| Ammoniacal N | 0.04, g/L | -- | -- |

| TOC | 20.14, g/m3 | -- | -- |

| Volatile solid | 45.84, g/m3 | -- | -- |

| C/N | 12.36 | -- | -- |

| TS, % | -- | 5.65% | 13.14% |

| Hyperparameter | Hyperparameter Range | Set of Optimized Hyperparameters |

|---|---|---|

| Preset | Bayesian approach | -- |

| Number of iterations | 30 | -- |

| Acquiring function | Potential improvements per second | |

| Time limit for training | False | |

| Functional basis function | Constant, Zero and Linear | Zero |

| Signal standard deviation | 19.93 | |

| Sigma value | 0.0001–281.76 | 0.00013 |

| Kernel function | Non-isotropic: Quadratic Rational, Matern 3/2 and 5/2, Squared Exp Isotropic: Quadratic Rational Squared Exp, Matern 3/2 and 5/2. | Isotropic Matern 3/2 |

| Scale of Kernel | 0.045–45 | 0.9792 |

| Standardization | True, False | False |

| Statistical Indices | Validation | Test |

|---|---|---|

| R2 | 0.9478 | 0.9547 |

| MSE | 36.243 | 21.145 |

| RMSE | 6.0202 | 4.598 |

| MAPE | 0.1% | 0.085% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alruqi, M.; Sharma, P. Biomethane Production from the Mixture of Sugarcane Vinasse, Solid Waste and Spent Tea Waste: A Bayesian Approach for Hyperparameter Optimization for Gaussian Process Regression. Fermentation 2023, 9, 120. https://doi.org/10.3390/fermentation9020120

Alruqi M, Sharma P. Biomethane Production from the Mixture of Sugarcane Vinasse, Solid Waste and Spent Tea Waste: A Bayesian Approach for Hyperparameter Optimization for Gaussian Process Regression. Fermentation. 2023; 9(2):120. https://doi.org/10.3390/fermentation9020120

Chicago/Turabian StyleAlruqi, Mansoor, and Prabhakar Sharma. 2023. "Biomethane Production from the Mixture of Sugarcane Vinasse, Solid Waste and Spent Tea Waste: A Bayesian Approach for Hyperparameter Optimization for Gaussian Process Regression" Fermentation 9, no. 2: 120. https://doi.org/10.3390/fermentation9020120

APA StyleAlruqi, M., & Sharma, P. (2023). Biomethane Production from the Mixture of Sugarcane Vinasse, Solid Waste and Spent Tea Waste: A Bayesian Approach for Hyperparameter Optimization for Gaussian Process Regression. Fermentation, 9(2), 120. https://doi.org/10.3390/fermentation9020120