Lignocellulosic Biorefinery Technologies: A Perception into Recent Advances in Biomass Fractionation, Biorefineries, Economic Hurdles and Market Outlook

Abstract

1. Introduction

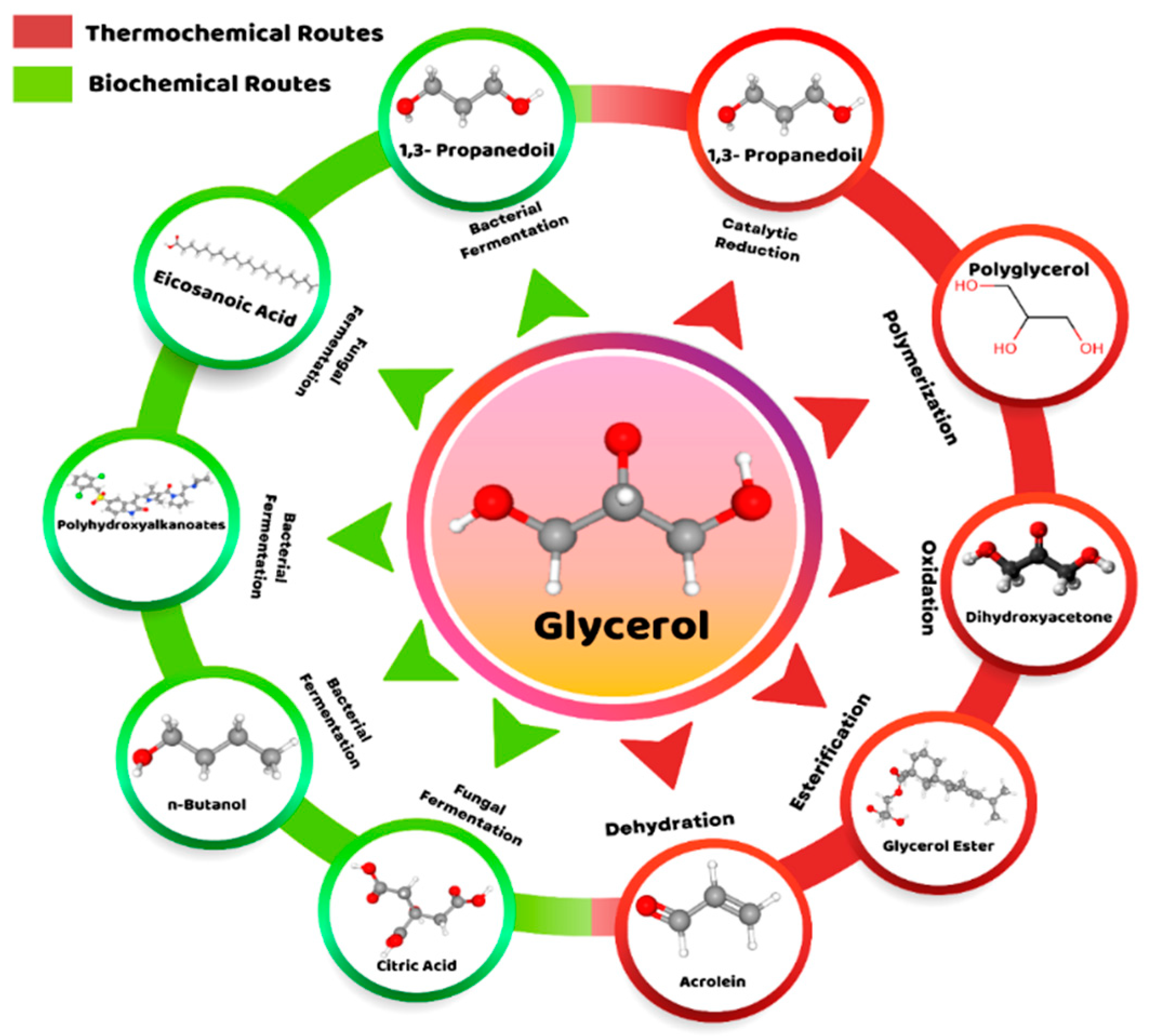

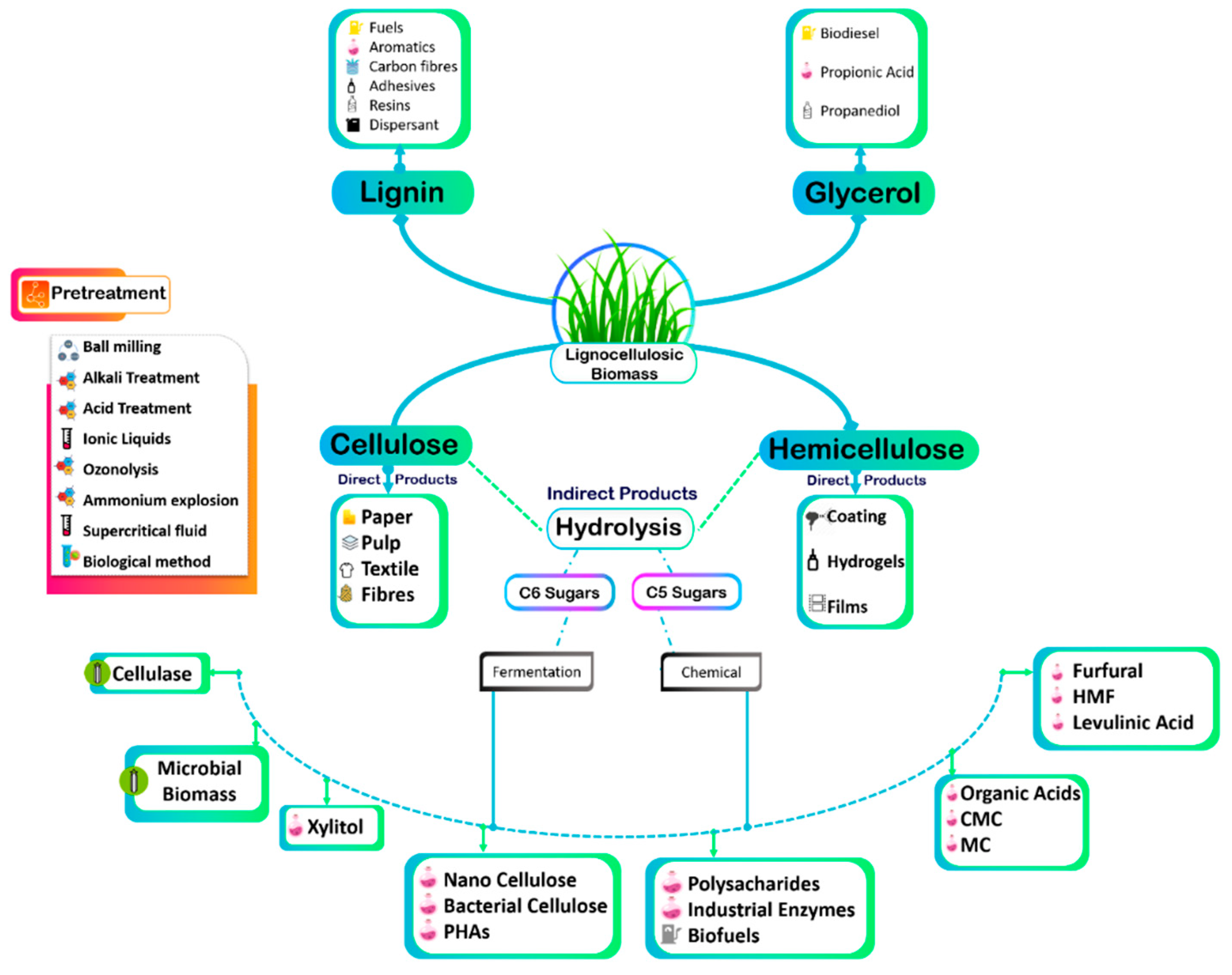

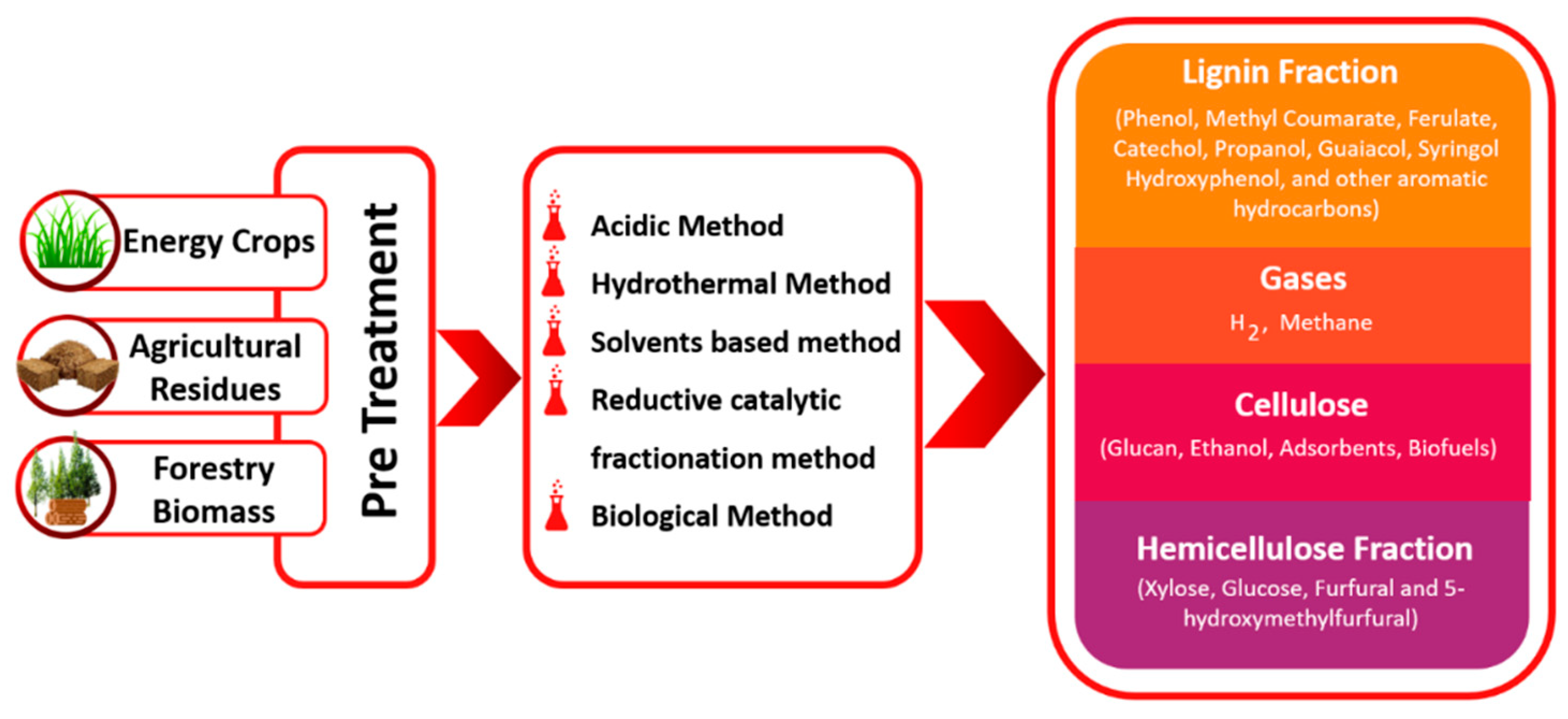

2. Fractionation of Biopolymers for Biofuel and Chemicals

| Substrate | Method | Conditions | Monomers | Yield | References |

|---|---|---|---|---|---|

| Black liquor | Hydrothermal treatment followed by wet oxidation | 115–220 °C and N2 | Monosaccharide | <73% | [15] |

| Birch chips | Reductive Catalytic Fractionation | RuN/ZnO/C catalyst and Methanol | Phenolic monomers | 46.4 wt% lignin | [16] |

| Monosaccharide | 82 wt% cellulose | Monosaccharide | 82 wt% cellulose | ||

| Wheat straw | Hydrothermal Treatment | 220 °C | Monosaccharide | 43% | [17] |

| Paulownia wood | Microwave treatment followed by hydrothermal | 200–230 °C | Monosaccharide | 80% | [18] |

| Pinewood | Green solvent (Dimethyl Carbonate) | H2SO4 as catalyst; ethylene glycol as stabilizing agent | Phenolic monomers | 9 wt% | [19] |

| Monosaccharide | 84.7% | ||||

| Poplar | Acid-Catalyzed Biphasic Water/Phenol System | Acidic water/phenol at 120 °C | Monosaccharide | 77% | [13] |

| Dry olive pomace | Hydrothermal treatment followed by dilute acid | 115–220 °C and 1–2% sulfuric acid | Monosaccharide | <85% | [20] |

| Sawdusts of spruce | Ionic liquids followed by fermentation | 1-ethyl-3-methylimidazolium acetate | Monosaccharide | 49.3% | [21] |

| Ethanol | 54.5% | ||||

| Sawdusts of oak | Monosaccharide | 59.3% | |||

| Ethanol | 53.9% | ||||

| Corn Stover | Reductive Catalytic Fractionation followed by biphasic extraction | 5 wt% Ru/C powder and 2 wt% Ru/alumina pellets | Phenolic monomers | 45.8 ± 1.2 wt% lignin | [22] |

| Switchgrass | 41.5 ± 0.9 wt% lignin | ||||

| Miscanthus | 43.8 ± 1.0 wt% lignin | ||||

| Sugarcane bagasse | 33.7 ± 2.4 wt% lignin | ||||

| Wheat Straw | 20.0 ± 2.2 wt% lignin | ||||

| Flax Shave | Reductive Catalytic Fractionation | 3 wt% Ru/C and Ethanol | Phenolic monomers | 9.5 wt% lignin | [23] |

| Black liquor solid | Hydrothermal | 300 °C | Phenolic monomers | 86.7% | [24] |

| Pine wood | Reductive Catalytic Fractionation | 5 wt% Pd/C and Methanol | Phenolic monomers | 56.3 wt% lignin | [25] |

| Eucalyptus grandis | Reductive Catalytic Fractionation followed by FeCl3 catalysis | 10 wt% Pd/C and Methanol | Phenolic monomers | 49.8 wt% lignin | [26] |

| Monosaccharide | 87.9 wt% cellulose | ||||

| Miscanthus × giganteus | Deep Eutectic Solvents | Choline chloride/glycerol with heteropoly acids | Monosaccharide | 80% | [27] |

| Black liquor | Hydrothermal treatment followed by alkali | 300 °C and alkalis (NaOH, KOH, Na2CO3 and K2CO3) | Phenolic monomers | 22 wt% | [28] |

| Black locust bark | Reductive Catalytic Fractionation followed by liquid/liquid extraction | Ru/C and Methanol | Phenolic monomers | 35.1 wt% lignin | [29] |

| Bamboo sawdust | Reductive Catalytic Fractionation followed by enzymatic hydrolysis process | Pd/C and Methanol | Phenolic monomers | <32.2 wt% lignin | [30] |

| Monosaccharide | <80.6 wt% cellulose | ||||

| Birch sawdust | Reductive Catalytic Fractionation | Co/C and Ethanol | Phenolic monomers | 34 wt% lignin | [31] |

| Wheat straw | Organic solvents followed by alkaline treatment and fermentation | Acetone | Phenolic monomers | <16% | [32] |

| Ethanol | <71.1% | ||||

| Willow (Salix matsudana cv. Zhuliu) | Deep Eutectic Solvents | Choline chloride to lactic acid (molar ratio 1:2, 1:4, 1:6, 1:8, 1:10, 1:12) | Phenolic monomers | 91.8 wt% lignin | [33] |

| Municipal solid wastes and corn stover (20:80) | Ionic liquids followed by acid hydrolysis | 1-Ethyl-3-methylimidazolium chloride and 1-Butyl-3-methylidazolium chloride with | Phenolic monomers | 22% | [34] |

| Monosaccharide | 51–70% | ||||

| Eucalyptus | Ionic liquids followed by fermentation | 1-butyl-3-methylimidazolium acetate | Monosaccharide | <42.6% | [35] |

| Cedar | <42.1% | ||||

| Corn Stover | Reductive Catalytic Fractionation | 5 wt% Ni/C and Methanol | Phenolic monomers | 28–30 wt% lignin | [36] |

| Wheat straw | Deep Eutectic Solvents | Choline chloride to oxalic acid dihydrate | Phenolic monomers | 57.9% | [37] |

| Corn cob | Mild acid followed by hydrothermal | 310 °C | Phenolic monomers | 1.26 wt% lignin | [38] |

| Switchgrass | Ionic liquids | 1-butyl-3-methylimidazolium acetate | Monosaccharide | <60.1% | [39] |

| Phenolic monomers | <86.6% | ||||

| Wheat straw | Organic solvent followed by acid hydrolysis | 50% w/w aqueous EtOH | Phenolic monomers | 84% | [40] |

| Monosaccharide | 86% | ||||

| Eucalyptus wood chips | Organic solvent followed by acid catalysis | Methyl isobutyl ketone:methanol:water (25:42:33) with 5%H3PO4 | Phenolic monomers | 13.7 wt% | [41] |

| Monosaccharide | 17.8 wt% | ||||

| wheat straw | Sequential acid–alkaline treatment | dilute sulfuric acid (DAP) (0.1–0.75%, v/v) and dilute sodium hydroxide (AKP) (0.25–3%, w/v) with <121 °C and reaction times (5–60 min) | Monosaccharide | 78% | [42] |

3. Necessity of Fractionation: Advantages and Disadvantages

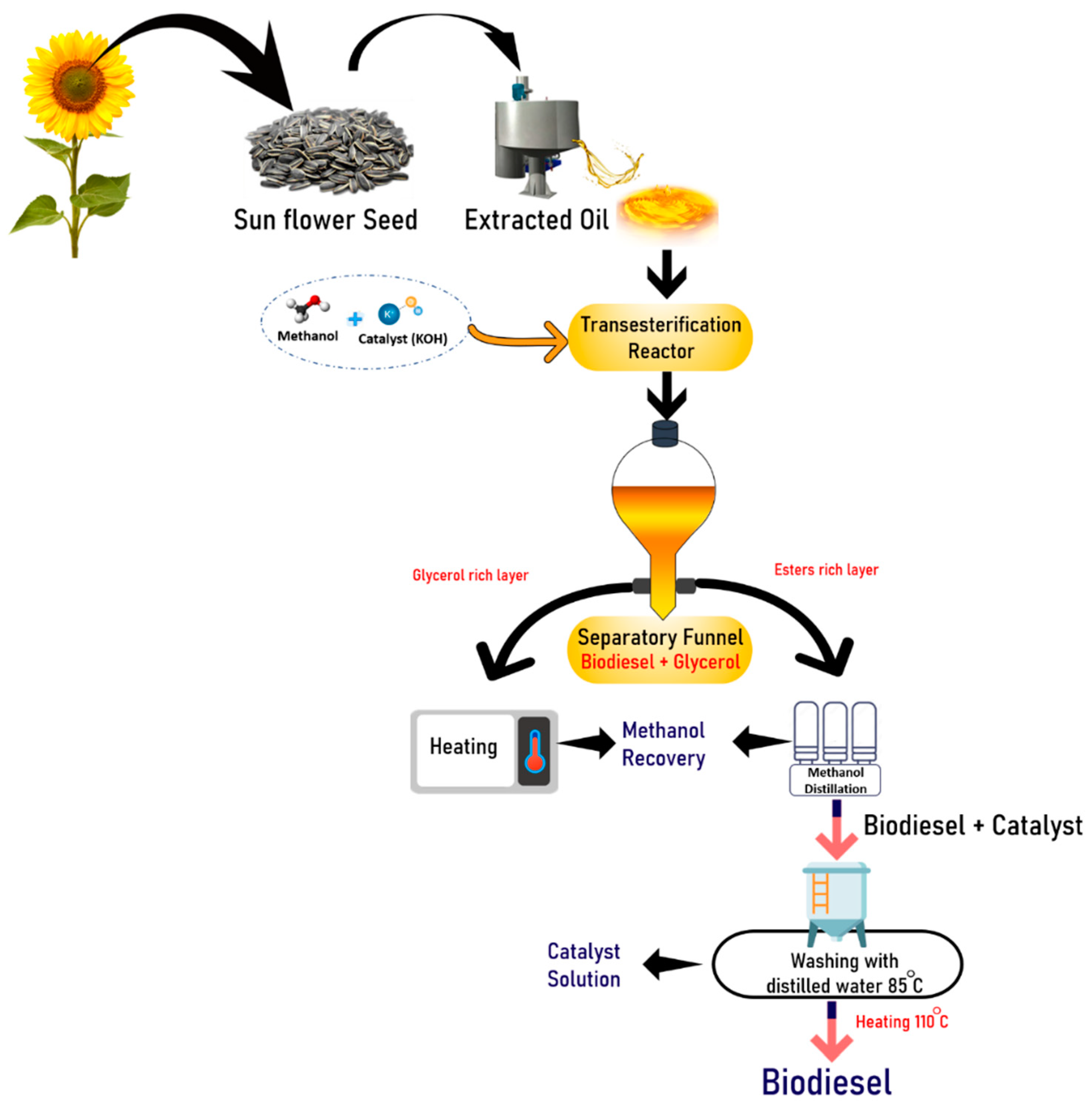

4. Concept of Biorefinery

| S. No. | Biorefinery Type | Feedstock | Processes Involved | Final Products | Product Yield | Reference |

|---|---|---|---|---|---|---|

| 1 | Phase I | Castor oil | Fe3O4 nanoparticles and ethylene glycol in a transesterification process, as an additive. | Biolubricant | 94% | [83] |

| 2 | Phase I | Prosopis julifera seed | MgO nanocatalyst and ethanol in a transesterification process, as an additive. | Biodiesel | 94.83% | [84] |

| 3 | Phase I | Castor oil | Catalytic immobilized cation using mussel shell based CaO doped with praseodymium as catalyst (Pr-CaO) | Biodiesel | 87.42% | [85] |

| 4 | Phase II | birch sawdust (SD) | acidogenic fermentation (AF) and anerobic digestion | Green hydrogen along with carboxylic acids, biomethane, biohythane | bio H₂ (121.4 mL/gVS), carboxylic acids (0.24 g/g VS), bioCH4 (246 mL/gVS), biohythane (8-14L) | [86] |

| 5 | Phase II | birch wood | catalytic hydrogenolysis (using Pd/C) and hydrothermal processes | phenolic monomers and carbon quantum dots (CQDs) | phenolic monomers (44.6 wt%), CQDs (21.7%) | [87] |

| 6 | Phase I | Black mustard seed oil | Transesterification using KOH and NaOH as catalyst | Biodiesel | 97.34% | [88] |

| 7 | Phase I | Rubber oil | base catalyzed transesterification using KOH as catalyst | Biodiesel | 98.71% | [89] |

| 8 | Phase II | Eucalyptus biomass | reductive catalytic fractionation followed by FeCl3 catalysis, respectively | Phenolic monomers, 5-hydroxymethylfurfural, levulinic acid and furfural | Phenolic monomers (49.8 wt%) | [90] |

| 9 | Phase I | Hiptage benghalensis seed | Transesterification | Biodiesel | ∼93%. | [91] |

| 10 | Phase I | Sterculia foetida seed | In-situ acid catalyzed transesterification | Biodiesel | 95.91% | [26] |

| 11 | Phase I | Sterculia foetida oil | In-situ acid catalyzed transesterification | Biodiesel | 91.58% | [26] |

| 12 | Phase III | birch wood | Catalytic Transformation using Pd/C followed by catalytic transfer hydrogenation via Ru/Nb2O5 catalyst and THF/concentrated seawater biphasic system | Furfural, 5-hydroxymethylfurfural, Arenes | -HMF and furfural (upto 24.5 wt%); Arenes (upto 85.6 wt%) | [92] |

| beech wood | ||||||

| corn stalks | ||||||

| pine wood | ||||||

| 13 | Phase I | Pistacia chinensis seed oil | Catalytic immobilized cation using (GO-SO3H/CM@Fe3O4) | Biodiesel | 94% | [93] |

| 14 | Phase I | waste cooking oil (WCO) | base catalyzed transesterification using KOH as catalyst | Biodiesel | 94% | [94] |

| 15 | Phase I | Sterculia feotida oil | Tranesterification using KOH as catalyst and ultrasound anf infrared techniques | Biodiesel | 98.55% (infrared), (99.41%) (ultrasound) | [95] |

| 16 | Phase II | Castor plant | Saccharification, Fermentation and Transesterfication | Bioethanol and Biodiesel | 81.1 g ethanol/kg castor plant, 85% biodiesel | [96] |

| 17 | Phase 1 | Waste cooking oil | Catalytic immobilized cation using CZO nanocomposite | Biodiesel | 97.71% | [97] |

| 18 | Phase I | waste cooking oil | base catalyzed transesterification using KOH as catalyst | Biodiesel | 99.38 wt% | [98] |

| 19 | Phase III | Coffee waste Sugarcane Oil palm Banana Rice, corn, cut flowers | Process 1- fermentation of the sugars present in the waste by a thermotolerant mutant Kluyveromyces marxianus | Bioethanol, ammonia-fertilizer, Bio chemicals, bio-oils, Gasoline | - | [99] |

| Process 2- Conversion of resulting sugar-depleted solids(mostly protein) by Yarrowia lipolytica NRRL YB-567var. | ||||||

| Process 3- Conversion of the lignocellulosic fraction of the waste by Saccharomyces cerevisiae NRRL Y-50183 | ||||||

| Process 4- anaerobic digestion by RhodotorulaglutinisNRRL Y-12906 | ||||||

| Process 5- pyrocracking processes to produce renewable gasoline and biochar. | ||||||

| 20 | Phase III | Waste newspaper + High-density polyethylene | Pyrolysis at heating rate of 20 Cms−1 and the final temperature from 500–800 °C for 50 s | Aalcohols and Hydrocarbons | 85.88% | [100] |

| 21 | Phase III | Coconut husks + Waste tamarind seeds | Green solvent (deep eutectic solvent composed of choline chloride and oxalic acid dihydrate) | Biodegradable plastics | - | [101] |

| 22 | Phase III | Birch wood | Catalytic hydrogenolysis | Carbon Quantum Dots | [102] | |

| Monomeric phenols | 4-propanol guaiacol (10.2 wt%) and 4-propanol syringol (29.7 wt%) | |||||

| 23 | Phase III | Wheat straw + Waste polyurethane (PU) plastic | Pyrolysis at a heating rate of 20 Cmin−1 | Gas (hydrogen, methane, carbondioxide), char and tar | - | [103] |

| 24 | Phase III | Bean crop residues + plastic sheets (LDPE) and spent strawberry growing medium + plastic growbags (LDPE) | Slow pyrolysis | Biochar | 34–50% | [104] |

| 25 | Phase III | Birch sawdust | Organosolv fractionation followed by acidogenic conversion and anerobic fermentation | Biohydrogen | 71% | [86] |

| Biomethane | 78–84% | |||||

| Biohythane, carboxylic acids | - | |||||

| 26 | Phase III | Agricultural waste | Acidogenic fermentation followed by anaerobic digestion | Biogas, fertilizers, compost, polyhydroxyalkanoates and volatile fatty acids | - | [105] |

| 27 | Phase III | Corn strover | Heat intergration followed by fermentation | Biodesiel, Bioglycerol | - | [106] |

| 28 | Phase III | Bamboo biomass | Hydrothermal and steam expolosion treatment followed by fermentation | Biohydrogen | 34.20% | [107] |

| 29 | Phase III | Wwheat bran + Sago waste + Rice bran | Fermentation using Bacillus sp. PM06 | Bioethanol | 27.67% | [108] |

| Multiple enzymes, acetic acid | ||||||

| 30 | Phase III | Residual Cardoon | Steam explosion | Enzymes, Biogas and 1,4-butanediol | - | [109] |

| 31 | Phase III | Eucalyptus sawdust | Reductive catalytic fractionation | Phenolics | 26.4–49.8% | [110] |

| Levulinic acid | 73.60% | |||||

| Furfural | 55.90% | |||||

| 32 | Phase | Almond shell waste stream | Organosolv fractionation using ethanol/water (70/30 v/v) | Phenolic alcohols | - | [111] |

| 33 | Phase III | Grass biomass | Alklaine treatment using 1 wt% NaOH | Hydroxycinnamates, pcoumaric acid ferulic acid | - | [26] |

4.1. Diverse Feedstocks, Multiple Processes and Multiple Products

4.2. Nanotechnology and Lignocellulosic Biorefineries

5. Key Factors Involved in Techno Economic Aspects of Biorefinery

5.1. Availability of Feedstocks

5.2. Conveyance

5.3. Downstream Processing Cost

5.4. Scale Up Obstructions and Hurdles

6. Commercialization and Market Outlook

7. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gundupalli, M.P.; Sriariyanun, M. Recent Trends and Updates for Chemical Pretreatment of Lignocellulosic Biomass. Appl. Sci. Eng. Prog. 2022, 16, 5842. [Google Scholar] [CrossRef]

- Rathore, A.S.; Singh, A. Biomass to Fuels and Chemicals: A Review of Enabling Processes and Technologies. J. Chem. Technol. Biotechnol. 2021, 97, 597–607. [Google Scholar] [CrossRef]

- Okolie, J.A.; Nanda, S.; Dalai, A.K.; Kozinski, J.A. Chemistry and Specialty Industrial Applications of Lignocellulosic Biomass. Waste Biomass Valorization 2021, 12, 2145–2169. [Google Scholar] [CrossRef]

- Sriariyanun, M.; Kitsubthawee, K. Trends in Lignocellulosic Biorefinery for Production of Value-Added Biochemicals. Appl. Sci. Eng. Prog. 2020, 13, 283–284. [Google Scholar] [CrossRef]

- Cheng, Y.-S.; Mutrakulcharoen, P.; Chuetor, S.; Cheenkachorn, K.; Tantayotai, P.; Panakkal, E.J.; Sriariyanun, M. Recent Situation and Progress in Biorefining Process of Lignocellulosic Biomass: Toward Green Economy. Appl. Sci. Eng. Prog. 2020, 13, 299–311. [Google Scholar] [CrossRef]

- Rabaçal, M.; Ferreira, A.F.; Silva, C.A.M.; Editors, M.C. Biorefineries Targeting Energy, High Value Products and Waste Valorisation; Springer: Berlin/Heidelberg, Germany, 2017; Volume 57. [Google Scholar]

- Zhang, K.; Pei, Z.; Wang, D. Organic Solvent Pretreatment of Lignocellulosic Biomass for Biofuels and Biochemicals: A Review. Bioresour. Technol. 2016, 199, 21–33. [Google Scholar] [CrossRef]

- Brodeur, G.; Yau, E.; Badal, K.; Collier, J.; Ramachandran, K.B.; Ramakrishnan, S. Chemical and Physicochemical Pretreatment of Lignocellulosic Biomass: A Review. Enzym. Res. 2011, 2011, 1–17. [Google Scholar] [CrossRef]

- Isikgor, F.H.; Becer, C.R. Lignocellulosic Biomass: A Sustainable Platform for the Production of Bio-Based Chemicals and Polymers. Polym. Chem. 2015, 6, 4497–4559. [Google Scholar] [CrossRef]

- Galbe, M.; Wallberg, O. Pretreatment for Biorefineries: A Review of Common Methods for Efficient Utilisation of Lignocellulosic Materials. Biotechnol. Biofuels 2019, 12, 1–26. [Google Scholar] [CrossRef]

- Shen, X.; Sun, R. Recent Advances in Lignocellulose Prior-Fractionation for Biomaterials, Biochemicals, and Bioenergy. Carbohydr. Polym. 2021, 261, 117884. [Google Scholar] [CrossRef]

- Zhang, Y.; Ni, S.; Wu, R.; Fu, Y.; Qin, M.; Willför, S.; Xu, C. Green Fractionation Approaches for Isolation of Biopolymers and the Critical Technical Challenges. Ind. Crops Prod. 2022, 177, 114451. [Google Scholar] [CrossRef]

- Wang, G.; Qi, S.; Xia, Y.; Parvez, A.M.; Si, C.; Ni, Y. Mild One-Pot Lignocellulose Fractionation Based on Acid-Catalyzed Biphasic Water/Phenol System to Enhance Components’ Processability. ACS Sustain. Chem. Eng. 2020, 8. [Google Scholar] [CrossRef]

- Medina, J.D.C.; Woiciechowski, A.; Filho, A.Z.; Noseda, M.D.; Kaur, B.S.; Soccol, C.R. Lignin Preparation from Oil Palm Empty Fruit Bunches by Sequential Acid/Alkaline Treatment—A Biorefinery Approach. Bioresour. Technol. 2015, 194, 172–178. [Google Scholar] [CrossRef] [PubMed]

- Maitz, S.; Siebenhofer, M.; Kienberger, M. Conversion of Carbohydrates to Carboxylic Acids during Hydrothermal and Oxidative Treatment of Concentrated Kraft Black Liquor. SSRN Electron. J. 2022, 19, 101148. [Google Scholar] [CrossRef]

- Liu, Z.; Li, H.; Gao, X.; Guo, X.; Wang, S.; Fang, Y.; Song, G. Rational Highly Dispersed Ruthenium for Reductive Catalytic Fractionation of Lignocellulose. Nat. Commun. 2022, 13, 4716. [Google Scholar] [CrossRef]

- Rodríguez, F.; Aguilar-Garnica, E.; Santiago-Toribio, A.; Sánchez, A. Polysaccharides Release in a Laboratory-Scale Batch Hydrothermal Pretreatment of Wheat Straw under Rigorous Isothermal Operation. Molecules 2022, 27, 26. [Google Scholar] [CrossRef]

- del Río, P.G.; Gullón, B.; Romaní, A.; Garrote, G. Fast-Growing Paulownia Wood Fractionation by Microwave-Assisted Hydrothermal Treatment: A Kinetic Assessment. Bioresour. Technol. 2021, 338, 125535. [Google Scholar] [CrossRef]

- de Santi, A.; Galkin, M.V.; Lahive, C.W.; Deuss, P.J.; Barta, K. Lignin-First Fractionation of Softwood Lignocellulose Using a Mild Dimethyl Carbonate and Ethylene Glycol Organosolv Process. ChemSusChem 2020, 13, 4468–4477. [Google Scholar] [CrossRef]

- Manzanares, P.; Ballesteros, I.; Negro, M.J.; González, A.; Oliva, J.M.; Ballesteros, M. Processing of Extracted Olive Oil Pomace Residue by Hydrothermal or Dilute Acid Pretreatment and Enzymatic Hydrolysis in a Biorefinery Context. Renew. Energy 2020, 145, 1235–1245. [Google Scholar] [CrossRef]

- Alayoubi, R.; Mehmood, N.; Husson, E.; Kouzayha, A.; Tabcheh, M.; Chaveriat, L.; Sarazin, C.; Gosselin, I. Low Temperature Ionic Liquid Pretreatment of Lignocellulosic Biomass to Enhance Bioethanol Yield. Renew. Energy 2020, 145, 1808–1816. [Google Scholar] [CrossRef]

- Ebikade, O.E.; Samulewicz, N.; Xuan, S.; Sheehan, J.D.; Wu, C.; Vlachos, D.G. Reductive Catalytic Fractionation of Agricultural Residue and Energy Crop Lignin and Application of Lignin Oil in Antimicrobials. Green Chem. 2020, 22, 7435–7447. [Google Scholar] [CrossRef]

- Kazachenko, A.S.; Tarabanko, V.E.; Miroshnikova, A.V.; Sychev, V.V.; Skripnikov, A.M.; Malyar, Y.N.; Mikhlin, Y.L.; Baryshnikov, S.V.; Taran, O.P. Reductive Catalytic Fractionation of Flax Shive over Ru/c Catalysts. Catalysts 2021, 11, 42. [Google Scholar] [CrossRef]

- Zhao, Y.; Tian, Y.; Zhou, H.; Tian, Y. Hydrothermal Conversion of Black Liquor to Phenolics and Hydrochar: Characterization, Application and Comparison with Lignin. Fuel 2020, 280, 118651. [Google Scholar] [CrossRef]

- van Aelst, K.; van Sinay, E.; Vangeel, T.; Cooreman, E.; van den Bossche, G.; Renders, T.; van Aelst, J.; van den Bosch, S.; Sels, B.F. Reductive Catalytic Fractionation of Pine Wood: Elucidating and Quantifying the Molecular Structures in the Lignin Oil. Chem. Sci. 2020, 11, 1498–11508. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, K.; Xiao, L.P.; Sun, R.C.; Song, G. Total Utilization of Lignin and Carbohydrates in Eucalyptus Grandis: An Integrated Biorefinery Strategy towards Phenolics, Levulinic Acid, and Furfural. Biotechnol. Biofuels 2020, 13, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Guo, Z.; Zhang, Q.; You, T.; Ji, Z.; Zhang, X.; Qin, Y.; Xu, F. Heteropoly Acids Enhanced Neutral Deep Eutectic Solvent Pretreatment for Enzymatic Hydrolysis and Ethanol Fermentation of Miscanthus × Giganteus under Mild Conditions. Bioresour. Technol. 2019, 293, 122036. [Google Scholar] [CrossRef] [PubMed]

- Peng, C.; Zhang, G.; Han, J.; Li, X. Hydrothermal Conversion of Lignin and Black Liquor for Phenolics with the Aids of Alkali and Hydrogen Donor. Carbon Resour. Convers. 2019, 2, 141–150. [Google Scholar] [CrossRef]

- Vangeel, T.; Renders, T.; van Aelst, K.; Cooreman, E.; van den Bosch, S.; van den Bossche, G.; Koelewijn, S.F.; Courtin, C.M.; Sels, B.F. Reductive Catalytic Fractionation of Black Locust Bark. Green Chem. 2019, 21, 5841–5851. [Google Scholar] [CrossRef]

- Zhang, K.; Li, H.; Xiao, L.P.; Wang, B.; Sun, R.C.; Song, G. Sequential Utilization of Bamboo Biomass through Reductive Catalytic Fractionation of Lignin. Bioresour. Technol. 2019, 285, 121335. [Google Scholar] [CrossRef]

- Rautiainen, S.; di Francesco, D.; Katea, S.N.; Westin, G.; Tungasmita, D.N.; Samec, J.S.M. Lignin Valorization by Cobalt-Catalyzed Fractionation of Lignocellulose to Yield Monophenolic Compounds. ChemSusChem 2019, 12, 404–408. [Google Scholar] [CrossRef]

- Yuan, Z.; Wen, Y.; Kapu, N.S.; Beatson, R. Evaluation of an Organosolv-Based Biorefinery Process to Fractionate Wheat Straw into Ethanol and Co-Products. Ind. Crops Prod. 2018, 121, 294–302. [Google Scholar] [CrossRef]

- Li, R.; Kong, J.; Liu, H.; Chen, P.; Liu, G.; Li, F.; Lv, W. A Sulfate Radical Based Ferrous-Peroxydisulfate Oxidative System for Indomethacin Degradation in Aqueous Solutions. RSC Adv. 2017, 7, 22802–22809. [Google Scholar] [CrossRef]

- Li, C.; Liang, L.; Sun, N.; Thompson, V.S.; Xu, F.; Narani, A.; He, Q.; Tanjore, D.; Pray, T.R.; Simmons, B.A.; et al. Scale-up and Process Integration of Sugar Production by Acidolysis of Municipal Solid Waste/Corn Stover Blends in Ionic Liquids. Biotechnol. Biofuels 2017, 10, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Yamada, R.; Nakashima, K.; Asai-Nakashima, N.; Tokuhara, W.; Ishida, N.; Katahira, S.; Kamiya, N.; Ogino, C.; Kondo, A. Direct Ethanol Production from Ionic Liquid-Pretreated Lignocellulosic Biomass by Cellulase-Displaying Yeasts. Appl. Biochem. Biotechnol. 2017, 182, 229–237. [Google Scholar] [CrossRef]

- Anderson, E.M.; Katahira, R.; Reed, M.; Resch, M.G.; Karp, E.M.; Beckham, G.T.; Román-Leshkov, Y. Reductive Catalytic Fractionation of Corn Stover Lignin. ACS Sustain. Chem. Eng. 2016, 4, 6940–6950. [Google Scholar] [CrossRef]

- Jablonský, M.; Škulcová, A.; Kamenská, L.; Vrška, M.; Šima, J. Deep Eutectic Solvents: Fractionation of Wheat Straw. Bioresources 2015, 10, 8039–8047. [Google Scholar] [CrossRef]

- Wang, C.; Lyu, G.; Yang, G.; Chen, J.; Jiang, W. Characterization and Hydrothermal Conversion of Lignin Produced from Corncob Acid Hydrolysis Residue. Bioresources 2014, 9, 4596–4607. [Google Scholar] [CrossRef]

- Sun, N.; Parthasarathi, R.; Socha, A.M.; Shi, J.; Zhang, S.; Stavila, V.; Sale, K.L.; Simmons, B.A.; Singh, S. Understanding Pretreatment Efficacy of Four Cholinium and Imidazolium Ionic Liquids by Chemistry and Computation. Green Chem. 2014, 16, 2546–2557. [Google Scholar] [CrossRef]

- Wildschut, J.; Smit, A.T.; Reith, J.H.; Huijgen, W.J.J. Ethanol-Based Organosolv Fractionation of Wheat Straw for the Production of Lignin and Enzymatically Digestible Cellulose. Bioresour. Technol. 2013, 135, 58–66. [Google Scholar] [CrossRef]

- Klamrassamee, T.; Champreda, V.; Reunglek, V.; Laosiripojana, N. Comparison of Homogeneous and Heterogeneous Acid Promoters in Single-Step Aqueous-Organosolv Fractionation of Eucalyptus Wood Chips. Bioresour. Technol. 2013, 147, 276–284. [Google Scholar] [CrossRef]

- Sanchez, A.; Gil, J.C.; Rojas-Rejón, O.A.; de Alba, A.P.; Medina, A.; Flores, R.; Puente, R. Sequential Pretreatment Strategies under Mild Conditions for Efficient Enzymatic Hydrolysis of Wheat Straw. Bioprocess Biosyst. Eng. 2015, 38, 1127–1141. [Google Scholar] [CrossRef] [PubMed]

- del Río, P.G.; Gullón, B.; Wu, J.; Saddler, J.; Garrote, G.; Romaní, A. Current Breakthroughs in the Hardwood Biorefineries: Hydrothermal Processing for the Co-Production of Xylooligosaccharides and Bioethanol. Bioresour. Technol. 2022, 343, 126100. [Google Scholar] [CrossRef] [PubMed]

- Gomes, D.G.; Teixeira, J.A.; Domingues, L. Economic Determinants on the Implementation of a Eucalyptus Wood Biorefinery Producing Biofuels, Energy and High Added-Value Compounds. Appl. Energy 2021, 303, 117662. [Google Scholar] [CrossRef]

- Sun, Z.; Liu, X.; Dong, X.; Zhang, X.; Tan, Y.; Yuan, F.; Zheng, S.; Li, C. Synergistic Activation of Peroxymonosulfate via in Situ Growth FeCo2O4 Nanoparticles on Natural Rectorite: Role of Transition Metal Ions and Hydroxyl Groups. Chemosphere 2021, 263, 127965. [Google Scholar] [CrossRef] [PubMed]

- Ferreira, J.A.; Taherzadeh, M.J. Improving the Economy of Lignocellulose-Based Biorefineries with Organosolv Pretreatment. Bioresour. Technol. 2020, 299, 122695. [Google Scholar] [CrossRef] [PubMed]

- Amini, E.; Valls, C.; Roncero, M.B. Ionic Liquid-Assisted Bioconversion of Lignocellulosic Biomass for the Development of Value-Added Products. J. Clean. Prod. 2021, 326, 129275. [Google Scholar] [CrossRef]

- Scelsi, E.; Angelini, A.; Pastore, C. Deep Eutectic Solvents for the Valorisation of Lignocellulosic Biomasses towards Fine Chemicals. Biomass 2021, 1, 29–59. [Google Scholar] [CrossRef]

- Yu, D.; Mou, H.; Fu, H.; Lan, X.; Wang, Y.; Mu, T. “Inverted” Deep Eutectic Solvents Based on Host-Guest Interactions. Chem. Asian J. 2019, 14, 4183–4188. [Google Scholar] [CrossRef]

- Smith, E.L.; Abbott, A.P.; Ryder, K.S. Deep Eutectic Solvents (DESs) and Their Applications. Chem. Rev. 2014, 114, 11060–11082. [Google Scholar] [CrossRef]

- Abbott, A.P.; Boothby, D.; Capper, G.; Davies, D.L.; Rasheed, R.K. Deep Eutectic Solvents Formed between Choline Chloride and Carboxylic Acids: Versatile Alternatives to Ionic Liquids. J. Am. Chem. Soc. 2004, 126, 9142–9147. [Google Scholar] [CrossRef]

- Hak, C.; Panchai, P.; Nutongkaew, T.; Grisdanurak, N.; Tulaphol, S. One-Pot Levulinic Acid Production from Rice Straw by Acid Hydrolysis in Deep Eutectic Solvent. Chem. Eng. Commun. 2022, 1–13. [Google Scholar] [CrossRef]

- Li, P.; Yang, C.; Jiang, Z.; Jin, Y.; Wu, W. Lignocellulose Pretreatment by Deep Eutectic Solvents and Related Technologies: A Review. J. Bioresour. Bioprod. 2023, 8, 33–44. [Google Scholar] [CrossRef]

- Song, Y.; Chandra, R.P.; Zhang, X.; Tan, T.; Saddler, J.N. Comparing a Deep Eutectic Solvent (DES) to a Hydrotrope for Their Ability to Enhance the Fractionation and Enzymatic Hydrolysis of Willow and Corn Stover. Sustain. Energy Fuels 2019, 3, 1329–1337. [Google Scholar] [CrossRef]

- Cheng, C.; Li, P.; Yu, W.; Shen, D.; Gu, S. Catalytic Hydrogenolysis of Lignin in Ethanol/Isopropanol over an Activated Carbon Supported Nickel-Copper Catalyst. Bioresour. Technol. 2021, 319, 124238. [Google Scholar] [CrossRef]

- Menezes, D.B.; Brazil, O.A.V.; Romanholo-Ferreira, L.F.; de Lourdes, T.M.; Polizeli, M.; Ruzene, D.S.; Silva, D.P.; Costa, L.P.; Hernández-Macedo, M.L. Prospecting Fungal Ligninases Using Corncob Lignocellulosic Fractions. Cellulose 2017, 24, 4355–4365. [Google Scholar] [CrossRef]

- Alonso, D.M.; Hakim, S.H.; Zhou, S.; Won, W.; Hosseinaei, O.; Tao, J.; Garcia-Negron, V.; Motagamwala, A.H.; Mellmer, M.A.; Huang, K.; et al. Increasing the Revenue from Lignocellulosic Biomass: Maximizing Feedstock Utilization. Sci. Adv. 2017, 3, e1603301. [Google Scholar] [CrossRef] [PubMed]

- Bittencourt, G.A.; da Barreto, E.S.; Brandão, R.L.; Baêta, B.E.L.; Gurgel, L.V.A. Fractionation of Sugarcane Bagasse Using Hydrothermal and Advanced Oxidative Pretreatments for Bioethanol and Biogas Production in Lignocellulose Biorefineries. Bioresour. Technol. 2019, 292, 121963. [Google Scholar] [CrossRef]

- Xu, J.; Dai, L.; Zhang, C.; Gui, Y.; Yuan, L.; Lei, Y.; Fan, B. Ionic Liquid-Aided Hydrothermal Treatment of Lignocellulose for the Synergistic Outputs of Carbon Dots and Enhanced Enzymatic Hydrolysis. Bioresour. Technol. 2020, 305, 123043. [Google Scholar] [CrossRef]

- Cheng, Y.; Qu, Y.; Yang, S.; Zhuang, K.; Wang, J. Staged Biorefinery of Moso Bamboo by Integrating Polysaccharide Hydrolysis and Lignin Reductive Catalytic Fractionation (RCF) for the Sequential Production of Sugars and Aromatics. Ind. Crops Prod. 2021, 164, 113358. [Google Scholar] [CrossRef]

- Kuznetsov, B.N.; Baryshnikov, S.V.; Miroshnikova, A.V.; Kazachenko, A.S.; Malyar, Y.N.; Skripnikov, A.M.; Taran, O.P. Fractionation of Birch Wood by Integrating Alkaline-Acid Treatments and Hydrogenation in Ethanol over a Bifunctional Ruthenium Catalyst. Catalysts 2021, 11, 1362. [Google Scholar] [CrossRef]

- Shen, B.; Hou, S.; Jia, Y.; Yang, C.; Su, Y.; Ling, Z.; Huang, C.; Lai, C.; Yong, Q. Synergistic Effects of Hydrothermal and Deep Eutectic Solvent Pretreatment on Co-Production of Xylo-Oligosaccharides and Enzymatic Hydrolysis of Poplar. Bioresour. Technol. 2021, 341, 125787. [Google Scholar] [CrossRef] [PubMed]

- Toscan, A.; Fontana, R.C.; Andreaus, J.; Camassola, M.; Lukasik, R.M.; Dillon, A.J.P. New Two-Stage Pretreatment for the Fractionation of Lignocellulosic Components Using Hydrothermal Pretreatment Followed by Imidazole Delignification: Focus on the Polysaccharide Valorization. Bioresour. Technol. 2019, 285, 121346. [Google Scholar] [CrossRef] [PubMed]

- Phojaroen, J.; Jiradechakorn, T.; Kirdponpattara, S.; Sriariyanun, M.; Junthip, J.; Chuetor, S. Performance Evaluation of Combined Hydrothermal-Mechanical Pretreatment of Lignocellulosic Biomass for Enzymatic Enhancement. Polymers 2022, 14, 2313. [Google Scholar] [CrossRef] [PubMed]

- Gundupalli, M.P.; Tantayotai, P.; Panakkal, E.J.; Chuetor, S.; Kirdponpattara, S.; Thomas, A.S.S.; Sharma, B.K.; Sriariyanun, M. Hydrothermal Pretreatment Optimization and Deep Eutectic Solvent Pretreatment of Lignocellulosic Biomass: An Integrated Approach. Bioresour. Technol. Rep. 2022, 17, 100957. [Google Scholar] [CrossRef]

- Ou, L.; Dou, C.; Yu, J.-H.; Kim, H.; Park, Y.-C.; Park, S.; Kelley, S.; Lee, E.Y. Techno-Economic Analysis of Sugar Production from Lignocellulosic Biomass with Utilization of Hemicellulose and Lignin for High-Value Co-Products. Biofuels Bioprod. Biorefining 2020, 15, 404–415. [Google Scholar] [CrossRef]

- Zang, G.; Shah, A.; Wan, C. Techno-Economic Analysis of an Integrated Biorefinery Strategy Based on One-Pot Biomass Fractionation and Furfural Production. J. Clean. Prod. 2020, 260, 120837. [Google Scholar] [CrossRef]

- Kulas, D.G.; Thies, M.C.; Shonnard, D.R. Techno-Economic Analysis and Life Cycle Assessment of Waste Lignin Fractionation and Valorization Using the ALPHA Process. ACS Sustain. Chem. Eng. 2021, 9, 5388–5395. [Google Scholar] [CrossRef]

- Rajendran, K.; Murthy, G.S. How Does Technology Pathway Choice Influence Economic Viability and Environmental Impacts of Lignocellulosic Biorefineries? Biotechnol. Biofuels 2017, 10, 268. [Google Scholar] [CrossRef]

- Kim, H.; Lee, S.; Won, W. Economical Process for the Co-Production of Renewable Polymers and Value-Added Chemicals from Lignocellulosic Biomass. J. Clean. Prod. 2020, 276, 124237. [Google Scholar] [CrossRef]

- Bello, S.; Salim, I.; Feijoo, G.; Moreira, M.T. Inventory Review and Environmental Evaluation of First- and Second-Generation Sugars through Life Cycle Assessment. Environ. Sci. Pollut. Res. 2021, 28, 27345–27361. [Google Scholar] [CrossRef]

- Yadav, P.; Athanassiadis, D.; Antonopoulou, I.; Rova, U.; Christakopoulos, P.; Tysklind, M.; Matsakas, L. Environmental Impact and Cost Assessment of a Novel Lignin Production Method. J. Clean. Prod. 2021, 279, 123515. [Google Scholar] [CrossRef]

- Luo, L.; van der Voet, E.; Huppes, G. Biorefining of Lignocellulosic Feedstock Technical, Economic and Environmental Considerations. Bioresour. Technol. 2010, 101, 5023–5032. [Google Scholar] [CrossRef]

- Banu, J.R.; Preethi; Kavitha, S.; Tyagi, V.K.; Gunasekaran, M.; Karthikeyan, O.P.; Kumar, G. Lignocellulosic Biomass Based Biorefinery: A Successful Platform towards Circular Bioeconomy. Fuel 2021, 302, 121086. [Google Scholar] [CrossRef]

- Fernández-Rodríguez, J.; Erdocia, X.; Alriols, M.G.; Labidi, J. Techno-Economic Analysis of Different Integrated Biorefinery Scenarios Using Lignocellulosic Waste Streams as Source for Phenolic Alcohols Production. J. Clean. Prod. 2021, 285, 124829. [Google Scholar] [CrossRef]

- Mirkouei, A.; Haapala, K.R.; Sessions, J.; Murthy, G.S. A Review and Future Directions in Techno-Economic Modeling and Optimization of Upstream Forest Biomass to Bio-Oil Supply Chains. Renew. Sustain. Energy Rev. 2017, 67, 15–35. [Google Scholar] [CrossRef]

- Hess, J.R.; Lamers, P.; Roni, M.S.; Jacobson, J.J.; Heath, B. IEA Bioenergy Task 40 Sustainable International Bioenergy Trade: Securing Supply and Demand (Country Report 2014 United States); Office of Scientific and Technical Information (OSTI): Oak Ridge, TN, USA, 2015.

- van Ree, R.; Sanders, J.; Bakker, R.; Blaauw, R.; Zwart, R.; Drift, B. van der Biofuel-Driven Biorefineries for the Co-Production of Transportation Fuels and Added-Value Products; Woodhead Publishing Limited: Sawston, UK, 2011. [Google Scholar]

- Hingsamer, M.; Jungmeier, G. Biorefineries. In The Role of Bioenergy in the Bioeconomy; Elsevier: Amsterdam, The Netherlands, 2019; pp. 179–222. [Google Scholar]

- Cherubini, F.; Jungmeier, G.; Wellisch, M.; Willke, T.; Skiadas, I.; Van Ree, R.; de Jong, E. Toward a Common Classification Approach for Biorefinery Systems Related Papers Modeling and Analysis Toward a Common Classifi Cation Approach for Biorefi Nery Systems. Biofuels Bioprod. Biorefining 2009, 3, 534–546. [Google Scholar] [CrossRef]

- Valentine, J.; Clifton-Brown, J.; Hastings, A.; Robson, P.; Allison, G.; Smith, P. Food vs. Fuel: The Use of Land for Lignocellulosic ‘next Generation’ Energy Crops That Minimize Competition with Primary Food Production. GCB Bioenergy 2011, 4, 1–19. [Google Scholar] [CrossRef]

- Wellisch, M.; Jungmeier, G.; Karbowski, A.; Patel, M.K.; Rogulska, M. Biorefinery Systems-Potential Contributors to Sustainable Innovation. Biofuels Bioprod. Biorefining 2010, 4, 275–286. [Google Scholar] [CrossRef]

- Brahma, S.; Nath, B.; Basumatary, B.; Das, B.; Saikia, P.; Patir, K.; Basumatary, S. Biodiesel Production from Mixed Oils: A Sustainable Approach towards Industrial Biofuel Production. Chem. Eng. J. Adv. 2022, 10, 100284. [Google Scholar] [CrossRef]

- Naik, S.N.; Goud, V.V.; Rout, P.K.; Dalai, A.K. Production of First and Second Generation Biofuels: A Comprehensive Review. Renew. Sustain. Energy Rev. 2010, 14, 578–597. [Google Scholar] [CrossRef]

- Ahmad, U.; Raza Naqvi, S.; Ali, I.; Saleem, F.; Taqi Mehran, M.; Sikandar, U.; Juchelková, D. Biolubricant Production from Castor Oil Using Iron Oxide Nanoparticles as an Additive: Experimental, Modelling and Tribological Assessment. Fuel 2022, 324, 124565. [Google Scholar] [CrossRef]

- Hundie, K.B.; Akuma, D.A. Optimization of Biodiesel Production Parameters from Prosopis Julifera Seed Using Definitive Screening Design. Heliyon 2022, 8, e08965. [Google Scholar] [CrossRef] [PubMed]

- Khan, S.G.; Hassan, M.; Anwar, M.; Khan, U.M.; Zhao, C. Mussel Shell Based CaO Nano-Catalyst Doped with Praseodymium to Enhance Biodiesel Production from Castor Oil. Fuel 2022, 330, 125480. [Google Scholar] [CrossRef]

- Sarkar, O.; Rova, U.; Christakopoulos, P.; Matsakas, L. Organosolv Pretreated Birch Sawdust for the Production of Green Hydrogen and Renewable Chemicals in an Integrated Biorefinery Approach. Bioresour. Technol. 2022, 344, 126164. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Zhu, J.; Song, W.; Xiao, L.P. Integrated Cascade Biorefinery Processes to Transform Woody Biomass Into Phenolic Monomers and Carbon Quantum Dots. Front. Bioeng. Biotechnol. 2021, 9, 803138. [Google Scholar] [CrossRef]

- Aslan, V.; Eryilmaz, T. Polynomial Regression Method for Optimization of Biodiesel Production from Black Mustard (Brassica nigra L.) Seed Oil Using Methanol, Ethanol, NaOH, and KOH. Energy 2020, 209, 118386. [Google Scholar] [CrossRef]

- Chhabra, M.; Dwivedi, G.; Baredar, P.; Shukla, A.K.; Garg, A.; Jain, S. Production & Optimization of Biodiesel from Rubber Oil Using BBD Technique. Mater. Today Proc. 2021, 38, 69–73. [Google Scholar] [CrossRef]

- Dhar Dubey, K.K.; Jeyaseelan, C.; Upadhyaya, K.C.; Chimote, V.; Veluchamy, R.; Kumar, A. Biodiesel Production from Hiptage Benghalensis Seed Oil. Ind. Crops Prod. 2020, 144, 112027. [Google Scholar] [CrossRef]

- Ms, K. In Situ Acid Catalysed Transesterification of Biodiesel Production from Sterculia Foetida Oil and Seed. Int. J. Green Energy 2019, 16, 1465–1474. [Google Scholar] [CrossRef]

- Guo, T.; Li, X.; Liu, X.; Guo, Y.; Wang, Y. Catalytic Transformation of Lignocellulosic Biomass into Arenes, 5-Hydroxymethylfurfural, and Furfural. ChemSusChem 2018, 11, 2758–2765. [Google Scholar] [CrossRef]

- Li, T.F.; Shen, C.; Zhang, H.X.; Wang, X.Q.; Jiao, J.; Wang, W.; Gai, Q.Y.; Liu, J.Z.; Liu, T.S.; Fu, Y.J. Transesterification of Pistacia Chinensis Seed Oil Using a Porous Cellulose-Based Magnetic Heterogeneous. Int. J. Green Energy 2018, 16, 228–235. [Google Scholar] [CrossRef]

- Sahar; Sadaf, S.; Iqbal, J.; Ullah, I.; Bhatti, H.N.; Nouren, S.; Habib-ur-Rehman; Nisar, J.; Iqbal, M. Biodiesel Production from Waste Cooking Oil: An Efficient Technique to Convert Waste into Biodiesel. Sustain. Cities Soc. 2018, 41, 220–226. [Google Scholar] [CrossRef]

- Kusumo, F.; Silitonga, A.S.; Ong, H.C.; Masjuki, H.H.; Mahlia, T.M.I. A Comparative Study of Ultrasound and Infrared Transesterification of Sterculia Foetida Oil for Biodiesel Production. Energy Sources Part A Recover. Util. Environ. Eff. 2017, 39, 1339–1346. [Google Scholar] [CrossRef]

- Bateni, H.; Karimi, K. Biodiesel Production from Castor Plant Integrating Ethanol Production via a Biorefinery Approach. Chem. Eng. Res. Des. 2016, 107, 4–12. [Google Scholar] [CrossRef]

- Gurunathan, B.; Ravi, A. Biodiesel Production from Waste Cooking Oil Using Copper Doped Zinc Oxide Nanocomposite as Heterogeneous Catalyst. Bioresour. Technol. 2015, 188, 124–127. [Google Scholar] [CrossRef] [PubMed]

- Hamze, H.; Akia, M.; Yazdani, F. Optimization of Biodiesel Production from the Waste Cooking Oil Using Response Surface Methodology. Process Saf. Environ. Prot. 2015, 94, 1–10. [Google Scholar] [CrossRef]

- Galindo-Leva, L.Á.; Hughes, S.R.; López-Núñez, J.C.; Jarodsky, J.M.; Erickson, A.; Lindquist, M.R.; Cox, E.J.; Bischoff, K.M.; Hoecker, E.C.; Liu, S.; et al. Growth, Ethanol Production, and Inulinase Activity on Various Inulin Substrates by Mutant Kluyveromyces Marxianus Strains NRRL Y-50798 and NRRL Y-50799. J. Ind. Microbiol. Biotechnol. 2016, 43, 927–939. [Google Scholar] [CrossRef]

- Chen, W.; Shi, S.; Chen, M.; Zhou, X. Fast Co-Pyrolysis of Waste Newspaper with High-Density Polyethylene for High Yields of Alcohols and Hydrocarbons. Waste Manag. 2017, 67, 155–162. [Google Scholar] [CrossRef]

- De, D.; Naga Sai, M.S.; Aniya, V.; Satyavathi, B. Strategic Biorefinery Platform for Green Valorization of Agro-Industrial Residues: A Sustainable Approach towards Biodegradable Plastics. J. Clean. Prod. 2021, 290, 125178. [Google Scholar] [CrossRef]

- Chen, L.; van Muyden, A.P.; Cui, X.; Fei, Z.; Yan, N.; Laurenczy, G.; Dyson, P.J. Lignin First: Confirming the Role of the Metal Catalyst in Reductive Fractionation. JACS Au 2021, 1, 729–733. [Google Scholar] [CrossRef]

- Wang, X.; Jin, Q.; Wang, L.; Bai, S.; Mikulčić, H.; Vujanović, M.; Tan, H. Synergistic Effect of Biomass and Polyurethane Waste Co-Pyrolysis on Soot Formation at High Temperatures. J. Environ. Manag. 2019, 239, 306–315. [Google Scholar] [CrossRef]

- Rathnayake, D.; Ehidiamhen, P.O.; Egene, C.E.; Stevens, C.V.; Meers, E.; Mašek, O.; Ronsse, F. Investigation of Biomass and Agricultural Plastic Co-Pyrolysis: Effect on Biochar Yield and Properties. J. Anal. Appl. Pyrolysis 2021, 155, 105029. [Google Scholar] [CrossRef]

- Righetti, E.; Nortilli, S.; Fatone, F.; Frison, N.; Bolzonella, D. A Multiproduct Biorefinery Approach for the Production of Hydrogen, Methane and Volatile Fatty Acids from Agricultural Waste. Waste Biomass Valorization 2020, 11, 5239–5246. [Google Scholar] [CrossRef]

- Nhien, L.C.; van Duc Long, N.; Lee, M. Novel Heat-Integrated Hybrid Distillation and Adsorption Process for Coproduction of Cellulosic Ethanol, Heat, and Electricity from Actual Lignocellulosic Fermentation Broth. Energies 2021, 14, 3377. [Google Scholar] [CrossRef]

- Dai, N.H.; Huynh, K.T.T.; Nguyen, T.A.D.; Do, V.V.T.; van Tran, M. Hydrothermal and Steam Explosion Pretreatment of Bambusa Stenostachya Bamboo. Waste Biomass Valorization 2021, 12, 4103–4112. [Google Scholar] [CrossRef]

- Rajesh, R.; Gummadi, S.N. Production of Multienzymes, Bioethanol, and Acetic Acid by Novel Bacillus Sp. PM06 from Various Lignocellulosic Biomass. Biomass Convers. Biorefinery 2022, 1–13. [Google Scholar] [CrossRef]

- de Bari, I.; Giuliano, A.; Petrone, M.T.; Stoppiello, G.; Fatta, V.; Giardi, C.; Razza, F.; Novelli, A. From Cardoon Lignocellulosic Biomass to Bio-1,4 Butanediol: An Integrated Biorefinery Model. Processes 2020, 8, 1585. [Google Scholar] [CrossRef]

- Karlen, S.D.; Fasahati, P.; Mazaheri, M.; Serate, J.; Smith, R.A.; Sirobhushanam, S.; Chen, M.; Tymokhin, V.I.; Cass, C.L.; Liu, S.; et al. Assessing the Viability of Recovery of Hydroxycinnamic Acids from Lignocellulosic Biorefinery Alkaline Pretreatment Waste Streams. ChemSusChem 2020, 13, 2012–2024. [Google Scholar] [CrossRef]

- Zhang, Y.; Oates, L.G.; Serate, J.; Xie, D.; Pohlmann, E.; Bukhman, Y.V.; Karlen, S.D.; Young, M.K.; Higbee, A.; Eilert, D.; et al. Diverse Lignocellulosic Feedstocks Can Achieve High Field-Scale Ethanol Yields While Providing Flexibility for the Biorefinery and Landscape-Level Environmental Benefits. GCB Bioenergy 2018, 10, 825–840. [Google Scholar] [CrossRef]

- Sharma, B.; Brandt, C.; McCullough-Amal, D.; Langholtz, M.; Webb, E. Assessment of the Feedstock Supply for Siting Single- and Multiple-Feedstock Biorefineries in the USA and Identification of Prevalent Feedstocks. Biofuels Bioprod. Biorefining 2020, 14, 578–593. [Google Scholar] [CrossRef]

- Oke, M.A.; Annuar, M.S.M.; Simarani, K. Mixed Feedstock Approach to Lignocellulosic Ethanol Production—Prospects and Limitations. Bioenergy Res. 2016, 9, 1189–1203. [Google Scholar] [CrossRef]

- Clauser, N.M.; Felissia, F.E.; Area, M.C.; Vallejos, M.E. A Framework for the Design and Analysis of Integrated Multi-Product Biorefineries from Agricultural and Forestry Wastes. Renew. Sustain. Energy Rev. 2021, 139, 110687. [Google Scholar] [CrossRef]

- Pyrgakis, K.A.; Kokossis, A.C. A Total Site Synthesis Approach for the Selection, Integration and Planning of Multiple-Feedstock Biorefineries. Comput. Chem. Eng. 2019, 122, 326–355. [Google Scholar] [CrossRef]

- Engelberth, A.S. Evaluating Economic Potential of Food Waste Valorization: Onward to a Diverse Feedstock Biorefinery. Curr. Opin. Green Sustain. Chem. 2020, 26, 100385. [Google Scholar] [CrossRef]

- Ashraf, M.T.; Schmidt, J.E. Process Simulation and Economic Assessment of Hydrothermal Pretreatment and Enzymatic Hydrolysis of Multi-Feedstock Lignocellulose Separate vs. Combined Processing. Bioresour. Technol. 2018, 249, 835–843. [Google Scholar] [CrossRef]

- Berchem, T.; Schmetz, Q.; Lepage, T.; Richel, A. Single and Mixed Feedstocks Biorefining: Comparison of Primary Metabolites Recovery and Lignin Recombination During an Alkaline Process. Front. Chem. 2020, 8, 479. [Google Scholar] [CrossRef]

- Meramo-Hurtado, S.I.; Sanchez-Tuiran, E.; Ponce-Ortega, J.M.; El-Halwagi, M.M.; Ojeda-Delgado, K.A. Synthesis and Sustainability Evaluation of a Lignocellulosic Multifeedstock Biorefinery Considering Technical Performance Indicators. ACS Omega 2020, 5, 9259–9275. [Google Scholar] [CrossRef]

- Rai, M.; Paralikar, P.; Jogee, P.; Agarkar, G.; Ingle, A.P.; Derita, M.; Zacchino, S. Synergistic Antimicrobial Potential of Essential Oils in Combination with Nanoparticles: Emerging Trends and Future Perspectives. Int. J. Pharm. 2017, 519, 67–78. [Google Scholar] [CrossRef]

- Bianchi, A.; Lux, F.; Tillement, O.; Crémillieux, Y. Contrast Enhanced Lung MRI in Mice Using Ultra-Short Echo Time Radial Imaging and Intratracheally Administrated Gd-DOTA-Based Nanoparticles. Magn. Reson. Med. 2012, 70, 1419–1426. [Google Scholar] [CrossRef]

- Abraham, R.E.; Puri, M. Nano-Immobilized Cellulases for Biomass Processing with Application in Biofuel Production. Methods Enzym. 2020, 630, 327–346. [Google Scholar] [CrossRef]

- Thanigaivel, S.; Priya, A.K.; Dutta, K.; Rajendran, S.; Sekar, K.; Jalil, A.A.; Soto-Moscoso, M. Role of Nanotechnology for the Conversion of Lignocellulosic Biomass into Biopotent Energy: A Biorefinery Approach for Waste to Value-Added Products. Fuel 2022, 322, 124236. [Google Scholar] [CrossRef]

- de Bhowmick, G.; Sarmah, A.K.; Sen, R. Lignocellulosic Biorefinery as a Model for Sustainable Development of Biofuels and Value Added Products. Bioresour. Technol. 2018, 247, 1144–1154. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, S.; Singh, O.V. Bioconversion of Lignocellulosic Biomass: Biochemical and Molecular Perspectives. J. Ind. Microbiol. Biotechnol. 2008, 35, 377–391. [Google Scholar] [CrossRef]

- Cherubini, F. The Biorefinery Concept: Using Biomass Instead of Oil for Producing Energy and Chemicals. Energy Convers. Manag. 2010, 51, 1412–1421. [Google Scholar] [CrossRef]

- FitzPatrick, M.; Champagne, P.; Cunningham, M.F.; Whitney, R.A. A Biorefinery Processing Perspective: Treatment of Lignocellulosic Materials for the Production of Value-Added Products. Bioresour. Technol. 2010, 101, 8915–8922. [Google Scholar] [CrossRef]

- Brandt, A.; Gräsvik, J.; Hallett, J.P.; Welton, T. Deconstruction of Lignocellulosic Biomass with Ionic Liquids. Green Chem. 2013, 15, 550. [Google Scholar] [CrossRef]

- Taherzadeh, M.; Karimi, K. Pretreatment of Lignocellulosic Wastes to Improve Ethanol and Biogas Production: A Review. Int. J. Mol. Sci. 2008, 9, 1621–1651. [Google Scholar] [CrossRef]

- Menon, V.; Rao, M. Trends in Bioconversion of Lignocellulose: Biofuels, Platform Chemicals & Biorefinery Concept. Prog. Energy Combust. Sci. 2012, 38, 522–550. [Google Scholar] [CrossRef]

- Vohra, M.; Manwar, J.; Manmode, R.; Padgilwar, S.; Patil, S. Bioethanol Production: Feedstock and Current Technologies. J. Environ. Chem. Eng. 2014, 2, 573–584. [Google Scholar] [CrossRef]

- de Souza, A.P.; Grandis, A.; Leite, D.C.C.; Buckeridge, M.S. Sugarcane as a Bioenergy Source: History, Performance, and Perspectives for Second-Generation Bioethanol. Bioenergy Res. 2013, 7, 24–35. [Google Scholar] [CrossRef]

- Laopaiboon, L.; Nuanpeng, S.; Srinophakun, P.; Klanrit, P.; Laopaiboon, P. Ethanol Production from Sweet Sorghum Juice Using Very High Gravity Technology: Effects of Carbon and Nitrogen Supplementations. Bioresour. Technol. 2009, 100, 4176–4182. [Google Scholar] [CrossRef]

- de Vries, S.C.; van de Ven, G.W.J.; van Ittersum, M.K.; Giller, K.E. Resource Use Efficiency and Environmental Performance of Nine Major Biofuel Crops, Processed by First-Generation Conversion Techniques. Biomass Bioenergy 2010, 34, 588–601. [Google Scholar] [CrossRef]

- Watson, S.; White, P.; Johnson, L. Description, Development, Structure, and Composition of the Corn Kernel. In Corn: Chemistry and Technology; CABI: Wallingford, UK, 2003. [Google Scholar]

- Wong, J.H.; Lau, T.; Cai, N.; Singh, J.; Pedersen, J.F.; Vensel, W.H.; Hurkman, W.J.; Wilson, J.D.; Lemaux, P.G.; Buchanan, B.B. Digestibility of Protein and Starch from Sorghum (Sorghum Bicolor) Is Linked to Biochemical and Structural Features of Grain Endosperm. J. Cereal Sci. 2009, 49, 73–82. [Google Scholar] [CrossRef]

- Ziska, L.H.; Runion, G.B.; Tomecek, M.; Prior, S.A.; Torbet, H.A.; Sicher, R. An Evaluation of Cassava, Sweet Potato and Field Corn as Potential Carbohydrate Sources for Bioethanol Production in Alabama and Maryland. Biomass Bioenergy 2009, 33, 1503–1508. [Google Scholar] [CrossRef]

- Okudoh, V.; Trois, C.; Workneh, T.; Schmidt, S. The Potential of Cassava Biomass and Applicable Technologies for Sustainable Biogas Production in South Africa: A Review. Renew. Sustain. Energy Rev. 2014, 39, 1035–1052. [Google Scholar] [CrossRef]

- Heaton, E.A.; Dohleman, F.G.; Miguez, A.F.; Juvik, J.A.; Lozovaya, V.; Widholm, J.; Zabotina, O.A.; McIsaac, G.F.; David, M.B.; Voigt, T.B.; et al. Miscanthus. A Promising Biomass Crop. In Advances in Botanical Research; Elsevier: Amsterdam, The Netherlands, 2010; Volume 56. [Google Scholar]

- Ko, J.K.; Lee, J.H.; Jung, J.H.; Lee, S.-M. Recent Advances and Future Directions in Plant and Yeast Engineering to Improve Lignocellulosic Biofuel Production. Renew. Sustain. Energy Rev. 2020, 134, 110390. [Google Scholar] [CrossRef]

- Saini, R.; Osorio-Gonzalez, C.S.; Hegde, K.; Brar, S.K.; Magdouli, S.; Vezina, P.; Avalos-Ramirez, A. Lignocellulosic Biomass-Based Biorefinery: An Insight into Commercialization and Economic Standout. Curr. Sustain. Renew. Energy Rep. 2020, 7, 122–136. [Google Scholar] [CrossRef]

- Searcy, E.; Flynn, P.; Ghafoori, E.; Kumar, A. The Relative Cost of Biomass Energy Transport. Appl. Biochem. Biotechnol. 2007, 137–140, 639–652. [Google Scholar] [CrossRef]

- Sultana, A.; Kumar, A. Optimal Configuration and Combination of Multiple Lignocellulosic Biomass Feedstocks Delivery to a Biorefinery. Bioresour. Technol. 2011, 102, 9947–9956. [Google Scholar] [CrossRef] [PubMed]

- Caputo, A.C.; Palumbo, M.; Pelagagge, P.M.; Scacchia, F. Economics of Biomass Energy Utilization in Combustion and Gasification Plants: Effects of Logistic Variables. Biomass Bioenergy 2005, 28, 35–51. [Google Scholar] [CrossRef]

- Bhutto, A.W.; Qureshi, K.; Harijan, K.; Abro, R.; Abbas, T.; Bazmi, A.A.; Karim, S.; Yu, G. Insight into Progress in Pre-Treatment of Lignocellulosic Biomass. Energy 2017, 122, 724–745. [Google Scholar] [CrossRef]

- Jambo, S.A.; Abdulla, R.; Azhar, S.H.M.; Marbawi, H.; Gansau, J.A.; Ravindra, P. A Review on Third Generation Bioethanol Feedstock. Renew. Sustain. Energy Rev. 2016, 65, 756–769. [Google Scholar] [CrossRef]

- Wang, H.; Pu, Y.; Ragauskas, A.; Yang, B. From Lignin to Valuable Products–Strategies, Challenges, and Prospects. Bioresour Technol. 2019, 271, 449–461. [Google Scholar] [CrossRef] [PubMed]

- Haldar, D.; Purkait, M.K. Lignocellulosic Conversion into Value-Added Products: A Review. Process. Biochem. 2020, 89, 110–133. [Google Scholar] [CrossRef]

- Chandel, A.K.; Garlapati, V.K.; Singh, A.K.; Antunes, F.A.F.; da Silva, S.S. The Path Forward for Lignocellulose Biorefineries: Bottlenecks, Solutions, and Perspective on Commercialization. Bioresour. Technol. 2018, 264, 370–381. [Google Scholar] [CrossRef]

- Junqueira, T.L.; Cavalett, O.; Bonomi, A. The Virtual Sugarcane BiorefineryA Simulation Tool to Support Public Policies Formulation in Bioenergy. Ind. Biotechnol. 2016, 12, 62–67. [Google Scholar] [CrossRef]

- Sanford, K.; Chotani, G.; Danielson, N.; Zahn, J.A. Scaling up of Renewable Chemicals. Curr. Opin. Biotechnol. 2016, 38, 112–122. [Google Scholar] [CrossRef]

- Choi, S.; Song, C.W.; Shin, J.H.; Lee, S.Y. Biorefineries for the Production of Top Building Block Chemicals and Their Derivatives. Metab. Eng. 2015, 28, 223–239. [Google Scholar] [CrossRef]

- Chandra, R.; Takeuchi, H.; Hasegawa, T. Methane Production from Lignocellulosic Agricultural Crop Wastes: A Review in Context to Second Generation of Biofuel Production. Renew. Sustain. Energy Rev. 2012, 16, 1462–1476. [Google Scholar] [CrossRef]

- Arevalo-Gallegos, A.; Ahmad, Z.; Asgher, M.; Parra-Saldivar, R.; Iqbal, H.M.N. Lignocellulose: A Sustainable Material to Produce Value-Added Products with a Zero Waste ApproachA Review. Int. J. Biol. Macromol. 2017, 99, 308–318. [Google Scholar] [CrossRef]

- Liu, L.; Li, Z.; Hou, W.; Shen, H. Direct Conversion of Lignocellulose to Levulinic Acid Catalyzed by Ionic Liquid. Carbohydr. Polym. 2018, 181, 778–784. [Google Scholar] [CrossRef] [PubMed]

- Badgujar, K.C.; Bhanage, B.M. The Green Metric Evaluation and Synthesis of Diesel-Blend Compounds from Biomass Derived Levulinic Acid in Supercritical Carbon Dioxide. Biomass Bioenergy 2016, 84, 12–21. [Google Scholar] [CrossRef]

- Chen, P.; Tao, S.; Zheng, P. Efficient and Repeated Production of Succinic Acid by Turning Sugarcane Bagasse into Sugar and Support. Bioresour. Technol. 2016, 211, 406–413. [Google Scholar] [CrossRef] [PubMed]

- Heng, K.S.; Hatti-Kaul, R.; Adam, F.; Fukui, T.; Sudesh, K. Conversion of Rice Husks to Polyhydroxyalkanoates (PHA) via a Three-Step Process: Optimized Alkaline Pretreatment, Enzymatic Hydrolysis, and Biosynthesis by Burkholderia Cepacia USM (JCM 15050). J. Chem. Technol. Biotechnol. 2017, 92, 100–108. [Google Scholar] [CrossRef]

- Batalha, L.A.R.; Han, Q.; Jameel, H.; Chang, H.; Colodette, J.L.; Gomes, F.J.B. Production of Fermentable Sugars from Sugarcane Bagasse by Enzymatic Hydrolysis after Autohydrolysis and Mechanical Refining. Bioresour. Technol. 2015, 180, 97–105. [Google Scholar] [CrossRef] [PubMed]

- Kuhn, E.M.; O’Brien, M.H.; Ciesielski, P.N.; Schell, D.J. Pilot-Scale Batch Alkaline Pretreatment of Corn Stover. ACS Sustain. Chem. Eng. 2015, 4, 944–956. [Google Scholar] [CrossRef]

- Chiarello, L.M.; Ramos, C.E.A.; Neves, P.V.; Ramos, L.P. Production of Cellulosic Ethanol from Steam-Exploded Eucalyptus Urograndis and Sugarcane Bagasse at High Total Solids and Low Enzyme Loadings. Sustain. Chem. Process. 2016, 4, 15. [Google Scholar] [CrossRef]

- Raud, M.; Kikas, T.; Sippula, O.; Shurpali, N.J. Potentials and Challenges in Lignocellulosic Biofuel Production Technology. Renew. Sustain. Energy Rev. 2019, 111, 44–56. [Google Scholar] [CrossRef]

- Dale, B. Time to Rethink Cellulosic Biofuels? Biofuels Bioprod. Biorefining 2018, 12, 5–7. [Google Scholar] [CrossRef]

- da Silva, A.R.G.; Giuliano, A.; Errico, M.; Rong, B.-G.; Barletta, D. Economic Value and Environmental Impact Analysis of Lignocellulosic Ethanol Production: Assessment of Different Pretreatment Processes. Clean Technol. Environ. Policy 2019, 21, 637–654. [Google Scholar] [CrossRef]

- Albashabsheh, N.T.; Stamm, J.L.H. Optimization of Lignocellulosic Biomass-to-Biofuel Supply Chains with Mobile Pelleting. Transp. Res. E Logist. Transp. Rev. 2019, 122, 545–562. [Google Scholar] [CrossRef]

- Zhao, L.; Zhang, X.; Xu, J.; Ou, X.; Chang, S.; Wu, M. Techno-Economic Analysis of Bioethanol Production from Lignocellulosic Biomass in China: Dilute-Acid Pretreatment and Enzymatic Hydrolysis of Corn Stover. Energies 2015, 8, 4096–4117. [Google Scholar] [CrossRef]

- Sindhu, R.; Binod, P.; Pandey, A. Biological Pretreatment of Lignocellulosic Biomass An Overview. Bioresour. Technol. 2016, 199, 76–82. [Google Scholar] [CrossRef]

- Rocha-Martín, J.; Martinez-Bernal, C.; Pérez-Cobas, Y.; Reyes-Sosa, F.M.; García, B.D. Additives Enhancing Enzymatic Hydrolysis of Lignocellulosic Biomass. Bioresour. Technol. 2017, 244, 48–56. [Google Scholar] [CrossRef] [PubMed]

- Sabaini, P.S.; Boateng, A.A.; Schaffer, M.; Mullen, C.A.; Elkasabi, Y.; McMahan, C.M.; Macken, N. Techno-Economic Analysis of Guayule (Parthenium Argentatum) Pyrolysis Biorefining: Production of Biofuels from Guayule Bagasse via Tail-Gas Reactive Pyrolysis. Ind. Crops Prod. 2018, 112, 82–89. [Google Scholar] [CrossRef]

- Nunes, L.J.R.; Causer, T.P.; Ciolkosz, D. Biomass for Energy: A Review on Supply Chain Management Models. Renew. Sustain. Energy Rev. 2020, 120, 109658. [Google Scholar] [CrossRef]

- Huang, C.; Chen, X.; Xiong, L.; Chen, X.; Ma, L.; Chen, Y. Single Cell Oil Production from Low-Cost Substrates: The Possibility and Potential of Its Industrialization. Biotechnol. Adv. 2013, 31, 129–139. [Google Scholar] [CrossRef] [PubMed]

- Konwar, L.J.; Mikkola, J.P.; Bordoloi, N.; Saikia, R.; Chutia, R.S.; Kataki, R. Sidestreams From Bioenergy and Biorefinery Complexes as a Resource for Circular Bioeconomy. Waste Biorefinery Potential Perspect. 2018, 85–125. [Google Scholar] [CrossRef]

- Chandel, A.K.; Philippini, R.R.; Martiniano, S.; Ascencio, J.J.; Hilares, R.T.; Ramos, L.; Rodhe, A.V. Lignocellulose biorefinery: Technical challenges, perspectives on industrialization, and solutions. In Production of Top 12 Biochemicals Selected by USDOE from Renewable Resources: Status and Innovation; Elsevier: Amsterdam, The Netherlands, 2022; pp. 1–39. [Google Scholar] [CrossRef]

| Fractionation Methods | Physicochemical | Chemical | Biological |

|---|---|---|---|

| Mode of Action | Breakdown of cell wall components | Removal of lignin and/or hemicellulose increases the accessible surface area of cellulose | Degradation of polysaccharides to subsequent components |

| Examples | Pyrolysis, Steam explosion, Liquid hot water treatment, Wet oxidation, Ammonia fibre expansion | Acid and Alkaline treatment, Deep eutectic solvents, Organosolv method, Ionic liquid treatment, supercritical fluids | Microbes, Enzymes |

| Associated costs | High (need for high pressure and temperature) | Medium (need for expensive chemicals such as organosolv, ionic liquid) | Medium (necessitates elaborative setups) |

| Energy and chemical requirement | High | High | Low |

| Applicable to diverse biomass | Yes | Yes | Yes |

| Inhibitors generation | Low | High | Low |

| Effectiveness of the process | Medium (can be slow) | High | Medium (also, slow) |

| Environmental, health and safety concerns | Low | High | High |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

K.N, Y.; T.M, M.U.; S, K.; Sachdeva, S.; Thakur, S.; S, A.K.; J, R.B. Lignocellulosic Biorefinery Technologies: A Perception into Recent Advances in Biomass Fractionation, Biorefineries, Economic Hurdles and Market Outlook. Fermentation 2023, 9, 238. https://doi.org/10.3390/fermentation9030238

K.N Y, T.M MU, S K, Sachdeva S, Thakur S, S AK, J RB. Lignocellulosic Biorefinery Technologies: A Perception into Recent Advances in Biomass Fractionation, Biorefineries, Economic Hurdles and Market Outlook. Fermentation. 2023; 9(3):238. https://doi.org/10.3390/fermentation9030238

Chicago/Turabian StyleK.N, Yogalakshmi, Mohamed Usman T.M, Kavitha S, Saloni Sachdeva, Shivani Thakur, Adish Kumar S, and Rajesh Banu J. 2023. "Lignocellulosic Biorefinery Technologies: A Perception into Recent Advances in Biomass Fractionation, Biorefineries, Economic Hurdles and Market Outlook" Fermentation 9, no. 3: 238. https://doi.org/10.3390/fermentation9030238

APA StyleK.N, Y., T.M, M. U., S, K., Sachdeva, S., Thakur, S., S, A. K., & J, R. B. (2023). Lignocellulosic Biorefinery Technologies: A Perception into Recent Advances in Biomass Fractionation, Biorefineries, Economic Hurdles and Market Outlook. Fermentation, 9(3), 238. https://doi.org/10.3390/fermentation9030238