Enhancing Docosahexaenoic Acid Production of Isochrysis galbana from Starch-Rich Food Processing Byproducts

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Leftover Dough Hydrolysates

2.3. Microalgal Strain and Cultivation Conditions

2.4. Experimental Design

2.5. Analytical Methods

2.6. Data Analysis

3. Results and Discussion

3.1. Characteristics of Leftover Dough and Its Hydrolysates

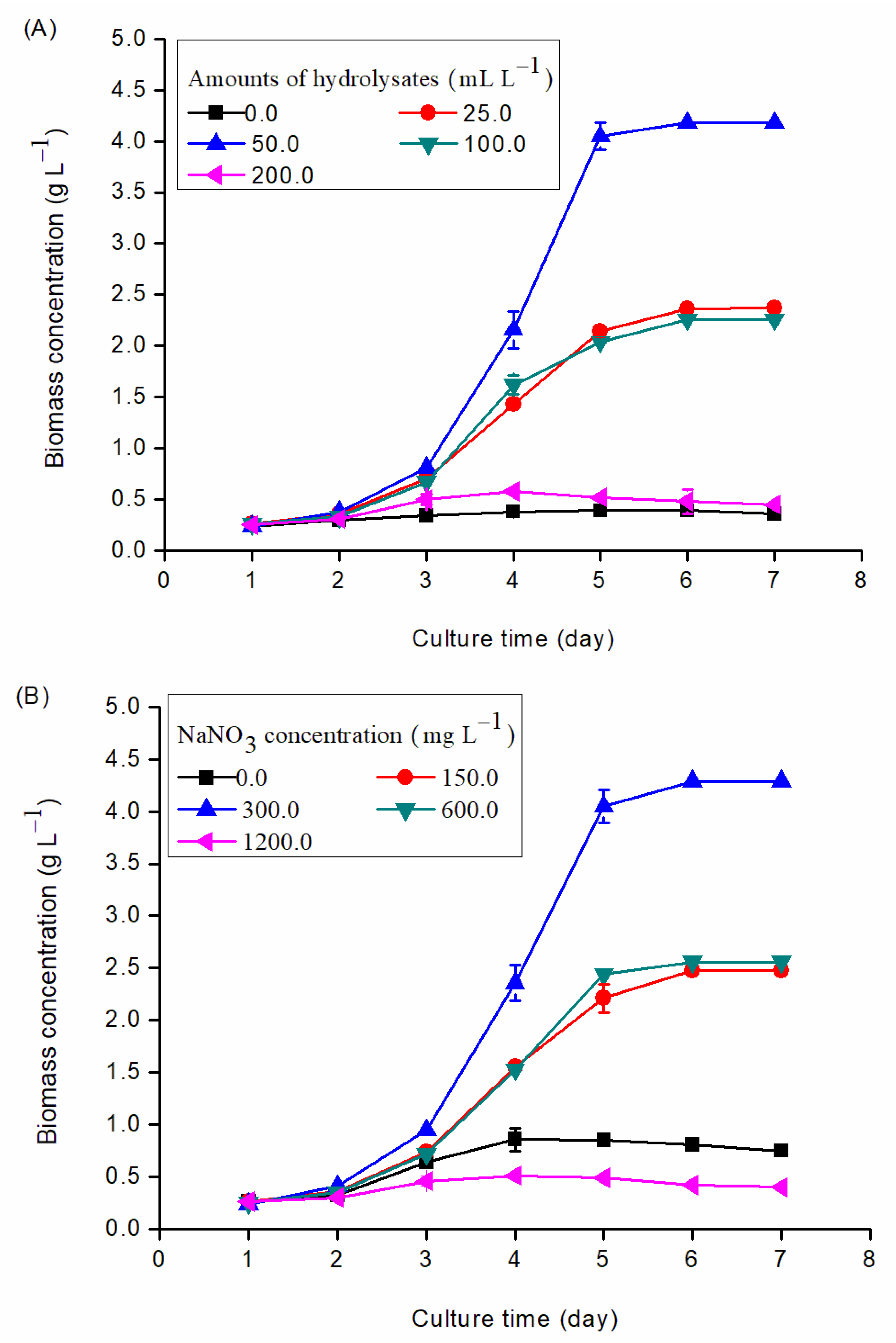

3.2. Effects of Different Amounts of Hydrolysates and NaNO3 Concentrations on Cell Growth of I. galbana

3.2.1. Effects of Different Amounts of Hydrolysates

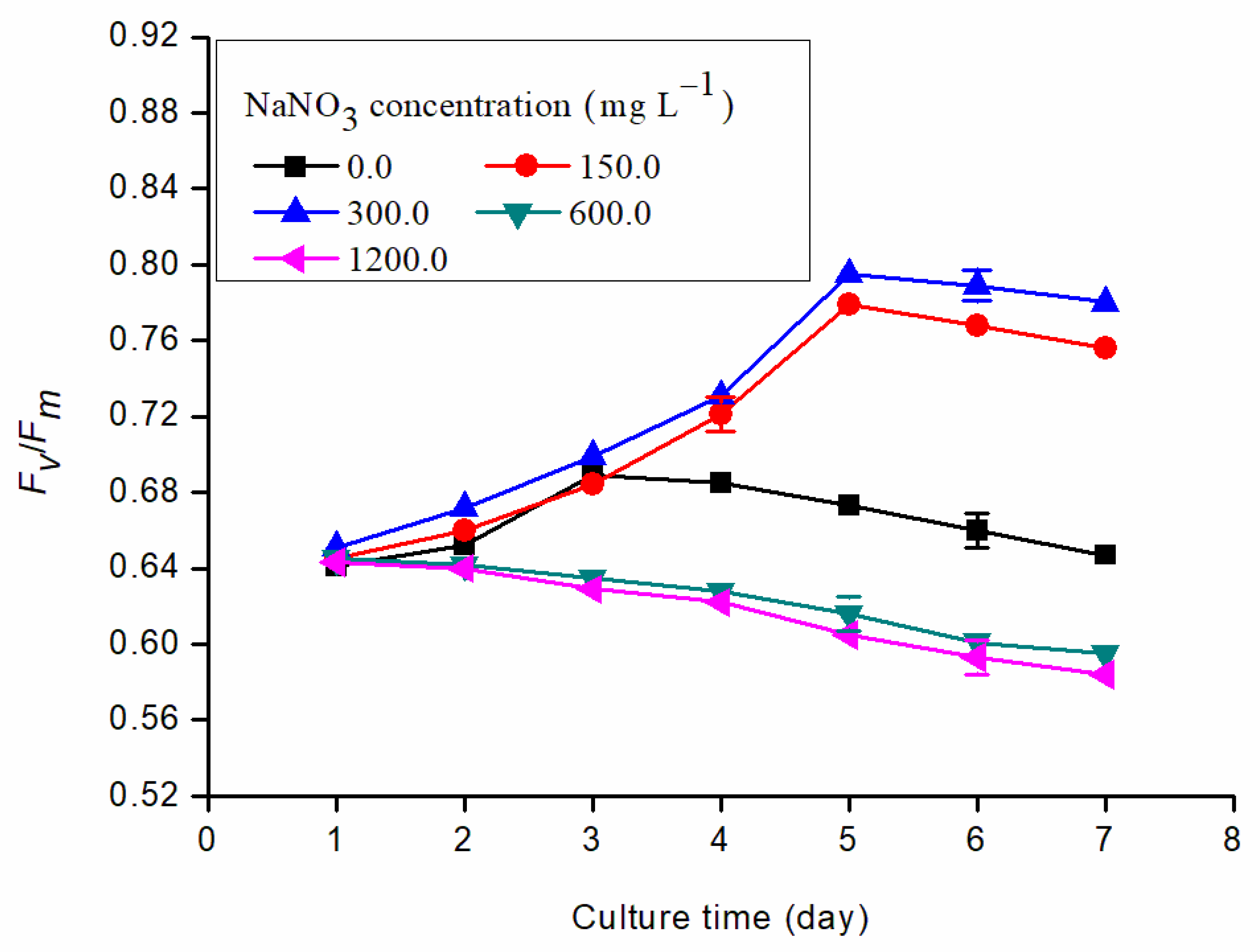

3.2.2. Effects of NaNO3 Concentration

3.3. Effects of Different Amounts of Hydrolysates and NaNO3 Concentrations on Lipid Accumulation and DHA Production of I. galbana

3.3.1. Effects of Different Amounts of Hydrolysates

3.3.2. Effects of NaNO3 Concentrations

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zheng, H.L.; Ge, F.R.; Song, K.Y.; Yang, Z.X.; Li, J.M.; Yan, F.; Wu, X.D.; Zhang, Q.; Liu, Y.H.; Ruan, R. Docosahexaenoic acid production of the marine microalga Isochrysis galbana cultivated on renewable substrates from food processing waste under CO2 enrichment. Sci. Total Environ. 2022, 848, 157654. [Google Scholar] [CrossRef]

- Mata, T.M.; Martins, A.A.; Caetano, N.S. Microalgae for biodiesel production and other applications: A review. Renew. Sust. Energy Rev. 2010, 14, 217–232. [Google Scholar] [CrossRef]

- Jakhwal, P.; Biswas, J.K.; Tiwari, A.; Kwon, E.E.; Bhatnagar, A. Genetic and non-genetic tailoring of microalgae for the enhanced production of eicosapentaenoic acid (EPA) and docosahexaenoic acid (DHA)—A review. Bioresour. Technol. 2022, 344, 126250. [Google Scholar] [CrossRef]

- Chi, G.X.; Xu, Y.Y.; Cao, X.Y.; Li, Z.P.; Cao, M.F.; Chisti, Y.; He, N. Production of polyunsaturated fatty acids by Schizochytrium (Aurantiochytrium) spp. Biotechnol. Adv. 2022, 55, 107897. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Y.; Chen, F. Effects of temperature and temperature shift on docosahexaenoic acid production by the marine microalge Crypthecodinium cohnii. J. Am. Oil Chem. Soc. 2000, 77, 613–617. [Google Scholar] [CrossRef]

- Burja, A.M.; Armenta, R.E.; Radianingtyas, H.; Barrow, C.J. Evaluation of fatty acid extraction methods for Thraustochytrium sp. ONC-T18. J. Agric. Food Chem. 2007, 55, 4795–4801. [Google Scholar] [CrossRef] [PubMed]

- Lv, B.; Ye, B.C.; Zhou, J.C.; Li, X.; Wang, A.M.; Gu, Z.F.; Zheng, X. Effects of indoor and outdoor culture on cell growth and pigment content of Isochrysis galbana. Aquaculture 2021, 10, 1–5. [Google Scholar]

- Wang, Y.Y.; Xu, S.M.; Cao, J.Y.; Wu, M.N.; Lin, J.H.; Zhou, C.X.; Zhang, L.; Zhou, H.B.; Li, Y.R.; Xu, J.L.; et al. Co-cultivation of Isochrysis galbana and Marinobacter sp. can enhance algal growth and docosahexaenoic acid production. Aquaculture 2022, 556, 738248. [Google Scholar] [CrossRef]

- Wang, X.X.; Fosse, H.K.; Li, K.S.; Chauton, M.S.; Vadstein, O.; Reitan, K.I. Influence of nitrogen limitation on lipid accumulation and EPA and DHA content in four marine microalgae for possible use in aquafeed. Front. Mar. Sci. 2019, 6, 95. [Google Scholar] [CrossRef]

- Li, L.; Zhang, L.T.; Zhang, Z.; Liu, J.G. Comparison of heat resistance and application potential of two lipid-rich Isochrysis galbana strains. Algal Res. 2016, 20, 1–6. [Google Scholar] [CrossRef]

- Guillard, R.R.L. Culture of phytoplankton for feeding marine invertebrate. In Culture of Marine Invertebrates Animals; Smith, W.L., Chanley, M.H., Eds.; Plenum: New York, NY, USA, 1975; pp. 29–60. [Google Scholar]

- Zheng, H.L.; Gao, Z.; Yin, F.W.; Ji, X.J.; Huang, H. Effect of CO2 supply conditions on lipid production of Chlorella vulgaris from enzymatic hydrolysates of lipid-extracted microalgal biomass residues. Bioresour. Technol. 2012, 126, 24–30. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Vaidyanathan, S. Simultaneous assay of pigments, carbohydrates, proteins and lipids in microalgae. Anal. Chim. Acta. 2013, 776, 31–40. [Google Scholar] [CrossRef] [PubMed]

- Zor, T.; Selinger, Z. Linearization of the Bradford protein assay increases its sensitivity: Theoretical and experimental studies. Anal. Biochem. 1996, 236, 302–308. [Google Scholar] [CrossRef] [PubMed]

- Yan, L.S.; Zhang, H.M.; Chen, J.W.; Lin, Z.X.; Jin, Q.; Jia, H.H.; Huang, H. Dilute sulfuric acid cycle spray flow-through pretreatment of corn stover for enhancement of sugar recovery. Bioresour. Technol. 2009, 100, 1803–1808. [Google Scholar] [CrossRef] [PubMed]

- Collos, Y.; Mornet, F.; Sciandra, A.; Waser, N.; Larson, A.; Harrison, P.J. An optical method for the rapid measurement of micromolar concentrations of nitrate in marine phytoplankton cultures. J. Appl. Phycol. 1999, 11, 179–184. [Google Scholar] [CrossRef]

- Yu, J.J.; Hu, H.C.; Wu, X.D.; Zhou, T.; Liu, Y.H.; Ruan, R.; Zheng, H.L. Coupling of biochar-mediated absorption and algal-bacterial system to enhance nutrients recovery from swine wastewater. Sci. Total Environ. 2020, 701, 134935. [Google Scholar] [CrossRef]

- Bligh, E.G.; Dyer, W.M. A rapid method of lipid extraction and purification. Can. J. Biochem. Physiol. 1959, 37, 911–917. [Google Scholar] [CrossRef]

- Metchalfe, L.D.; Schmitz, A.A. The rapid preparation of fatty acid esters for gas chromatographic analysis. Anal. Chem. 1961, 33, 363–372. [Google Scholar] [CrossRef]

- Huang, H.; Li, X.K.; Zhang, K.; Shi, H.F.; Xia, C.B. Study on the purification of arachidonic acid by urea inclusion. Chem. Bioeng. 2006, 23, 29–31. [Google Scholar]

- You, K.; Ge, F.R.; Wu, X.D.; Song, K.Y.; Yang, Z.X.; Zhang, Q.; Liu, Y.H.; Ruan, R.; Zheng, H.L. Nutrients recovery from piggery wastewater and starch wastewater via microalgae-bacteria consortia. Algal Res. 2021, 60, 102551. [Google Scholar] [CrossRef]

- Oliver, L.; Fernández-de-Castro, L.; Dietrich, T.; Villaran, M.C.; Barrio, R.J. Production of docosahexaenoic acid and odd-chain fatty acids by microalgae Schizochytrium limacinum grown on waste-derived volatile fatty acids. Appl. Sci. 2022, 12, 3976. [Google Scholar] [CrossRef]

- Rohman, F.S.; Roslan, M.F.; Muhammad, D.; Shoparwe, N.F.; Hamid, A.A. Multi-objective optimal control of docosahexaenoic acid (DHA) production in fed-batch fermentation by Schizochytrium sp. Biocatal. Agric. Biotech. 2022, 45, 102490. [Google Scholar] [CrossRef]

- He, D.M.; Wang, N.; Sun, K.F.; Huang, Z.H.; Duan, S.S. Effect of glucose and sodium acetate on mixtrophic growth of Isochrysis zhanjiangensis. Ecol. Sci. 2012, 31, 126–129. [Google Scholar]

- Gim, G.H.; Ryu, J.; Kim, M.J.; Kim, P.; Kim, S.W. Effects of carbon source and light intensity on the growth and total lipid production of three microalgae under different culture conditions. J. Ind. Microbiol. Biotechnol. 2016, 43, 605–616. [Google Scholar] [CrossRef]

- Cheirsilp, B.; Torpee, S. Enhanced growth and lipid production of microalgae under mixotrophic culture condition: Effect of light intensity, glucose concentration and fed-batch cultivation. Bioresour. Technol. 2012, 110, 510–516. [Google Scholar] [CrossRef]

- Nadushan, R.M.; Hosseinzade, I. Optimization of production and antioxidant activity of fucoxanthin from marine haptophyte algae, Isochrysis galbana. Iran. J. Fish. Sci. 2020, 19, 2901–2908. [Google Scholar]

- Che, C.A.; Kim, S.H.; Hong, H.J.; Kityo, M.K.; Sunwoo, I.Y.; Jeong, G.T.; Kim, S.K. Optimization of light intensity and photoperiod for Isochrysis galbana culture to improve the biomass and lipid production using 14-L photobioreactors with mixed light emitting diodes (LEDs) wavelength under two-phase culture system. Bioresour. Technol. 2019, 285, 121323. [Google Scholar] [CrossRef]

- Yaakob, M.A.; Mohamed, R.M.S.R.; Al-Gheethi, A.; Gokare, R.A.; Ambati, R.R. Influence of nitrogen and phosphorus on microalgal growth, biomass, lipid, and fatty acid production: An overview. Cells 2021, 10, 393. [Google Scholar] [CrossRef]

- Jin, H.F.; Lim, B.; Lee, K. Influence of nitrate feeding on carbon dioxide fixation by microalgae. J. Environ. Sci. Health Part A Toxic Hazard. Subst. Environ. Eng. 2006, 41, 2813–2824. [Google Scholar] [CrossRef]

- Yeesang, C.; Cheirsilp, B. Effect of nitrogen, salt, and iron content in the growth medium and light intensity on lipid production by microalgae isolated from freshwater sources in Thailand. Bioresour. Technol. 2011, 102, 3034–3040. [Google Scholar] [CrossRef]

- Yeh, K.L.; Chang, J.S. Effects of cultivation conditions and media composition on cell growth and lipid productivity of indigenous microalga Chlorella vulgaris ESP-31. Bioresour. Technol. 2012, 105, 120–127. [Google Scholar] [CrossRef] [PubMed]

- Ramírez-Romero, A.; Magalhães, B.D.C.; Dimitriades-Lemaire, A.; Sassi, J.F.; Delrue, F.; Steyer, J.P. Chlorellaceae feedstock selection under balanced nutrient limitation. Fermentation 2022, 8, 554. [Google Scholar] [CrossRef]

- Khatiwada, J.R.; Guo, H.; Shrestha, S.; Chio, C.; Chen, X.; Mokale, K.A.L.; Qin, W. Cultivation of microalgae in unsterile malting effluent for biomass production and lipid productivity improvement. Fermentation 2022, 8, 186. [Google Scholar] [CrossRef]

- Xu, N.J.; Zhang, X.C.; Fan, X.; Han, L.J.; Zeng, C.K. Effects of nitrogen source and concentration on growth rate and fatty acid composition of Ellipsoidion sp. (Eustigmatophyta). J. Appl. Phycol. 2001, 13, 463–469. [Google Scholar] [CrossRef]

- Goncalves, E.C.; Wilkie, A.C.; Kirst, M.; Rathinasabapathi, B. Metabolic regulation of triacylglycerol accumulation in the green algae: Identification of potential targets for engineering to improve oil yield. Plant Biotechnol. J. 2016, 14, 1649–1660. [Google Scholar] [CrossRef]

| Parameters | Composition (wt%) |

|---|---|

| Moisture | 36 ± 1 |

| Starch | 51 ± 2 |

| Protein | 5 ± 0 |

| Ash | 8 ± 1 |

| Parameters | Concentration | Parameters | Concentration |

|---|---|---|---|

| pH | 6.3 ± 0.0 | Si (mg L−1) | 27.0 ± 1.0 |

| Protein (g L−1) | 45.6 ± 0.9 | Co (mg L−1) | 0.0 ± 0.0 |

| Starch (g L−1) | 0.0 ± 0.0 | Ca (mg L−1) | 92.0 ± 8.0 |

| Glucose (g L−1) | 248.0 ± 5.0 | Mg (mg L−1) | 176.0 ± 12.0 |

| Cu (mg L−1) | 33.0 ± 2.0 | K (mg L−1) | 450.0 ± 18.0 |

| Fe (mg L−1) | 52.0 ± 2.0 | Pb (mg L−1) | 0.0 ± 0.0 |

| B (mg L−1) | 11.0 ± 0.0 | P (mg L−1) | 397.0 ± 13.0 |

| Zn (mg L−1) | 24.0 ± 1.0 | Na (mg L−1) | 11.0 ± 0.0 |

| Mn (mg L−1) | 9.0 ± 0.0 | As (mg L−1) | 0.0 ± 0.0 |

| Mo (mg L−1) | 0.0 ± 0.0 | Se (mg L−1) | 8.0 ± 0.0 |

| Parameters | Amount of Leftover Dough Hydrolysates (mL L−1) | NaNO3 Concentration (mg L−1) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 0.0 | 25.0 | 50.0 | 100.0 | 200.0 | 0.0 | 150.0 | 300.0 | 600.0 | 1200.0 | |

| Xmax (g L−1) | 0.39 ± 0.00 | 2.37 ± 0.02 | 4.18 ± 0.02 | 2.26 ± 0.06 | 0.58 ± 0.00 | 0.86 ± 0.03 | 2.48 ± 0.00 | 4.29 ± 0.04 | 2.56 ± 0.07 | 0.51 ± 0.02 |

| Pmax (g L−1 d−1) | 0.05 ± 0.00 | 0.53 ± 0.05 | 0.96 ± 0.06 | 0.45 ± 0.02 | 0.09 ± 0.00 | 0.13 ± 0.01 | 0.55 ± 0.07 | 0.99 ± 0.06 | 0.49 ± 0.03 | 0.09 ± 0.00 |

| μmax (d−1) | 0.04 ± 0.00 | 0.84 ± 0.06 | 1.45 ± 0.08 | 0.74 ± 0.04 | 0.11 ± 0.01 | 0.15 ± 0.00 | 0.89 ± 0.09 | 1.42 ± 0.05 | 0.77 ± 0.02 | 0.10 ± 0.01 |

| Parameters | Amount of Leftover Dough Hydrolysates (mL L−1) | NaNO3 Concentration (mg L−1) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 0.0 | 25.0 | 50.0 | 100.0 | 200.0 | 0.0 | 150.0 | 300.0 | 600.0 | 1200.0 | |

| Lipid content (%) | 14 ± 0 | 37 ± 0 | 35 ± 2 | 15 ± 1 | 16 ± 0 | 33 ± 1 | 35 ± 0 | 37 ± 2 | 12 ± 0 | 10 ± 0 |

| Lipid productivity (mg L−1d−1) | 7.8 ± 0.0 | 203.5 ± 1.0 | 343.4 ± 4.5 | 78.6 ± 1.1 | 11.0 ± 0.0 | 35.8 ± 1.2 | 202.0 ± 3.7 | 366.3 ± 6.4 | 71.5 ± 2.3 | 5.9 ± 0.0 |

| Maximum lipid yield (mg L−1) | 54.6 ± 1.4 | 1461.5 ± 8.7 | 2436.0 ± 10.0 | 565.5 ± 5.2 | 92.8 ± 3.0 | 283.8 ± 4.5 | 1449.0 ± 9.0 | 2601.1 ± 9.7 | 512.4 ± 6.9 | 51.0 ± 1.0 |

| DHA content (%) | 7 ± 0 | 14 ± 0 | 14 ± 1 | 8 ± 1 | 8 ± 0 | 12 ± 1 | 11 ± 0 | 13 ± 1 | 5 ± 1 | 4 ± 0 |

| Maximum DHA yield (mg L−1) | 3.8 ± 0.0 | 204.6 ± 1.9 | 341.3 ± 4.6 | 45.2 ± 1.0 | 7.4 ± 0.1 | 34.1 ± 0.2 | 159.4 ± 5.8 | 338.1 ± 2.6 | 25.6 ± 0.0 | 2.0 ± 0.0 |

| Parameters | Amount of Leftover Dough Hydrolysates (mL L−1) | NaNO3 Concentration (mg L−1) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 0.0 | 25.0 | 50.0 | 100.0 | 200.0 | 0.0 | 150.0 | 300.0 | 600.0 | 1200.0 | |

| C14:0 | 15 ± 0 | 10 ± 0 * | 11 ± 0 | 12 ± 0 | 14 ± 0 | 13 ± 0 | 10 ± 0 | 10 ± 0 | 15 ± 0 | 17 ± 0 |

| C16:0 | 13 ± 1 | 9 ± 0 | 7 ± 0 | 11 ± 0 | 13 ± 1 | 9 ± 1 | 7 ± 0 | 8 ± 0 | 13 ± 0 | 14 ± 1 |

| C16:1 | 7 ± 0 | 3 ± 0 | 4 ± 0 | 5 ± 0 | 7 ± 0 | 6 ± 0 | 6 ± 0 | 4 ± 0 | 2 ± 0 | 6 ± 0 |

| C18:0 | 6 ± 0 | 3 ± 0 | 3 ± 0 | 4 ± 0 | 4 ± 0 | 4 ± 0 | 2 ± 0 | 2 ± 0 | 5 ± 0 | 4 ± 0 |

| C18:1 | 17 ± 0 | 12 ± 0 | 13 ± 0 | 15 ± 1 | 16 ± 0 | 15 ± 1 | 16 ± 0 | 14 ± 0 | 10 ± 1 | 15 ± 0 |

| C18:2 | 3 ± 0 | 5 ± 0 | 4 ± 0 | 3 ± 0 | 3 ± 0 | 6 ± 0 | 5 ± 0 | 4 ± 0 | 2 ± 0 | 5 ± 0 |

| C18:3 | 8 ± 0 | 12 ± 0 | 11 ± 0 | 10 ± 0 | 9 ± 0 | 11 ± 0 | 13 ± 0 | 12 ± 0 | 14 ± 0 | 6 ± 0 |

| C18:4 | 8 ± 0 | 14 ± 0 | 15 ± 0 | 11 ± 0 | 8 ± 0 | 10 ± 0 | 15 ± 0 | 16 ± 0 | 14 ± 0 | 8 ± 0 |

| C20:0 | 6 ± 0 | 7 ± 0 | 5 ± 0 | 8 ± 0 | 8 ± 0 | 5 ± 0 | 4 ± 0 | 6 ± 0 | 8 ± 0 | 10 ± 0 |

| C22:5 | 3 ± 0 | 6 ± 0 | 7 ± 0 | 5 ± 0 | 3 ± 0 | 3 ± 0 | 6 ± 0 | 6 ± 0 | 5 ± 0 | 2 ± 0 |

| C22:6 | 7 ± 0 | 14 ± 0 | 14 ± 0 | 8 ± 0 | 8 ± 0 | 12 ± 0 | 11 ± 0 | 13 ± 0 | 5 ± 0 | 4 ± 0 |

| Others | 7 ± 0 | 5 ± 0 | 6 ± 0 | 8 ± 1 | 7 ± 0 | 6 ± 0 | 5 ± 0 | 5 ± 0 | 7 ± 1 | 9 ± 0 |

| Unsaturated fatty acids | 54 ± 1 | 66 ± 0 | 68 ± 0 | 57 ± 0 | 54 ± 1 | 63 ± 1 | 72 ± 0 | 69 ± 0 | 52 ± 0 | 46 ± 1 |

| Saturated fatty acids | 38 ± 0 | 29 ± 1 | 26 ± 1 | 35 ± 1 | 38 ± 0 | 31 ± 1 | 23 ± 1 | 26 ± 1 | 41 ± 1 | 45 ± 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ge, F.; Song, K.; Yang, Z.; Li, J.; Yan, F.; Zhang, M.; Huang, B.; Fu, G.; Zheng, H. Enhancing Docosahexaenoic Acid Production of Isochrysis galbana from Starch-Rich Food Processing Byproducts. Fermentation 2023, 9, 158. https://doi.org/10.3390/fermentation9020158

Ge F, Song K, Yang Z, Li J, Yan F, Zhang M, Huang B, Fu G, Zheng H. Enhancing Docosahexaenoic Acid Production of Isochrysis galbana from Starch-Rich Food Processing Byproducts. Fermentation. 2023; 9(2):158. https://doi.org/10.3390/fermentation9020158

Chicago/Turabian StyleGe, Fengru, Kunyan Song, Zixiang Yang, Jinmeng Li, Feng Yan, Mengyan Zhang, Binbin Huang, Guiming Fu, and Hongli Zheng. 2023. "Enhancing Docosahexaenoic Acid Production of Isochrysis galbana from Starch-Rich Food Processing Byproducts" Fermentation 9, no. 2: 158. https://doi.org/10.3390/fermentation9020158

APA StyleGe, F., Song, K., Yang, Z., Li, J., Yan, F., Zhang, M., Huang, B., Fu, G., & Zheng, H. (2023). Enhancing Docosahexaenoic Acid Production of Isochrysis galbana from Starch-Rich Food Processing Byproducts. Fermentation, 9(2), 158. https://doi.org/10.3390/fermentation9020158