Impacts of Reduced (Vacuum) Pressure on Yeast Fermentation as Assessed Using Standard Methods and Automated Image Analysis

Abstract

1. Introduction

2. Materials and Methods

2.1. Design of Experiment

2.2. Yeast Strain and Media

2.3. Yeast Propagation

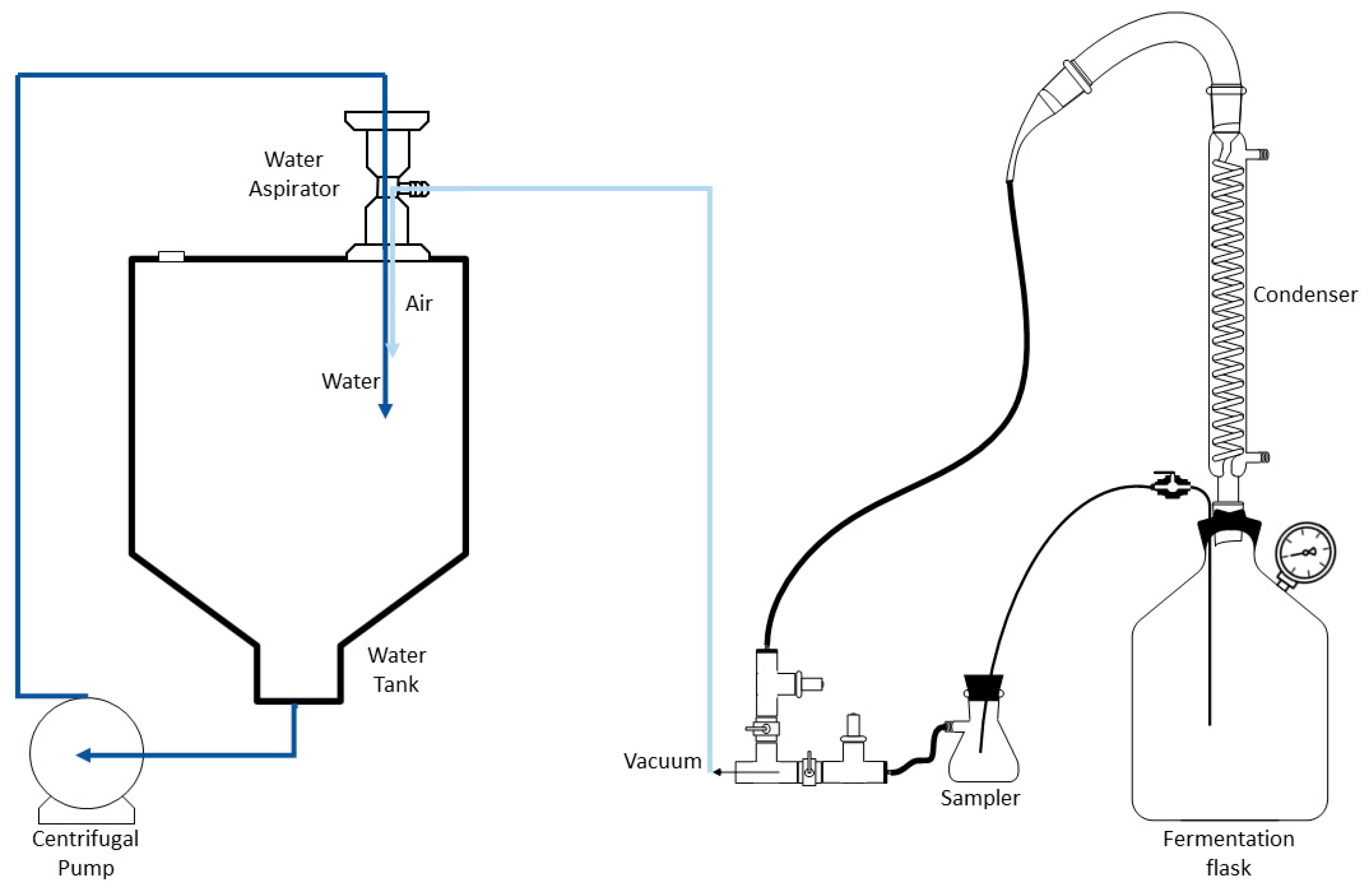

2.4. Fermentation

2.5. Measured Fermentation Attributes

2.6. Models

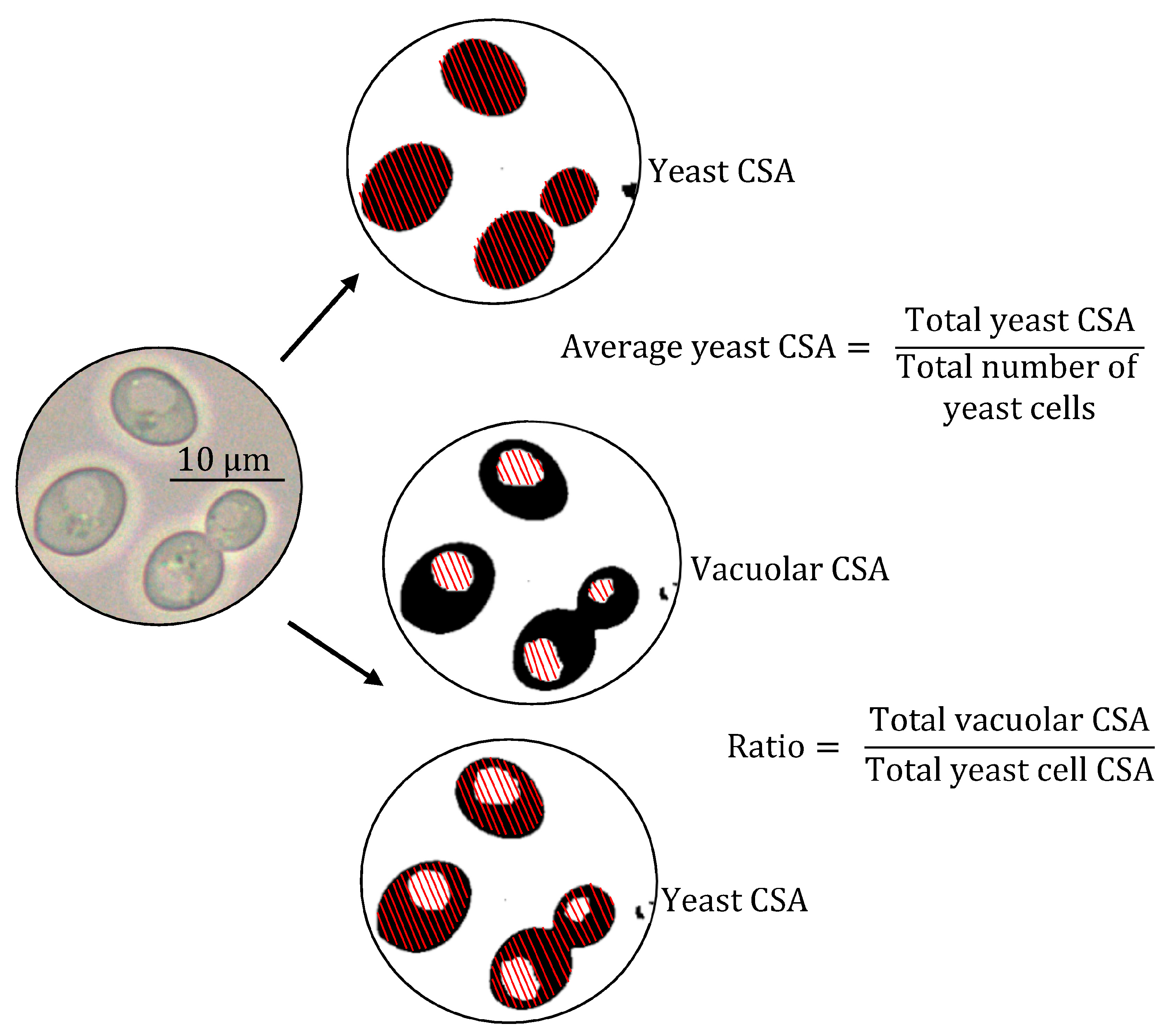

2.7. Measurement of Yeast Morphology

2.8. Statistical Analysis

3. Results and Discussion

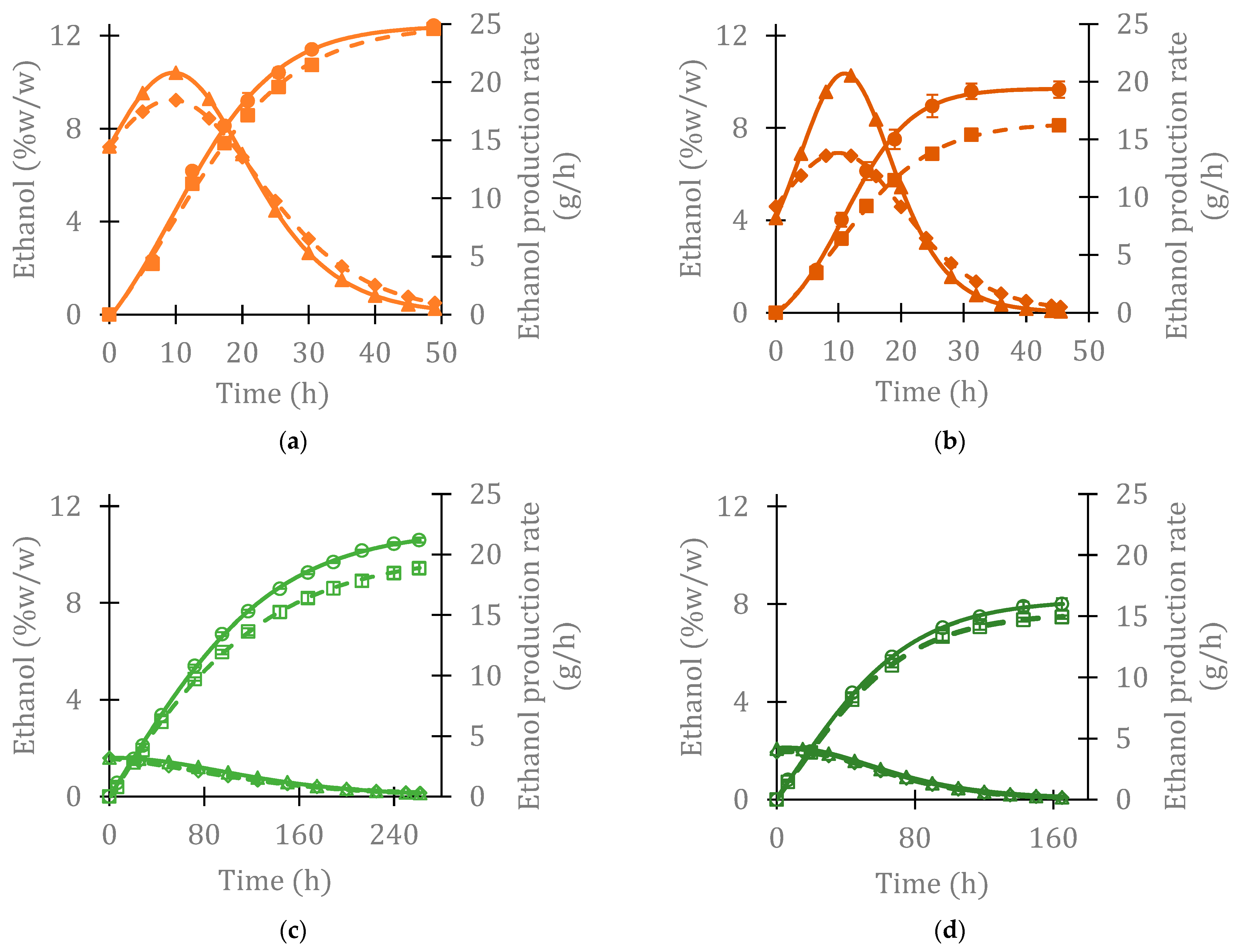

3.1. Fermentation Attributes

3.1.1. Sugar Consumption

3.1.2. Cells in Suspension

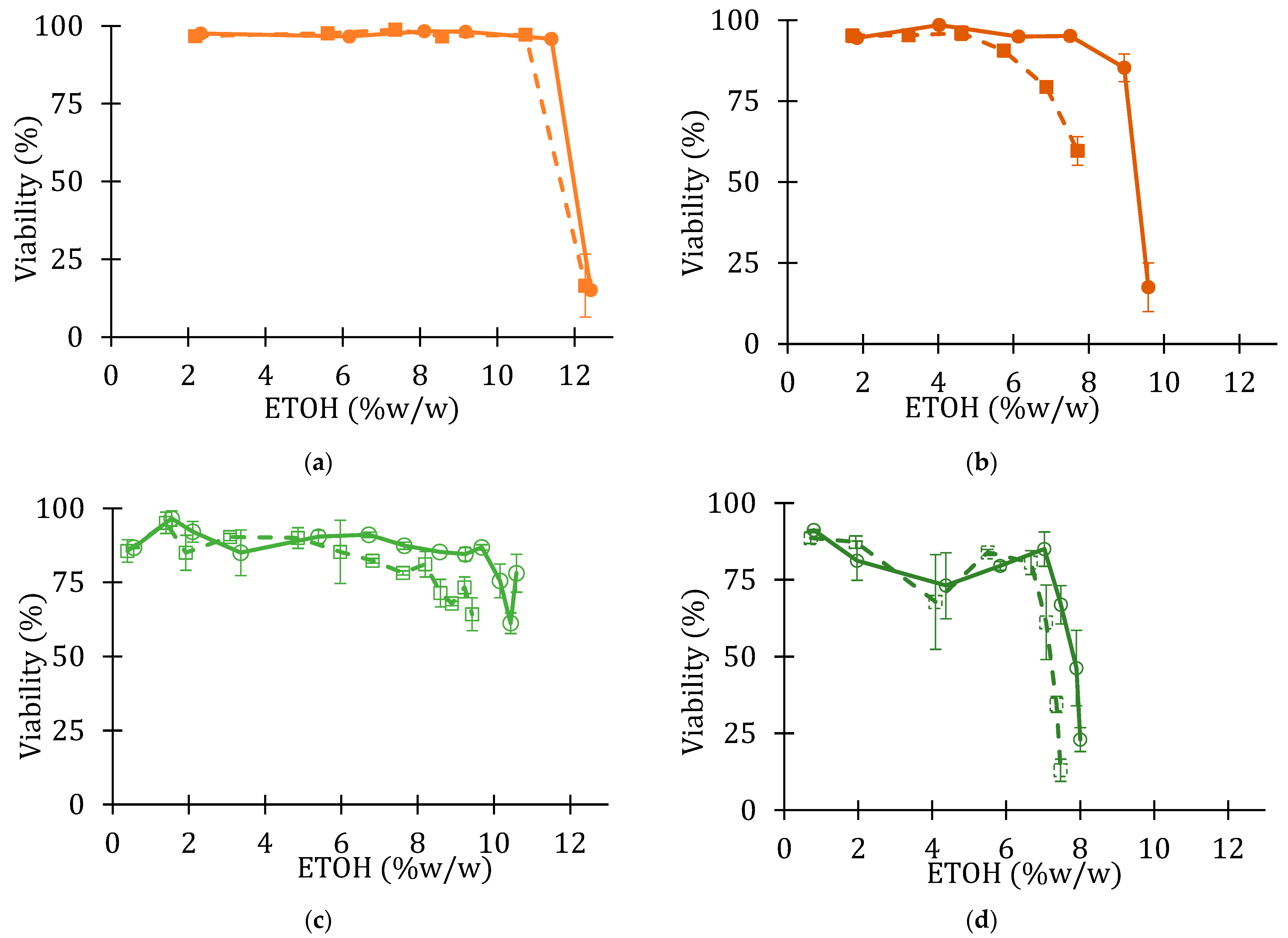

3.1.3. Cell Viability

3.2. Yeast Morphology Assessment

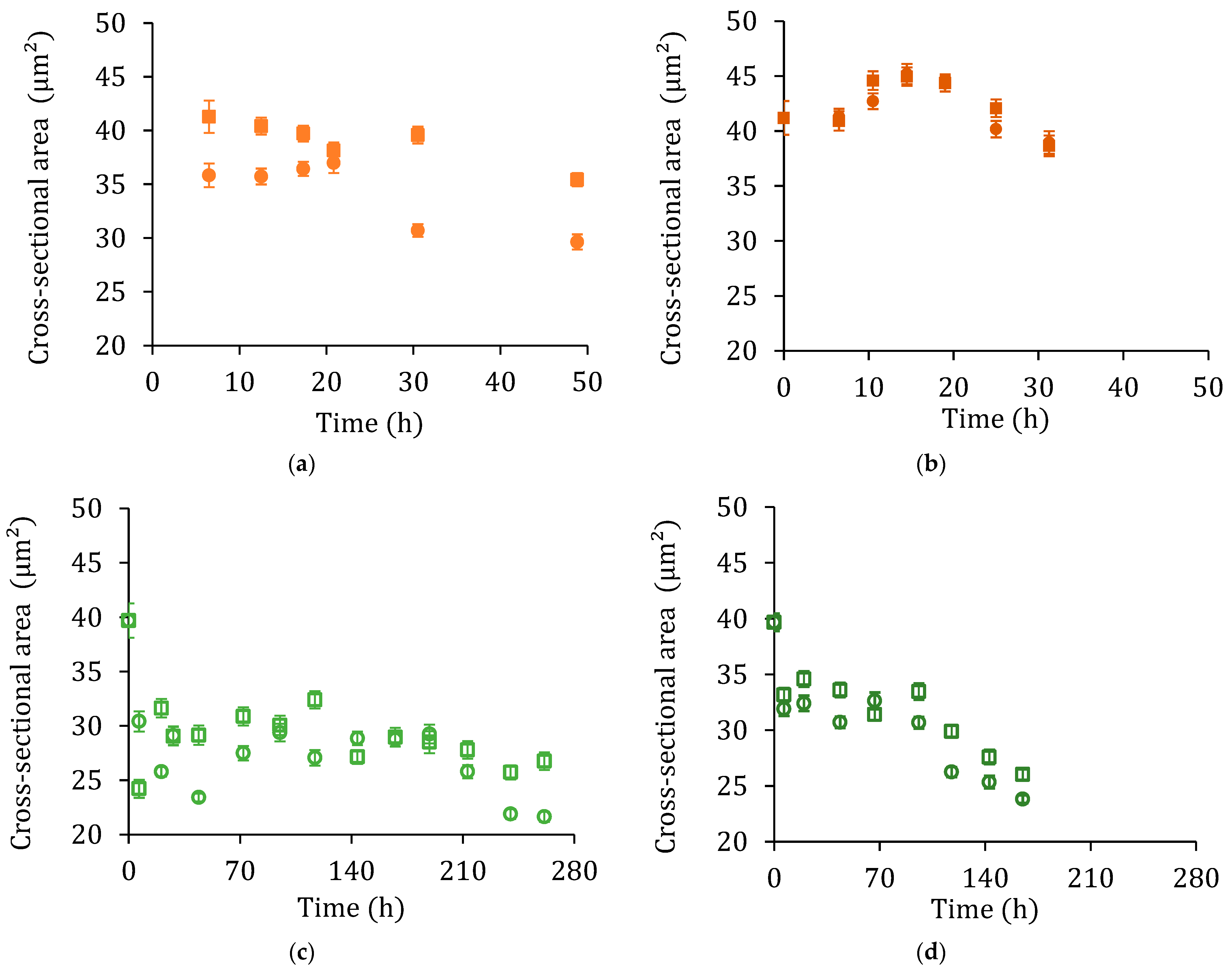

3.2.1. Yeast CSA

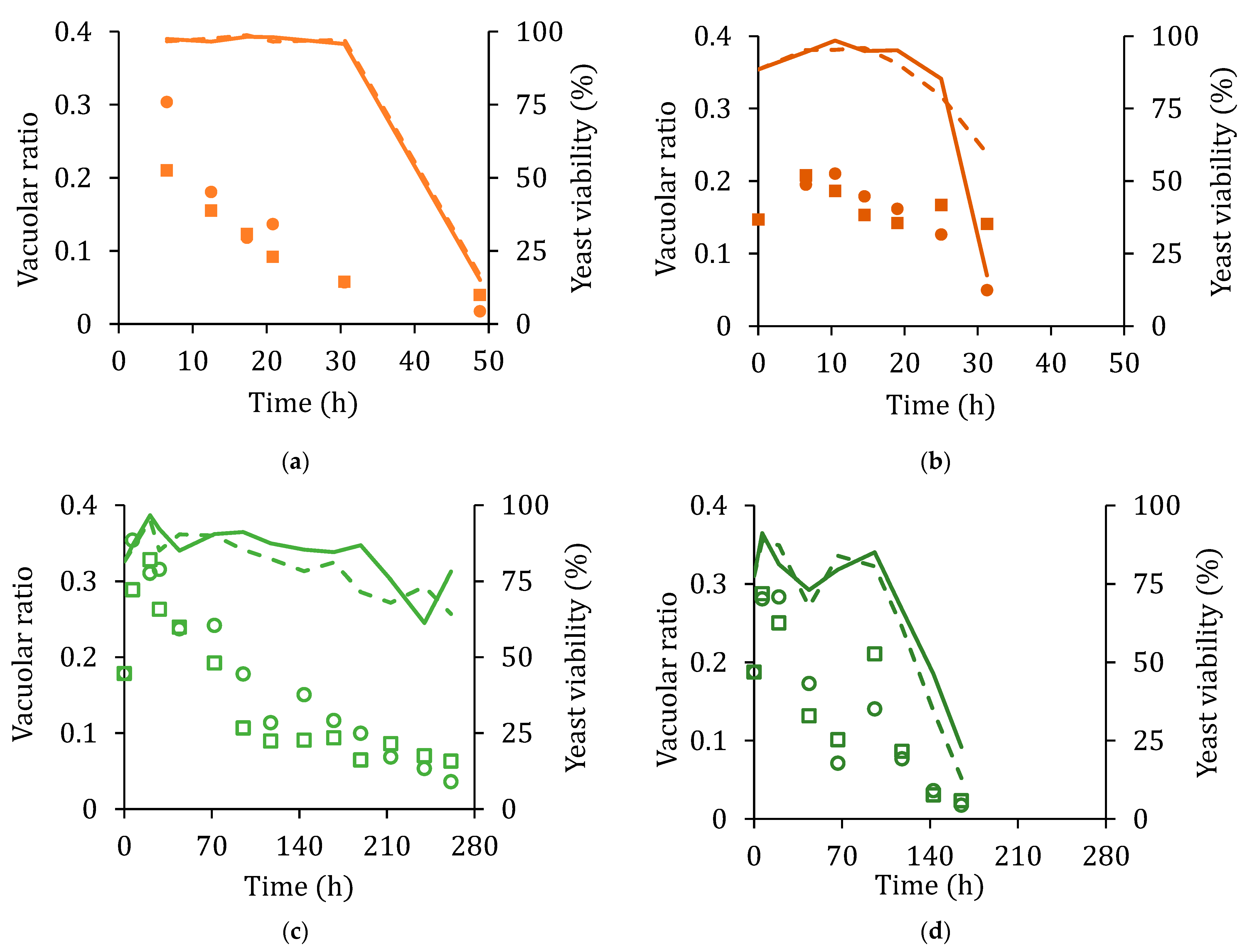

3.2.2. Vacuolar Ratio

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Guadalupe-Daqui, M.; MacIntosh, A.J. Rapid beer fermentation: The effect of vacuum pressure on a pilot scale lager fermentation. J. Am. Soc. Brew. Chem. 2019, 77, 235–242. [Google Scholar] [CrossRef]

- Dixon, N.M.; Kell, D.B. The inhibition by CO2 of the growth and metabolism of micro-organisms. J. Appl. Bacteriol. 1989, 67, 109–136. [Google Scholar] [CrossRef]

- Lekkas, C.; Stewart, G.G.; Hill, A.E.; Taidi, B.; Hodgson, J.A. The importance of free amino nitrogen in wort and beer. Tech. Q. 2005, 42, 113–116. [Google Scholar]

- Cysewski, G.R.; Wilke, C.R. Rapid ethanol fermentations using vacuum and cell recycle. Biotech. Bioeng. 1977, 19, 1125–1142. [Google Scholar] [CrossRef]

- Nguyen, V.; Kosuge, H.; Auresenia, J.; Tan, R.; Brondial, Y. Effect of vacuum pressure on ethanol fermentation. J. Appl. Sci. 2009, 9, 3020–3026. [Google Scholar] [CrossRef]

- Ramalingham, A.; Finn, R.K. Vacuferm process: A new approach to fermentation alcohol. Biotech. Bioeng. 1977, 19, 583–589. [Google Scholar] [CrossRef]

- Lekkas, C.; Stewart, G.G.; Hill, A.E.; Taidi, B.; Hodgson, J.A. Elucidation of the role of nitrogenous wort components in yeast fermentation. J. Inst. Brew. 2007, 113, 3–8. [Google Scholar] [CrossRef]

- Paik, J.; Low, N.H.; Ingledew, W.M. Malt extract relationship of chemical composition to fermentability. J. Am. Soc. Brew. Chem. 1990, 49, 8–13. [Google Scholar] [CrossRef]

- Piddock, M.P.; Kreisz, S.; Heldt-Hansen, H.P.; Nielsen, K.F.; Olsson, L. Physiological characterization of brewer’s yeast in high-gravity beer fermentations with glucose or maltose syrups as adjuncts. Appl. Microbiol. Biotechnol. 2009, 84, 453–464. [Google Scholar] [CrossRef]

- Fernández, S.; Machuca, N.; González, M.G.; Sierra, J.A. Accelerated fermentation of high-gravity worts and its effect on yeast performance. J. Am. Soc. Brew. Chem. 1985, 43, 109–113. [Google Scholar] [CrossRef]

- White, J.; Munns, D.J. Influence of temperature on yeast growth and fermentation. J. Inst. Brew. 1951, 57, 280–284. [Google Scholar] [CrossRef]

- Mo, F.; Zhao, H.; Lei, H.; Zhao, M. Effects of nitrogen composition on fermentation performance of brewer’s yeast and the absorption of peptides with different molecular weights. Appl. Biochem. Biotech. 2013, 171, 1339–1350. [Google Scholar] [CrossRef]

- Almeida, R.B.; Almeida e Silva, J.B.; Lima, U.A.; Silva, D.P.; Assis, A.N. Evaluation of fermentation parameters during high-gravity beer production. Braz. J. Chem. Eng. 2019, 18, 459–465. [Google Scholar] [CrossRef]

- Lei, H.; Zhao, H.; Yu, Z.; Zhao, M. Effects of wort gravity and nitrogen level on fermentation performance of brewer’s yeast and the formation of flavor volatiles. Appl. Biochem. Biotech. 2012, 166, 1562–1574. [Google Scholar] [CrossRef]

- D’Amore, T.; Panchal, C.J.; Russell, I.; Stewart, G.G. A study of ethanol tolerance in yeast. Crit. Rev. Biotech. 1990, 9, 287–304. [Google Scholar] [CrossRef]

- Ruis, H.; Schüller, C. Stress signaling in yeast. BioEssays 1995, 17, 959–965. [Google Scholar] [CrossRef]

- Martinez-Pastor, M.T.; Marchler, G.; Schuller, C.; Marchler-Bauer, A.; Ruis, H.; Estruch, R. The Saccharomyces cerevisiae zinc finger proteins Msn2p and Msn4p are required for transcriptional induction through the stress response element (STRE). EMBO J. 1996, 15, 2227–2235. [Google Scholar] [CrossRef]

- Schmitt, A.P.; McEntee, K. Msn2p, a zinc finger protein, is the transcriptional activator of the multistress response in Saccharomyces cerevisiae. Proc. Natl. Acad. Sci. USA 1996, 93, 5777–5782. [Google Scholar] [CrossRef]

- Chatterjee, M.T.; Khalawan, S.A.; Curran, B.P.G. Cellular lipid composition influences stress activation of the yeast general stress response element (STRE). Microbiol. Read. 2000, 146, 877–884. [Google Scholar] [CrossRef]

- Gibson, B.R.; Lawrence, S.J.; Leclaire, J.P.R.; Powell, C.D.; Smart, K.A. Yeast responses to stresses associated with industrial brewery handling. FEMS Microbes. 2007, 31, 535–569. [Google Scholar] [CrossRef]

- Saini, P.; Beniwal, A.; Kokkiligadda, A.; Vij, S. Response and tolerance of yeast to changing environmental stress during ethanol fermentation. Proc. Biochem. 2018, 72, 1–12. [Google Scholar] [CrossRef]

- Wang, J.; Ding, H.; Zheng, F.; Li, Y.; Liu, C.; Niu, C.; Li, Q. Physiological changes of beer brewer’s yeast during serial beer fermentation. J. Am. Soc. Brew. Chem. 2019, 77, 10–20. [Google Scholar] [CrossRef]

- Zakhartsev, M.; Reuss, M. Cell size and morphological properties of yeast Saccharomyces cerevisiae in relation to growth temperature. FEMS Yeast Res. 2018, 18, foy052. [Google Scholar] [CrossRef]

- Pratt, P.; Bryce, J.; Stewart, G.G. The yeast vacuole—A scanning electron microscopy study during high gravity wort fermentations. J. Inst. Brew. 2007, 113, 50–60. [Google Scholar] [CrossRef]

- Mansure, J.J.C.; Panek, A.D.; Crowe, L.M.; Crow, J.H. Trehalose inhibits ethanol effects on intact yeast cells and liposomes. Int. J. Biochem. and Biophy. 1994, 1191, 309–316. [Google Scholar] [CrossRef] [PubMed]

- Izawa, S.; Ikeda, K.; Miki, T.; Wakai, Y.; Inoue, Y. Vacuolar morphology of Saccharomyces cerevisiae during the process of wine making and Japanese sake brewing. Appl. Microbiol. Biotech. 2010, 88, 277–282. [Google Scholar] [CrossRef]

- Pratt, P.; Bryce, J.; Stewart, G.G. The effects of osmotic pressure and ethanol on yeast viability and morphology. J. Inst. Brew. 2003, 109, 218–228. [Google Scholar] [CrossRef]

- Coelho, M.; Belo, I.; Pinheiro, R.; Amaral, A.; Mota, M.; Coutinho, J.; Ferreira, E. Effect of hyperbaric stress on yeast morphology: Study by automated image analysis. Appl. Microbiol. Biotech. 2004, 66, 318–324. [Google Scholar] [CrossRef]

- Ginovart, M.; Carbó, R.; Blanco, M.; Portell, X. Digital image analysis of yeast single cells growing in two different oxygen concentrations to analyze the population growth and to assist individual-based modeling. Front. Microbiol. 2018, 8, 2628. [Google Scholar] [CrossRef]

- Stolze, N.; Bader, C.; Henning, C.; Mastin, J.; Holmes, A.; Sutlief, A. Automated image analysis with ImageJ of yeast colony forming units from cannabis flowers. J. Microbiol. Meth. 2019, 164, 105681. [Google Scholar] [CrossRef]

- Wilson, C.; Lukowicz, R.; Merchant, S.; Valquier-Flynn, H.; Caballero, J.; Sandoval, J.; Okuom, M.; Huber, C.; Brooks, T.D.; Wilson, E.; et al. Quantitative and qualitative assessment methods for biofilm growth: A mini-review. Res. Rev. J. Eng. Technol. 2017, 6, 1–42. [Google Scholar]

- Grishagin, I.V. Automatic cell counting with ImageJ. Anal. Biochem. 2015, 473, 63–65. [Google Scholar] [CrossRef] [PubMed]

- Guadalupe-Daqui, M.; Chen, M.; Thompson-Witrick, K.A.; MacIntosh, A.J. Yeast morphology assessment through automated image analysis during fermentation. Fermentation 2021, 7, 44. [Google Scholar] [CrossRef]

- Hill, A.E.; Stewart, G.G. Free amino nitrogen in brewing. Fermentation 2019, 5, 22. [Google Scholar] [CrossRef]

- Pugh, T.A.; Maurer, J.M.; Pringle, A.T. The impact of wort nitrogen limitation on yeast fermentation performance and diacetyl. Tech. Q. 1997, 34, 185–189. [Google Scholar]

- Jones, B.L.; Budde, A.D. How various malt endoproteinase classes affect wort soluble protein levels. J. Cereal Sci. 2005, 41, 95–106. [Google Scholar] [CrossRef]

- Liu, C.; Li, K.; Wen, Y.; Geng, B.; Liu, Q.; Lin, Y. Chapter One—Bioethanol: New opportunities for an ancient product. In Advances in Bioenergy; Li, Y., Ge, X., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; Volume 4, pp. 1–34. [Google Scholar]

- Reddy, L.; Reddy, O. Effect of fermentation conditions on yeast growth and volatile composition of wine produced from mango (Mangifer indica L.) fruit juice. Food Bioprod. Proc. 2011, 89, 487–491. [Google Scholar] [CrossRef]

- Torija, M.; Rozès, N.; Poblet, M.; Guillamón, J.; Mas, A. Effects of fermentation temperature on the strain population of Saccharomyces cerevisiae. Int. J. Food Microbiol. 2003, 80, 47–53. [Google Scholar] [CrossRef]

- Camargos, C.V.; Moraes, V.D.; de Oliveira, L.M.; Guidini, C.Z.; Ribeiro, E.J.; Santos, L.D. High gravity and very high gravity fermentation of sugarcane molasses by flocculating Saccharomyces cerevisiae: Experimental investigation and kinetic modeling. Appl. Biochem. Biotech. 2021, 193, 807–821. [Google Scholar] [CrossRef]

- ASBC Methods of Analysis, online. Method Yeast-4. MICROSCOPIC YEAST CELL COUNTING. Approved (1958), Rev. (2016). American Society of Brewing Chemists, St. Paul, MN, USA. Available online: https://www.asbcnet.org/Methods/About/Pages/Cite.aspx (accessed on 31 December 2022).

- Painting, K.; Kirsop, B. A quick method for estimating the percentage of viable cells in a yeast population, using methylene blue staining. World J. Microbiol. Biotechnol. 1990, 6, 346–347. [Google Scholar] [CrossRef]

- ASBC Methods of Analysis, Online. Method Wort-12. Ninhydrin Method (International Method). Approved (1975 ), Rev. (2010). American Society of Brewing Chemists, St. Paul, MN, USA. Available online: http://dx.doi.org/10.1094/ASBCMOA-Wort-12 (accessed on 31 December 2022).

- Rudolph, A.; MacIntosh, A.J.; Speers, R.A.; St. Mary, C. Modeling Yeast in Suspension during Laboratory and Commercial Fermentations to Detect Aberrant Fermentation Processes. J. Am. Soc. Brew. Chem. 2020, 78, 63–73. [Google Scholar] [CrossRef]

- ASBC Methods of Analysis, online. Method Yeast-14. MINIATURE FERMENTATION ASSAY. Approved (2011). American Society of Brewing Chemists, St. Paul, MN, USA. Available online: http://dx.doi.org/10.1094/ASBCMOA-Yeast-14 (accessed on 31 December 2022).

- Powell, C.D.; Quain, D.E.; Katherine, S.A. The impact of brewing yeast cell age on fermentation performance, attenuation and flocculation. FEMS Microbiol. 2003, 3, 149–157. [Google Scholar] [CrossRef] [PubMed]

- Stewart, G.G.; Russel, I.; Anstruther, A. Handbook of Brewing; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Jin, Y.; Weisman, L.S. The vacuole/lysosome is required for cell-cycle progression. eLife 2015, 4, e08160. [Google Scholar] [CrossRef] [PubMed]

- Chan, Y.M.; Wallace, M.F. Organelle size scaling of the budding yeast vacuole is tuned by membrane trafficking rates. Biophys. J. 2014, 106, 1986–1996. [Google Scholar] [CrossRef] [PubMed]

| Ingredients | Formulation 1 a | Formulation 2 b |

|---|---|---|

| Distilled water | 15.0 kg | 15.0 kg |

| Molasses | 1.3 kg | 1.3 kg |

| Sucrose | 3.7 kg | 3.7 kg |

| Yeast extract | 0.0 g | 154.0 g |

| Extrinsic Factors | |||

|---|---|---|---|

| Configuration | Temperature (°C) | FAN (mg/L) | CO2 Pressure (kPa) |

| Low temperature High FAN (LTHF) | 30 | 300 | 24.1 |

| 30 | 300 | 101.3 | |

| High temperature High FAN (HTHF) | 35 | 300 | 24.1 |

| 35 | 300 | 101.3 | |

| Low temperature Low FAN (LTLF) | 30 | 17 | 24.1 |

| 30 | 17 | 101.3 | |

| High temperature Low FAN (HTLF) | 35 | 17 | 24.1 |

| 35 | 17 | 101.3 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guadalupe-Daqui, M.; Chen, M.; Sarnoski, P.J.; Goodrich-Schneider, R.M.; MacIntosh, A.J. Impacts of Reduced (Vacuum) Pressure on Yeast Fermentation as Assessed Using Standard Methods and Automated Image Analysis. Fermentation 2023, 9, 155. https://doi.org/10.3390/fermentation9020155

Guadalupe-Daqui M, Chen M, Sarnoski PJ, Goodrich-Schneider RM, MacIntosh AJ. Impacts of Reduced (Vacuum) Pressure on Yeast Fermentation as Assessed Using Standard Methods and Automated Image Analysis. Fermentation. 2023; 9(2):155. https://doi.org/10.3390/fermentation9020155

Chicago/Turabian StyleGuadalupe-Daqui, Mario, Mandi Chen, Paul J. Sarnoski, Renée M. Goodrich-Schneider, and Andrew J. MacIntosh. 2023. "Impacts of Reduced (Vacuum) Pressure on Yeast Fermentation as Assessed Using Standard Methods and Automated Image Analysis" Fermentation 9, no. 2: 155. https://doi.org/10.3390/fermentation9020155

APA StyleGuadalupe-Daqui, M., Chen, M., Sarnoski, P. J., Goodrich-Schneider, R. M., & MacIntosh, A. J. (2023). Impacts of Reduced (Vacuum) Pressure on Yeast Fermentation as Assessed Using Standard Methods and Automated Image Analysis. Fermentation, 9(2), 155. https://doi.org/10.3390/fermentation9020155