Physicochemical and Rheological Properties of Stirred Yoghurt during Storage Induced from High-Intensity Thermosonicated Goat and Cow Milk

Abstract

1. Introduction

2. Materials and Methods

2.1. Samples

2.2. Homogenization and High-Intensity Thermosonication Process

2.3. Particle Size Measurements

2.4. The pH, Soluble Calcium and Phosphorus Analyses

2.5. Stirred Yoghurt Preparation

2.6. Rheological Properties

2.7. Syneresis

2.8. Titratable Acidity and pH Values

2.9. Confocal Scanning Laser Microscopy (CSLM)

2.10. Color Measurements

2.11. Sensory Properties

2.12. Electronic Nose

2.13. Statistical Analysis

3. Results and Discussion

3.1. Particle Size Measurements

3.2. The pH, Soluble Calcium and Phosphorus Analyses

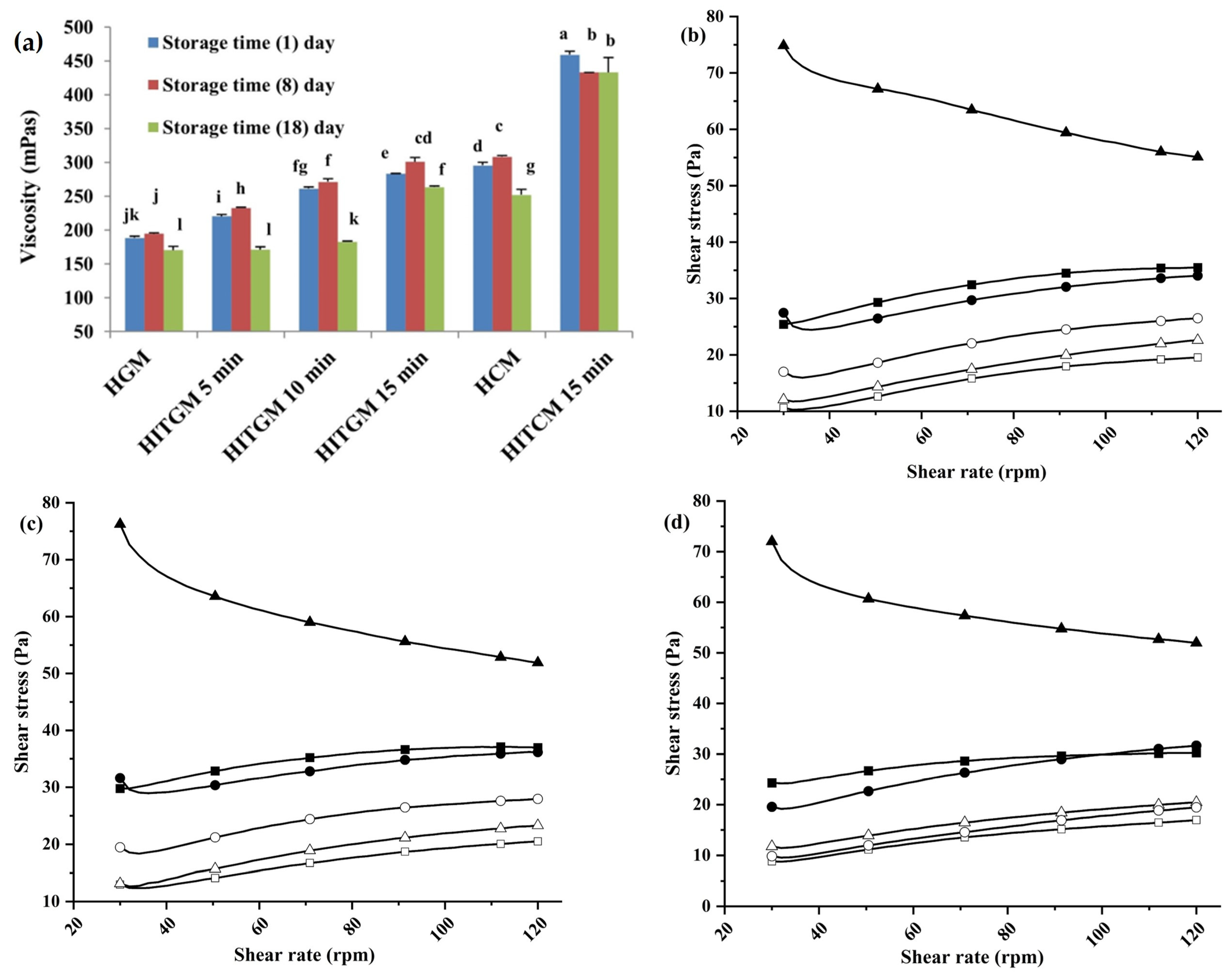

3.3. Rheological Properties

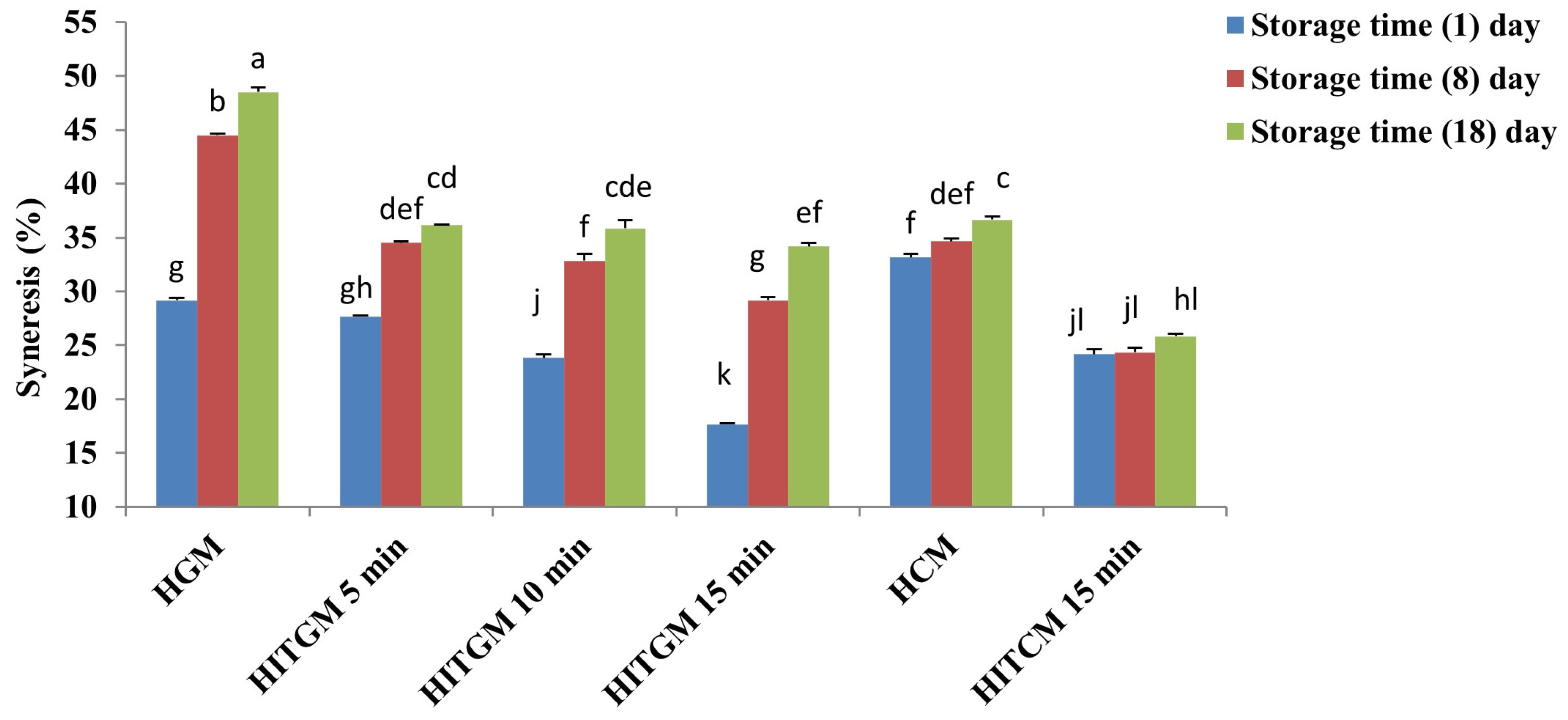

3.4. Syneresis

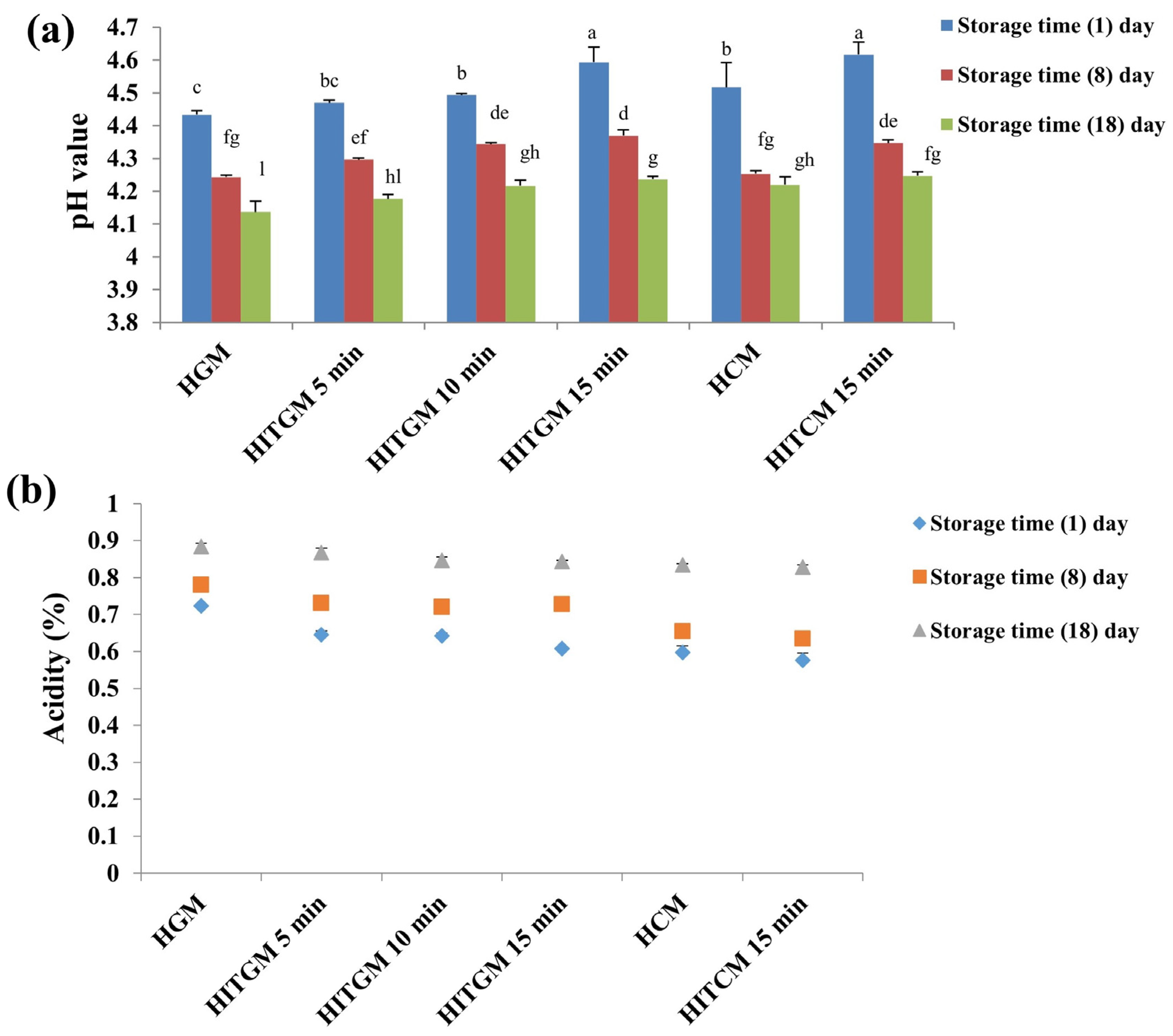

3.5. Titratable Acidity and pH Values

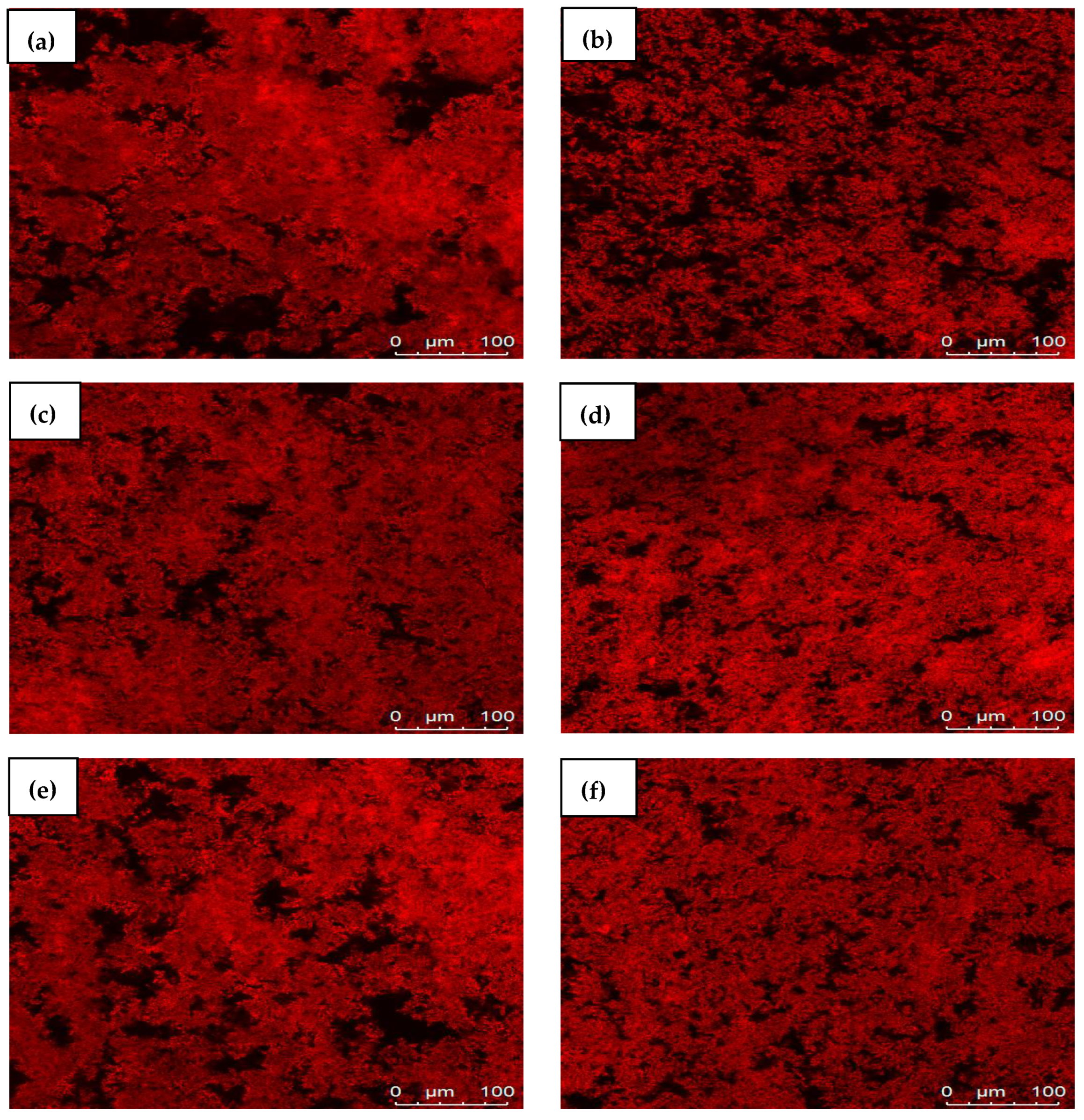

3.6. Confocal Scanning Laser Microscopy (CSLM)

3.7. Color Measurements

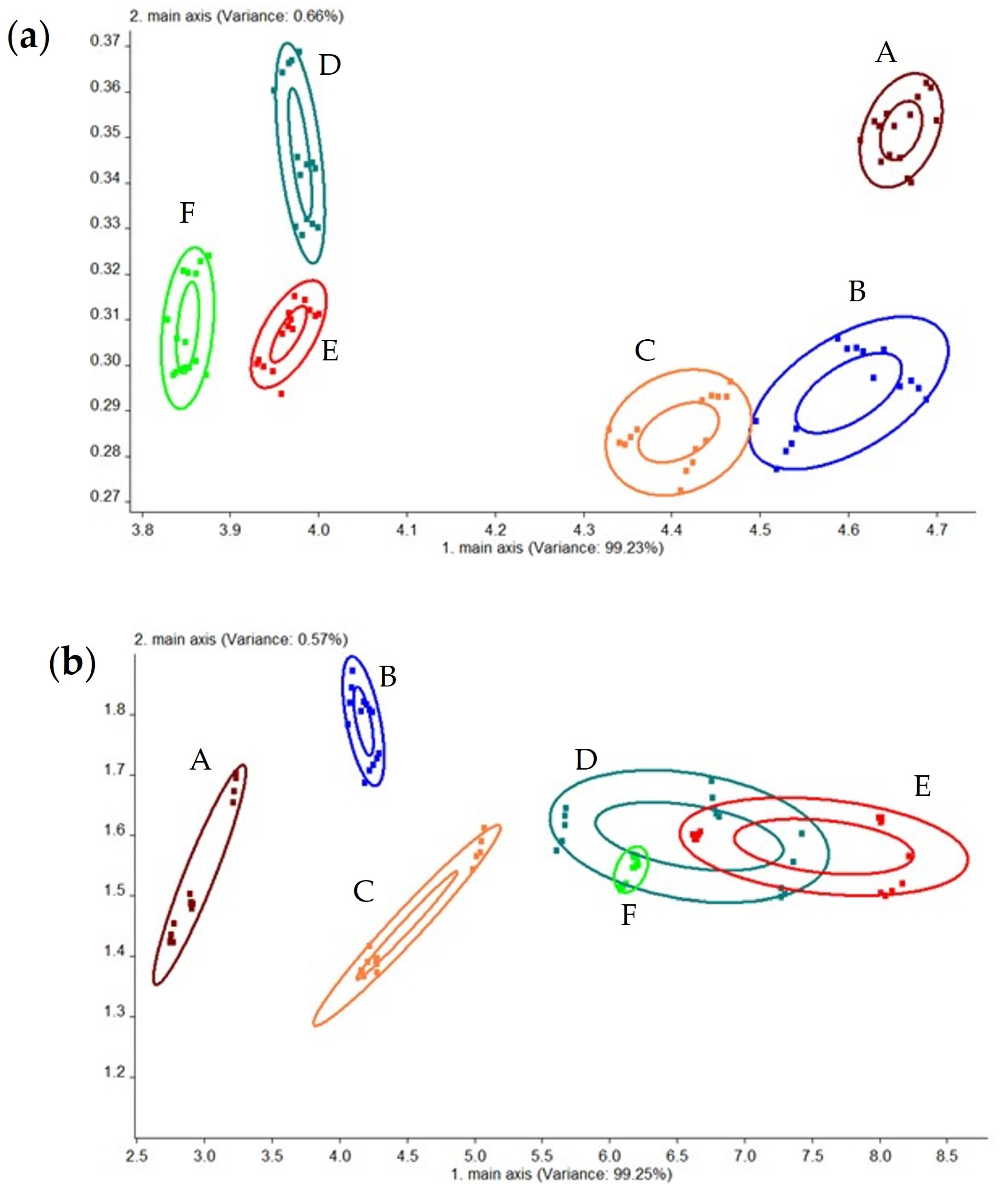

3.8. Electronic Nose

3.9. Sensory Evaluation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hassan, A.; Amjad, I. Nutritional evaluation of yoghurt prepared by different starter cultures and their physiochemical analysis during storage. Afr. J. Biotechnol. 2010, 9, 2913–2917. [Google Scholar]

- Slačanac, V.; Božanić, R.; Hardi, J.; Rezessyné szabó, J.; Lučan, M.; Krstanović, V. Nutritional and therapeutic value of fermented caprine milk. Int. J. Dairy Technol. 2010, 63, 171–189. [Google Scholar] [CrossRef]

- Verruck, S.; Dantas, A.; Prudencio, E.S. Functionality of the components from goat’s milk, recent advances for functional dairy products development and its implications on human health. J. Funct. Foods. 2019, 52, 243–257. [Google Scholar] [CrossRef]

- Vianna, F.S.; da Cruz Silva Canto, A.C.V.; Costa-Lima, B.; Salim, A.P.; Balthazar, C.F.; Costa, M.P.; Panzenhagen, P.; Rachid, R.; Franco, R.M.; Adam, C. Milk from different species on physicochemical and microstructural yoghurt properties. Ciência Rural. 2019, 49, 6. [Google Scholar] [CrossRef]

- El-Shafei, S.M.S.; Sakr, S.S.; Abou-Soliman, N.H.I. The impact of supplementing goats’ milk with quinoa extract on some properties of yoghurt. Int. J. Dairy Technol. 2020, 73, 126–133. [Google Scholar] [CrossRef]

- Lu, A.; Wei, X.; Cai, R.; Xiao, S.; Yuan, H.; Gong, J.; Chu, B.; Xiao, G. Modeling the effect of vibration on the quality of stirred yogurt during transportation. Food Sci. Biotechnol. 2020, 29, 889–896. [Google Scholar] [CrossRef]

- Delgado, K.F.; Frasao, S.; Pereira, M.; Adam, C.; Junior, C. Different alternatives to improve rheological and textural characteristics of fermented goat products—A Review. Rheol Open Access 2017, 1, 2–6. [Google Scholar]

- Wu, H.; Hulbert, G.J.; Mount, J.R. Effects of ultrasound on milk homogenization and fermentation with yogurt starter. Innov. Food Sci. Emerg. Technol. 2000, 1, 211–218. [Google Scholar] [CrossRef]

- Nguyen, N.H.A.; Anema, S.G. Effect of ultrasonication on the properties of skim milk used in the formation of acid gels. Innov. Food Sci. Emerg. Technol. 2010, 11, 616–622. [Google Scholar] [CrossRef]

- Nguyen, N.H.A.; Anema, S.G. Ultrasonication of reconstituted whole milk and its effect on acid gelation. Food Chem. 2017, 217, 593–601. [Google Scholar] [CrossRef]

- Villamiel, M.; de Jong, P. Influence of high-intensity ultrasound and heat treatment in continuous flow on fat, proteins, and native enzymes of milk. J. Agric. Food Chem. 2000, 48, 472–478. [Google Scholar] [CrossRef] [PubMed]

- Riener, J.; Noci, F.; Cronin, D.A.; Morgan, D.J.; Lyng, J.G. The effect of thermosonication of milk on selected physicochemical and microstructural properties of yoghurt gels during fermentation. Food Chem. 2009, 114, 905–911. [Google Scholar] [CrossRef]

- Sfakianakis, P.; Tzia, C. conventional and innovative processing of milk for yogurt manufacture; development of texture and flavor: A Review. Foods 2014, 3, 176–193. [Google Scholar] [CrossRef] [PubMed]

- Erkaya, T.; Başlar, M.; Şengül, M.; Ertugay, M.F. Effect of thermosonication on physicochemical, microbiological and sensorial characteristics of ayran during storage. Ultrason. Sonochem. 2015, 23, 406–412. [Google Scholar] [CrossRef]

- Sfakianakis, P.; Topakas, E.; Tzia, C. Comparative study on high-intensity ultrasound and pressure milk homogenization: Effect on the kinetics of yogurt fermentation process. Food Bioprocess Technol. 2015, 8, 548–557. [Google Scholar] [CrossRef]

- Riener, J.; Noci, F.; Cronin, D.A.; Morgan, D.J.; Lyng, J.G. A comparison of selected quality characteristics of yoghurts prepared from thermosonicated and conventionally heated milks. Food Chem. 2010, 119, 1108–1113. [Google Scholar] [CrossRef]

- Madadlou, A.; Emam-Djomeh, Z.; Mousavi, M.E.; Mohamadifar, M.; Ehsani, M. Acid-induced gelation behavior of sonicated casein solutions. Ultrason. Sonochem. 2010, 17, 153–158. [Google Scholar] [CrossRef]

- Ragab, E.S.; Lu, J.; Pang, X.Y.; Nassar, K.S.; Yang, B.Y.; Zhang, S.W.; Lv, J.P. Effect of thermosonication process on physicochemical properties and microbial load of goat’s milk. J. Food Sci. Technol. 2019, 56, 5309–5316. [Google Scholar] [CrossRef]

- Li, S.; Ye, A.; Singh, H. Effects of seasonal variations on the quality of set yogurt, stirred yogurt, and greek-style yogurt. J. Dairy Sci. 2021, 104, 1424–1432. [Google Scholar] [CrossRef]

- Gursoy, O.; Yilmaz, Y.; Gokce, O.; Ertan, K. Effect of ultrasound power on physicochemical and rheological properties of yoghurt drink produced with thermosonicated milk. Emir. J. Food Agric. 2016, 28, 235–241. [Google Scholar] [CrossRef]

- Andoyo, R.; Guyomarc’h, F.; Cauty, C.; Famelart, M.H. Model mixtures evidence the respective roles of whey protein particles and casein micelles during acid gelation. Food Hydrocoll. 2014, 37, 203–212. [Google Scholar] [CrossRef]

- Nassar, K.S.; Zhang, S.; Lu, J.; Pang, X.; Ragab, E.S.; Yue, Y.; Lv, J. Combined effects of high-pressure treatment and storage temperature on the physicochemical properties of caprine milk. Int. Dairy J. 2019, 96, 66–72. [Google Scholar] [CrossRef]

- Ampuero, S.; Bosset, J.O. The electronic nose applied to dairy products: A review. Sens. Actuators B Chem. 2003, 94, 1–12. [Google Scholar] [CrossRef]

- Ragab, E.S.; Zhang, S.; Pang, X.; Lu, J.; Nassar, K.S.; Yang, B.; Obaroakpo, U.J.; Lv, J. Ultrasound improves the rheological properties and microstructure of rennet-induced gel from goat milk. Int. Dairy J. 2020, 104, 104642. [Google Scholar] [CrossRef]

- Chandrapala, J.; Zisu, B.; Palmer, M.; Kentish, S.; Ashokkumar, M. Effects of ultrasound on the thermal and structural characteristics of proteins in reconstituted whey protein concentrate. Ultrason. Sonochem. 2011, 18, 951–957. [Google Scholar] [CrossRef] [PubMed]

- Ertugay, M.F.; Sengül, M. Effect of ultrasound treatment on milk homogenization and particle size distribution of fat. Turk. J. Vet. Anim. Sci. 2004, 28, 303–308. [Google Scholar]

- Chandrapala, J.; Ong, L.; Zisu, B.; Gras, S.L.; Ashokkumar, M.; Kentish, S.E. The effect of sonication and high pressure homogenization on the properties of pure cream. Innov. Food Sci. Emerg. Technol. 2016, 33, 298–307. [Google Scholar] [CrossRef]

- Walstra, P.; Geurts, T.J.; Walstra, P.; Wouters, J.T.M. Dairy Science and Technology; CRC Press: Boca Raton, FL, USA, 2005; ISBN 1420028014. [Google Scholar]

- Shanmugam, A.; Chandrapala, J.; Ashokkumar, M. The effect of ultrasound on the physical and functional properties of skim milk. Innov. Food Sci. Emerg. Technol. 2012, 16, 251–258. [Google Scholar] [CrossRef]

- Tabatabaie, F.; Mortazavi, A.; Ebadi, A.G. Effect of power ultrasound and microstructure change of casein micelle in yoghurt. Asian J. Chem. 2009, 21, 1589–1594. [Google Scholar]

- Van Vliet, T.; Van Dijkl, H.J.M.; Zoon, P.; Walstra, P. Relation between syneresis and rheological properties of particle gels. Colloid Polym. Sci. 1991, 269, 620–627. [Google Scholar] [CrossRef]

- Ragab, E.; Yacoub, S.; Nassar, K.; Zhang, S.; Lv, J. Textural and microstructural properties of set yoghurt produced from goat milk treated by homogenization and thermosonication. Alex. Sci. Exch. J. 2021, 42, 985–995. [Google Scholar] [CrossRef]

- Moreno-Montoro, M.; Navarro-Alarcón, M.; Bergillos-Meca, T.; Giménez-Martínez, R.; Sánchez-Hernández, S.; Olalla-Herrera, M. Physicochemical, nutritional, and organoleptic characterization of a skimmed goat milk fermented with the probiotic strain Lactobacillus plantarum C4. Nutrients 2018, 10, 633. [Google Scholar] [CrossRef] [PubMed]

- de Morais, J.L.; Garcia, E.F.; Viera, V.B.; Pontes, E.D.S.; de Araújo, M.G.G.; de Figueirêdo, R.M.F.; dos Santos Moreira, I.; do Egito, A.S.; Dos Santos, K.M.O.; Soares, J.K.B. Autochthonous adjunct culture of limosilactobacillus mucosae cnpc007 improved the techno-functional, physicochemical, and sensory properties of goat milk greek-style yogurt. J. Dairy Sci. 2022, 105, 1889–1899. [Google Scholar] [CrossRef]

- Bermúdez-Aguirre, D.; Mawson, R.; Versteeg, K.; Barbosa-Cánovas, G.V. Composition properties, physicochemical characteristics and shelf life of whole milk after thermal and thermo-sonication treatments. J. Food Qual. 2009, 32, 283–302. [Google Scholar] [CrossRef]

- Ozdemir, U.; Kilic, M. Influence of fermentation conditions on rheological properties and serum separation of Aryan. J. Texture Stud. 2004, 35, 415–428. [Google Scholar] [CrossRef]

for the stirred yoghurt from homogenized goat milk,

for the stirred yoghurt from homogenized goat milk,

from goat milk, high-intensity thermosonicated for 5 min,

from goat milk, high-intensity thermosonicated for 5 min,

from goat milk, high-intensity thermosonicated for 10 min,

from goat milk, high-intensity thermosonicated for 10 min,

from goat milk, high-intensity thermosonicated for 15 min,

from goat milk, high-intensity thermosonicated for 15 min,

homogenized cow milk and

homogenized cow milk and

from cow milk, high-intensity thermosonicated for 15 min. Data points not connected by the same letter are significantly different from each other (p < 0.05).

from cow milk, high-intensity thermosonicated for 15 min. Data points not connected by the same letter are significantly different from each other (p < 0.05).

for the stirred yoghurt from homogenized goat milk,

for the stirred yoghurt from homogenized goat milk,

from goat milk, high-intensity thermosonicated for 5 min,

from goat milk, high-intensity thermosonicated for 5 min,

from goat milk, high-intensity thermosonicated for 10 min,

from goat milk, high-intensity thermosonicated for 10 min,

from goat milk, high-intensity thermosonicated for 15 min,

from goat milk, high-intensity thermosonicated for 15 min,

homogenized cow milk and

homogenized cow milk and

from cow milk, high-intensity thermosonicated for 15 min. Data points not connected by the same letter are significantly different from each other (p < 0.05).

from cow milk, high-intensity thermosonicated for 15 min. Data points not connected by the same letter are significantly different from each other (p < 0.05).

| Samples | Particle Size (nm) * | Soluble Calcium (mg/100 g) | Soluble Phosphorus (mg/100 g) | pH Values | Fat Size (nm) |

|---|---|---|---|---|---|

| HGM | 302.9 ± 3.63 c | 298.25 ± 6.21 cb | 692.31 ± 14.89 cb | 6.45 ± 0.004 b | 503 ± 4.01 b |

| HITGM 5 min | 294.9 ± 1.10 cd | 289.40 ± 0.47 cb | 695.83 ± 0.86 cb | 6.45 ± 0.001 b | 356 ± 6.48 c |

| HITGM 10 min | 283.3 ± 0.20 d | 279.31 ± 3.44 c | 676.89 ± 6.32 c | 6.41 ± 0.012 c | 272 ± 0.77 d |

| HITGM 15 min | 295.6 ± 0.65 cd | 310.62 ± 2.16 b | 713.44 ± 0.76 b | 6.45 ± 0.004 b | 292 ± 1.43 d |

| HCM | 426.2 ± 1.39 a | 367.56 ± 31.85 a | 944.28 ± 17.84 a | 6.79 ± 0.004 a | 915 ± 43.45 a |

| HITCM 15 min | 354.0 ± 3.18 b | 378.21 ± 2.05 a | 954.28 ± 17.84 a | 6.79 ± 0.009 a | 289 ± 0.60 d |

| Samples | Color Values | |||||

|---|---|---|---|---|---|---|

| Storage 1 Day | Storage 18 Days | |||||

| L* | a* | b* | L* | a* | b* | |

| HGM | 97.92 ± 0.11 d | −2.03 ± 0.08 ab | 9.48 ± 0.1 cd | 99.52 ± 0.07 a | −3.01 ± 0.36 c | 8.51 ± 0.32 f |

| HITGM 5 min | 98.77 ± 0.52 bc | −3.19 ± 0.45 c | 9.38 ± 0.09 d | 99.58 ± 0.06 a | −2.75 ± 0.17 c | 8.91 ± 0.12 e |

| HITGM 10 min | 98.38 ± 0.06 cd | −1.87 ± 0.05 a | 7.76 ± 0.21 gh | 99.17 ± 0.25 ab | −1.89 ± 0.44 a | 7.4 ± 0.22 h |

| HITGM 15 min | 99.15 ± 0.04 ab | −1.96 ± 0.01 a | 8.15 ± 0.23 fg | 99.43 ± 0.36 a | −1.79 ± 0.06 a | 7.69 ± 0.05 h |

| HCM | 98.32 ± 0.03 cd | −2.64 ± 0.06 bc | 10.24 ± 0.3 a | 98.51 ± 0.39 c | −2.86 ± 0.05 c | 10.05 ± 0.02 ab |

| HITCM 15 min | 98.69 ± 0.14 bc | −2.83 ± 0.02 bc | 9.22 ± 0.21 de | 99.33 ± 0.39 a | −2.01 ± 0.34 ab | 9.78 ± 0.07 bc |

| Samples | Days | Stirred Yoghurt | |||||

|---|---|---|---|---|---|---|---|

| Appearance/Color | Consistency | Odor | Taste | Acidity | Acceptability | ||

| HGM | 1 | 7.14 ± 0.64 | 5.25 ± 0.43 | 4.42 ± 0.49 | 4.43 ± 0.49 | 5.50 ± 0.50 | 4.57 ± 0.40 |

| 8 | 7.57 ± 0.72 | 5.40 ± 0.48 | 5.29 ± 0.69 | 4.43 ± 0.49 | 4.85 ± 0.34 | 5.29 ± 0.45 | |

| 18 | 8.00 ± 0.76 | 5.20 ± 0.74 | 4.71 ± 0.45 | 4.71 ± 0.45 | 6.00 ± 0.75 | 5.43 ± 0.49 | |

| HITGM 5 min | 1 | 7.00 ± 0.53 | 5.50 ± 0.50 | 5.43 ± 0.90 | 5.00 ± 0.75 | 5.86 ± 0.34 | 5.29 ± 0.45 |

| 8 | 7.86 ± 0.83 | 6.40 ± 0.80 | 5.57 ± 0.72 | 5.86 ± 0.83 | 6.00 ± 0.76 | 6.29 ± 0.45 | |

| 18 | 8.14 ± 0.83 | 6.60 ± 0.48 | 6.42 ± 0.49 | 6.42 ± 0.49 | 7.00 ± 0.75 | 6.29 ± 0.45 | |

| HITGM 10 min | 1 | 7.57 ± 0.49 | 5.75 ± 0.43 | 6.57 ± 0.90 | 6.29 ± 0.69 | 6.28 ± 0.69 | 6.43 ± 0.49 |

| 8 | 8.00 ± 0.75 | 6.80 ± 0.74 | 6.71 ± 0.69 | 6.43 ± 0.72 | 7.33 ± 0.47 | 6.43 ± 0.49 | |

| 18 | 8.00 ± 0.76 | 7.20 ± 0.75 | 6.85 ± 0.63 | 7.14 ± 0.64 | 7.42 ± 0.49 | 7.00 ± 0.75 | |

| HITGM 15 min | 1 | 7.57 ± 0.49 | 7.25 ± 0.43 | 7.28 ± 1.03 | 7.14 ± 0.63 | 6.57 ± 0.73 | 7.42 ± 0.49 |

| 8 | 8.14 ± 0.63 | 8.00 ± 0.63 | 7.71 ± 0.69 | 7.28 ± 0.69 | 7.71 ± 0.45 | 7.57 ± 0.49 | |

| 18 | 8.29 ± 0.45 | 8.20 ± 0.40 | 7.85 ± 0.64 | 7.71 ± 0.45 | 7.71 ± 0.45 | 8.00 ± 0.53 | |

| HCM | 1 | 7.14 ± 0.35 | 7.50 ± 0.50 | 7.71 ± 0.69 | 8.00 ± 0.01 | 6.86 ± 0.83 | 7.71 ± 0.69 |

| 8 | 8.43 ± 0.49 | 8.00 ± 0.63 | 7.71 ± 0.69 | 8.00 ± 0.01 | 8.43 ± 0.49 | 7.71 ± 0.45 | |

| 18 | 8.43 ± 0.49 | 8.20 ± 0.40 | 8.00 ± 0.53 | 8.00 ± 0.53 | 8.42 ± 0.49 | 8.14 ± 0.34 | |

| HITCM 15 min | 1 | 7.71 ± 0.69 | 8.25 ± 0.47 | 8.00 ± 0.53 | 8.29 ± 0.45 | 7.43 ± 0.73 | 8.00 ± 0.53 |

| 8 | 8.86 ± 0.34 | 8.60 ± 0.48 | 8.28 ± 0.45 | 8.28 ± 0.45 | 8.57 ± 0.45 | 8.29 ± 0.45 | |

| 18 | 8.86 ± 0.34 | 8.60 ± 0.49 | 8.42 ± 0.49 | 8.28 ± 0.45 | 8.71 ± 0.45 | 8.57 ± 0.49 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ragab, E.S.; Zhang, S.; Korma, S.A.; Buniowska-Olejnik, M.; Nasser, S.A.A.; Esatbeyoglu, T.; Lv, J.; Nassar, K.S. Physicochemical and Rheological Properties of Stirred Yoghurt during Storage Induced from High-Intensity Thermosonicated Goat and Cow Milk. Fermentation 2023, 9, 42. https://doi.org/10.3390/fermentation9010042

Ragab ES, Zhang S, Korma SA, Buniowska-Olejnik M, Nasser SAA, Esatbeyoglu T, Lv J, Nassar KS. Physicochemical and Rheological Properties of Stirred Yoghurt during Storage Induced from High-Intensity Thermosonicated Goat and Cow Milk. Fermentation. 2023; 9(1):42. https://doi.org/10.3390/fermentation9010042

Chicago/Turabian StyleRagab, Eman Saad, Shuwen Zhang, Sameh A. Korma, Magdalena Buniowska-Olejnik, Sahar Abd Allah Nasser, Tuba Esatbeyoglu, Jiaping Lv, and Khaled Sobhy Nassar. 2023. "Physicochemical and Rheological Properties of Stirred Yoghurt during Storage Induced from High-Intensity Thermosonicated Goat and Cow Milk" Fermentation 9, no. 1: 42. https://doi.org/10.3390/fermentation9010042

APA StyleRagab, E. S., Zhang, S., Korma, S. A., Buniowska-Olejnik, M., Nasser, S. A. A., Esatbeyoglu, T., Lv, J., & Nassar, K. S. (2023). Physicochemical and Rheological Properties of Stirred Yoghurt during Storage Induced from High-Intensity Thermosonicated Goat and Cow Milk. Fermentation, 9(1), 42. https://doi.org/10.3390/fermentation9010042