Abstract

The need for a more sustainable society has prompted the development of bio-based processes to produce fuels, chemicals, and materials in substitution for fossil-based ones. In this context, microorganisms have been employed to convert renewable carbon sources into various products. The methylotrophic yeast Komagataella phaffii has been extensively used in the production of heterologous proteins. More recently, it has been explored as a host organism to produce various chemicals through new metabolic engineering and synthetic biology tools. This review first summarizes Komagataella taxonomy and diversity and then highlights the recent approaches in cell engineering to produce renewable chemicals and proteins. Finally, strategies to optimize and develop new fermentative processes using K. phaffii as a cell factory are presented and discussed. The yeast K. phaffii shows an outstanding performance for renewable chemicals and protein production due to its ability to metabolize different carbon sources and the availability of engineering tools. Indeed, it has been employed in producing alcohols, carboxylic acids, proteins, and other compounds using different carbon sources, including glycerol, glucose, xylose, methanol, and even CO2.

1. Introduction

The urgency for effective strategies to mitigate climate change is evident. Environmental issues caused by deliberate petroleum exploitation to produce chemicals, energy, and materials are a major concern regarding global warming. In this context, the global economy needs to be transformed faster, and the circular bioeconomy seems to be the right way to achieve it. This new form of economy aims to reuse, recycle, and remanufacture biomass (from agroecological systems, forestry, and urban wastes) to generate valuable products, such as fuels, biomaterials, and fine chemicals [1]. The circular bioeconomy benefits from integrated frameworks to utilize biomass and address its uses to human needs. One of the major areas that compose this framework is biotechnology, which has the potential to lead bioeconomy global advances even further [2]. The extensive range of roles that biotechnology plays alongside bioengineering provides new techniques to modify the DNA of several microorganisms and plants. Such modifications can improve the utilization of lignocellulosic biomass as raw material through the heterologous protein expression and the production of renewable chemicals, biofuels, and materials [3].

Lignocellulosic biomass polymeric carbohydrates, cellulose, and hemicellulose are mainly composed of glucose and xylose. Glucose is a C6 sugar easily consumed by most microorganisms and can be converted into an extensive range of different chemicals. Xylose, a C5 sugar, can be naturally consumed by filamentous fungi, yeasts, and bacteria. However, this pentose is more challenging to metabolize with the same efficiency as glucose. Nonetheless, xylose can also be converted into various chemicals, such as xylitol [4] and xylonic acid [5]. Recently, advances in genetic manipulation techniques have opened up the range of microorganisms that can produce fine chemicals from glucose and xylose with higher yields and productivity. The yeast Komagataella phaffii is one example of it. Recent research enabled this yeast to consume these sugars and other substrates and produce various chemicals of industrial interest, as will be discussed in this review.

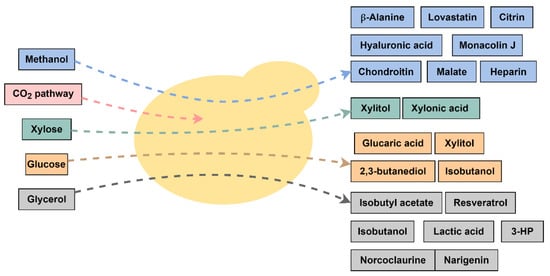

Komagataella phaffii (previously Pichia pastoris) is a well-known methylotrophic yeast. It has many valuable features such as low nutritional requirement, the ability to reach high cell densities (even in acidic culture media), and is widely employed in biotechnological processes to produce heterologous proteins of commercial interest [6]. Therefore, its ability to use methanol as a carbon and energy source, its non-fermentative utilization of glucose under aerobic conditions, and its efficiency to grow on glycerol are some of the main reasons for the preferential choice of this yeast for bioprocess development [7]. These characteristics transformed K. phaffii into a suitable host for many industrial applications. More recently, this yeast has been called the “biotech yeast” for its broad utilization as a cell factory for synthetic biology and metabolic engineering aiming for valuable chemical compound productions (Figure 1) [7,8].

Figure 1.

Representative scheme of the different carbon sources and chemicals produced by engineered K. phaffii strains. 3-HP = 3-hydroxy propionic acid.

K. phaffii has already been used as a successful host for heterologous protein production. However, optimizing K. phaffii to produce chemicals is still necessary, mainly aiming at methanol metabolism, fermentation parameters, and the construction of new genetic tools, such as promoters and plasmids. New methods, platforms, and strategies have been developed to enable more feasible ways to engineer this yeast to address these necessities [9]. Strategies to increase the efficiency rate of target integration genes in the K. phaffii genome through the knockout of homologous genes (ku70 [10] and Dnl4p [11]), and also the utilization of CRISPR/Cas9 to facilitate the genome editing of K. phaffii [12], have already been used. Several examples of the available tools to enhance K. phaffii utilization as a good biotechnology host are summarized in [13].

Previous works have focused on genetic tools and modifications to transform K. phaffii into a robust host aiming at biotechnological approaches [7,14,15]. In this review, we outline the recent advances (last five years) in bioengineering of the yeast K. phaffii for producing renewable chemicals and proteins. The first section briefly explains K. phaffii primordial characteristics and taxonomy. Subsequently, a detailed description of the yeast metabolism of different carbon sources (methanol, glycerol, glucose, and xylose) alongside strategies for the metabolic engineering of the yeast to produce the desired chemicals. The global market size and value (ie., used in this work as the mathematical predictions of the annual volume and value of a product, based on the available data of the past years) of these products is also shown. Additionally, we revise the recent strategies to improve fermentative processes with K. phaffii. Finally, the last sections discuss the challenges and prospects of K. phaffii industrial utilization in producing renewable chemicals.

2. Komagataella Taxonomy and Diversity

The obligate aerobic yeast Komagataella phaffii is a non-pathogenic certified and generally recognized as a safe (GRAS) microorganism. It is classified in the Saccharomycetales order and Saccharomycetaceae family. For being capable of using methanol as the only carbon source, K. phaffii is methylotrophic and was anteriorly known as Pichia pastoris. Phylogenetic studies placed P. pastoris in the genus Komagataella proposed by Yamada et al. (1995) after the analysis of partial sequences of rRNAs subunits (18S and 26S) of the 12 strains of methanol assimilating yeasts [16]. Supporting this previous study, Kurtzman and Robnett (1998) compared gene sequences (D1/D2 LSU rRNA) of about 500 species of Ascomycetous yeasts. The multigenic sequence analysis sustained the phylogenetic position of Pichia pastoris in the Komagataella genus [17].

The first species of P. pastoris (described initially as Zygosaccharomyces pastoris) isolated from a chestnut tree was described in 1919 by Guilliermond [18]. Komagataella genus is currently composed of seven species, with most of them (including K. phaffii) isolated from tree exudates in North America and Europe (Table 1) [19]. All species have spherical to ovoid shapes white/cream colonies, and during asexual reproduction, haploid cells multiply via multilateral budding and do not have pseudohyphae or true hyphae. In sexual reproduction (diploid cells), the ascospore is hat-shaped, ranging from 1 to 4 spores (that can be conjugated or not) [20]. The Komagataella species can grow at high cell densities using methanol, glucose, or glycerol as a carbon source with a doubling time of 2 to 3 h, and ammonium can be used as a nitrogen source during growth [19,20]. Recently, it was demonstrated that some species from Komagataella, including K. phaffii, possess the capacity to grow on xylose [21].

Table 1.

Komagataella species diversity and its characteristics.

Since all species have similar phenotypic and fermentative features, they cannot be distinguished using the conventional taxonomy, for example, morphological tests, that are usually used for yeasts. Therefore, gene sequence analysis (D1/D2 LSU rRNA, ITS, EF-1α) and other gene markers tracking are necessary for the correct species placement and identification [20,22]. Several genome sequencing and transcriptome studies have been conducted throughout the years [23,24,25]. A recent study sequenced the genome of all seven type species of Komagataella and its strains (a total of 25 isolates), identifying strains capable of growing using xylose as the sole carbon source, and which have a higher tolerance to stress conditions, such as alkaline pH [21].

The genomes of the two most studied species of the genus, K. pastoris and K. phaffii (previously both species were classified as P. pastoris), have close genome structures to K. ulmi and K. kurtzmanii, respectively. All species are capable of growing in glucose, glycerol, methanol, and ethanol. All 25 strains could grow at acidic pH (4.0) after 7 days, whereas at pH 9.0, all the species were strongly affected. Only the K. pseudopastoris (anteriorly known as P. pseudopastoris) and K. kurtzmanii CBS 12,817 strains were able to adapt and had better growth when compared to the other species [21]. Commonly, non-engineered yeasts in this genus do not present exponential growth on xylose; however, as indicated in the study of Heistinger et al. (2022), all seven species are capable of using this sugar and grow at slow rates. The species K. pastoris CBS 704 and K. populi CBS 12,362 showed the best growth on xylose [21].

Despite the initial studies on Komagataella diversity, the strains of K. phaffii X33 (prototrophic strain) and GS115 (HIS− phenotype) are the ones most used in biotechnological applications, and are mainly used in studies of heterologous expression [22]. In recent years, there have been impressive methodological developments to model and analyze the metabolism of K. phaffii and engineer its genome and metabolic pathways, including improvements in genome modification with homologous recombination and target-guided gene cloning using CRISPR/Cas9 [14]. Indeed, the information about the genetic and physiological profile of this specie and the availability of genetic tools to manipulate it has been crucial for works on metabolic engineering and recombinant protein production studies. The most recent data will be presented and discussed in the following sections.

3. Production of Renewable Chemicals from Glycerol by K. phaffii

3.1. Metabolism of Glycerol

Glycerol is a carbon source widely used by microorganisms through central carbon metabolism [26]. Due to its higher reduction degree than glucose, the primary carbon source for most microorganisms, glycerol can be used to produce reduced fuel and chemicals at higher yields [27]. In addition, as a significant side stream byproduct in biodiesel production, there has been a growing interest in using glycerol to generate value-added products within the global scenario of renewable and environment-friendly energy, waste reduction, and a more sustainable society [26]. However, its industrial utilization by natural microorganisms is usually limited by the production titers, rates, or yields.

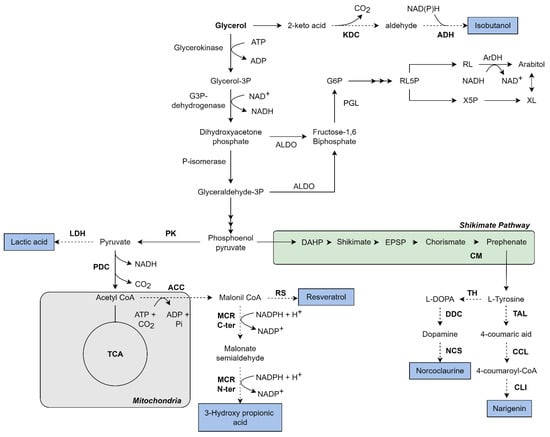

K. phaffii utilizes glycerol as a carbon source very efficiently. Glycerol conversion connects to central carbon metabolism in glycolysis via glyceraldehyde-3-phosphate formation (Figure 2). For such, it is phosphorylated to glycerol 3-phosphate by the cytoplasmic glycerol kinase, sequentially glycerol 3-phosphate dehydrogenase oxidates glycerol-3P to form dihydroxy acetone phosphate (DHAP). Finally, DHAP is converted into glyceraldehyde-3-phosphate by triose phosphate isomerase and enters glycolysis (Figure 2) [28]. Despite the oxidative pathway being preferred in glycerol assimilation, the conversion to glyceraldehyde-3-phosphate can also converge to gluconeogenesis by the activity of a cytosolic aldolase (FBA1-2) that catalyzes the reversible reaction of dihydroxyacetone phosphate and glyceraldehyde 3-phosphate into fructose 1,6-bisphosphate (F-1,6BP). The F-1,6BP is converted into Fructose-6P (F-6P) by a phosphofructokinase (FBP1), and the F-6P can enter the pentose phosphate pathway (PPP), an important pathway to regenerate the reducing cofactor NADPH [29].

Figure 2.

Metabolic pathway to glycerol assimilation and production of a variety of chemicals by K. phaffii. Black arrows represent the native glycerol metabolism; dotted arrows represent an overexpressed/heterologous pathway. Bold enzyme names represent an overexpressed/heterologous enzyme, and the blue boxes represent the final product. Some reactions are summarized for better comprehension. Additionally, not all cofactors are represented in the figure. G6P: Glucose-6-phosphate; RL5P: Ribulose-5-phosphate; RL: Ribulose; X5P: Xylulose-5-phosphate; XL: Xylulose; DHAP: 3-deoxy-D-arabinoheptulosonate-7-phosphate; EPSP: 5-O-(1-carboxyvinyl)-3-phosphoshikimate; KDC: Keto-acid decarboxylase; ADH: Alcohol dehydrogenase; ArDH: Arabitol dehydrogenase; ALDO: Adolase; PGL: Phosphoglucose isomerase; LDH: Lactate dehydrogenase; PDC: Pyruvate decarboxylase; PK: Pyruvate kinase; ACC: Acetyl-CoA carboxylase; RS: Resveratrol synthase; MCR (C-ter/N-ter): Malonyl CoA reductase; CM: Chorismate isomerase; TH: Tyrosine hydroxylase; DOC: DOPA decarboxylase; NCS: Norcoclaurine synthase; TAL: Tyrosine ammonia lyase; CCL: 4-coumarate CoA ligase; CLI: Chalcone isomerase. The figure of own authorship is based on KEGG pathways (www.genome.jp—accessed on 13 September 2022) and in the literature cited in the text.

Glycerol is regularly used as the primary initial carbon source for K. phaffii cell growth, which allows yeast growth rates similar to those obtained on glucose [30]. In contrast to S. cerevisiae, K. phaffii can maintain its respiratory metabolism and all its related pathways, such as oxidative phosphorylation, electron transport chain, oxidative balance cofactors, and ATP generation, even in the presence of an excess of glucose, and also demonstrates similar biomass production and substrate uptake kinetics when fed with glucose and glycerol [25]. The efficient use of glycerol as a carbon source by K. phaffii is mainly due to the active transport of glycerol via an H+/glycerol carrier system that allows the utilization of an electrochemical gradient of H+ protons across the membrane for the cellular influx of glycerol [31].

3.2. K. phaffii Engineering for Renewable Chemicals from Glycerol

Lignocellulosic valorization through chemical production from glucose and xylose has been widely evaluated and applied. Similarly, using crude glycerol, a byproduct of biodiesel production, to produce platform and fine chemicals is attractive [26]. Its valorization is an exciting option in developing a glycerol-based integrated biorefinery concept due to the high production volumes of crude glycerol in the biodiesel production chain [26,32]. The chemical composition of crude glycerol is variable and can contain 60–80% glycerol, 10–20% of soap or other organic compounds, and 10–20% methanol [33]. Methanol is toxic for most microbes, except for methylotrophic microorganisms. Thus, as K. phaffii is able to grow in methanol as the sole carbon source, this yeast is a very well-fit microorganism for utilizing crude glycerol as a primary carbon source for the production of renewables chemicals [14]. Indeed, new metabolic pathway designs and engineering tools for K. phaffii increased in the last few years, mainly towards producing complex (secondary) metabolites from glycerol [14]. K. phaffii engineered strains for the production of different chemicals from glycerol, including lactic acid, 3-hydroxypropionic acid (3-HP), isobutanol, isobutyl acetate, resveratrol, norcoclaurine, and narigenin, have been constructed. The details are presented and discussed in the following sections.

3.2.1. Lactic Acid Production from Glycerol by K. phaffii

Lactic acid (2-hydroxypropanoic acid) is one of the most important industrially used acids. A wide range of organisms can produce lactic acid, including the lactic acid bacteria (LAB) (e.g., strains from Lactobacillus genus), filamentous fungi (e.g., genus Rhizopus), yeasts (Kluyveromyces lactis and Saccharomyces cerevisiae), and also by microalgae (e.g., Scenedesmus obliquus) [34,35]. More information about lactic acid production by different microorganisms is revised in [35]. Moreover, lactic acid can also be obtained by chemical synthesis [36].

Lactic acid has several applications, such as in the food industry, primarily as an acidulant and preservative chemical agent; and in the pharmaceutical and chemical industries, mainly as a pH regulator, humectant, and solvent. In addition, its monomeric form can be used to produce biodegradable poly-lactic acid (PLA). The PLA has several industrial applications, such as automobile, packaging, and cosmetic industries [34]. The manufacturing of biodegradable PLA materials, ecologically feasible alternatives to the consistent use of petroleum for plastic production, has contributed immensely to the global attention to the biotechnological production of lactic acid. Indeed, the lactic acid market in 2021 was valued at USD 2.9 billion, and the annual growth expectation is of 8.0% rate until 2030 (www.grandviewresearch.com—accessed on 14 September 2022).

Lactic acid production through the biological route is advantageous compared to the chemical one. The main advantage regarding the biotechnological production of lactic acid is that the microorganisms can be engineered to produce only one isomer of lactic acid (L-lactic acid), which facilitates the subsequent production of PLA [37]. K. phaffii is one candidate organism for its production using glycerol as substrate [36,37]. As K. phaffii does not produce lactic acid naturally, a biotechnological route for glycerol utilization in fermentative production was proposed (Figure 2). The gene ldh that codifies for the enzyme lactate dehydrogenase (LDH) was cloned into the yeast through homologous recombination. Additionally, a new homologous lactate transporter (PAS) was identified and overexpressed to enhance lactic acid production in the LDH-expressing strains. The strains were evaluated by their abilities to produce lactic acid in different oxygen concentrations using glycerol as the sole carbon source. The results demonstrated that a higher lactic acid production could be achieved in limited oxygen conditions, though it can guide the yeast through a fermentative metabolism. Under the best conditions, the engineered strain (GLS) was able to produce lactic acid with a yield of 0.7 g/g (Table 2) when fed with pure glycerol (40 g/L). This was the first reported work concerning K. phaffii genetic modification to produce lactic acid from glycerol [36].

Table 2.

Production of chemicals from different carbon sources by engineered K. phaffii strains.

A subsequent study approached a different strategy to increase the lactic acid production by K. phaffii. As the pyruvate leads to lactic acid production (Figure 2), the authors performed an overexpression of LDH enzymes in combination with the pyruvate decarboxylase (PDC) deletion. This strategy aimed to guide the pyruvate towards lactic acid production and decrease the formation of by-products (e.g., acetic acid). The best strain produced lactic acid with a yield of 0.65 g/g under oxygen-limited condition. Although the acetic acid production was reduced by 20%, the metabolic flux was guided into arabitol formation. The NADH regeneration necessity can explain the flux deviation to arabitol under oxygen-limited conditions. This cofactor unbalance can lead the glycerol metabolism towards the reoxidation of NADH by the reduction of xylulose or ribulose, producing arabitol as a resulting metabolite (Figure 2) [37].

To further investigate glycerol metabolism and the production of lactic acid and arabitol in K. phaffii strains, the lactic acid producer strain GLp was extensively investigated under different growth conditions. Once more, lactic acid production was proven better (5-folds higher) in conditions of oxygen limitation, although the arabitol formation is also better in the same conditions. To overcome this issue, a putative arabitol dehydrogenase gene (ArDH) was disrupted. As expected, the gene deletion decreased the arabitol production (50% less), leaving only residual concentrations, and increased the lactic acid production yield by 20% (when compared to previous study (Table 2) [37,38].

3.2.2. 3-Hydroxy-Propionic Acid (3-HP) Production from Glycerol in K. phaffii

3-Hydroxy propionic acid or 3-hydroxypropanoate (3-HP) is a three-carbon organic compound and is a lactic acid isomer (2-hydroxypropanoic acid). 3-HP is an important building block, mostly used in producing petroleum-based chemicals such as acrylic acid and biopolymers (poly 3-HP) [39,54]. The 3-HP is a versatile molecule for the production of platform chemicals due to its compositional particularity of having a carboxyl and a hydroxyl group. Besides acrylic acid and poly 3-HP, it can be used to produce a wide range of chemicals (e.g., methyl acrylate, ethyl 3-HP, acrylamide, 1,3-propanediol and malonic acid) [54]. Such a wide range of possibilities involving 3-HP utilization increased its global market value, and in 2021 it was valued at USD 111.74 million, with an annual growth expectation of 4.71%, and possibly reaching USD 147.24 million in 6 years (www.marketwatch.com—accessed on 1 September 2022).

Despite the diverse applications, no biological processes are commercially available to produce 3-HP; on the other hand, several patents have been claimed in the past few years, mostly regarding the conversion of 3-HP into acrylic acid in one step reaction. Some microorganisms can produce 3-HP naturally, including Lactobacillus sp., and several microorganisms have been modified to enhance the 3-HP production, although the titers, rates and yields (TRY), are not optimum yet [55]. For a more comprehensive view on 3-HP biological production, see [54], and for process engineering for 3-HP production from glycerol through the last few years, see [55].

Nonetheless, the strain engineering of microorganisms aiming to enhance the 3-HP TRY is still necessary to develop a feasible application of the industrial 3-HP biological process [54]. In this context, K. phaffii is a suitable candidate to produce 3-HP from glycerol, as this yeast has a naturally well-established glycerol metabolism. To this end, 3-HP was produced in a strain of P. pastoris expressing the genes leads to the 3-HP production through the malonyl-CoA pathway (Figure 2). Three heterologous genes were expressed in K. phafffii, encoding for malonyl-CoA reductase from Chloroflexus aurantiacus (mcrCa), an acetyl-CoA carboxylase from Yarrowia lipolytica (ACCYl), and a cytosolic NADH kinase from S. cerevisiae (cPOSSc). As a result, the recombinant strain of K. phaffii was able to produce 24.75 g/L of 3-HP, with a yield of 0.13 Cmol/Cmol, and 0.54 g/L/h in a fed-batch fermentation. The authors also detected arabitol as a byproduct at the end of the fermentation [39].

3.2.3. Isobutanol and Isobutyl Acetate Production from Glycerol in K. phaffii

The four-carbon aliphatic alcohol isobutanol is a valuable platform compound extensively used in various industries such as food, chemicals, and pharmaceuticals [56]. The production of this compound through fermentation by microorganisms is considered a possibility as a second-generation biofuel. When set side by side with ethanol, the prevailing biofuel produced (first generation), isobutanol, presents elevated ignition power, less corrosive, and lower aqueous miscibility [57]. Furthermore, isobutanol (due to its chemical and physical characteristics) is conformable with the procedures and processes commonly applied in the gasoline industry. Consequently, there is no need for profound changes in infrastructure [58].

The Crabtree-negative methylotrophic yeast, K. phaffii, was metabolically engineered to produce isobutanol and isobutyl acetate from glucose and glycerol (Table 2) [40]. For the production of isobutanol, genes of the native amino acid biosynthetic pathway were overexpressed, guiding the carbon flux into the 2-keto acids degradation pathway (commonly known as the Ehrlich pathway). In this route, the enzyme 2-keto acid decarboxylase (KDC) decarboxylated the 2-keto acid into an aldehyde that is reduced into alcohol by an alcohol dehydrogenase (ADH) (Figure 2). The first strategy to increase alcohol production was through the Ehrlich pathway, employing new KDC and ADH enzymes selected to be expressed in K. phaffii. For the KDC, two enzymes were screened, one from L. lactis (ARO10) and the other from S. cerevisiae (TH13). Two enzymes (both from S. cerevisiae) were selected for ADH, ADH6, and ADH7. Additionally, aiming to enhance the isobutanol production, the media was supplemented with 2-ketoisovalerate, a precursor of the Ehrlich pathway. The heterologous expression of KDC and ADH with supplemented media resulted in the production of 284 mg/L of isobutanol [40].

Aiming to enhance isobutanol production, and considering cost-effective approaches, another strategy to improve the level of this compound was applied. Hereupon, the overexpression of part of the L-valine biosynthetic pathway was performed in the engineered strain, eliminating the supplementation of the costly 2-ketoisovalerate [40]. When this approach was applied in S. cerevisiae, the levels of isobutanol generation were not elevated, but in contrast, in K. phaffii, the production of isobutanol reached 0.89 g/L. Further, the fine-tuning expression of critical enzymes boosted the isobutanol production to 2.22 g/L, which represents a 43-fold enhancement compared to the first results. Additionally, to explore the versatility of this yeast, a gene (ATF1 from S. cerevisiae) that codes for an alcohol O-acyltransferase was heterologously expressed in K. phaffii to produce different volatile esters, which resulted in the production of 51 mg/L of isobutyl acetate ester and 24 mg/L isopentyl acetate ester [40].

3.2.4. Aromatic Secondary Metabolite Production from Glycerol in K. phaffii

Plant phenolic compounds, such as stilbenoids, flavonoids, and benzylisoquinoline alkaloids (BIAs), are mostly generated from the amino acid L-tyrosine (L-Tyr). These metabolites have a valuable application in the pharmaceutical and food industries. Considering the commercial interest in these aromatic compounds, producing them at high levels by microorganisms is of great interest to [31].

In that way, engineering yeasts have been studied for the overproduction of the amino acid L-Tyr. An engineered K. phaffii L-Tyr strain was obtained to enhance the production of phenolic compounds such as resveratrol, naringenin, norcoclaurine, and reticuline (Figure 2) (Table 2). The overexpression of a phosphate synthase (ARO4K229L) and chorismate mutase (ARO7G141S), both from S. cerevisiae, improved the L-Tyr concentration using glycerol as a carbon source in K. phaffii [31]. The ARO4K229L is a phosphate mutase, an enzyme involved in the shikimate pathway, which is a route that synthesizes the amino acids phenylalanine, tyrosine, and tryptophan. The shikimate pathway is shown in Figure 2, where the enzyme chorismate mutase (CM) modifies chorismate into prephenate, the precursor for aromatic amino acids, such as L-tyrosine.

With the enhancement of tyrosine production by the engineered K. phaffii strain, the resveratrol production reached 451 mg/L, whereas naringenin was 306 mg/L. When a fed-batch approach was performed with glycerol as a carbon source, the amount of these aromatic metabolites was even more significant, reaching 1825 mg/L for the resveratrol and 1067 mg/L for naringenin. These values are the highest reported in the literature for the two compounds [31]. This work mentioned above was the first to evaluate the potential of K. phaffii to produce phenolic metabolites using crude glycerol, confirming the importance and versatility of this yeast to generate a range of compounds of interest.

3.3. Glycerol Co-Utilization by K. phaffii

Among the major characteristics of K. phaffii, the ability to use glucose and glycerol as carbon sources in fast growth rates, resulting in high cell densities, turns attention to the use of this yeast in different applications [7]. One of the main challenges to producing high amounts of a compound of interest is the carbon distribution, which can go for cell growth and synthesis of the product itself. When a mixed carbon source is utilized, it is possible that the cell metabolism could be reasonably split, redirecting the substrates in pathways for the growth and production of aimed compounds. A new study reported an engineered strain of K. phaffii, GS115, that was able to co-utilize glucose and glycerol, redirecting the consumption of glycerol for growth, whereas maintaining the glucose for product generation [59].

For this purpose, the identification of K. phaffii potential genes involved in the carbon catabolite repression was performed. In this search, the deletion of the glucose sensor (gss1) eliminated the glucose-induced suppression of glycerol use in media containing glucose and glycerol. When the transcriptome of the control (non-deleted strain) and the deleted mutant was compared, it was possible to identify that the genes related to glycerol metabolism were under glucose regulation. Then, the overexpression of these genes related to glycerol utilization pathways (gt1, gut1, and gut2) made it feasible for the mutated K. phaffii to co-utilize both substrates. Moreover, the knockout of targeted genes lowered the carbon flux from glucose onto major cell pathways, such as glycolysis [60]. Through the metabolic engineering of K. phaffii, the new strain was able to utilize glycerol for cell growth, whereas glucose was used for product formation [60]. The co-utilization of different substrates is an interesting and versatile strategy, highlighting K. phaffii as an alternative microbial platform for producing value-added products.

4. Renewables from Sugars and Lignocellulosic Hydrolysates

Lignocellulose is one of the most abundant and promising renewable resources, with a global annual yield of around 1.3 billion tons [61]. It can be obtained from agricultural residues after crop processing, forest residues, energy feedstock residues, municipalities, and others [62]. Lignocellulose consists of a complex tridimensional polymer that composes the cell wall matrix of plant biomass, which is usually a remnant material after the extraction of sugars for first-generation bioethanol production or other processes [63]. It is composed of cellulose (38–50% on average), hemicellulose (23–32%), lignin (15–25%), and small amounts of pectin, nitrogen compounds, and inorganic compounds. This ratio may vary depending on plant biomass source, such as herbs, softwood, or hardwood (Table 3) [64].

Table 3.

Composition of different lignocellulosic biomasses and hydrolysates.

Cellulose is a linear polymer of glucose monomers linked by β-(1-4) glycosidic bonds that form long and stable glucan microfibrils, providing support to the plant cell wall. Hemicellulose is a mixture of linear and branched polysaccharides connected by acetyl and methyl groups creating an amorphous structure. Xyloglucan, formed by glucose core chain, and heteroxylan, formed by xylose core chain, are the major components of hemicelluloses in plants. These polymers often present heterogeneous side chains of different hexoses (glucose, galactose, mannose, and fucose), pentoses (xylose and arabinose), and uronic acids (glucuronic acid and galacturonic acid). There may also be side branches of methyl, feruloyl, and acetyl groups [66]. Lignin is a heterogeneous aromatic polymer formed by coupling monomers of monolignols such as coniferyl alcohol, sinapyl alcohol, and p-coumaryl alcohol, in a complex structure linked by either carbon-carbon bond connections or ether linkages. A detailed description of lignocellulose is given at [67].

Because of the high degree of polymerization, the production of bioproducts from lignocellulosic biomass requires pretreatment processes to separate or solubilize complex components and release fermentable sugars, e.g., glucose and xylose. Primary, pretreatment methods are applied towards the degradation of the lignin matrix and the removal of hemicellulose fraction. This also reduces cellulose crystallization and increases its surface to later enzymatic and microbial digestion [68].

Pretreatment processes are generally classified as physical, chemical, physicochemical, or biological, and their combinations. Over the last three decades, several pretreatment methods have been developed to provide fast degradation of lignin and high sugar availability with the efficient hydrolysis of cellulose and hemicellulose., including chemical (organic solvents like acid, alkaline, and others), physical (grinding and milling), physio-chemical (hot water, ammonia fiber explosion, and steam explosion), and biological (enzymatic digestion). For detailed data about pretreatments and their applications, refer to [65,68].

During lignocellulosic biomass pretreatment and hydrolysis processes, the cellulose and hemicellulose breakdown, and the sugars are released into the fermentation media, called hydrolysate. In addition, several bioactive compounds are also released or formed during these processes, which can be grouped as organic acids (acetic acid, formic acid, levulinic acid), furaldehydes (furfural and 5-hydroxymethylfurfural), and phenolic compounds (ferulic acid, coumaric acid, vanillin, syringaldehyde, coniferyl alcohol, and others) [69]. In general, lignocellulose inhibitors damage cell membranes and inhibit key metabolic enzymes, affecting the fermentative bioprocess by inhibiting microbial metabolism [69]. Aldehydes can also generate reactive oxygen species (ROS) and lead to their accumulation in the cytoplasm. These toxic molecules inhibit the central carbon metabolism enzymes, such as alcohol dehydrogenase, pyruvate dehydrogenase, and aldehyde dehydrogenase. A more detailed view of lignocellulose-derived inhibitors formation and their effects are described in [69,70]. Apart from biomass constitution, the type and conditions of pretreatments also determine the nature and abundance of the inhibitors released [65]. Some examples of the composition of lignocellulose hydrolysates are presented in the table (Table 3).

To overcome the negative effects of lignocellulose-derived inhibitors, the cells developed strategies to detoxify these compounds and repair damages. Yeast response to lignocellulose inhibitors involves cellular modifications to transcriptional and proteomic levels, resulting in changes in metabolic fluxes and cell reorganization to increase detoxification mechanisms and cell membrane composition [70,71]. For instance, the detoxification of furaldehydes occurs through the compound’s NADH- and NADPH-dependent reduction, which affects the yeast’s redox balance and fermentation pathways. In K. phaffii and S. cerevisiae, the presence of furfural and HMF leads to the increased expression of several classes of genes and also of oxidoreductases encoding genes that reduce aldehydes into less toxic corresponding alcohols [71].

K. phaffii shows a dose-dependent response to furaldehydes with a relatively high tolerance to these lignocellulose-derived molecules, maintaining cell viability in the presence of 1.25 g/L furfural and 0.25 g/L HMF. In the presence of these furaldehydes, K. phaffii transcriptome analysis revealed the up-regulation of genes involved in oxidoreduction processes and transmembrane transport [71]. Transcriptional profiling of K. phaffii in the presence of acetic acid revealed up-regulation of genes involved in nucleic acid processing, methylation, and Rho protein signal transduction regulation, while the presence of furaldehyde revealed up-regulation of genes involved in oxidoreduction and membrane transport [71]. In addition, K. phaffii has been shown to sustain growth in the presence of up to 6 g/L of acetic acid in a defined medium. Moreover, the up regulation of genes involved in transmembrane transport, RNA processing, and regulation of metabolic processes was also reported in K. phaffii in the presence of 10% diluted acid hydrolysate. In contrast, cellular viability was completely inhibited in the presence of 30% diluted acid hydrolysate [71].

4.1. Metabolic Engineering of K. phaffii to Produce Renewables Chemicals from Glucose

To produce high value-added products from lignocellulose-derived sugars, it requires K. phaffii to incorporate metabolic adaptations to effectively utilize its most abundant C6 and C5 sugars: glucose and xylose [72]. Bio-based chemicals such as ethanol, butanol, and organic acids, showed a compound annual growth rate (i.e., mean annual growth rate of an investment over a period) of 16.16% (USD 6474 million) in 2017. It is expected to reach around USD 23 million by 2025, with biofuels accounting for the highest revenue [64]. In this context, valorizing renewable feedstock into value-added renewable chemicals is an urgent goal.

Several groups have been working in the metabolic engineering of K. phaffii to produce renewable chemicals from glucose and xylose in the last couple of years (Table 2). The strategies employed are presented below.

4.1.1. Isobutanol Production from Glucose in K. phaffii

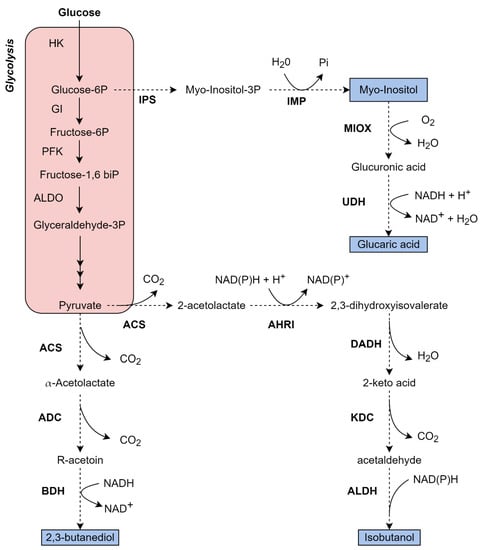

As mentioned above, isobutanol (C4H10O) is a branched chain alcohol with the potential as biofuel in substitution of gasoline for high-performance petrol engines [73]. The production of isobutanol creates the opportunity for a range of downstream products. It can be converted into para-xylene via isobutylene and oxidized to terephthalic acid for the production of PET [74]. Bioproduction has been attained in S. cerevisiae; however, its natural susceptibility to the Crabtree effect drives to low isobutanol yield against the preference for ethanol production. In K. phaffii, isobutanol production can be achieved using glycerol and glucose as substrates (Table 2). Different to with glycerol, the production of isobutanol in K. phaffii using glucose was achieved by exploiting the yeast’s endogenous L-valine pathway through overexpression of PpIlv6, PpIlv2, PpIlv5, and PpIlv3, under GAP promoter in two integrative expression plasmids and diverting the intermediates into the 2-keto acid degradation pathway through the heterologous expression of keto acid decarboxylase (KDC) from Lactococcus lactis (LlkivD) and ADH7 from S. cerevisiae (ScADH7). The highest yield of 22.21 mg/g of isobutanol was obtained directly from glucose (Figure 3). Previous work on engineered S. cerevisiae has reached up to 8.49 g/L of isobutanol [75]. In a different approach, the production of isobutanol in S. cerevisiae was regulated with an optogenetic system called OptoEXP and OptoINVRT. These tools enabled the gene regulation through light pulses (using as a model the blue light-activated EL222 [76]) and the production of three different chemicals of industrial interest, lactate, 2-methyl-1-butanol and isobutanol, the latter with titers of 8.49 ± 0.31 g/L [75]. More information about the microbial production of isobutanol and its future perspectives can be found in [77].

Figure 3.

Metabolic pathway to glucose assimilation and production of a variety of chemicals by K. phaffii. Black arrows in the red boxes summarize the native glucose metabolism; dotted arrows represent an overexpressed/heterologous pathway. Bold enzyme names represent an overexpressed/heterologous enzyme, and the blue boxes represent the product formation. Some reactions are summarized for better comprehension, also, not all cofactors are represented in the figure. HK: Hexokinase; GI: Glucose isomerase; PFK: Phosphofructokinase; ALDO: Fructose-1,6-biphosphato aldolase; ACS: Acetolactate synthase; ADC: Acetolactate decarboxylase; BDH: Butanediol dehydrogenase; AHRI: Acetohydroxy acid reductor isomerase; DADH: Dihydroxy acid dehydratase; KDC: Keto-acid decarboxylase; ALDH: Aldehyde dehydrogenase; IPS: Inositol phosphate synthase; IMP: Inositol monophosphatase; MIOX: Inositol oxygenase; UDH: Uronate dehydrogenase. The figure of own authorship is based on KEGG pathways (www.genome.jp—accessed on 13 September 2022) and in the literature cited in the text.

4.1.2. 2,3-Butanediol Production from Glucose in K. phaffii

2,3-butanediol (2,3-BD) (C4H10O2) is another bulk platform biochemical that microorganisms can produce from lignocellulose-derived sugars. It can be converted into methyl ethyl ketone, gamma-butyrolactone, and 1,3-butadiene with potential applications in the fuel, polymer, food, and pharmaceutical industries [78]. Heterologous production of 2,3-BD via GRAS microorganisms, such as E. coli and S. cerevisiae, has been reported, with the highest production of 100 g/L of 2,3-BD in S. cerevisiae from glucose and galactose. K. phaffii strains were engineered for the production of 2,3-BD isomer (2R, 3R)-2,3-BD with the expression of codon-optimized sequences of acetolactate synthetase (AlsS) and acetolactate decarboxylase (AlsD) retrieved from B. subtilis under pGAP promoter, and also a 2,3-butanediol dehydrogenase (BDH1) from S. cerevisiae was overexpressed in K. phaffii, thus, the heterologous BDH1 did not increased the 2,3-BD production. [41]. The highest 2,3-BD production from glucose was achieved in fed-batch optimized cultivation, reaching 74 g/L with yield and productivity of 0.3 and 0.81 g/L/h, respectively, with 99% enantiopurity (Table 2). This result was close to the 100 g/L production of 2,3-BD previously achieved in S. cerevisiae by [79] with 0.35 yield and productivity of 0.33 g/L/h with 98% enantiopurity.

4.1.3. Inositol Production from Glucose in K. phaffii

Myo-inositol (inositol) (C6H12O6) is a carbocyclic sugar present in microorganisms, plants, and animals. Dietary inositol has been found to benefit treatments of neurological and endocrine diseases and is also regarded as an essential nutrient for aquatic animals [43,80]. Recently, K. phaffii was exploited for inositol production through enhancing its native inositol biosynthesis pathway [43]. The production of 0.71 g/L was obtained by the overexpression of endogenous inositol-3-phosphate synthase (PpIPS) and the knock out of inositol transporters PpITR1 and PpITR2, and B-subunit of 6-phosphofructokinase gene pfk2. The introduction of heterologous inositol-3-phosphate synthase (IPS), inositol monophosphatase (IMP) (Figure 3), and the further substitution of promoters zwf (encoding glucose-6-phosphate dehydrogenase), pgi (encoding glucose-6-phosphate isomerase), and pfk1 (encoding α-subunit of 6-phosphofructokinase) for glycerol-induced pGUT, could improve inositol production up to 30.71 g/L in high-cell-density fermentation, where glycerol was first used as sole carbon source then glucose was added into the medium for inositol production when wet cell weight reached about 0.2 g/mL (Table 2).

4.1.4. Glucaric Acid Production from Glucose in K. phaffii

Glucaric acid (C6H10O8) is a natural valuable organic acid that can be found in fruits, vegetables, and mammals. Glucaric acid have a range of utilizations in the chemical, pharmaceutical, and food industry and has also been identified as a “top value-added chemical from biomass” for its potential use in the formation of biodegradable detergents and polymers, and metal complexation agents [81]. The co-expression of heterologous mouse MIOX and urinate dehydrogenase (Udh) from P. putida in K. phaffii led to the accumulation of 107 mg/L of glucaric acid from glucose. In contrast, the co-expression of native MIOX and Udh produced no glucaric acid from the same carbon source (Figure 3). The optimization of cultivation with the addition of myo-inositol increased glucaric acid concentration from 785.4 mg/L to 1697.6 mg/L in flasks, and production reached 6.61 g/L in fed-batch culture, the highest among other hosts such as E. coli and Granulobacter sp. (Table 2) [42].

4.2. Metabolic Engineering of K. phaffii to Produce Renewables Chemicals from Xylose

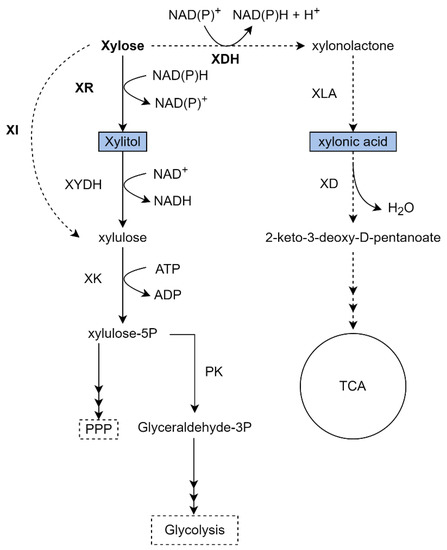

Xylose is another abundant substrate for biotechnological processes. In yeast species that naturally utilize xylose, the metabolism of the pentose starts with its conversion to xylitol, mediated by a NAD(P)H-dependent xylose reductase, followed by the conversion to xylulose, mediated by an NAD+-dependent xylitol dehydrogenase. Xylulose is therefore phosphorylated by a xylulokinase and enters the pentose phosphate pathway (PPP) as xylulose-5P (Figure 4). An isomerase pathway found mainly in bacteria allows direct conversion of xylose to xylulose via xylose isomerase. In addition, Archaea can assimilate xylose by a non-phosphorylate pathway (NP) converting it into xylonolactone by a xylose dehydrogenase reaction. Xylonolactone will be further converted into xylonate rather spontaneously or with the aid of a xylonolactonase. Xylonate is then dehydrated into 2-keto-3-D-deoxypentanoate to enter the central carbon metabolism [82].

Figure 4.

Metabolic pathways to xylose assimilation and production of a variety of chemicals by K. phaffii. Black arrows represent the native xylose metabolism, dotted arrows represent an overexpressed/heterologous pathway. Bold enzyme names represent an overexpressed/heterologous enzyme, and the blue boxes represents the product formation. Some reactions are summarized for better comprehension. XR: Xylose reductase; XI: Xylose isomerase; XYDH: Xylitol dehydrogenase; XK: Xylulo kinase; PK: Phosphoketolase; XDH: Xylose dehydrogenase; XLA: Xylono lactonase; XD: Xylonate dehydratase. The figure of own authorship is based on KEGG pathways (www.genome.jp—accessed on 13 September 2022) and in the literature cited in the text.

Despite Komagataella, species are generally described as non-xylose utilizing organisms; an examination of K. phaffii genome revealed genes encoding for putative XR and a putative XDH homologous to other yeasts, such as S. cerevisiae (56% identity) and Kluyveromyces marxianus (57% identity) [83]. Recent findings also show that several Komagataella species, including K. phaffii, can grow on xylose as the sole carbon source, suggesting a hidden pathway of xylose utilization [21]. The introduction of a XI from Orpinomyces sp. in K. phaffii, in association with adaptive evolution, effectively enhanced the flux of xylose towards PPP (Figure 4), enhancing the consumption rate of xylose from 0.193 g/g to 0.378 g/g after 50 generations [83]. Recent advances in using xylose as a substrate for chemical production in K. phaffii refer to xylitol [84] and xylonic acid [45] production (Table 2).

4.2.1. Xylitol Production from Xylose in K. phaffii

Xylitol (C5H12O5) is a natural occurring pentahydroxy sugar alcohol found in a variety of fruits, vegetables, and mushrooms, with high application potential in personal care, pharmaceuticals, and the food industry, as a sweetener that is similar to sucralose but does not require insulin to be metabolized [4,84]; current production is around 200,000 tons [74]. The global market of xylitol exceeded USD 880 million and is expected to expand to over USD 1 billion by 2026 [84]. The biological production of xylitol in yeasts occurs in a single step where xylose is reduced to xylitol by a XR (Figure 4). Recombinant K. phaffii strains for xylitol production from xylose and hemicellulose hydrolysate were obtained through (over)expression of XR (XYL1) from P. stipitis solely or in combination with glucose dehydrogenase (gdh) from Bacillus subtilis, so that the oxidation of glucose could be used to re-generate NAD(P)H required by the XR reaction [44]. The highest conversion rate by the recombinant strain was 320 mM of xylitol from 400 mM of xylose, with a productivity value of 2.44 g/L/h in a defined medium with both modifications. 300 mM of xylitol from 420 mM of xylose, with a productivity value of 0.46 g/L/h, was obtained in hemicellulose hydrolysate (Table 2).

4.2.2. Xylonic Acid Production from Xylose in K. phaffii

Xylonic acid (C5H10O6) is an organic compound obtained from the microbial oxidation of xylose by naturally or engineered species. It has been reported for serval industrial applications such as a cement additive, plasticizer, cleaner agent, polyamide and polyester co-polymerization, and as a precursor of other value-added chemicals such as ethylene glycol, glycolic acid, and 1,2,4-butanetriol (reviewed in [5]). Several archaea and some bacteria produce xylonic acid by the conversion of xylose to xylonolactone by a xylose dehydrogenase (XDH), which is then converted to xylonic acid in a spontaneous hydration reaction catalyzed by a xylonolactonase (XLA) (Figure 4) [5,82]. Yeasts, on the contrary, are not naturally capable of producing xylonic acid. Therefore, various yeast strains have conquered xylonic acid by the introduction of a heterologous xylose dehydrogenase pathway [5].

The recent construction of K. phaffii strains with putative heterologous XDHs was described in [45]. To this end, 11 putative protein sequences of XDH from bacteria and filamentous fungi were identified and overexpressed in K. phaffii. Six strains were able to produce xylonic acid. Strains with bacterial XDHs were able to produce tenfold more xylonic acid than the strains with fungal XDHs. The best strain produced up to 37 g/L of xylonic acid in defined medium and up to 11 g/L in sugarcane bagasse hydrolysate, with the highest yield of 0.96 g/g and 0.43 g/g, respectively (Table 2).

5. Renewables from Methanol and CO2

Methanol is produced in large volumes worldwide, with a production capacity achieving more than 100 million metric tons per year. This C1 nonfood feedstock can be derived from fossil raw materials or renewable resources such as biomass, glycerol, methane, and carbon dioxide, rendering it a flexible and attractive alternative to sugar-based substrates [85]. In addition, methanol is more reduced than most carbohydrates, which can enhance the yields of metabolites produced by microorganisms when using this carbon source as a substrate or co-substrate [86].

Several studies have focused on engineering relevant industrial microorganisms, such as E. coli and S. cerevisiae, for methanol metabolism [87]. However, implementing the methanol assimilation pathway in non-native methylotrophs is quite challenging. It involves a complete change in the microorganism’s lifestyle, requiring, at least, the capacity to build essential cellular metabolites from a single carbon molecule and tolerance to the highly toxic intermediate compounds produced. Despite the achievements, until now, growth performances of the engineered cells on methanol are far from those observed for natural methylotrophs [87].

Several native methylotrophic microorganisms, including K. phaffii, Ogataea (Hansenula) polymorpha, and Bacillus methanolicus, are naturally capable of utilizing C1 compounds as a source of energy and carbon through different metabolic routes [85,88,89]. Among them, K. phaffii presents some prominent properties that make this yeast an interesting host for biotechnological processes. For example, we can cite resistance to high concentrations of methanol and other stressful industrial conditions, growth to high cell densities, and ability to express recombinant protein efficiently [7,85]. In addition, several tools are available for synthetic and metabolic engineering for this yeast and well-established fermentation processes [90,91]. Therefore, K. phaffii has been widely used for the recombinant protein production of several biopharmaceuticals and industrial enzymes, as demonstrated in this review (as discussed in the next section), and, more recently, has also been employed for the production of chemicals and other valued added compounds, although mainly using sugars as carbon sources as previously presented here [14,85].

In K. phaffii, methanol metabolism initiates with its oxidation to formaldehyde. Then, the formaldehyde can follow either an assimilatory or dissimilatory pathway. In the assimilatory pathway, localized in peroxisomes, formaldehyde is condensed to phosphosugars and enters the central metabolism, yielding biomass. In the dissimilatory pathway, localized both in peroxisome and in the cytosol, the formaldehyde is oxidized to CO2, yielding NADH (Figure 5) [92].

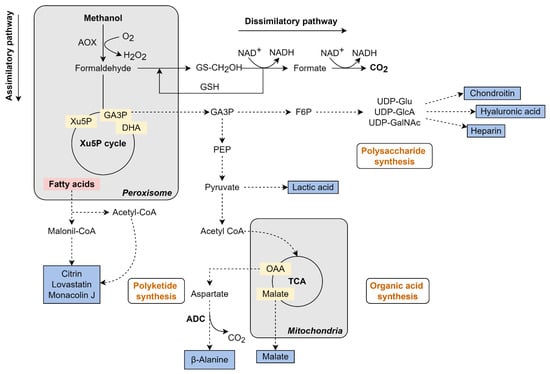

Figure 5.

Metabolic pathways that led to methanol assimilation and production of a variety of chemicals by K. phaffii. Black arrows represent the native methanol metabolism, dotted arrows represent an overexpressed/heterologous pathway. Bold enzyme names represent an overexpressed/heterologous enzyme, and the blue boxes represents the product formation. Some reactions are summarized for better comprehension, also, not all cofactors are represented in the figure. AOX: Alcohol oxidase; Xu5P: Xylulose-5-phosphate; DHA: Dihydroxyacetone; GAP: Glyceraldehyde-3-phosphate; XuMP: Xylulose-monophosphate cycle; PEP: Phosphoenol pyruvate; F6P: Fructose-6-phosphate; OAA: Oxalacetate; ADC: L-aspartate decarboxylase. The figure of own authorship is based on KEGG pathways (www.genome.jp—accessed on 13 September 2022) and in the literature cited in the text.

The first enzymatic reaction occurs in the peroxisomes, where methanol is oxidized to formaldehyde with the release of hydrogen peroxide (H2O2) by the action of the key-enzyme alcohol oxidase (AOX). As H2O2 is toxic to the cell, the compartmentalization of the process in the peroxisomes aid in protecting the cell until the catalase converts it into H2O and O2 as well as could alleviate the toxicity caused by formaldehyde accumulation (Figure 5) [85]. K. phaffii has two isoforms of AOX, encoded by the genes AOX1 and AOX2, which share 97% of identity at the protein level. Among them, AOX1 represents the major AOX protein expressed during growth on methanol, whose content could reach 20% to 30% of the total protein [85].

In the assimilatory pathway, formaldehyde is then combined with xylulose-5-phosphate (X5P) by the enzyme dihydroxyacetone synthase (Das1 and Das2 in K. phaffii), generating dihydroxyacetone (DHA) and glyceraldehyde-3-phosphate (GAP). A total of 1 mol of GAP are produced from 3 mol of methanol, which is used to generate biomass and energy. X5P is recycled by sugar phosphates interconversions catalyzed by PPP isoenzymes in the peroxisomes [89,92]. This compartmentalized and cyclic C1 assimilation process is called Xylulose-Monophosphate cycle (XuMP) (Figure 5) [89].

Part of the formaldehyde generated in the methanol oxidation reaction follows the dissimilatory pathway. In this case, the formaldehyde flows into the cytosol and reacts with glutathione through the formaldehyde dehydrogenase, S-formylglutathione hydrolase, and formate dehydrogenase enzymes, yielding CO2 and NADH (Figure 5) [89]. Although the C1 carbon is lost in the process, it is an essential route for energy generation (in the form of the reducing power NADH) and formaldehyde detoxification, thereby affecting the ability of cell growth on methanol [85].

5.1. K. phaffii Engineering for CO2 Assimilation

Exploring the methanol-assimilation pathway, a K. phaffii strain able to grow using CO2 as a sole carbon source, was recently reported [92]. In the synthetic autotroph strain, the peroxisomal pathway for methanol assimilation was rewired to a CO2-fixation pathway that resembles the Calvin-Benson-Bassham cycle (CBB). For this, eight heterologous genes were expressed and combined with the XuMP: six CBB enzymes (RuBisCO form II encoded by cbbM, PGK1, TDH3, TPI1, TKL1, PRK) and two chaperones (groEL, groES) to assist RuBisCO folding. In addition, the native genes DAS1, DAS2, and AOX1, were deleted to separate the CO2-fixation machinery from energy generation. Thus, methanol was used to provide energy via the dissimilatory pathway [92]. Moreover, adaptive laboratory evolution (ALE) was employed to increase the growth rates of the strain on CO2, resulting in a gain of more than 2-fold (from 0.008 h−1 to 0.018 h−1) [92].

The Improved phenotypes of these evolved CO2-assimilating K. phaffii yeasts were further investigated [93]. Reverse genetic engineering was used to evaluate the mutations found in the genes encoding for the heterologous phosphoribulokinase (PRK) and the native nicotinic acid mononucleotide adenylyltransferase (NMA1). The results showed that lower activities of the mutated enzymes, which affect the availability of ATP and other consequences, are beneficial to the autotrophic phenotype. Furthermore, through a second evolution round, it was identified that facilitating peroxisomal import can be another engineering strategy to improve the autotrophic growth of K. phaffii [93].

These studies represent a remarkable advance in microbial utilization of one carbon (C1) feedstocks, since synthetic autotrophs can be used as an industrial platform for the production of several value-added chemicals and enzymes. Besides, this approach may have a significant role in the circular bioeconomy, promoting more sustainable biotechnological bioprocesses and also contributing to mitigating the atmospheric greenhouse gas CO2 [92,93]. However, despite the huge potential of the implementation of the CO2-assimilating pathway, many challenges should be addressed before it can be successfully explored in industrial production bioprocesses.

5.2. Metabolic Engineering of K. phaffii for Production of Renewables from Methanol

C1 substrates, such as CO2, methane, and methanol, have been considered next-generation feedstocks since they are relatively inexpensive due to their natural abundance, low production cost, or availability as industrial by-products [94]. In particular, methanol has gained attention as it can be produced directly from methane and CO2 using renewable resources [87]. Considering that, the native capacity of K. phaffii to metabolize methanol has been the focus of several studies to develop biotechnological fermentation processes. Although methanol has been widely employed in several bioprocesses related to recombinant protein expression by K. phaffii, only more recently, methanol has been explored as a substrate or co-substrate for the synthesis of various chemical compounds. We can cite, for example, the production of β -alanine, organic acids, alkenes, fatty acids, and pharmaceutical compounds, such as methyl salicylic acid and lovastatin (Table 2) [14,46,47,48,49,50,85].

5.2.1. β-Alanine Production from Methanol in K. phaffii

β-alanine is a natural β-amino acid that can be used to synthesize several nitrogen-containing compounds for the food and pharmaceutical industry. Biological production of β -alanine is obtained via L-aspartate decarboxylation. Considering that aspartate is one of the main amino acid pools in K phaffii, different bacterial L-aspartate decarboxylase (ADC) genes were expressed in the yeast to evaluate β-alanine production (Figure 5) [46]. Further improvement on β-alanine synthesis was achieved by increasing the ADC copy number and the supply of the C4 precursor aspartate. The engineered strain produced 1.2 g/L of β -alanine in shake-flask culture and reached a titer of 5.6 g/L in a fermenter using a two-stage strategy with high initial biomass (Table 2). This study was the first attempt to produce amino acids in K. phaffii using methanol as substrate, indicating the great potential of the yeast for fermentative production of amino acids [46].

5.2.2. Organic Acids Production from Methanol in K. phaffii

Malic acid, like other C4 dicarboxylic acids, and lactic acid, are on the top of the most relevant bio-based chemicals that can be produced through microbial processes from renewable resources [74,81]. Both compounds have high commercial value and a broad range of applications in the industrial sector, with a global market size estimated at USD 182.6 million in 2018 for malic acid (https://www.grandviewresearch.com/industry-analysis/malic-acid-market—accessed on 17 August 2022) and USD 2.9 billion in 2021 for lactic acid (https://www.grandviewresearch.com/industry-analysis/lactic-acid-and-poly-lactic-acid-market—accessed on 17 August 2022).

Considering that, K. phaffii has been engineered to produce organic acids using methanol [47,48]. The expression of multiple copies of the D-lactate dehydrogenase gene from Leuconostoc mesenteroides via gene integration into the rDNA locus of K. phaffii and post-transformational vector amplification, led to a D-lactic acid production of 3.48 g/L by the recombinant cells after 96 h of cultivation [47]. In another study, the conversion of methanol into malic acid was reported [48]. Guo et al. [48] evaluated three different malic acid accumulation modules in K. phaffii. Among them, the reductive TCA pathway derived from Rhizopus oryzae showed the best results for malic acid production. Additional metabolic engineering was also tested to optimize the strain, which included: (i) overexpression of the SpMAE transporter, (ii) deletion of genes related to by-product formation, and (iii) modifications on the methanol metabolism pathway. The resulting strain could produce 2.79 g/L of malic acid from methanol [48]. Although a malic acid titer of 42.28 g/L has been already obtained by a recombinant K. phaffii strain during the cultivation on glucose and using methanol as inducer [95], it was the first report of malic acid production using methanol as the only carbon source (Table 2) (Figure 5).

5.2.3. Biopolymers Production from Methanol in K. phaffii

Biopolymers have also been produced in K. phaffii. Hyaluronic acid is a glycosaminoglycan polysaccharide with remarkable biological activity. Because of that, it is widely used in the medical and pharmaceutical sectors, with a global market valued at USD 9.1 billion in 2019 (reviewed in [96]). The commercial production of hyaluronic acid is mainly from animal tissue extraction and, more recently, by fermentation using the pathogenic bacteria Streptococcus sp. [96]. However, attempts have been developed to produce this polysaccharide using other non-pathogenic host strains [53]. Considering that, K. phaffii was engineered to express the hyaluronan synthase (xhasA2) and UDP-glucose dehydrogenase (xhasB) from Xenopus laevis, in combination with the overexpression of native genes involved with the hyaluronic acid biosynthesis (hasC, hasD, hasE). The engineered yeasts produced an amount of 0.8–1.7 g/L of hyaluronic acid with a molecular weight from 1.2 to 2.5 MDa (Table 2), using glucose as the main substrate and methanol as co-substrate and inducer (Figure 5) [53].

Exploring the natural occurrence of the biosynthesis pathway of sulfation in the yeast, the production of chondroitin sulfate, another clinically relevant biopolymer, has been proposed and implemented in K. phaffii (Figure 5). Chondroitin is a glycosaminoglycan composed of sulfated disaccharides repetitions of glucuronic acid (GlcA) and N-acetylgalactosamine (GalNAc) linked by β (1 → 3) and β (1 → 4) bonds [51]. Initially, an engineered strain was constructed by introducing the chondroitin biosynthesis pathway harboring the genes kfoC and kfoA from Escherichia coli, which led to the synthesis of the intermediate metabolites UDP-GlcA and UDP-GalNAc, and tuaD from Bacillus subtilis, which encoded a chondroitin polymerase responsible for the polysaccharide formation. The resulting strain produced 5.5 mg/L of chondroitin [51]. For further improvement, combined strategies were employed, such as codon optimization, expression of the chondroitin-4-O-sulfotransferase (C4ST), and increased supply of the 3′-phosphoadenosine-5′-phosphosulfate (PAPS, a universal donor for sulfonated molecules). As a result, the yeast was capable of synthesizing 2.1 g/L of chondroitin sulfate from methanol [51].

Recently, this previously engineered strain [51] was used as a host to express sulfotransferases and an epimerase for in vitro biosynthesis of heparin [52]. Taking into consideration the successful expression of all required enzymes, the authors proposed the construction of a yeast platform for complete biosynthesis of heparin from methanol. The recombinant K. phaffii, co-expressing heparosan synthesis enzymes (tuaD, KfiC, KfiA), bifunctional enzyme NDST, sulfotransferases (2-OST, 6-OST and 3-OST), and epimerase C5 epi, showed production of 2.08 g/L of the bioengineered heparin, with a molecular weight of 349 kDa, in fed-batch cultures [52]. Heparin is a linear and unbranched glycosaminoglycan widely used as an anticoagulant drug. The global market was valued at USD 7.3 billion in 2021 and is growing with the increasing worldwide demand (https://www.grandviewresearch.com/industry-analysis/heparin-market—accessed on 17 August 2022).

5.2.4. Polyketides Production from Methanol in K. phaffii

The potential of K. phaffii as a microbial chassis for polyketide biosynthesis has also been evaluated (Figure 5) [49,50,97]. Polyketides are a class of secondary metabolites produced by several organisms, showing structural diversity and bioactivity, making some interesting pharmaceutical drugs [14,50]. The synthesis of the polyketide 6-methyl salicylic acid (6MSA) was described by Gao et al. [50]. In K. phaffii, through overexpression of the 6-methyl salicylic acid synthase gene (atX) from Aspergillus terreus and phosphopantetheinyl transferase gene (npgA) from Aspergillus nidulans, a production of 2.2 g/L 6MSA was achieved during cultivation in bioreactor [50]. Later, the same research group reported the synthesis of the polyketide citrinin by K. phaffii [97]. For this, the citrinin biosynthetic pathway, which genes are derived from Monascus purpureus (pksCT, mpl1, mpl2, and mpl4) and Monascus ruber (mpl6, mpl7), was introduced into the yeast together with the expression of the transferase npgA-encoding gene. The engineered strain was able to accumulate 0.6 mg/L of the polyketide using methanol as a carbon source and inducer [97].

Lovastatin, a common pharmaceutical drug used in hypercholesterolemia treatment, and its precursor monacolin J, are other examples of polyketides produced in K. phaffii [49]. The commercial product is obtained mainly from fermentation using an Aspergillus terreus strain. The metabolic engineering of other microbial hosts, such as K. phaffii, can be an alternative to reduce the long fermentation period required by filamentous fungi and limit multiple byproduct formation [49]. For production in K. phaffii, the complex monacolin J and lovastatin biosynthetic pathways were assembled and implemented in the yeast, resulting in 3.3 and 21 mg/L of lovastatin and monacolin J, respectively. Using a buffered medium, an improvement in product concentration of approximately three times was observed during shake flask cultivation.

Furthermore, the pathway was split into two modules and implemented in two separated strains to reduce the metabolic burden and avoid the accumulation of intermediate metabolites. During bioreactor cultivation, the co-culture system enabled the production of 250 mg/L of lovastatin and 593 mg/L monacolin J using methanol as substrate. These results demonstrated that microbial consortium could be an efficient strategy for metabolite production. However, it depends on cell internalization of the intermediate compounds [14]. This study was the first report of biosynthesis of lovastatin in a heterologous host; additionally, the compound production was comparable to that obtained with the native A. terreus strain [49].

As can be seen, several studies demonstrate the potential of K. phaffii as a microbial chassis to produce value-added chemicals using methanol as a carbon source. However, methanol fermentation efficiency is still lower than sugar-based processes. To overcome the current proof-of-concept stage, some problems should be addressed, including the cellular toxicity of methanol and the intermediate formaldehyde, as well as the carbon loss (via the dissimilatory pathway) that reduce product yields [85,88]. Therefore, further improvements are required for the industrial application of K. phaffii in methanol bioconversions.

6. Komagataella phaffii Application in Protein Production

Komagataella phaffii has been one of the most used species for the cost-effective production of recombinant protein, capable of expressing a range of enzymes with industrial and pharmaceutical relevance (Table 4). This fact is due to the ability of this microorganism to grow to very high cell densities (biomass over 100 g/L using methanol) and produce amounts of recombinant protein ranging from milligrams to grams for both research (laboratory) and industry purposes [19,98]. Anteriorly, Pichia pastoris (include K. phaffii and K. pastoris strains) first caught attention by being used as a single-cell protein (SCP) by Phillips Petroleum and commercialized for animal supplementation [72,99]. Later, with more advanced genetic manipulation of K. phaffii and the isolation of different promoters, especially the alcohol oxidase genes (AOX), glyceraldehyde-3-phosphate dehydrogenase (GAP), and the 3-phosphoglyceratekinase gene (PGK1), the development of expression vectors, new techniques, and protocols for genetic transformation, culminated in the creation of the current successful heterologous expression system [99,100,101].

Table 4.

Examples of heterologous proteins expressed in K. phaffii and production yields.

Among the main advantages of recombinant expression in K. phaffii are rapid growth in cheaper culture media, scaling up of protein production, easy maintenance, and genetic manipulation. In addition, these organisms are capable of performing most post-translational modifications such as glycosylation (N or O), formation of disulfide bridges, and adequate folding of the protein of interest, allowing the production of a cost-competitive enzyme with minimal processing in the following steps [6,72,99]. Moreover, the choice of a promoter (constitutive or induced), selection marks (dominant or auxotrophic), and signal peptides for extracellular secretion (when desired), are essential for the successful production of the protein of interest. Additionally, integrated vectors into the genome potentially increase the genetic stability of the engineered strains even in continuous and large-scale fermentation processes [99].

Several studies have reported the production of recombinant proteins in K. phaffii, registering more than 500 biopharmaceutical proteins, such as insulin, anti-microbial peptides, human serum albumin (HSA), and epidermal growth factor [98]. These proteins represent a growing market in the therapeutics biotechnology business. Since K. phaffii has the status GRAS, a range of approved biopharmaceuticals such as vaccines is being extensively studied for production in this yeast. For instance, the production of protein candidates for subunit vaccines has been expressed in K. phaffii to be used against malaria [102], dengue [103], chikungunya [104], tuberculosis [105,125], and SARS [126,127]. Further, the expression of SARS-CoV-2 Spike RBD (receptor binding domain) in K. phaffii was scaled-up reaching yields above 45 mg/L of 90% pure protein. This work provided an alternative for the production of neutralizing antibodies and the possible development of SARS-CoV-2 vaccines to combat the COVID-19 pandemic [106].

Additionally, other important therapeutic proteins were produced at high levels in K. phaffii, such as biologically active human proinsulin [107] and human epidermal growth [108]. The interleukin-1beta involved in different physiological responses was successfully expressed in K. phaffii, and its activity was detected to inhibit the growth of B16 melanoma cells [109]. Currently, different active antimicrobials against pathogens (bacteria and fungi) like Hispidalin [110], the Hybrid cecropinA-thanatin [111], PAF102 peptide (under GAP regulation) [112], and fowlicidins [113] have been produced in K. phaffii. Moreover, K. phaffii achieved one of the highest concentrations (8.86 g/L) of a human serum albumin, an important protein with different therapeutic functions [114]. All these cited proteins were expressed under the regulation of the AOX promoter unless otherwise specified.

The global market for recombinant proteins is expected to reach USD 1.7 billion by 2026 [128]. In the food, feed, detergent, and clothes industries, many relevant enzymes for biotechnology applications have been produced in K. phaffii, such as lignocellulolytic enzymes (responsible for the degradation of main components of the plant cell wall, such as cellulose, hemicellulose, pectin, lignin, and others) [116,129]. A wide range of these enzymes is naturally produced by fungal strains like Trichoderma spp., Penicillium spp., Aspergillus spp., Humicola spp., Thermomyces, and Myceliophthora spp. [130]. To produce purified and high yields of the targeted proteins from these fungi, using heterologous expression in K. phaffii is highly favorable. Additionally, an important fact is that K. phaffii does not secrete endogenous lignocellulolytic enzymes in significant amounts. Thus, recombinant strains of this yeast can provide heterologous enzyme preparations without the need for many purification steps, reducing the time and cost of the process [99,116].

Cellulases such as endoglucanases [115], cellobiohydrolases [116], and β-glucosidases [131], have been expressed in K. phaffii allowing purification, biochemical characterization, and biotechnological applications. These proteins can be used in paper and pulp, textile, and detergent industries, and applied in biorefineries for the bioconversion of lignocellulosic biomass [132]. In this context, to aid in the degradation of cellulose chains, the oxidative enzymes called lytic polysaccharide monooxygenases (LPMOs) and classified as auxiliary activity (AA) proteins have been produced in K. phaffii [118,133], as well as expansins (AA proteins), which act in synergy with cellulases to enhance sugar release from the substrate [119].

Likewise, hemicellulases like xylanases and β-xilosidases have been extensively expressed in K. phaffii. These enzymes can be applied in the textile, paper, and pulp industries, and hemicellulose deconstruction [120,134,135]. Other enzymes that can be utilized with xylanases and β-xilosidases to increase hemicellulose degradation have also been expressed in this yeast, including feruloyl esterase, acetyl xylan esterase, and α-L-arabinofuranosidases [121,122,123]. The recombinant mannanases and pectinases produced in K. phaffii are very relevant for the food industry and have been used in preparation for prebiotics and juice clarification, respectively [117,136]. Furthermore, successfully recombinant lipases produced in K. phaffii expression system are being studied as biocatalysts for the conversion of biomass fatty acids in biodiesel [124,137].

Several proteins of industrial and medical importance have been produced in K. phaffii and approved by regulatory institutions so far, noting the efficient expression system established in this yeast. Meaningful progress has been made with improved protein expression levels with different approaches. However, protein production still needs to be optimized and maximized for large-scale processes utilized in industry.

7. Strategies to Develop and Optimize Fermentative Processes

The production of proteins and chemicals in K. phaffii can be a powerful tool to address global needs. However, despite the increasing development of this microbial platform, their fermentation processes have still not achieved the same maturity as conventional biochemical processes [138,139,140]. There is a disparity between a promising laboratory scale and its industrial application; although many studies have demonstrated proof-of-concept pathways for new molecules, a much smaller amount of these works have focused on bioprocess design, optimization strategies, mathematical modeling, or scaling-up processes [139,141,142,143]. Integrating strain engineering and fermentation strategies is crucial for improving bioprocess efficiency. The technology transfer of bioprocesses in host systems is usually a result of iterative process optimizations and biological re-design cycles [144]. In this sense, a deep understanding of cell factories, process development, optimization, and scaling-up must be part of the same improvement. As strain engineering has been discussed in the previous sections, this one will focus on fermentation characteristics and strategies to produce a maximum amount of product in the minimum process time with quality specifications.

Despite the existence of conditions widely used in the fermentative processes in K. phaffii, optimal conditions differ according to the target product, the combination of genetic construction, or whether the production occurs under the control of inducible or constitutive promoters [98,140]. The most successful process development in K. phaffii suggests that the optimized process moves away from standard protocols and adapts process parameters to specific strain/product/bioreactor [140,145]. The main factors are discussed in detail in the following and summarized on Table 5.

Table 5.

Strategies for process development, simulation, and optimization with K. phaffii.

7.1. Fermentation Parameters

The efficiency of fermentation processes is strongly influenced by operational parameters such as temperature, pH, dissolved oxygen (DO), medium composition, and osmolality. For K. phaffii cultivation, several authors use a similar range of optimal set-point and control strategies for these parameters, mainly based on standard protocols (Table 5) [98,138,142,154].

The required growth temperature for K. phaffii is 28–30 °C [98,155]. A temperature greater than 32 °C could cause cell death and reduce protein expression. For heterologous protein production, in some cases, reducing the cultivation temperature may improve protein production by increasing yeast viability (despite decreasing growth rate), decreasing folding stress, and reducing proteolytic activity against the target protein [98,155]. Besides that, decreasing the cultivation temperature increases the oxygen solubility and consequently improves the oxygen transfer rate [155]. Studies focused on the temperature effect indicated that the improvement in efficiency depends on the target product and should be evaluated in each case [155,159].