Chemical and Sensory Characterization of Vidal Icewines Fermented with Different Yeast Strains

Abstract

:1. Introduction

2. Materials and Methods

2.1. Icewine Samples

2.2. Chemicals and Reagents

2.3. Descriptive Sensory Analysis (DA)

2.3.1. Panel

2.3.2. Training

2.3.3. Sample Evaluation

2.4. Analysis of Volatile Aroma Compounds

2.5. Statistical Analysis

3. Results and Discussion

3.1. Samples of Icewines

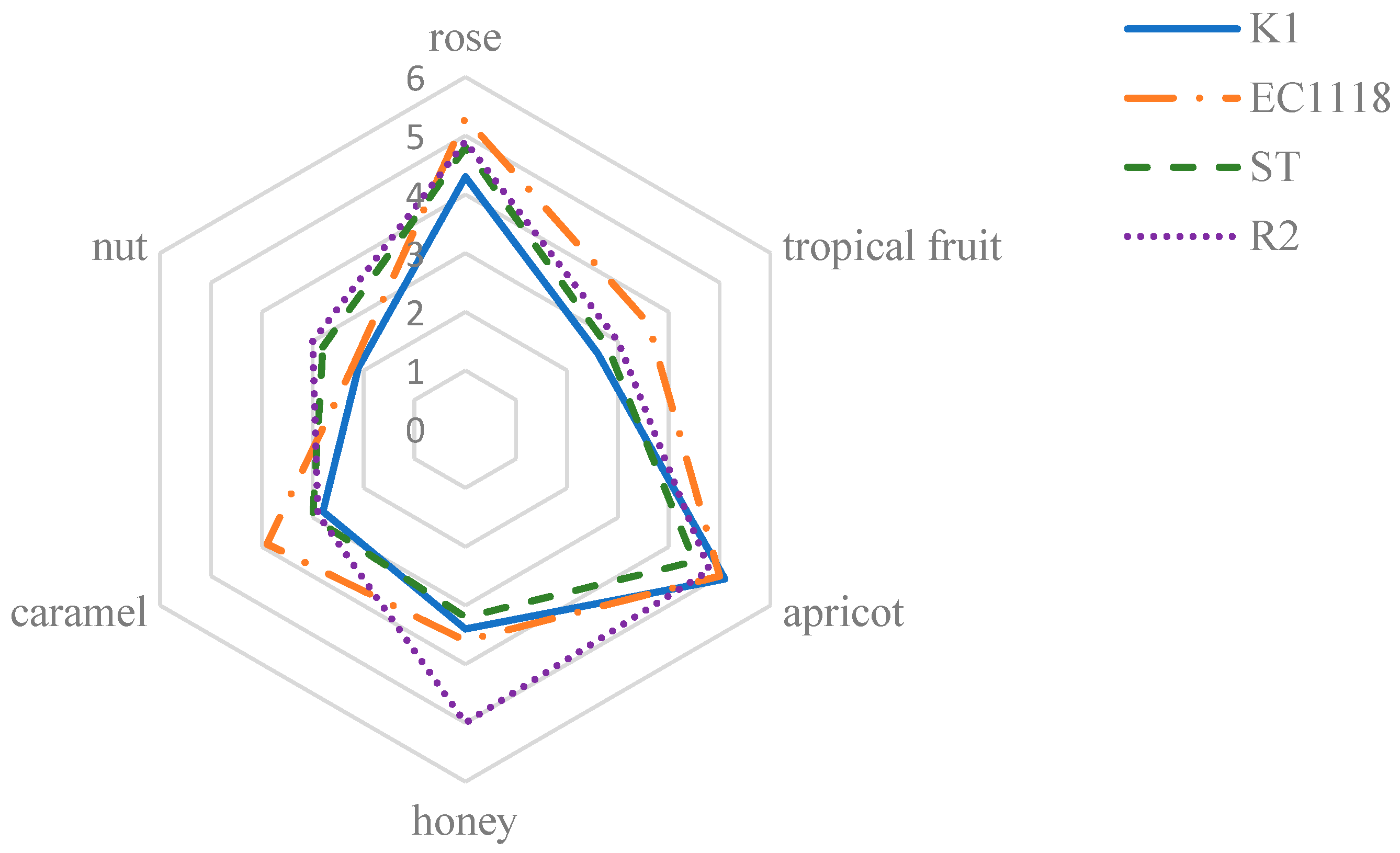

3.2. Sensory Analysis

3.3. Chemical Analysis

3.3.1. Volatile Profiling of Icewines Fermented by Different Yeasts

3.3.2. Chemical Characteristic of Icewines Fermented by Different Yeasts

3.4. Relationships between the Sensory Attributes and Aroma Compounds

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cliff, M.A.; Yuksel, D.; Girard, B.; King, M. Characterization of Canadian ice wines by sensory and compositional analyses. Am. J. Enol. Viticult. 2002, 53, 46–53. [Google Scholar]

- Tang, K.; Li, J.M.; Wang, B.; Ma, L.; Xu, Y. Evaluation of nonvolatile flavor compounds in Vidal icewine from China. Am. J. Enol. Viticult. 2013, 64, 110–117. [Google Scholar] [CrossRef]

- Nurgel, C.; Pickering, G.J.; Inglis, D. Sensory and chemical characteristics of Canadian ice wines. J. Sci. Food Agric. 2004, 84, 1675–1684. [Google Scholar] [CrossRef]

- Ma, Y.; Tang, K.; Xu, Y.; Li, J.M. Characterization of the key aroma compounds in Chinese Vidal icewine by gas chromatography-olfactometry, quantitative measurements, aroma recombination, and omission tests. J. Agric. Food Chem. 2017, 65, 394–401. [Google Scholar] [CrossRef]

- Ma, Y.; Xu, Y.; Tang, K. The Aroma of Icewine: A Review on How Environmental, Viticultural and Oenological Factors Affect the Aroma of Icewine. J. Agric. Food Chem. 2021, 69, 6943–6957. [Google Scholar] [CrossRef]

- Belda, I.; Ruiz, J.; Esteban-Fernández, A.; Navascués, E.; Marquina, D.; Santos, A.; Moreno-Arribas, M.V. Microbial contribution to wine aroma and its intended use for wine quality improvement. Molecules 2017, 22, 189. [Google Scholar] [CrossRef] [Green Version]

- Borren, E.; Tian, B. The Important Contribution of Non-Saccharomyces Yeasts to the Aroma Complexity of Wine: A Review. Foods 2021, 10, 13. [Google Scholar] [CrossRef]

- Molina, A.M.; Guadalupe, V.; Varela, C.; Swiegers, J.H.; Pretorius, I.S.; Agosin, E. Differential synthesis of fermentative aroma compounds of two related commercial wine yeast strains. Food Chem. 2009, 117, 189–195. [Google Scholar] [CrossRef]

- Swiegers, J.H.; Bartowsky, E.J.; Henschke, P.A.; Pretorius, I.S. Yeast and bacterial modulation of wine aroma and flavour. Aust. J. Grape Wine Res. 2005, 11, 139–173. [Google Scholar] [CrossRef]

- Pigeau, G.M. Icewine Fermentation by Saccharomyces Cervisiae: Fundamental Stress Responses and Comparative Fermentation Dynamics. Ph.D. Thesis, Brock University, St. Catharines, ON, Canada, 2006. [Google Scholar]

- Kontkanen, D.; Inglis, D.; Pickering, G.; Reynolds, A. Effect of yeast inoculation rate, acclimatization, and nutrient addition on Icewine fermentation. Am. J. Enol. Viticult. 2004, 55, 363–370. [Google Scholar]

- Crandles, M.; Reynolds, A.G.; Khairallah, R.; Bowen, A. The effect of yeast strain on odor active compounds in Riesling and Vidal blanc icewines. LWT-Food Sci. Technol. 2015, 64, 243–258. [Google Scholar] [CrossRef]

- Erasmus, D.J.; Cliff, M.; van Vuuren, H.J.J. Impact of yeast strain on the production of acetic acid, glycerol, and the sensory attributes of icewine. Am. J. Enol. Viticult. 2004, 55, 371–378. [Google Scholar]

- Fuleki, T. Performance of five yeast strains in icewine fermentation. Am. Soc. Enol. Vitic. 1994, 45, 359A. [Google Scholar]

- Yang, F. Study of New Yeast Strains as Novel Starter Cultures for Riesling Icewine Production. Master’s Thesis, Brock University, St. Catharines, ON, Canada, 2011. [Google Scholar]

- Synos, K.; Reynolds, A.G.; Bowen, A.J. Effect of yeast strain on aroma compounds in Cabernet franc icewines. LWT-Food Sci. Technol. 2015, 64, 227–235. [Google Scholar] [CrossRef]

- Pigeau, G.M.; Bozza, E.; Kaiser, K.; Inglis, D.L. Concentration effect of Riesling Icewine juice on yeast performance and wine acidity. J. Appl. Microbiol. 2007, 103, 1691–1698. [Google Scholar] [CrossRef] [Green Version]

- ISO-8586-1. Sensory Analysis: General Guidance for the Selection, Training and Monitoring of Assessors, Selected Assessors; International Organization for Standardization: Geneva, Switzerland, 1993. [Google Scholar]

- ISO-8586-2. Sensory Analysis: General Guidance for the Selection, Training and Monitoring of Assessors, Expert Sensory Assessors; International Organization for Standardization: Geneva, Switzerland, 2008. [Google Scholar]

- Huang, L.; Ma, Y.; Tian, X.; Li, J.M.; Li, L.X.; Tang, K.; Xu, Y. Chemosensory characteristics of regional Vidal icewines from China and Canada. Food Chem. 2018, 261, 66–74. [Google Scholar] [CrossRef]

- Albert, A.; Varela, P.; Salvador, A.; Hough, G.; Fiszman, S. Overcoming the issues in the sensory description of hot served food with a complex texture. Application of QDA®, flash profiling and projective mapping using panels with different degrees of training. Food Qual. Prefer. 2011, 22, 463–473. [Google Scholar] [CrossRef]

- ISO-4121. Sensory Analysis-Guidelines for the Use of Quantitative Response Scales; International Organization for Standardization: Geneva, Switzerland, 2003. [Google Scholar]

- Wang, L.L.; Fan, S.S.; Yan, Y.; Yang, L.; Chen, S.; Xu, Y. Characterization of potent odorants causing a pickle-like off-odor in moutai-aroma type baijiu by comparative aroma extract dilution analysis, quantitative measurements, aroma addition, and omission studies. J. Agric. Food Chem. 2020, 68, 1666–1677. [Google Scholar] [CrossRef]

- Erasmus, D.J.; Van der Merwe, G.K.; van Vuuren, H.J.J. Genome-wide expression analyses: Metabolic adaptation of Saccharomyces cerevisiae to high sugar stress. FEMS Yeast Res. 2003, 3, 375–399. [Google Scholar] [CrossRef] [Green Version]

- Cliff, M.A.; Pickering, G.J. Determination of odour detection thresholds for acetic acid and ethyl acetate in ice wine. J. Wine Res. 2006, 17, 45–52. [Google Scholar] [CrossRef]

- He, Y.X.; Liu, Z.P.; Qian, M.; Yu, X.W.; Xu, Y.; Chen, S. Unraveling the chemosensory characteristics of strong-aroma type Baijiu from different regions using comprehensive two-dimensional gas chromatography-time-of-flight mass spectrometry and descriptive sensory analysis. Food Chem. 2020, 331, 127335. [Google Scholar] [CrossRef]

- Dunkel, A.; Steinhaus, M.; Kotthoff, M.; Nowak, B.; Krautwurst, D.; Schieberle, P.; Hofmann, T. Nature’s chemical signatures in human olfaction: A foodborne perspective for future biotechnology. Angew. Chem. Int. Edit. 2014, 53, 7124–7143. [Google Scholar] [CrossRef]

- Bowen, A.J.; Reynolds, A.G. Odor potency of aroma compounds in Riesling and Vidal blanc table wines and icewines by gas chromatography-olfactometry-mass spectrometry. J. Agric. Food Chem. 2012, 60, 2874–2883. [Google Scholar] [CrossRef]

- Pineau, B.; Barbe, J.C.; Van Leeuwen, C.; Dubourdieu, D. Which impact for β-damascenone on red wines aroma? J. Agric. Food Chem. 2007, 55, 4103–4108. [Google Scholar] [CrossRef]

- Bowen, A.J.; Reynolds, A.G. Aroma compounds in Ontario Vidal and Riesling icewines. I. Effects of harvest date. Food Res. Int. 2015, 76, 540–549. [Google Scholar] [CrossRef]

| Treatment | Residual Sugar (g/L) | Ethanol (%, v/v) | Titratable Acidity (g/L) | Acetic Acid (g/L) | pH |

|---|---|---|---|---|---|

| EC1118 | 183.45 ± 1.22 | 10.5 ± 0.1 | 11.2 ± 0.5 | 1.11 ± 0.02 | 3.51 |

| R2 | 170.21 ± 1.05 | 11.4 ± 0.2 | 12.8 ± 0.4 | 1.40 ± 0.02 | 3.45 |

| K1 | 181.33 ± 2.11 | 10.6 ± 0.1 | 12.1 ± 0.4 | 1.22 ± 0.03 | 3.52 |

| ST | 178.92 ± 1.57 | 10.8 ± 0.1 | 12.2 ± 0.3 | 0.92 ± 0.11 | 3.52 |

| K1 | EC1118 | ST | R2 | |

|---|---|---|---|---|

| Esters | 97 | 91 | 93 | 117 |

| Alcohols | 79 | 81 | 73 | 105 |

| Ketones | 50 | 49 | 46 | 55 |

| Aromatic compounds | 34 | 35 | 32 | 31 |

| Terpenes | 25 | 24 | 24 | 26 |

| Aldehydes | 18 | 23 | 14 | 26 |

| Furans | 18 | 19 | 19 | 23 |

| Acids | 19 | 21 | 19 | 22 |

| Nitrogen-containing compounds | 17 | 21 | 10 | 18 |

| Phenols | 17 | 18 | 17 | 17 |

| Lactones | 11 | 11 | 11 | 11 |

| Sulfides | 6 | 6 | 6 | 6 |

| Total | 391 | 399 | 364 | 457 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, K.; Sun, Y.; Zhang, X.; Li, J.; Xu, Y. Chemical and Sensory Characterization of Vidal Icewines Fermented with Different Yeast Strains. Fermentation 2021, 7, 211. https://doi.org/10.3390/fermentation7040211

Tang K, Sun Y, Zhang X, Li J, Xu Y. Chemical and Sensory Characterization of Vidal Icewines Fermented with Different Yeast Strains. Fermentation. 2021; 7(4):211. https://doi.org/10.3390/fermentation7040211

Chicago/Turabian StyleTang, Ke, Yulu Sun, Xiaoqian Zhang, Jiming Li, and Yan Xu. 2021. "Chemical and Sensory Characterization of Vidal Icewines Fermented with Different Yeast Strains" Fermentation 7, no. 4: 211. https://doi.org/10.3390/fermentation7040211

APA StyleTang, K., Sun, Y., Zhang, X., Li, J., & Xu, Y. (2021). Chemical and Sensory Characterization of Vidal Icewines Fermented with Different Yeast Strains. Fermentation, 7(4), 211. https://doi.org/10.3390/fermentation7040211