Abstract

Plant-based beverages are growing in popularity due to the rise of vegetarianism and other health trends. A probiotic almond beverage that combines the properties of almonds, inulin, and Lacticaseibacillus rhamnosus GR-1 may meet the demand for a non-dairy health-promoting food. The purpose of this study was to investigate the viability of L. rhamnosus GR-1 and pH in five fermented almond beverage samples, supplemented with either 2% or 5% (w/v) short-chain or long-chain inulin over 9 h of fermentation and 30 days of refrigerated storage. All almond beverage samples achieved a mean viable count of at least 107 CFU/mL during 9h of fermentation and 30 days of refrigerated storage. The probiotic almond beverage supplemented with 2% (w/v) short-chain inulin had a significantly higher mean microbial count (p = 0.048) and lower pH (p < 0.001) throughout fermentation, while the control and the long-chain inulin treatments had the lowest viable counts and acidity, respectively. This study shows that the addition of short-chain and long-chain inulin had no adverse effects on the viability of L. rhamnosus GR-1. Therefore, the probiotic almond beverage has the potential to be a valid alternative to dairy-based probiotic products.

1. Introduction

The proportion of Canadians reducing or eliminating animal products from their diet has markedly increased over the past 15 years [1]. A 2018 survey estimates that 5.6% of Canadians identified as vegetarian (4.5%) and vegan (1.1%), which was more prevalent among those under 38 years of age [1]. Many people choose a vegetarian diet out of concern for animal welfare, environmental sustainability, health, and cultural and religious beliefs among communities that may limit the consumption of animal products [2,3,4]. Diets that emphasize plant-based foods are typically higher in dietary fibre, fruit and vegetables rich in phytochemicals, vitamins, and minerals and exhibit lower cholesterol and saturated fat content [5]. This dietary pattern has been associated with the reduced risk of cardiovascular disease, some cancers, and diabetes [5]. Consequently, Canada’s updated Food Guide now recommends shifting towards a dietary pattern that includes plant-based foods more often to encourage the population to limit their intake of processed meats and foods high in sodium and saturated fat [5,6].

Along with the growing trend of vegetarianism, probiotics are growing in appreciation for their positive effects on human health [3]. Probiotics are defined as live bacteria that deliver therapeutic benefits to the host when consumed in adequate amounts [7,8]. The therapeutic effects of each probiotic strain are different [9], and foods must contain a minimum of 106 colony forming units (CFU) per gram at the time of consumption, survive gastric transit, and attach to the gut epithelium to effectively transfer their benefits to the host [4,7]. However, the presence of antimicrobial compounds in food, oxygen, acidic pH, product storage conditions, and shelf-life can significantly affect the viability of probiotic strains in food matrixes by the time they reach the consumer [10,11]. One of the most researched probiotic strains, Lacticaseibacillus rhamnosus GR-1 (LGR-1), previously classified as Lactobacillus rhamnosus GR-1, is a bile-resistant bacterium that survives transport through the human gastrointestinal tract and effectively colonizes the intestinal and vaginal tracts [12,13]. LGR-1 is well-known for its urogenital health effects in women by reducing the recurrence of vaginosis and urinary tract infections [13]. The strain has also been shown to have potential applications for allergies, gut-associated complications, and cardiovascular health through its immunomodulation capacity [13]. LGR-1 has been demonstrated to be safe through its application in immunocompromised patients with HIV and inflammatory bowel disease without induction of the systemic immune or inflammatory responses [14,15].

Dairy products, such as yogurt and cheese, are the most common vehicle to deliver probiotics [10]. Although dairy products remain at the forefront of probiotic food development, non-dairy food products have increased in popularity owing to their unique characteristics and advantages [4,16]. These advantages include meeting the needs of vegetarians, providing lactose-free and low-cholesterol-content products to those who suffer from lactose intolerance and diet-related disease, and improving the nutritional value of non-dairy foods [16]. In recent years, legumes and nut matrixes have been used to produce new nutritious, dairy-free milk alternatives to cow’s milk [17]. The most common dairy substitutes are soy, almond, and rice-based beverages, but other plant substitutes are gaining interest [18]. For instance, Dimitrellou et al. (2021) developed a fermented emmer-based beverage fortified with fruit juice using Lactiplantibacillus plantarum, yielding high viability of probiotic bacteria throughout 28-day storage [19]. Masia et al. (2021) found that L. rhamnosus and Bifidobacterium were able to grow and survive in soy, oat, and coconut bases over 21 days of storage and improved the flavour and gel-firmness in oat and coconut samples, respectively [20].

“Milk” derived from almonds has been of interest due to its health-promoting effects, including its antioxidant and immune-enhancing effects and cardioprotective properties [21,22]. Almonds are a nutrient-dense food with a valuable source of mono- and polyunsaturated fatty acids, high-quality protein, dietary fibre, phytochemicals, vitamins, and minerals [23,24]. Previous studies have shown the potential of almond beverage as a carrier for probiotics and a suitable alternative to cow’s milk because of its similar ranking of sensory attributes [3]. For instance, He and Hekmat (2014) were able to successfully grow LGR-1 in almond beverage, obtaining viable counts of at least 107 CFU/mL after 28 days of storage [3]. Similarly, Bernat et al. (2015) fermented almond beverage with L. reuteri and Streptococcus thermophilus and also maintained significant probiotic yields during storage [25]. Almond beverage has a low carbohydrate content compared to cow milk, which can affect the level of growth and acidification that can be achieved [25]. Therefore, research suggests that the addition of prebiotics, such as inulin, can induce a synergistic effect to help improve the growth and survival of probiotic strains in non-dairy products [25,26].

Prebiotics are non-digestible carbohydrates that beneficially affect the host by stimulating the growth and/or activity in the gastrointestinal microflora that confers health benefits [27]. Inulin is a fermentable dietary fibre commonly derived from chicory root that increases the activity of LGR-1 [26]. Its properties are attributed to the degree of polymerization (DP), affecting the growth and viability of probiotics differently. Long-chain inulin has 23–25 units of DP and is more viscous and heat-stable and less soluble compared to short-chain inulin, containing 11 units of DP or less [26]. Canbulat and Ozcan (2015) showed that yogurt supplemented with short-chain inulin increased the viability of L. rhamnosus to at least 106–7 CFU/mL and received a better rating in the sensory evaluation than the sample containing long-chain inulin [26]. Inulin also produces technological benefits for fermented products, such as enhancing the textural and sensory properties [26,27]. The health benefits provided by inulin are those typically associated with dietary fibre, including constipation relief, cholesterol-lowering effects, blood glucose control, and colon cancer risk reduction [25,26]. Since many North Americans fail to meet the daily recommendation for fibre, fortification of a probiotic almond beverage with inulin fibre can help consumers enhance their fibre intake and receive additional health benefits [27]. Therefore, the nutritional profile of almonds and inulin with the benefits of LGR-1 may meet the demand for a health-promoting, non-dairy, probiotic product.

Although previous studies have evaluated the viability of LGR-1 in almond beverages, no studies have examined the effects of prebiotics on LGR-1 growth and survival in an almond beverage. Therefore, the purpose of this study was to evaluate the effect of prebiotic fortification with short-chain and long-chain inulin on the growth and viability of LGR-1 in an almond beverage over 9 h of fermentation and 30 days of refrigerated storage.

2. Materials and Methods

2.1. Probiotic Stock Solution Preparation

Ten percent weight per volume (w/v) of liquid LGR-1 culture (109 CFU/mL) (Canadian Centre for Human Microbiome and Probiotic Research, Lawson Health Research Institute, London, ON, Canada) was aseptically inoculated into sterilized de Man, Rogosa and, Sharpe (MRS) broth (EMD Millipore Corporation., Gibbstown, NJ, USA) and incubated anaerobically using a GasPak system (BD GasPakTM EZ Container System, Becton Dickinson & Co., Sparks, BD, USA) at 37 °C for 24 h. The probiotic stock solution was stored under refrigerated conditions at 4 °C and prepared every 8–10 days to maintain propagation and viable counts of LGR-1.

2.2. Probiotic Mother Culture Preparation

Unsweetened original almond beverage (Almond Breeze Unsweetened Original Almondmilk, Blue Diamond Almonds, Sacramento, CA, USA) was purchased from the Real Canadian Superstore, St. Thomas, ON, Canada, and autoclaved at 121 °C for 15 min. The almond beverage was cooled to 37 °C using a water bath. Subsequently, 10% (w/v) LGR-1 stock solution was aseptically inoculated in the almond beverage and then stirred, covered with aluminum foil, and incubated anaerobically using the GasPak system (BD GasPakTM EZ Container System, Becton Dickinson & Co., Sparks, BD, USA) at 37 °C for 24 h.

2.3. Almond Beverage Preparation and Fermentation

The almond beverage (Almond Breeze Unsweetened Original Almondmilk, Blue Diamond Almonds, USA) was divided into five beakers, representing five treatments. Treatment 1 contained solely almond beverage (control), Treatments 2 and 3 contained 2% and 5% (w/v) short-chain inulin (Orafti P95 Oligofructose Powder, Quadra Chemicals, Canada), respectively, and Treatments 4 and 5 contained 2% and 5% (w/v) long-chain inulin (Orafti HP Inulin Powder, Quadra Chemicals, Canada), respectively. Inulin powder was gradually added to the almond beverage treatments to avoid clumping and mixed until fully dissolved. All almond beverage treatments were autoclaved at 121 °C for 15 min and subsequently cooled with a water bath until a temperature of 37 °C was reached.

Then, 4% (w/v) of stirred liquid probiotic mother culture was aseptically inoculated in each of the almond beverage treatments and thoroughly mixed. Each treatment was divided into six beakers. Beakers 1–3 represented three fermentation timepoints (3, 6, 9 h), and beakers 4–6 represented three refrigerated storage timepoints (1, 15, 30 days). Each beaker was covered with aluminum foil.

Microbial counts and pH measurements were performed in three-hour intervals for a total of nine hours of fermentation and every 15 days over 30 days of cold storage. Beakers 1–3 were incubated anaerobically using the GasPak system (BD GasPakTM EZ Container System, Becton Dickinson & Co., Sparks, BD, USA) at 37 °C for 3, 6, and 9 h, respectively, and discarded once measurements were completed. Beakers 4–6 were incubated anaerobically at 37 °C for nine hours, then refrigerated at 4 °C for 1, 15, and 30 days of storage, respectively. The experiment was performed in duplicate, and thus, two true replications were carried out for each almond beverage treatment.

2.4. Microbial Analysis

Enumeration of LGR-1 from all almond beverage samples was performed after each fermentation (3, 6, 9 h) and cold storage (1, 15, 30 days) timepoint. Serial dilutions and subsequent plating were used to determine microbial counts. From the almond beverage samples, 1 mL aliquots were diluted in sterile 0.85% saline solution to 10−2, 10−4, 10−5, 10−6, and 10−7 dilution factors. Using a calibrated pipette, two 0.1 mL aliquots from each of the 10−5, 10−6, and 10−7 sample dilutions were transferred to two separate selective MRS agar plates. Agar plates were prepared using 5.22% (w/v) MRS (EMD Millipore Corporation, Gibbstown, NJ, USA), 1.5% (w/v) agar (EMD Millipore Corporation, Gibbstown, NJ, USA), and 0.0015% of the selective agent, fusidic acid (Enzo Life Sciences, Farmingdale, NY, USA) in distilled water. Using a sterile bent rod, the sample was spread evenly on the center of the agar plate, then plates were inverted and incubated anaerobically at 37 °C for 48 h. Viable counts were examined and recorded as colony-forming units (CFU) per mL. An average bacterial count was determined from the two duplicate plates, for each sample.

2.5. Analysis of pH

The pH of all almond beverage treatments was measured after 3, 6, and 9 h of fermentation as well as after 1, 15, and 30 days of refrigerated storage using a calibrated pH meter (VWR SympHonyTM B10P pH Meter, VMR International, Radnor, PA, USA). An average pH value was determined through two replicates of each treatment.

2.6. Statistical Analysis

All statistical analyses were conducted using SPSS Statistics, v. 27.0 (IBM Corporation, Armonk, NY, USA). Data were expressed as the average of two replicate determinations and presented as a mean ± standard deviation (SD). A one-way repeated measure analysis of variance (ANOVA) was used to analyze the viability of LGR-1 and pH between treatments and between fermentation and storage time. A one-way repeated measures ANOVA and Tukey’s test were also used to compare for differences between mean scores. A p-value of <0.05 was considered to be statistically significant.

3. Results

3.1. Microbial Analysis

LGR-1 reached mean viable counts of at least 107 CFU/mL in all five almond beverage treatments at all fermentation timepoints (Table 1). The initial mean counts (×107 CFU/mL) of LGR-1 at 3 h of fermentation for Treatments 1–5 were 1.00 ± 0.08, 4.57 ± 6.29, 3.32 ± 3.13, 1.00 ± 0.00, and 1.67 ± 0.46, respectively. After 9 h of fermentation, the mean microbial counts were 6.00 ± 4.61, 35.50 ± 34.46, 13.00 ± 5.48, 15.25 ± 10.99, 12.50 ± 5.97 in Treatments 1–5, respectively. Significant differences in mean microbial counts during 9h of fermentation were observed for Treatment 4 (p = 0.045) and Treatment 5 (p = 0.025) (Table 1). After 9h of fermentation, Treatments 4 and 5 had a mean microbial count of 15.25 (±10.99) and 12.50 (±5.97), respectively, which were both significantly higher (p < 0.05) compared to 3 h of fermentation, where the samples had a mean count of 1.00 (±0.00) and 1.67 (±0.46), respectively (Table 1). No significant differences in mean counts over 9h of fermentation were found for the remaining treatments (p > 0.05). When comparing the differences in mean microbial counts between the five treatments during each fermentation timepoint, the viability of LGR-1 in prebiotic fortified almond beverage treatments was comparable to the control. There were no statistically significant differences (p > 0.05) in mean counts of LGR-1. The results indicate no adverse effects of short-chain inulin or long-chain inulin on the growth or viability of LGR-1 during fermentation. Overall, total mean microbial counts for all timepoints were significantly different between treatments (p = 0.48), and all treatments increased significantly with each fermentation timepoint (p = 0.001). Treatment 2 had significantly higher (p < 0.05) mean counts of 18.61 (±23.43), and Treatment 1 had significantly (p < 0.05) lower mean counts of 4.48 (±4.04).

Table 1.

Viable counts (mean ± SD) of LGR-1 in probiotic almond beverage supplemented with short-chain inulin and long-chain inulin following 3, 6, and 9 h of fermentation.

During refrigerated storage, LGR-1 reached viable counts of at least 107 CFU/mL in all five almond beverage treatments (Table 2). Significant differences in mean microbial counts over 30 days of storage were found for Treatment 2 (p = 0.011). For example, Treatment 2 had the highest mean microbial count of 26.25 (±11.09) at 30 days of storage compared to all other treatments, which was significantly higher than 11.00 (±2.00) at day 1 of storage (p < 0.05) (Table 2). No significant differences in mean counts over 30 days of storage were found for the remaining treatments (p > 0.05). Additionally, no significant differences were detected for the mean microbial counts between treatments at each storage timepoint (p > 0.05). There was no significant difference in the viability of LGR-1 in the almond beverage when either short-chain or long-chain inulin fibre was added. Therefore, these results also demonstrate that short-chain and long-chain inulin fortification of the almond beverage to produce a non-dairy probiotic beverage did not adversely impact the growth, viability, survival, and shelf life of LGR-1.

Table 2.

Viable counts (mean ± SD) of LGR-1 in probiotic almond beverage supplemented with short-chain inulin and long-chain inulin following 1, 15, and 30 days of storage.

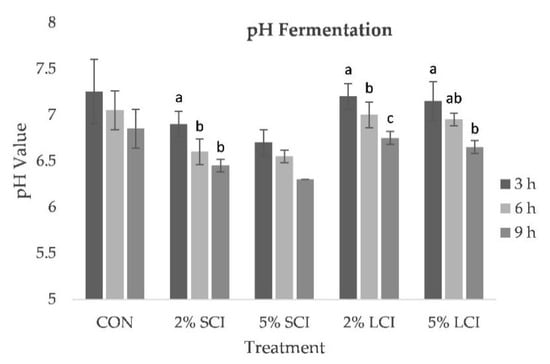

3.2. pH Analysis

Bacterial counts and pH were both measured in the same sample during fermentation and the storage period. There was a general decrease in pH over 9 h of fermentation in all almond beverage treatments. Significant differences were detected for Treatment 2 (p = 0.016), Treatment 4 (p = 0.016), and Treatment 5 (p = 0.05) (Figure 1). For example, Treatment 4 had a mean pH of 7.20 (±0.14) at 3 h, which significantly decreased to 6.75 (±0.07) after 9 h (p = 0.016). When comparing the differences in pH between the five treatments during 9h of fermentation, significant differences in pH were observed for each timepoint (p < 0.05). Treatment 3 had a significantly lowest mean pH of 6.70 (±0.14), 6.55 (±0.07), and 6.30 (±0.00) for 3 h (p = 0.015), 6 h (p = 0.003), 9 h (p = 0.009), respectively, followed by Treatments 2, 5, 4, and 1 (Figure 1). Similarly, the overall mean pH for all timepoints was significantly different between treatments (p < 0.001). Treatment 3 had a significantly lower (p < 0.05) pH of 6.52 (±0.19), and Treatment 1 had a significantly higher (p < 0.05) pH of 7.05 (±0.27).

Figure 1.

pH values of the five almond beverage treatments taken at 3, 6, and 9 h of fermentation. CON, control; SCI, short chain inulin; LCI, long-chain inulin). Means with different letters in the same group indicate significant differences between measurement times (p < 0.05).

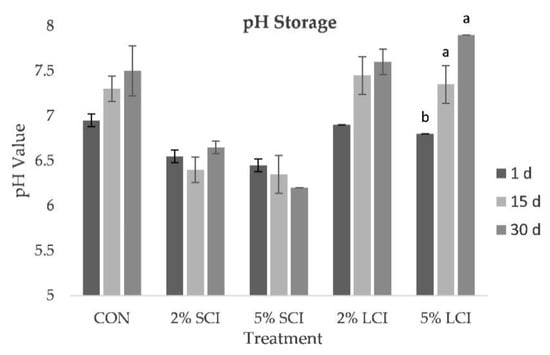

During refrigerated storage, there was a general increase in the pH of the almond beverage treatments over 30 days, except for Treatment 3; however, significant differences were only found in Treatment 5 (p = 0.024) (Figure 2). After 30 days of storage, Treatment 5 had a mean pH of 7.90 (±0.00), which was significantly higher (p < 0.05) compared to 1 day of storage, where the sample had a mean pH of 6.80 (±0.00) (Figure 2). Additionally, significant differences were found between treatments at each storage timepoint (p < 0.05). Treatment 3 had the significantly lowest mean pH of 6.45 (±0.07), 6.35 (±0.21), and 6.20 (±0.00) for 3 h (p = 0.004), 6 h (p = 0.013), 9 h (p = 0.001), respectively. The overall mean pH for all timepoints was significantly different between treatments (p < 0.001). Treatment 3 had a significantly lower (p < 0.05) pH of 6.33 (±0.15), and Treatment 5 had a significantly higher (p < 0.05) pH of 7.35 (±0.50).

Figure 2.

pH values of the five almond beverage treatments taken at 1, 15, and 30 days of storage. CON, control; SCI, short-chain inulin; LCI, long-chain inulin. Means with different letters in the same group indicate significant differences between measurement times (p < 0.05).

4. Discussion

Plant-based beverages are growing in popularity owing to their lactose-free, vegan, and cholesterol-free characteristics, which align well with the current demand for healthier products [28]. The primary objective of the present study was to determine the effect of short-chain inulin and long-chain inulin supplementation on the growth and viability of LGR-1 in a fermented almond beverage over 9 h of fermentation and 30 days of refrigerated storage. This formulation is a promising non-dairy alternative for probiotic delivery and presents a new functional food that may meet current diet and health trends.

During 9 h of fermentation, all almond beverage treatments supported the growth of LGR-1 and reached viable counts of at least 107 CFU/mL, which was maintained over 30 days of refrigerated storage (Table 1 and Table 2). This value exceeds the minimum recommended microbial load of 106 CFU/mL for probiotic benefits [8], suggesting LGR-1 is a good candidate for probiotic plant-based fermented products. This finding is in line with the results of previous studies demonstrating the ability of LGR-1 to thrive in a variety of non-dairy matrixes, including legume milk-like beverages, fruit juices, and vegetable juices [3,29,30], as well as other novel functional foods, such as fermented rice pudding, probiotic yogurt fortified with cereal grains and legumes, and fermented yogurt supplemented with soy beverage [9,31,32]. All studies reported its ability to acidify and grow, reaching viable counts of at least 107–109 CFU/mL, and no undesirable effects on its viability or the sensory properties of the final products.

Prebiotics can play a role in the stimulation or proliferation of probiotic bacteria in various fermented products and can also enhance survivability during storage [4,32]. Among these, inulin has previously been shown to exert a protective effect on lactic acid bacteria, such as LGR-1 [33]. Change in microbial counts between fermentation timepoints was significantly different (p < 0.05) for almond beverage treated with 2% and 5% long-chain inulin (Treatments 4 and 5), with increased LGR-1 counts for 6 h vs. 3 h (Table 1). However, this trend was reversed during storage, as a significant increase (p < 0.05) in the viable counts of LGR-1 were only observed for the almond beverage treated with 2% short-chain inulin (Treatment 2) between day 15 and day 30 of storage (Table 2). Overall, the almond beverage treated with 2% short-chain inulin had the highest LGR-1 counts while the control (Treatment 1) had the lowest counts during both fermentation (p < 0.05) and storage (p > 0.05). The prebiotic activity of inulin varies with the DP, with shorter-chain inulin being more efficient at promoting the growth and viability of probiotic cultures [33,34]. Although there was no significant difference in LGR-1 counts between treatments for the duration of fermentation or storage (p > 0.05), our results show no adverse effects of short-chain and long-chain inulin fortification of the almond beverage, as demonstrated by the similar counts among formulations (Table 1 and Table 2). This finding is consistent with other studies that report no difference in the growth or viability of probiotic bacteria between fermented samples supplemented with short- and long-chain inulin [9,29,35,36].

In contrast, other studies have shown that the addition of inulin fibre increases cell viability in non-dairy matrixes [37,38,39]. A similar study by Bernet et al. (2014) evaluated the effect of different sugar and inulin combinations on almond beverage fermentation with L. reuteri and S. thermophilus and found 2% (w/v) inulin had a positive effect on probiotic survival throughout storage [25]. Similar results were reported by Savedboworn et al. (2017), whereby the addition of 2% inulin (w/v) to fermented rice extracts resulted in the highest survival rate of L. plantarum during storage [38]. Choudhary et al. (2019) found an increase in various Lactobacillus counts with the supplementation of inulin in soymilk, with no differences between higher concentrations [39]. The differences between the aforementioned studies and our results could arise from the probiotic strain-specific response or the product formulations [40].

Evaluation of the pH showed increased acidity for all treatments over the 9 h fermentation period (p < 0.05), which averaged 6.82. This value is much higher than other studies performed in plant-based beverages [20,24,25,37], which could be related to the different probiotic strains, the concentrations used, or the different product formulations compared to the present study. Treatments 2, 4, and 5 experienced a significant increase (p < 0.05) in acidity during fermentation, and pH generally increased over storage time, with significant differences (p < 0.05) only observed for Treatment 5 between day 1 and day 15 (Figure 1 and Figure 2). These results differ from other studies, which have observed maintenance in pH or an increased acidity over the storage period [26,35,36,37].

Considering almond beverage has a low carbohydrate content, carbohydrate supplementation, such as inulin, may help improve probiotic growth and acidification [25,41]. The treatments containing short-chain inulin (Treatments 2 and 3) had the highest acidity, whereas the control had the lowest acidity throughout fermentation, followed by almond beverage treated with long-chain inulin during storage (p < 0.05) (Figure 1 and Figure 2). The results of Aryana et al. (2007) and Li et al. (2019) were also similar to the present study since they observed higher acidity for treatments containing short-chain inulin but lowest acidity for the control during storage [35,42]. While the pH is generally higher than that of standard dairy products, differences may be attributed to the lower buffering capacity and protein content of the almond beverage than cow milk [25]. Nonetheless, the lower acidification of prebiotic supplemented treatments may increase the shelf life of the probiotic product since excess acidification during storage can be detrimental to bacterial viability, limiting product shelf life [33,43].

The current study should be further investigated to explore the sensory characteristics of this new almond beverage formulation to determine if the product is acceptable among consumers for flavour, appearance, and texture. Probiotic success is dependent on the ability to survive within the gastrointestinal tract, and food substrate can be critical in regulating colonization since it might help buffer the bacteria through the stomach or contain functional ingredients, such as inulin, that could interact with them [37]. Consequently, researchers should investigate whether the viability of LGR-1 is adequately preserved in the gastrointestinal tract through simulated gastric and intestinal juice models and assess potential functional properties of the developed product to postulate if the bacteria can colonize the human colon and exert health benefits.

5. Conclusions

An almond beverage fortified with short-chain and long-chain inulin and fermented by LGR-1 was a feasible alternative to dairy-based probiotic products. All treatments achieved and maintained viable counts, exceeding the minimum requirement for probiotic classification. Notably, the almond beverage supplemented with short-chain inulin had the highest viable counts and lowest pH throughout fermentation, while the control and the long-chain inulin treatments had the lowest viable counts and acidity, respectively. The nutritional profile of almonds and inulin with the benefits of LGR-1 represents a new non-dairy functional food with potential health benefits that expands the probiotic food market. This formulation is suitable for many different targeted groups, including vegetarians, lactose-intolerant, or those seeking lower cholesterol and saturated fat options.

Author Contributions

L.M. performed the experiments, collected and organized data for statistical analysis, and drafted the manuscript. S.H. designed the study, conducted data analysis, and revised the manuscript for final publication. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Acknowledgments

The authors acknowledge Brescia University College at University of Western Ontario, Canada, for providing the use of the food science laboratory and the laboratory equipment necessary for this study.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Charlebois, S.; Somogyi, S.; Music, J. Plant-Based Dieting and Meat Attachment: Protein Wars and the Changing Canadian Consumer (Preliminary Results); Dalhousie University: Halifax, NS, Canada, 2018. [Google Scholar]

- Radnitz, C.; Beezhold, B.; DiMatteo, J. Investigation of Lifestyle Choices of Individuals Following a Vegan Diet for Health and Ethical Reasons. Appetite 2015, 90, 31–36. [Google Scholar] [CrossRef]

- He, S.; Hekmat, S. Sensory Evaluation of Non-Dairy Probiotic Beverages. J. Food Res. 2014, 4, 186. [Google Scholar] [CrossRef]

- Ranadheera, C.; Vidanarachchi, J.; Rocha, R.; Cruz, A.; Ajlouni, S. Probiotic Delivery through Fermentation: Dairy vs. Non-Dairy Beverages. Fermentation 2017, 3, 67. [Google Scholar] [CrossRef]

- Vergeer, L.; Vanderlee, L.; White, C.M.; Rynard, V.L.; Hammond, D. Vegetarianism and Other Eating Practices among Youth and Young Adults in Major Canadian Cities. Public Health Nutr. 2020, 23, 609–619. [Google Scholar] [CrossRef] [PubMed]

- Valdes, M.; Conklin, A.; Veenstra, G.; Black, J.L. Plant-Based Dietary Practices in Canada: Examining Definitions, Prevalence and Correlates of Animal Source Food Exclusions Using Nationally Representative Data from the 2015 Canadian Community Health Survey–Nutrition. Public Health Nutr. 2021, 24, 777–786. [Google Scholar] [CrossRef]

- Valero-Cases, E.; Cerdá-Bernad, D.; Pastor, J.-J.; Frutos, M.-J. Non-Dairy Fermented Beverages as Potential Carriers to Ensure Probiotics, Prebiotics, and Bioactive Compounds Arrival to the Gut and Their Health Benefits. Nutrients 2020, 12, 1666. [Google Scholar] [CrossRef] [PubMed]

- Probiotics in Food: Health and Nutritional Properties and Guidelines for Evaluation; Food and Agriculture Organization of the United Nations, World Health Organization, Eds.; FAO food and nutrition paper; Food and Agriculture Organization of the United Nations: Rome, Italy; World Health Organization: Geneva, Switzerland, 2006; ISBN 978-92-5-105513-7. [Google Scholar]

- Williams, M.; Hekmat, S. Lactobacillus Rhamnosus GR-1 in Fermented Rice Pudding Supplemented with Short Chain Inulin, Long Chain Inulin, and Oat as a Novel Functional Food. Fermentation 2017, 3, 55. [Google Scholar] [CrossRef]

- Martins, M.L.; Martins, E.M.F.; De Oliveira Martins, A.D.; Pires, B.A.; De Almeida, B.; Campos, R.C.; Montanary, S.R. Probiotics in nondairy matrixes: A potential combination for the enrichment and elaboration of dual functionality beverages. In Value-Added Ingredients and Enrichments of Beverages; Elsevier: Amsterdam, The Netherlands, 2019; pp. 233–263. ISBN 978-0-12-816687-1. [Google Scholar]

- Aspri, M.; Papademas, P.; Tsaltas, D. Review on Non-Dairy Probiotics and Their Use in Non-Dairy Based Products. Fermentation 2020, 6, 30. [Google Scholar] [CrossRef]

- Hekmat, S.; Soltani, H.; Reid, G. Growth and Survival of Lactobacillus Reuteri RC-14 and Lactobacillus Rhamnosus GR-1 in Yogurt for Use as a Functional Food. Innov. Food Sci. Emerg. Technol. 2009, 10, 293–296. [Google Scholar] [CrossRef]

- Petrova, M.I.; Reid, G.; ter Haar, J.A. Lacticaseibacillus Rhamnosus GR-1, a.k.a. Lactobacillus Rhamnosus GR-1: Past and Future Perspectives. Trends Microbiol. 2021, 1–15, in press. [Google Scholar] [CrossRef]

- Irvine, S.L.; Hummelen, R.; Hekmat, S. Probiotic Yogurt Consumption May Improve Gastrointestinal Symptoms, Productivity, and Nutritional Intake of People Living with Human Immunodeficiency Virus in Mwanza, Tanzania. Nutr. Res. 2011, 31, 875–881. [Google Scholar] [CrossRef] [PubMed]

- Lorea Baroja, M.; Kirjavainen, P.V.; Hekmat, S.; Reid, G. Anti-Inflammatory Effects of Probiotic Yogurt in Inflammatory Bowel Disease Patients. Clin. Exp. Immunol. 2007, 149, 470–479. [Google Scholar] [CrossRef]

- Min, M.; Bunt, C.R.; Mason, S.L.; Hussain, M.A. Non-Dairy Probiotic Food Products: An Emerging Group of Functional Foods. Crit. Rev. Food Sci. Nutr. 2019, 59, 2626–2641. [Google Scholar] [CrossRef] [PubMed]

- Martins, E.M.F.; Ramos, A.M.; Vanzela, E.S.L.; Stringheta, P.C.; De Oliveira Pinto, C.L.; Martins, J.M. Products of Vegetable Origin: A New Alternative for the Consumption of Probiotic Bacteria. Food Res. Int. 2013, 51, 764–770. [Google Scholar] [CrossRef]

- Roselló-Soto, E.; Garcia, C.; Fessard, A.; Barba, F.; Munekata, P.; Lorenzo, J.; Remize, F. Nutritional and Microbiological Quality of Tiger Nut Tubers (Cyperus Esculentus), Derived Plant-Based and Lactic Fermented Beverages. Fermentation 2018, 5, 3. [Google Scholar] [CrossRef]

- Dimitrellou, D.; Kandylis, P.; Kokkinomagoulos, E.; Hatzikamari, M.; Bekatorou, A. Emmer-Based Beverage Fortified with Fruit Juices. Appl. Sci. 2021, 11, 3116. [Google Scholar] [CrossRef]

- Masiá, C.; Geppel, A.; Jensen, P.E.; Buldo, P. Effect of Lactobacillus Rhamnosus on Physicochemical Properties of Fermented Plant-Based Raw Materials. Foods 2021, 10, 573. [Google Scholar] [CrossRef]

- Lipan, L.; Rusu, B.; Sendra, E.; Hernández, F.; Vázquez-Araújo, L.; Vodnar, D.C.; Carbonell-Barrachina, Á.A. Spray Drying and Storage of Probiotic-enriched Almond Milk: Probiotic Survival and Physicochemical Properties. J. Sci. Food Agric. 2020, 100, 3697–3708. [Google Scholar] [CrossRef] [PubMed]

- Kundu, P.; Dhankhar, J.; Sharma, A. Development of Non Dairy Milk Alternative Using Soymilk and Almond Milk. Curr. Res. Nutr. Food Sci. J. 2018, 6, 203–210. [Google Scholar] [CrossRef]

- Wang, X.; Ye, A.; Singh, H. Structural and Physicochemical Changes in Almond Milk during in Vitro Gastric Digestion: Impact on the Delivery of Protein and Lipids. Food Funct. 2020, 11, 4314–4326. [Google Scholar] [CrossRef] [PubMed]

- Bernat, N.; Chafera, M.; Chiralt, A.; González-Martínez, C. Probiotic Fermented Almond “Milk” as an Alternative to Cow-Milk Yoghurt. Int. J. Food Stud. 2015, 4, 2. [Google Scholar] [CrossRef]

- Bernat, N.; Cháfer, M.; Chiralt, A.; González-Martínez, C. Development of a Non-Dairy Probiotic Fermented Product Based on Almond Milk and Inulin. Food Sci. Technol. Int. 2015, 21, 440–453. [Google Scholar] [CrossRef]

- Canbulat, Z.; Ozcan, T. Effects of Short-Chain and Long-Chain Inulin on the Quality of Probiotic Yogurt Containing Lactobacillus Rhamnosus. J. Food Process. Preserv. 2015, 39, 1251–1260. [Google Scholar] [CrossRef]

- Schaafsma, G.; Slavin, J.L. Significance of Inulin Fructans in the Human Diet. Compr. Rev. Food Sci. Food Saf. 2015, 14, 37–47. [Google Scholar] [CrossRef]

- Bernat, N.; Cháfer, M.; Chiralt, A.; González-Martínez, C. Vegetable Milks and Their Fermented Derivative Products. Int. J. Food Stud. 2014, 3. [Google Scholar] [CrossRef]

- White, J.; Hekmat, S. Development of Probiotic Fruit Juices Using Lactobacillus Rhamnosus GR-1 Fortified with Short Chain and Long Chain Inulin Fiber. Fermentation 2018, 4, 27. [Google Scholar] [CrossRef]

- Dunkley, K.E.; Hekmat, S. Development of Probiotic Vegetable Juice Using Lactobacillus Rhamnosus GR-1. Nutr. Food Sci. 2019, 50, 955–968. [Google Scholar] [CrossRef]

- Fatima, S.M.; Hekmat, S. Microbial and Sensory Analysis of Soy and Cow Milk-Based Yogurt as a Probiotic Matrix for Lactobacillus Rhamnosus GR-1. Fermentation 2020, 6, 74. [Google Scholar] [CrossRef]

- Soltani, M.; Hekmat, S.; Ahmadi, L. Microbial and Sensory Evaluation of Probiotic Yoghurt Supplemented with Cereal/Pseudo-Cereal Grains and Legumes. Int. J. Dairy Technol. 2018, 71, 141–148. [Google Scholar] [CrossRef]

- Akalin, A.S.; Gönç, S.; Ünal, G.; Fenderya, S. Effects of Fructooligosaccharide and Whey Protein Concentrate on the Viability of Starter Culture in Reduced-Fat Probiotic Yogurt during Storage. J. Food Sci. 2007, 72, M222–M227. [Google Scholar] [CrossRef]

- Makras, L.; Acker, G.V.; Vuyst, L.D. Lactobacillus Paracasei Subsp. Paracasei 8700:2 Degrades Inulin-Type Fructans Exhibiting Different Degrees of Polymerization. Appl. Environ. Microbiol. 2005, 71, 6531–6537. [Google Scholar] [CrossRef]

- Aryana, K.J.; Plauche, S.; Rao, R.M.; McGrew, P.; Shah, N.P. Fat-Free Plain Yogurt Manufactured with Inulins of Various Chain Lengths and Lactobacillus Acidophilus. J. Food Sci. 2007, 72, M79–M84. [Google Scholar] [CrossRef] [PubMed]

- Pimentel, T.C.; Garcia, S.; Prudêncio, S.H. Effect of Long-Chain Inulin on the Texture Profile and Survival of Lactobacillus Paracasei Ssp. Paracasei in Set Yoghurts during Refrigerated Storage. Int. J. Dairy Technol. 2012, 65, 104–110. [Google Scholar] [CrossRef]

- Bernat, N.; Cháfer, M.; Chiralt, A.; González-Martínez, C. Hazelnut Milk Fermentation Using Probiotic Lactobacillus Rhamnosus GG and Inulin. Int. J. Food Sci. Technol. 2014, 49, 2553–2562. [Google Scholar] [CrossRef]

- Savedboworn, W.; Niyomrat, S.; Naknovn, J.; Phattayakorn, K. Impact of Inulin on Viability and Storage Stability of Probiotic Lactobacillus Plantarum TISTR 2075 in Fermented Rice Extract. Agric. Nat. Resour. 2017, 51, 463–469. [Google Scholar] [CrossRef]

- Choudhary, S.; Singh, M.; Sharma, D.; Attri, S.; Sharma, K.; Goel, G. Principal Component Analysis of Stimulatory Effect of Synbiotic Combination of Indigenous Probiotic and Inulin on Antioxidant Activity of Soymilk. Probiotics Antimicrob. Proteins 2019, 11, 813–819. [Google Scholar] [CrossRef] [PubMed]

- Mohammadi, R.; Mortazavian, A.M. Review Article: Technological Aspects of Prebiotics in Probiotic Fermented Milks. Food Rev. Int. 2011, 27, 192–212. [Google Scholar] [CrossRef]

- Esmaeilnejad Moghadam, B.; Keivaninahr, F.; Fouladi, M.; Rezaei Mokarram, R.; Nazemi, A. Inulin Addition to Yoghurt: Prebiotic Activity, Health Effects and Sensory Properties. Int. J. Dairy Technol. 2019, 72, 183–198. [Google Scholar] [CrossRef]

- Li, Y.; Shabani, K.I.; Qin, X.; Yang, R.; Jin, X.; Ma, X.; Liu, X. Effects of Cross-Linked Inulin with Different Polymerisation Degrees on Physicochemical and Sensory Properties of Set-Style Yoghurt. Int. Dairy J. 2019, 94, 46–52. [Google Scholar] [CrossRef]

- Gomand, F.; Borges, F.; Burgain, J.; Guerin, J.; Revol-Junelles, A.-M.; Gaiani, C. Food Matrix Design for Effective Lactic Acid Bacteria Delivery. Annu. Rev. Food Sci. Technol. 2019, 10, 285–310. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).