Gasification of Woody Biomasses and Forestry Residues: Simulation, Performance Analysis, and Environmental Impact

Abstract

1. Introduction

2. Material and Methods

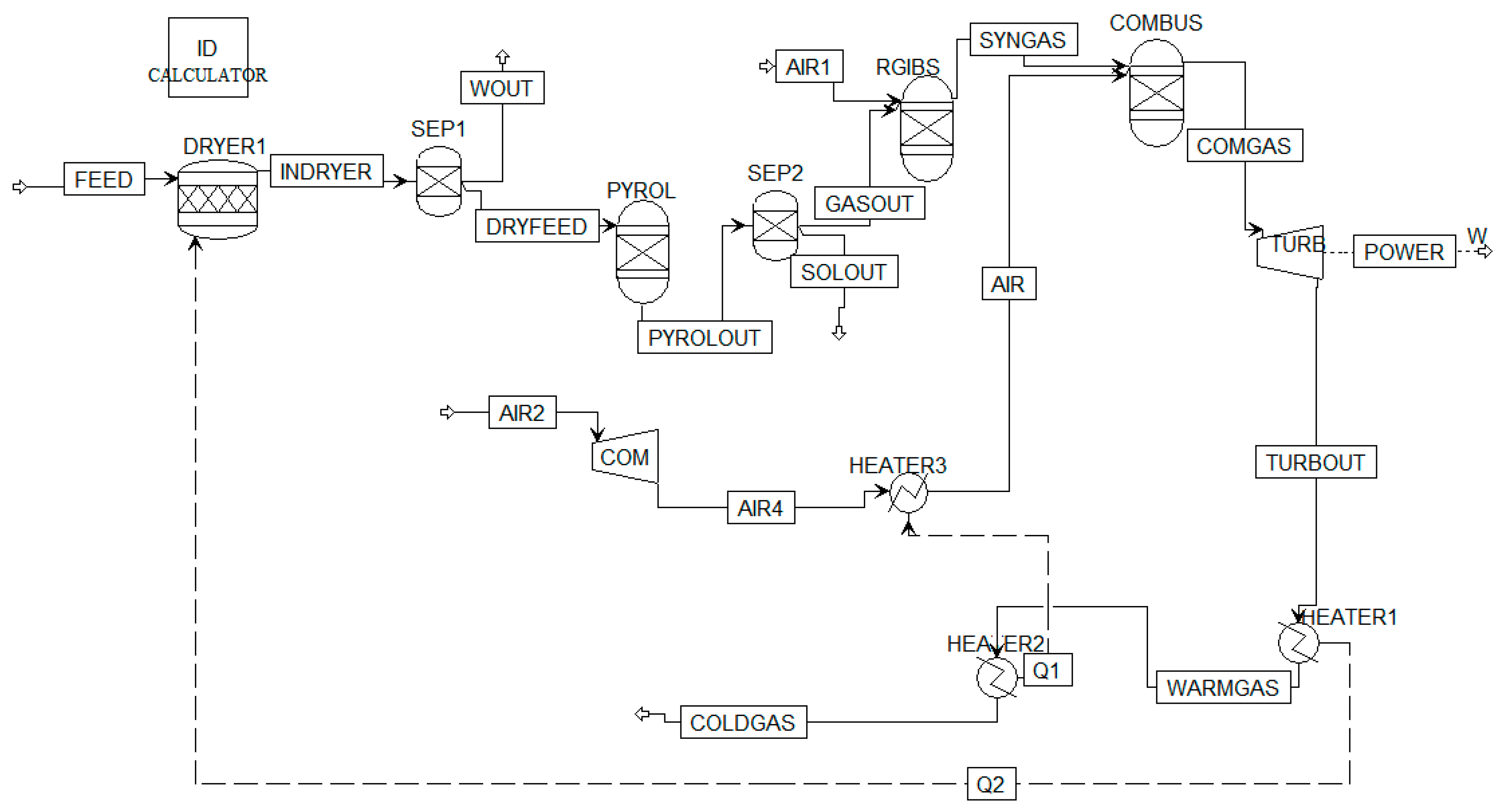

2.1. System Description

2.2. Simulation Model Implementation

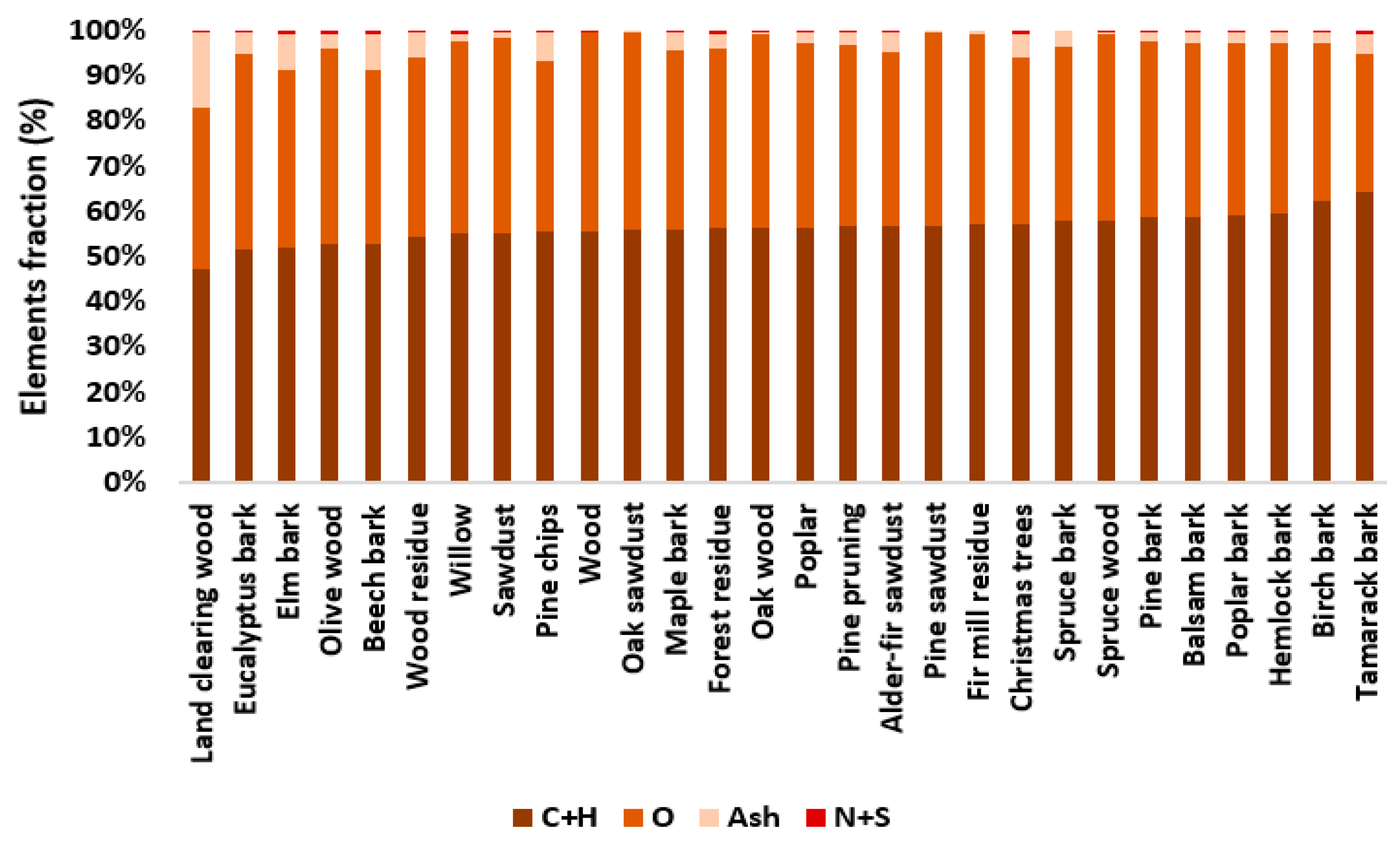

2.2.1. Model Inputs

- Feedstock composition (using ultimate and proximate analysis of biomass feedstocks)

- Initial conditions of input feedstock (i.e., temperature: 25 °C, pressure: 1 atm, and the mass flow rate: 1 ton/h)

- Initial conditions of dryer (temperature: 150 °C and pressure: 1 atm)

- Initial conditions and yield distribution through the pyrolysis (temperature: 500 °C, pressure: 1 atm, and the yield distribution is described based on the ultimate and proximate analysis of biomass feedstocks [24])

- Initial conditions of input air to the gasifier (temperature: 25 °C, pressure: 1 atm, and the mass flow rate is defined based on air-to-fuel ratio [AFR] of 2 [42])

- Initial conditions through the gasifier (temperature: 900 °C and pressure: 1 atm)

- Initial conditions in the combustion chamber (pressure: 11 atm and heat duty: 0 kW by considering an adiabatic reactor)

- Initial conditions in the gas turbine (Isentropic efficiency: 92% and pressure ratio: 0.5 [41])

- Initial conditions of input air to the combustion chamber (temperature: 25 °C and pressure: 1 atm)

- Output temperature of flue gas: 200 °C

2.2.2. Model Output

2.2.3. Model Implementation

2.2.4. Model Convergence

2.3. Environmental Impact Assessment

3. Results and Discussion

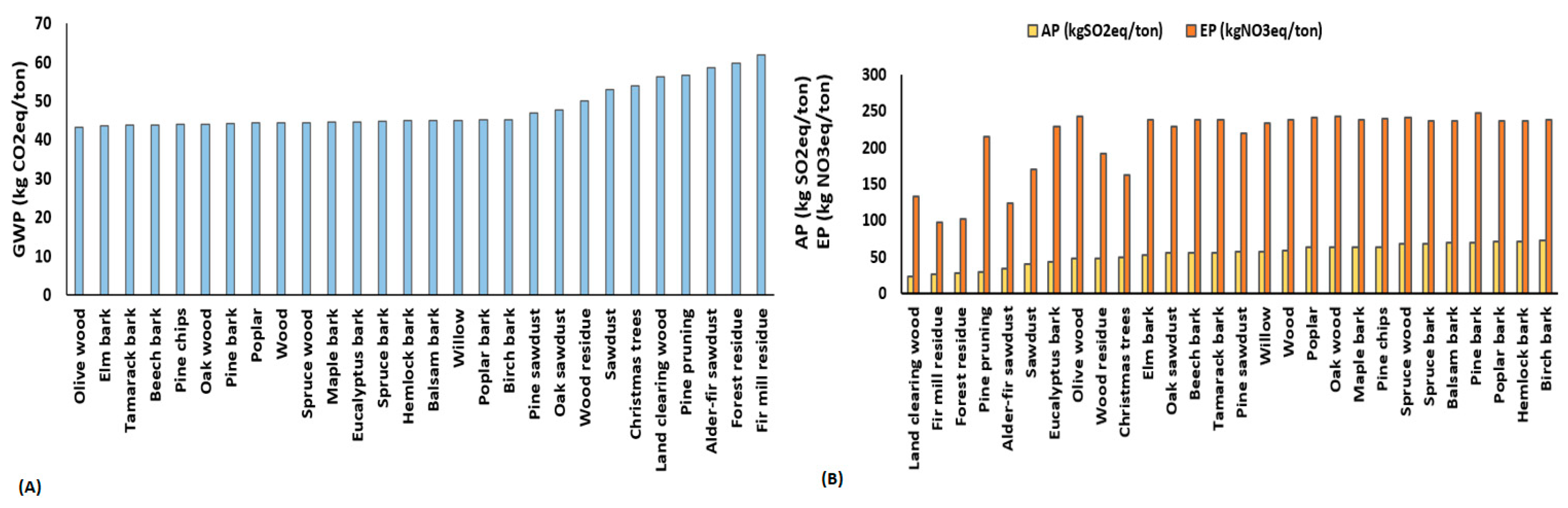

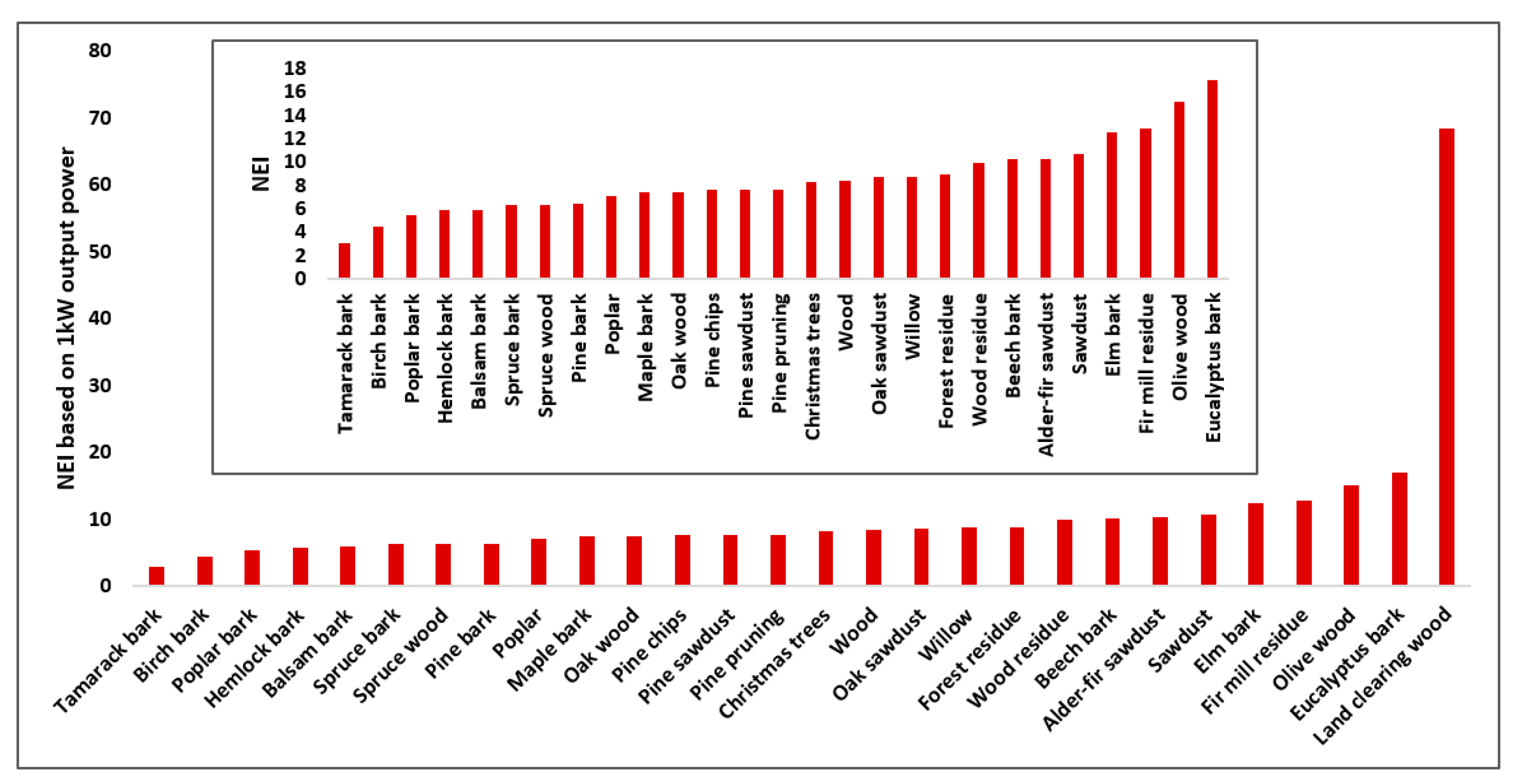

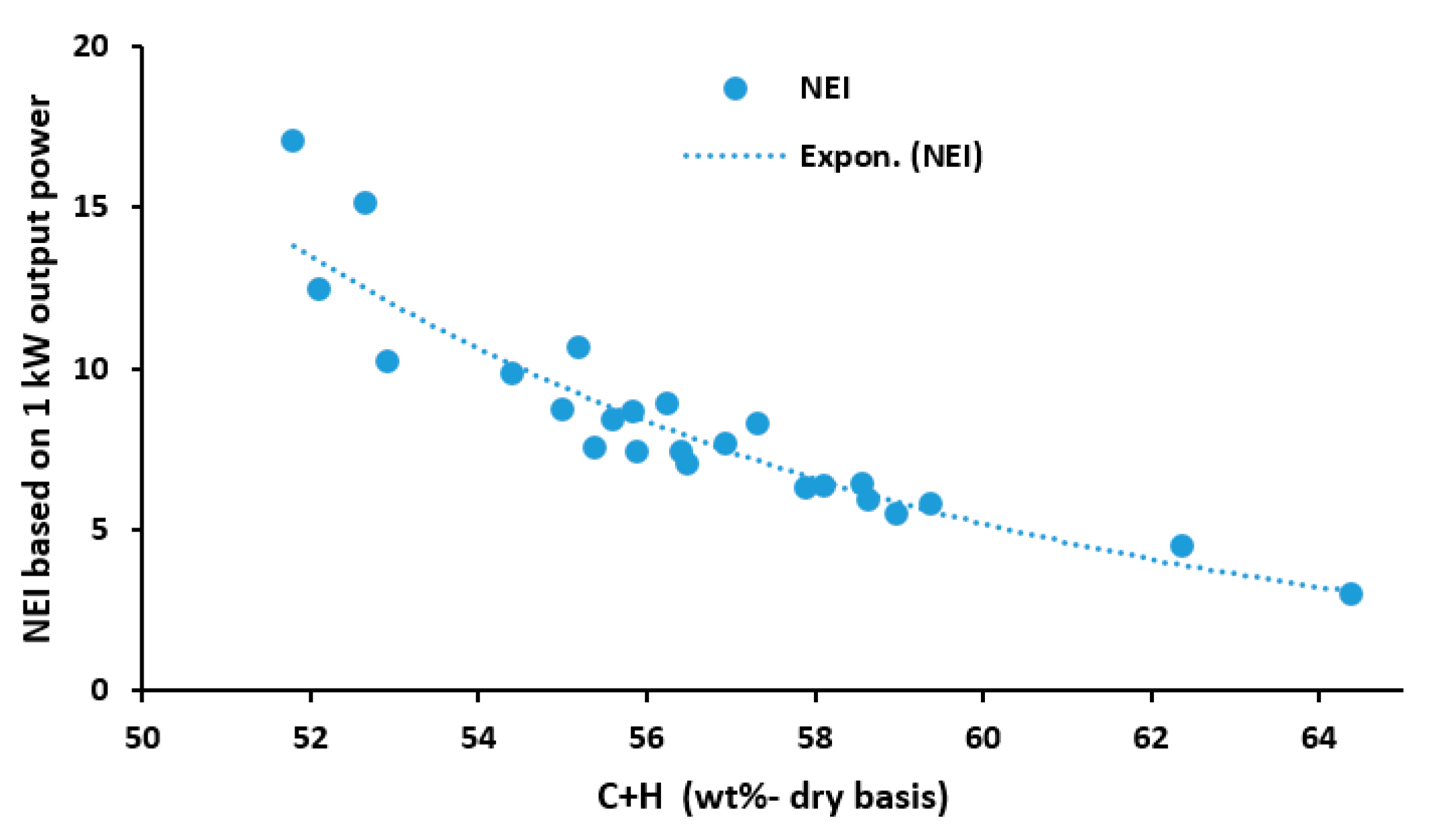

3.1. Performance Analysis

3.2. Environmental Impact Assessment

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Rajaeifar, M.A.; Akram, A.; Ghobadian, B.; Rafiee, S.; Heijungs, R.; Tabatabaei, M. Environmental impact assessment of olive pomace oil biodiesel production and consumption: A comparative lifecycle assessment. Energy 2016, 106, 87–102. [Google Scholar] [CrossRef]

- Talebnia, F.; Karakashev, D.B.; Angelidaki, I. Production of bioethanol from wheat straw: An overview on pretreatment, hydrolysis and fermentation. Bioresour. Technol. 2010, 101, 4744–4753. [Google Scholar] [CrossRef]

- Safarian, S.; Unnthorsson, R.; Richter, C. Techno-Economic Analysis of Power Production by Using Waste Biomass Gasification. J. Power Energy Eng. 2020, 8, 1–8. [Google Scholar] [CrossRef]

- Puig-Arnavat, M.; Hernández, J.A.; Bruno, J.C.; Coronas, A. Artificial neural network models for biomass gasification in fluidized bed gasifiers. Biomass- Bioenergy 2013, 49, 279–289. [Google Scholar] [CrossRef]

- Speirs, J.; McGlade, C.; Slade, R. Uncertainty in the availability of natural resources: Fossil fuels, critical metals and biomass. Energy Policy 2015, 87, 654–664. [Google Scholar] [CrossRef]

- Xie, J.; Zhong, W.; Jin, B.; Shao, Y.; Liu, H. Simulation on gasification of forestry residues in fluidized beds by Eulerian–Lagrangian approach. Bioresour. Technol. 2012, 121, 36–46. [Google Scholar] [CrossRef]

- Nasir, V.; Cool, J. A review on wood machining: Characterization, optimization, and monitoring of the sawing process. Wood Mater. Sci. Eng. 2020, 15, 1–16. [Google Scholar] [CrossRef]

- Nasir, V.; Nourian, S.; Avramidis, S.; Cool, J. Classification of thermally treated wood using machine learning techniques. WWood Sci. Technol. 2019, 53, 275–288. [Google Scholar] [CrossRef]

- Nasir, V.; Nourian, S.; Avramidis, S.; Cool, J. Prediction of physical and mechanical properties of thermally modified wood based on color change evaluated by means of “group method of data handling”(GMDH) neural network. Holzforschung 2019, 73, 381–392. [Google Scholar] [CrossRef]

- Lauri, P.; Havlík, P.; Kindermann, G.; Forsell, N.; Böttcher, H.; Obersteiner, M. Woody biomass energy potential in 2050. Energy Policy 2014, 66, 19–31. [Google Scholar] [CrossRef]

- IEA. International Energy Association (IEA) Database; 2013; Available online: http://www.iea.org/ (accessed on 10 April 2021).

- Safarian, S.; Unnthorsson, R.; Richter, C. Hydrogen production via biomass gasification: Simulation and performance analysis under different gasifying agents. Biofuels 2021, 2021, 1–10. [Google Scholar] [CrossRef]

- Safarian, S.; Unnthorsson, R.; Richter, C. Techno-economic and environmental assessment of power supply chain by using waste biomass gasification in Iceland. Biophys. Econ. Sustain. 2020, 5, 1–13. [Google Scholar] [CrossRef]

- Burra, K.; Gupta, A. Synergistic effects in steam gasification of combined biomass and plastic waste mixtures. Appl. Energy 2018, 211, 230–236. [Google Scholar] [CrossRef]

- Sripada, P.P.; Xu, T.; Kibria, M.; Bhattacharya, S. Comparison of entrained flow gasification behaviour of Victorian brown coal and biomass. Fuel 2017, 203, 942–953. [Google Scholar] [CrossRef]

- Mahishi, M.; Goswami, D. An experimental study of hydrogen production by gasification of biomass in the presence of a CO2 sorbent. Int. J. Hydrogen Energy 2007, 32, 2803–2808. [Google Scholar] [CrossRef]

- Li, Y.-H.; Chen, H.-H. Analysis of syngas production rate in empty fruit bunch steam gasification with varying control factors. Int. J. Hydrog. Energy 2018, 43, 667–675. [Google Scholar] [CrossRef]

- Wang, Z.; Burra, K.G.; Zhang, M.; Li, X.; He, X.; Lei, T.; Gupta, A.K. Syngas evolution and energy efficiency in CO2-assisted gasification of pine bark. Appl. Energy 2020, 269, 114996. [Google Scholar] [CrossRef]

- Eikeland, M.S.; Thapa, R.K.; Halvorsen, B.M. Aspen plus simulation of biomass gasification with known reaction kinetic. In Proceedings of the 56th Conference on Simulation and Modelling (SIMS 56), Linköping University, Linköping, Sweden, 7–9 October 2015. [Google Scholar]

- Fernandez-Lopez, M.; Pedroche, J.; Valverde, J.; Sanchez-Silva, L. Simulation of the gasification of animal wastes in a dual gasifier using Aspen Plus®. Energy Convers. Manag. 2017, 140, 211–217. [Google Scholar] [CrossRef]

- Gagliano, A.; Nocera, F.; Bruno, M.; Cardillo, G. Development of an equilibrium-based model of gasification of biomass by Aspen Plus. Energy Procedia 2017, 111, 1010–1019. [Google Scholar] [CrossRef]

- Han, J.; Liang, Y.; Hu, J.; Qin, L.; Street, J.; Lu, Y.; Yu, F. Modeling downdraft biomass gasification process by restricting chemical reaction equilibrium with Aspen Plus. Energy Convers. Manag. 2017, 153, 641–648. [Google Scholar] [CrossRef]

- Hantoko, D.; Yan, M.; Prabowo, B.; Susanto, H.; Li, X.; Chen, C. Aspen Plus modeling approach in solid waste gasification. In Current Developments in Biotechnology and Bioengineering; Elsevier: Amsterdam, The Netherlands, 2019; pp. 259–281. [Google Scholar]

- Kaushal, P.; Tyagi, R. Advanced simulation of biomass gasification in a fluidized bed reactor using ASPEN PLUS. Renew. Energy 2017, 101, 629–636. [Google Scholar] [CrossRef]

- Liu, R.; Graebner, M.; Tsiava, R.; Zhang, T.; Xu, S. Simulation analysis of the system integrating oxy-fuel combustion and char gasification. J. Energy Resour. Technol. 2021, 143, 1–12. [Google Scholar] [CrossRef]

- Moshi, R.E.; Jande, Y.A.C.; Kivevele, T.T.; Kim, W.S. Simulation and performance analysis of municipal solid waste gasification in a novel hybrid fixed bed gasifier using Aspen plus. Energy Sources Part A Recover. Util. Environ. Eff. 2020, 2020, 1–13. [Google Scholar]

- Porcu, A.; Sollai, S.; Marotto, D.; Mureddu, M.; Ferrara, F.; Pettinau, A. Techno-Economic Analysis of a Small-Scale Biomass-to-Energy BFB Gasification-Based System. Energies 2019, 12, 494. [Google Scholar] [CrossRef]

- Samadi, S.H.; Ghobadian, B.; Nosrati, M. Prediction and estimation of biomass energy from agricultural residues using air gasification technology in Iran. Renew. Energy 2020, 149, 1077–1091. [Google Scholar] [CrossRef]

- Li, X.; Grace, J.; Watkinson, A.; Lim, C.; Ergüdenler, A. Equilibrium modeling of gasification: A free energy minimization approach and its application to a circulating fluidized bed coal gasifier. Fuel 2001, 80, 195–207. [Google Scholar] [CrossRef]

- Zainal, Z.; Ali, R.; Lean, C.; Seetharamu, K. Prediction of performance of a downdraft gasifier using equilibrium modeling for different biomass materials. Energy Convers. Manag. 2001, 42, 1499–1515. [Google Scholar] [CrossRef]

- Ramanan, M.V.; Lakshmanan, E.; Sethumadhavan, R.; Renganarayanan, S. Modeling and experimental validation of cashew nut shell char gasification adopting chemical equilibrium approach. Energy Fuels 2008, 22, 2070–2078. [Google Scholar] [CrossRef]

- Dhanavath, K.N.; Shah, K.; Bhargava, S.K.; Bankupalli, S.; Parthasarathy, R. Oxygen–steam gasification of karanja press seed cake: Fixed bed experiments, ASPEN Plus process model development and benchmarking with saw dust, rice husk and sunflower husk. J. Environ. Chem. Eng. 2018, 6, 3061–3069. [Google Scholar] [CrossRef]

- Haugen, H.H.; Halvorsen, B.M.; Eikeland, M.S. Simulation of gasification of livestock manure with Aspen Plus. In Proceedings of the 56th Conference on Simulation and Modelling (SIMS 56), Linköping University, Linköping, Sweden, 7–9 October 2015. [Google Scholar]

- Villarini, M.; Marcantonio, V.; Colantoni, A.; Bocci, E. Sensitivity analysis of different parameters on the performance of a CHP internal combustion engine system fed by a biomass waste gasifier. Energies 2019, 12, 688. [Google Scholar] [CrossRef]

- Monir, M.U.; Aziz, A.A.; Kristanti, R.A.; Yousuf, A. Co-gasification of empty fruit bunch in a downdraft reactor: A pilot scale approach. Bioresour. Technol. Rep. 2018, 1, 39–49. [Google Scholar] [CrossRef]

- Ramzan, N.; Ashraf, A.; Naveed, S.; Malik, A. Simulation of hybrid biomass gasification using Aspen plus: A comparative performance analysis for food, municipal solid and poultry waste. Biomass Bioenergy 2011, 35, 3962–3969. [Google Scholar] [CrossRef]

- Shahabuddin, M.; Bhattacharya, S. Effect of reactant types (steam, CO2 and steam+ CO2) on the gasification performance of coal using entrained flow gasifier. Int. J. Energy Res. 2021. [Google Scholar] [CrossRef]

- Pilar González-Vázquez, M.; Rubiera, F.; Pevida, C.; Pio, D.T.; Tarelho, L.A. Thermodynamic Analysis of Biomass Gasification Using Aspen Plus: Comparison of Stoichiometric and Non-Stoichiometric Models. Energies 2021, 14, 189. [Google Scholar] [CrossRef]

- Safarianbana, S.; Unnthorsson, R.; Richter, C. Development of a new stoichiometric equilibrium-based model for wood chips and mixed paper wastes gasification by ASPEN Plus. In Conference Development of a New Stoichiometric Equilibrium-Based Model for Wood Chips and Mixed Paper Wastes Gasification by ASPEN Plus; American Society of Mechanical Engineers: New York, NY, USA, 2019; Volume 59438, p. V006T06A2. [Google Scholar]

- Safarian, S.; Bararzadeh, M. Exergy analysis of high-performance cycles for gas turbine with air-bottoming. J. Mech. Eng. Res. 2012, 5, 38–49. [Google Scholar]

- Nguyen, T.L.T.; Hermansen, J.E.; Nielsen, R.G. Environmental assessment of gasification technology for biomass conversion to energy in comparison with other alternatives: The case of wheat straw. J. Clean. Prod. 2013, 53, 138–148. [Google Scholar] [CrossRef]

- Safarian, S.; Unnthorsson, R.; Richter, C. Performance analysis of power generation by wood and woody biomass gasification in a downdraft gasifier. Int. J. Appl. Power Eng. 2021, 10, 80–88. [Google Scholar]

- Safarian, S.; Unnthorsson, R.; Richter, C. Simulation of small-scale waste biomass gasification integrated power production: A comparative performance analysis for timber and wood waste. Int. J. Appl. Power Eng. 2020, 9, 147–152. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Baxter, D.; Andersen, L.K.; Vassileva, C.G. An overview of the chemical composition of biomass. Fuel 2010, 89, 913–933. [Google Scholar] [CrossRef]

- Miles, T.J.; Baxter, L.; Bryers, R.; Jenkins, B.; Oden, L. Alkali Deposits Found in Biomass Power Plants: A Preliminary Investigation of Their Extent and Nature. 1995. Available online: https://www.nrel.gov/docs/legosti/fy96/8142v1.pdf (accessed on 10 April 2021).

- Bryers, R.W. Fireside slagging, fouling, and high-temperature corrosion of heat-transfer surface due to impurities in steam-raising fuels. Prog. Energy Combust. Sci. 1996, 22, 29–120. [Google Scholar] [CrossRef]

- Theis, M.; Skrifvars, B.-J.; Hupa, M.; Tran, H. Fouling tendency of ash resulting from burning mixtures of biofuels. Part 1: Deposition rates. Fuel 2006, 85, 1125–1130. [Google Scholar] [CrossRef]

- Theis, M.; Skrifvars, B.-J.; Zevenhoven, M.; Hupa, M.; Tran, H. Fouling tendency of ash resulting from burning mixtures of biofuels. Part 2: Deposit chemistry. Fuel 2006, 85, 1992–2001. [Google Scholar] [CrossRef]

- Zevenhoven-Onderwater, M.; Backman, R.; Skrifvars, B.-J.; Hupa, M. The ash chemistry in fluidised bed gasification of biomass fuels. Part I: Predicting the chemistry of melting ashes and ash–bed material interaction. Fuel 2001, 80, 1489–1502. [Google Scholar] [CrossRef]

- Zevenhoven-Onderwater, M.; Blomquist, J.-P.; Skrifvars, B.-J.; Backman, R.; Hupa, M. The prediction of behaviour of ashes from five different solid fuels in fluidised bed combustion. Fuel 2000, 79, 1353–1361. [Google Scholar] [CrossRef]

- Demirbas, A. Combustion characteristics of different biomass fuels. Prog. Energy Combust. Sci. 2004, 30, 219–230. [Google Scholar] [CrossRef]

- Vamvuka, D.; Zografos, D. Predicting the behaviour of ash from agricultural wastes during combustion. Fuel 2004, 83, 2051–2057. [Google Scholar] [CrossRef]

- Vamvuka, D.; Zografos, D.; Alevizos, G. Control methods for mitigating biomass ash-related problems in fluidized beds. Bioresour. Technol. 2008, 99, 3534–3544. [Google Scholar] [CrossRef]

- Moilanen, A. Thermogravimetric Characterisations of Biomass and Waste for Gasification Processes; VTT: Espoo, Finland, 2006. [Google Scholar]

- Masiá, A.T.; Buhre, B.; Gupta, R.; Wall, T. Characterising ash of biomass and waste. Fuel Process. Technol. 2007, 88, 1071–1081. [Google Scholar] [CrossRef]

- Lapuerta, M.; Hernández, J.J.; Pazo, A.; López, J. Gasification and co-gasification of biomass wastes: Effect of the biomass origin and the gasifier operating conditions. Fuel Process. Technol. 2008, 89, 828–837. [Google Scholar] [CrossRef]

- Tillman, D.A. Biomass cofiring: The technology, the experience, the combustion consequences. Biomass Bioenergy 2000, 19, 365–384. [Google Scholar] [CrossRef]

- Demirbas, A. Potential applications of renewable energy sources, biomass combustion problems in boiler power systems and combustion related environmental issues. Prog. Energy Combust. Sci. 2005, 31, 171–192. [Google Scholar] [CrossRef]

- Wei, X.; Schnell, U.; Hein, K.R. Behaviour of gaseous chlorine and alkali metals during biomass thermal utilisation. Fuel 2005, 84, 841–848. [Google Scholar] [CrossRef]

- Safarian, S.; Ebrahimi Saryazdi, S.M.; Unnthorsson, R.; Richter, C. Artificial neural network integrated with thermodynamic equilibrium modeling of downdraft biomass gasification-power production plant. Energy 2020, 213, 118800. [Google Scholar] [CrossRef]

- Safarian, S.; Ebrahimi Saryazdi, S.M.; Unnthorsson, R.; Richter, C. Artificial Neural Network Modeling of Bioethanol Production Via Syngas Fermentation. Biophys. Econ. Sustain. 2021, 6, 1–13. [Google Scholar] [CrossRef]

- Damartzis, T.; Michailos, S.; Zabaniotou, A. Energetic assessment of a combined heat and power integrated biomass gasification–internal combustion engine system by using Aspen Plus®. Fuel Process. Technol. 2012, 95, 37–44. [Google Scholar] [CrossRef]

- Safarian, S.; Unnthorsson, R.; Richter, C. The equivalence of stoichiometric and non-stoichiometric methods for modeling gasification and other reaction equilibria. Renew. Sustain. Energy Rev. 2020, 131, 109982. [Google Scholar] [CrossRef]

- Safarian, S.; Unnthorsson, R.; Richter, C. Simulation and Performance Analysis of Integrated Gasification–Syngas Fermentation Plant for Lignocellulosic Ethanol Production. Fermentation 2020, 6, 68. [Google Scholar] [CrossRef]

- Safarian, S.; Bararzadeh, M. Exergy Recovery in Gas Pressure Compression Stations (GPCSs). Gas Process. 2015, 3, 11–18. [Google Scholar]

- Safarian, S.; Mousavi, M. Improvement of overall efficiency in the gas transmission networks: Employing energy recovery systems. Gas Process. J. 2015, 2, 1–24. [Google Scholar]

- Kim, T.; Tae, S.; Chae, C.U. Analysis of environmental impact for concrete using LCA by varying the recycling components, the compressive strength and the admixture material mixing. Sustainability 2016, 8, 389. [Google Scholar] [CrossRef]

- Paengjuntuek, W.; Boonmak, J.; Mungkalasiri, J. Environmental assessment of integrated biomass gasification fuel cell for power generation system. Int. J. Environ. Sci. Dev. 2015, 6, 445–450. [Google Scholar] [CrossRef]

- Balaman, Ş.Y. Chapter 4—Sustainability Issues in Biomass-Based Production Chains. Decis. Mak. Biomass Based Prod. Chain. 2019, 77–112. [Google Scholar] [CrossRef]

- Schreiber, A.; Zapp, P.; Marx, J. Meta-Analysis of life cycle assessment studies on electricity generation with carbon capture and storage. J. Ind. Ecol. 2012, 16, S155–S168. [Google Scholar] [CrossRef]

- Kim, T.H.; Chae, C.U. Environmental impact analysis of acidification and eutrophication due to emissions from the production of concrete. Sustainability 2016, 8, 578. [Google Scholar] [CrossRef]

- Kuo, P.-C.; Wu, W.; Chen, W.-H. Gasification performances of raw and torrefied biomass in a downdraft fixed bed gasifier using thermodynamic analysis. Fuel 2014, 117, 1231–1241. [Google Scholar] [CrossRef]

- Lv, P.; Xiong, Z.; Chang, J.; Wu, C.; Chen, Y.; Zhu, J. An experimental study on biomass air–steam gasification in a fluidized bed. Bioresour. Technol. 2004, 95, 95–101. [Google Scholar] [CrossRef] [PubMed]

| Step | Unit | Amount |

|---|---|---|

| Diesel fuel used in trucks | L/km·ton | 0.06 |

| Electricity for pressing and cutting | kWh/ton | 5.48 |

| Fuel oil used for gasifier (for start-up) | L/ton | 0.2 |

| Electricity used for gasifier | kWh/ton | 83 |

| Isentropic efficiency of compressor | % | 90 |

| Mechanical efficiency of compressor | % | 99 |

| Isentropic efficiency of gas turbine | % | 92 |

| Proximate Analysis (wt%) | Elemental Analysis (wt% − Dry Basis) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| M | VM | FC | A | C | O | H | N | S | ||

| 1 | Alder-fir sawdust | 52.6 | 76.6 | 19.2 | 4.2 | 50.9656 | 38.5116 | 5.8438 | 0.479 | 0 |

| 2 | Balsam bark | 8.4 | 77.4 | 20 | 2.6 | 52.596 | 38.473 | 6.0388 | 0.1948 | 0.0974 |

| 3 | Beech bark | 8.4 | 73.7 | 18.5 | 7.8 | 47.3908 | 38.5396 | 5.532 | 0.6454 | 0.0922 |

| 4 | Birch bark | 8.4 | 78.5 | 19.4 | 2.1 | 55.803 | 34.9503 | 6.5593 | 0.4895 | 0.0979 |

| 5 | Christmas trees | 37.8 | 74.2 | 20.7 | 5.1 | 51.7205 | 36.7263 | 5.5991 | 0.4745 | 0.3796 |

| 6 | Elm bark | 8.4 | 73.1 | 18.8 | 8.1 | 46.7771 | 39.0575 | 5.3302 | 0.6433 | 0.0919 |

| 7 | Eucalyptus bark | 12 | 78 | 17.2 | 4.8 | 46.3624 | 43.1256 | 5.4264 | 0.2856 | 0 |

| 8 | Fir mill residue | 62.9 | 82 | 17.5 | 0.5 | 51.143 | 42.2875 | 5.97 | 0.0995 | 0 |

| 9 | Forest residue | 56.8 | 79.9 | 16.9 | 3.2 | 51.0136 | 39.7848 | 5.2272 | 0.6776 | 0.0968 |

| 10 | Hemlock bark | 8.4 | 72 | 25.5 | 2.5 | 53.625 | 37.83 | 5.7525 | 0.195 | 0.0975 |

| 11 | Land clearing wood | 49.2 | 69.7 | 13.8 | 16.5 | 42.3345 | 35.738 | 5.01 | 0.334 | 0.0835 |

| 12 | Maple bark | 8.4 | 76.6 | 19.4 | 4 | 49.92 | 39.648 | 5.952 | 0.384 | 0.096 |

| 13 | Oak sawdust | 11.5 | 86.3 | 13.4 | 0.3 | 49.9497 | 43.7683 | 5.8823 | 0.0997 | 0 |

| 14 | Oak wood | 6.5 | 78.1 | 21.4 | 0.5 | 50.347 | 42.6855 | 6.0695 | 0.2985 | 0.0995 |

| 15 | Olive wood | 6.6 | 79.6 | 17.2 | 3.2 | 47.432 | 43.4632 | 5.2272 | 0.6776 | 0 |

| 16 | Pine bark | 4.7 | 73.7 | 24.4 | 1.9 | 52.7778 | 39.1419 | 5.7879 | 0.2943 | 0.0981 |

| 17 | Pine chips | 7.6 | 72.4 | 21.6 | 6 | 49.632 | 38.07 | 5.734 | 0.47 | 0.094 |

| 18 | Pine pruning | 47.4 | 82.2 | 15.1 | 2.7 | 50.4987 | 40.1849 | 6.1299 | 0.4865 | 0 |

| 19 | Pine sawdust | 15.3 | 83.1 | 16.8 | 0.1 | 50.949 | 42.8571 | 5.994 | 0.0999 | 0 |

| 20 | Poplar | 6.8 | 85.6 | 12.3 | 2.1 | 50.5164 | 40.8243 | 5.9719 | 0.5874 | 0 |

| 21 | Poplar bark | 8.4 | 80.3 | 17.5 | 2.2 | 52.4208 | 38.4354 | 6.5526 | 0.2934 | 0.0978 |

| 22 | Sawdust | 34.9 | 84.6 | 14.3 | 1.1 | 49.2522 | 43.2193 | 5.934 | 0.4945 | 0 |

| 23 | Spruce bark | 8.4 | 73.4 | 23.4 | 3.2 | 51.8848 | 38.72 | 6.0016 | 0.0968 | 0.0968 |

| 24 | Spruce wood | 6.7 | 81.2 | 18.3 | 0.5 | 52.0385 | 40.994 | 6.0695 | 0.2985 | 0.0995 |

| 25 | Tamarack bark | 8.4 | 69.5 | 26.3 | 4.2 | 54.606 | 30.656 | 9.7716 | 0.6706 | 0.0958 |

| 26 | Willow | 10.1 | 82.5 | 15.9 | 1.6 | 49.0032 | 42.7056 | 6.0024 | 0.5904 | 0.0984 |

| 27 | Wood | 7.8 | 84.1 | 15.7 | 0.2 | 49.5008 | 44.0118 | 6.0878 | 0.0998 | 0.0998 |

| 28 | Wood residue | 26.4 | 78 | 16.6 | 5.4 | 48.6244 | 39.6374 | 5.7706 | 0,.73 | 0.0946 |

| Input | Unit | GWP Factor (kgCO2eq/unit) | AP Factor (gSO2eq/unit) | EP Factor (gNO3eq/unit) |

|---|---|---|---|---|

| Electricity generated from geothermal | kWh | 0.058 | 1.95 | 2.8 |

| Transport by truck | ton·km | 0.3 | 2.1 | 4.2 |

| Liquid fuel used in gasifier | lit | 2.76 | 10.5 | 21 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Safarian, S.; Ebrahimi Saryazdi, S.M.; Unnthorsson, R.; Richter, C. Gasification of Woody Biomasses and Forestry Residues: Simulation, Performance Analysis, and Environmental Impact. Fermentation 2021, 7, 61. https://doi.org/10.3390/fermentation7020061

Safarian S, Ebrahimi Saryazdi SM, Unnthorsson R, Richter C. Gasification of Woody Biomasses and Forestry Residues: Simulation, Performance Analysis, and Environmental Impact. Fermentation. 2021; 7(2):61. https://doi.org/10.3390/fermentation7020061

Chicago/Turabian StyleSafarian, Sahar, Seyed Mohammad Ebrahimi Saryazdi, Runar Unnthorsson, and Christiaan Richter. 2021. "Gasification of Woody Biomasses and Forestry Residues: Simulation, Performance Analysis, and Environmental Impact" Fermentation 7, no. 2: 61. https://doi.org/10.3390/fermentation7020061

APA StyleSafarian, S., Ebrahimi Saryazdi, S. M., Unnthorsson, R., & Richter, C. (2021). Gasification of Woody Biomasses and Forestry Residues: Simulation, Performance Analysis, and Environmental Impact. Fermentation, 7(2), 61. https://doi.org/10.3390/fermentation7020061