Abstract

This paper aimed to compare the quality indicators of hull-less (naked) barley malt with malt obtained from hulled barley, according to the recommended values for standard pale malt. Five domestic hull-less barley varieties (Osvit, Mandatar, GZ-184, Osk.8.26/1–14 and Osk.6.24/4–12) and five hulled (Barun, OsLukas, Vanessa, Casanova, and Maestro) barley varieties were malted according to the standard procedure. The results of starting barley quality indicators (hectolitre weight, protein, starch, 1000 kernel weight, first class grain) and of finished malts (malt moisture, extract, extract difference, friability, wort viscosity, soluble protein, Kolbach index, wort color, and wort pH) were then compared. The results indicate that the main problem of hull-less barley is the resistance to deeper modification of grain. This is expressed as lower water absorption during steeping, and lower friability. The intensification of the process of malting could be boosted with the extension of steeping time and decreased temperatures during germination. This should result with higher friability but other indicators of malt quality should also show better values.

1. Introduction

Most barley varieties have an outer husk called a hull. If the hull does not adhere to the kernel, the barley is considered to be hull-less. The hull-less grain trait is controlled by a single recessive gene nud, located on the long arm of chromosome 7H [1]. Barley variety, particularly Hordeum vulgare L. var. nudum Hook. f. has a loosely attached hull and during harvest, the hull falls off by itself which makes the cleaning processing much easier and economical. This also aids in reducing the germ damage and flour loss during milling.

The development of new hull-less barley varieties started in the 1970s in Canada. This kind of barley was designated and used as cattle feed, but the growing interest lead for it to be repurposed for human nutrition. Subsequently, this expanded its designation to raw material for malt in brewing and distilled products (Scotch, Whisky). The utilization of hull-less barley in the industry of strong alcoholic drinks such as Whisk or Scotch is mainly propelled by the fact that it showed higher alcohol yields, and resolved filtration issues that have been previously associated with hull-less barley [2]. Currently, hull-less barley cultivars, even though they are suitable for quality malt production, are not the top wanted varieties for brewing. Big malting and brewing companies are still suspicious of its brewing properties [3]. Nevertheless, its application in the brewing industry is still a novelty. The most important advantage of hull-less barley utilization in the brewing industry is the economical aspect. Namely, because the hull is absent (the hull makes 10% of dry matter loss in barley grains) [4], hull-less barley significantly boosts malt extracts by 5–7% (minimally > 2) in comparison with hulled barley [5,6,7,8,9]. According to Edney and Langrell [6], the lack of hull during mashing helps in eliminating the extraction of specific polysaccharides from hulls, which have been identified to cause premature yeast flocculation during fermentation. Some hull compounds (tannins and other polyphenols) are considered to be undesirable. The use of hull-less barley malt has some restrictions due to the fact that the intact hulls affect the efficiency of the lautering operation. However, with new technologies, such as mash filters and centrifuges, an increased interest in the advantages of hull-less barley malt emerged [8].

Malting of hull-less barley, however, does have certain disadvantages and puts many challenges before maltsters and brewers. The most obvious differences can be noticed in chemical and physical characteristics. The missing hull makes the barley embryo susceptible to damage during handling and malting which can result in inadequate endosperm modification [8] or incomplete germination [10]. According to several authors, poorly modified or incompletely degraded grains can be related to many undesirable quality characteristics of dry malt [6,8]. For instance, poor modifications of hull-less barley malt could cause a reduced level of extract. This is presumably related to unmodified cell walls that are known to restrict starch hydrolysis and, consequently the solubilization of starch during the stage of mashing [11].

Friability values for malt from hull-less barley appear to be much lower than the recommended values for hulled barley malt [6,7]. Water uptake during steeping is much easier and quicker in hull-less barley than in hulled barley [12], but Bhatty [13] reported that hull-less barley is harder than hulled malting barley. To adequately process hard, steely barley, prolonged steeping and germination times may be required. This requires alterations and adjustments of standard malting conditions. The Kilning step may also cause problems because the absence of a hull allows high kilning temperatures to cause hull-less malt to become extra hard.

To keep up with the world′s trends, several Croatian hull-less barley varieties have been created. Currently, there are several Croatian varieties of hull-less barley being developed at the Agronomic Institute in Osijek. Hull-less barley is also well known for its positive physiological effects on human health and is recognized as a functional food. It is rich in dietary fiber and minerals (calcium, phosphorus, iron, copper, zinc, and selenium).

The effects of the malting procedure applied to five domestic hull-less barley varieties (Osvit, Mandatar, GZ-184, Osk.8.26/1–14 and Osk.6.24/4–12) and five hulled (Barun, OsLukas, Vanessa, Casanova, and Maestro) varieties were investigated in this paper. The aim was to assess the malting quality of available varieties of hull-less barley from the brewing point of view and to determine their brewing potential in comparison to hulled varieties that are well established as brewing.

2. Materials and Methods

2.1. Materials

Ten genotypes of hull-less and hulled barley (Hordeum vulgare L.), obtained from the Agricultural Institute Osijek, Osijek, Croatia, were used for the comparative study of the grain quality and malting performance. The study was conducted on the two varieties (Osvit, Mandatar) and three advanced breeding lines (GZ-184, Osk.8.26/1–14 and Osk.6.24/4–12) of hull-less barley and five varieties of hulled barley (Barun, Lukas, Vanessa, Casanova, and Maestro) during four (2015/2016, 2016/2017, 2017/2018 and 2018/2019) consecutive seasons. Lines and varieties of hull-less and hulled barley were grown in experimental fields of Agricultural Institute Osijek located in the eastern part of Croatia. The exploratory experiments were set on an area of 7.56 m2 field plots arranged in a complete randomized block design. All barley samples included are two-rowed winter type barleys. Vanessa and Casanova were included in this research as commonly used standard malting barley varieties.

2.2. Barley Samples Analysis

After the harvest, barley grain samples were cleaned and protein, starch, and hectoliter weight were determined by Infratec 1241 Grain Analyzer (FOSS, Hillerød, Denmark), with a calibration supplied by the manufacturer. Measurement of the thousand kernel weight was done by an electronic counting machine and includes counting and weighing the seeds. Sieve analysis of barley samples was done according to MEBAK [14] (Mitteleuropäischen Brautechnischen Analysenkommission). In sieve analysis, three sieves were used with oblong (slotted) holes 2.8, 2.5, and 2.2 mm in width. The amount of grain remaining on 2.8 + 2.5 mm sieves is reported as sieve analysis over 2.5 mm, i.e., 1st class grain, and the grain passing through 2.2 mm sieve is reported as sieve analysis under 2.2 mm. Grains of size higher than 2.5 mm were used for the micro-malting procedure.

2.3. Micro-Malting Procedure

Micro-malting of barley grain samples was done according to standard laboratory procedure at the Agricultural Institute Osijek, Croatia. Before micro-malting, the grain samples were screened over a 2.5 mm sieve and five hundred grams of each variety was placed into boxes of the micro-malting unit (Automated Joe White Malting Systems Micro-malting unit, Perth, Australia) in a randomized order. Barley samples were steeped to reach approximately 44–46% of the grain moisture following 37 h interrupted steep program (16 °C, 5 h submerged, 17 °C, 12 h air rest with 100% airflow, 17 °C, 6 h submerged, 18 °C, 12 h air rest with 100% airflow, 17 °C, 2 h submerged). After 96 h of germination (17 °C, 75% airflow, 1.5 turn every 2 h) green malts were subjected to 18 h integrated kilning program (60 °C, 6 h; 65 °C, 3 h; 68 °C, 2 h; 70 °C, 2 h; 80 °C, 2 h; 83 °C, 2 h; 85 °C, 1 h) to produce approximately 5–7% moisture malt. Dried rootlets were easily removed and malt samples were stored in plastic wide mouth jars with matching insert plug and screw lid at room temperature until analysis.

2.4. Malt Analysis

Malts quality attributes were determined according to European Brewery Convention methods [15]. The following parameters were determined: friability, malt extract content, extract difference between fine and coarse ground malt, malt soluble protein content, Kolbach index, wort color and pH, and viscosity.

2.5. Statistical Analysis

Statistical analysis (shown in Tables 3 and 4) was carried out using the analysis of variance (ANOVA) and Fisher’s least significant difference test (LSD), with a statistical significance set at p < 0.05. Statistical analysis was carried out using Statistica 13.1. (TIBCO Software Inc., Palo Alto, CA, USA).

The statistical calculation that was carried out as a principal component analysis (PCA) aims to best represent the variation in the data based on a multitude of original variables. Calculation of each principal component can be seen as statistical model building based on the data, scores (distance from the PC origin for every data point), loadings (variable contributions for each PC), and residuals [16]. Components are created in a way that the first component explains the most variation, the second component explains the second most variation while reducing the correlation with the first component, etc. PCA efficiently solves collinearity between variables [17] and was hence used to analyze the quality and agronomic data sets of explored cultivars. The presence of some collinearity in parameters derived from given data points towards this multivariate approach, therefore, PC analysis presented itself as the optimal statistical method in that regard. All the variables were log-transformed and components explaining at least 10% of variation present in the dataset were analyzed. The analysis was performed with PAST software (v. 3.26, 2001).

3. Results and Discussion

In Table 1 the results of basic barley quality indicators are presented. Since the share of proteins is immensely important for maltsters and brewers, this can be observed from their point of view. It can be seen that hull-less barley contains significantly more proteins (13–15% in 2016, 2017, and 2019) than the hulled varieties. In 2018, the protein content dropped for both hull-less and hulled varieties and amounted to 10–12% for hull-less (the lowest was for Osvit, while Osk.6.24/4–12 showed the highest value for 2018). Hulled barley also showed low values for protein content in 2018. Namely, all values were below 10% (OsLukas and Maestro with 8.83%) and Casanova having 9.08%. It seems that the year had some influence on the protein content and Casanova showed the best adoptive properties; this should be considered in future research plans. Grains that underwent thermal or water stress during the grain-filling period exhibited higher protein content than grain samples from barley crops that have not suffered stress [18,19,20]. Often, fertilization during a drought period will result in higher protein content in smaller/thinner grains. According to Magliano et al. [21], protein content in grains corresponds to the environmental settings, such as nitrogen availability, thus making the crop’s protein content closely related to the amount of available nitrogen per unit of actual yield. Namely, higher precipitation during the growing period cause a higher yield but as a consequence brings a dilution effect of the nitrogen content in the grain [22].

Table 1.

Barley quality indicators.

First class grains were more pronounced in hulled barley varieties and hull-less barley showed certain discrepancies and lower values throughout the observed years. This is also an important factor for maltsters and affects the suitability of barley for malting.

In Table 2, basic malt quality indicators are presented. Malt extract is usually a basic indicator of the malting procedure success and grain quality. Extract represents water-soluble components (fermentable and non-fermentable) that end up in wort. The obtained results indicate that hull-less barley, in general, has somewhat higher values of extract than the hulled varieties used in this research. In research published in 2016 by Krstanović et al. [7], malting procedures A and D for the GZ-184 variety resulted in higher extract values, which are in accordance with the obtained results.

Table 2.

Malt quality indicators.

Extract difference (fine and coarse grind) is an indirect measure of malt modification [23]. A significant difference between hulled and hull-less malt extracts can be noted in this research. Namely, hull-less varieties showed significantly higher values for this quality indicator, for all years. Values for hulled varieties amounted to max 5.89% while hull-less varieties values were constantly and significantly higher than 5%. Interestingly, both min and max values can be designated to the same line (Osk.8.26/1–14), but in different years with the max being 13.75% in 2016 and min was 5.93% in 2019. In general, lower extract difference values indicate the existence of parts of non-degraded endosperm with lower enzyme activity (giving lower wort quality). Extract difference also correlates with friability values. Namely, the increase in friability results in decreased extract difference and, consequently, lower values of congress wort viscosity.

When comparing hulled and hull-less varieties, a relatively high soluble protein content in hull-less barley and malt (Table 1 and Table 2) is noted. However, this is followed by a low soluble protein content which can be caused by weak grain degradation (and consequently low friability), as can be seen from Table 2. In 2019, protein levels were high for both types of barley, but hull-less showed maximal levels >15%. However, it seems that soluble protein in malt was not significantly affected by the elevated protein content.

Hull-less barely is challenging for maltsters, but several authors have reported very successful malting using hull-less barely, especially regarding friability values [6,7,23,24,25,26]. Friability values for hull-less barley malt showed very low values in this research. The minimum value was 13.12% for Osvit in 2017, and the highest value for friability was recorded in Osk.8.26/1–14 in 2019, amounting to 47.74%. Hulled barley varieties maintained more steady values (especially Casanova) and Meastro showed the highest value in 2019 with 91.24%. This shows that the grain modification during malting via adjusted malting conditions is possible. Similar values were obtained by Krstanović et al. [7] who subjected two hull-less varieties Matko and GZ-184 to four different malting procedures. The control samples were subjected to the standard MEBAK micromalting procedure (A). The results showed that the intensification of the process of germination should be combined with the extension of soaking time, which should lead to improvements in the friability of malt and better value for other indicators of malt quality, which is the main guide for future research in this field.

Viscosity values correlate with friability values in such a way that higher friability values make congress wort viscosity lower, which is the case in this research. Namely, the lowest viscosity value was detected in GZ-184 in 2019 and was 1.96%, while the highest viscosity value was 4.97% for Mandatar in 2016. Hulled barley varieties generally showed lower values for viscosity, as can be seen in Table 2. This indicates the connection of deeper grain degradation with different components which causes the increase in wort viscosity values (β-glucans, pentosanes, residual starch) which is in accordance with previous research [7,8,11].

The Kolbach index indicates the level of protein degradation in the malt grain, and optimal values for standard malt range from 38–42% [27]. The results obtained in this research show that hull-less barley varieties have a somewhat lower Kolbach index than the hulled ones. The min value (28.85%) for Kolbach index in hull-less varieties was recorded in Osk.8.26/1–14 in 2016 and the max value (35.98%) was achieved in 2018 in the GZ-184 variety. The results are in accordance with the results of malt hull-less barley varieties in Canada [24]. Similarly, Edney, and Langrell [6] reported Kolbach index values higher than 40% for the hull-less variety CDC Dawn in cases with a longer germination period. Similar results regarding Kolbach index values were described by Krstanović et al. [7] (2015), where the values of the Kolbach index reached 41% in the modified malting process. In a previous study published by Šimić et al. [28], there were also reported differences in malting behavior between hull-less and hulled varieties. Results obtained for the friability, difference in extract yield between finely and coarsely ground malt, wort viscosity and Kolbach index revealed that malting varieties achieved better cytolytic and proteolytic modification than hull-less barley lines.

In order to detect the significant differences between barley types we condensed the data from Table 1 and Table 2 into Table 3 and Table 4. They show the mean values (sum of quality parameters divided by four years) of barley and malt quality indicators and give a clear insight into statistical difference between data sets. It is visible from Table 3 that starting quality indicators for hull-less and hulled barley show statistical difference. This is especially pronounced for yield, where there is a statistical difference (p < 0.05) for every year and between hull-less and hulled barley type. There is a certain overlap in some quality indicators, mostly between hull-less and hull-less and hulled and hulled barley types, but between some years hull-less and hulled showed no statistical difference (p > 0.05) in hectoliter weight (hull-less 2016/hulled 2017), 1000 kernel weight (hulled 2019/hull-less 2019/hull-less 2016) and starch content (hulled 2017/ hulled 2019/hull-less 2019/hull-less2016). Protein content was greatly affected by the type of barley and showed higher values for hull-less types, with the max value being 14.92% for hull-less barley in 2019. However, there is no statistically significant difference between hull-less varieties in 2016 and 2017. Hulled varieties showed lower max value, amounting up to 12.19% in 2017. Another important quality indicator is the share of first class grains. Namely, in order to meet the maltsters’ quality requirements, barley grains must also have a specific protein level, and high proportion of plump grains [22]. However, research conducted by Magliano et al. [21], showed that thin grains can contain more proteins than plump ones. This would mean that the reduced protein content can originate from a great share of plump grains while the small ones were selected and discarded during sieving. Perhaps hulled barley in 2018, which had 9.24% protein and >96% first class grains, is a good example for this theory. This is something to consider prior future protein content analysis.

Table 3.

Mean values for barley quality indicators for each year.

Table 4.

Mean values malt quality indicators for each year.

Table 4 shows the mean values for malt quality indicators from which a recognizable statistical difference can be noted between parameters. Malt samples show a distinct statistical difference between the analyzed data, with no overlaps between barley types and years. Only hull-less barley in 2016 showed on overlap for soluble proteins with both, hull-less and hulled barley in 2019. This is not surprising for hull-less barley in 2019, because it had similar content of protein in grains (14.92%) as 2016 (14.55%) which resulted in equal share of proteins in wort (4.58%). It is, however, interesting that hulled barley contained 12.08% of proteins in 2019 and the amount of soluble proteins in wort amounted to 4.55%, which is very close to the hull-less varieties in 2016 (4.58%). According to Edney Langrell [6], higher levels of soluble protein are detected in “better-modified” malts and could be correlated with higher extract levels. Extract levels for the aforementioned malts (hull-less 2016/2019 and hulled 2019) in this research are higher than 80% but do not represent the maximal extract values (85.32% for hull-less in 2016) in this research. They also show significant differences between all analyzed samples, regardless of being of the hull-less or hulled type. Friability levels vary, but are significantly different for each year and for both types of barley. In general, mean values for hull-less barleys′ friability are circa two-fold lower than for the hulled barley′s for every year (2016—25.06/59.70%; 2017—18.60/36.60%; 2018—33.31/58.37%; 2019—34.04/72.73%). Viscosity mean values generally show increased values for hull-less varieties for every year. In a study conducted by Krstanović et al. [7], a narrow connection between β-glucan content and viscosity was determined, meaning that lower β-glucan content in hull-less barley reduces the viscosity of wort. Hull-less barley is known to have a higher β-glucan content [28] and thus increased viscosity values, which are considered problematic during filtration in the brewing process. Viscosity values are approximately 1.4–1.5 times higher for hull-less barley, with the exception for 2016 where viscosity was 2.5 times higher than in hulled varieties.

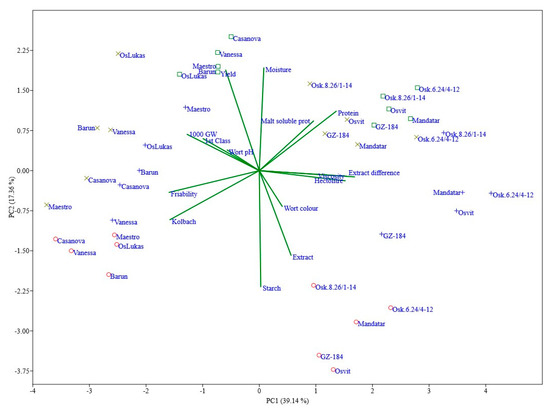

To test whether the observed differences in agronomic and quality parameters explored through four growing seasons between different types of cultivars (hulled vs. hull-less) were genotype-specific, and to what extent, the PCA analysis was chosen. The first two PCs explained 56.5% of the variation present in the dataset (Figure 1). Cultivars showed distinct reactions towards forming two major groups at the basic level, meaning hull-less (first and fourth quadrant) vs. hulled (second and third quadrant). Variation among different growing years (seasons) displayed distinctiveness in groupings where cultivars mostly kept to their group defined by the year of cultivation, confounding well the seasonal reactions. Hull-less cultivars were determined by bi-plot vectors indicating mostly quality parameters, however, one must be aware of some vectors/traits having an overall negative impact on quality even though they display an increase in value (viscosity, extract difference, protein content). The best performing year quality-wise for the hull-less cultivars was 2018 (red circle), where the whole group concentrated to the relative proximity of the vector for the extract trait. High protein synthesis seasons were determined to be 2017 (green square) and 2019 (olive x) where these seasonal groups also intermingled between vectors for protein, viscosity, extract difference, and hectoliter. On the other hand, the hulled barley cultivars showed an inclination more towards agronomic traits and some key quality parameters (friability and Kolbach index). The best season in the agronomic sense was 2017 (green square), where the whole group of hulled cultivars swarmed firmly around the grain yield vector. Inversely, the best seasons for quality parameters among hulled cultivars were 2016 (blue cross) and 2018 (red circle). Eigenvalues of parameters explaining at least 10% of variation were the first four (PC1–PC4), eigenvalues of PC5 and up were excluded from further analysis and their influence may be considered negligible in describing variation between the cultivars and/or growing seasons.

Figure 1.

PCA bi-plot of ten winter barley varieties and their respective agronomic and quality traits observed through four growing seasons (2016—blue cross; 2017—green square; 2018—red circle; 2019—olive x).

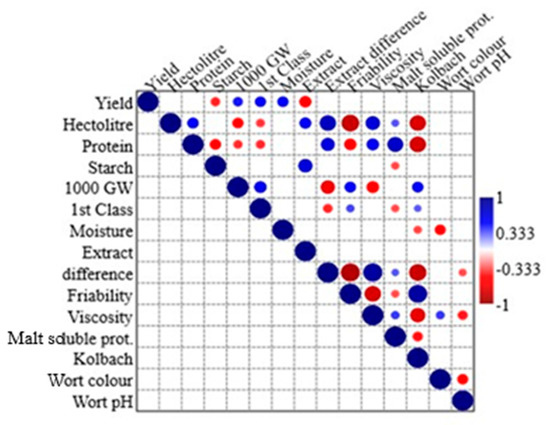

In addition, and as a complement to the PCA, the correlation matrix was calculated for better distinction and understanding of inter-trait relationships. As shown in Figure 2, the most significant correlation is stated with extract difference, friability, viscosity, malt soluble protein, and Kolbach index traits. Agronomic traits that showed the most significant correlation were mainly hectolitre and protein content, in addition to traits such as grain yield and 1000 grain weight that display their significance a tad lower on the scale. In a previous study, it was reported that 1000 grain weight has not been an accurate predictor of malting quality attributes between varieties, but when results were observed within varieties, higher 1000 grain weight was correlated with higher extract [29]. Here, we found no correlation between 1000 grain weight and malt extract content, which is in accordance with Swanston et al. [30], who observed no correlation between 1000 grain weight and either extract or predicted spirit yield. The results of this study showed that higher 1000 grain weight positively influenced endosperm cytolytic and proteolytic degradation, indicated through lower extract difference and wort viscosity, and a higher friability and Kolbach index.

Figure 2.

Correlation matrix of agronomic and quality traits for winter barley cultivars observed through four growing seasons (2016–2019) (Note to correlation key and the scale reads: positive—blue, negative—red; smaller circle—lesser significance; bigger circle—greater significance; non-significant values are not shown (blank square)).

A positive correlation was determined between viscosity, extract difference, protein content, and malt soluble protein traits, as well as between the Kolbach index and friability. Negative correlations were determined among friability and hectoliter, friability and extract difference, Kolbach index and hectoliter, Kolbach index and protein content, Kolbach index and extract difference, Kolbach index and viscosity, viscosity, and friability.

4. Conclusions

The results indicate that hull-less barley displays a stronger resistance to grain modification (expressed as lower water absorption during steeping, and very low friability values) than hulled barley varieties. This problem should be addressed in the further selection processes of domestic hull-less barley varieties intended for malting. Additionally, proper modification and optimization (extension of steeping time and decreased temperatures during germination) of the malting process could aid grain modification which should lead to improvements in the friability of malt and better value for other indicators of malt quality. Future aspects should include extensive research on the malting process modifications and optimization which could result in better quality hull-less barley malt. Additional experiments should be addressing the influence of agro-climatic conditions on friability since the results of this research indicate that this could be a significant factor in obtaining acceptable values of friability.

Author Contributions

Conceptualization, A.L. and G.Š.; methodology, A.L. and G.Š.; software, K.M.; investigation, K.H., K.D.; data curation, K.M., I.A.; writing—original draft preparation, K.H.; writing—review and editing, K.H. and V.K.; All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Restrictions apply to the availability of these data. Data was obtained from the Agricultural Institute Osijek and are available [from the authors] with the permission of the Agricultural Institute Osijek.

Acknowledgments

The authors would like to thank the Agricultural Institute Osijek for financial.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Kikuchi, S.; Taketa, S.; Ichii, M.; Kawasaki, S. Efficient fine mapping of the naked caryopsis gene (nud) by HEGS (High Efficiency Genome Scanning)/AFLP in barley. Theor. Appl. Genet. 2003, 108, 73–78. [Google Scholar] [CrossRef] [PubMed]

- Agu, R.C.; Bringhurst, T.A.; Brosnan, J.M.; Pearson, S. Potential of Hull-less Barley Malt for Use in Malt and Grain Whisky Production. J. Inst. Brew. 2009, 115, 128–133. [Google Scholar] [CrossRef]

- Shaveta, S.; Kaur, H.; Kaur, S. Hulless Barley: A new era of research for food purposes. J. Cereal Res. 2019, 11. [Google Scholar] [CrossRef]

- Rennecke, D.; Sommer, W. Use of naked barley in the brewing and malting process. Lebensmittelindustrie 1979, 26, 66–68. [Google Scholar]

- Kerry, J.A.; Barr, A.R. Genetic variation in Key Malting Quality Trails in Hulles Barley. In Proceedings of the 7th Australian Barley Symposium, Perth, Australia, 17–21 September 1995; pp. 266–268. [Google Scholar]

- Edney, M.J.; Langrell, D.E. Evaluating the Malting Quality of Hulless CDC Dawn, Acid-Dehusked Harrington, and Harrington Barley. J. Am. Soc. Brew. Chem. 2004, 62, 18–22. [Google Scholar] [CrossRef]

- Krstanović, V.; Mastanjević, K.; Velić, N.; Slačanac, V.; Vacek, K.; Gagula, G.; Mastanjević, K. Influence of malting procedure on the quality of hulless barley malt. In Proceedings of the 8th International Congress FLOUR-BREAD 2015 and 10th Croatian Congress of Cereal Technologists BRAŠNO-KRUH 2015, Opatija, Croatia, 29–30 October 2015; p. 168. [Google Scholar]

- Evans, D.E.; Stenholm, K.; Vilpola, A.; Home, S.; Hughes, G.; Evans, E.; Vilpola, A.; Stewart, D.C.; Stenholm, K.; Pöyri, S.; et al. Producing a Quality Malt from Hulless Barley. MBAA Tech. Q. 2014, 35, 375–382. [Google Scholar]

- Rossnagel, B.G.; Legge, W.; Edney, M.; Beattie, A.; Scoles, G. 5% > extract and more $ for brewers—Hulless barley malt a dramatic difference. American society of Brewing Chemists & Master Brewers Association of the Americas. In Proceedings of the 2012 World Brewing Congress, Portland, OR, USA, 28 July–1 August 2012. [Google Scholar]

- Box, A.J.; Barr, A.R. Hulless barley in Australia-The potential and progress. In Proceedings of the 8th Australian Barley Technical Symposium, Gold Coast, Australia, 7–12 September 1997; pp. 4–16. [Google Scholar]

- Evans, E.; Vilpola, A.; Stewart, D.C.; Stenholm, K.; Pöyri, S.; Washington, J.M.; Barr, A.R.; Home, S. Pilot scale investigation of the importance of the barley husk for mash filtration. MBAA Tech. Q. 1999, 36, 375–382. [Google Scholar]

- Sing, T.; Sosulski, F.W. Malting of hulles barley cultivarand Glenlea (T. aestivum) utility wheat. J. Food Sci. 1985, 50, 342–346. [Google Scholar] [CrossRef]

- Bhatty, R.S. The Potential of Hull-less Barley—A Review. Cereal. Chem. 1986, 63, 97–103. [Google Scholar]

- MEBAK®. Methodensammlung der Mitteleuropäischen Analysenkommission; Jacob, F., Ed.; Selbstverlag der MEBAK®: Freising-Weihenstephan, Gemany, 2011. [Google Scholar]

- European Brewery Convention (EBC), Analytica, 5th ed.; Fachverlag Hans Carl: D-Nürnberg, Germany, 1998.

- Bro, R.; Smilde, A.K. Principal component analysis. Anal. Methods 2014, 6, 2812–2831. [Google Scholar] [CrossRef]

- Wold, S.; Esbensen, K.; Geladi, P. Principal Component Analysis. Chemom. Intell. Lab. Syst. 1987, 2, 37–52. [Google Scholar] [CrossRef]

- Fathi, G.; McDonald, G.K.; Lance, R.C.M. Effect of post-anthesis water stress on the yield and grain protein concentration of barley grown al two levels of nitrogen. Aust. J. Agric. Res. 1997, 48, 67–80. [Google Scholar] [CrossRef]

- Passarella, V.S.; Savin, R.; Slafer, G.A. Are temperature effects on weight and quality of barley grains modified by resource availability? Aust. J. Agric. Res. 2008, 59, 510–516. [Google Scholar] [CrossRef]

- Savin, R.; Stone, P.J.; Nicolas, M.E.; Wardlaw, I.F. Grain growth and malting quality of barley. 1. Effects of heat stress andmoderately high temperature. Aust. J. Agric. Res. 1997, 48, 615–624. [Google Scholar] [CrossRef]

- Magliano, P.N.; Prystupa, P.; Gutiérrez-Boem, F.H. Protein content of grains of different size fractions in malting barley. J. Inst. Brew. 2014, 120, 347–352. [Google Scholar] [CrossRef]

- Jedel, P.E.; Helm, J.H. Assessment of western Canadian Barleys of historical interest: I. Yield and agronomic traits. Crop. Sci. 1994, 34, 922–927. [Google Scholar] [CrossRef]

- Briggs, D.E. Malts and Malting; Blackie Academic & Professional: London, UK, 1998; ISBN 978-0-412-29800-4. [Google Scholar]

- Li, Y.; McCaig, R.; Egi, A.; Edney, M.; Rossnagel, B.; Sawatzky, K.; Izydorczyk, M. Malting Characteristics of Three Canadian Hulless Barley Varieties, CDC Freedom, CDC McGwire, and CDC Gainer. J. Am. Soc. Brew. Chem. 2006, 64, 111–117. [Google Scholar] [CrossRef]

- McCaig, R. Malting and Brewing Trials with 2011 Crop Hulless Barley. Available online: http://cmbtc.com/wp-content/uploads/2015/11/Malting-and-Brewing-Trials-with-2011-Hulless-Variety-CDC-Clear.pdf (accessed on 30 November 2020).

- Edney, M.J.; MacLeod, A.L.; LaBerge, D.E. Evolution of a quality testing program for improving malting barley in Canada. Can. J. Plant. Sci. 2014, 94, 535–544. [Google Scholar] [CrossRef]

- Kunze, W. Technology Brewing and Malting, 6th ed.; VLB: Berlin, Germany, 2019.

- Simic, G.; Horvat, D.; Dvojkovic, K.; Abicic, I.; Viljevac Vuletic, M.; Tucak, M.; Lalic, A. Evaluation of Total Phenolic Content and Antioxidant Activity of Malting and Hulless Barley Grain and Malt Extracts. Czech. J. Food Sci. 2017, 35, 73–78. [Google Scholar] [CrossRef]

- Bathgate, G.N. Quality requirements for malting. Asp. Appl. Biol. 1987, 15, 18–31. [Google Scholar]

- Swanston, J.S.; Middlefell-Williams, J.E.; Forster, B.P.; Thomas, W.T.B. Effects of Grain and Malt beta-Glucan on Distilling Quality in a Population of Hull-less Barley. J. Inst. Brew. 2011, 117, 389–393. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).