Influence of Harvest Date and Grape Variety on Sensory Attributes and Aroma Compounds in Experimental Icewines of Ukraine

Abstract

1. Introduction

2. Materials and Methods

2.1. Grapes

2.2. Wines

2.3. Chemical Methods

2.4. Sensory Analysis

2.5. Statistical Analysis

3. Results

3.1. Physicochemical Analysis

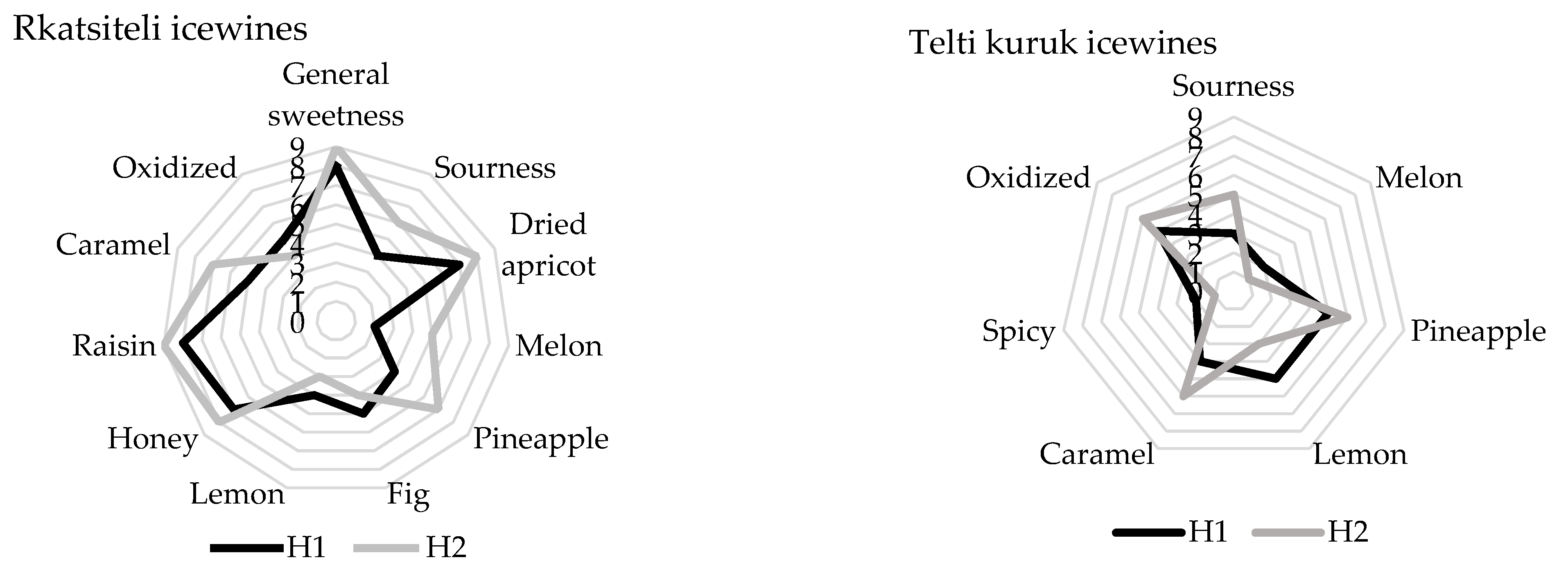

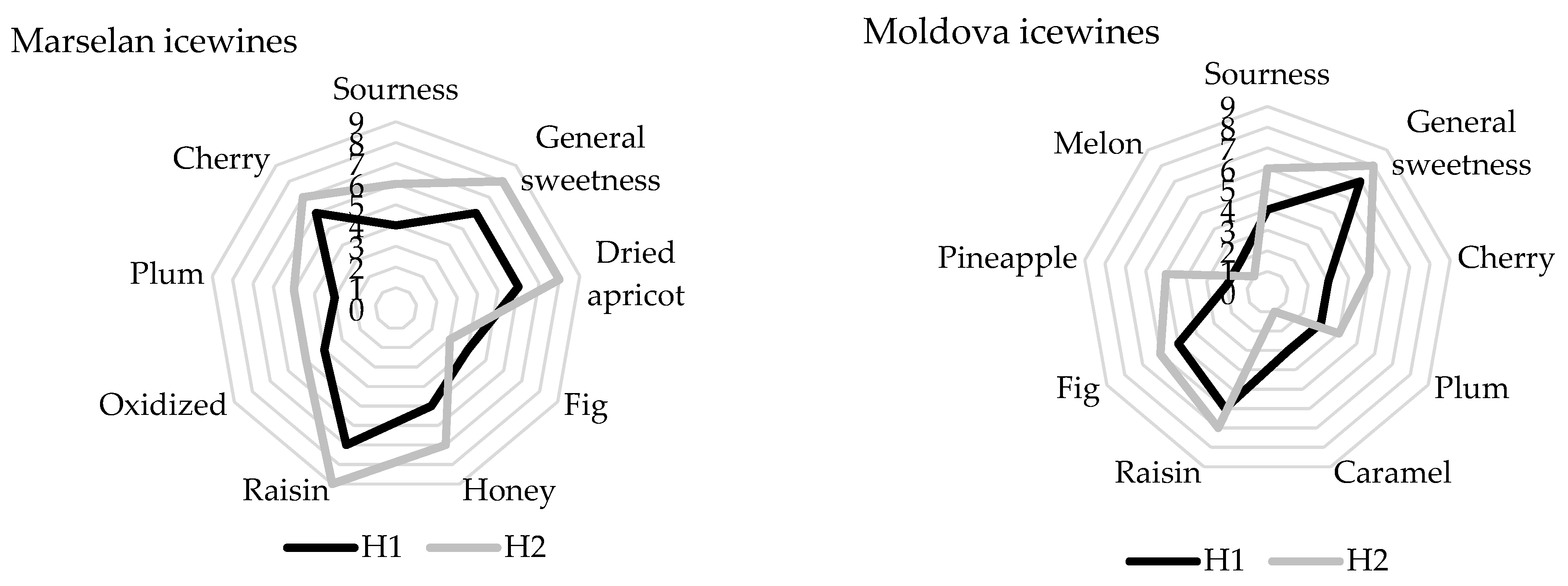

3.2. Sensory Analysis

3.3. Aroma Compounds

3.3.1. Odor Activity

3.3.2. Aroma Components

4. Discussion

4.1. Must and Wine Chemical Analysis

4.2. Sensory Analysis

4.3. Aroma Compounds

4.4. Higher and Terpene Alcohols

4.5. Esters

4.6. Aldehydes, Acids, Lactones, and Phenols

5. Conclusions

Author Contributions

Funding

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- VQA Ontario. Available online: http://www.vqaontario.com/Regulations/Standards (accessed on 15 September 2020).

- Special Wines. 4.1 Basic definition (6/76). International Code of Oenological Practices. OIV Code Sheet. Issue 2015/01. Available online: http://www.oiv.int/public/medias/7213/oiv-international-code-of-oenological-practices-2020-en.pdf (accessed on 15 September 2020).

- Bezhuashvili, M.; Tskhvedadze, L.; Surguladze, M.; Shoshiashvili, G.; Kharadze, S.; Gagunashvili, L.; Vashakidze, P. Stress-metabolitesphytoalexins-stilbenoids of grape skin Rkatsiteli variety (Vitisvinifera L.) in condition gray mildew. Eurasian J. Biosci. 2019, 13, 549–554. [Google Scholar]

- Ostapenko, V.; Tkachenko, O.; Iukuridze, E. Sensory and chemical attributes of dessert wines made by different freezing methods of Marselan grapes. Ukr. Food J. 2017, 6, 278–290. [Google Scholar] [CrossRef]

- INRA. 2020. Available online: http://www7.inra.fr/internet/Directions/DIC/ACTUALITES/DOSSIERS/qualite-aliments/vin-cepage-’Marselan’.htm (accessed on 15 September 2020).

- Ostapenko, V.; Kameneva, N. Suitability of the technical grape variety of the Northern Black Sea Coast in the traditional production for “Iсewine”. Ukr. Food J. 2017, 6, 727–737. [Google Scholar] [CrossRef]

- Ostapenko, V. Analysis on application of different grape varieties in the production of icewine. A review. Ukr. Food J. 2016, 5, 678–694. [Google Scholar] [CrossRef]

- Moriondo, M.; Jones, G.V.; Bois, B.; Dibari, C.; Ferrise, R.; Trombi, G.; Bindi, M. Projected shifts of wine regions in response to climate change. Clim. Chang. 2013, 119, 825–839. [Google Scholar] [CrossRef]

- Van Leeuwen, C.; Darriet, P. The impact of climate change on viticulture and wine quality. J. Wine Econ. 2016, 11, 150–167. [Google Scholar] [CrossRef]

- Santillán, D.; Iglesias, A.; La Jeunesse, I.; Garrote, L.; Sotes, V. Vineyards in transition: A global assessment of the adaptation needs of grape producing regions under climate change. Sci. Total Environ. 2019, 657, 839–852. [Google Scholar] [CrossRef]

- Cardell, M.F.; Amengual, A.; Romero, R. Future effects of climate change on the suitability of wine grape production across Europe. Reg. Environ. Chang. 2019, 19, 2299–2310. [Google Scholar] [CrossRef]

- Tkachenko, O.; Bilko, M.; Ostryk, A.; Ostapenko, V. Regulation of icewine production in the world. In Proceedings of the Youth Scientific Achievements to the 21st Century Nutrition Problem Solution: Collection of Abstracts of 83 International Scientific Conference of Young Scientists and Students, Kyiv, Ukraine, 5–6 April 2017. [Google Scholar]

- Cyr, D.; Kusy, M. Canadian ice wine production: A case for the use of weather derivatives. J. Wine Econ. 2007, 2, 145–167. [Google Scholar] [CrossRef]

- Tkachenko, O.B.; Trinkal, O.V. The aroma peculiarities of some white wines from autochthonous grapes varieties from Western Europe and Ukraine. East. Eur. J. Enterp. Technol. 2015, 10, 40–45. [Google Scholar] [CrossRef][Green Version]

- Tkachenko, O.B.; Trinkal, O.V.; Pashkovski, A.I. The influence of agrometeorological conditions of the vegetation period on the technological properties of grapes. Technol. Audit Prod. Reserves 2015, 3, 18–21. [Google Scholar] [CrossRef][Green Version]

- Reynolds, A.G. Managing Wine Quality. In Oenology and Wine Quality; Woodhead Publishing: Oxford, UK, 2010; Volume 2. [Google Scholar]

- Lukić, I.; Radeka, S.; Grozaj, N.; Staver, M.; Peršurić, Đ. Changes in physico-chemical and volatile aroma compound composition of Gewürztraminer wine as a result of late and ice harvest. Food Chem. 2016, 196, 1048–1057. [Google Scholar] [CrossRef] [PubMed]

- Lan, Y.-B.; Qian, X.; Yang, Z.-J.; Xiang, X.-F.; Yang, W.-X.; Liu, T.; Zhu, B.-Q.; Pan, Q.-H.; Duan, C.-Q. Striking changes in volatile profiles at sub-zero temperatures during over-ripening of ‘Beibinghong’ grapes in Northeastern China. Food Chem. 2016, 212, 172–182. [Google Scholar] [CrossRef] [PubMed]

- Huang, L.; Ma, Y.; Tian, X.; Li, J.-M.; Li, L.-X.; Tang, K.; Xu, Y. Chemosensory characteristics of regional Vidal icewines from China and Canada. Food Chem. 2018, 261, 66–74. [Google Scholar] [CrossRef] [PubMed]

- Ma, Y.; Tang, K.; Xu, Y.; Li, J.M. Characterization of the key aroma compounds in Chinese Vidal icewine by gas chromatography-olfactometry, quantitative measurements, aroma recombination, and omission tests. J. Agric. Food Chem. 2017, 65, 394–401. [Google Scholar] [CrossRef]

- Synos, K.; Reynolds, A.G.; Bowen, A.J. Effect of yeast strain on aroma compounds in Cabernet franc icewines. Lwt-Food Sci. Technol. 2015, 64, 227–235. [Google Scholar] [CrossRef]

- Bowen, A.J.; Reynolds, A.G. Odor potency of aroma compounds in Riesling and Vidal blanc table wines and icewines by gas chromatography-olfactometry-mass spectrometry. J. Agric. Food Chem. 2012, 60, 2874–2883. [Google Scholar] [CrossRef]

- Crandles, M.; Reynolds, A.G.; Khairallah, R.; Bowen, A. The effect of yeast strain on odor active compounds in Riesling and Vidal blanc icewines. Lwt-Food Sci. Technol. 2015, 64, 243–258. [Google Scholar] [CrossRef]

- Nurgel, C.; Pickering, G.J.; Inglis, D.L. Sensory and chemical characteristics of Canadian ice wines. J. Sci. Food Agric. 2004, 84, 1675–1684. [Google Scholar] [CrossRef]

- Clary, C.; Gamache, A.; Cliff, M.; Fellman, J.; Edwards, C. Flavor and Aroma attributes of Riesling wines produced by freeze concentration and microwave vacuum dehydration. J. Food Process. Preserv. 2006, 30, 393–406. [Google Scholar] [CrossRef]

- Lutskova, V.A. Development of Icewine Technology in the Agricultural Climatic Conditions of the Northern Black Sea Coast. Ph.D. Thesis, Kyiv National University of food Technologies, Kyiv, Ukraine, 4 December 2019. Available online: https://drive.google.com/file/d/1tCXnzFCpXn0t1JoFJjPBlYCwY9p-7WCy/view (accessed on 29 September 2020).

- TC U 37471967-11.02.11. In Technological Instructions for the Processing of Wine Materials at the Enterprises of the Wine Industry; Ministry of Agrarian Policy and Food of Ukraine: Kyiv, Ukraine, 2014.

- Compendium of International Methods of Wine and Must Analysis; International Organisation of Vine and Wine: Paris, France, 2016; Volume 1, pp. 64–65.

- Zoecklein, B.W.; Fugelsang, K.C.; Gump, B.H.; Nury, F.S. Volatile acidity. In Wine Analysis and Production; Springer: Boston, MA, USA, 1995; pp. 192–198. [Google Scholar]

- Noble, A.C.; Arnold, R.A.; Masuda, B.M.; Pecore, S.D.; Schmidt, J.O.; Stern, P.M. Progress towards a standardized system of wine aroma terminology. Am. J. Enol. Vitic. 1984, 35, 107–109. [Google Scholar]

- Jackson, R.S. Wine Tasting A Professional Handbook; Academic Press: London, UK, 2002. [Google Scholar]

- Romashkina, G.F.; Tatarova, G.G. Concording coefficient in sociological data analysis. Sociology 2005, 20, 131–158. [Google Scholar]

- Jing, W.; Min, L.; Jixin, L.; Tengzhen, M.; Shunyu, H.; Morata, A.; Lepe, J.A.S. Biotechnology of ice wine production. In Advances in Biotechnology for Food Industry; Academic Press: Cambridge, MA, USA, 2018; pp. 267–300. [Google Scholar]

- Guth, H. Identification of character impact odorants of different white wine varieties. J. Agric. Food Chem. 1997, 45, 3022–3026. [Google Scholar] [CrossRef]

- Buttery, B.G.; Turnbaugh, J.G.; Ling, L.C. Contribution of volatiles to rice aroma. J. Agric. Food Chem. 1988, 36, 1006–1009. [Google Scholar] [CrossRef]

- Pérez-López, A.J.; Carbonell-Barrachina, Á.A. Volatile odour components and sensory quality of fresh and processed mandarin juices. J. Sci. Food Agric. 2006, 86, 2404–2411. [Google Scholar] [CrossRef]

- Takoi, K.; Koie, K.; Itoga, Y.; Katayama, K.; Shimase, M.; Nakayama, Y.; Watari, J. Biotransformation of hop-derived monoterpene alcohols by lager yeast and their contribution to the flavor of hopped beer. J. Agric. Food Chem. 2010, 58, 5050–5058. [Google Scholar] [CrossRef]

- Ferreira, V.; Lopez, R.; Cacho, J. Quantitative determination of the odorants of young red wines from different grape varieties. J. Sci. Food Agric. 2000, 80, 1659–1667. [Google Scholar] [CrossRef]

- Franco, M.; Peinado, R.; Medina, M.; Moreno, J. Off-vine grape drying effect on volatile compounds and aromatic series in must from Pedro Ximenez grape variety. J. Agric. Food Chem. 2004, 52, 3905–3910. [Google Scholar] [CrossRef]

- Gao, W.; Fan, W.; Xu, Y. Characterization of the key odorants in light aroma type Chinese liquor by gas chromatography-olfactometry, quantitative measurements, aroma recombination, and omission studies. J. Agric. Food Chem. 2014, 62, 5796–5804. [Google Scholar] [CrossRef]

- Jin, B.; Wang, D.; Xu, Y.; Zhao, G. Study on olfactory thresholds for several aroma components in Chinese rice wine. Sci. Technol. Food Ind. 2012, 33, 35–138. [Google Scholar]

- López, R.; Aznar, M.; Cacho, J.; Ferreira, V. Determination of minor and trace volatile compounds in wine by solid-phase extraction and gas chromatography with mass spectrometric detection. J. Chromatogr. 2002, 966, 167–177. [Google Scholar] [CrossRef]

- Saenz-Navajas, M.P.; Campo, E.; Cullere, L.; Fernandez-Zurbano, P.; Valentin, D.; Ferreira, V. Effects of the nonvolatile matrix on the aroma perception of wine. J. Agric. Food Chem. 2010, 58, 5574–5585. [Google Scholar] [CrossRef] [PubMed]

- Etiévant, P.X. Wine. In Volatile Compounds in Foods and Beverages; Maarse, H., Ed.; Marcel Dekker: New York, NY, USA, 1991; Volume 14, pp. 483–546. [Google Scholar]

- Gallander, G. Effect of Grape Maturity on the Composition and Quality of Ohio Vidal Blanc Wines. Am. J. Enol. Vitic. 1983, 34, 139–141. [Google Scholar]

- Gulua, L.; Nikolaishvili, L.; Turmanidze, T.; Jgenti, M.; Bezhuashvili, M.; FitzGerald, R. Chemical constituents, antioxidant and anti-lipase activity of the selected wines produced in Georgia. Ukr. Food J. 2018, 7, 177–191. [Google Scholar] [CrossRef]

- Zhan, J.C. Wine Grape Varieties; China Agricultural University: Beijing, China, 2010; Chapter 4; pp. 85–106. [Google Scholar]

- Pozzatti, M.; Guerra, C.; Martins, G.; dos Santos, I.; Wagner, R.; Ferrão, M.; Manfroi, V. Effects of winemaking on ‘Marselan’ red wines: Volatile compounds and sensory aspects. Ciência E Técnica Vitivinic. 2020, 35, 63–75. [Google Scholar] [CrossRef]

- Lu, Y.; Sun, F.; Wang, W.; Liu, Y.; Wang, J.; Sun, J.; Gao, Z. Effects of spontaneous fermentation on the microorganisms diversity and volatile compounds during Marselan from grape to wine. Food Sci. Technol. 2020, 134, 110193. [Google Scholar] [CrossRef]

- Dos Santos, C.E.; Debastiani, R.; Souza, V.S.; Peretti, D.E.; Jobim, P.F.; Yoneama, M.L.; Dias, J.F. The influence of the winemaking process on the elemental composition of the Marselan red wine. J. Sci. Food Agric. 2019, 99, 4642–4650. [Google Scholar] [CrossRef]

- Tao, Y.; Li, H.; Wang, H.; Zhang, L. Volatile compounds of young Cabernet Sauvignon red wine from Changli County (China). J. Food Compos. Anal. 2008, 21, 689–694. [Google Scholar] [CrossRef]

- Rapp, A.; Mandery, H. Wine aroma. Experientia 1986, 42, 873–884. [Google Scholar] [CrossRef]

- Francis, I.L.; Newton, J.L. Determining wine aroma from compositional data. Aust. J. Grape Wine Res. 2005, 11, 114–126. [Google Scholar] [CrossRef]

- Lyu, J.; Ma, Y.; Xu, Y.; Nie, Y.; Tang, K. Characterization of the key aroma compounds in Marselan wine by gas chromatography-olfactometry, quantitative measurements, aroma recombination, and omission tests. Molecules 2019, 24, 2978. [Google Scholar] [CrossRef] [PubMed]

- Tkachenko, O.B.; Trinkal, O.V. Chemistry of wine aromas. Food Sci. Technol. 2015, 1, 42–50. [Google Scholar] [CrossRef][Green Version]

- Bindon, K.; Varela, C.; Kennedy, J.; Holt, H.; & Herderich, M. Relationships between harvest time and wine composition in Vitis vinifera L. cv. Cabernet Sauvignon 1. Grape and wine chemistry. Food Chem. 2013, 138, 1696–1705. [Google Scholar] [CrossRef] [PubMed]

- Ruiz, M.J.; Zea, L.; Moyano, L.; Medina, M. Aroma active compounds during the drying of grapes cv. Pedro Ximenez destined to the production of sweet Sherry wine. Eur. Food Res. Technol. 2010, 230, 429–435. [Google Scholar] [CrossRef]

- Genovese, A.; Gambuti, A.; Piombino, P.; Moio, L. Sensory properties and aroma compounds of sweet Fiano wine. Food Chem. 2007, 103, 1228–1236. [Google Scholar] [CrossRef]

- Sarrazin, E.; Dubourdieu, D.; Darriet, P. Characterization of key-aroma compounds of botrytized wines, influence of grape botrytization. Food Chem. 2007, 103, 536–545. [Google Scholar] [CrossRef]

- Miklósy, É.; Kerényi, Z. Comparison of the volatile aroma components in noble rotted grape berries from two different locations of the Tokaj wine district in Hungary. Anal. Chim. Acta 2004, 513, 177–181. [Google Scholar] [CrossRef]

- Patel, S.; Shibamoto, T. Effect of 20 different yeast strains on the production of volatile components in Symphony wine. J. Food Compos. Anal. 2003, 16, 469–476. [Google Scholar] [CrossRef]

- Arapitsas, P.; Antonopoulos, A.; Stefanou, E.; Dourtoglou, V.G. Artificial aging of wines using oak chips. Food Chem. 2004, 86, 563–570. [Google Scholar] [CrossRef]

- Bowen, A.J.; Reynolds, A.G. Aroma compounds in Ontario Vidal and Riesling icewines. I. Effects of harvest date. Food Res. Int. 2015, 76, 540–549. [Google Scholar] [CrossRef]

- Chevance, F.; Guyot-Declerck, C.; Dupont, J.; Collin, S. Investigation of the β-damascenone level in fresh and aged commercial beers. J. Agric. Food Chem. 2002, 50, 3818–3821. [Google Scholar] [CrossRef]

- Winterhalter, P.; Gök, R. TDN and β-Damascenone: Two important carotenoid metabolites in wine. In Carotenoid Cleavage Products; American Chemical Society: Washington, DC, USA, 2013; pp. 125–137. [Google Scholar]

- Khairallah, R.; Reynolds, A.G.; and Bowen, A.J. Harvest date effects on aroma compounds in aged Riesling icewines. J. Sci. Food Agric. 2016, 96, 4398–4409. [Google Scholar] [CrossRef] [PubMed]

| Grape Variety | Maturation Period, Days [6] | The Origin of Grapes and a Brief Ampelographic Description |

|---|---|---|

| Rkatsiteli | Late maturing, 155–170 | 100%—V. vinifera. Technical white grape variety. The cluster is small, long, conical. The berry is round or oval. The skin is thin, very strong. The flesh is juicy. The variety is moderately resistant to mildew, weakly affected by gray rot, resistance to powdery mildew is low. Frost resistance is moderate. |

| Telti kuruk | Late maturing, 155–160 | 100%—V. vinifera. Technical white grape variety. Bunch of medium size, elongated-cylindrical-conical. Berry of medium size or small, slightly oval, yellowish-green, with a thick waxy coating. The skin is thin, strong. The pulp is juicy. Frost resistance is under study. |

| Marselan | Late maturing, 170–190 | 100%—V. vinifera. Technical red grape variety. Crossing scheme: Cabernet Sauvignon and Grenache. The cluster is small. The berry is round, small. The skin is thick, very strong. The pulp is juicy. The variety is resistant to fungal diseases. Frost resistance is under study. |

| Moldova | Late maturing, 155–180 | 56.19%—V. vinifera, 3.13%—V. labrusca, 29%—V. rupestris, 6.25%—V. berlandieri, 5.28%—V. lincecumii. Table red grapes. Hybrid, crossbreeding scheme: Guzal kara x Save Villar 12-375. The cluster is large, medium-dense. The berry is large, oval. The skin is thick, the pulp is juicy. The variety is resistant to mildew and gray rot. Frost resistance is high. |

| Cas Number | Compound | Supplier | Quantification Ion (m/z) | Qualitative Ions (m/z) | Odor Characteristics |

|---|---|---|---|---|---|

| 111-27-3 | 1-Hexanol | Sigma-Aldrich | 56 | 69, 84 | Leaf, grassy, resin, medicinal |

| 78-83-1 | Isobutanol | Aldrich | 43 | 42, 41, 74 | Fruity, floral |

| 71-23-8 | 1-Propanol | Sigma-Aldrich | 31 | 59, 42 | Sweet, fruit |

| 3391-86-4 | 1-Octen-3-ol | Acros Organics | 57 | 72, 85, 99 | Mushroom |

| 98-55-5 | α-Terpineol | Aldrich | 59 | 75, 63 | Lilac, citrus, lime |

| 100-51-6 | Benzyl alcohol | Aldrich | 79 | 85, 93 | flower, fruit |

| 543-49-7 | 2-heptanol | Aldrich | 58 | 73, 87 | lemon, citrus |

| 111-87-5 | 1-octanol | Sigma-Aldrich | 56 | 41, 69, 84 | rose, citrus |

| 60-12-8 | Phenylethyl Alcohol | Aldrich | 91 | 122, 65, 51 | Burnt, rose, oily, honey |

| 106-24-1 | Geraniol | Aldrich | 90 | 41, 66 | Citrus |

| 106-22-9 | Citronellol | Aldrich | 55 | 41, 67, 156 | Rose, citrus |

| 78-70-6 | Linalool | Sigma-Aldrich | 71 | 93, 121, 154 | Lemon, flower |

| 123-92-2 | Isoamyl acetate | Aldrich | 43 | 70, 55, 87 | Pear |

| 123-66-0 | Ethyl hexanoate | Aldrich | 88 | 99, 60, 144 | Fruity, apple |

| 7452-79-1 | Ethyl 2-methyl butyrate | Aldrich | 57 | 102, 74, 130 | Blackberry, pineapple |

| 105-54-4 | Ethyl butyrate | Aldrich | 71 | 43, 88, 116 | Blackberries, tropical fruits |

| 108-64-5 | Ethyl 3-methyl butyrate | Aldrich | 88 | 41, 70, 130 | Berry, cherry |

| 106-32-1 | Ethyl octanoate | Aldrich | 88 | 101, 127, 172 | pomegranate, pineapple, peach |

| 103-45-7 | 2-Phenethyl acetate | Aldrich | 104 | 43, 91, 78 | Ripe fruit, floral |

| 110-38-3 | Ethyl decanoate | Aldrich | 88 | 101, 73, 155 | Sweet, herbal |

| 93-89-0 | Ethyl benzoate | Aldrich | 105 | 122, 77, 172 | Chamomile, flower, celery, fruit |

| 142-62-1 | Hexyl acetate | Aldrich | 60 | 56, 84, 69 | Apples, pears, cherries |

| 4455-13-4 | Ethyl acetate | Aldrich | 30 | 44, 68 | Pear, fruit |

| 98-01-1 | Furfural | Aldrich | 96 | 67, 42, 51 | Bread, pastries |

| 100-52-7 | Benzaldehyde | Bedoukian | 46 | 85, 93, 98 | Almonds |

| 121-33-5 | Vanillin aldehyde | Bedoukian | 45 | 73, 79, 85 | Vanilla |

| 97-53-0 | Eugenol | Aldrich | 43 | 78, 96 | Spicy cloves, spices, oak |

| 142-62-1 | Hexanoic acid | Aldrich | 60 | 45, 68 | Fruit, herb |

| 103-82-2 | Phenylacetic acid | Aldrich | 60 | 56, 46 | Honey |

| 124-07-2 | Octanoic acid | Aldrich | 60 | 78, 81 | Oil |

| 104-61-0 | γ-nonalactone | Aldrich | 85 | 41, 114, 156 | Oil, honey, coconut |

| 2628-17-3 | 4-vinylphenol | Aldrich | 150 | 54, 97, 110 | Oak |

| 7786-61-0 | 2-methoxy-4-vinylphenol | Aldrich | 150 | 54, 97 | Spices, cloves |

| H1 | H2 | Significance a | |

|---|---|---|---|

| Rkatsiteli musts | |||

| Brix | 29.5a | 33.4b | *** |

| pH | 3.5a | 3.7b | ** |

| Titratable acidity (g/L) | 8.9a | 8.4b | ** |

| Telti kuruk musts | |||

| Brix | 30.0a | 35.7b | *** |

| pH | 3.4a | 3.6 b | * |

| Titratable acidity (g/L) | 9.1a | 9.2a | ns |

| Marselan musts | |||

| Brix | 28.5a | 35.2b | *** |

| pH | 3.8a | 3.8a | ns |

| Titratable acidity (g/L) | 8.6a | 8.0b | *** |

| Moldova musts | |||

| Brix | 29.2a | 34.8b | *** |

| pH | 3.7a | 3.7a | ns |

| Titratable acidity (g/L) | 9.1a | 8.5b | ** |

| H1 | H2 | Significance a | |

|---|---|---|---|

| Rkatsiteli icewines | |||

| Brix | 145.0a | 155.7b | *** |

| pH | 3.6a | 3.7b | * |

| Titratable acidity (g/L) | 9.0a | 8.6b | ** |

| Ethanol (% v/v) | 10.5a | 11.0b | ** |

| Volatile acidity (g/L) | 0.8a | 0.95b | *** |

| Telti kuruk icewines | |||

| Brix | 158.7a | 170.1b | *** |

| pH | 3.5a | 3.6b | * |

| Titratable acidity (g/L) | 9.5a | 9.5a | ns |

| Ethanol (% v/v) | 10.2a | 11.6b | *** |

| Volatile acidity (g/L) | 0.85a | 1.0b | *** |

| Marselan icewines | |||

| Brix | 142.6a | 164.3b | *** |

| pH | 3.8a | 3.9b | * |

| Titratable acidity (g/L) | 9.0a | 8.5b | *** |

| Ethanol (% v/v) | 9.6a | 10.3b | *** |

| Volatile acidity (g/L) | 0.8a | 0.9b | ** |

| Moldova icewines | |||

| Brix | 144.0a | 158.2b | *** |

| pH | 3.7a | 3.7a | ns |

| Titratable acidity (g/L) | 9.5a | 8.4b | *** |

| Ethanol (% v/v) | 9.7a | 10.5b | *** |

| Volatile acidity (g/L) | 0.8a | 0.95b | *** |

| Compound | Rkatsiteli | Significance a | Telti Kuruk | Significance a | Threshold (μg/L) | ||

|---|---|---|---|---|---|---|---|

| H1 | H2 | H1 | H2 | ||||

| Higher and terpene alcohols | |||||||

| Isobutanol | 1260.11a | 1260.74a | ns | 2120.41a | 3260.3b | *** | 40,000 [34] |

| 1-Propanol | 129.52a | 139.71b | ** | 150.7a | 200.2b | *** | 120 [34] |

| 1-Octen-3-ol | 2.5a | 2.5a | ns | 1.5a | 3.0b | * | 1 [35] |

| α-Terpineol | 30.18a | 35.32b | *** | 80.11a | 85.46b | ** | 250 [36] |

| Isoamyl alcohol | nd | 560.26b | ** | 300.5a | 570b | *** | 30,000 [34] |

| 1-octanol | 150.12a | 120.1b | *** | 180.7a | 125.2b | *** | 120 [34] |

| Phenylethyl Alcohol | 90.45a | 60.03b | *** | 70.85a | 50.74b | *** | 10,000 [34] |

| Geraniol | 6.5a | 5.2b | * | 6.9a | 3.12b | ** | 7 [37] |

| Citronellol | nd | 6.24b | * | 6.56a | 6.81a | ns | 100 [34] |

| Linalool | 4a | 4a | ns | 2a | 3b | * | 15 [34] |

| Esters | |||||||

| Ethyl hexanoate | 102.54a | 114.25b | ** | 110.14a | 126.2b | ** | 5 [34] |

| Ethyl 2-methyl butyrate | 10.12a | 10.56a | ns | 10.19a | 14.15b | * | 18 [34] |

| Ethyl butyrate | 50.45a | 48.42b | * | 51.11a | 52.1b | * | 20 [34] |

| Ethyl 3-methyl butyrate | 26.21a | 30.76b | * | 10.23a | 27.71b | ** | 3 [34] |

| Ethyl octanoate | 400.29a | 420.8b | ** | 200.19a | 270.16b | *** | 2 [34] |

| Ethyl decanoate | 150.5a | 160.48b | ** | 115.62a | 120.32b | ** | 200 [38] |

| Ethyl benzoate | 170.52a | 140.43b | *** | 90.17a | 60.36b | *** | 575 [38] |

| Acetates | |||||||

| Hexyl acetate | 180.11a | 180.33a | ns | nd | nd | - | 670 [39] |

| Ethyl acetate | 70.12a | 80.26b | ** | 50.48a | 70.78b | *** | 32,600 [40] |

| 2-Phenethyl acetate | 350.19a | 150.35b | *** | 400.51a | 170.19b | *** | 250 [34] |

| Isoamyl acetate | 126.14a | 107.23b | *** | 105.1a | 106.5b | ** | 30 [34] |

| Aldehyde | |||||||

| Vanillin aldehyde | nd | 10.4b | * | nd | nd | - | 26 [41] |

| Acids | |||||||

| Hexanoic acid | 3458a | 3488b | ** | 4120a | 4137b | ** | 3000 [34] |

| Phenylacetic acid | 560a | 500b | ** | 600a | 480b | *** | 10,000 [34] |

| Octanoic acid | 1110a | 1112b | * | 1000a | 1010b | * | 7000 [34] |

| Phenols | |||||||

| 4-vinylphenol | 9.47 | nd | * | 7.5 | nd | * | 180 [42] |

| 2-methoxy-4-inylphenol | 3.32a | 2.36b | ** | 1.3 | nd | * | 9.5 [43] |

| Eugenol | 5.15a | 3.17b | *** | 1.4 | nd | * | 6 [38] |

| Compound | Moldova | Significance a | Marselan | Significance a | Threshold (μg/L) | ||

|---|---|---|---|---|---|---|---|

| H1 | H2 | H1 | H2 | ||||

| Higher and terpene alcohols | |||||||

| 1-Hexanol | 1200.15a | 1110.52b | *** | 1220.45a | 1110.67b | *** | 8000 [34] |

| Isobutanol | 1020.24a | 2010b | *** | 1550.17a | 2010.26b | *** | 40,000 [34] |

| 1-Propanol | 130.19a | 129.47b | * | 130.8a | 128.4b | * | 120 [34] |

| 1-Octen-3-ol | 2.4a | 3.0b | * | 2.3a | 5.2b | ** | 1 [35] |

| α-Terpineol | 10.15a | 12.27b | * | 20.75a | 26.43b | ** | 250 [36] |

| Benzyl alcohol | 10.37a | 20.96b | ** | 50.81a | 57.18b | ** | 10,000 [34] |

| Isoamyl alcohol | 200a | 80b | *** | 100a | 200b | *** | 30,000 [34] |

| 1-octanol | 120 | nd | ** | 121a | 120b | *** | 120 [34] |

| Phenylethyl Alcohol | 10.76a | 30.72b | *** | 10.4a | 50.81b | ** | 10,000 [34] |

| Geraniol | 4.47a | 5.5b | ** | 4.13a | 4.17 a | ns | 7 [37] |

| Citronellol | 1.61 | nd | * | 2.45 | nd | * | 100 [34] |

| Linalool | 3.2a | 3.24 a | ns | 2.25 | nd | * | 15 [34] |

| Esters | |||||||

| Ethyl hexanoate | 123.11a | 159.19b | *** | 137.75a | 164.19b | *** | 5 [34] |

| Ethyl 2-methyl butyrate | 11.9a | 15.1b | ** | 25.5a | 15.4b | *** | 18 [34] |

| Ethyl butyrate | 60.52a | 30.63b | *** | 45.31a | 15.24b | *** | 20 [34] |

| Ethyl 3-methyl butyrate | 13.7a | 12.61b | ** | 11.28a | 9.17b | *** | 3 [34] |

| Ethyl octanoate | 75.13a | 91.64b | *** | 84.14a | 92.97b | *** | 2 [34] |

| Ethyl decanoate | 115.52a | 130.71b | *** | nd | nd | - | 200 [38] |

| Ethyl benzoate | 20.1a | 20.15a | ns | 80.75a | 25.84b | *** | 575 [38] |

| Acetates | |||||||

| Hexyl acetate | 210.7a | 280.24b | *** | 180.79a | 200.8b | *** | 670 [39] |

| Ethyl acetate | nd | nd | - | 35.17a | 38.93b | ** | 32,600 [40] |

| 2-Phenethyl acetate | 250.52a | 245.78b | *** | 263.87a | 219.14b | *** | 250 [34] |

| Isoamyl acetate | 104.47a | 100.55b | ** | 110.64a | 105.37b | * | 30 [34] |

| Aldehyde | |||||||

| Furfural | 30.35a | 50.47b | *** | 10.15a | 50.5b | *** | 14,100 [38] |

| Benzaldehyde | nd | nd | - | 6.17a | 10.87b | *** | 2000 [44] |

| Vanillin aldehyde | 12.14a | 15.15b | * | nd | 6.37b | * | 26 [41] |

| Acids | |||||||

| Hexanoic acid | 3205.23a | 3240.51b | *** | 3140.62a | 3170.74b | *** | 3000 [34] |

| Phenylacetic acid | 640.63a | 410.74b | *** | 510.49a | 520.81b | *** | 10,000 [34] |

| Octanoic acid | 650.54a | 660.78b | ** | 580.91a | 600.62b | *** | 7000 [34] |

| Lactone | |||||||

| γ-nonalactone | 40.14a | 41.96b | * | nd | nd | - | 30 [38] |

| Phenols | |||||||

| 4-vinylphenol | 4.36 | nd | * | nd | nd | - | 180 [42] |

| 2-methoxy-4Vinylphenol | 4.54a | 2.69b | ** | nd | nd | - | 9.5 [43] |

| Eugenol | 1.5a | 2.13b | * | nd | nd | - | 6 [38] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lutskova, V.; Martirosyan, I. Influence of Harvest Date and Grape Variety on Sensory Attributes and Aroma Compounds in Experimental Icewines of Ukraine. Fermentation 2021, 7, 7. https://doi.org/10.3390/fermentation7010007

Lutskova V, Martirosyan I. Influence of Harvest Date and Grape Variety on Sensory Attributes and Aroma Compounds in Experimental Icewines of Ukraine. Fermentation. 2021; 7(1):7. https://doi.org/10.3390/fermentation7010007

Chicago/Turabian StyleLutskova, Viktoriia, and Irina Martirosyan. 2021. "Influence of Harvest Date and Grape Variety on Sensory Attributes and Aroma Compounds in Experimental Icewines of Ukraine" Fermentation 7, no. 1: 7. https://doi.org/10.3390/fermentation7010007

APA StyleLutskova, V., & Martirosyan, I. (2021). Influence of Harvest Date and Grape Variety on Sensory Attributes and Aroma Compounds in Experimental Icewines of Ukraine. Fermentation, 7(1), 7. https://doi.org/10.3390/fermentation7010007