Nutritional and Microbiological Quality of Tiger Nut Tubers (Cyperus esculentus), Derived Plant-Based and Lactic Fermented Beverages

Abstract

1. Introduction

2. Nutritional Characteristics and Bioactive Compounds of Tiger Nut

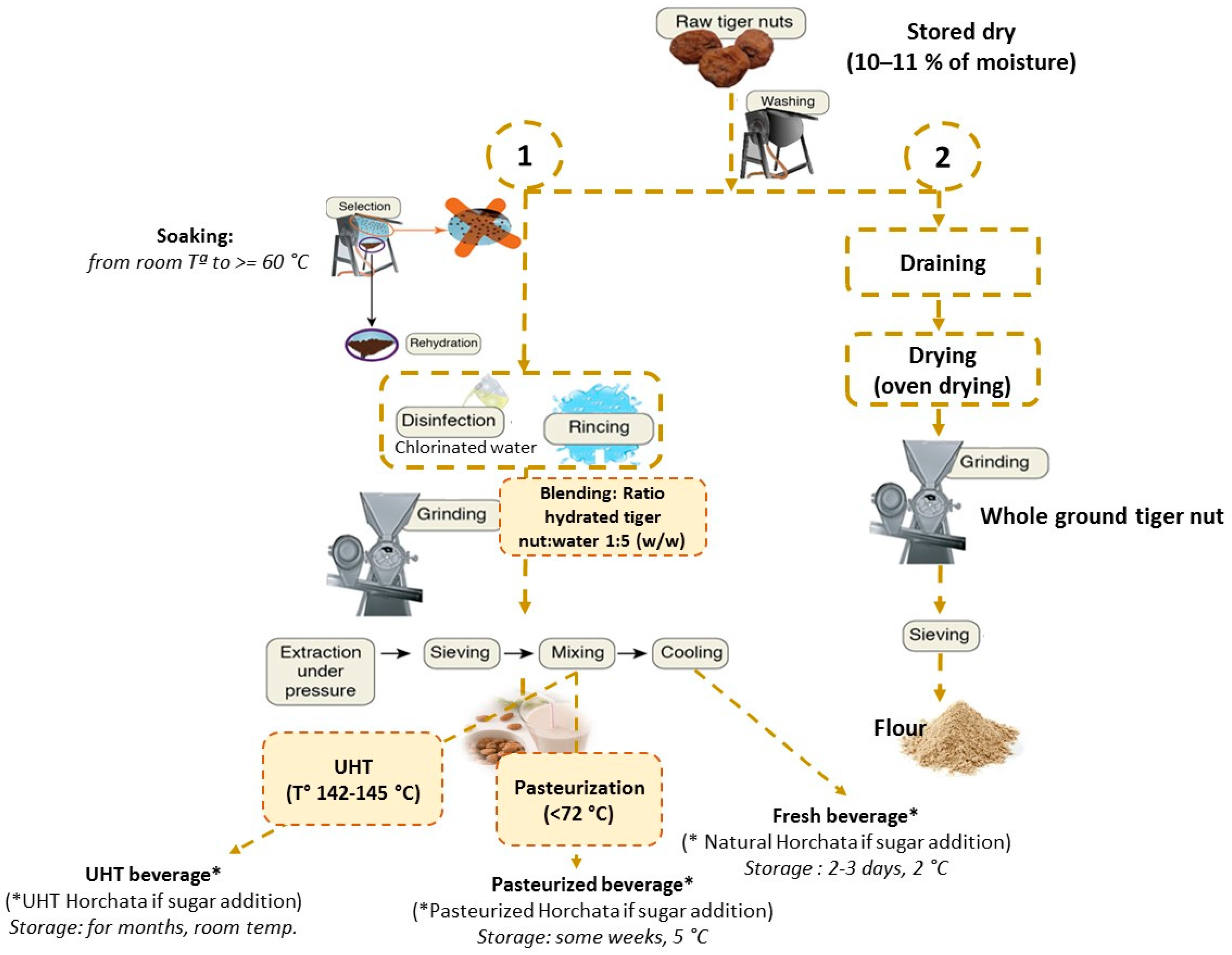

3. Nutritional Characteristics of Tiger Nut-Based Beverages

4. Products Obtained by Lactic Fermentation or Lactic Acid Bacteria Addition

5. Safety and Microbiological Quality

6. Conclusions and Future Research for Functional Beverages and Foods

Funding

Conflicts of Interest

References

- Slavin, J.L.; Lloyd, B. Health benefits of fruits and vegetables. Adv. Nutr. 2012, 3, 506–516. [Google Scholar] [CrossRef] [PubMed]

- Nishida, C.; Uauy, R.; Kumanyika, S.; Shetty, P. The Joint WHO/FAO Expert Consultation on diet, nutrition and the prevention of chronic diseases: Process, product and policy implications. Public Health Nutr. 2004, 7, 245–250. [Google Scholar] [CrossRef] [PubMed]

- Chandrasekara, A.; Josheph Kumar, T. Roots and tuber crops as functional foods: A review on phytochemical constituents and their potential health benefits. Int. J. Food Sci. 2016, 2016, 1–15. [Google Scholar] [CrossRef] [PubMed]

- Wild, D.; Robins, G.G.; Burley, V.J.; Howdle, P.D. Evidence of high sugar intake, and low fibre and mineral intake, in the gluten-free diet. Aliment. Pharmacol. Ther. 2010, 32, 573–581. [Google Scholar] [CrossRef]

- Vici, G.; Belli, L.; Biondi, M.; Polzonetti, V. Gluten free diet and nutrient deficiencies: A review. Clin. Nutr. 2016, 35, 1236–1241. [Google Scholar] [CrossRef]

- Jeske, S.; Arendt, E.K. Past, present and future: The strength of plant-based dairy substitutes based on gluten-free raw materials. Food Res. Int. 2018, 110, 42–51. [Google Scholar] [CrossRef]

- Marsh, A.J.; Hill, C.; Ross, R.P.; Cotter, P.D. Fermented beverages with health-promoting potential: Past and future perspectives. Trends Food Sci. Technol. 2014, 38, 113–124. [Google Scholar] [CrossRef]

- Mäkinen, O.E.; Wanhalinna, V.; Zannini, E.; Arendt, E.K. Foods for special dietary needs: Non-dairy plant-based milk substitutes and fermented dairy-type products. Crit. Rev. Food Sci. Nutr. 2016, 56, 339–349. [Google Scholar] [CrossRef] [PubMed]

- Caplice, E.; Fitzgerald, G.F. Food fermentations: Role of microorganisms in food production and preservation. Int. J. Food Microbiol. 1999, 50, 131–149. [Google Scholar] [CrossRef]

- Hugenholtz, J. Traditional biotechnology for new foods and beverages. Curr. Opin. Biotechnol. 2013, 24, 155–159. [Google Scholar] [CrossRef]

- Hill, C.; Guarner, F.; Reid, G.; Gibson, G.R.; Merenstein, D.J.; Pot, B.; Morelli, L.; Canani, R.B.; Flint, H.J.; Salminen, S.; et al. The International Scientific Association for Probiotics and Prebiotics consensus statement on the scope and appropriate use of the term probiotic. Nat. Rev. Gastroenterol. Hepatol. 2014, 11, 506–514. [Google Scholar] [CrossRef] [PubMed]

- Oyewole, O.B. Lactic fermented foods in Africa and their benefits. Food Control 1997, 8, 289–297. [Google Scholar] [CrossRef]

- Lee, C.-H. Lactic acid fermented foods and their benefits in Asia. Food Control 1997, 8, 259–269. [Google Scholar] [CrossRef]

- Tamang, J.P.; Watanabe, K.; Holzapfel, W.H. Review: Diversity of microorganisms in global fermented foods and beverages. Front. Microbiol. 2016, 7, 377. [Google Scholar] [CrossRef] [PubMed]

- Blandino, A.; Al-Aseeri, M.E.; Pandiella, S.S.; Cantero, D.; Webb, C. Cereal-based fermented foods and beverages. Food Res. Int. 2003, 36, 527–543. [Google Scholar] [CrossRef]

- Di Cagno, R.; Coda, R.; De Angelis, M.; Gobbetti, M. Exploitation of vegetables and fruits through lactic acid fermentation. Food Microbiol. 2013, 33, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Fessard, A.; Kapoor, A.; Patche, J.; Assemat, S.; Hoarau, M.; Bourdon, E.; Bahorun, T.; Remize, F. Lactic fermentation as an efficient tool to enhance the antioxidant activity of tropical fruit juices and teas. Microorganisms 2017, 5, 23. [Google Scholar] [CrossRef]

- De Castro, O.; Gargiulo, R.; Del Guacchio, E.; Caputo, P.; De Luca, P. A molecular survey concerning the origin of Cyperus esculentus (Cyperaceae, Poales): Two sides of the same coin (weed vs. crop). Ann. Bot. 2015, 115, 733–745. [Google Scholar] [CrossRef]

- Sánchez-Zapata, E.; Fernández-López, J.; Angel Pérez-Alvarez, J. Tiger nut (Cyperus esculentus) commercialization: Health aspects, composition, properties, and food applications. Compr. Rev. Food Sci. Food Saf. 2012, 11, 366–377. [Google Scholar] [CrossRef]

- Bamishaiye, E.; Bamishaiye, O. Tiger nut: As a plant, its derivatives and benefits. Afr. J. Food Agric. Nutr. Dev. 2011, 11, 5157–5170. [Google Scholar] [CrossRef]

- Van Wyk, B.-E. The potential of South African plants in the development of new food and beverage products. S. Afr. J. Bot. 2011, 77, 857–868. [Google Scholar] [CrossRef]

- Belewu, M.A.; Belewu, K. Comparative physicochemical evaluation of tigernut, soybean and coconut milk sources. Int. J. Agric. Biol. 2007, 9, 785–787. [Google Scholar]

- Maduka, N.; Ire, F.; Njoku, H. Fermentation of tigernut by lactic acid bacteria and tigernut-milk drink fermentation by lactic acid bacteria as a potential probiotic product. Asian J. Sci. Technol. 2017, 8, 5167–5172. [Google Scholar]

- Oa, O. Determination of amino acids and physico-chemical properties of juice samples produced from five varieties of tigernut (Cyperus esculentus). Chem. Res. J. 2016, 1, 1–6. [Google Scholar]

- Codina, I.; Trujillo, A.J.; Ferragut, V. Horchata. In Traditional Foods; Springer: Boston, MA, USA, 2016; pp. 345–356. [Google Scholar]

- Sánchez-Zapata, E.; Fernández-López, J.; Pérez-Alvarez, J.A.; Soares, J.; Sousa, S.; Gomes, A.M.P.; Pintado, M.M.E. In vitro evaluation of “horchata” co-products as carbon source for probiotic bacteria growth. Food Bioprod. Process. 2013, 91, 279–286. [Google Scholar] [CrossRef]

- Agbaje, R.B.; Oyetayo, O.V.; Ojokoh, A.O. Assessment of the microbial and physico-chemical composition of tigernut subjected to different fermentation methods. Pak. J. Nutr. 2015, 14, 742–748. [Google Scholar] [CrossRef]

- Kizzie-Hayford, N.; Jaros, D.; Zahn, S.; Rohm, H. Effects of protein enrichment on the microbiological, physicochemical and sensory properties of fermented tiger nut milk. LWT Food Sci. Technol. 2016, 74, 319–324. [Google Scholar] [CrossRef]

- Akoma, O.; Elekwa, U.O.; Afodunrinbi, A.T.; Onyeukwu, G.C. Yogurt from Coconut and Tigernuts. J. Food Technol. Afr. 2000, 5, 132–134. [Google Scholar] [CrossRef]

- Ukwuru, M. Production and quality assessment of tiger nut (Cyperus esculentus) imitation milk during storage. J. Food Sci. Technol. 2008, 45, 180–182. [Google Scholar]

- Sanful, R.E. The use of tiger-nut (Cyperus esculentus), cow milk and their composite as substrates for yoghurt production. Pak. J. Nutr. 2009, 8, 755–758. [Google Scholar] [CrossRef]

- Sánchez-Zapata, E.; Fuentes-Zaragoza, E.; Viuda-Martos, M.; Fernández-López, J.; Sendra, E.; Sayas, E.; Pérez-Alvarez, J.A. Reclaim of the by-products from “Horchata” elaboration process. Food Bioprocess Technol. 2012, 5, 954–963. [Google Scholar] [CrossRef]

- USDA Branded Food Products Database. Available online: https://ndb.nal.usda.gov/ndb/ (accessed on 26 November 2018).

- Roselló-Soto, E.; Poojary, M.M.; Barba, F.J.; Lorenzo, J.M.; Mañes, J.; Moltó, J.C. Tiger nut and its by-products valorization: From extraction of oil and valuable compounds to development of new healthy products. Innov. Food Sci. Emerg. Technol. 2018, 45, 306–312. [Google Scholar] [CrossRef]

- Kim, M.; No, S.; Yoon, S.H. Stereospecific analysis of fatty acid composition of Chufa (Cyperus esculentus L.) tuber oil. J. Am. Oil Chem. Soc. 2007, 84, 1079–1080. [Google Scholar] [CrossRef]

- Yeboah, S.O.; Mitei, Y.C.; Ngila, J.C.; Wessjohann, L.; Schmidt, J. Compositional and structural studies of the oils from two edible seeds: Tiger nut, Cyperus esculentum, and asiato, Pachira insignis, from Ghana. Food Res. Int. 2012, 47, 259–266. [Google Scholar] [CrossRef]

- Arafat, S.; Gaafar, A.; Basuny, A.M.; Nassef, S. Chufa tubers (Cyperus esculentus L.) as a new source of food. World Appl. Sci. J. 2009, 7, 151–156. [Google Scholar]

- Ezeh, O.; Niranjan, K.; Gordon, M.H. Effect of enzyme pre-treatments on bioactive compounds in extracted tiger nut oil and sugars in residual meals. J. Am. Oil Chem. Soc. 2016, 93, 1541–1549. [Google Scholar] [CrossRef] [PubMed]

- Lopéz-Cortés, I.; Salazar-García, D.C.; Malheiro, R.; Guardiola, V.; Pereira, J.A. Chemometrics as a tool to discriminate geographical origin of Cyperus esculentus L. based on chemical composition. Ind. Crops Prod. 2013, 51, 19–25. [Google Scholar] [CrossRef]

- Codina-Torrella, I.; Guamis, B.; Trujillo, A.J. Characterization and comparison of tiger nuts (Cyperus esculentus L.) from different geographical origin: Physico-chemical characteristics and protein fractionation. Ind. Crops Prod. 2015, 65, 406–414. [Google Scholar] [CrossRef]

- Olabiyi, A.A.; Carvalho, F.B.; Bottari, N.B.; Lopes, T.F.; da Costa, P.; Stefanelo, N.; Morsch, V.M.; Akindahunsi, A.A.; Oboh, G.; Schetinger, M.R. Dietary supplementation of tiger nut alters biochemical parameters relevant to erectile function in L-NAME treated rats. Food Res. Int. 2018, 109, 358–367. [Google Scholar] [CrossRef]

- Adekanmi, O.K.; Oluwatooyin, O.F.; Yemisi, A.A. Influence of processing techniques on the nutrients and antinutrients of tigernut (Cyperus esculentus L.). World J. Dairy Food Sci. 2009, 4, 88–93. [Google Scholar]

- Ekeanyanwu, R.C.; Njoku, O.; Ononogbu, I.C. The phytochemical composition and some biochemical effects of Nigerian tigernut (Cyperus esculentus L.) tuber. Pak. J. Nutr. 2010, 9, 709–715. [Google Scholar] [CrossRef]

- El-Adawy, T.A. Nutritional composition and antinutritional factors of chickpeas (Cicer arietinum L.) undergoing different cooking methods and germination. Plant Foods Hum. Nutr. 2002, 57, 83–97. [Google Scholar] [CrossRef] [PubMed]

- Ezeocha, V.; Ojimelukwe, P. The impact of cooking on the proximate composition and anti-nutritional factors of water yam (Dioscorea alata). J. Stored Prod. Postharvest Res. 2012, 3, 172–176. [Google Scholar] [CrossRef]

- Omoruyi, F.O.; Dilworth, L.; Asemota, H.N. Anti-nutritional factors, zinc, iron and calcium in some Caribbean tuber crops and the effect of boiling or roasting. Nutr. Food Sci. 2007, 37, 8–15. [Google Scholar] [CrossRef]

- Hamdy, S.M.; Shabaan, A.M.; Abdel Latif, A.K.M.; Abdel-Aziz, A.M.; Amin, A.M. Protective effect of hesperidin and tiger nut against acrylamide toxicity in female rats. Exp. Toxicol. Pathol. 2017, 69, 580–588. [Google Scholar] [CrossRef] [PubMed]

- Oladele, A.K.; Adebowale, J.O.; Bamidele, O.P. Phenolic profile and antioxidant activity of brown and yellow varieties of tigernut (Cyperus esculentus L.). Niger. Food J. 2017, 35, 51–59. [Google Scholar]

- Roselló-Soto, E.; Barba, F.J.; Lorenzo, J.M.; Munekata, P.E.S.; Gómez, B.; Moltó, J.C. Phenolic profile of oils obtained from “horchata” by-products assisted by supercritical-CO2 and its relationship with antioxidant and lipid oxidation parameters: Triple TOF-LC-MS-MS characterization. Food Chem. 2019, 274, 865–871. [Google Scholar] [CrossRef] [PubMed]

- Parker, M.L.; Ng, A.; Smith, A.C.; Waldron, K.W. Esterified phenolics of the cell walls of Chufa (Cyperus esculentus L.) tubers and their role in texture. J. Agric. Food Chem. 2000, 48, 6284–6291. [Google Scholar] [CrossRef] [PubMed]

- Kizzie-Hayford, N.; Jaros, D.; Schneider, Y.; Rohm, H. Characteristics of tiger nut milk: Effects of milling. Int. J. Food Sci. Technol. 2015, 50, 381–388. [Google Scholar] [CrossRef]

- Chalupa-Krebzdak, S.; Long, C.J.; Bohrer, B.M. Nutrient density and nutritional value of milk and plant-based milk alternatives. Int. Dairy J. 2018, 87, 84–92. [Google Scholar] [CrossRef]

- FAO/WHO. FAO expert consultation. Dietary protein quality evaluation in human nutrition. In FAO Food and Nutrition Paper; FAO/WHO: Auckland, New Zealand, 2013; Vol. 92, p. 19. ISBN 9789251074176. [Google Scholar]

- Roselló-Soto, E.; Poojary, M.M.; Barba, F.J.; Koubaa, M.; Lorenzo, J.M.; Mañes, J.; Moltó, J.C. Thermal and non-thermal preservation techniques of tiger nuts’ beverage “horchata de chufa”. Implications for food safety, nutritional and quality properties. Food Res. Int. 2018, 105, 945–951. [Google Scholar] [CrossRef] [PubMed]

- Rubert, J.; Monforte, A.; Hurkova, K.; Pérez-Martínez, G.; Blesa, J.; Navarro, J.L.; Stranka, M.; Soriano, J.M.; Hajslova, J. Untargeted metabolomics of fresh and heat treatment Tiger nut (Cyperus esculentus L.) milks reveals further insight into food quality and nutrition. J. Chromatogr. A 2017, 1514, 80–87. [Google Scholar] [CrossRef] [PubMed]

- Corona, O.; Randazzo, W.; Miceli, A.; Guarcello, R.; Francesca, N.; Erten, H.; Moschetti, G.; Settanni, L. Characterization of kefir-like beverages produced from vegetable juices. LWT Food Sci. Technol. 2016, 66, 572–581. [Google Scholar] [CrossRef]

- Septembre-Malaterre, A.; Remize, F.; Poucheret, P. Fruits and vegetables, as a source of nutritional compounds and phytochemicals: Changes in bioactive compounds during lactic fermentation. Food Res. Int. 2017. [Google Scholar] [CrossRef] [PubMed]

- Randazzo, W.; Corona, O.; Guarcello, R.; Francesca, N.; Germanà, M.A.; Erten, H.; Moschetti, G.; Settanni, L. Development of new non-dairy beverages from Mediterranean fruit juices fermented with water kefir microorganisms. Food Microbiol. 2016, 54, 40–51. [Google Scholar] [CrossRef]

- Altay, F.; Karbancıoglu-Güler, F.; Daskaya-Dikmen, C. A review on traditional Turkish fermented non-alcoholic beverages: Microbiota, fermentation process and quality characteristics. Int. J. Food Microbiol. 2013, 167, 44–56. [Google Scholar] [CrossRef] [PubMed]

- Filannino, P.; Azzi, L.; Cavoski, I.; Vincentini, O.; Rizzello, C.G.; Gobbetti, M.; Di Cagno, R. Exploitation of the health-promoting and sensory properties of organic pomegranate (Punica granatum L.) juice through lactic acid fermentation. Int. J. Food Microbiol. 2013, 163, 184–192. [Google Scholar] [CrossRef]

- Cui, X.-H.; Chen, S.-J.; Wang, Y.; Han, J.-R. Fermentation conditions of walnut milk beverage inoculated with kefir grains. LWT Food Sci. Technol. 2013, 50, 349–352. [Google Scholar] [CrossRef]

- Tabanelli, G.; Pasini, F.; Riciputi, Y.; Vannini, L.; Gozzi, G.; Balestra, F.; Caboni, M.F.; Gardini, F.; Montanari, C. Fermented nut-based vegan food: Characterization of a home made product and scale-up to an industrial pilot-scale production. J. Food Sci. 2018, 83, 711–722. [Google Scholar] [CrossRef]

- Yépez, A.; Russo, P.; Spano, G.; Khomenko, I.; Biasioli, F.; Capozzi, V.; Aznar, R. In situ riboflavin fortification of different kefir-like cereal-based beverages using selected Andean LAB strains. Food Microbiol. 2019, 77, 61–68. [Google Scholar] [CrossRef]

- Capozzi, V.; Russo, P.; Dueñas, M.T.; López, P.; Spano, G. Lactic acid bacteria producing B-group vitamins: A great potential for functional cereals products. Appl. Microbiol. Biotechnol. 2012, 96, 1383–1394. [Google Scholar] [CrossRef]

- Caggianiello, G.; Kleerebezem, M.; Spano, G. Exopolysaccharides produced by lactic acid bacteria: From health-promoting benefits to stress tolerance mechanisms. Appl. Microbiol. Biotechnol. 2016, 100, 3877–3886. [Google Scholar] [CrossRef]

- Galle, S.; Schwab, C.; Arendt, E.; Gänzle, M. Exopolysaccharide-forming Weissella strains as starter cultures for sorghum and wheat sourdoughs. J. Agric. Food Chem. 2010, 58, 5834–5841. [Google Scholar] [CrossRef] [PubMed]

- Sathe, S.J.; Nawani, N.N.; Dhakephalkar, P.K.; Kapadnis, B.P. Antifungal lactic acid bacteria with potential to prolong shelf-life of fresh vegetables. J. Appl. Microbiol. 2007, 103, 2622–2628. [Google Scholar] [CrossRef] [PubMed]

- Russo, P.; Arena, M.P.; Fiocco, D.; Capozzi, V.; Drider, D.; Spano, G. Lactobacillus plantarum with broad antifungal activity: A promising approach to increase safety and shelf-life of cereal-based products. Int. J. Food Microbiol. 2016. [Google Scholar] [CrossRef] [PubMed]

- Trias, R.; Bañeras, L.; Montesinos, E.; Badosa, E. Lactic acid bacteria from fresh fruit and vegetables as biocontrol agents of phytopathogenic bacteria and fungi. Int. Microbiol. 2008, 11, 231–236. [Google Scholar] [CrossRef]

- Min, M.; Bunt, C.R.; Mason, S.L.; Hussain, M.A. Non-dairy probiotic food products: An emerging group of functional foods. Crit. Rev. Food Sci. Nutr. 2018, 1–16. [Google Scholar] [CrossRef] [PubMed]

- Salmerón, I. Fermented cereal beverages: From probiotic, prebiotic and synbiotic towards Nanoscience designed healthy drinks. Lett. Appl. Microbiol. 2017, 65, 114–124. [Google Scholar] [CrossRef] [PubMed]

- Mridula, D.; Sharma, M. Development of non-dairy probiotic drink utilizing sprouted cereals, legume and soymilk. LWT Food Sci. Technol. 2015, 62, 482–487. [Google Scholar] [CrossRef]

- Panghal, A.; Janghu, S.; Virkar, K.; Gat, Y.; Kumar, V.; Chhikara, N. Potential non-dairy probiotic products—A healthy approach. Food Biosci. 2018, 21, 80–89. [Google Scholar] [CrossRef]

- Kandylis, P.; Pissaridi, K.; Bekatorou, A.; Kanellaki, M.; Koutinas, A.A. Dairy and non-dairy probiotic beverages. Curr. Opin. Food Sci. 2016, 7, 58–63. [Google Scholar] [CrossRef]

- Corbo, M.R.; Bevilacqua, A.; Petruzzi, L.; Casanova, F.P.; Sinigaglia, M. Functional beverages: The emerging side of functional foods. Compr. Rev. Food Sci. Food Saf. 2014, 13, 1192–1206. [Google Scholar] [CrossRef]

- Gheziel, C.; Russo, P.; Arena, M.P.; Spano, G.; Ouzari, H.-I.; Kheroua, O.; Saidi, D.; Fiocco, D.; Kaddouri, H.; Capozzi, V. Evaluating the probiotic potential of Lactobacillus plantarum strains from Algerian infant feces: Towards the design of probiotic starter cultures tailored for developing countries. Probiotics Antimicrob. Proteins 2018, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Viana de Souza, J.; Silva Dias, F. Protective, technological, and functional properties of select autochthonous lactic acid bacteria from goat dairy products. Curr. Opin. Food Sci. 2017, 13, 1–9. [Google Scholar] [CrossRef]

- Ruas-Madiedo, P.; Hugenholtz, J.; Zoon, P. An overview of the functionality of exopolysaccharides produced by lactic acid bacteria. Int. Dairy J. 2002, 12, 163–171. [Google Scholar] [CrossRef]

- Li, C.; Li, W.; Chen, X.; Feng, M.; Rui, X.; Jiang, M.; Dong, M. Microbiological, physicochemical and rheological properties of fermented soymilk produced with exopolysaccharide (EPS) producing lactic acid bacteria strains. LWT Food Sci. Technol. 2014, 57, 477–485. [Google Scholar] [CrossRef]

- Juvonen, R.; Honkapää, K.; Maina, N.H.; Shi, Q.; Viljanen, K.; Maaheimo, H.; Virkki, L.; Tenkanen, M.; Lantto, R. The impact of fermentation with exopolysaccharide producing lactic acid bacteria on rheological, chemical and sensory properties of pureed carrots (Daucus carota L.). Int. J. Food Microbiol. 2015, 207, 109–118. [Google Scholar] [CrossRef] [PubMed]

- Patel, A.; Prajapati, J. Food and health applications of exopolysaccharides produced by lactic acid bacteria. Adv. Dairy Res. 2013, 1. [Google Scholar] [CrossRef]

- Abdulkadir, M.; Danjuma, J.B. Microbial profile and nutritional quality during the fermentation of cereal based weaning food fortified with soya bean and tiger nut using starter culture. World Sci. News 2015, 24, 103–115. [Google Scholar]

- Chen, X.; Li, L.; Liu, X.; Luo, R.; Liao, G.; Li, L.; Liu, J.; Cheng, J.; Lu, Y.; Chen, Y. Oleic acid protects saturated fatty acid mediated lipotoxicity in hepatocytes and rat of non-alcoholic steatohepatitis. Life Sci. 2018, 203, 291–304. [Google Scholar] [CrossRef]

- Pimentel Duavy, S.M.; Torres Salazar, G.J.; de Oliveira Leite, A.; Ecker, A.; Vargas Barbosa, N. Effect of dietary supplementation with olive and sunflower oils on lipid profile and liver histology in rats fed high cholesterol diet. Asian Pac. J. Trop. Med. 2017, 10, 539–543. [Google Scholar] [CrossRef] [PubMed]

- Ayeh-Kumi, P.F.; Tetteh-Quarcoo, P.B.; Duedu, K.O.; Obeng, A.S.; Addo-Osafo, K.; Mortu, S.; Asmah, R.H. A survey of pathogens associated with Cyperus esculentus L (tiger nuts) tubers sold in a Ghanaian city. BMC Res. Notes 2014, 7, 343. [Google Scholar] [CrossRef] [PubMed]

- Rubert, J.; Soler, C.; Mañes, J. Occurrence of fourteen mycotoxins in tiger-nuts. Food Control 2012, 25, 374–379. [Google Scholar] [CrossRef]

- Rubert, J.; Sebastià, N.; Soriano, J.M.; Soler, C.; Mañes, J. One-year monitoring of aflatoxins and ochratoxin A in tiger-nuts and their beverages. Food Chem. 2011, 127, 822–826. [Google Scholar] [CrossRef] [PubMed]

- Sebastià, N.; El-Shenawy, M.; Mañes, J.; Soriano, J.M. Assessment of microbial quality of commercial and home-made tiger-nut beverages. Lett. Appl. Microbiol. 2012, 54, 299–305. [Google Scholar] [CrossRef] [PubMed]

- Juodeikiene, G.; Bartkiene, E.; Viskelis, P.; Urbonaviciene, D.; Eidukonyte, D.; Bobinas, C. Fermentation Processes Using Lactic Acid Bacteria Producing Bacteriocins for Preservation and Improving Functional Properties of Food Products; Petre, M., Ed.; InTech: Rijeka, Croatia, 2012; ISBN 978-953-307-820-5. [Google Scholar]

- Dalié, D.K.D.; Deschamps, A.M.; Richard-Forget, F. Lactic acid bacteria—Potential for control of mould growth and mycotoxins: A review. Food Control 2010, 21, 370–380. [Google Scholar] [CrossRef]

- Chiocchetti, G.M.; Jadán-Piedra, C.; Monedero, V.; Zúñiga, M.; Vélez, D.; Devesa, V. Use of lactic acid bacteria and yeasts to reduce exposure to chemical food contaminants and toxicity. Crit. Rev. Food Sci. Nutr. 2018, 1–12. [Google Scholar] [CrossRef]

- Sõukand, R.; Pieroni, A.; Biró, M.; Dénes, A.; Dogan, Y.; Hajdari, A.; Kalle, R.; Reade, B.; Mustafa, B.; Nedelcheva, A.; et al. An ethnobotanical perspective on traditional fermented plant foods and beverages in Eastern Europe. J. Ethnopharmacol. 2015, 170, 284–296. [Google Scholar] [CrossRef]

- Wouters, D.; Grosu-Tudor, S.; Zamfir, M.; De Vuyst, L. Bacterial community dynamics, lactic acid bacteria species diversity and metabolite kinetics of traditional Romanian vegetable fermentations. J. Sci. Food Agric. 2013, 93, 749–760. [Google Scholar] [CrossRef]

- Padonou, W.S.; Nielsen, D.S.; Hounhouigan, J.D.; Thorsen, L.; Nago, M.C.; Jakobsen, M. The microbiota of Lafun, an African traditional cassava food product. Int. J. Food Microbiol. 2009, 133, 22–30. [Google Scholar] [CrossRef]

- Peng, Q.; Jiang, S.; Chen, J.; Ma, C.; Huo, D.; Shao, Y.; Zhang, J. Unique Microbial Diversity and Metabolic Pathway Features of Fermented Vegetables from Hainan, China. Front. Microbiol. 2018, 9, 399. [Google Scholar] [CrossRef] [PubMed]

- Wuyts, S.; Van Beeck, W.; Oerlemans, E.F.M.; Wittouck, S.; Claes, I.J.J.; De Boeck, I.; Weckx, S.; Lievens, B.; De Vuyst, L.; Lebeer, S. Carrot juice fermentations as man-made microbial ecosystems dominated by lactic acid bacteria. Appl. Environ. Microbiol. 2018, 84. [Google Scholar] [CrossRef] [PubMed]

- Beganović, J.; Kos, B.; Leboš Pavunc, A.; Uroić, K.; Jokić, M.; Šušković, J. Traditionally produced sauerkraut as source of autochthonous functional starter cultures. Microbiol. Res. 2013. [Google Scholar] [CrossRef] [PubMed]

- Di Cagno, R.; Surico, R.F.; Paradiso, A.; De Angelis, M.; Salmon, J.-C.; Buchin, S.; De Gara, L.; Gobbetti, M. Effect of autochthonous lactic acid bacteria starters on health-promoting and sensory properties of tomato juices. Int. J. Food Microbiol. 2009, 128, 473–483. [Google Scholar] [CrossRef] [PubMed]

- Fessard, A.; Bourdon, E.; Payet, B.; Remize, F. Identification, stress tolerance, and antioxidant activity of lactic acid bacteria isolated from tropically grown fruits and leaves. Can. J. Microbiol. 2016, 62, 550–561. [Google Scholar] [CrossRef]

- Capozzi, V.; Fragasso, M.; Romaniello, R.; Berbegal, C.; Russo, P.; Spano, G.; Capozzi, V.; Fragasso, M.; Romaniello, R.; Berbegal, C.; et al. Spontaneous food fermentations and potential risks for human health. Fermentation 2017, 3, 49. [Google Scholar] [CrossRef]

| Compound | Concentration | Ref. |

|---|---|---|

| Apigenin | 7.91–50.58 mg GAE/100 g | [48] |

| Caffeic acid | 1.07–15.25 mg GAE/100 g | [48] |

| 3.90–102.19 µg RE/kg | [49] | |

| (Epi)Catechin | 8.83 × 10−4 − 6.58 mg GAE/100 g | [48] |

| Cinnamic acid | 0–40.66 µg RE/kg | [49] |

| Coumaric acid | 0-6801.0 µg/g | [50] |

| 4.20 × 10−4 − 17.25 mg GAE/100 g | [48] | |

| 0–126.76 µg RE/kg | [49] | |

| Ferulic acid | 3.5–2,284 µg/g | [50] |

| 33.79–58.38 mg GAE/100 g | [48] | |

| 0–22.33 µg RE/kg | [49] | |

| Diferulic acid | 0.0–829.0 µg/g | [50] |

| Ferulic acid-4-O-glucoside | 0–46.95 µg RE/kg | [49] |

| Gallic acid | 3.95 × 10−3 − 1.74 mg GAE/100 g | [48] |

| Homovanillyl alcohol | 0–4.54 µg RE/kg | [49] |

| p-Hydroxybenzaldehyde | 0–16.47 mg GAE/100 g | [48] |

| 4.0–337.0 µg/g | [50] | |

| p-Hydroxybenzoic acid | 0–8.3 µg/g | [50] |

| 2.18–29.12 mg GAE/100 g | [48] | |

| 2.52–67.70 µg RE/kg | [49] | |

| Isohydroxymatairesinol | 0–1331.45 | [49] |

| Kaempferol | 3.62–24.44 mg GAE/100 g | [48] |

| Luteolin | 7.29–72.17 mg GAE/100 g | [48] |

| 24-Methylcholestanol ferulate | 0–45.40 µg RE/kg | [49] |

| Naringenin | 2.38 × 10−3 − 16.16 mg GAE/100 g | [48] |

| Peonidin | 0–7.81 µg RE/kg | [49] |

| Protocatechuic acid | 0.61–0.79 mg GAE/100 g | [48] |

| Quercetin | 3.76 × 10−3-60.63 mg GAE/100 g | [48] |

| trans-Resveratrol-3-O-glucoside | 0–25.68 µg RE/kg | [49] |

| Scopoletin | 0–310.80 µg RE/kg | [49] |

| Sesamin | 0-28.67 µg RE/kg | [49] |

| Sinapinic acid | 8.53 × 10−1 − 20.97 mg GAE/100 g | [48] |

| Sinensetin | 0–16.07 µg RE/kg | [49] |

| Syringic acid | 4.58 × 10−4 − 4.12 mg GAE/100 g | [48] |

| Vanillic acid | 3.0–25.3 µg/g | [50] |

| 5.88–15.20 mg GAE/100 g | [48] | |

| 0–10.84 µg RE/kg | [49] | |

| Vanillin | 15.5–68.7 µg/g | [50] |

| ethyl Vanillin | 0–25.38 µg RE/kg | [49] |

| 4-Vinylphenol | 0–1084.48 µg RE/kg | [49] |

| Nutrient | Tiger Nut Tuber (g/100g) a | Horchata De Chufa (g/100g) a | Tiger Nut Beverage (g/100g) | |

|---|---|---|---|---|

| Total fat | 24.49 | 3.09 | 1.26–1.59 b | 1.88–2.27 c |

| SFA (% total fatty acid) | 17.5 | |||

| MUFA (% total fatty acid) | 72.9 | |||

| PUFA (% total fatty acid) | 9.3 | |||

| Ratio n-6/n-3 | 22 | |||

| Proteins | 5.04 | 0.91 | 2.34–2.51 b | 0.47–0.54 c |

| Ash | 1.7 | 0.25 | 0.31–0.39 b | 0.16–0.18 c |

| Carbohydrates | 43.3 | nd | 1.93–2.34 b | 2.31–2.74 c |

| Total dietary fiber | 8.91 | 1.03 | 0.23–0.31 b | 0.53–0.65 c |

| Sucrose | 13.03 | >10 | ||

| Total energy (kcal/100g) | 413.8 | >71.45 | 28.42–33.71 b | 28.04–33.55 c |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Roselló-Soto, E.; Garcia, C.; Fessard, A.; Barba, F.J.; Munekata, P.E.S.; Lorenzo, J.M.; Remize, F. Nutritional and Microbiological Quality of Tiger Nut Tubers (Cyperus esculentus), Derived Plant-Based and Lactic Fermented Beverages. Fermentation 2019, 5, 3. https://doi.org/10.3390/fermentation5010003

Roselló-Soto E, Garcia C, Fessard A, Barba FJ, Munekata PES, Lorenzo JM, Remize F. Nutritional and Microbiological Quality of Tiger Nut Tubers (Cyperus esculentus), Derived Plant-Based and Lactic Fermented Beverages. Fermentation. 2019; 5(1):3. https://doi.org/10.3390/fermentation5010003

Chicago/Turabian StyleRoselló-Soto, Elena, Cyrielle Garcia, Amandine Fessard, Francisco J. Barba, Paulo E. S. Munekata, Jose M. Lorenzo, and Fabienne Remize. 2019. "Nutritional and Microbiological Quality of Tiger Nut Tubers (Cyperus esculentus), Derived Plant-Based and Lactic Fermented Beverages" Fermentation 5, no. 1: 3. https://doi.org/10.3390/fermentation5010003

APA StyleRoselló-Soto, E., Garcia, C., Fessard, A., Barba, F. J., Munekata, P. E. S., Lorenzo, J. M., & Remize, F. (2019). Nutritional and Microbiological Quality of Tiger Nut Tubers (Cyperus esculentus), Derived Plant-Based and Lactic Fermented Beverages. Fermentation, 5(1), 3. https://doi.org/10.3390/fermentation5010003