Abstract

Whole-plant corn silage is a critical feedstuff in global ruminant production, and its nutrient composition is closely tied to harvest timing. As starch acts as the primary energy source in silage-based diets, investigating changes in starch degradation rate provides a theoretical basis for optimizing the efficient utilization of whole-plant corn and its silage in ruminant production. In this study, whole-plant corn (harvested from the milk stage to full ripening stage) and its corresponding silage were used as experimental materials. An in vitro simulated rumen fermentation system was employed to determine the contents of starch, prolamin, amylose, and amylopectin in the samples. The results showed that with delayed harvest time, starch content in both whole-plant corn and its silage increased significantly; prolamin and amylose contents first decreased, then increased; amylopectin content first rose significantly before decreasing; and both starch disappearance rate and speed exhibited a trend of first increasing, then decreasing. After silage fermentation, the silage had significant increases in starch, amylose, and amylopectin contents, and starch disappearance rate; prolamin content decreased; and starch disappearance speed increased extremely significantly. This study indicates that whole-plant corn harvest time and silage fermentation regulate the ruminal starch degradation pattern by altering starch structure, prolamin content, and the proportion of rapidly degradable starch.

1. Introduction

With the rapid increase in the number of livestock and poultry globally, the problem of competition for grain between humans and livestock is becoming increasingly serious, and animal husbandry is also being affected. The development of animal husbandry is limited by the supply of high-quality silage [1]. Silage technology can greatly alleviate shortages of coarse feed resources in the breeding process [2]. It is therefore widely used and able to preserve green feed well [3]. Whole-plant corn silage is widely used in ruminant production because it has a high nutritional value and good animal palatability [4]. High-quality whole-plant corn silage can not only improve the health of ruminants but also improve the economic benefits of breeding [5].

The main nutritional value of corn silage comes from starch, and its starch utilization efficiency is affected by the structure of the starch [6]. The starch structure of corn silage is affected by the harvesting time of raw materials and the fermentation effect of silage, which further affects the degradation rate of starch in the rumen [7]. During corn growth, starch accumulates continuously and its structure optimizes steadily over time [8]. From the milk stage to the dough stage, starch synthesis and metabolism are highly active: the proportion of amylopectin increases gradually, and starch granules arrange more tightly—both of which enhance the stability of the starch structure [9]. Silage fermentation also exerts a crucial effect. In an anaerobic environment, microorganisms such as lactic acid bacteria proliferate extensively, and the enzymes they secrete can modify starch structure (e.g., hydrolyzing partial glycosidic bonds and altering the amylose-to-amylopectin ratio), thereby influencing the ruminal starch degradation rate [10]. At the same time, the harvest time also affects the starch structure and gliadin content of corn, thus also affecting its rumen disappearance rate [11]. As harvest timing is delayed, the prolamin content in corn kernels increases. Prolamin binds tightly to starch granules, forming starch–protein complexes—analogous to a “protective layer” surrounding starch granules. This binding impedes the access of rumen microorganisms to starch and their subsequent degradation of it, thereby reducing the ruminal starch disappearance rate [12]. At present, the research on starch structure is limited to the influence of internal nutrition structure, unrelated to in vitro fermentation. Therefore, it is of great significance to explore the influencing factors of the starch disappearance rate of whole-plant corn and whole-plant corn silage to make effective use of whole-plant corn and whole-plant corn silage in livestock production.

We hypothesize that the starch structure of whole-plant corn is altered by harvest timing and silage fermentation, and that this modified starch structure can directly influence the ruminal starch degradation rate. In this study, the starch content, gliadin content, amylopectin content, disappearance rate, and rumen dynamic degradation parameters of whole-plant corn silage collected at different harvest times were studied using the wet chemistry method and simulated rumen fermentation system in vitro, which provided a theoretical basis for the effective utilization of whole-plant corn silage in livestock production.

2. Materials and Methods

2.1. Experiment Design

A 2 × 5 full-factor design was adopted in this experiment. Factor 1 was the type of whole-plant corn (raw material and silage), and factor 2 was the harvest time. Silage corn (variety Liangyu 99) was planted in Changchun City, Jilin Province, China, in 2023. Based on the maturity of whole-plant corn, the experiment was performed on 1 September (milk stage), 8 September (early dough stage), 15 September (mid-dough stage), 20 September (late dough stage), and September 25 (full ripening stage) at a stubble height of 40 cm. For each harvest, 20 plants were randomly selected through multipoint random sampling. After cutting took place using the whole-plant corn cutter (Changchun, China) and whole-plant corn was crushed to about 2 cm in length, multipoint sampling was carried out, and then random sampling was performed using the quartering method. Half of the samples were reserved as raw materials, and the other half were sprayed with Lactobacillus plantarum (Borui Science and Technology Co., Ltd., Changchun, China) and then fermented in a 1L PVC small tank for 60 days, and the compaction density was 800 kg/m3. After fermentation, the silage samples were mixed for the subsequent in vitro simulated rumen fermentation test. Samples were taken at 0, 3, 6, 12, 24, 48, and 72 h after culture. For each harvest time of whole-plant corn and whole-plant corn silage, three repetitions were set at different in vitro culture time points for subsequent disappearance rate determination.

2.2. Test Animals and Diet Formulation

Rumen fluid was given to three male small-tailed Han sheep (40 ± 2.5 kg) with permanent rumen fistulae. All of the experimental animals were quarantined, fed in a single cage, and allowed to drink freely. The collection of rumen fluid is carried out before morning feeding. The diet formula is shown in Table 1. All of the animal test procedures were performed according to the Guidelines for the Care and Use of Experimental Animals of Jilin Agricultural University (JLAU-ACUC2023-012). This test refers to the China Meat Sheep Feeding Standard (NY/T816-2004) [13], and the formula is shown in Table 1.

Table 1.

Dietary formula and nutritional composition (%DM).

2.3. In Vitro Rumen Fermentation

Rumen fluid was collected evenly from the rumen of the fistulated sheep using a rigid PVC tube before morning feeding on the day of the experiment. The collected rumen fluid was filtered through four layers of filter mesh into a thermos (preheated to 39 °C) for later use. The buffer solution was prepared in advance following the method described by Menke (1979) [14], and CO2; was bubbled through it until a color change occurred, after which it was set aside for use. The sampling site was in close proximity to the laboratory, and the experiment was carried out immediately after sampling.

We evenly mixed the filtered rumen fluid and buffer solution in a ratio of 1:2 and continuously introduced CO2 for 1 min. Then, we added 120 mL of mixed fermentation solution into each in vitro culture flask and continuously introduced CO2 for 30 s, immediately closed the bottle cap, and then put it into a constant-temperature air bath incubator (Shanghai Hetian Scientific Instruments Co., Ltd. for cultivation, Shanghai, China) (39 °C, 80 rpm).

2.4. Determination Index and Method

2.4.1. Nutrient Index Content, Starch Disappearance Rate, and Disappearance Rate

Crude protein (CP) was determined using the Kelvin method [15]. The in vitro dry matter disappearance rate (IVDMD) and in vitro starch disappearance rate (IVStarchD) were calculated using the formulas outlined by Huang [16] and DeFeo [17], respectively.

2.4.2. Dynamic Degradation Model of Rumen

Ørskov [18] proposed the rumen dynamic degradation model of feed:

Deg (t) = a + b(1 − e−ct)

Among these parameters, Deg (t) represents the degradation rate of rumen dry matter or specific nutrients in feed samples after t hours of incubation in the rumen. This indicator directly reflects the extent to which feed is decomposed and utilized by rumen microorganisms at a specific incubation time point, and serves as a core observed value for evaluating the degradation characteristics of feed. In this formula, a represents the fast degradation fraction (%). Its determination is typically achieved through correction using the “0-hour degradation rate”: After placing the feed sample in a rumen nylon bag, the bag is immediately retrieved and processed following the same rinsing and drying procedures as applied to other incubation time points. The measured dry matter loss rate from this process represents the a value. b represents the slow degradation fraction (%). It is calculated as “the potential maximum degradation rate (a + b) minus the rapidly degradable fraction (a)”. The potential maximum degradation rate is derived from model fitting after extending the incubation time (typically 72–96 h, until the degradation rate no longer changes significantly). c represents the degradation rate of b (%/h). This parameter is obtained by fitting the measured degradation rates at different incubation time points (e.g., 3, 6, 12, 24, 48, and 72 h; the specific time points should be adjusted based on feed type and pre-experiment results) through nonlinear regression analysis. t represents the incubation time of feed in the rumen (h).

The model accurately describes the disappearance rate of feed ingredients at various time points and is widely used.

2.4.3. Gliadin, Amylopectin, and Amylose Content

The content of relevant indicators in the sample was determined using an immunosorbent assay (Enzyme-linked Biotech Co., Ltd., Shanghai, China); we followed the assay’s instructions for use. The core principle of the determination is the “double-antibody sandwich method”, which is based on the specific binding reaction between antigen and antibody, as well as the enzyme-catalyzed color reaction.

2.5. Data Statistics and Analysis

The relationship between the two factors was analyzed using general linear models in IBM SPSS Statistics 23 software. A statistical analysis model (Yijk = μ + Fi + Vj + Fi × Vj + eijk) was used to analyze different harvesting times and silage fermentation and their interaction. Duncan’s multiple comparison method was used to test the significance of factors 1 and 2 and their interaction (factor 1 × factor 2). p < 0.05 was considered significant, and p < 0.01 was considered extremely significant.

3. Results

3.1. Starch and Structural Nutrient Content of Whole-Plant Corn and Whole-Plant Corn Silage

As can be seen in Table 2, when the harvest time was delayed, the dry matter content and the protein and starch content of whole-plant corn and whole-plant corn silage significantly increased and then decreased (p < 0.01), and the starch content of whole-plant corn silage after undergoing silage fermentation was significantly higher than that of whole-plant corn (p < 0.01). The gliadin content first decreased and then increased. After silage fermentation, the gliadin content of whole-plant corn silage was significantly lower than that of whole-plant corn on 15 September, 20 September, and September 25 (p < 0.01). The amylopectin content first increased and then decreased significantly (p < 0.01). The amylopectin content in whole-plant corn silage after undergoing silage fermentation was significantly higher than that in whole-plant corn (p < 0.01). The amylose content first decreased and then increased significantly (p < 0.01). The amylose content in whole-plant corn silage was significantly higher than that in whole-plant corn silage (p < 0.01). Additionally, the contents of various nutrients were significantly affected by the interaction between silage fermentation and harvesting time (p < 0.01).

Table 2.

Nutrient content of whole-plant corn and whole-plant corn silage (%DM).

3.2. In Vitro Dry Matter Disappearance Rate of Whole-Plant Corn and Whole-Plant Corn Silage

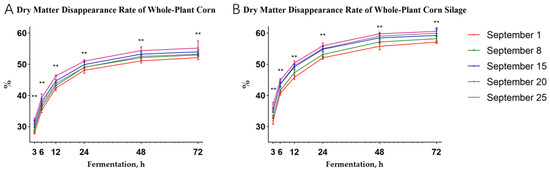

As shown in Figure 1, the dry matter disappearance rate of whole-plant corn and whole-plant corn silage first increased and then decreased along with harvesting time. The dry matter disappearance rate of whole-plant corn harvested on 20 September was significantly higher than that harvested at 3 h, 6 h, 12 h, and 24 h (p < 0.01), and the dry matter disappearance rate of whole-plant corn silage harvested on 20 September was significantly higher than that harvested at 3 h and 6 h (p < 0.01). The dry matter disappearance rate of whole-plant corn silage after undergoing silage fermentation was significantly higher than that of whole-plant corn (p < 0.01). Moreover, the dry matter disappearance rate in vitro was significantly affected by the interaction between silage fermentation and harvesting time (p < 0.05).

Figure 1.

Dry matter disappearance rate of whole-plant corn and whole-plant corn silage (%). (A) Dry matter disappearance rate of whole-plant corn; (B) dry matter disappearance rate of whole-plant corn silage. Note: ** indicates an extremely significant difference (p < 0.01).

3.3. In Vitro Starch Disappearance Rate of Whole-Plant Corn and Whole-Plant Corn Silage

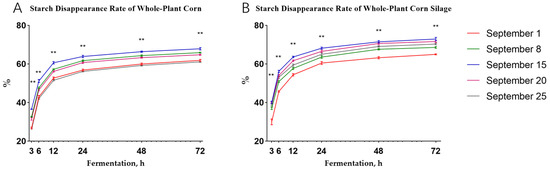

As shown in Figure 2, the starch disappearance rate of whole-plant corn and whole-plant corn silage first increased and then decreased significantly along with the delay in the harvest time (p < 0.01). The starch disappearance rate of whole-plant corn and whole-plant corn silage tended to be stable after 24 h. After silage fermentation, the starch disappearance rate of whole-plant corn silage was significantly higher than that of whole-plant corn (p < 0.01). Furthermore, the starch disappearance rate in vitro was significantly affected by the interaction between silage fermentation and harvest time (p < 0.01).

Figure 2.

Starch disappearance rate of whole-plant corn and whole-plant corn silage (%). (A) Starch disappearance rate of whole-plant corn; (B) starch disappearance rate of whole-plant corn silage. Note: ** indicates an extremely significant difference (p < 0.01).

3.4. Starch Disappearance Speed of Whole-Plant Corn and Whole-Plant Corn Silage

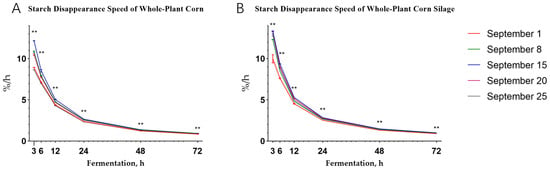

As shown in Figure 3, the starch disappearance speed of whole-plant corn and whole-plant corn silage first increased and then decreased significantly along with the delay in harvest time (p < 0.01). The starch disappearance speed of whole-plant corn and whole-plant corn silage tended to be stable after 24 h. After silage fermentation, the starch disappearance speed of whole-plant corn silage was significantly higher than that of whole-plant corn (p < 0.01). The starch disappearance speed was significantly affected by the interaction between silage fermentation and harvest time (p < 0.01).

Figure 3.

Starch disappearance speed of whole-plant corn and whole-plant corn silage (%/h). (A) Starch disappearance speed of whole-plant corn; (B) starch disappearance speed of whole-plant corn silage. Note: ** indicates an extremely significant difference (p < 0.01).

3.5. Dynamic Degradation Parameters of Whole-Plant Corn and Whole-Plant Corn Silage Starch in Rumen

It can be seen from Table 3 that with the delay in harvesting time, the starch rapid degradation parameter a of whole-plant corn shows a trend of increasing first and then decreasing, and the starch rapid degradation parameter a of whole-plant corn silage generally shows a trend of increasing. The starch slow degradation parameter b of whole-plant corn shows a trend of first decreasing and then increasing, and the starch slow degradation parameter b of whole-plant corn silage generally shows a trend of decreasing. The starch degradation parameter c of whole-plant maize had no obvious change trend. After silage fermentation, the fast degradation parameter a of starch in whole-plant corn silage increased, while the slow degradation parameter b and degradation parameter c decreased.

Table 3.

Dynamic degradation parameters of starch in whole-plant corn and whole-plant corn silage in rumen.

3.6. Loss Rate of Gliadin in Whole-Plant Corn and Whole-Plant Corn Silage

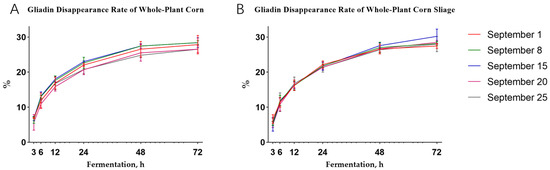

As shown in Figure 4, the gliadin disappearance rate of whole-plant corn and whole-plant corn silage did not change significantly with the delay in harvesting time (p > 0.05), but they generally showed a trend of first decreasing and then increasing. There was no significant difference in the gliadin disappearance rate between whole-plant corn and whole-plant corn silage (p > 0.05).

Figure 4.

Gliadin disappearance rate of whole-plant corn and whole-plant corn silage (%). (A) Gliadin disappearance rate of whole-plant corn; (B) gliadin disappearance rate of whole-plant corn silage.

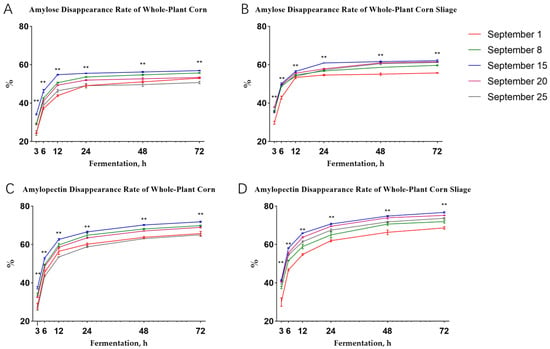

3.7. Loss Rate of Amylose and Amylopectin in Whole-Plant Corn and Whole-Plant Corn Silage

As can be seen from Figure 5, the amylose disappearance rate and amylopectin disappearance rate of whole-plant corn and whole-plant corn silage showed a significant trend of first increasing and then decreasing with the delay in harvesting time (p < 0.01). The disappearance rate of amylose and amylopectin in whole-plant corn silage was significantly higher than that in whole-plant corn (p < 0.01). The disappearance rate was significantly affected by the interaction between silage fermentation and harvesting time (p < 0.01).

Figure 5.

Amylose and amylopectin disappearance rate of whole-plant corn and whole-plant corn silage (%). (A) Amylose disappearance rate of whole-plant corn; (B) amylose disappearance rate of whole-plant corn silage; (C) amylopectin disappearance rate of whole-plant corn; (D) amylopectin disappearance rate of whole-plant corn silage. Note: ** indicates an extremely significant difference (p < 0.01).

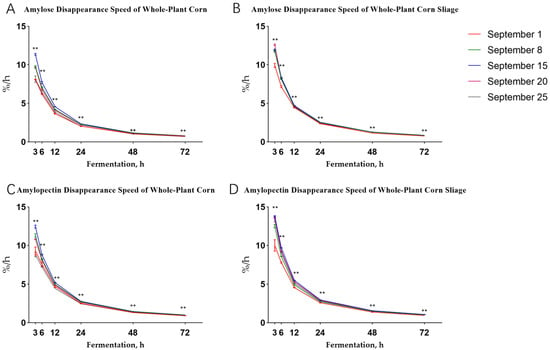

3.8. Loss Speed of Amylose and Amylopectin in Whole-Plant Corn and Whole-Plant Corn Silage

As shown in Figure 6, the disappearance speed of amylose and amylopectin in whole-plant corn and whole-plant corn silage first increased and then decreased significantly with the delay in harvesting time (p < 0.01). The disappearance speed of amylose and amylopectin in whole-plant corn silage was significantly higher than that in whole-plant corn (p < 0.01). The disappearance speed was significantly affected by the interaction between silage fermentation and harvesting time (p < 0.01).

Figure 6.

Amylose and amylopectin disappearance speed of whole-plant corn and whole-plant corn silage (%/h). (A) Amylose disappearance speed of whole-plant corn; (B) amylose disappearance speed of whole-plant corn silage; (C) amylopectin disappearance speed of whole-plant corn; (D) amylopectin disappearance speed of whole-plant corn silage. Note: ** indicates an extremely significant difference (p < 0.01).

3.9. Degradation Parameters of Amylose and Amylopectin in Rumen of Whole-Plant Corn and Whole-Plant Corn Silage

As can be seen in Table 4, with the delay in harvesting time, the amylose rapid degradation parameter a of whole-plant corn generally shows a downward trend, while the rapid degradation parameter a of whole-plant corn silage generally shows an increasing trend. The slow degradation parameter b and degradation parameter c of whole-plant corn generally show an increasing trend, and the slow degradation parameter b and degradation parameter c of whole-plant corn silage generally show a downward trend. After silage fermentation, the rapid degradation parameter a of whole-plant corn silage increased, the slow degradation parameter b decreased, and the degradation parameter c decreased, but this change trend was small. The amylopectin degradation parameter a of whole-plant corn first increased and then decreased, and the rapid degradation parameter a of whole-plant corn silage showed an overall increase. The slow degradation rate parameter b of whole-plant corn first decreased and then increased, the slow degradation rate parameter b of whole-plant corn silage decreased, and the degradation parameter c of whole-plant corn and whole-plant corn silage decreased. After silage fermentation, the amylose degradation parameter a increased, while the amylose degradation parameter b and amylose degradation parameter c decreased. The fast degradation parameter a of amylopectin increased, the slow degradation parameter b decreased, and the degradation parameter c decreased.

Table 4.

Dynamic degradation parameters of amylose and amylopectin in whole-plant corn and whole-plant corn silage in rumen.

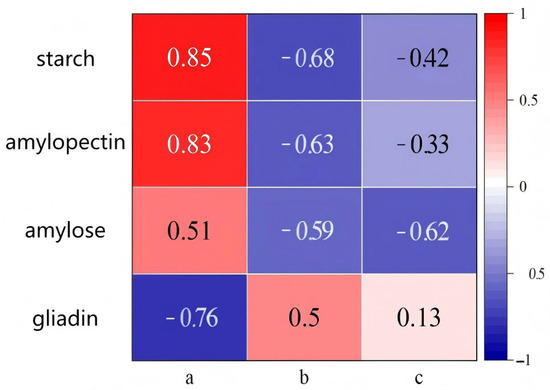

3.10. Correlation Analysis

It can be seen in Figure 7 that the starch content and starch structure in whole-plant corn and whole-plant corn silage are positively correlated with the rapid starch degradation parameter a, but the gliadin content is negatively correlated with the rapid starch degradation parameter a. Among them, the starch content and amylopectin content have positive correlation coefficients of 0.85 and 0.83, but the gliadin content has a negative correlation coefficient of −0.76. The starch content and starch structure in whole-plant corn and whole-plant corn silage showed a negative correlation with the starch slow degradation parameter b, the gliadin content showed a positive correlation with the starch slow degradation parameter b, and the gliadin content showed a weak positive correlation. Among them, the starch content and amylopectin content had strong negative correlation coefficients of −0.68 and −0.63, and the gliadin content had a weak positive correlation coefficient of 0.50. The degradation parameter c was negatively correlated with the starch content, amylose content, and amylopectin content. The amylose content had a negative correlation coefficient of −0.62 with the degradation parameter c.

Figure 7.

Correlation analysis of starch content, structure, and gliadin content of whole-plant corn and whole-plant corn silage with rumen degradation parameters.

4. Discussion

The harvest time of corn affects its maturity, which directly affects its nutrient content [19]. When harvest time is delayed, corn seeds mature, starch deposition in the seeds continues, and the starch content increases [20]. In this experiment, the starch content of whole-plant corn and whole-plant corn silage reached the highest value on 15 September and then gradually decreased. When the whole-plant corn reached the mature stage, the fiber content gradually increased, and the starch content was also lower than that in the wax mature stage [21]. The whole-plant corn gradually reached the mature stage from 20 September to September 25, so its starch content was lower than that on 15 September. Harvesting at the right time is key to ensuring a high utilization rate of silage corn [22]. In this experiment, the starch disappearance rate of whole-plant corn and whole-plant corn silage first increased and then decreased with the delay in harvesting time, and the starch disappearance rate of whole-plant corn and whole-plant corn silage reached the highest values on 15 September; these findings are the same as those of Bal, M.A. [23] et al. With the delay in harvest time, the starch content in whole-plant corn and whole-plant corn silage increased, which promoted the synthesis of microbial synthetic protein in the rumen, resulting in an increase in the rumen disappearance rate of starch [24]. With the delay in harvest time, the parameters a and c of starch rapid degradation first increased and then decreased, while the parameter b of starch slow degradation increased gradually. The results showed that the proportion of easily degradable components was higher at the initial stage of maize nutrient accumulation, and with the further increase in maturity, the change in the maize tissue structure led to an increase in degradation resistance, an increase in the proportion of slow degradable components, and a decrease in the proportion of fast degradable components. With the accumulation of the nutrient contents of whole-plant corn and whole-plant corn silage, the slow degradation components decreases, but with the further accumulation of nutrients, it reaches a certain ripening degree, the structural characteristics of the starch change, degradation is inhibited, and its slow degradation components begin to gradually rise [25].

Gliadin can bind to starch to form a protective film, reducing its digestion rate [26]. The removal of gliadin can result in a porous structure being formed on the surface of starch, which can significantly improve its in vitro fermentation characteristics [27]. In this experiment, the gliadin content of whole-plant corn and whole-plant corn silage first decreased and then increased with the delay in harvest time, and the disappearance rate also first decreased and then increased. In this experiment, the content of gliadin in whole-plant corn and whole-plant corn silage decreased in the early harvest stage, and the inhibition of starch degradation decreased. In the late harvest stage, the content of gliadin increased, the binding amount of gliadin and starch increased, and the starch disappearance rate decreased. The content of gliadin in whole-plant corn is higher than that in whole-plant corn silage, which proves that the silage process will destroy and degrade the gliadin structure and make the starch disappearance rate of whole-plant corn silage higher than that of whole-plant corn. This result is the same as the research results of Xu, H [28] and Dehghan-Banadaky M [29]. The disappearance rate of gliadin in the rumen was inversely proportional to the disappearance rate of starch in the rumen, indicating that gliadin could affect the digestibility of starch in the rumen. In addition, gliadin can improve the gel texture characteristics of starch. Zein can attach to the surface of starch molecules, hinder the aggregation and rearrangement of amylose molecules in starch, and make it difficult for water molecules to bind to starch molecules, thus affecting the functional structure of starch [30]. Amylopectin also exhibits a higher degradation rate in the rumen, a specialized digestive environment. The rumen hosts a large community of microorganisms that secrete various hydrolases, and the branched structure of amylopectin renders it a more susceptible target for degradation by these rumen microorganisms [31]. Amylopectin is more easily digested than amylose and consumed more in rumen digestion. In this experiment, the ratio of amylopectin/amylose decreased; this is the same result as that found by Srichuwong et al. [32]. This proportional change may directly impact the energy supply efficiency of whole-plant corn silage. Specifically, amylopectin exhibits high ruminal degradability; thus, a reduction in its relative proportion decreases the “rapid energy-supplying fraction” in the silage, which could prolong the overall starch degradation cycle in the ruminant rumen [33]. Amylose has a “binding” effect on amylopectin. With the increase in the amylose content, the “binding” effect also increases, meaning that amylopectin cannot be fully stretched [34], resulting in a low disappearance rate of amylopectin in early-stage in vitro fermentation. With the delay in harvest time, the rumen starch disappearance rate showed the same change rule as amylopectin but the opposite change rule to amylose. Amylose is generally interspersed with amylopectin during starch granule formation, preventing it from binding to digestive enzymes and reducing starch degradation [35]. In this experiment, the disappearance rate of amylose and amylopectin first increased and then decreased with the delay in harvest time. The amylose and amylopectin content of starch is the main factor determining the starch properties of plants [36]. The delay in harvest time leads to an increase in maize maturity, which affects its amylose and amylopectin content and then affects the degradation rate.

The starch content and starch structure in whole-plant corn and whole-plant corn silage showed a positive correlation with the starch rapid degradation parameter a, whereas gliadin showed a negative correlation with the starch rapid degradation parameter a. The correlation coefficients between the starch content and amylopectin content and rapid degradation parameter a were 0.85 and 0.83, showing a strong positive correlation, indicating that the amylopectin content accounted for more of the effect of the starch content on the rapid degradation parameter a. Due to the special branch structure of amylopectin, amylopectin is easier to digest and improves the starch digestion rate [37], so it has a greater impact on the rapid degradation parameter a. There was a negative correlation between the starch content and starch structure and the starch slow degradation parameter b and a positive correlation between gliadin and the starch slow degradation parameter b. The starch content and amylopectin content had a strong negative correlation with the slow degradation parameter b, indicating that the higher the starch content and amylopectin content, the lower the slow degradation parameter b, and the higher the gliadin content, the higher the slow degradation parameter b and the lower the degradation rate. The degradation parameter c was negatively correlated with the starch content, amylose content, and amylopectin content. The amylose content had a great negative effect on the degradation parameter c, which indicates that the higher the amylose content, the lower the degradation parameter c. Because amylose had a strong negative correlation with the slow degradation parameter b, this affected the degradation parameter c. The correlation coefficient between gliadin and the degradation parameter c was low, indicating that gliadin only had a small effect on the degradation parameter c. In conclusion, the higher the starch content and amylopectin content in whole-plant corn and whole-plant corn silage, the higher the starch disappearance rate; the higher the amylose content, the lower the starch disappearance rate. Gliadin only had a small effect on the starch disappearance rate.

5. Conclusions

Silage fermentation can increase the amylopectin content in whole-plant corn starch, increase the proportion of rapidly degradable starch, reduce the gliadin content, and increase the rumen disappearance rate and the disappearance rate of whole-plant corn silage starch. The deposition of starch and gliadin in corn starch with different structures changed along with different harvest times, which led to the rumen degradation of whole-plant corn silage starch changing along with harvest time.

Author Contributions

L.Z.: writing—original draft, data curation, software, validation, visualization. S.L. (Shiqin Liu): writing—review and editing, resources. L.Z.: writing—review and editing, investigation. X.W.: writing—review and editing, investigation. H.W.: writing—formal analysis, methodology. S.L. (Songze Li): writing—formal analysis, methodology. Y.Z.: writing—review and editing, investigation, funding acquisition. X.Z.: writing—review and editing, supervision. L.Z.: writing—review and editing, formal analysis, methodology. X.Z.: writing—funding acquisition, supervision. X.Z.: writing—review and editing, formal analysis, methodology. X.Z.: resources. All authors have read and agreed to the published version of the manuscript.

Funding

This study was partially supported by the National Key Research and Development Program of China (2023YFD1300905).

Institutional Review Board Statement

The animal study protocol was approved by the animal care committee of Jilin Agricultural University (protocol code: JLAU-ACUC2023-012 and date of approval: 12 December 2023).

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding authors.

Conflicts of Interest

Authors Yuguo Zhen and Xuefeng Zhang are employed by the company “Changchun Borui Science & Technology Co., Ltd.”, but for the purposes of this investigation, there was no financing relationship with the company; therefore, there are no conflicts of interest. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| IVDMD | In vitro dry matter disappearance rate |

| DM | Dry matter content |

| CP | Crude protein content |

| Sta | Starch content |

| Gli | Gliadin content |

| AP | Amylopectin content |

| AS | Amylose content |

| A | Rapid degradation parameter a |

| B | Slow degradation parameter b |

| C | Degradation parameter c |

References

- Lv, X.; Chen, L.; Zhou, C.; Zhang, G.; Xie, J.; Kang, J.; Tan, Z.; Tang, S.; Kong, Z.; Liu, Z.; et al. Application of Different Proportions of Sweet Sorghum Silage as a Substitute for Corn Silage in Dairy Cows. Food Sci. Nutr. 2023, 11, 3575–3587. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhao, X.; Chen, W.; Zhou, Z.; Meng, Q.; Wu, H. Effects of Adding Various Silage Additives to Whole Corn Crops at Ensiling on Performance, Rumen Fermentation, and Serum Physiological Characteristics of Growing-Finishing Cattle. Animals 2019, 9, 695. [Google Scholar] [CrossRef] [PubMed]

- Wilkinson, J.M.; Rinne, M. Highlights of Progress in Silage Conservation and Future Perspectives. Grass Forage Sci. 2018, 73, 40–52. [Google Scholar] [CrossRef]

- Rojas-Bourrillon, A.; Russell, J.R.; Trenkle, A.; McGilliard, A.D. Effects of Rolling on the Composition and Utilization by Growing Steers of Whole-Plant Corn Silage. J. Anim. Sci. 1987, 64, 303–311. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, G.; Wu, H.; Meng, Q.; Khan, M.Z.; Zhou, Z. Effect of Hybrid Type on Fermentation and Nutritional Parameters of Whole Plant Corn Silage. Animals 2021, 11, 1587. [Google Scholar] [CrossRef]

- Johnson, L.; Harrison, J.H.; Hunt, C.; Shinners, K.; Doggett, C.G.; Sapienza, D. Nutritive Value of Corn Silage as Affected by Maturity and Mechanical Processing: A Contemporary Review. J. Dairy Sci. 1999, 82, 2813–2825. [Google Scholar] [CrossRef]

- Peyrat, J.; Nozière, P.; Le Morvan, A.; Férard, A.; Protin, P.V.; Baumont, R. Effects of Ensiling Maize and Sample Conditioning on in Situ Rumen Degradation of Dry Matter, Starch and Fibre. Anim. Feed Sci. Technol. 2014, 196, 12–21. [Google Scholar] [CrossRef]

- Ferraretto, L.F.; Crump, P.M.; Shaver, R.D. Effect of Ensiling Time and Exogenous Protease Addition to Whole-Plant Corn Silage of Various Hybrids, Maturities, and Chop Lengths on Nitrogen Fractions and Ruminal in Vitro Starch Digestibility. J. Dairy Sci. 2015, 98, 8869–8881. [Google Scholar] [CrossRef]

- Hasjim, J.; Srichuwong, S.; Scott, M.P.; Jane, J. Kernel Composition, Starch Structure, and Enzyme Digestibility of Opaque-2 Maize and Quality Protein Maize. J. Agric. Food Chem. 2009, 57, 2049–2055. [Google Scholar] [CrossRef]

- Campling, R.C. The Feeding Value of Maize: A Review. Ann. Appl. Biol. 1977, 87, 284–290. [Google Scholar] [CrossRef]

- de Souza, A.M.; Neumann, M.; Rampim, L.; de Almeida, E.R.; Matchula, A.F.; Cristo, F.B.; Faria, M.V. Effect of Storage Time on the Chemical Composition of Whole and Grainless Corn Plant Silage Harvested at Different Maturity Stages. Rev. Bras. Zootec. 2022, 51, e20200180. [Google Scholar] [CrossRef]

- Kljak, K.; Grbeša, D.; Duvnjak, M. The Effect of Ensiling on the Starch Digestibility Rate of Rehydrated Grain Silages in Pigs Depends on the Hardness of the Maize Hybrid. Agriculture 2025, 15, 783. [Google Scholar] [CrossRef]

- NY/T816-2004; Chinese Feeding Standard for Mutton Sheep. China Agricultural Press: Beijing, China, 2004.

- Menke, K.H.; Raab, L.; Salewski, A.; Steingass, H.; Fritz, D.; Schneider, W. The Estimation of the Digestibility and Metabolizable Energy Content of Ruminant Feedingstuffs from the Gas Production When They Are Incubated with Rumen Liquor in Vitro. J. Agric. Sci. 1979, 93, 217–222. [Google Scholar] [CrossRef]

- Kirk, P.L. Kjeldahl Method for Total Nitrogen. Available online: https://pubs.acs.org/doi/pdf/10.1021/ac60038a038 (accessed on 16 July 2025).

- Huang, Z.; Urriola, P.E.; Shurson, G.C. Use of in Vitro Dry Matter Digestibility and Gas Production to Predict Apparent Total Tract Digestibility of Total Dietary Fiber for Growing Pigs. J. Anim. Sci. 2017, 95, 5474–5484. [Google Scholar] [CrossRef] [PubMed]

- DeFeo, M.E.; Shampoe, K.V.; Carvalho, P.H.V.; Silva, F.A.S.; Felix, T.L. In Vitro and in Situ Techniques Yield Different Estimates of Ruminal Disappearance of Barley. Transl. Anim. Sci. 2020, 4, 141–148. [Google Scholar] [CrossRef]

- Ørskov, E.R. The in Situ Technique for the Estimation of Forage Degradability in Ruminants. In Forage Evaluation in Ruminant Nutrition; CABI Books: Wallingford, UK, 2000; pp. 175–188. ISBN 978-0-85199-344-7. [Google Scholar]

- Russell, J.R. Influence of Harvest Date on the Nutritive Value and Ensiling Characteristics of Maize Stover. Anim. Feed Sci. Technol. 1986, 14, 11–27. [Google Scholar] [CrossRef]

- Xie, Z.L.; Zhang, T.F.; Chen, X.Z.; Li, G.D.; Zhang, J.G. Effects of Maturity Stages on the Nutritive Composition and Silage Quality of Whole Crop Wheat. Asian-Australas. J. Anim. Sci. 2012, 25, 1374–1380. [Google Scholar] [CrossRef]

- Johnson, L.M.; Harrison, J.H.; Davidson, D.; Mahanna, W.C.; Shinners, K.; Linder, D. Corn Silage Management: Effects of Maturity, Inoculation, and Mechanical Processing on Pack Density and Aerobic Stability. J. Dairy Sci. 2002, 85, 434–444. [Google Scholar] [CrossRef]

- Ferraretto, L.F.; Shaver, R.D.; Luck, B.D. Silage Review: Recent Advances and Future Technologies for Whole-Plant and Fractionated Corn Silage Harvesting. J. Dairy Sci. 2018, 101, 3937–3951. [Google Scholar] [CrossRef]

- Bal, M.A.; Shaver, R.D.; Shinners, K.J.; Coors, J.G.; Lauer, J.G.; Straub, R.J.; Koegel, R.G. Stage of Maturity, Processing, and Hybrid Effects on Ruminal in Situ Disappearance of Whole-Plant Corn Silage. Anim. Feed Sci. Technol. 2000, 86, 83–94. [Google Scholar] [CrossRef]

- Cui, Y.; Liu, H.; Gao, Z.; Xu, J.; Liu, B.; Guo, M.; Yang, X.; Niu, J.; Zhu, X.; Ma, S.; et al. Whole-Plant Corn Silage Improves Rumen Fermentation and Growth Performance of Beef Cattle by Altering Rumen Microbiota. Appl. Microbiol. Biotechnol. 2022, 106, 4187–4198. [Google Scholar] [CrossRef] [PubMed]

- Philippeau, C.; Landry, J.; Michalet-Doreau, B. Influence of the Protein Distribution of Maize Endosperm on Ruminal Starch Degradability. J. Sci. Food Agric. 2000, 80, 404–408. [Google Scholar] [CrossRef]

- Seifried, N.; Steingaß, H.; Schipprack, W.; Rodehutscord, M. Variation in Ruminal in Situ Degradation of Crude Protein and Starch from Maize Grains Compared to in Vitro Gas Production Kinetics and Physical and Chemical Characteristics. Arch. Anim. Nutr. 2016, 70, 333–349. [Google Scholar] [CrossRef]

- Zadeike, D.; Gaizauskaite, Z.; Svazas, M.; Gruzauskas, R.; Gruzauskas, V.; Damasius, J.; Juodeikiene, G. Application of Solid-State Fermentation for the Improving of Extruded Corn Dry-Milling By-Products and Their Protein Functional Properties. Life 2022, 12, 1909. [Google Scholar] [CrossRef]

- Xu, H.; Zhou, J.; Liu, X.; Yu, J.; Copeland, L.; Wang, S. Methods for Characterizing the Structure of Starch in Relation to Its Applications: A Comprehensive Review. Crit. Rev. Food Sci. Nutr. 2023, 63, 4799–4816. [Google Scholar] [CrossRef] [PubMed]

- Dehghan-banadaky, M.; Corbett, R.; Oba, M. Effects of Barley Grain Processing on Productivity of Cattle. Anim. Feed Sci. Technol. 2007, 137, 1–24. [Google Scholar] [CrossRef]

- Huang, M.; Li, L.; Cheng, X.; Qiu, R.; Wang, Y.; Zhou, X.; Zong, X. Study on the Influence Mechanism of Endogenous Protein Components on the Characteristics of Distiller’s Grains Starch. Food Chem. 2025, 486, 144689. [Google Scholar] [CrossRef]

- Piao, M.; Hu, F.; Kong, F.; Liu, Y.; Wang, S.; Cui, K.; Sun, T.; Diao, Q.; Tu, Y. Effects of Dietary Amylose to Amylopectin Ratio on Growth Performance, Carcass Quality Characteristics and Meat Fatty Acids in Chinese Qinchuan Cattle. J. Integr. Agric. 2021, 20, 3256–3269. [Google Scholar] [CrossRef]

- Srichuwong, S.; Sunarti, T.C.; Mishima, T.; Isono, N.; Hisamatsu, M. Starches from Different Botanical Sources I: Contribution of Amylopectin Fine Structure to Thermal Properties and Enzyme Digestibility. Carbohydr. Polym. 2005, 60, 529–538. [Google Scholar] [CrossRef]

- Zhao, F.; Ren, W.; Zhang, A.; Jiang, N.; Liu, W.; Wang, F. Effects of Different Amylose to Amylopectin Ratios on Rumen Fermentation and Development in Fattening Lambs. Asian-Australas. J. Anim. Sci. 2018, 31, 1611–1618. [Google Scholar] [CrossRef]

- Yan, X.; Wu, Z.-Z.; Li, M.-Y.; Yin, F.; Ren, K.-X.; Tao, H. The Combined Effects of Extrusion and Heat-Moisture Treatment on the Physicochemical Properties and Digestibility of Corn Starch. Int. J. Biol. Macromol. 2019, 134, 1108–1112. [Google Scholar] [CrossRef]

- Stevnebø, A.; Sahlström, S.; Svihus, B. Starch Structure and Degree of Starch Hydrolysis of Small and Large Starch Granules from Barley Varieties with Varying Amylose Content. Anim. Feed Sci. Technol. 2006, 130, 23–38. [Google Scholar] [CrossRef]

- French, D. Chemical and Physical Properties of Starch. J. Anim. Sci. 1973, 37, 1048–1061. [Google Scholar] [CrossRef]

- Zhu, F. Relationships between Amylopectin Internal Molecular Structure and Physicochemical Properties of Starch. Trends Food Sci. Technol. 2018, 78, 234–242. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).