Electro-Composting: An Emerging Technology

Abstract

1. Introduction

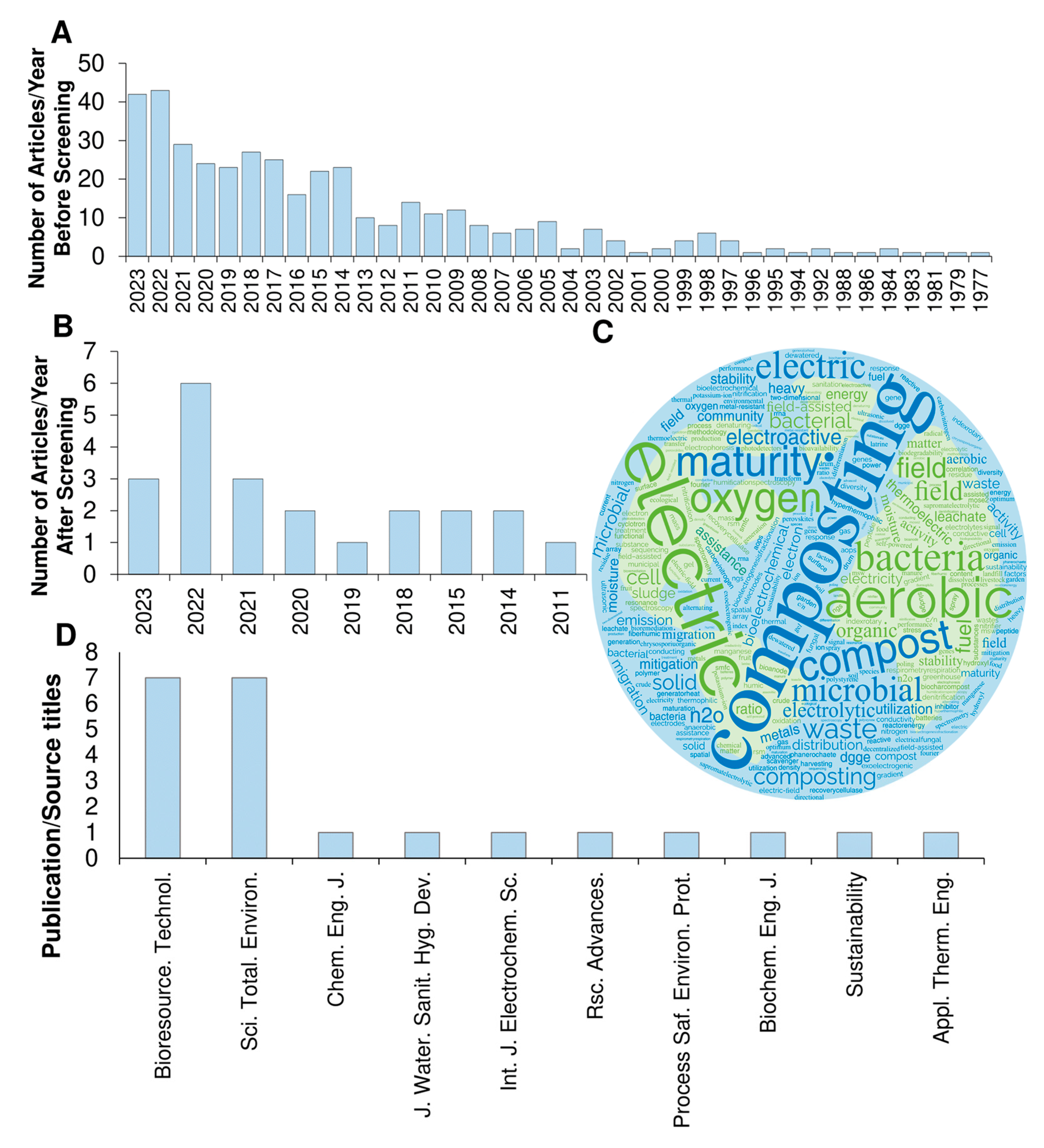

2. Materials and Methods

3. Results and Discussion

3.1. Electric Field-Assisted Aerobic Composting (EAAC)

3.1.1. Materials for the EAAC Setup

3.1.2. Design of EAAC Composters

3.1.3. Operating Conditions During EAAC

3.1.4. Temperature Evolution During EAAC

3.1.5. Compost Maturity in EAAC

3.1.6. Microbial Communities in EAAC

3.1.7. Major Impacts of EAAC

3.1.8. Comparative Evaluation of EAAC

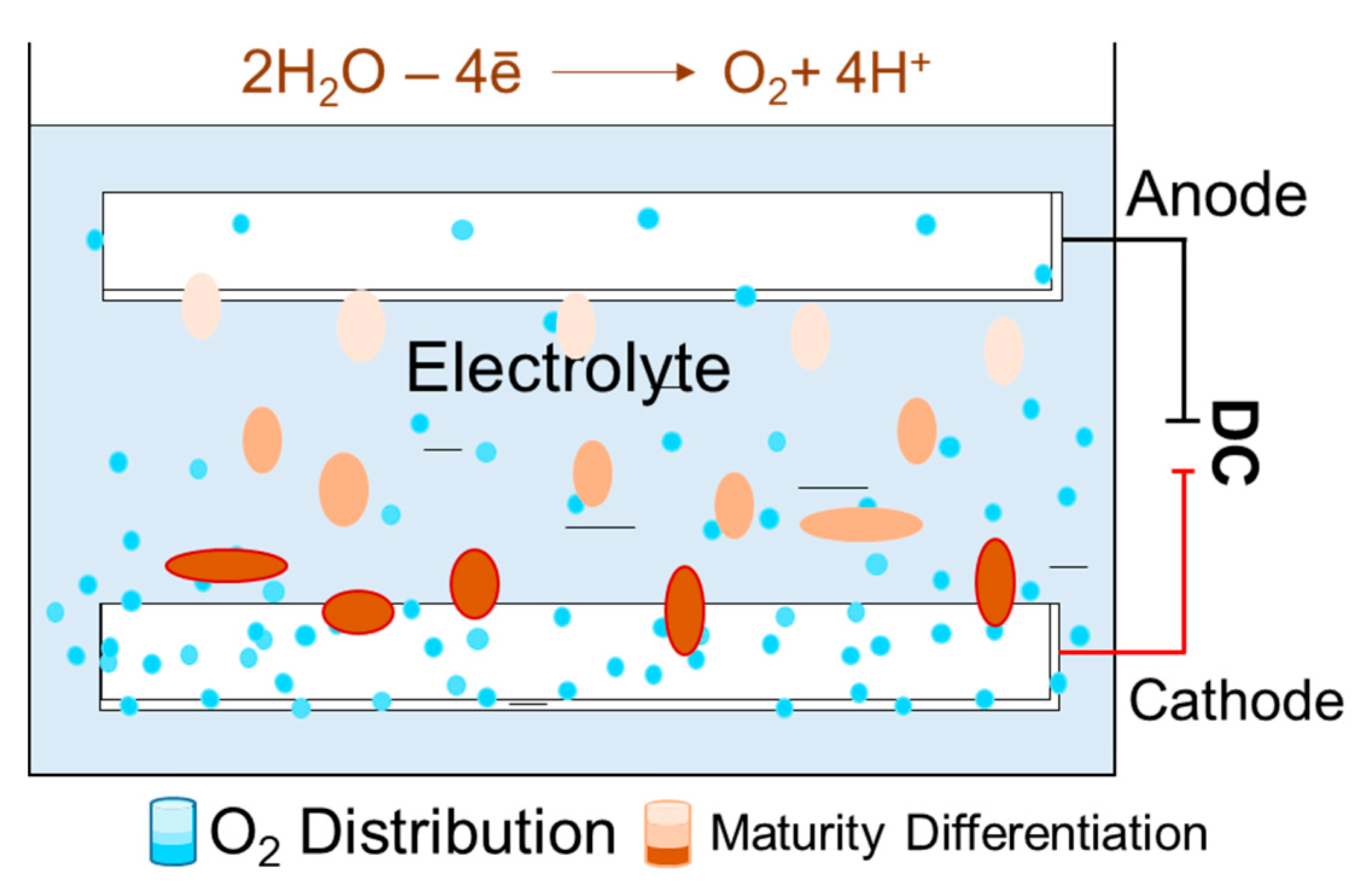

3.2. Electrolytic Oxygen Aerobic Composting (EOAC)

3.2.1. Materials for the Setup of EOAC

3.2.2. Design of EOAC Composters

3.2.3. Operating Conditions During EOAC

3.2.4. Temperature Evolution During EOAC

3.2.5. Compost Maturity in EOAC

3.2.6. Microbial Community of EOAC

3.2.7. Major Impacts of EOAC

3.2.8. Comparative Evaluation of EOAC

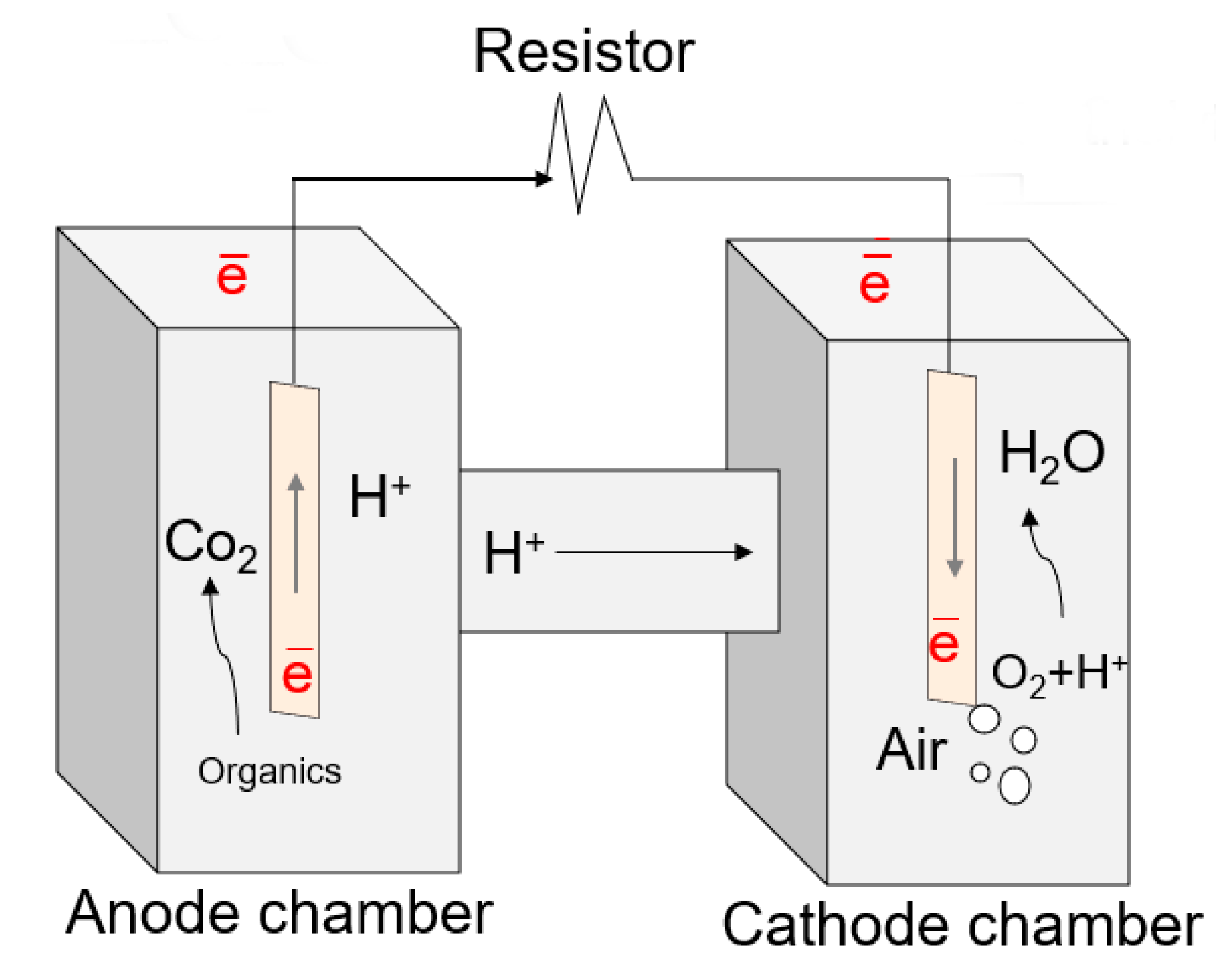

3.3. Microbial Fuel Cells (MFCs)

3.3.1. Materials for the Setup of Compost MFCs

3.3.2. Design of MFC Composters

3.3.3. Operating Conditions in Compost MFCs

3.3.4. Temperature Evolution in Compost MFCs

3.3.5. Maturity in Compost MFCs

3.3.6. Microbial Community of Compost MFCs

3.3.7. Major Impacts of MFCs

3.3.8. Comparative Evaluation of MFCs

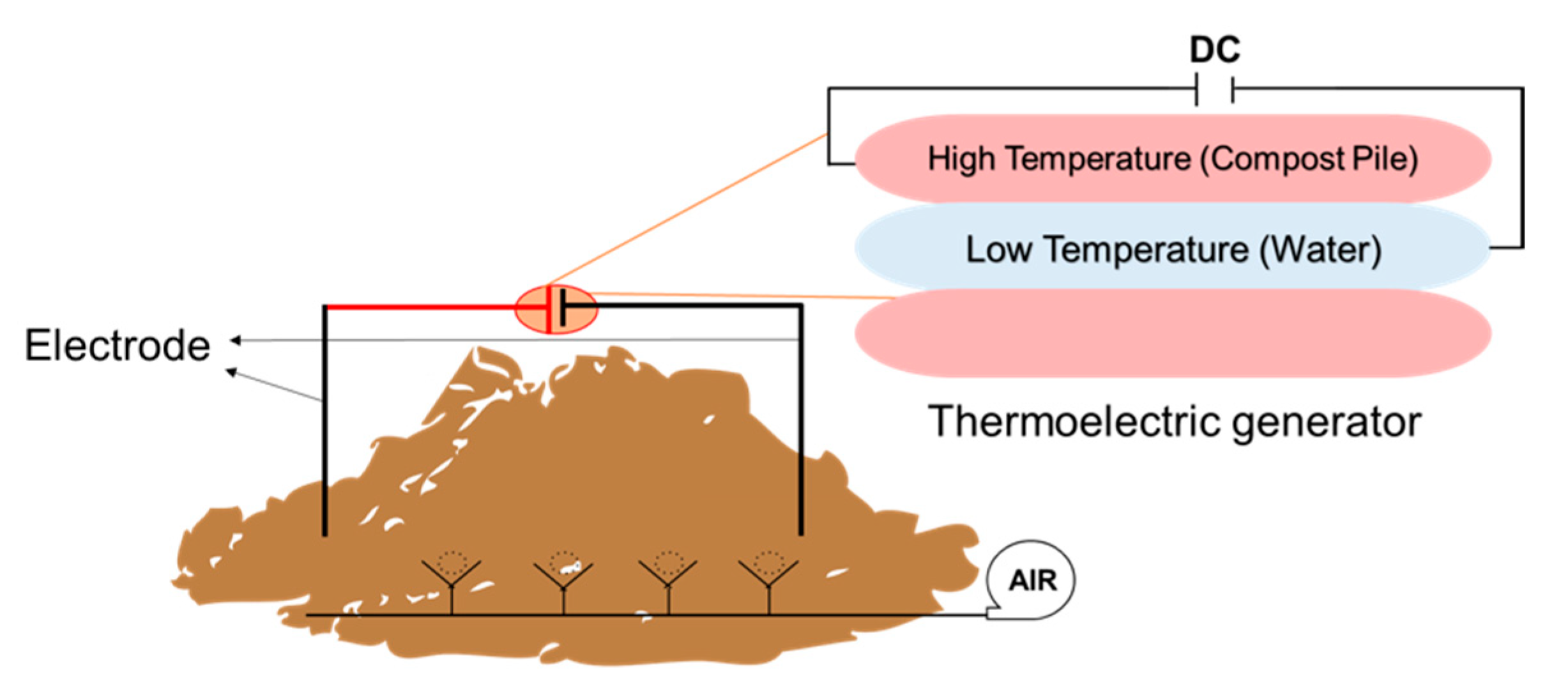

3.4. Thermoelectric Generators (TEGs)

3.4.1. Materials for the Setup of TEGs

3.4.2. Design of TEG Composters

3.4.3. Operating Conditions During TEGs

3.4.4. Temperature Evolution During TEGs

3.4.5. Compost Maturity in TEGs

3.4.6. Microbial Community of TEGs

3.4.7. Major Impacts of TEGs

3.4.8. Comparative Evaluation of TEGs

3.5. Three-Chamber Bioelectrochemically Assisted Anaerobic Composting (AnCBE, III)

3.5.1. Important Materials for the Setup of AnCBE, III

3.5.2. Design of the AnCBE, III Composter

3.5.3. Operating Conditions During AnCBE, III

3.5.4. Temperature Evolution During AnCBE, III

3.5.5. Compost Maturity in AnCBE, III

3.5.6. Microbial Community of AnCBE, III

3.5.7. Major Impacts of AnCBE, III

3.5.8. Comparative Evaluation of AnCBE, III

3.6. Comparative Performance Evaluation of Electro-Composting Systems

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cao, Y.; Wang, X.; Zhang, X.; Misselbrook, T.; Bai, Z.; Ma, L. Nitrifier denitrification dominates nitrous oxide production in composting and can be inhibited by a bioelectrochemical nitrification inhibitor. Bioresour. Technol. 2021, 341, 125851. [Google Scholar] [CrossRef]

- Fu, T.; Tang, J.; Wu, J.; Shen, C.; Shangguan, H.; Zeng, R.J.; Zhou, S. Alternating electric field enables hyperthermophilic composting of organic solid wastes. Sci. Total. Environ. 2022, 828, 154439. [Google Scholar] [CrossRef]

- Tang, J.; Li, X.; Zhao, W.; Wang, Y.; Cui, P.; Zeng, R.J.; Yu, L.; Zhou, S. Electric field induces electron flow to simultaneously enhance the maturity of aerobic composting and mitigate greenhouse gas emissions. Bioresour. Technol. 2019, 279, 234–242. [Google Scholar] [CrossRef] [PubMed]

- Cao, Y.; Wang, X.; Zhang, X.; Misselbrook, T.; Bai, Z.; Ma, L. An electric field immobilizes heavy metals through promoting combination with humic substances during composting. Bioresour. Technol. 2021, 330, 124996. [Google Scholar] [CrossRef] [PubMed]

- Cao, Y.; Wang, X.; Zhang, X.; Misselbrook, T.H.; Bai, Z.; Wang, H.; Ma, L. The effects of electric field assisted composting on ammonia and nitrous oxide emissions varied with different electrolytes. Bioresour. Technol. 2022, 344, 126194. [Google Scholar] [CrossRef]

- Tang, J.; Li, X.; Cui, P.; Lin, J.; Zeng, R.J.; Lin, H.; Zhou, S. Nitrification plays a key role in N2O emission in electric-field assisted aerobic composting. Bioresour. Technol. 2020, 297, 122470. [Google Scholar] [CrossRef] [PubMed]

- Fu, T.; Shangguan, H.; Shen, C.; Mi, H.; Wu, J.; Li, L.; Tang, J.; Zeng, R.J.; Zhou, S. Moisture migration driven by the electric field causes the directional differentiation of compost maturity. Sci. Total. Environ. 2022, 811, 152415. [Google Scholar] [CrossRef]

- Wang, C.-T.; Lee, Y.-C.; Liao, F.-Y. Effect of Composting Parameters on the Power Performance of Solid Microbial Fuel Cells. Sustainability 2015, 7, 12634–12643. [Google Scholar] [CrossRef]

- Pant, D.; Van Bogaert, G.; Diels, L.; Vanbroekhoven, K. A review of the substrates used in microbial fuel cells (MFCs) for sustainable energy production. Bioresour. Technol. 2010, 101, 1533–1543. [Google Scholar] [CrossRef]

- Moqsud, M.A.; Omine, K.; Yasufuku, N.; Hyodo, M.; Nakata, Y. Microbial fuel cell (MFC) for bioelectricity generation from organic wastes. Waste Manag. 2013, 33, 2465–2469. [Google Scholar] [CrossRef]

- Shangguan, H.; Fu, T.; Wu, J.; Tang, J.; Zeng, R.J.; Zhou, S. Use of an in situ thermoelectric generator for electric field-assisted aerobic composting. Sci. Total. Environ. 2020, 742, 140618. [Google Scholar] [CrossRef]

- Mengist, W.; Soromessa, T.; Legese, G. Ecosystem services research in mountainous regions: A systematic literature review on current knowledge and research gaps. Sci. Total. Environ. 2020, 702, 134581. [Google Scholar] [CrossRef] [PubMed]

- Mi, H.; Shen, C.; Ding, T.; Zheng, X.; Tang, J.; Lin, H.; Zhou, S. Identifying the role of array electrodes in improving the compost quality of food waste during electric field-assisted aerobic composting. Bioresour. Technol. 2023, 388, 129763. [Google Scholar] [CrossRef]

- He, Y.; Lin, R.; Yu, X.; Ma, Y.; Li, J.; Xie, L. Simultaneous enhancement on lignocellulose degradation and humic acid formation using the electric field coupled with an iron anode in the co-composting of food waste and agricultural waste. Chem. Eng. J. 2023, 475, 145846. [Google Scholar] [CrossRef]

- Fu, T.; Shangguan, H.; Wu, J.; Tang, J.; Yuan, H.; Zhou, S. Insight into the synergistic effects of conductive biochar for accelerating maturation during electric field-assisted aerobic composting. Bioresour. Technol. 2021, 337, 125359. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Zhao, Y.; Xu, A.; Chang, H.; Lin, G.; Li, R. Conductive biochar promotes oxygen utilization to inhibit greenhouse gas emissions during electric field-assisted aerobic composting. Sci. Total. Environ. 2022, 842, 156929. [Google Scholar] [CrossRef]

- Li, X.; Wang, S.; Zhao, S.; Chang, H.; Li, Y.; Zhao, Y. Effects of an assistive electric field on heavy metal passivation during manure composting. Sci. Total. Environ. 2023, 901, 165909. [Google Scholar] [CrossRef]

- Shangguan, H.; Fu, T.; Shen, C.; Mi, H.; Wei, J.; Tang, J.; Zhou, S. In situ generated oxygen distribution causes maturity differentiation during electrolytic oxygen aerobic composting. Sci. Total. Environ. 2022, 850, 157939. [Google Scholar] [CrossRef]

- Wei, J.; Shangguan, H.; Shen, C.; Mi, H.; Liu, X.; Fu, T.; Tang, J.; Zhou, S. Deciphering the structural characteristics and molecular transformation of dissolved organic matter during the electrolytic oxygen aerobic composting process. Sci. Total. Environ. 2022, 845, 157174. [Google Scholar] [CrossRef]

- Castro, C.J.; Goodwill, J.E.; Rogers, B.; Henderson, M.; Butler, C.S. Deployment of the microbial fuel cell latrine in Ghana for decentralized sanitation. J. Water Sanit. Hyg. Dev. 2014, 4, 663–671. [Google Scholar] [CrossRef]

- Wang, X.; Tang, J.; Cui, J.; Liu, Q.; Giesy, J.P.; Hecker, M. Synergy of Electricity Generation and Waste Disposal in SolidState Microbial Fuel Cell (MFC) of Cow Manure Composting. Int. J. Electrochem. Sci. 2014, 9, 3144–3157. [Google Scholar] [CrossRef]

- Sugimoto, Y.; Tashima, D.; Asano, Y. A simple method to harness DC (direct current) electrical energy generated by bacterial activity. Process. Saf. Environ. Prot. 2011, 89, 323–326. [Google Scholar] [CrossRef]

- Nandy, A.; Kumar, V.; Khamrai, M.; Kundu, P.P. MFC with vermicompost soil: Power generation with additional importance of waste management. RSC Adv. 2015, 5, 41300–41306. [Google Scholar] [CrossRef]

- Rodrigues, C.R.S.; Machado, T.; Pires, A.L.; Chaves, B.; Carpinteiro, F.S.; Pereira, A.M. Recovery of thermal energy released in the composting process and their conversion into electricity utilizing thermoelectric generators. Appl. Therm. Eng. 2018, 138, 319–324. [Google Scholar] [CrossRef]

- Yu, H.; Jiang, J.; Zhao, Q.; Kabutey, F.T.; Zhang, Y.; Wang, K.; Lee, D.-J. Enhanced electricity generation and organic matter degradation during three-chamber bioelectrochemically assisted anaerobic composting of dewatered sludge. Biochem. Eng. J. 2018, 133, 196–204. [Google Scholar] [CrossRef]

| Search Terms | Result |

|---|---|

| compost* AND electrode | 399 |

| compost* AND “electric field” | 48 |

| compost* AND electrolyte | 221 |

| compost* AND “fuel cell” | 104 |

| compost* AND “electrical current” | 16 |

| compost* AND “microbial stimulation” | 9 |

| compost* AND electrostatic | 111 |

| compost* AND MFC | 64 |

| compost* AND bioelectrochemical | 26 |

| compost* AND “electr* bacteria” | 7 |

| compost* AND “electro catalyst” | 3 |

| compost* AND electrically evoked | 7 |

| compost* AND electrification | 5 |

| compost* AND electromagnetic | 142 |

| compost* AND “Electro* Biofilm” | 4 |

| compost* AND electro-based | 2 |

| compost* AND electrotechnology | 1 |

| Parameter | EAAC | EOAC |

|---|---|---|

| Composting Efficiency | High: 33% reduction in composting time and enhanced humification, 28% higher HI, and 38% higher GI [3,7] | High: Enhanced oxygenation and degradation rate [19] |

| Energy Use | Moderate: Requires external DC power (2–10 V) [3] | High: Requires continuous electrolysis for O2 production [19] |

| GHG Emissions (CO2, CH4, N2O) | Reduced CH4 and N2O by up to 75.5% [1] | Significantly lower CH4 and CO2 emissions due to optimal oxygenation [18] |

| Economic Costs | Moderate initial investment but low operating costs [3] | High capital costs, but moderate operating costs [18] |

| Operational Complexity | Medium, requires electrode maintenance and controlled aeration [4] | High, complex setup with electrolysis equipment [18] |

| Composting Temperature | 65–91 °C | 60–84 °C |

| System Type | Aerobic | Aerobic |

| Oxygen Control | Electrode-driven oxygen boost | In situ oxygen via electrolysis |

| Energy Recovery | None | None |

| Electrodes Used | Yes | Yes |

| Parameter | MFC | TEG | AnCBE, III |

|---|---|---|---|

| Composting Efficiency | Moderate: COD removal up to 66%, C/N ratio = 31.4:1, moisture = 60% [8,23] | Moderate: GI improved from 107% to 118% in 15 days [11] | High: 42.3% TOC removal in 42 days, surpassing AnCBE, II [25] |

| Energy Use | Low: Generates energy rather than consuming it [23] | Low: Compost heat is converted to electricity [24,25] | High: Requires energy for microbial stimulation [25] |

| GHG Emissions (CO2, CH4, N2O) | CO2 reduction due to microbial metabolism, minor CH4, and N2O impact [20] | Neutral impact, does not alter microbial metabolism [11] | Potential to mitigate CH4 emissions due to microbial electron transfer [25] |

| Economic Costs | Moderate initial investment, low operational costs [20] | High cost due to thermoelectric material requirements [11] | High capital costs, and specialised materials increase expenses [25] |

| Operational Complexity | High, requires optimised moisture levels and has limited scalability [22] | Medium, scalable, but requires temperature control [24] | A high, complex system with multiple chambers and membranes [25] |

| Composting Temperature | 30–60 °C | 55–80 °C | 35–55 °C |

| System Type | Hybrid anaerobic–aerobic | Aerobic | Anaerobic |

| Oxygen Control | None | Not applicable | Anaerobic; oxygen excluded |

| Energy Recovery | Electricity and biogas | Electrical via thermoelectricity | Biogas |

| Electrodes Used | Yes | No | Yes |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hozad, A.S.; Abendroth, C. Electro-Composting: An Emerging Technology. Fermentation 2025, 11, 401. https://doi.org/10.3390/fermentation11070401

Hozad AS, Abendroth C. Electro-Composting: An Emerging Technology. Fermentation. 2025; 11(7):401. https://doi.org/10.3390/fermentation11070401

Chicago/Turabian StyleHozad, Ahmad Shabir, and Christian Abendroth. 2025. "Electro-Composting: An Emerging Technology" Fermentation 11, no. 7: 401. https://doi.org/10.3390/fermentation11070401

APA StyleHozad, A. S., & Abendroth, C. (2025). Electro-Composting: An Emerging Technology. Fermentation, 11(7), 401. https://doi.org/10.3390/fermentation11070401