Advancing Sparkling Wine in the 21st Century: From Traditional Methods to Modern Innovations and Market Trends

Abstract

1. Historical Background

2. Raw Materials and Base Wine Production

2.1. Grapes Characteristics

2.2. The Base Wine Production

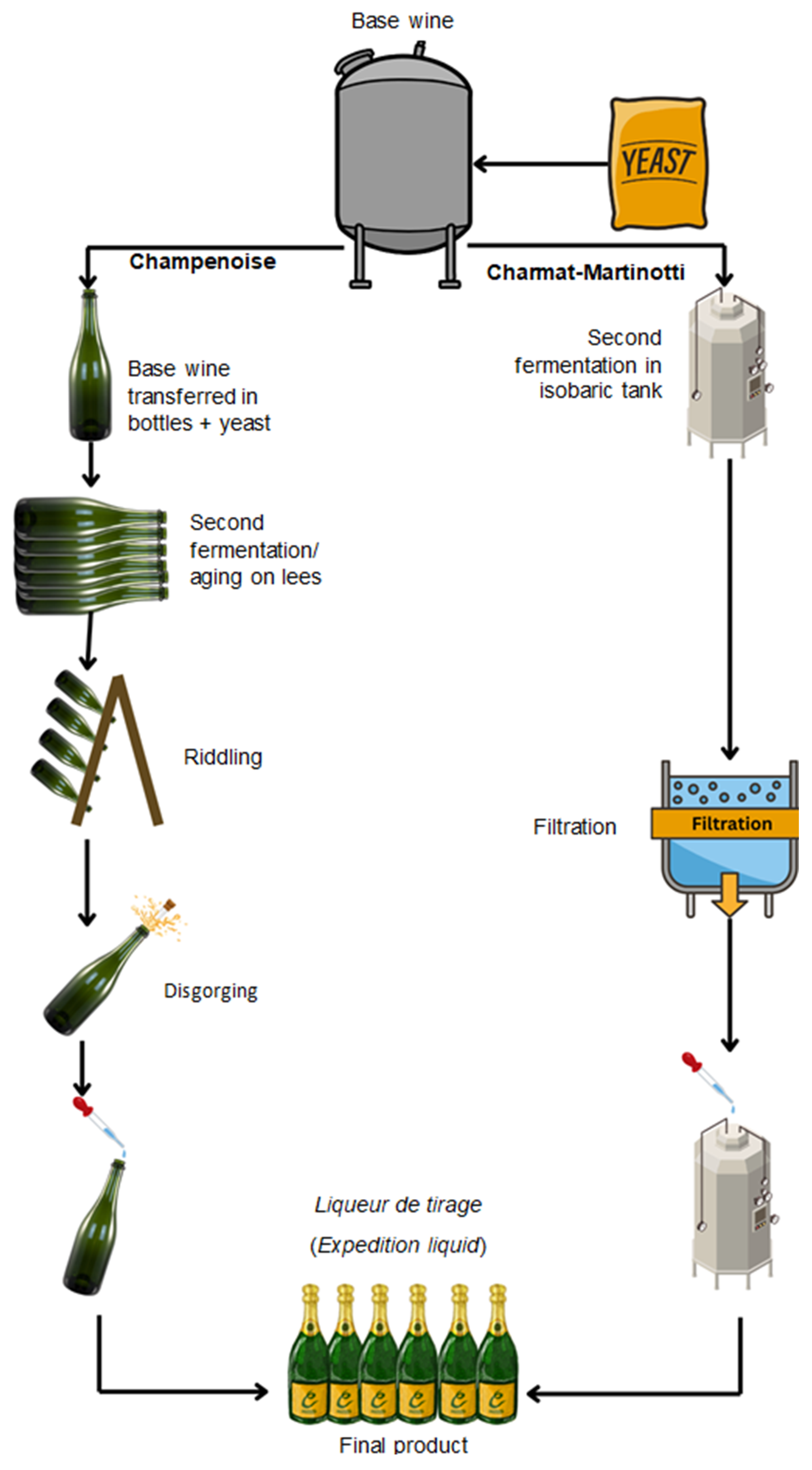

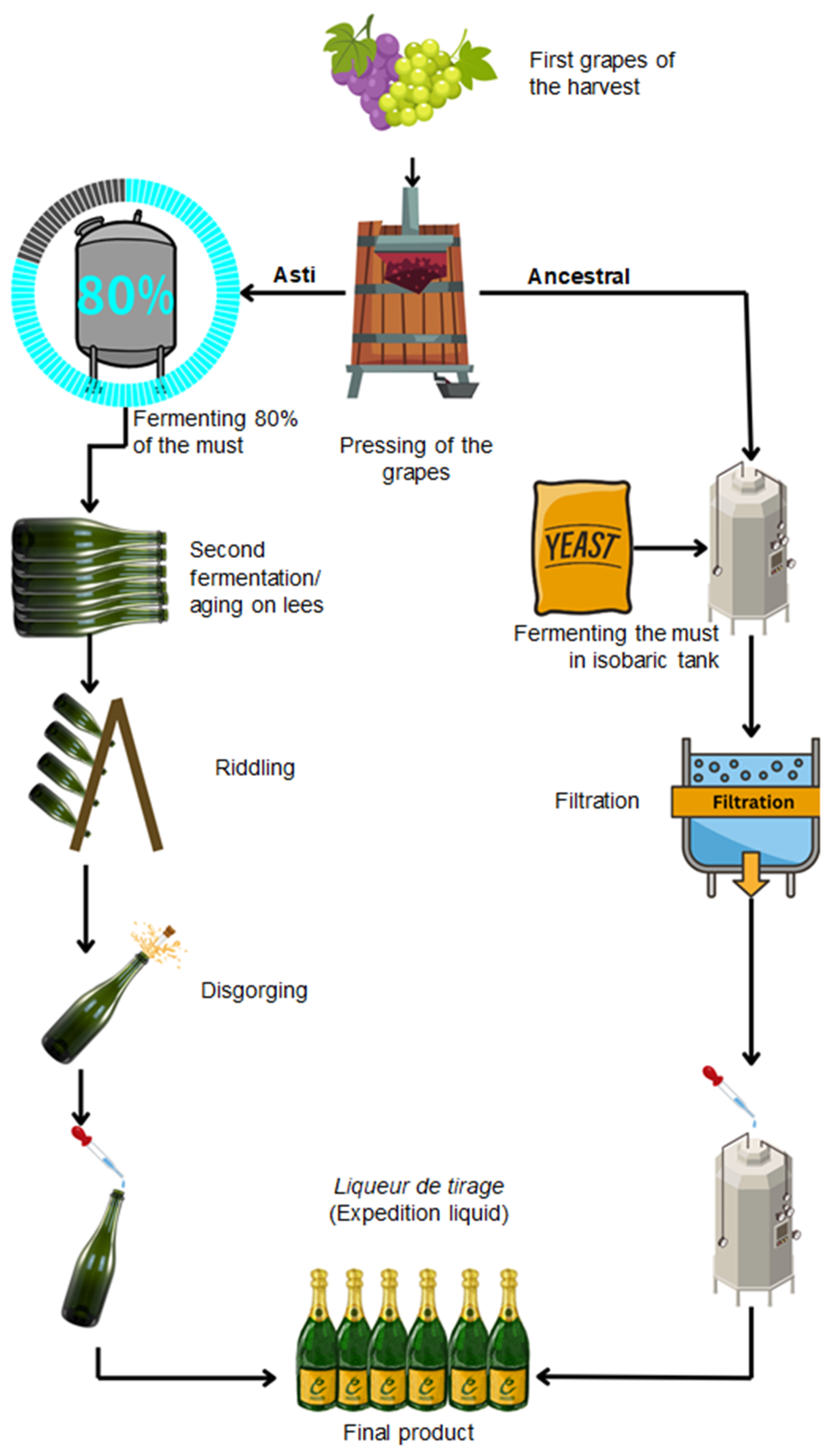

2.3. Sparkling Wine Technologies

3. Modern Advances in Sparkling Wine Technologies

3.1. Exploration of New Grape Varieties

| Geographical Region | Grape Variety | Genetic Origin | Oenological Characteristics Compared to Classical Varies | Sensory Characteristics | References |

|---|---|---|---|---|---|

| Brazil | Moscato Embrapa | Couderc 13 × July Muscat (Brazil) |

| Intense Muscat and fruity notes (banana, green apple, pineapple) | [21,30] |

| Villenave | V. labrusca × Riesling renano (France) |

| Optimum acidity, floral and fruity notes | ||

| Niagara | V. vinifera × V. labrusca from Santa Catarina State (USA) |

| Fruity notes (green apple) | ||

| Goethe | Carter × Black Hamburg (USA) |

| High yield, fruity aroma | ||

| Syrah | Dureza × Mondeuse Blanche |

| Fruity notes | [19,20] | |

| Chenin blanc | Sauvignon blanc × Trousseau |

| Fruity aroma | [20] | |

| Italy | Maresco | - |

| Floral, fruity and fatty notes | [20] |

| Grillo | Catarratto Bianco Comune × Muscat d’Alexandrie |

| Herbaceous and vegetal, floral, and exotic fruit notes | [20,30] | |

| Spain | Albarín | - |

| Citrus, exotic fruits High aroma intensity | [25] |

| Prieto Picudo | ? × Savagnin blanc | Fruity, intense odors | [26] | ||

| France | Voltis | Villaris × VRH3159-2-12 | - | - | [28] |

| China | Meili | Merlot × Riesling × Muscat |

| Pineapple, apple, roses | [29] |

3.2. Technological and Composition-Related Advances

3.2.1. Sustainability and Production Optimization

3.2.2. Yeast Selection and Inoculum

3.2.3. Aging on Lees and Storage

3.3. Nutritional-Related Effects of Wine Components

3.4. Market Trends

4. Future Perspective and Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Stevenson, T. The Sotheby’s Wine Encyclopedia, 4th ed.; DK Publishing: London, UK, 2005. [Google Scholar]

- Cotea, V.V.; Focea, M.C.; Luchian, C.E.; Colibaba, L.C.; Scutarașu, E.C.; Marius, N.; Zamfir, C.I.; Popîrdă, A. Influence of different commercial yeasts on volatile fraction of sparkling wines. Foods 2021, 10, 247. [Google Scholar] [CrossRef] [PubMed]

- Cotea, V. Tehnologia Vinurilor Efervescente; Romanian Academy: Bucharest, Romania, 2005. [Google Scholar]

- Buxaderas, S.; López-Tamames, E. Sparkling wines: Features and trends from tradition. Adv. Food Nutr. Res. 2012, 66, 1–45. [Google Scholar] [CrossRef] [PubMed]

- White, E. Champagne industry in France: Competitor marketing and branding strategies. Bachelor Com. Best Bus. Res. Pap. 2018, 11, 106–119. [Google Scholar]

- Ibern-Gómez, M.; Andrés-Lacueva, C.; Lamuela-Raventós, R.M.; Buxaderas, S.; Singleton, V.L.; de la Torre-Boronat, M.C. Browning of Cava (sparkling wine) during aging in contact with lees due to the phenolic composition. Am. J. Enol. Vitic. 2000, 51, 29–36. [Google Scholar] [CrossRef]

- Ribéreau-Gayon, P.; Glories, Y.; Maujean, A.; Dubourdieu, D. Handbook of Enology, 2nd ed.; John Wiley & Sons, Lts: Chichester, UK, 2006; Volume 1, pp. 397–445. [Google Scholar]

- Di Gianvito, P.; Arfelli, G.; Suzzi, G.; Tofalo, R. New trends in sparkling wine production: Yeast rational selection in alcoholic beverages. In Alcoholic Beverages; Grumezescu, A.M., Holban, A.M., Eds.; Woodhead publishing: Duxford, UK, 2019; Volume 7, pp. 347–386. [Google Scholar] [CrossRef]

- Togores, J.H. Tratado de Enología; Mundiprensa: Madrid, Spain, 2018. [Google Scholar]

- Butnariu, M. Biotechnology of flavored or special wines. In Biotechnological Progress and Beverage Consumption; Grumăzescu, A., Holban, A.M., Eds.; Woodhead Publishing: Cambridge, UK, 2020; Volume 19, pp. 253–282. [Google Scholar] [CrossRef]

- Sawyer, S.; Longo, R.; Solomon, M.; Nicolotti, L.; Westmore, H.; Merry, A.; Gnoinski, G.; Ylia, A.; Dambergs, R.; Kerslake, F. Autolysis and the duration of ageing on lees independently influence the aroma composition of traditional method sparkling wine. Aust. J. Grape Wine Res. 2021, 28, 146–159. [Google Scholar] [CrossRef]

- Cisilotto, B.; Scariot, F.J.; Schwarz, L.V.; Rocha, R.K.M.; Delamare, A.P.L.; Echeverrigaray, S. Are the characteristics of sparkling wines obtained by the Traditional or Charmat methods quite different from each other? OENO One 2023, 57, 321–331. [Google Scholar] [CrossRef]

- Ubeda, C.; Callejón, R.M.; Troncoso, A.M.; Peña-Neira, A.; Morales, M.L. Volatile profile characterisation of Chilean sparkling wines produced by traditional and Charmat methods via sequential stir bar sorptive extraction. Food Chem. 2016, 207, 261–271. [Google Scholar] [CrossRef] [PubMed]

- Cravero, M.C. Innovations in sparkling wine production: A review on the sensory aspects and the consumer’s point of view. Beverages 2023, 9, 80. [Google Scholar] [CrossRef]

- OIV. International Code of Oenological Practices. Available online: https://www.oiv.int/standards/international-code-of-oenological-practices (accessed on 4 March 2025).

- Robinson, J.; Harding, J. The Oxford Companion to Wine, 4th ed.; Oxford University Press: New York, NY, USA, 2015. [Google Scholar]

- Just-Borràs, A.; Alday-Hernández, M.; García-Roldán, A.; Bustamante, M.; Gombau, J.; Cabanillas, P.; Rozès, N.; Canals, J.M.; Zamora, F. Assessment of physicochemical and sensory characteristics of commercial sparkling wines obtained through ancestral and traditional methods. Beverages 2024, 10, 103. [Google Scholar] [CrossRef]

- Focea, M.C. Studies on the Influence of Different Yeast Strains on the Quality of Sparkling Wines Produced by Traditional Method. Ph.D. Thesis, IULS, Iași, Romania, 2023. [Google Scholar]

- De Souza Nascimento, A.M.; De Souza, J.F.; Lima, M.D.S.; Pereira, G.E. Volatile profiles of sparkling wines produced by the traditional method from a semi-arid region. Beverages 2018, 4, 103. [Google Scholar] [CrossRef]

- Eder, M.L.R.; Rosa, A.L. Non-Conventional grape varieties and yeast starters for first and second fermentation in sparkling wine production using the traditional method. Fermentation 2021, 7, 321. [Google Scholar] [CrossRef]

- Caliari, V.; Burin, V.M.; Rosier, J.P.; Bordignon Luiz, M.T. Aromatic profile of Brazilian sparkling wines produced with classical and innovative grape varieties. Food Res. Int. 2014, 62, 965–973. [Google Scholar] [CrossRef]

- Maia, J.D.G.; Camargo, U.A.; Tonietto, J.; Zanus, M.C.; Quecini, V.; Ferreira, M.E.; Ritschel, P. Grapevine breeding programs in Brazil. In Grapevine Breeding Programs for the Wine Industry; Reynolds, A., Ed.; Woodhead Publishing: Cambridge, UK, 2015; pp. 247–271. [Google Scholar] [CrossRef]

- Ferreira-Lima, N.E.; Burin, V.M.; Bordignon-Luiz, M.T. Characterization of Goethe white wines: Influence of different storage conditions on the wine evolution during bottle aging. Eur. Food Res. Technol. 2013, 237, 509–520. [Google Scholar] [CrossRef]

- Nicolini, G.; Versini, G.; Moser, S.; Carlin, S.; Massolini, U. Aroma characteristics of wines from the cultivar ‘Manzoni bianco’ (‘White Riesling’ × ‘Pinot blanc’). Mitt. Klosterneubg. 2003, 53, 251–257. [Google Scholar]

- Pérez-Magariño, S.; Ortega-Heras, M.; Martínez-Lapuente, L.; Guadalupe, Z.; Ayestarán, B. Multivariate analysis for the differentiation of sparkling wines elaborated from autochthonous Spanish grape varieties: Volatile compounds, amino acids and biogenic amines. Eur. Food Res. Technol. 2013, 236, 827–841. [Google Scholar] [CrossRef]

- Doncieux, A.; Yobrégat, O.; Prudham, S.; Caillon, S.; Renard, D. Agrobiodiversity dynamics in a French wine-growing region. OENO One 2022, 56, 183–199. [Google Scholar] [CrossRef]

- Rousseau, J.; Chanfreau, S.; Bontemps, É. Les cépages résistants and maladies cryptogamiques. Rev. Des Anol. 2013, 149, 228. [Google Scholar]

- Li, E.H.; Zhang, Z.W.; Gao, H. Resistance of new grape strain 8804 to Plasmopara viticola. In Proceedings of the 5th International Symposium of Viticulture and Enology; Li, H., Ed.; Northwest A & F University Press: Yangling, China, 2007; pp. 73–77. [Google Scholar]

- Song, J.; Li, H.; Liang, Y.; Tao, Y.; Mi, C.; Qian, M.C.; Wang, H. Characterisation of volatile components of red and sparkling wines from a new wine grape cultivar ‘Meili’ (Vitis vinifera L.). Vitis 2013, 52, 41. Available online: https://dialnet.unirioja.es/servlet/articulo?codigo=4232830 (accessed on 26 February 2025).

- Vitis International Variety Catalogue. Available online: https://www.vivc.de (accessed on 26 February 2025).

- Pomarici, E.; Vecchio, R. Millennial generation attitudes to sustainable wine: An exploratory study on Italian consumers. J. Clean. Prod. 2014, 66, 537–545. [Google Scholar] [CrossRef]

- Giovenzana, V.; Beghi, R.; Vagnoli, P.; Iacono, F.; Guidetti, R.; Nardi, T. Evaluation of energy saving using a new yeast combined with temperature management in sparkling base wine fermentation. AJEV 2016, 67, 308–314. [Google Scholar] [CrossRef]

- Shanshiashvili, G.; Baviera, M.; Fracassetti, D. Exploring grape pressing for sparkling wine production: A comprehensive literature review on physicochemical parameters and technological applications. Appl. Food Res. 2024, 4, 100454. [Google Scholar] [CrossRef]

- Boselli, E.; Di Lecce, G.; Alberti, F.; Frega, N.G. Nitrogen gas affects the quality and the phenolic profile of must obtained from vacuum-pressed white grapes. LWT-Food Sci. Technol. 2010, 43, 1494–1500. [Google Scholar] [CrossRef]

- Puig-Pujol, A.; Bertran, E.; García-Martínez, T.; Capdevila, F.; Mínguez, S.; Mauricio, J.C. Application of a new organic yeast immobilization method for sparkling wine production. AJEV 2013, 64, 386–394. [Google Scholar] [CrossRef]

- Garofalo, C.; Arena, M.P.; Laddomada, B.; Cappello, M.S.; Bleve, G.; Grieco, F.; Beneduce, L.; Berbegal, C.; Spano, G.; Capozzi, V. Starter cultures for sparkling wine. Fermentation 2016, 2, 21. [Google Scholar] [CrossRef]

- Comitini, F.; Capece, A.; Ciani, M.; Romano, P. New insights on the use of wine yeasts. Curr. Opin. Food Sci. 2017, 13, 44–49. [Google Scholar] [CrossRef]

- Berbegal, C.; Polo, L.; García-Esparza, M.J.; Álvarez, I.; Zamora, F.; Ferrer, S.; Pardo, I. Influence of the dry yeast preparation method on final sparkling wine characteristics. Fermentation 2022, 8, 313. [Google Scholar] [CrossRef]

- Ivit, N.N.; Kemp, B. The impact of non-Saccharomyces yeast on traditional method sparkling wine. Fermentation 2018, 4, 73. [Google Scholar] [CrossRef]

- Todd, B.E.N.; Fleet, G.H.; Henschke, P.A. Promotion of autolysis through the interaction of killer and sensitive yeasts: Potential application in sparkling wine production. AJEV 2000, 51, 65–72. [Google Scholar] [CrossRef]

- Núnez, Y.P.; Carrascosa, A.V.; González, R.; Polo, M.C.; Martínez-Rodríguez, A. Isolation and characterization of a thermally extracted yeast cell wall fraction potentially useful for improving the foaming properties of sparkling wines. J. Agric. Food Chem. 2006, 54, 7898–7903. [Google Scholar] [CrossRef] [PubMed]

- Focea, M.C.; Luchian, C.E.; Moroşanu, A.M.; Niculaua, M.; Cotea, V.V.; Odăgeriu, G.; Zamfir, C.I. Content of metals and organic acids from experimental sparkling white wine. BIO Web Conf. 2017, 9, 02007. [Google Scholar] [CrossRef]

- Gnoinski, G.B.; Schmidt, S.A.; Close, D.C.; Goemann, K.; Pinfold, T.L.; Kerslake, F.L. Novel methods to manipulate autolysis in sparkling wine: Effects on yeast. Molecules 2021, 26, 387. [Google Scholar] [CrossRef]

- Lasanta, C.; Cejudo, C.; Gómez, J.; Caro, I. Influence of prefermentative cold maceration on the chemical and sensory properties of red wines produced in warm climates. Processes 2023, 11, 374. [Google Scholar] [CrossRef]

- La Gatta, B.; Picariello, G.; Rutigliano, M.; Lopriore, G.; Petrella, G.; Rusco, G.; Tremonte, P.; Di Luccia, A. Addition of lees from base wine in the production of Bombino sparkling wine. Eur. Food Res. Technol. 2016, 242, 1307–1317. [Google Scholar] [CrossRef]

- Benucci, I. Impact of post-bottling storage conditions on colour and sensory profile of a rosé sparkling wine. LWT-Food Sci. Technol. 2019, 118, 108732. [Google Scholar] [CrossRef]

- Darias-Martín, J.; Díaz-González, D.; Díaz-Romero, C. Influence of two pressing processes on the quality of must in white wine production. J. Food Eng. 2004, 63, 335–340. [Google Scholar] [CrossRef]

- Dumas, V.; Saurin, N.; Destrac-Irvine, A.; Dedet, S.; Veyret, M.; Marchal, C.; Ojeda, H.; Van Leeuwen, C.; Duchêne, E. Influence of grape juice extraction methods on basic analytical parameters. Vitis 2020, 59, 77–83. [Google Scholar] [CrossRef]

- Peinado, R.A.; Moreno, J.J.; Villalba, J.M.; González-Reyes, J.A.; Ortega, J.M.; Mauricio, J.C. Yeast biocapsules: A new immobilization method and their applications. Enzym. Microb. Technol. 2006, 40, 79–84. [Google Scholar] [CrossRef]

- Verbelen, P.J.; De Schutter, D.P.; Delvaux, F.; Verstrepen, K.J.; Delvaux, F.R. Immobilized yeast cell systems for continuous fermentation applications. Biotechnol. Lett. 2006, 28, 1515–1525. [Google Scholar] [CrossRef]

- Palomero, F.; Morata, A.; Benito, S.; Calderón, F.; Suárez-Lepe, J.A. New genera of yeasts for over-lees aging of red wine. Food Chem. 2009, 112, 432–441. [Google Scholar] [CrossRef]

- González-Royo, E.; Pascual, O.; Kontoudakis, N.; Esteruelas, M.; Esteve-Zarzoso, B.; Mas, A.; Canals, J.M.; Zamora, F. Oenological consequences of sequential inoculation with non-Saccharomyces yeasts (Torulaspora delbrueckii or Metschnikowia pulcherrima) and Saccharomyces cerevisiae in base wine for sparkling wine production. Eur. Food Res. Technol. 2015, 240, 999–1012. [Google Scholar] [CrossRef]

- Fernández-Fernández, E.; Rodríguez-Nogales, J.M.; Vila-Crespo, J.; Falqué-López, E. Application of immobilized yeasts for improved production of sparkling wines. Fermentation 2022, 8, 559. [Google Scholar] [CrossRef]

- Peinado, R.A.; Moreno, J.J.; Maestre, O.; Ortega, J.M.; Medina, M.; Mauricio, J.C. Gluconic acid consumption in wines by Schizosaccharomyces pombe and its effect on the concentrations of major volatile compounds and polyols. J. Agric. Food Chem. 2004, 52, 493–497. [Google Scholar] [CrossRef] [PubMed]

- Benito, S.; Palomero, F.; Morata, A.; Calderón, F.; Palmero, D.; Suárez-Lepe, J.A. Physiological features of Schizosaccharomyces pombe of interest in making of white wines. Eur. Food Res. Technol. 2013, 236, 29–36. [Google Scholar] [CrossRef]

- Gobert, A.; Tourdot-Maréchal, T.; Morge, C.; Sparrow, C.; Liu, Y.; Quintanilla-Casas, B.; Vichi, S.; Alexandre, H. Non-Saccharomyces yeasts nitrogen source preferences: Impact on sequential fermentation and wine volatile compounds profile. Front. Microbiol. 2017, 8, 2175. [Google Scholar] [CrossRef]

- Velázquez, R.; Zamora, E.; Álvarez, M.L.; Ramírez, M. Using Torulaspora delbrueckii killer yeasts in the elaboration of base wine and traditional sparkling wine. Int. J. Food Microbiol. 2019, 289, 134–144. [Google Scholar] [CrossRef]

- Tofalo, R.; Perpetuini, G.; Rossetti, A.P.; Gaggiotti, S.; Piva, A.; Olivastri, L.; Cichelli, A.; Compagnone, D.; Arfelli, G. Impact of Saccharomyces cerevisiae and non-Saccharomyces yeasts to improve traditional sparkling wines production. Food Microbiol. 2022, 108, 104097. [Google Scholar] [CrossRef]

- Englezos, V.; Rantsiou, K.; Torchio, F.; Rolle, L.; Gerbi, V.; Cocolin, L. Exploitation of the non-Saccharomyces yeast Starmerella bacillaris (synonym Candida zemplinina) in wine fermentation: Physiological and molecular characterizations. Int. J. Food Microbiol. 2015, 199, 33–40. [Google Scholar] [CrossRef]

- Nisiotou, A.; Sgouros, G.; Mallouchos, A.; Nisiotis, C.S.; Michaelidis, C.; Tassou, C.; Banilas, G. The use of indigenous Saccharomyces cerevisiae and Starmerella bacillaris strains as a tool to create chemical complexity in local wines. Food Res. Int. 2018, 111, 498–508. [Google Scholar] [CrossRef]

- Tudela, R.; Gallardo-Chacón, J.J.; Rius, N.; López-Tamames, E.; Buxaderas, S. Ultrastructural changes of sparkling wine lees during long-term aging in real enological conditions. FEMS Yeast Res. 2012, 12, 466–476. [Google Scholar] [CrossRef]

- Cebollero, E.; Carrascosa, A.V.; Gonzalez, R. Evidence for yeast autophagy during simulation of sparkling wine aging: A reappraisal of the mechanism of yeast autolysis in wine. Biotechnol. Prog. 2005, 21, 614–616. [Google Scholar] [CrossRef]

- Charpentier, C.; Aussenac, J.; Charpentier, M.; Prome, J.; Duteurtre, B.; Feuillat, M. Release of nucleotides and nucleosides during yeast autolysis: Kinetics and potential impact on flavor. J. Agric. Food Chem. 2005, 53, 3000–3007. [Google Scholar] [CrossRef] [PubMed]

- Alexandre, H.; Guilloux-Benatier, M. Yeast autolysis in sparkling wine–a review. Aust. J. Grape Wine Res. 2006, 12, 119–127. [Google Scholar] [CrossRef]

- Pons-Mercadé, P.; Giménez, P.; Vilomara, G.; Conde, M.; Cantos, A.; Rozès, N.; Ferrer, S.; Canals, J.; Zamora, F. Monitoring yeast autolysis in sparkling wines from nine consecutive vintages produced by the traditional method. Aust. J. Grape Wine Res. 2021, 28, 347–357. [Google Scholar] [CrossRef]

- Charnock, H.M.; Cairns, G.; Pickering, G.J.; Kemp, B.S. Production method and wine style influence metal profiles in sparkling wines. AJEV 2022, 73, 170–182. [Google Scholar] [CrossRef]

- Kourkoutas, Y.; Manojlović, V.; Nedović, V.A. Immobilization of microbial cells for alcoholic and malolactic fermentation of wine and cider. In Encapsulation Technologies for Active Food Ingredients and Food Processing; Zuidam, N.J., Nedovic, V., Eds.; Springer eBooks: Berlin/Heidelberg, Germany, 2010; pp. 327–343. [Google Scholar] [CrossRef]

- De Lerma, N.L.; Peinado, R.A.; Puig-Pujol, A.; Mauricio, J.C.; Moreno, J.; García-Martínez, T. Influence of two yeast strains in free, bioimmobilized or immobilized with alginate forms on the aromatic profile of long aged sparkling wines. Food Chem. 2018, 250, 22–29. [Google Scholar] [CrossRef]

- Peršurić, A.S.I.; Rossi, S.; Bestulić, E.; Radeka, S. Perceptions of wine health benefits and effects of wine consumption on well-being. Ekon. Poljopr. 2023, 70, 145–167. [Google Scholar] [CrossRef]

- Schutte, R.; Papageorgiou, M.; Najlah, M.; Huisman, H.W.; Ricci, C.; Zhang, J.; Milner, N.; Schutte, A.E. Drink types unmask the health risks associated with alcohol intake—Prospective evidence from the general population. Clin. Nutr. 2020, 39, 3168–3174. [Google Scholar] [CrossRef]

- Vauzour, D.; Corona, G.; Hercelin, J.; Garnotel, R.; Gillery, P.; Lovegrove, J.A.; Williams, C.M.; Spencer, J.P. Potential health effects of champagne wine consumption. J. Wine Res. 2011, 22, 175–180. [Google Scholar] [CrossRef]

- Stefenon, C.; De M Bonesi, C.; Marzarotto, V.; Barnabé, D.; Spinelli Webber, V.; Vanderlinde, R. Phenolic composition and antioxidant activity in sparkling wines: Modulation by the ageing on lees. Food Chem. 2013, 145, 292–299. [Google Scholar] [CrossRef]

- Rodriguez-Nogales, J.M.; Fernández-Fernández, E.; Gómez, M.; Vila-Crespo, J. Antioxidant properties of sparkling wines produced with β-glucanases and commercial yeast preparations. J. Food Sci. 2012, 77, C1005–C1010. [Google Scholar] [CrossRef]

- Moreno-Arribas, M.V.; Bartolomé, B.; Peñalvo, J.L.; Pérez-Matute, P.; Motilva, M.J. Relationship between wine consumption, diet and microbiome modulation in Alzheimer’s disease. Nutrients 2020, 12, 3082. [Google Scholar] [CrossRef] [PubMed]

- Tamargo, A.; Cueva, C.; Silva, M.; Molinero, N.; Miralles, B.; Bartolomé, B.; Moreno-Arribas, M.V. Gastrointestinal co-digestion of wine polyphenols with glucose/whey proteins affects their bioaccessibility and impact on colonic microbiota. Food Res. Int. 2022, 155, 111010. [Google Scholar] [CrossRef]

- Vázquez-Agell, M.; Sacanella, E.; Tobias, E.; Monagas, M.; Antúnez, E.; Zamora-Ros, R.; Andrés-Lacueva, C.; Lamuela-Raventós, R.M.; Fernández-Solá, J.; Nicolás, J.M.; et al. Inflammatory markers of atherosclerosis are decreased after moderate consumption of cava (sparkling wine) in men with low cardiovascular risk. J. Nutr. 2007, 137, 2279–2284. [Google Scholar] [CrossRef] [PubMed]

- Fracassetti, D.; Gabrielli, M.; Costa, C.; Tomás-Barberán, F.A.; Tirelli, A. Characterization and suitability of polyphenols-based formulas to replace sulfur dioxide for storage of sparkling white wine. Food Contr. 2015, 60, 606–614. [Google Scholar] [CrossRef]

- OIV. OIV Focus. The Global Sparkling Wine Market. Available online: https://www.oiv.int/public/medias/7291/oiv-sparkling-focus-2020.pdf (accessed on 27 February 2025).

- Sparkling Wine Production and Exports Down 8% in 2023. Available online: https://ec.europa.eu/eurostat/web/products-eurostat-news/w/ddn-20241230-1 (accessed on 27 February 2025).

- Scutarașu, E.C.; Luchian, C.E.; Vlase, L.; Nagy, K.; Colibaba, L.C.; Trincă, L.C.; Cotea, V.V. Influence evaluation of enzyme treatments on aroma profile of white wines. Agronomy 2022, 12, 2897. [Google Scholar] [CrossRef]

- Qiu, X.; Yu, L.; Wang, W.; Yan, R.; Zhang, Z.; Yang, H.; Zhu, D.; Zhu, B. Comparative evaluation of microbiota dynamics and metabolites correlation between spontaneous and inoculated fermentations of nanfeng tangerine wine. Front. Microbiol. 2021, 12, 649978. [Google Scholar] [CrossRef]

- Zhao, X.; Xiang, F.; Tang, F.; Cai, W.; Guo, Z.; Hou, Q.; Yang, X.; Song, W.; Shan, C. Bacterial communities and prediction of microbial metabolic pathway in rice wine koji from different regions in China. Front. Microbiol. 2022, 12, 748779. [Google Scholar] [CrossRef]

- Panesar, P.S.; Joshi, V.K.; Bali, V.; Oanesar, R. Technology for production of fortified and sparkling fruit wines. In Science and Technology of Fruit Wine Production; Kosseva, M.R., Joshi, V.K., Panesar, P.S., Eds.; Academic Press: London, UK, 2017; pp. 487–530. [Google Scholar] [CrossRef]

- Jones, J.E.; Kerslake, F.L.; Close, D.C.; Dambergs, R.G. Viticulture for sparkling wine production: A review. AJEV 2014, 65, 407–416. [Google Scholar] [CrossRef]

- Bucher, T.; Deroover, K.; Stockley, C. Low-alcohol wine: A narrative review on consumer perception and behaviour. Beverages 2018, 4, 82. [Google Scholar] [CrossRef]

- Belisario-Sánchez, Y.Y.; Taboada-Rodríguez, A.; Marin-Iniesta, F.; Iguaz-Gainza, A.; López-Gómez, A. Aroma recovery in wine dealcoholization by SCC distillation. Food Bioprocess Technol. 2012, 5, 2529–2539. [Google Scholar] [CrossRef]

- Luchian, C.E.; Scutarașu, E.C.; Colibaba, L.C.; Focea, M.C.; Cotea, V. Trends in reducing the effects of global warming: Applications of reverse osmosis to obtain sparkling wines with moderate alcohol concentrations. In Global Warming and the Wine Industry—Challenges, Innovations and Future Prospects; Cosme, F., Nunes, F.M., Filipe-Ribeiro, L., Eds.; IntechOpen eBooks: London, UK, 2023. [Google Scholar] [CrossRef]

- Schmidtke, L.M.; Blackman, J.W.; Agboola, S.O. Production technologies for reduced alcoholic wines. J. Food Sci. 2012, 71, R25–R41. [Google Scholar] [CrossRef]

| Technological Phase | Main Focus | References |

|---|---|---|

| Production optimization | Reducing costs and time; focus on sustainability | [31] |

| Primary fermentation at higher temperatures | Energy savings without negative effects on quality | [32] |

| Pressing and maceration | Influence of different pressing forces on potassium levels, acidity, polyphenols and antioxidants | [23,33,34] |

| Increased phenolic content when pressing with nitrogen flow is used | [34] | |

| Yeast selection | Use of immobilized yeast, co-inoculation and their influence on volatile fraction and sensory profile | [2,35,36,37] |

| Secondary fermentation | Differences in physicochemical and volatile parameters depending on inoculation method | [38] |

| Aging on lees | Yeast autolysis and its effects on wine composition and quality | [39,40,41,42] |

| Ultrasound utilization, enzymes activity and microwaves application to accelerate the autolysis process | [43,44,45] | |

| Storage conditions | Changes in chromatic and sensory features | [46] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luchian, C.E.; Grosaru, D.; Scutarașu, E.C.; Colibaba, L.C.; Scutarașu, A.; Cotea, V.V. Advancing Sparkling Wine in the 21st Century: From Traditional Methods to Modern Innovations and Market Trends. Fermentation 2025, 11, 174. https://doi.org/10.3390/fermentation11040174

Luchian CE, Grosaru D, Scutarașu EC, Colibaba LC, Scutarașu A, Cotea VV. Advancing Sparkling Wine in the 21st Century: From Traditional Methods to Modern Innovations and Market Trends. Fermentation. 2025; 11(4):174. https://doi.org/10.3390/fermentation11040174

Chicago/Turabian StyleLuchian, Camelia Elena, Dragoș Grosaru, Elena Cristina Scutarașu, Lucia Cintia Colibaba, Andrei Scutarașu, and Valeriu V. Cotea. 2025. "Advancing Sparkling Wine in the 21st Century: From Traditional Methods to Modern Innovations and Market Trends" Fermentation 11, no. 4: 174. https://doi.org/10.3390/fermentation11040174

APA StyleLuchian, C. E., Grosaru, D., Scutarașu, E. C., Colibaba, L. C., Scutarașu, A., & Cotea, V. V. (2025). Advancing Sparkling Wine in the 21st Century: From Traditional Methods to Modern Innovations and Market Trends. Fermentation, 11(4), 174. https://doi.org/10.3390/fermentation11040174