Abstract

The interest in biogas, which is a renewable energy source, has been growing rapidly in recent years. It is prohibited to discharge digestates resulting from the biogas process into the environment, and they have a very high pollutant load. In this study, basal media (BBM) was added to five different biogas liquid digestates (BLD). Microalgae tolerant to their own environment adapted to the environment, and an increase was observed in cell densities. As a result, microalgal biomass was obtained, and its potential for biodiesel, which is a renewable energy source, was investigated by extracting oil from the obtained microalgal biomass. In all groups, NH4 removal was 99%. Chemical oxygen demand (COD) removal was determined to be in the range of 82–96%. When biomass and lipid production values were analyzed, it was seen that the most effective groups were M4 and M5. Based on the estimated biodiesel properties, it was concluded that all groups are usable. Finally, it was concluded that BLD, which is a pollutant in the biogas sector, can be converted into biodiesel. The research revealed that the M4 (BLD 20% + BBM 80%) and M5 (BLD 40% + BBM 60%) treatments, which had the highest levels of BLD among the treatments, were promising in terms of CO2 removal, microalgae yield, chemical removal, and estimated biodiesel potential.

1. Introduction

In recent years, with the rapid growth of the renewable energy market, the renewable energy economy has become more efficient, interconnected, and nature-based. The term “biogas” basically refers to the production of usable gas from organic waste. Biogas consists of about 50–80% methane (CH4), 20–50% carbon dioxide (CO2), hydrogen sulfide (H2S), and some minor components such as water [1,2]. The use of biogas for energy production has recently gained considerable attention because it can replace fossil fuels, curb greenhouse gas emissions, and reduce the need for foreign energy [3]. There are different raw materials that can be used for biogas production. These are food waste, vegetable waste, animal waste, household waste, and sewage sludge. Among these organic wastes, the most basic type of raw material used is animal waste. Turkey has a significantly high biogas potential that can be achieved through outputs obtained from agricultural and livestock products [4]. Considering organic wastes within the scope of green economy and adopting a zero-waste approach may contribute to this situation. Biogas production supports the green economy and zero-waste policy as it contributes to the utilization of waste [5]. The realization of biogas production is not only a solution to environmental problems, but it also yields a significant improvement in people’s living standards. Animal manure used in biogas production becomes more useful as a result of the fermentation process during its conversion into biogas and is utilized in agriculture. However, care must be taken to ensure that it does not cause nitrate pollution in the soil when used in agriculture [6]. For example, a very high level of efficiency can be achieved in biogas production through chicken manure. The use of chicken manure is also important for agricultural land, but when applied directly, it leads to salinity in the soil. However, in biogas production, fermented chicken manure becomes much more efficient and promotes sustainable living [1]. Although digestate produced as a result of fermentation of organic waste and residual materials with biogas production may be used as a soil conditioner, it must first be subjected to a biological treatment due to its COD load of 40,000 mg L−1 to discharge to the environment. In Türkiye, approximately 12.7 million tons of waste was reported to be generated as biogas liquid digestate (BLD), which is the most serious issue for biogas plants in the country [7]. BLD derived from biogas production is considered a nutrient-rich medium, especially for microalgae species adapted to high nutrient loads and elevated ammonia levels. Among the species found to grow well in the BLD medium are Chlorella vulgaris, Chlorella sorokiniana, Scenedesmus dimorphus, and Scenedesmus quadricauda. The primary reasons for the successful microalgal growth in BLD are its high tolerance to ammonia loads and its efficiency in nutrient removal [8].

This study aimed to treat BLD with microalgae and determine the estimated biodiesel parameters of the microalgal biomass obtained. Specifically, it focused on the propagation of microalgae present in BLD, which is one of the results of the biogas process, recovering nitrogen, phosphorus, and ammonia from the digestate with these microalgae, and finally investigating the biodiesel potential of these microalgal biomasses.

2. Materials and Methods

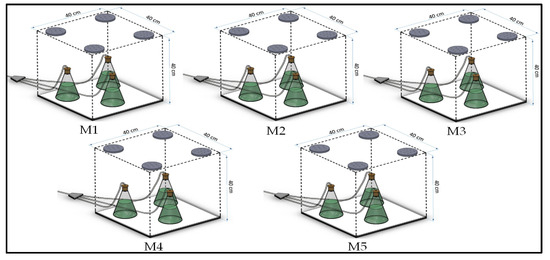

This study was carried out in the Algal Biomass Laboratory of the Department of Agricultural Machinery and Technology Engineering under the Faculty of Agriculture of Isparta University of Applied Sciences. BLD was obtained from AKINCI Biogas and Energy Systems Co. in Afyonkarahisar, Türkiye. For the experiment, five distinct BLD doses were used with three replications (Figure 1). The experiment was carried out in 0.5 L capacity flasks. The duration of the experiment was seven days. Basal medium (Table 1) was added to each treatment at the same ratio in the experiment. The illumination intensity required for cultivation was set to 150 μmol photons/m2/s. The chemical characteristics of the groups are given in Table 2.

Figure 1.

Study plan (M1: BLD 2.5% + BBM 97.5%. M2: BLD 10% + BBM 90%. M3: BLD 15% + BBM 85%. M4: BLD 20% + BBM 80%. M5: BLD 40% + BBM 60%).

Table 1.

Composition and preparation of basal media.

Table 2.

The chemical characteristics of the groups.

2.1. The Detection of Microalgae Species in BLD, Biomass Yield, Nutrient, and CO2 Removal

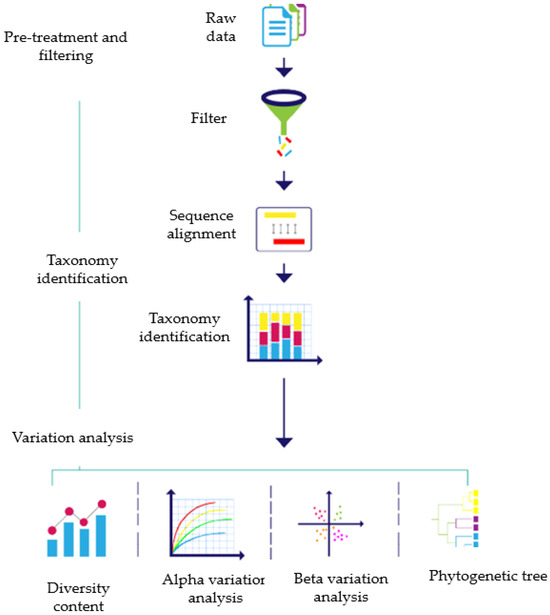

Detection of microalgae species in digestate content-metagenome analysis: Metagenome analysis for species identification of microalgal communities involves bulk examining genetic material (DNA) directly from environmental samples and classifying the resulting genetic sequences to the species level by bioinformatics tools. This approach is extremely useful in revealing the composition of complex microbial communities without requiring culture. For the species taxonomic classification of the biomass obtained in the research, the steps in Figure 2 were utilized.

Figure 2.

The steps of species taxonomic classification.

The amplification and sequencing of specific regions of ribosomal RNA genes, which are widely used in identifying microalgal communities, is referred to as metagenomic analysis. 16S rRNA genes are typically used for prokaryotes, while 18S rRNA genes are employed for eukaryotic microalgae [9]. The sequencing method involving PCR amplification of specific marker genes (e.g., rbcL and ITS) for the genetic identification of microalgae is referred to as next-generation sequencing (NGS). It is specifically used to classify small microalgal species such as phytoplankton [10]. In this study, the NGS method was used for microalgal species identification, and the 16S metagenomic analysis was performed using QIIME2.

Biomass yield of microalgae: This analysis aims to determine the dry weight of biomass per unit volume. Filter papers were dried at 60 °C. Dried Whatman GF/C filter papers with a pore diameter of 0.45 μm were tared with a 0.0001 g precision balance. Then, 1 mL of cultures was filtered using sample filter papers. The filter papers on which the samples were filtered were dried in an oven (Memmert brand) at 105 °C for 3–4 h. The dried filter papers were then weighed with a precision balance, and the dry weight per liter was calculated in grams (g).

Nutrient removal: Nutrient removals during microalgae cultivation in BLD media were determined. The parameters determined were COD, , , TN, and TP. Spectrophotometric kits were used to determine the removal of each parameter. While NH4 was analyzed based on TS EN ISO 14911 [11], nitrate (NO3) was determined according to TS EN ISO 10304-1 [12]. The analysis of COD was performed in line with the American Public Health Association (APHA 5220B) [13].

removal: During the study period, the amount of carbon dioxide consumed in each treatment varied depending on the BLD doses and the biomass yield. The amount of consumed at the end of the study was calculated using Equation (1) [14,15,16,17]. Microalgae reduce approximately 0.29 kg of emissions during the treatment of 1 m³ of wastewater [18]. The absorption by microalgae generates economic benefits through carbon trading while reducing wastewater treatment costs by consuming nutrients in the wastewater. This process offers a sustainable solution where environmental benefits align with economic value. Microalgae provide an innovative and cost-effective method for both carbon management and wastewater treatment [19]. In this study, removal was calculated based on the amount of microalgal biomass harvested at five different BLD doses.

2.2. Fatty Acid Methyl Esters

Microalgae obtained at the end of the experiment were harvested by a table-type centrifuge (EBA 200, Hettich, Westphalia, Germany). Microalgal biomasses obtained at the end of harvesting were dried in an oven at 55 °C for 48 h. Oils were extracted according to the Bligh and Dyer method, and their fatty acid components were prepared for derivatization (Column CPWAX 52 CB (50 × 0.25 (0.2)); the device used AGILENT 5975 C AGILENT 7890A GC; programme: MSDCHEM, Santa Clara, CA, USA). The initial temperature of the oven was 80 °C. After being held at 60 °C for 4 min, the temperature was increased by 13 °C per minute to reach 175 °C. It was maintained at 175 °C for 27 min. Then, the temperature was increased by 4 °C per minute to reach 215 °C, where it was held for 5 min. Subsequently, the temperature was raised by 4 °C per minute to 240 °C, and it was held at this temperature for 15 min. The detector and injector temperatures were set to 240 °C. The injection volume was 1 µL. Derivatization was performed using methanolic HCl with a concentration of 1.5 M at a derivatization temperature of 80 °C and a derivatization period of 2 h [20].

2.3. Estimated Biodiesel Properties

The quantity of monounsaturated (MUFA) and polyunsaturated fatty acids (PUFA) (wt%) existing in microalgae oil was considered to determine the degree of unsaturation (DU) and the long-chain saturated factor (LCSF) [21].

where DU refers to the degree of unsaturation (%), m refers to the proportion of MUFA (wt%), and p refers to the proportion of PUFA (wt%). LCSF was acquired based on Equation (3) by considering the fatty acids composition and assigning a greater amount of weight to the composition of fatty acids that have a long chain.

where LCSF is the long-chain saturated factor and C16, C18, and C20 are the weight percentages of each fatty acid (wt%).

Biodiesel properties estimated according to the fatty acid compositions of microalgae oil under five different dosages of nutrient media were evaluated in view of cetane number (CN), saponification value (SV), and iodine value (IV) [22]. The CN, SV, and IV were calculated as per Equations (4)–(6):

D is the number of double bonds, M is the molecular mass, and N is the percentage of each fatty acid component. LCSF was correlated with cold filter plugging point (CFPP) using Equation (7) [21].

Cloud point (CP): Equation (8) was used for the CP, which is one of the biodiesel properties of microalgal biomass obtained from the treatments [23].

Kinematic viscosity (KV): Equation (9) was used to determine the kinematic viscosity value.

In the equation above, Mwi refers to the molecular weight of a fatty acid, Ni is the percentage of a given fatty acid in biodiesel, and Di is the number of double bonds in a given fatty acid.

Oxidation stability (OS): Equation (10) was used to calculate Bis Allylic Position Equivalence (BAPE), while Equation (11) was used for oxidation stability [24].

Density (ρ): Equation (12) was used to determine the density (ρ) value, which is one of the estimated biodiesel parameters of microalgal biomass obtained at the end of microalgae cultivation in different BLD environments [23].

In the given equation, ρ refers to density, Mwi is the molecular weight of a fatty acid, Ni is the percentage of the given fatty acid in biodiesel, and Di is the number of double bonds in the given fatty acid.

High heating value (HHV): Equation (13) was used to determine the HHV value, which is one of the estimated biodiesel parameters of microalgal biomass obtained at the end of the cultivation of five different BLD environments [23].

3. Results and Discussion

3.1. Microalgae Species Detection in Digestate Content, COD and Nutrient Removal, Biomass Yield, and CO2 Removal

The present study aimed to increase the cell density with microalgae basal environment existing at five different doses of BLD. The microalgae samples were subjected to the steps in metagenome analysis given in the method section. As a result of the metagenome analysis, it was determined that the class was cyanobacteria and the genus was Anabaena (Figure 3).

Figure 3.

Taxonomic classification of microalgae detected in the study.

The taxonomic classification of Anabaena is also important in understanding its ecological functions, industrial applications, and environmental management strategies. Since cyanobacteria such as Anabaena are capable of nitrogen fixation, they can play a crucial role as biofertilizers in agriculture and in nutrient removal in wastewater treatment [25]. Classification leads to targeting such applications, selecting the right strains, and understanding ecosystem dynamics.

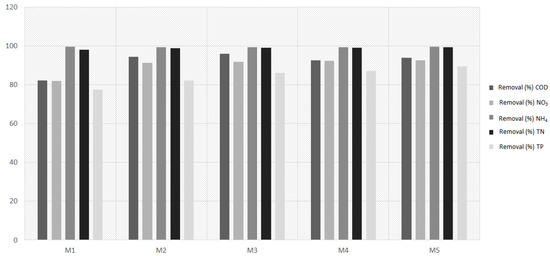

COD removal is a critical parameter in wastewater treatment. In this study, COD removal efficiencies ranged from 82.14% to 95.78%. This indicates that the groups were successful in achieving effective COD removal. Nitrogen pollution in soil poses significant threats in terms of water pollution, eutrophication, reduced soil fertility, and health risks. For instance, an excessive nitrate load in soil can leach into groundwater and surface water, contaminating drinking water sources. Consequently, it can lead to severe health issues, such as the blue baby syndrome in infants and an increased cancer risk in adults. These problems can be mitigated through environmentally friendly methods. This study investigated nitrate removal efficiencies, achieving values ranging between 82% and 92.4%. High ammonium concentrations increase soil salinity and cause damage to plant roots. Ammonium can also leach into groundwater and surface water, leading to water pollution and negatively affecting aquatic ecosystems. Since methods such as biological nitrogen removal are recommended for ammonium reduction, microalgae were utilized in this study. According to the results of the present study, 99% ammonium removal was observed in all the groups, which indicates that all the groups performed successfully. High levels of total nitrogen (TN) and total phosphorus (TP) may cause soil and water pollution, resulting in a decline in oxygen levels in water resources and harming aquatic ecosystems. From a soil fertility perspective, it might bring about negative impacts such as increased salinity. Biological methods are recommended to improve TN and TP levels. In this study, TN and TP removal efficiencies were determined to range between 98–99.4% and 77.4–89.4%, respectively (Figure 4). In a study on agricultural-industrial wastewater-microalgae, the parameters of COD, NH4-N, and NO3-N were examined in a canal-type pond reactor. A removal efficiency of 61.8% was achieved for COD, 67% for NH4-N, and 17.22% for NO3-N [23]. In another study on agricultural-industrial wastewater-microalgae, research was conducted using two different doses, and COD removal was determined to be between 73% and 94.9%. The rate of TN removal ranged from 30% to 48%, while TP removal values were reported between 1.1% and 47.2%. For NH4-N removal, values between 68.5% and 72.7% were observed, and NO3-N removal was stated to range between 17.6% and 19.6% [26].

Figure 4.

COD and nutrient removal.

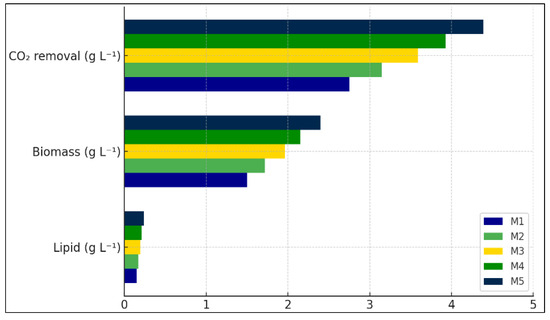

In this study, the primary purpose of the applications was to obtain biomass by ensuring the development of microalgae existing in BLD environments and, thus, microalgae growth. Afterwards, it aimed to determine their biodiesel potential. In this context, biomass yields between 1.5 g L−1 and 2.4 g L−1 were recorded at five different BLD environments. The highest biomass yield was determined in M5. In direct proportion to the biomass data, CO2 removal values were similar. CO2 removal values were calculated between 2.75 g L−1 and 4.39 g L−1 (Figure 5).

Figure 5.

Microalgal biomass, lipid, and CO2 removal.

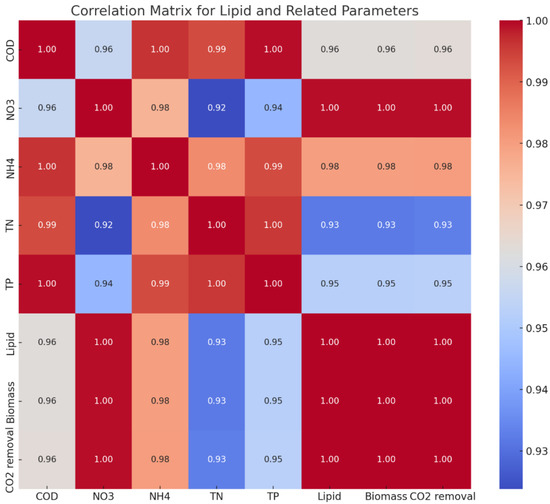

The groups with the highest lipid yield were M4 and M5. As far as microalgal biomass and CO2 removal are concerned, it is possible to say that M4 and M5 were the best-performing applications. This showed that biogas plants can be an industrial solution for BLD. With this study, a direct model emerges for climate action from Sustainable Development Goals. In addition, it is important for the protection of soil and water resources by preventing nitrate pollution. The correlation matrix illustrating the relationship between the waste characteristics of the groups and the obtained lipid, biomass, and CO2 removal is presented in Figure 6.

Figure 6.

The correlation matrix of groups (wastewater-lipid-biomass-CO2 removal).

There is a perfect positive correlation (1.00) between lipid, biomass, and CO2 removal. This indicates that as microalgae biomass increases, lipid production and carbon removal also increase. Lipid has a strong positive correlation with COD (0.96), demonstrating that organic matter in the environment is critical for microalgae growth and lipid production. There is also a perfect positive correlation (1.00) between biomass and CO2 removal, indicating that the higher the microalgae biomass, the greater the CO2 removal. Lipid exhibits strong positive correlations with these parameters, ranging from 0.93 to 0.98. This highlights the significant role of nutrients such as NO3, NH4, TN, and TP in lipid production. TP emerges as an important factor for both lipid production and biomass growth (0.95).

3.2. Effects of Dosages of Biogas Liquid Digestate on Fatty Acid Compositions Produced from Cyanobacteria

The selection of the most optimal nutrient medium directly affects biodiesel quality. Independent of the specific cultivation systems in wastewater treatments, the algal lipid content and the structure of fatty acids can be significantly affected by cultivation treatments [27]. Fatty acid methyl esters were determined after derivatization (Table 3).

Table 3.

Fatty acid compositions produced from cyanobacteria under five different BLD environments.

There are differences among BLD dosages. The main fatty acids were C18:1 oleic acid, C18:2 linoleic acid, and C16:0 palmitic acid (Table 2). The most common fatty acid profiles of algae mainly involve linoleic, linolenic, stearic, palmitic, and oleic acids [24]. In addition to these, other fatty acid forms also exist in small quantities, affecting fuel properties to a certain degree. Yet, no single fatty acid is accountable for any specific fuel property [28]. When the oleic acid value was evaluated, it was determined that the highest value was 40.76% in M5, and the lowest value was 24.82% in M1. In a study examining the properties of various potential biodiesel components, it was stated that high oleic acid is needed when long-term storage is required because high oleic acid value may increase oxidative stability [29]. The study reported a reasonable balance of fuel properties in oils with high oleic acid content [30]. Regarding the linoleic acid value, it was found that M2 had the highest value among the treatments (30.59%), while M3 had the lowest value (18.5%). Based on palmitic acid levels, M3 had the highest value at 35.6%, while M4 had the lowest at 19.9%. In a study on agro-industrial waste microalgae, the values for oleic acid were within the range of 7.01–16.95%, while the values ranged from 5.49% to 14.5% for linoleic acid. In the same study, it was seen that palmitic acid had values between 23.54% and 35.24% [26]. For C16:0, the lowest value was 19.55%, and the highest value was 43.92%, while linoleic acid values were determined between 0.77% and 34.79% [27]. In a study about wastewater microalgae treatment in the rose industry, values between 5.49% and 14.5% were reported [26].

In terms of SFA obtained from cyanobacteria under five different BLD environments, the highest value was acquired from M3 treatment with 40.16%, and the lowest SFA value was calculated in the M4 application. The fatty acid profiles of oil obtained from the Scenedesmus obliquus strain cultivated in rose industry wastewater were analyzed. SFA values were reported to be in the range of 38–51.78% [26]. In another study in which microalgal biomass and the estimated biodiesel parameters of different wavelengths were investigated, SFA values were reported between 24.17% and 49.70% [27]. Each group has its advantages and disadvantages regarding SFA, MUFA, and PUFA values. For example, in M1, the PUFA ratio was high, which improves low-temperature flow properties. In M2, the MUFA ratio was higher than in M1. This provided better oxidative stability and flow properties. In M3, there was a high SFA content, which enhances oxidative stability, making it ideal for biodiesel. In M4, the high MUFA content offers a balanced profile for biodiesel. The low SFA content ensures good flow properties. M5, on the other hand, had the highest MUFA content. It provided an ideal balanced profile for biodiesel with well-balanced SFA and PUFA ratios. When evaluating fatty acid profiles for biodiesel, M3 stands out as the most suitable group for enhancing oxidative stability, with its high SFA and moderate MUFA levels. However, for a balanced option, M4 and M5 were ideal groups, offering both fluidity and stability with their high MUFA content. Among these, M5 provided the best overall balance. Considering both industrial applications and balance, M5, which had a high waste yield, can be regarded as an ideal option in terms of biodiesel fatty acid profiles. In the study investigating the estimated biodiesel properties of oil obtained from the Scenedesmus obliquus strain cultivated in rose industry wastewater, SFA, MUFA, and PUFA values were also evaluated. Among nine groups, SFA values ranged between 38% and 51.78%, MUFA values between 10.89% and 19.36%, and PUFA values between 24.58% and 34.20%.

3.3. Evaluation of Algal Lipids for Estimated Biodiesel Production

Table 3 presents the estimated biodiesel fuel properties with algal lipid parameters based on fatty acid profiles under five different BLD environments. The fatty acid profiles of the obtained biomass were analyzed. The obtained values changed from 73.1% for M3 to 100.73% for M5. M3 produced the lowest degree of unsaturation, while M5 yielded the highest unsaturation, which indicates that this BLD environment had a high PUFA content because DU is a weighted sum of the masses of monounsaturated and polyunsaturated fatty acids. The saponification value was analyzed, which is one of the important parameters in the quality control phase of biodiesel. The highest SV value among BLD environments was determined in M5 (192.85%). Also, the IV was analyzed, which is a critical factor affecting the chemical stability, performance, and storage life of biodiesel. According to the EN 14214 European standard [31], IV should be below 120 g I2/100 g. According to the ASTM D6751 [32] American standard, no value for IV is specified. In this study, it was calculated below 120 g I2/100 g in all the BLD environments. The study also investigated CN, which is a measure of the ignition quality of diesel fuel. CN is required to be a minimum of 47 according to the ASTM D6751 standard and a minimum of 51 according to the EN 14214 standard. In this study, it was determined that the CN coincided with the values specified in the standards. While there were no significant differences among the treatments, the highest CN value was calculated in M3 with 59.5%. It is stated that biodiesel with higher CNs provides a smoother engine operation and higher energy efficiency. It is also stated that biodiesel with a CN below the standard values may adversely affect the engine’s operation and produce a greater amount of emissions during combustion (Table 4).

Table 4.

Comparison of estimated biodiesel properties according to standards.

LCSF, which refers to the amount of long-chain saturated fatty acids present in biodiesel fuel, affects the physical properties of biodiesel. No direct LCSF limit is given in international standards. While a high LCSF value is known to increase the cold filter clogging point, it reduces the fluidity of the fuel at low temperatures and increases the risk of freezing. A low LCSF value is stated to improve the cold weather performance and maintain the fluidity of fuel [33]. Research and industrial applications of the recommended values for LCSF show that LCSF should be in the range of 3.5–5.0 in temperate climates and 1.0–3.0 in cold climates to achieve a certain CFPP value. In this study, the highest LCSF value was calculated for M3 with 5.45, and the lowest one was calculated for M4 with 3.22. For the study, the CFPP was analyzed, which is a significant parameter used to measure the performance and fluidity properties of biodiesel at low temperatures. Especially in cold climates, biodiesel with a high CFPP value can cause clogging in fuel filters and fuel lines. According to the ASTM D6751 standard, (−13)–(−5) was reported for the CFPP. On the other hand, according to the EN 14214 standard, (−20)–(+5) was stated for the CFPP value [28]. A CFPP value lower than the specified limit values ensures that the biodiesel flows smoothly even in cold weather conditions. In this study, the determined CFPP values of all treatments complied with the standards.

The study also investigated CP, which is defined as the temperature at which insoluble components (e.g., paraffin) crystallize and become cloudy when a fuel is cooled. Although no value was specified for this parameter according to the ASTM D6751 and EN 14214 standards, it was associated with CFPP [26]. If the CFPP value is between the limit values according to the standards, it is also considered suitable for CP. In this study, the highest CP value of 13.73 was calculated for M3, while the lowest CP value of 5.48 was calculated for M4. Differences among treatments were observed. Oxidation stability, which is a measure of the tendency of biodiesel to react with oxygen, is also a parameter that directly affects the storage time, engine performance, and environmental effects of biodiesel. According to the ASTM D6751 standard, it was stated that it should have a minimum oxidation stability of 3 h, and according to the EN 14214 standard, it should have a minimum oxidation stability of 6 h [26]. In this study, OS values, which are the estimated biodiesel properties, were also examined. It was determined that all treatments were suitable according to the ASTM D6751, while M3, M4, and M5 were suitable according to the EN 14214 standard. In a study predicting the biodiesel properties of two different systems and two different microalgae, it was reported that CN values demonstrated better performance and lower IV values provided an advantage in oxidation stability. However, the CFPP value was reported to be non-compliant with the standards, indicating that it is less suitable for cold weather conditions [34].

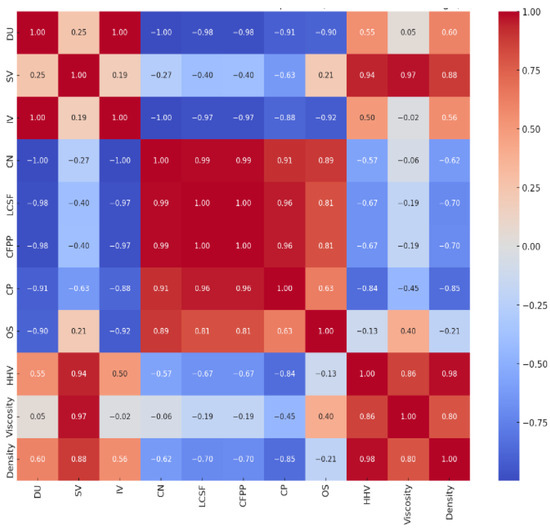

HHV values, which express the amount of energy released by fuel during combustion and are a vital criterion for the energy efficiency and performance of biodiesel, were also investigated. HHV directly affects engine efficiency, fuel economy, and energy output. The HHV of biodiesel is generally about 10% lower than that of petrodiesel, a factor that should be considered in the design of fuel. The correlation matrix of the predicted biodiesel properties is shown in Figure 7.

Figure 7.

Correlation matrix of estimated biodiesel properties.

There is a perfect positive correlation (1.00) between DU and IV, indicating that these two variables represent the degree of unsaturation and increase together. LCSF and CFPP show strong positive correlations (0.99) with CN, which demonstrates that the cold flow properties of the fuel are linked to the cetane number. HHV has a strong positive relationship with density (0.98), indicating that denser fuels tend to have higher energy values. There is also a positive correlation (0.86) with viscosity, suggesting that more viscous fuels may have higher energy values.

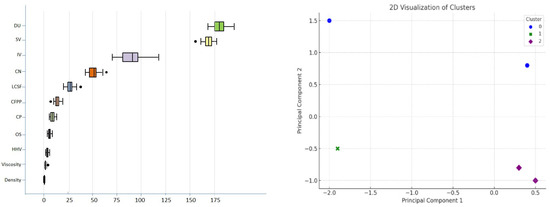

3.4. Cluster Analysis

Cluster analysis was performed, and the groups were divided into three clusters. According to the cluster analysis, the groups were clustered as Cluster 0: M4 and M5, Cluster 1: M3, and, finally, Cluster 2: M1 and M2 (Figure 8).

Figure 8.

Cluster analysis of treatments. Circles (outliers): The light-colored circular symbols outside the box represent outliers. Outliers are values that fall outside the range of Q1 − 1.5 * IQR (lower bound) or Q3 + 1.5 * IQR (upper bound). Here, IQR stands for interquartile range (Q3 − Q1).

General evaluation of cluster characteristics: Strengths of Cluster 0: The HHV value was the highest with an average value of 37.155, and energy density was high. The OS value had the best OS with an average of 6.745. It had balanced values of LCSF and CFPP. Cold weather performance was fairly satisfactory. Weaknesses of Cluster 0: DU and IV were slightly lower compared to the other clusters. Strengths of Cluster 1: CN was the highest in this cluster with 59.45. This indicated a high combustion quality. LCSF was high at 5.450, indicating good cold air fluidity. Weaknesses of Cluster 1: DU and IV were significantly lower than the other clusters, and product efficiency was lower. Strengths of Cluster 2: DU was the highest in this cluster with 100.315 and was the best group in terms of efficiency. IV offered a good balance of 95.855. Weaknesses of Cluster 2: OS was the lowest in this cluster with 5.880. Cluster 2 stands out in terms of energy efficiency. This group can be preferred in terms of overall production efficiency and balance. In terms of cold weather performance, Cluster 0 provides balance in these metrics. In addition, the high oxidation stability of this group is advantageous for the production of long-lasting fuel. In terms of combustion quality, Cluster 1 had the highest values in terms of CN. However, due to its low DU and IV, it should only be preferred if combustion quality is a priority. In terms of waste efficiency, Cluster 0 can be preferred.

4. Conclusions

This study demonstrated that microalgae cultivation in BLD environments is a sustainable method for biodiesel production. Microalgae effectively removed pollutants such as COD, NH4, TN, and TP while simultaneously producing biomass and lipids suitable for biodiesel. High removal efficiencies were observed across all groups, with NH4 removal reaching 99% and COD removal ranging from 82% to 96%. removal was strongly correlated with biomass production, indicating the dual environmental and economic benefits of this approach. The M4 (20% BLD + 80% BBM) and M5 (40% BLD + 60% BBM) groups showed the highest performance in terms of biomass, lipid content, and removal. The biodiesel derived from these groups met ASTM and EN standards, with M5 standing out as the most balanced in terms of energy density, oxidative stability, and cold-weather performance. In conclusion, this microalgae-based system offers an environmentally and economically efficient solution, combining wastewater management and renewable energy production. In conclusion, the research demonstrates that microalgae cultivation in BLD environments is a viable and sustainable method for biodiesel production, with significant environmental and economic benefits. The findings provide a strong foundation for scaling up this technology for industrial applications. When the application of M5 is preferred, an estimated reduction of 11.5 × 109 g of can be achieved across Türkiye. This study demonstrates that liquid digestate waste from biogas, one of the renewable energy sources, can be converted into another renewable energy source using microalgae.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors without undue reservation.

Acknowledgments

I would like to thank Kamil EKİNCİ for his guidance and contributions to the design of the research. Wastewater supply in this study was carried out by AKINCI Biogas and Energy Systems Co. The wastewater supply support from the AKINCI Biogas and Energy Systems Co. is thankfully acknowledged by the author.

Conflicts of Interest

The author declares no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| COD | Chemical oxygen demand |

| BLD | Biogas liquid digestate |

| BBM | Bold basal medium |

| CFPP | Cold filter plugging point |

| CN | Cetane number |

| CP | Cloud point |

| HHV | High heating value |

| LCSF | Long-chain saturated factor |

| DU | Degree of unsaturation |

| OS | Oxidation stability |

| SV | Saponification value |

| NGS | Next-generation sequencing |

| PCR | Polymerase chain reaction |

References

- Anaerobic Digestion: Products. Available online: https://enst.umd.edu/sites/enst.umd.edu/files/files/documents/Extension/Anaerobic-Digest_Products.pdf (accessed on 2 February 2025).

- Yıldırım, E. Effect of Rumen Fungi on Potential of Biogas Production in Anaerobic Digesters Fed with Different Lignocellulosic Compounds. Master’s Thesis, Boğaziçi Üniversitesi Çevre Bilimleri Enstitüsü, İstanbul, Turkey, 2016. [Google Scholar]

- Bascetincelik, A.; Ozturk, H.H.; Ekinci, K.; Kaya, D.; Kacira, M.; Karaca, C. Strategy Development and Determination of Barriers for Thermal Energy and Electricity Generation from Agricultural Biomass in Turkey. Energy Explor. Exploit. 2009, 27, 277–294. [Google Scholar] [CrossRef]

- Cengiz, K. Determination of biogas production potential from animal manure and GHG emission abatement in Turkey. Int. J. Agric. Biol. Eng. 2018, 11, 205–210. [Google Scholar]

- Song, Q.; Li, J.; Zeng, X. Minimizing the increasing solid waste through zero waste strategy. J. Clean. Prod. 2015, 104, 199–210. [Google Scholar] [CrossRef]

- Serdjuk, M.; Bodmer, U.; Hülsbergen, K.J. Integration of biogas production into organic arable farming systems: Crop yield response and economic effects. Org. Agr. 2018, 8, 301–314. [Google Scholar] [CrossRef]

- Workshop on Zero Waste Vision and the Management of Animal Wastes. Available online: https://webdosya.csb.gov.tr/db/bolu/icerikler/b-yogaz-yontemler--ve-ik-nc-l-urunler_prof.dr.-nur-ye-altinay-perendeci-20230107084153.pdf (accessed on 23 January 2025).

- Palikrousis, T.L.; Manolis, C.; Kalamaras, S.D.; Samaras, P. Effect of Light Intensity on the Growth and Nutrient Uptake of the Microalga Chlorella sorokiniana Cultivated in Biogas Plant Digestate. Water 2024, 16, 2782. [Google Scholar] [CrossRef]

- Caporaso, J.G.; Kuczynski, J.; Stombaugh, J.; Bittinger, K.; Bushman, F.D.; Costello, E.K.; Fierer, N.; Peña, A.G.; Goodrich, J.K.; Gordon, J.I.; et al. QIIME allows analysis of high-throughput community sequencing data. Nat. Methods 2011, 7, 335–336. [Google Scholar] [CrossRef] [PubMed]

- Hugerth, L.W.; Andersson, A.F. Analysing microbial community composition through amplicon sequencing: From sampling to hypothesis testing. Front. Microbiol. 2017, 8, 1561. [Google Scholar] [CrossRef] [PubMed]

- TS EN ISO 14911; Water quality—Determination of Dissolved Alkaline Earth and Alkali Metals Using ion Chromatography of cations. Turkish Standards Institution (TSE): Ankara, Turkey, 2022.

- TS EN ISO 10304-1; Water Quality—Determination of Dissolved Anions by Liquid Chromatography of Ions—Part 1: Determination of Bromide, Chloride, Fluoride, Nitrate, Nitrite, Phosphate and Sulfate. Turkish Standards Institution (TSE): Ankara, Turkey, 2022.

- APHA. Standard Methods for the Examination of Water and Wastewater, 20th ed.; American Public Health Association: Washington, DC, USA, 1998. [Google Scholar]

- Slade, R.; Bauen, A. Microalgae cultivation for biofuels: Cost, energy balance, environmental impacts and future prospects. Biomass Bioenergy 2013, 53, 29–38. [Google Scholar] [CrossRef]

- Shahid, A.; Malik, S.; Zhu, H.; Xu, J.; Nawaz, M.Z.; Nawaz, S.; Alam, M.A.; Mehmood, M.A. Cultivating microalgae in wastewater for biomass production, pollutant removal, and atmospheric carbon mitigation; a review. Sci. Total Environ. 2020, 704, 135303. [Google Scholar] [CrossRef]

- Li, S.; Luo, S.; Guo, R. Efficiency of CO2 fixation by microalgae in a closed raceway pond. Bioresour. Technol. 2013, 136, 267–272. [Google Scholar] [CrossRef]

- Zhao, Q.; Han, F.; You, Z.; Huang, Y.; She, X. Evaluation of the relationship of wastewater treatment and biodiesel production by microalgae cultivated in the photobioreactor. Fuel 2023, 350, 128750. [Google Scholar] [CrossRef]

- Nie, M.S. A new understanding of the development of water treatment technology. Water Supply Drain. 2007, 277. [Google Scholar] [CrossRef]

- Branco-Vieira, M.; Mata, T.M.; Martins, A.A.; Freitas, M.A.V.; Caetano, N.S. Economic analysis of microalgae biodiesel production in a small-scale facility. Energy Rep. 2020, 6, 325–332. [Google Scholar] [CrossRef]

- Bardakçı, B.; Seçilmiş, H. Isparta bölgesindeki gül yağının kimyasal içeriğinin GC-MS ve FTIR spektroskopisi tekniği ile incelenmesi. Süleyman Demirel Üniversitesi Fen Edeb. Fakültesi Fen Derg. 2006, 1, 64–69. [Google Scholar]

- Ramos, M.J.; Fernández, C.M.; Casas, A.; Rodríguez, L.; Pérez, Á. Influence of fatty acid composition of raw materials on biodiesel properties. Bioresour. Technol. 2009, 100, 261–268. [Google Scholar] [CrossRef] [PubMed]

- Krisnangkura, K. A simple method for estimation of cetane index of vegetable oil methyl esters. J. Am. Oil Chem. Soc. 1986, 63, 552–553. [Google Scholar] [CrossRef]

- Talebi, A.F.; Tabatabaei, M.; Chisti, Y. BiodieselAnalyzer: A user-friendly software for predicting the properties of prospective biodiesel. Biofuel Res. J. 2014, 1, 55–57. [Google Scholar] [CrossRef]

- Bart, J.C.J.; Palmeri, N.; Cavallaro, S. Emerging new energy crops for biodiesel production. Biodiesel Sci. Technol. 2010, 226–284. [Google Scholar] [CrossRef]

- Uysal, Ö.; Ekinci, K. Treatment of rose oil processing effluent with Chlorella sp. using photobioreactor and raceway. J. Environ. Manag. 2021, 295, 113089. [Google Scholar] [CrossRef]

- Uysal, F.Ö. Gül Yağı İşleme Atık Suyunun Acutodesmus Obliquus İle Arıtımı ve Elde Edilen Mikroalgal Kütleden Biyodizel, Biyokömür ve Biyogübre Üretim Potansiyelinin Araştırılması, Süreçlerin su Ayak İzi ve Enerji Analizleri. Ph.D. Thesis, Isparta Uygulamalı Bilimler Üniversitesi/Lisansüstü Eğitim Enstitüsü, Isparta, Turkey, 2022. [Google Scholar]

- Kurt, Ç.; Ekinci, K.; Uysal, Ö. The effect of LEDs on the growth and fatty acid composition of Botryococcus braunii. Renew. Energy 2022, 186, 66–73. [Google Scholar] [CrossRef]

- Dunn, R.O. Correlating the cloud point of biodiesel to the concentration and melting properties of the component fatty acid methyl esters. Energy Fuels 2018, 32, 455–464. [Google Scholar] [CrossRef]

- Knothe, G.; Matheaus, A.C.; Ryan, T.W., III. Cetane numbers of branched and straight chain fatty esters determined in an ignition quality tester. Fuel 2003, 82, 971–975. [Google Scholar] [CrossRef]

- Rashid, U.; Anwar, F.; Moser, B.R.; Knothe, G. Moringa oleifera oil: A possible source of biodiesel. Bioresour. Technol. 2008, 99, 8175–8179. [Google Scholar] [CrossRef]

- EN 14214; Liquid Petroleum Products—Fatty Acid Methyl Esters (FAME) for Use in Diesel Engines—Requirements and Test Methods. European Committee for Standardization (CEN): Brussels, Belgium, 2008.

- ASTM D6751; Standard Specification for Biodiesel Fuel Blend Stock (B100) for Middle Distillate Fuels. ASTM International: West Conshohocken, PA, USA, 2008.

- Özdemir, Z.Ö.; Mutlubaş, H. Biyodizel Üretim Yöntemleri ve Çevresel Etkileri. Kirklareli Univ. J. Eng. Sci. 2016, 2, 129–143. [Google Scholar]

- Gol, N.; Taghavijeloudar, M.; Jalilian, N.; Rezania, S. Microalgae cultivation in semi-transparent photovoltaic bioreactor for sustainable power generation, wastewater treatment and biodiesel production. Energy Convers. Manag. 2025, 325, 119417. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).