From Tea Fermentation to New Technologies: Multisectoral Applications of Kombucha SCOBY Through the Lens of Methodi Ordinatio

Abstract

1. Introduction

2. Materials and Methods

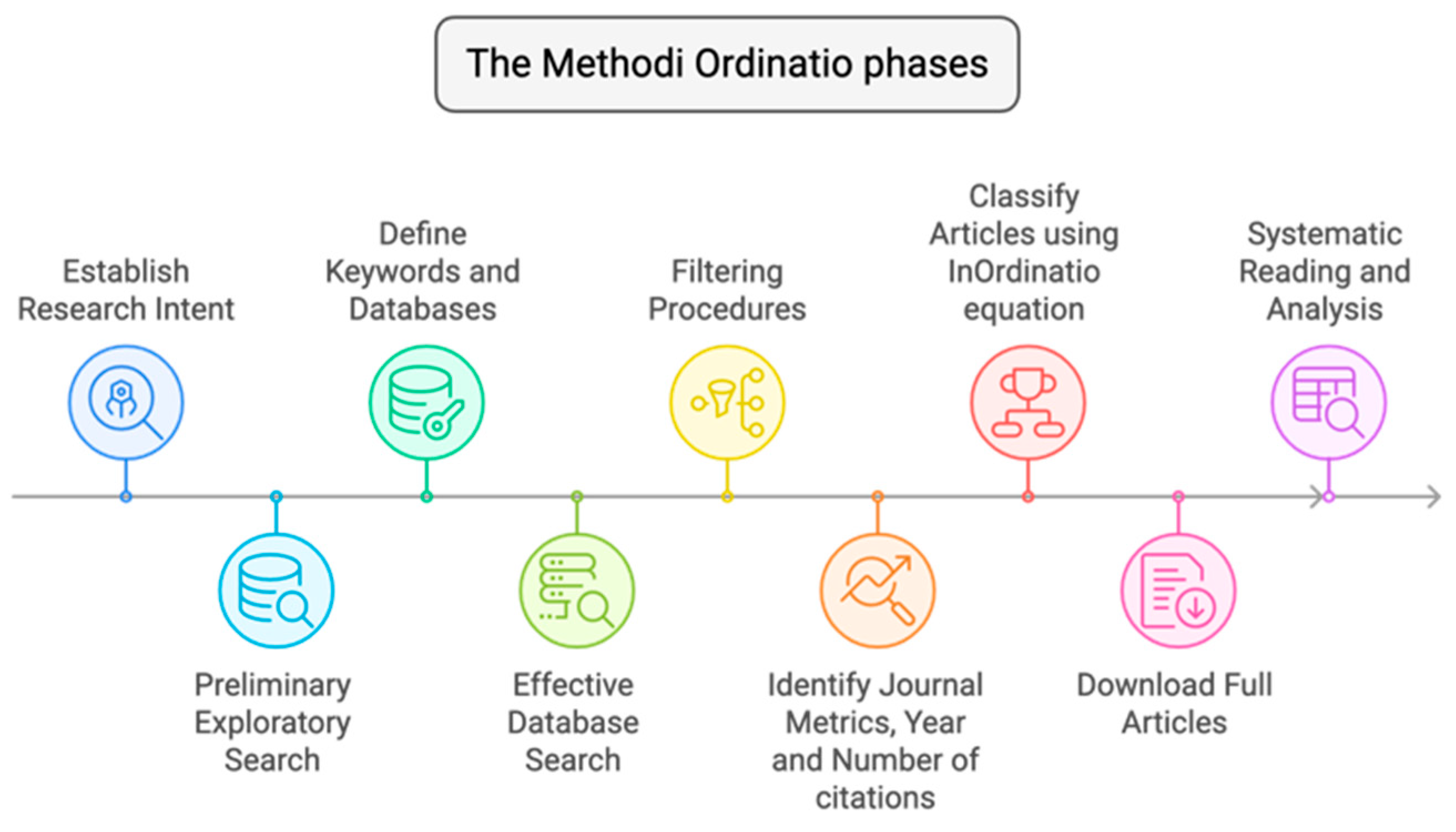

2.1. Systematic Mapping of Literature on Kombucha-Derived SCOBY

2.2. Data Analysis

3. Results

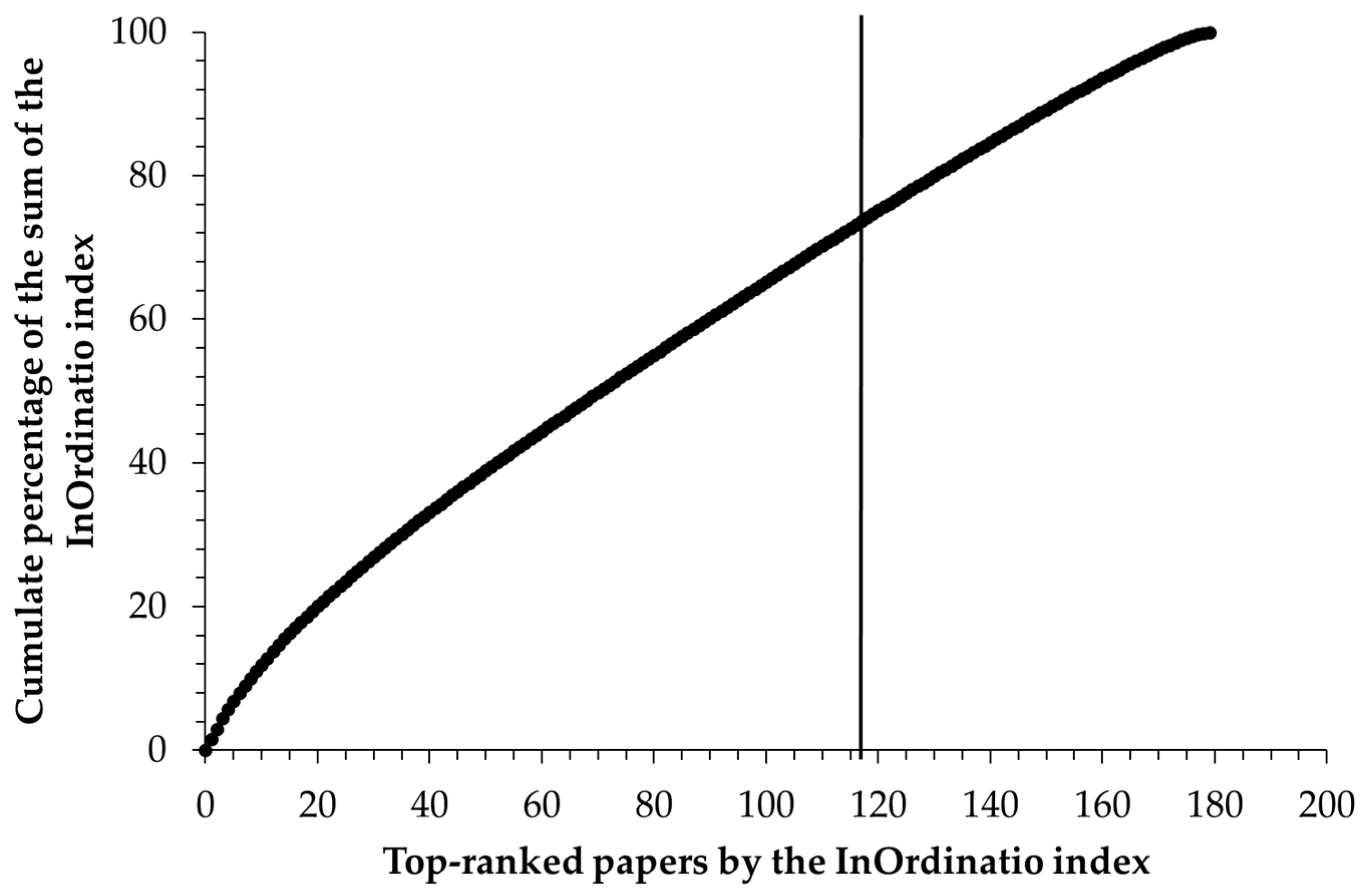

3.1. Methodi Ordinatio Analyses

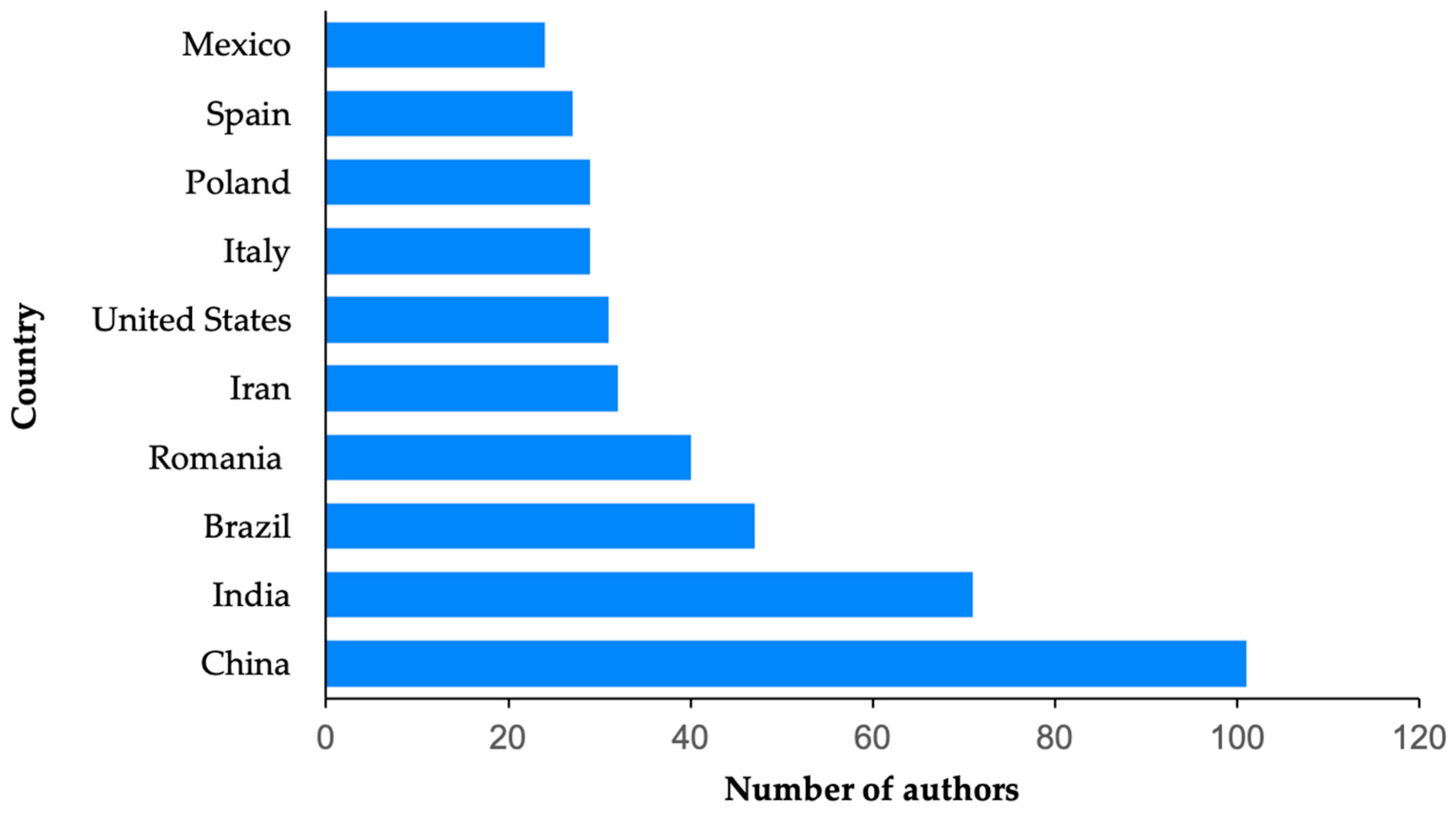

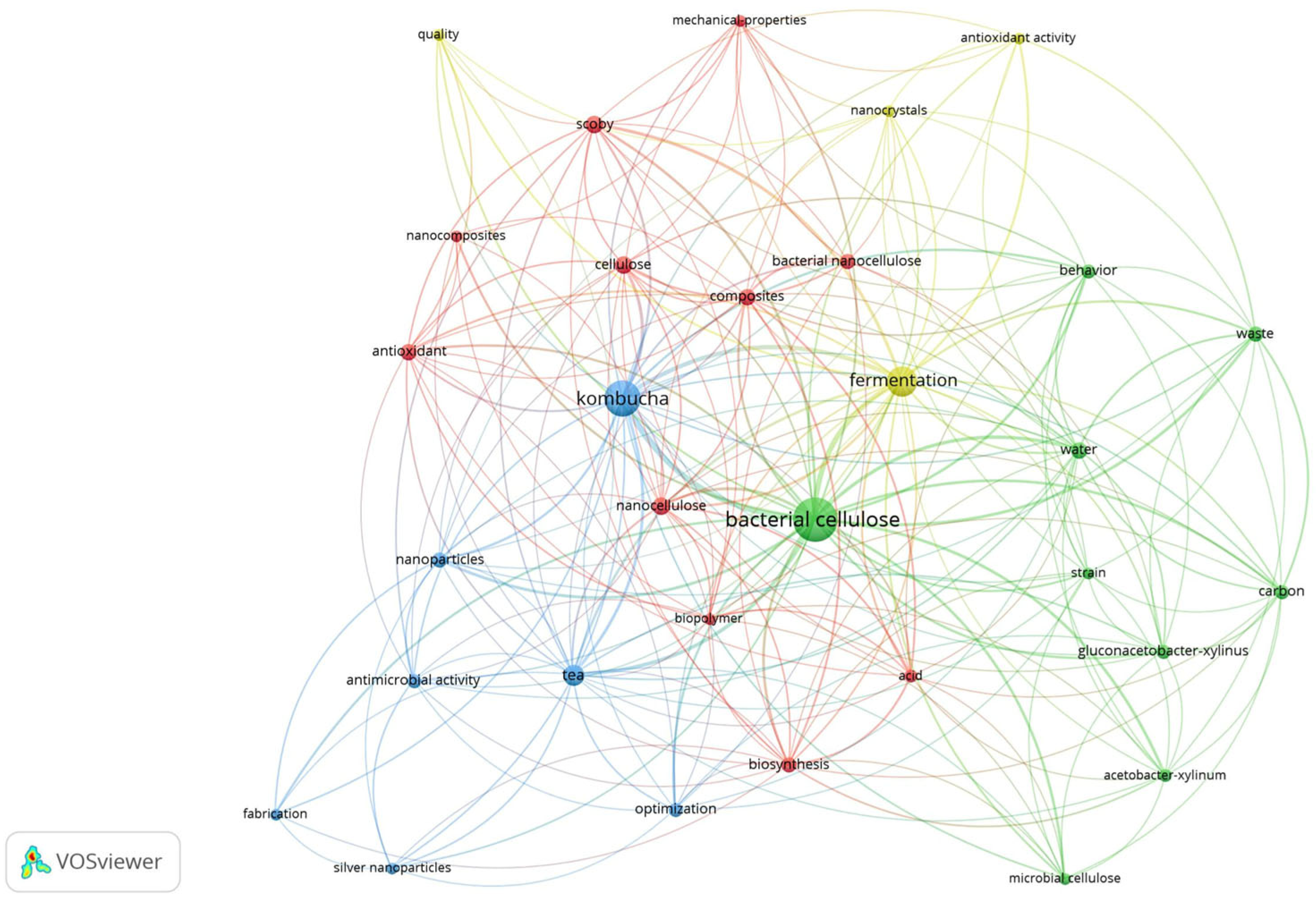

3.2. Bibliometric Analysis

3.3. SCOBY Applications

3.3.1. Bacterial Cellulose

Alternative Carbon Sources for SCOBY BC Production

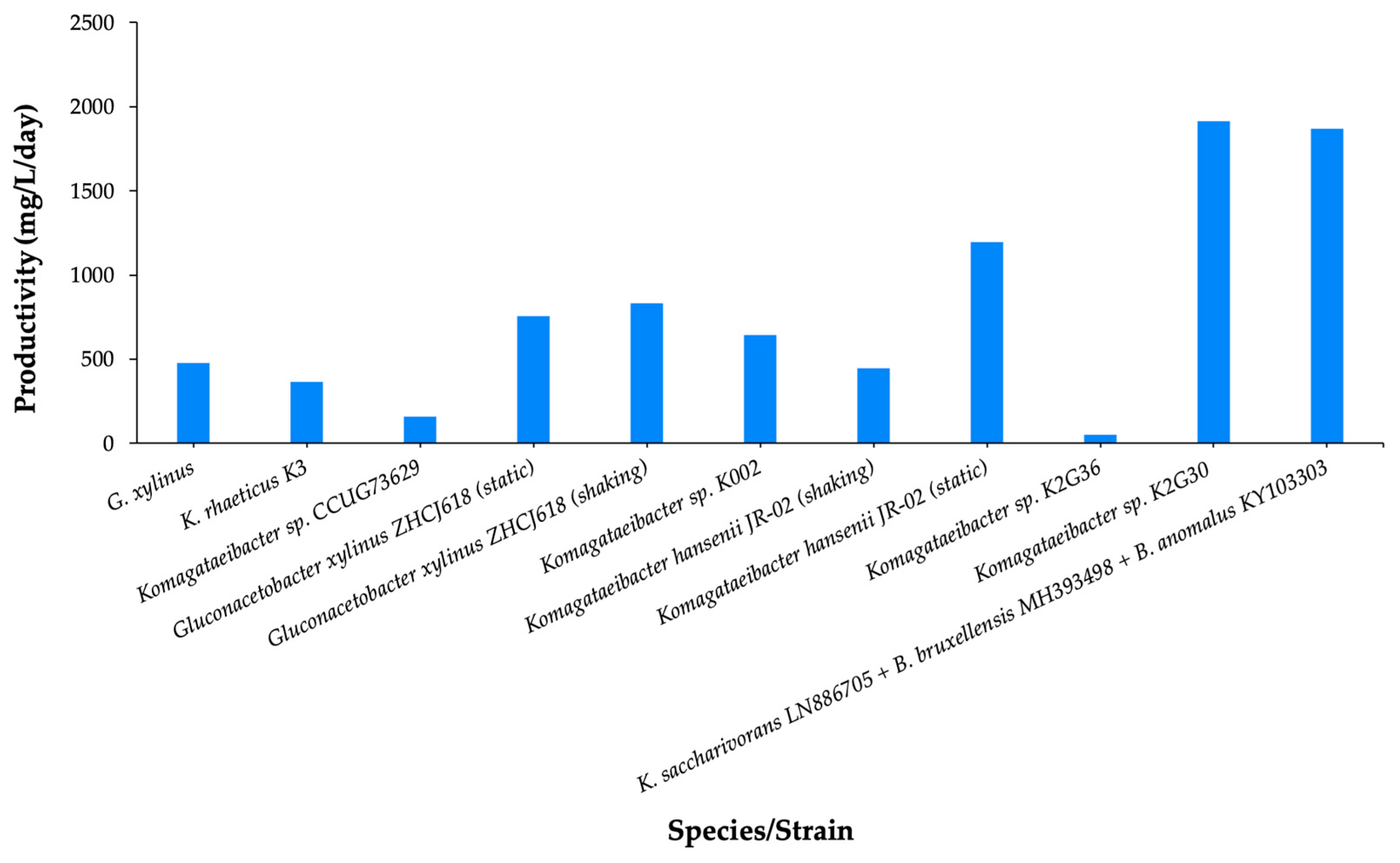

SCOBY Microbial Isolation

Nanomodification and Functionalization of SCOBY

3.3.2. SCOBY as a Biosustainable Material

SCOBY as a Biomaterial

SCOBY for Electrochemistry

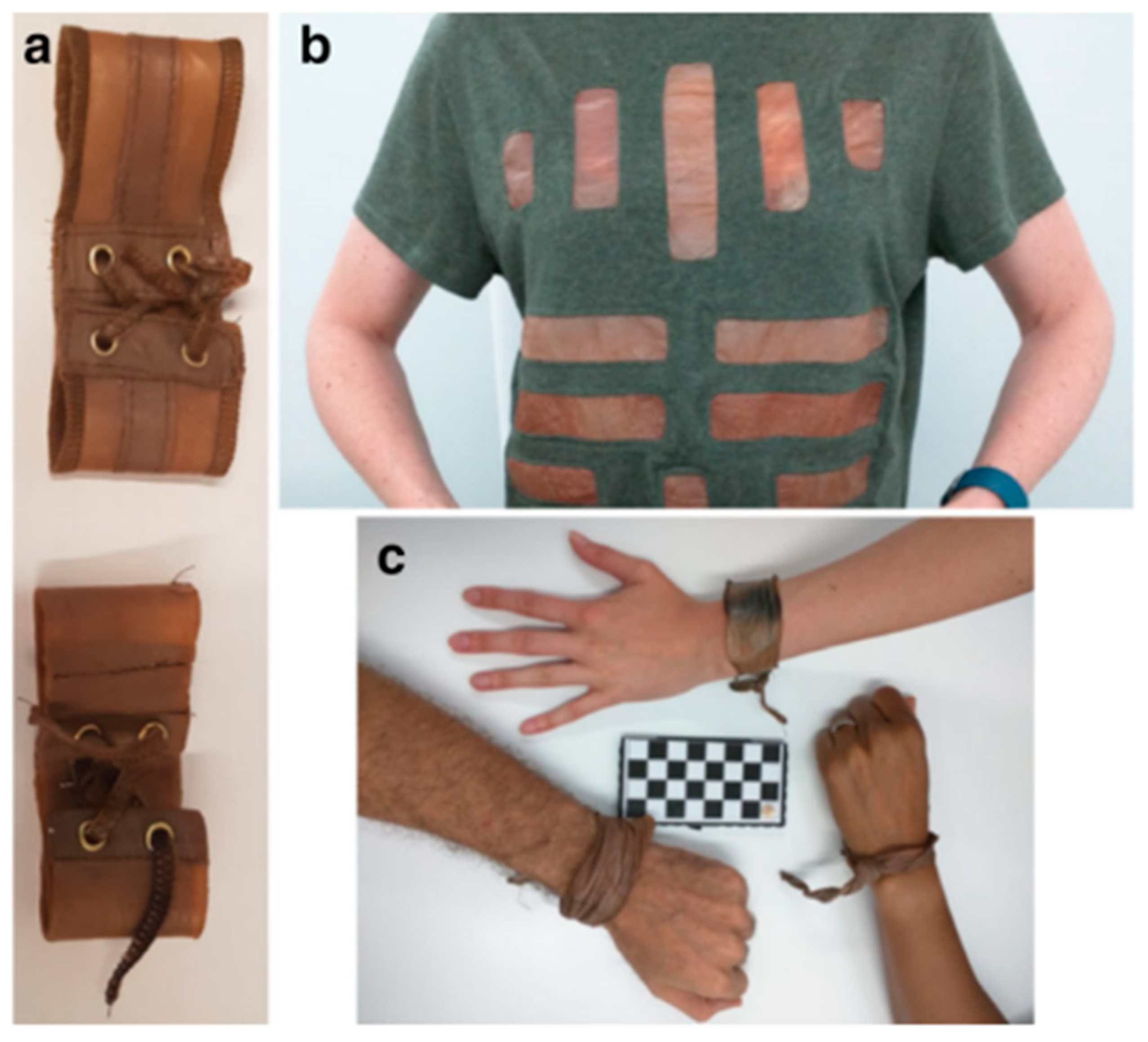

Textile Uses of SCOBY

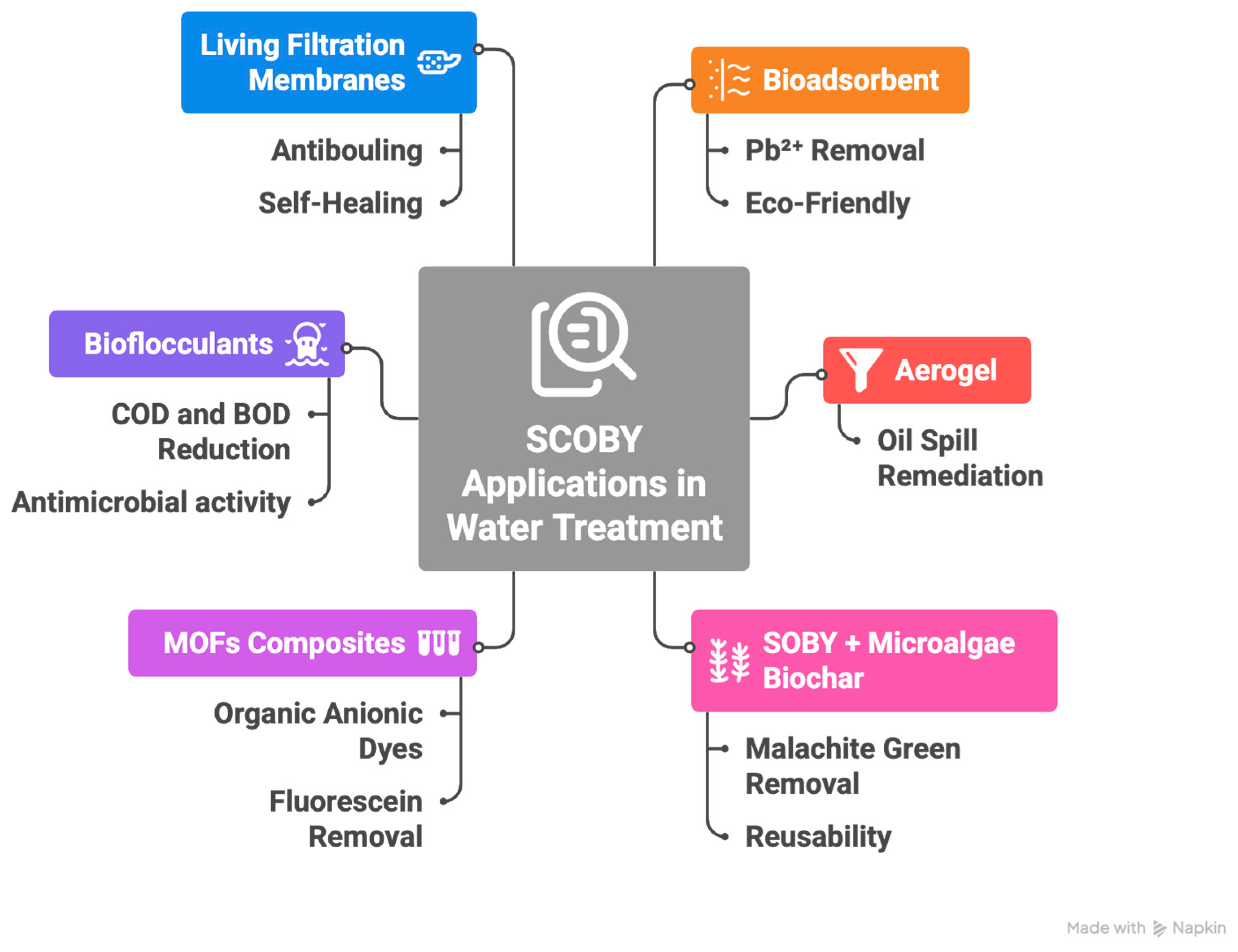

SCOBY in Water Treatment

3.3.3. Biomedical

SCOBY for Wound Healing

SCOBY in Tissue Engineering

SCOBY in Dermocosmetics

SCOBY for Dental Materials

3.3.4. Food Technology

Active Packaging

SCOBY in Food Technology

SCOBY for Pickering Emulsions

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AgNPs | Silver Nanoparticles |

| Au-CBC | Gold Nanoparticle-Functionalized Chitosan-Bacterial Cellulose Composites |

| BC | Bacterial Cellulose |

| BNC | Bacterial Nanocellulose |

| BOD | Biological Oxygen Demand |

| CBC-Au | Gold Nanoparticles in Chitosan-Bacterial Cellulose Composite |

| CMC | Carboxymethyl Cellulose |

| COD | Chemical Oxygen Demand |

| EDS | Energy Dispersive X-ray Spectroscopy |

| FeNPs | Iron Nanoparticles |

| FTIR | Fourier Transform Infrared Spectroscopy |

| GRAS | Generally Recognized As Safe |

| HAp/TiO2 | Hydroxyapatite/Titanium Dioxide Nanocomposites |

| HC | Hydrolyzed Collagen |

| HGBC | Hydrogel Bacterial Cellulose |

| IRR | Internal Rate of Return |

| JCR | Journal Citation Reports |

| KBC | Kombucha-Derived Bacterial Cellulose |

| LFMs | Living Filtration Membranes |

| PAE | Pomegranate Anthocyanin Extract |

| PLA | Polylactic Acid |

| PMMA | Polymethyl Methacrylate |

| ROI | Return on Investment |

| SCOBY | Symbiotic Consortium of Bacteria and Yeast |

| SeBNCSFa | Selenium Nanoparticles Ferulic Acid-Grafted Chitosan |

| SeNPsK | Selenium Nanoparticles Biosynthesized via Kombucha Fermentation |

| SeNPsSb | Phyto-Synthesized Selenium Nanoparticles |

| SNHA | Nanocellulose-Based Composite Coated with Hydroxyapatite |

| VFD | Vortex Fluidic Device |

| ZnO NPs | Zinc Oxide Nanoparticles |

References

- Jayabalan, R.; Malbaša, R.V.; Lončar, E.S.; Vitas, J.S.; Sathishkumar, M. A Review on Kombucha Tea-Microbiology, Composition, Fermentation, Beneficial Effects, Toxicity, and Tea Fungus. Compr. Rev. Food Sci. Food Saf. 2014, 13, 538–550. [Google Scholar] [CrossRef]

- Chakravorty, S.; Bhattacharya, S.; Chatzinotas, A.; Chakraborty, W.; Bhattacharya, D.; Gachhui, R. Kombucha Tea Fermentation: Microbial and Biochemical Dynamics. Int. J. Food Microbiol. 2016, 220, 63–72. [Google Scholar] [CrossRef]

- Harrison, K.; Curtin, C. Microbial Composition of Scoby Starter Cultures Used by Commercial Kombucha Brewers in North America. Microorganisms 2021, 9, 1060. [Google Scholar] [CrossRef] [PubMed]

- Ross, P.; Mayer, R.; Benziman, M. Cellulose Biosynthesis and Function in Bacteria. Microbiol. Rev. 1991, 55, 35–58. [Google Scholar] [CrossRef] [PubMed]

- Brown, R.M.; Willisont, J.H.M.; Richardson, C.L. Cellulose Biosynthesis in Acetobacter Xylinum: Visualization of the Site of Synthesis and Direct Measurement of the in Vivo Process. Proc. Natl. Acad. Sci. USA 1976, 73, 4565–4569. [Google Scholar] [CrossRef]

- Grand View Research. Kombucha Market Size, Share & Trends Analysis Report by Product (Organic, Conventional), by Distribution Channel, by Region, and Segment Forecasts, 2024–2030; Grand View Research: San Francisco, CA, USA, 2024; Available online: https://www.grandviewresearch.com/industry-analysis/kombucha-market (accessed on 3 October 2025).

- Kim, J.; Adhikari, K. Current Trends in Kombucha: Marketing Perspectives and the Need for Improved Sensory Research. Beverages 2020, 6, 15. [Google Scholar] [CrossRef]

- Gagliardi, T.R.; de Farias Nascimento, A.; Valencia, G.A. Kombucha Bacterial Cellulose: A Promising Biopolymer for Advanced Food and Nonfood Applications. Foods 2025, 14, 738. [Google Scholar] [CrossRef]

- Huang, Y.; Yang, H.; Yu, Y.; Li, H.; Li, H.; Bai, J.; Shi, F.; Liu, J. Bacterial Cellulose Biomass Aerogels for Oil-Water Separation and Thermal Insulation. J. Environ. Chem. Eng. 2023, 11, 110403. [Google Scholar] [CrossRef]

- Oliver-Ortega, H.; Geng, S.; Espinach, F.X.; Oksman, K.; Vilaseca, F. Bacterial Cellulose Network from Kombucha Fermentation Impregnated with Emulsion-Polymerized Poly(Methyl Methacrylate) to Form Nanocomposite. Polymers 2021, 13, 664. [Google Scholar] [CrossRef]

- Arteaga-Ballesteros, B.E.; Guevara-Morales, A.; Martín-Martínez, E.S.; Figueroa-López, U.; Vieyra, H. Composite of Polylactic Acid and Microcellulose from Kombucha Membranes. E-Polymers 2021, 20, 015–026. [Google Scholar] [CrossRef]

- Bovi, J.; Delgado, J.F.; de la Osa, O.; Peltzer, M.A.; Bernal, C.R.; Foresti, M.L. Biobased Composites of Poly(Lactic Acid) Melt Compounded with Bacterial and Vegetal Nanocelluloses Incorporated through Different Strategies. Polymers 2024, 16, 898. [Google Scholar] [CrossRef] [PubMed]

- Bueno, F.; Fultz, L.; Husseneder, C.; Keenan, M.; Sathivel, S. Biodegradability of Bacterial Cellulose Polymer below the Soil and Its Effects on Soil Bacteria Diversity. Polym. Degrad. Stab. 2023, 217, 110535. [Google Scholar] [CrossRef]

- Chong, H.L.; Cheung, K.M.; Jiang, Z.; Ngai, T. Surface Modification of Kombucha Bacterial Cellulose for High Water and Water Vapor Barrier: Enhanced Properties through Enzyme Etching and Cardanol-Silane Coating. Adv. Energy Sustain. Res. 2024, 5, 2300117. [Google Scholar] [CrossRef]

- He, S.; Wu, Y.; Zhang, Y.; Luo, X.; Gibson, C.T.; Gao, J.; Jellicoe, M.; Wang, H.; Young, D.J.; Raston, C.L. Enhanced Mechanical Strength of Vortex Fluidic Mediated Biomass-Based Biodegradable Films Composed from Agar, Alginate and Kombucha Cellulose Hydrolysates. Int. J. Biol. Macromol. 2023, 253, 127076. [Google Scholar] [CrossRef]

- Shyan, L.L.; Mat Nanyan, N.S.; Ismail, N.; Al-Gheethi, A.; Nguyen, H.H.T.; Vo, D.V.N.; El Enshasy, H.A. Effort to Mitigate Volatile Fatty Acid Inhibition by Using Mixed Inoculum and Compost for the Degradation of Food Waste and the Production of Biogas. Sustainability 2023, 15, 1185. [Google Scholar] [CrossRef]

- Imanbekova, M.; Abbasi, R.; Hu, X.; Sharma, M.; Vandewynckele-Bossut, M.; Haldavnekar, R.; Wachsmann-Hogiu, S. Physical Modifications of Kombucha-Derived Bacterial Nanocellulose: Toward a Functional Bionanocomposite Platform. Macromol. Mater. Eng. 2024, 309, 2400041. [Google Scholar] [CrossRef]

- Mortazavi Moghadam, F.S.; Mortazavi Moghadam, F.A. Kombucha Fungus Bio-Coating for Improving Mechanical and Antibacterial Properties of Cellulose Composites. Mater. Today Commun. 2024, 40. [Google Scholar] [CrossRef]

- Bergottini, V.M.; Bernhardt, D. Bacterial Cellulose Aerogel Enriched in Nanofibers Obtained from Kombucha SCOBY Byproduct. Mater. Today Commun. 2023, 35, 109609. [Google Scholar] [CrossRef]

- Mehrotra, N.; Bhuvana, T.; Tiwari, A.; Chandraprakash, C. Aerogel-like Biodegradable Acoustic Foams of Bacterial Cellulose. J. Appl. Polym. Sci. 2024, 141, e55881. [Google Scholar] [CrossRef]

- Machfidho, A.; Ismayati, M.; Sholikhah, K.W.; Kusumawati, A.N.; Salsabila, D.I.; Fatriasari, W.; Thangunpai, K.; Enomae, T.; Ihsanpuro, S.I.; Gabriel, A.A.; et al. Characteristics of Bacterial Nanocellulose Composite and Its Application as Self-Cooling Material. Carbohydr. Polym. Technol. Appl. 2023, 6, 100371. [Google Scholar] [CrossRef]

- Kamiński, K.; Jarosz, M.; Grudzień, J.; Pawlik, J.; Zastawnik, F.; Pandyra, P.; Kołodziejczyk, A.M. Hydrogel Bacterial Cellulose: A Path to Improved Materials for New Eco-Friendly Textiles. Cellulose 2020, 27, 5353–5365. [Google Scholar] [CrossRef]

- Domskiene, J.; Sederaviciute, F.; Simonaityte, J. Kombucha Bacterial Cellulose for Sustainable Fashion. Int. J. Cloth. Sci. Technol. 2019, 31, 644–652. [Google Scholar] [CrossRef]

- Nguyen, H.T.; Saha, N.; Ngwabebhoh, F.A.; Zandraa, O.; Saha, T.; Saha, P. Kombucha-Derived Bacterial Cellulose from Diverse Wastes: A Prudent Leather Alternative. Cellulose 2021, 28, 9335–9353. [Google Scholar] [CrossRef]

- Nguyen, H.T.; Saha, N.; Ngwabebhoh, F.A.; Zandraa, O.; Saha, T.; Saha, P. Silane-Modified Kombucha-Derived Cellulose/Polyurethane/Polylactic Acid Biocomposites for Prospective Application as Leather Alternative. Sustain. Mater. Technol. 2023, 36, e00611. [Google Scholar] [CrossRef]

- Ayyappan, V.G.; Vhatkar, S.S.; Bose, S.; Sampath, S.; Das, S.K.; Samanta, D.; Mandal, A.B. Incorporations of Gold, Silver and Carbon Nanomaterials to Kombucha-Derived Bacterial Cellulose: Development of Antibacterial Leather-like Materials. J. Indian Chem. Soc. 2022, 99, 100278. [Google Scholar] [CrossRef]

- Mukhtar, T.; Manj, R.Z.A.; Khan, I.A.; Raza, Z.A.; Aslam, M. A Prime Synergistic BC@PPy Flexible Conductive Matrix Proposed Candidate for Boosting the Breakthrough in Smart E-Textiles Power Supplies. Mater. Today Commun. 2024, 38, 108208. [Google Scholar] [CrossRef]

- Wood, J.; Verran, J.; Redfern, J. Bacterial Cellulose Grown from Kombucha: Assessment of Textile Performance Properties Using Fashion Apparel Tests. Text. Res. J. 2023, 93, 3094–3108. [Google Scholar] [CrossRef]

- Jaishankar, M.; Tseten, T.; Anbalagan, N.; Mathew, B.B.; Beeregowda, K.N. Toxicity, Mechanism and Health Effects of Some Heavy Metals. Interdiscip. Toxicol. 2014, 7, 60–72. [Google Scholar] [CrossRef]

- Partnerships and Cooperation for Water the United Nations World Water Development Report 2023 Facts, Figures and Action Examples; UNESCO: Paris, France, 2023.

- Srivastava, S.; Sinha, R.; Roy, D. Toxicological Effects of Malachite Green. Aquat. Toxicol. 2004, 66, 319–329. [Google Scholar] [CrossRef]

- Mousavi, S.M.; Hashemi, S.A.; Amani, A.M.; Esmaeili, H.; Ghasemi, Y.; Babapoor, A.; Mojoudi, F.; Arjomand, O. Pb(II) Removal from Synthetic Wastewater Using Kombucha Scoby and Graphene Oxide/Fe3O4. Phys. Chem. Res. 2018, 6, 759–771. [Google Scholar]

- Pathy, A.; Krishnamoorthy, N.; Chang, S.X.; Paramasivan, B. Malachite Green Removal Using Algal Biochar and Its Composites with Kombucha SCOBY: An Integrated Biosorption and Phycoremediation Approach. Surf. Interfaces 2022, 30, 101880. [Google Scholar] [CrossRef]

- de Oliveira, F.R.; França, S.L.B.; Rangel, L.A.D. Princípios de Economia Circular Para o Desenvolvimento de Produtos Em Arranjos Produtivos Locais. Interações 2019, 20, 1179–1193. [Google Scholar] [CrossRef]

- Bhupatiraju, S.; Nomaler, Ö.; Triulzi, G.; Verspagen, B. Knowledge Flows—Analyzing the Core Literature of Innovation, Entrepreneurship and Science and Technology Studies. Res. Policy 2012, 41, 1205–1218. [Google Scholar] [CrossRef]

- Haeussler, C.; Jiang, L.; Thursby, J.; Thursby, M. Specific and General Information Sharing among Competing Academic Researchers. Res. Policy 2014, 43, 465–475. [Google Scholar] [CrossRef]

- Higgins, J.P.; Green, S. Cochrane Handbook for Systematic Reviews of Interventions; The Cochrane Collaboration®: London, UK, 2008. [Google Scholar]

- Afonso, M.H.F.; de Souza, J.V.; Ensslin, S.R.; Ensslin, L. Como Construir Conhecimento Sobre o Tema de Pesquisa? Aplicação Do Processo Proknow-c Na Busca de Literatura Sobre Avaliação Do Desenvolvimento Sustentável. Rev. Gestão Soc. Ambient. 2012, 5, 47–62. [Google Scholar] [CrossRef]

- Pagani, R.N.; Kovaleski, J.L.; Resende, L.M. Methodi Ordinatio: A Proposed Methodology to Select and Rank Relevant Scientific Papers Encompassing the Impact Factor, Number of Citation, and Year of Publication. Scientometrics 2015, 105, 2109–2135. [Google Scholar] [CrossRef]

- Dima, S.O.; Panaitescu, D.M.; Orban, C.; Ghiurea, M.; Doncea, S.M.; Fierascu, R.C.; Nistor, C.L.; Alexandrescu, E.; Nicolae, C.A.; Trica, B.; et al. Bacterial Nanocellulose from Side-Streams of Kombucha Beverages Production: Preparation and Physical-Chemical Properties. Polymers 2017, 9, 374. [Google Scholar] [CrossRef]

- Nguyen, V.T.; Flanagan, B.; Gidley, M.J.; Dykes, G.A. Characterization of Cellulose Production by a Gluconacetobacter Xylinus Strain from Kombucha. Curr. Microbiol. 2008, 57, 449–453. [Google Scholar] [CrossRef]

- Machado, R.T.A.; Meneguin, A.B.; Sábio, R.M.; Franco, D.F.; Antonio, S.G.; Gutierrez, J.; Tercjak, A.; Berretta, A.A.; Ribeiro, S.J.L.; Lazarini, S.C.; et al. Komagataeibacter Rhaeticus Grown in Sugarcane Molasses-Supplemented Culture Medium as a Strategy for Enhancing Bacterial Cellulose Production. Ind. Crops Prod. 2018, 122, 637–646. [Google Scholar] [CrossRef]

- Ramírez Tapias, Y.A.; Di Monte, M.V.; Peltzer, M.A.; Salvay, A.G. Bacterial Cellulose Films Production by Kombucha Symbiotic Community Cultured on Different Herbal Infusions. Food Chem. 2022, 372, 131346. [Google Scholar] [CrossRef] [PubMed]

- Sharma, C.; Bhardwaj, N.K. Biotransformation of Fermented Black Tea into Bacterial Nanocellulose via Symbiotic Interplay of Microorganisms. Int. J. Biol. Macromol. 2019, 132, 166–177. [Google Scholar] [CrossRef] [PubMed]

- Sharma, C.; Bhardwaj, N.K. Fabrication of Natural-Origin Antibacterial Nanocellulose Films Using Bio-Extracts for Potential Use in Biomedical Industry. Int. J. Biol. Macromol. 2020, 145, 914–925. [Google Scholar] [CrossRef]

- Zhu, C.; Li, F.; Zhou, X.; Lin, L.; Zhang, T. Kombucha-Synthesized Bacterial Cellulose: Preparation, Characterization, and Biocompatibility Evaluation. J. Biomed. Mater. Res. Part A 2014, 102, 1548–1557. [Google Scholar] [CrossRef]

- Sharma, C.; Bhardwaj, N.K.; Pathak, P.; Dey, P.; Gautam, S.; Kumar, S.; Dutt Purohit, S. Bacterial Nanocellulose by Static, Static Intermittent Fed-Batch and Rotary Disc Bioreactor-Based Fermentation Routes Using Economical Black Tea Broth Medium: A Comparative Account. Int. J. Biol. Macromol. 2024, 277, 134228. [Google Scholar] [CrossRef]

- Tapias, Y.A.R.; Monte, M.V.D.; Peltzer, M.A.; Salvay, A.G. Kombucha Fermentation in Yerba Mate: Cellulose Production, Films Formulation and Its Characterisation. Carbohydr. Polym. Technol. Appl. 2023, 5, 100310. [Google Scholar] [CrossRef]

- Behera, B.; Laavanya, D.; Balasubramanian, P. Techno-Economic Feasibility Assessment of Bacterial Cellulose Biofilm Production during the Kombucha Fermentation Process. Bioresour. Technol. 2022, 346, 126659. [Google Scholar] [CrossRef] [PubMed]

- Leonarski, E.; Cesca, K.; Borges, O.M.A.; de Oliveira, D.; Poletto, P. Typical Kombucha Fermentation: Kinetic Evaluation of Beverage and Morphological Characterization of Bacterial Cellulose. J. Food Process. Preserv. 2021, 45, e16100. [Google Scholar] [CrossRef]

- Akintunde, M.O.; Adebayo-Tayo, B.C.; Ishola, M.M.; Zamani, A.; Horváth, I.S. Bacterial Cellulose Production from Agricultural Residues by Two Komagataeibacter Sp. Strains. Bioengineered 2022, 13, 10010–10025. [Google Scholar] [CrossRef]

- Li, Z.Y.; Azi, F.; Ge, Z.W.; Liu, Y.F.; Yin, X.T.; Dong, M.S. Bio-Conversion of Kitchen Waste into Bacterial Cellulose Using a New Multiple Carbon Utilizing Komagataeibacter rhaeticus: Fermentation Profiles and Genome-Wide Analysis. Int. J. Biol. Macromol. 2021, 191, 211–221. [Google Scholar] [CrossRef]

- Skiba, E.A.; Shavyrkina, N.A.; Skiba, M.A.; Mironova, G.F.; Budaeva, V.V. Biosynthesis of Bacterial Nanocellulose from Low-Cost Cellulosic Feedstocks: Effect of Microbial Producer. Int. J. Mol. Sci. 2023, 24, 14401. [Google Scholar] [CrossRef]

- Treviño-Garza, M.Z.; Guerrero-Medina, A.S.; González-Sánchez, R.A.; García-Gómez, C.; Guzmán-Velasco, A.; Báez-González, J.G.; Márquez-Reyes, J.M. Production of Microbial Cellulose Films from Green Tea (Camellia Sinensis) Kombucha with Various Carbon Sources. Coatings 2020, 10, 1132. [Google Scholar] [CrossRef]

- Subbiahdoss, G.; Osmen, S.; Reimhult, E. Cellulosic Biofilm Formation of Komagataeibacter in Kombucha at Oil-Water Interfaces. Biofilm 2022, 4, 100071. [Google Scholar] [CrossRef]

- Fiallos-Cárdenas, M.; Ramirez, A.D.; Pérez-Martínez, S.; Bonilla, H.R.; Ordoñez-Viñan, M.; Ruiz-Barzola, O.; Reinoso, M.A. Bacterial Nanocellulose Derived from Banana Leaf Extract: Yield and Variation Factors. Resources 2021, 10, 121. [Google Scholar] [CrossRef]

- Leonarski, E.; Cesca, K.; González, S.Y.G.; de Oliveira, D.; Poletto, P. Bacterial Cellulose Production from Acerola Industrial Waste Using Isolated Kombucha Strain. Cellulose 2021, 29, 7613–7627. [Google Scholar] [CrossRef]

- Feng, X.; Ge, Z.; Wang, Y.; Xia, X.; Zhao, B.; Dong, M. Production and Characterization of Bacterial Cellulose from Kombucha-Fermented Soy Whey. Food Prod. Process. Nutr. 2024, 6, 20. [Google Scholar] [CrossRef]

- Liu, X.; Cao, L.; Wang, S.; Huang, L.; Zhang, Y.; Tian, M.; Li, X.; Zhang, J. Isolation and Characterization of Bacterial Cellulose Produced from Soybean Whey and Soybean Hydrolyzate. Sci. Rep. 2023, 13, 16024. [Google Scholar] [CrossRef]

- de Oliveira Duarte, F.A.; Ramos, K.K.; Gini, C.; Morasi, R.M.; Silva, N.C.C.; Efraim, P. Microbiological Characterization of Kombucha and Biocellulose Film Produced with Black Tea and Cocoa Bean Shell Infusion. Food Res. Int. 2024, 190, 114568. [Google Scholar] [CrossRef]

- Bueno, F.; Spivak, D.A.; Sathivel, S. Evaluation of the Properties of Dry Bacterial Cellulose Synthesized from Coffee Kombucha Fermentation Dried with Different Drying Methods. Dry. Technol. 2024, 42, 142–154. [Google Scholar] [CrossRef]

- Zhang, J.; Chen, H.; Jin, M.; Zheng, F. Biosynthesis of Antibacterial Bacterial Cellulose In-Situ Using Yellow Wine Wastewater through Co-Fermentation. Ind. Crops Prod. 2024, 222, 119715. [Google Scholar] [CrossRef]

- Güzel, M. Valorisation of Bread Wastes via the Bacterial Cellulose Production. Biomass Convers. Biorefinery 2024, 15, 4777–4790. [Google Scholar] [CrossRef]

- Nguyen, H.T.; Ngwabebhoh, F.A.; Saha, N.; Zandraa, O.; Saha, T.; Saha, P. Development of Novel Biocomposites Based on the Clean Production of Microbial Cellulose from Dairy Waste (Sour Whey). J. Appl. Polym. Sci. 2022, 139, 51433. [Google Scholar] [CrossRef]

- Selvaraj, S.; Gurumurthy, K. Optimizing Bacterial Cellulose Production From Kombucha Tea Utilizing Molasses and Tea Dust in Growth Medium. Int. J. Polym. Sci. 2024, 2024, 2240464. [Google Scholar] [CrossRef]

- Khiabani, A.; Sarabi-Jamab, M.; Shakeri, M.S.; Pahlevanlo, A.; Emadzadeh, B. Bacterial Cellulose Biosynthesis: Optimization Strategy Using Iranian Nabat Industry Waste. Heliyon 2024, 10, e35986. [Google Scholar] [CrossRef]

- Hernández-Guerrero, M.; Gomez-Maldonado, D.; Gutiérrez-Castañeda, J.; Revah, S.; Campos-Terán, J.; Vigueras-Ramírez, G. Assessment of Culture Systems to Produce Bacterial Cellulose with a Kombucha Consortium. Appl. Biochem. Biotechnol. 2024, 196, 7816–7833. [Google Scholar] [CrossRef]

- Lazzaroli, C.; Sordini, B.; Daidone, L.; Veneziani, G.; Esposto, S.; Urbani, S.; Selvaggini, R.; Servili, M.; Taticchi, A. Recovery and Valorization of Food Industry By-Products through the Application of Olea Europaea L. Leaves in Kombucha Tea Manufacturing. Food Biosci. 2023, 53, 102551. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, X.; Qi, X.; Ren, L.; Qiang, T. Isolation and Identification of a Bacterial Cellulose Synthesizing Strain from Kombucha in Different Conditions: Gluconacetobacter Xylinus ZHCJ618. Food Sci. Biotechnol. 2018, 27, 705–713. [Google Scholar] [CrossRef]

- Jacek, P.; da Silva, F.A.G.S.; Dourado, F.; Bielecki, S.; Gama, M. Optimization and Characterization of Bacterial Nanocellulose Produced by Komagataeibacter Rhaeticus K3. Carbohydr. Polym. Technol. Appl. 2021, 2, 100022. [Google Scholar] [CrossRef]

- China, S.L.; De Vero, L.; Anguluri, K.; Brugnoli, M.; Mamlouk, D.; Gullo, M. Kombucha Tea as a Reservoir of Cellulose Producing Bacteria: Assessing Diversity among Komagataeibacter Isolates. Appl. Sci. 2021, 11, 1595. [Google Scholar] [CrossRef]

- Gupte, Y.; Kulkarni, A.; Raut, B.; Sarkar, P.; Choudhury, R.; Chawande, A.; Kumar, G.R.K.; Bhadra, B.; Satapathy, A.; Das, G.; et al. Characterization of Nanocellulose Production by Strains of Komagataeibacter Sp. Isolated from Organic Waste and Kombucha. Carbohydr. Polym. 2021, 266, 118176. [Google Scholar] [CrossRef]

- Li, J.; Chen, G.; Zhang, R.; Wu, H.; Zeng, W.; Liang, Z. Production of High Crystallinity Type-I Cellulose from Komagataeibacter Hansenii JR-02 Isolated from Kombucha Tea. Biotechnol. Appl. Biochem. 2019, 66, 108–118. [Google Scholar] [CrossRef]

- Sederavičiūtė, F.; Bekampienė, P.; Domskienė, J. Effect of Pretreatment Procedure on Properties of Kombucha Fermented Bacterial Cellulose Membrane. Polym. Test. 2019, 78, 105941. [Google Scholar] [CrossRef]

- Dey, B.; Jayaraman, S.; Balasubramanian, P. Investigating the Effects of Drying on the Physical Properties of Kombucha Bacterial Cellulose: Kinetic Study and Modeling Approach. J. Clean. Prod. 2024, 452, 142204. [Google Scholar] [CrossRef]

- Gayathri, V.; Lobo, N.P.; Vikash, V.L.; Kamini, N.R.; Samanta, D. Functionalization of Bacterial Cellulose and Related Surfaces Using a Facile Coupling Reaction by Thermoresponsive Catalyst. ACS Biomater. Sci. Eng. 2023, 9, 625–641. [Google Scholar] [CrossRef]

- Mauro, F.; Corrado, B.; De Gregorio, V.; Lagreca, E.; Di Natale, C.; Vecchione, R.; Netti, P.A. Exploring the Evolution of Bacterial Cellulose Precursors and Their Potential Use as Cellulose-Based Building Blocks. Sci. Rep. 2024, 14, 11613. [Google Scholar] [CrossRef]

- Adamatzky, A.; Tarabella, G.; Phillips, N.; Chiolerio, A.; D’Angelo, P.; Nikolaidou, A.; Sirakoulis, G.C. Kombucha Electronics: Electronic Circuits on Kombucha Mats. Sci. Rep. 2023, 13, 9367. [Google Scholar] [CrossRef] [PubMed]

- Nikolaidou, A.; Mougkogiannis, P.; Adamatzky, A. Electroactive Composite Biofilms Integrating Kombucha, Chlorella and Synthetic Proteinoid Proto-Brains. R. Soc. Open Sci. 2024, 11, 240238. [Google Scholar] [CrossRef] [PubMed]

- Nikolaidou, A.; Chiolerio, A.; Dehshibi, M.M.; Adamatzky, A. Functionalizing the Electrical Properties of Kombucha Zoogleal Mats for Biosensing Applications. ACS Omega 2024, 9, 30308–30320. [Google Scholar] [CrossRef]

- Dai, C.; Wan, J.; Geng, W.; Song, S.; Ma, F.; Shao, J. KOH Direct Treatment of Kombucha and in Situ Activation to Prepare Hierarchical Porous Carbon for High-Performance Supercapacitor Electrodes. J. Solid State Electrochem. 2017, 21, 2929–2938. [Google Scholar] [CrossRef]

- Adamatzky, A. Electrical Potential Spiking of Kombucha Zoogleal Mats: A Symbiotic Community of Bacteria and Yeasts. Bioelectricity 2023, 5, 99–108. [Google Scholar] [CrossRef]

- Kalaiappan, K.; Rengapillai, S.; Marimuthu, S.; Murugan, R.; Thiru, P. Kombucha SCOBY-Based Carbon and Graphene Oxide Wrapped Sulfur/Polyacrylonitrile as a High-Capacity Cathode in Lithium-Sulfur Batteries. Front. Chem. Sci. Eng. 2020, 14, 976–987. [Google Scholar] [CrossRef]

- Mougkogiannis, P.; Nikolaidou, A.; Adamatzky, A. Kombucha-Proteinoid Crystal Bioelectric Circuits. ACS Omega 2024, 9, 45386–45401. [Google Scholar] [CrossRef]

- Kiangkitiwan, N.; Srikulkit, K. Preparation and Properties of Bacterial Cellulose/Graphene Oxide Composite Films Using Dyeing Method. Polym. Eng. Sci. 2021, 61, 1854–1863. [Google Scholar] [CrossRef]

- Eggensperger, C.G.; Giagnorio, M.; Holland, M.C.; Dobosz, K.M.; Schiffman, J.D.; Tiraferri, A.; Zodrow, K.R. Sustainable Living Filtration Membranes. Environ. Sci. Technol. Lett. 2020, 7, 213–218. [Google Scholar] [CrossRef]

- Bechtel, C.W.; Park, J.; Jiang, D.; Bashammakh, M.A.; Pereault, F.; Zodrow, K.R. Living Filtration Membranes Demonstrate Antibiofouling Properties. ACS Environ. Sci. Technol. Water 2022, 2, 1–9. [Google Scholar] [CrossRef]

- Plaza-Joly, P.; Gallois, A.; Bosc-Rouessac, F.; Drobek, M.; Julbe, A. Synergistic Effect of UiO-66 Directly Grown on Kombucha-Derived Bacterial Cellulose for Dye Removal. Molecules 2024, 29, 3057. [Google Scholar] [CrossRef]

- Tsilo, P.H.; Basson, A.K.; Ntombela, Z.G.; Dlamini, N.G.; Pullabhotla, R.V.S.R. Application of Iron Nanoparticles Synthesized from a Bioflocculant Produced by Yeast Strain Pichia Kudriavzevii Obtained from Kombucha Tea SCOBY in the Treatment of Wastewater. Int. J. Mol. Sci. 2023, 24, 14731. [Google Scholar] [CrossRef]

- Tsilo, P.H.; Basson, A.K.; Ntombela, Z.G.; Maliehe, T.S.; Pullabhotla, R.V.S.R. Isolation and Optimization of Culture Conditions of a Bioflocculant-Producing Fungi from Kombucha Tea SCOBY. Microbiol Res. 2021, 12, 950–966. [Google Scholar] [CrossRef]

- Pogorelova, N.; Rogachev, E.; Digel, I.; Chernigova, S.; Nardin, D. Bacterial Cellulose Nanocomposites: Morphology and Mechanical Properties. Materials 2020, 13, 2849. [Google Scholar] [CrossRef]

- Jiang, Z.; Shi, Z.; Cheung, K.M.; Ngai, T. Robust, Flexible, and High-Barrier Films from Bacterial Cellulose Modified by Long-Chain Alkenyl Succinic Anhydrides. ACS Sustain. Chem. Eng. 2023, 11, 2486–2498. [Google Scholar] [CrossRef]

- Agüero, Á.; Corral Perianes, E.; Abarca de las Muelas, S.S.; Lascano, D.; de la Fuente García-Soto, M.d.M.; Peltzer, M.A.; Balart, R.; Arrieta, M.P. Plasticized Mechanical Recycled PLA Films Reinforced with Microbial Cellulose Particles Obtained from Kombucha Fermented in Yerba Mate Waste. Polymers 2023, 15, 285. [Google Scholar] [CrossRef]

- Yan, J.H.; Zheng, D.W.; Gu, H.Y.; Yu, Y.J.; Zeng, J.Y.; Chen, Q.W.; Yu, A.X.; Zhang, X.Z. In Situ Sprayed Biotherapeutic Gel Containing Stable Microbial Communities for Efficient Anti-Infection Treatment. Adv. Sci. 2023, 10, e2205480. [Google Scholar] [CrossRef]

- Pillai, M.M.; Tran, H.N.; Sathishkumar, G.; Manimekalai, K.; Yoon, J.H.; Lim, D.Y.; Noh, I.; Bhattacharyya, A. Symbiotic Culture of Nanocellulose Pellicle: A Potential Matrix for 3D Bioprinting. Mater. Sci. Eng. C 2021, 119, 111552. [Google Scholar] [CrossRef]

- El-Fallal, A.A.; Elfayoumy, R.A.; El-Zahed, M.M. Antibacterial Activity of Biosynthesized Zinc Oxide Nanoparticles Using Kombucha Extract. SN Appl. Sci. 2023, 5, 332. [Google Scholar] [CrossRef]

- Mirmohammadsadegh, N.; Shakoori, M.; Moghaddam, H.N.; Farhadi, R.; Shahverdi, A.R.; Amin, M. Wound Healing and Anti-Inflammatory Effects of Bacterial Cellulose Coated with Pistacia Atlantica Fruit Oil. DARU J. Pharm. Sci. 2022, 30, 1–10. [Google Scholar] [CrossRef]

- Candra, A.; Ahmed, Y.W.; Kitaw, S.L.; Anley, B.E.; Chen, K.J.; Tsai, H.C. A Green Method for Fabrication of a Biocompatible Gold-Decorated-Bacterial Cellulose Nanocomposite in Spent Coffee Grounds Kombucha: A Sustainable Approach for Augmented Wound Healing. J. Drug Deliv. Sci. Technol. 2024, 94, 105477. [Google Scholar] [CrossRef]

- Paramasivan, M.; Kumar, T.S.S.; Chandra, T.S. Microbial Synthesis of Hydroxyapatite-Nanocellulose Nanocomposites from Symbiotic Culture of Bacteria and Yeast Pellicle of Fermented Kombucha Tea. Sustainability 2022, 14, 8144. [Google Scholar] [CrossRef]

- Hong, F.; Wei, B.; Chen, L. Preliminary Study on Biosynthesis of Bacterial Nanocellulose Tubes in a Novel Double-Silicone-Tube Bioreactor for Potential Vascular Prosthesis. Biomed. Res. Int. 2015, 2015, 560365. [Google Scholar] [CrossRef] [PubMed]

- Bağlan, İ.; Yanbakan, E.; Tuncel, T.; Koçak Sezgin, A.; Bozoğlan, E.; Berikten, D.; Kar, F. 3D Printed Kombucha Biomaterial as a Tissue Scaffold and L929 Cell Cytotoxicity Assay. J. Cell Mol. Med. 2024, 28, e18316. [Google Scholar] [CrossRef]

- Ziemlewska, A.; Zagórska-Dziok, M.; Mokrzyńska, A.; Nizioł-Łukaszewska, Z.; Szczepanek, D.; Sowa, I.; Wójciak, M. Comparison of Anti-Inflammatory and Antibacterial Properties of Raphanus sativus L. Leaf and Root Kombucha-Fermented Extracts. Int. J. Mol. Sci. 2024, 25, 5622. [Google Scholar]

- Stanek-Wandzel, N.; Zarębska, M.; Wasilewski, T.; Hordyjewicz-Baran, Z.; Zajszły-Turko, E.; Tomaka, M.; Bujak, T.; Ziemlewska, A.; Nizioł-Łukaszewska, Z. Kombucha Fermentation as a Modern Way of Processing Vineyard By-Products into Cosmetic Raw Materials. Int. J. Cosmet. Sci. 2023, 45, 834–850. [Google Scholar]

- Donkor, E.S.; Kotey, F.C. Methicillin-Resistant Staphylococcus Aureus in the Oral Cavity: Implications for Antibiotic Prophylaxis and Surveillance. Infect. Dis. Res. Treat. 2020, 13, 1178633720976581. [Google Scholar] [CrossRef]

- Tritean, N.; Dimitriu, L.; Dima, Ș.O.; Stoica, R.; Trică, B.; Ghiurea, M.; Moraru, I.; Cimpean, A.; Oancea, F.; Constantinescu-Aruxandei, D. Cytocompatibility, Antimicrobial and Antioxidant Activity of a Mucoadhesive Biopolymeric Hydrogel Embedding Selenium Nanoparticles Phytosynthesized by Sea Buckthorn Leaf Extract. Pharmaceuticals 2024, 17, 23. [Google Scholar] [CrossRef]

- Tritean, N.; Dimitriu, L.; Dima, Ș.O.; Ghiurea, M.; Trică, B.; Nicolae, C.A.; Moraru, I.; Nicolescu, A.; Cimpean, A.; Oancea, F.; et al. Bioactive Hydrogel Formulation Based on Ferulic Acid-Grafted Nano-Chitosan and Bacterial Nanocellulose Enriched with Selenium Nanoparticles from Kombucha Fermentation. J. Funct. Biomater. 2024, 15, 202. [Google Scholar]

- Eskandari, F.; Borzou, S.; Razavian, A.; Babanouri, N.; Yousefi, K. Sustained Antibacterial Activity of Orthodontic Elastomeric Ligature Ties Coated with a Novel Kombucha-Derived Bacterial Nanocellulose: An in-Vitro Study. PLoS ONE 2024, 19, e0292966. [Google Scholar]

- Sfoglia, N.M.; Misturini, D.R.; Sant’Anna, V.; Fabricio, M.F.; Ayub, M.A.Z.; Hickert, L.R. Milk Whey Fermented by Kombucha SCOBY: Effect of Sugar on the Physicochemical and Microbiological Properties of the New Beverage. Waste Biomass Valorization 2024, 16, 1795–1803. [Google Scholar] [CrossRef]

- Kruk, M.; Trząskowska, M.; Ścibisz, I.; Pokorski, P. Application of the “Scoby” and Kombucha Tea for the Production of Fermented Milk Drinks. Microorganisms 2021, 9, 123. [Google Scholar] [CrossRef] [PubMed]

- Torán-Pereg, P.; del Noval, B.; Valenzuela, S.; Martinez, J.; Prado, D.; Perisé, R.; Arboleya, J.C. Microbiological and Sensory Characterization of Kombucha SCOBY for Culinary Applications. Int. J. Gastron. Food Sci. 2021, 23, 100314. [Google Scholar] [CrossRef]

- Kilmanoglu, H.; Akbas, M.; Yigit Cinar, A.; Durak, M.Z. Kombucha as Alternative Microbial Consortium for Sourdough Fermentation: Bread Characterization and Investigation of Shelf Life. Int. J. Gastron. Food Sci. 2024, 35, 100903. [Google Scholar] [CrossRef]

- Wu, J.; Li, L.; Ma, S. Effects of Kombucha Bacterial Cellulose on Wheat Dough Properties. Int. J. Food Sci. Technol. 2024, 59, 1876–1884. [Google Scholar] [CrossRef]

- Chong, A.Q.; Chin, N.L.; Talib, R.A.; Basha, R.K. Application of Scoby Bacterial Cellulose as Hydrocolloids on Physicochemical, Textural and Sensory Characteristics of Mango Jam. J. Sci. Food Agric. 2024, 105, 285–293. [Google Scholar] [CrossRef]

- Mehta, A.; Serventi, L.; Kumar, L.; Torrico, D.D. Effects of Repeated Tasting Sessions on Acceptability, Emotional Responses, and Purchasing Behaviors of Waste-to-Value-AddedSCOBY (Symbiotic Culture of Bacteria and Yeast) Ice Cream. J. Sens. Stud. 2024, 39, e12901. [Google Scholar] [CrossRef]

- Agüero, A.; Lascano, D.; Ivorra-Martinez, J.; Gómez-Caturla, J.; Arrieta, M.P.; Balart, R. Use of Bacterial Cellulose Obtained from Kombucha Fermentation in Spent Coffee Grounds for Active Composites Based on PLA and Maleinized Linseed Oil. Ind. Crops Prod. 2023, 202, 116971. [Google Scholar] [CrossRef]

- El-Shall, F.N.; Al-Shemy, M.T.; Dawwam, G.E. Multifunction Smart Nanocomposite Film for Food Packaging Based on Carboxymethyl Cellulose/Kombucha SCOBY/Pomegranate Anthocyanin Pigment. Int. J. Biol. Macromol. 2023, 242, 125101. [Google Scholar] [CrossRef]

- Muralidharan, V.; Jebathomas, C.R.T.; Sundaramoorthy, S.; Madhan, B.; Palanivel, S. Preparation and Evaluation of Novel Biodegradable Kombucha Cellulose-Based Multi-Layered Composite Tableware. Ind. Crops Prod. 2024, 215, 118629. [Google Scholar] [CrossRef]

- Doğan, N. Native Bacterial Cellulose Films Based on Kombucha Pellicle as a Potential Active Food Packaging. J. Food Sci. Technol. 2023, 60, 2893–2904. [Google Scholar] [CrossRef]

- Koreshkov, M.; Takatsuna, Y.; Bismarck, A.; Fritz, I.; Reimhult, E.; Zirbs, R. Sustainable Food Packaging Using Modified Kombucha-Derived Bacterial Cellulose Nanofillers in Biodegradable Polymers. RSC Sustain. 2024, 2, 2367–2376. [Google Scholar] [CrossRef]

- Nascimento, A.d.F.; Ramos, S.M.T.; Bergamo, V.N.; Araujo, E.d.S.; Ayala Valencia, G. Pickering Emulsions Stabilized Using Bacterial Cellulose From Kombucha. Starch/Staerke 2024, 77, 2400103. [Google Scholar] [CrossRef]

- Li, Z.; Hu, W.; Dong, J.; Azi, F.; Xu, X.; Tu, C.; Tang, S.; Dong, M. The Use of Bacterial Cellulose from Kombucha to Produce Curcumin Loaded Pickering Emulsion with Improved Stability and Antioxidant Properties. Food Sci. Hum. Wellness 2023, 12, 669–679. [Google Scholar] [CrossRef]

- Li, S.; Wang, X.; Luo, Y.; Chen, Z.; Yue, T.; Cai, R.; Muratkhan, M.; Zhao, Z.; Wang, Z. A Green Versatile Packaging Based on Alginate and Anthocyanin via Incorporating Bacterial Cellulose Nanocrystal-Stabilized Camellia Oil Pickering Emulsions. Int. J. Biol. Macromol. 2023, 249, 126134. [Google Scholar] [CrossRef]

- Charoenrak, S.; Charumanee, S.; Sirisa-ard, P.; Bovonsombut, S.; Kumdhitiahutsawakul, L.; Kiatkarun, S.; Pathom-Aree, W.; Chitov, T.; Bovonsombut, S. Nanobacterial Cellulose from Kombucha Fermentation as a Potential Protective Carrier of Lactobacillus Plantarum under Simulated Gastrointestinal Tract Conditions. Polymers 2023, 15, 1356. [Google Scholar] [CrossRef]

- Avcioglu, N.H.; Birben, M.; Seyis Bilkay, I. Optimization and Physicochemical Characterization of Enhanced Microbial Cellulose Production with a New Kombucha Consortium. Process Biochem. 2021, 108, 60–68. [Google Scholar] [CrossRef]

- Chaussé, J.; Girard, V.D.; Perron, T.; Challut, T.; Vermette, P. Characterization of Bacterial Cellulose Produced by the KomEt Strain Isolated from a Kombucha SCOBY. Biocatal. Agric. Biotechnol. 2024, 58, 103172. [Google Scholar] [CrossRef]

- Amorim, L.F.A.; Li, L.; Gomes, A.P.; Fangueiro, R.; Gouveia, I.C. Sustainable Bacterial Cellulose Production by Low Cost Feedstock: Evaluation of Apple and Tea by-Products as Alternative Sources of Nutrients. Cellulose 2023, 30, 5589–5606. [Google Scholar] [CrossRef]

- Hamed, D.A.; Maghrawy, H.H.; Abdel Kareem, H. Biosynthesis of Bacterial Cellulose Nanofibrils in Black Tea Media by a Symbiotic Culture of Bacteria and Yeast Isolated from Commercial Kombucha Beverage. World J. Microbiol. Biotechnol. 2023, 39, 48. [Google Scholar]

- Carney Almroth, B.M.; Åström, L.; Roslund, S.; Petersson, H.; Johansson, M.; Persson, N.K. Quantifying Shedding of Synthetic Fibers from Textiles; a Source of Microplastics Released into the Environment. Environ. Sci. Pollut. Res. 2018, 25, 1191–1199. [Google Scholar] [CrossRef] [PubMed]

- Candra, A.; Darge, H.F.; Ahmed, Y.W.; Saragi, I.R.; Kitaw, S.L.; Tsai, H.C. Eco-Benign Synthesis of Nano-gold Chitosan-Bacterial Cellulose in Spent Ground Coffee Kombucha Consortium: Characterization, Microbiome Community, and Biological Performance. Int. J. Biol. Macromol. 2023, 253, 126869. [Google Scholar] [CrossRef]

- Yakaew, P.; Phetchara, T.; Kampeerapappun, P.; Srikulkit, K. Chitosan-Coated Bacterial Cellulose (BC)/Hydrolyzed Collagen Films and Their Ascorbic Acid Loading/Releasing Performance: A Utilization of BC Waste from Kombucha Tea Fermentation. Polymers 2022, 14, 4544. [Google Scholar] [CrossRef] [PubMed]

- Sknepnek, A.; Filipović, S.; Pavlović, V.B.; Mirković, N.; Miletić, D.; Gržetić, J.; Mirković, M. Effects of Synthesis Parameters on Structure and Antimicrobial Properties of Bacterial Cellulose/Hydroxyapatite/TiO2 Polymer–Ceramic Composite Material. Polymers 2024, 16, 470. [Google Scholar] [CrossRef]

- Pihurov, M.; Păcularu-Burada, B.; Cotârleț, M.; Grigore-Gurgu, L.; Borda, D.; Stănciuc, N.; Kluz, M.; Bahrim, G.E. Kombucha and Water Kefir Grains Microbiomes’ Symbiotic Contribution to Postbiotics Enhancement. Foods 2023, 12, 2581. [Google Scholar] [CrossRef]

- Iguchi, M.; Yamanaka, S.; Budhiono, J.A. Review Bacterial Cellulose-a Masterpiece of Nature’s Arts. J. Mater. Sci. 2000, 35, 261–270. [Google Scholar] [CrossRef]

- Lin, D.; Liu, Z.; Shen, R.; Chen, S.; Yang, X. Bacterial Cellulose in Food Industry: Current Research and Future Prospects. Int. J. Biol. Macromol. 2020, 158, 1007–1019. [Google Scholar] [CrossRef]

- Sarkar, A.; Dickinson, E. Sustainable Food-Grade Pickering Emulsions Stabilized by Plant-Based Particles. Curr. Opin. Colloid Interface Sci. 2020, 49, 69–81. [Google Scholar] [CrossRef]

- Xia, T.; Xue, C.; Wei, Z. Physicochemical Characteristics, Applications and Research Trends of Edible Pickering Emulsions. Trends Food Sci. Technol. 2021, 107, 1–15. [Google Scholar] [CrossRef]

- Li, S.; Liu, R.; Zhao, J.; Zhang, S.; Hu, X.; Wang, X.; Gao, Z.; Yuan, Y.; Yue, T.; Cai, R.; et al. Enzymatically Green-Produced Bacterial Cellulose Nanoparticle-Stabilized Pickering Emulsion for Enhancing Anthocyanin Colorimetric Performance of Versatile Films. Food Chem. 2024, 453, 139700. [Google Scholar] [CrossRef]

- Wang, K.; Hazra, R.S.; Ma, Q.; Khan, M.R.H.; Al Hoque, A.; Jiang, L.; Quadir, M.; Zhang, Y.; Wang, S.; Han, G. Robust Biocompatible Bacterial Cellulose/Silk Nonwoven Fabric/Silk Sericin Sandwich Membrane with Strong UV-Blocking and Antioxidant Properties. Cellulose 2023, 30, 3973–3993. [Google Scholar] [CrossRef]

- Babapoor, A.; Rafiei, O.; Mousavi, Y.; Azizi, M.M.; Paar, M.; Nuri, A. Comparison and Optimization of Operational Parameters in Removal of Heavy Metal Ions from Aqueous Solutions by Low-Cost Adsorbents. Int. J. Chem. Eng. 2022, 2022. [Google Scholar] [CrossRef]

- Weihua, Q.; Hong, R.; Qianhui, W. Production of Bacterial Cellulose from Enzymatic Hydrolysate of Kitchen Waste by Fermentation with Kombucha. Biomass Convers. Biorefinery 2023, 13, 14485–14496. [Google Scholar] [CrossRef]

- Rolim, A.A.I.; Steffen, T.T.; Becker, D.; Leite, L.R.; Sagás, J.C.; Fontana, L.C.; Bond, D. Plasma Surface Treatment of Bacterial Cellulose to Increase Hydrophobicity. Cellulose 2024, 31, 4817–4831. [Google Scholar] [CrossRef]

- Dey, B.; Jayaraman, S.; Balasubramanian, P. Upcycling of Tea Processing Waste into Kombucha-Derived Bioactive Cellulosic Composite for Prospective Wound Dressing Action. 3 Biotech 2024, 14, 253. [Google Scholar] [CrossRef] [PubMed]

| Rank | Article Title | IF 1 | Citations | PA 2 | InOrdinatio | Ref. |

|---|---|---|---|---|---|---|

| 1 | Hydrogel bacterial cellulose: a path to improved materials for new eco-friendly textiles | 4.9 | 100 | 4 | 128.9 | [22] |

| 2 | Bacterial nanocellulose from side-streams of kombucha beverages production: Preparation and physical-chemical properties | 4.7 | 111 | 7 | 127.7 | [40] |

| 3 | Characterization of cellulose production by a Gluconacetobacter xylinus strain from Kombucha | 2.3 | 130 | 16 | 108.3 | [41] |

| 4 | Komagataeibacter rhaeticus grown in sugarcane molasses-supplemented culture medium as a strategy for enhancing bacterial cellulose production | 5.6 | 81 | 6 | 102.6 | [42] |

| 5 | Bacterial cellulose films production by Kombucha symbiotic community cultured on different herbal infusions | 8.5 | 57 | 2 | 97.5 | [43] |

| 6 | Biotransformation of fermented black tea into bacterial nanocellulose via symbiotic interplay of microorganisms | 7.7 | 59 | 5 | 86.7 | [44] |

| 7 | Fabrication of natural-origin antibacterial nanocellulose films using bio-extracts for potential use in biomedical industry | 7.7 | 53 | 4 | 84.7 | [45] |

| 8 | Pb(II) removal from synthetic wastewater using Kombucha Scoby and graphene oxide/Fe3O4 | 1.4 | 67 | 6 | 84.4 | [32] |

| 9 | Kombucha bacterial cellulose for sustainable fashion | 1 | 58 | 5 | 79 | [23] |

| 10 | Kombucha-synthesized bacterial cellulose: Preparation, characterization, and biocompatibility evaluation | 3.9 | 75 | 10 | 78.9 | [46] |

| Ranking | Raw Material Type | Raw Material/Substrate | Cultivation Method | BC Production (g/L) | Ref. |

|---|---|---|---|---|---|

| 4 | Agro-Industrial residue | Glucose Glucose + Sugarcane molassesSugarcane molasses | Static | 2.27 g/L 4.01 g/L 1.9 g/L 10 days | [42] |

| 5 | Herbal Infusion + carbon source | Black tea + sucrose green tea + sucrose yerba mate + sucrose lavender + sucrose oregano + sucrose fennel + sucrose | Static | 10.3 g/L 3.3 g/L 6.9 g/L 4.5 g/L 3.6 g/L 2.9 g/L 21 days | [43] |

| 14 | Agro-Industrial residue | Corncob enzymatic hydrolysate Sugarcane bagasse enzymatic hydrolysate | Continuous stirred agitation | 1.6 g/L 1.2 g/L 7 days | [51] |

| 27 | Domestic residue | kitchen waste enzymatic hydrolysate | Static | 4.76 g/L 10 days | [52] |

| 34 | Agro-Industrial residue + tea | Apple waste and tea byproducts | Static | 0.8 g/L 7 days | [126] |

| 40 | Herbal Infusion + carbon source | Green Tea + Dextrose | Static | 11.19 g/L 15 days | [54] |

| 47 | Herbal Infusion + carbon source | Yerba mate + sucrose | Static | 19.4 g/L 21 days | [48] |

| 49 | Agro-Industrial residue + Tea | Tea + Banana Leaf Extract | Static | 55 g/L 21 days | [56] |

| 51 | Agro-Industrial residue | Tofu soy whey + sucrose | Static | 42 g/L 11 days | [58] |

| 52 | Agro-Industrial residue | Acerola Industrial Waste | Static | 2.3 g/L 12 days | [57] |

| 59 | Agro-Industrial residue | Miscanthus enzymatic hydrolysate Oat hulls enzymatic hydrolysate | Static | 0.88 g/L 1.03 g/L 14 days | [53] |

| 70 | Agro-Industrial residue | Soybean whey Soybean hydrolysate | Static | 0.51 g/L 1 g/L 6 days | [59] |

| 74 | Fermentable agro-industrial wastewater + carbon source | Yellow wine wastewater + Fructose Corn Syrup | Static | 16.5 g/L 7 days | [62] |

| 75 | Food Waste | Dilute acid hydrolysates of different bread wastes | Static | 1.55 g/L–8.75 g/L 14 days | [63] |

| 104 | Agro-Industrial residue | Iranian Nabat Industry Waste | Continuous stirred agitation | 45.5 g/L 7 days | [66] |

| 107 | Synthetic lab medium Agricultural nutrient solution + carbon source | Yeast Nitrogen Base + glucose NPK fertilizer solution + glucose | Static | 8 g/L 8.8 g/L 17 days | [67] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vianna, N.d.M.; Albagli, G.; Pereira, A.d.S.; Amaral, P.F.F. From Tea Fermentation to New Technologies: Multisectoral Applications of Kombucha SCOBY Through the Lens of Methodi Ordinatio. Fermentation 2025, 11, 589. https://doi.org/10.3390/fermentation11100589

Vianna NdM, Albagli G, Pereira AdS, Amaral PFF. From Tea Fermentation to New Technologies: Multisectoral Applications of Kombucha SCOBY Through the Lens of Methodi Ordinatio. Fermentation. 2025; 11(10):589. https://doi.org/10.3390/fermentation11100589

Chicago/Turabian StyleVianna, Nicole de M., Gabriel Albagli, Adejanildo da S. Pereira, and Priscilla F. F. Amaral. 2025. "From Tea Fermentation to New Technologies: Multisectoral Applications of Kombucha SCOBY Through the Lens of Methodi Ordinatio" Fermentation 11, no. 10: 589. https://doi.org/10.3390/fermentation11100589

APA StyleVianna, N. d. M., Albagli, G., Pereira, A. d. S., & Amaral, P. F. F. (2025). From Tea Fermentation to New Technologies: Multisectoral Applications of Kombucha SCOBY Through the Lens of Methodi Ordinatio. Fermentation, 11(10), 589. https://doi.org/10.3390/fermentation11100589