Non-Thermal UV-C Processing as an Alternative to Pasteurisation in Fermented Dairy Beverages: Ayran and Kefir

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Experimental Design

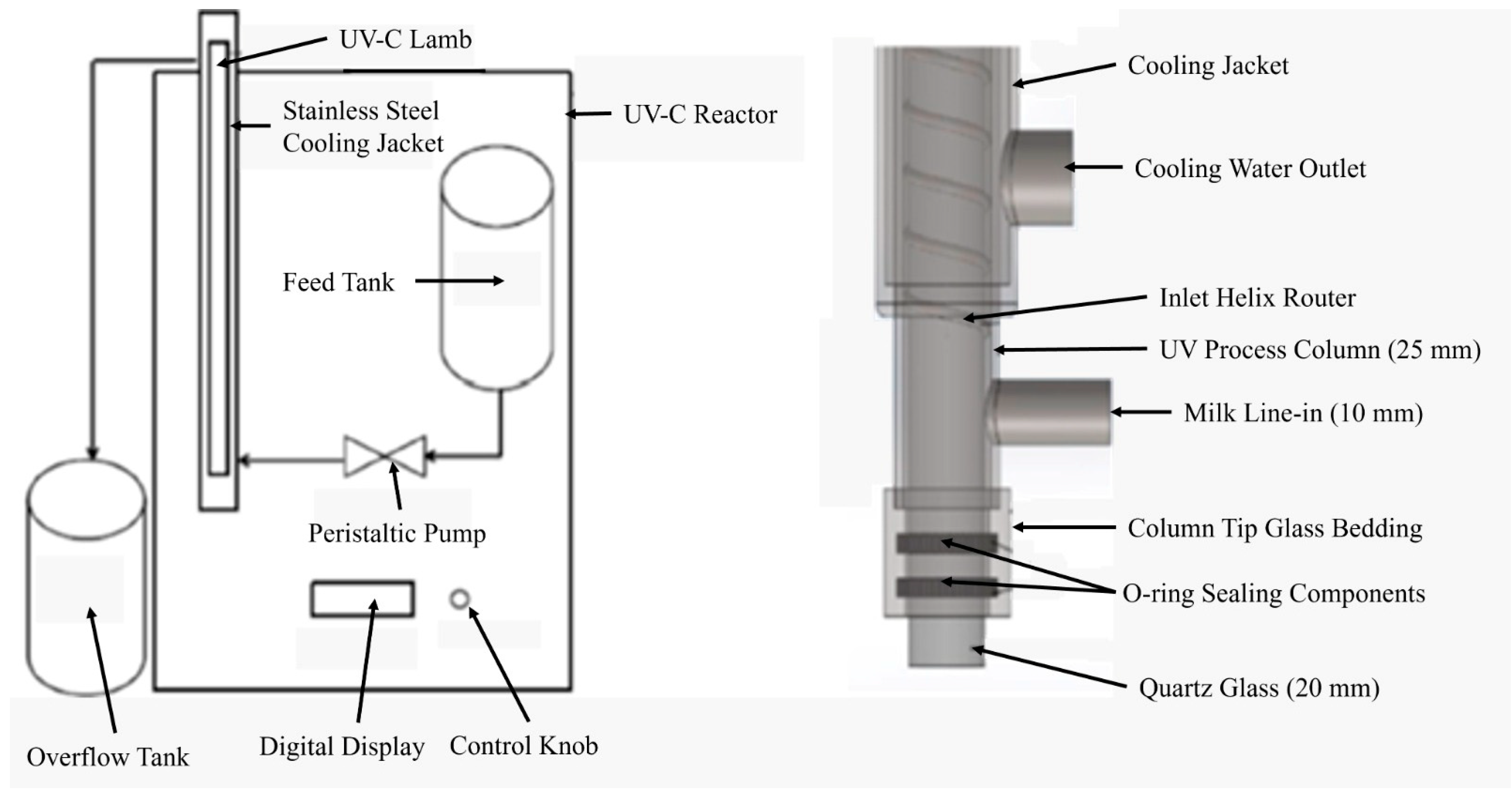

2.2.2. UV-C Treatment of Milk

2.2.3. Calculation of UV-C Radiation Dose

2.2.4. Cleaning of UV-C Reactor

2.2.5. Production of Ayran and Kefir

2.2.6. Microbial Analyses

2.2.7. Proximate Analyses

2.2.8. Syneresis (%)

2.2.9. Texture Analysis

2.2.10. Organic Acid Content

2.2.11. Sensory Analyses

2.2.12. Statistical Analyses

3. Result and Discussion

3.1. Microbiological Analyses

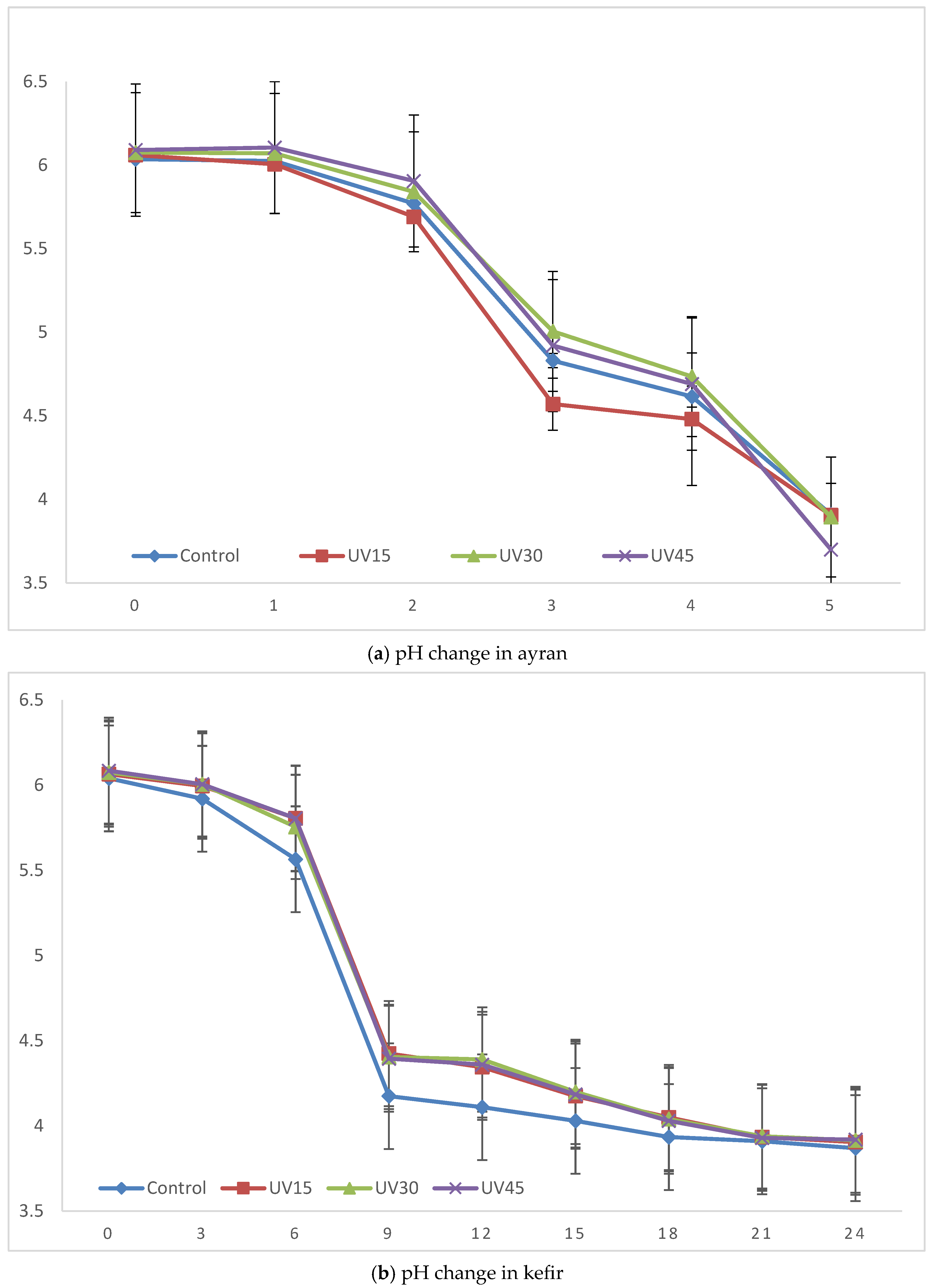

3.2. pH, Water Activity (aw), Dry Matter (%), Syneresis and Titratable Acidity (%)

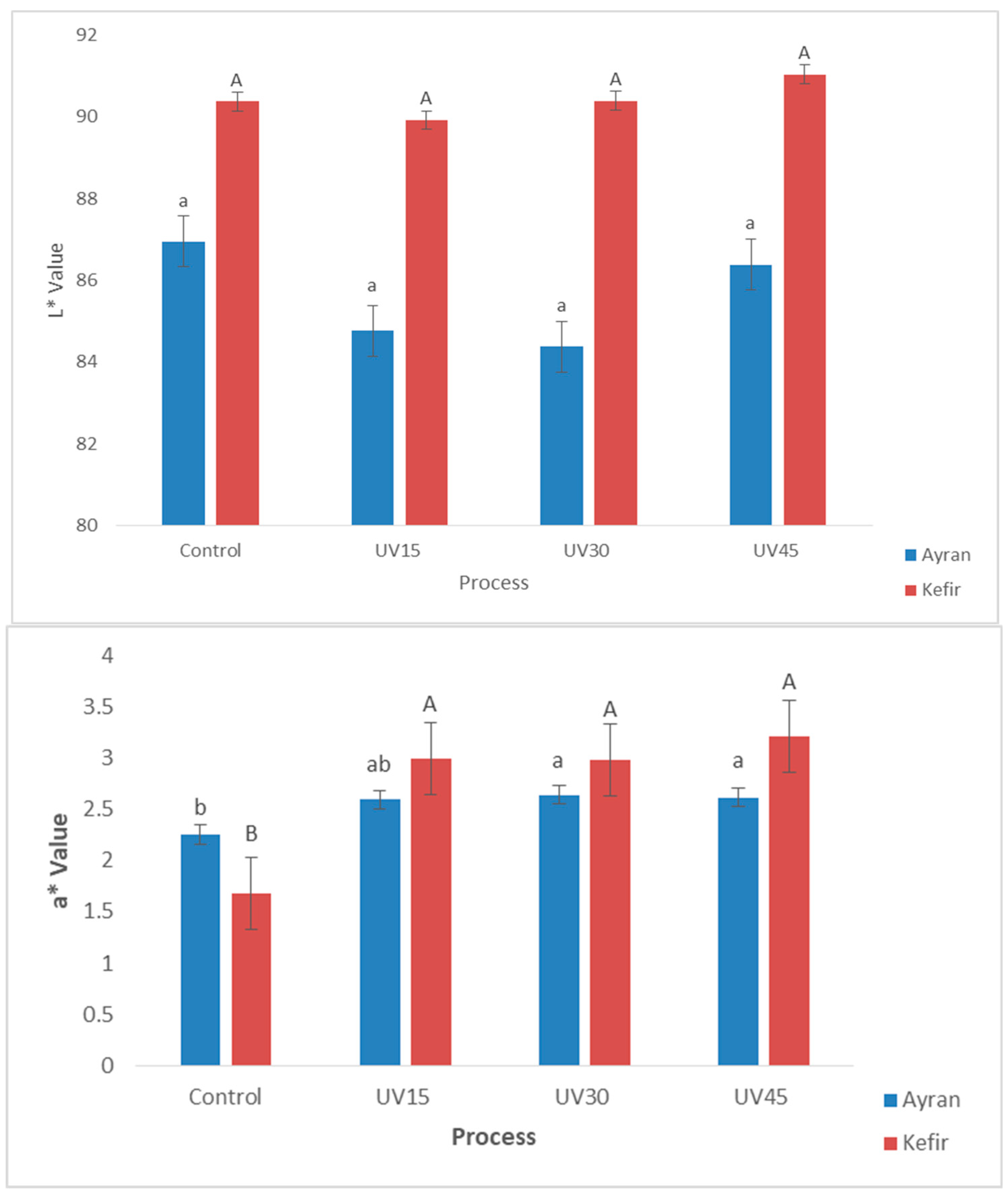

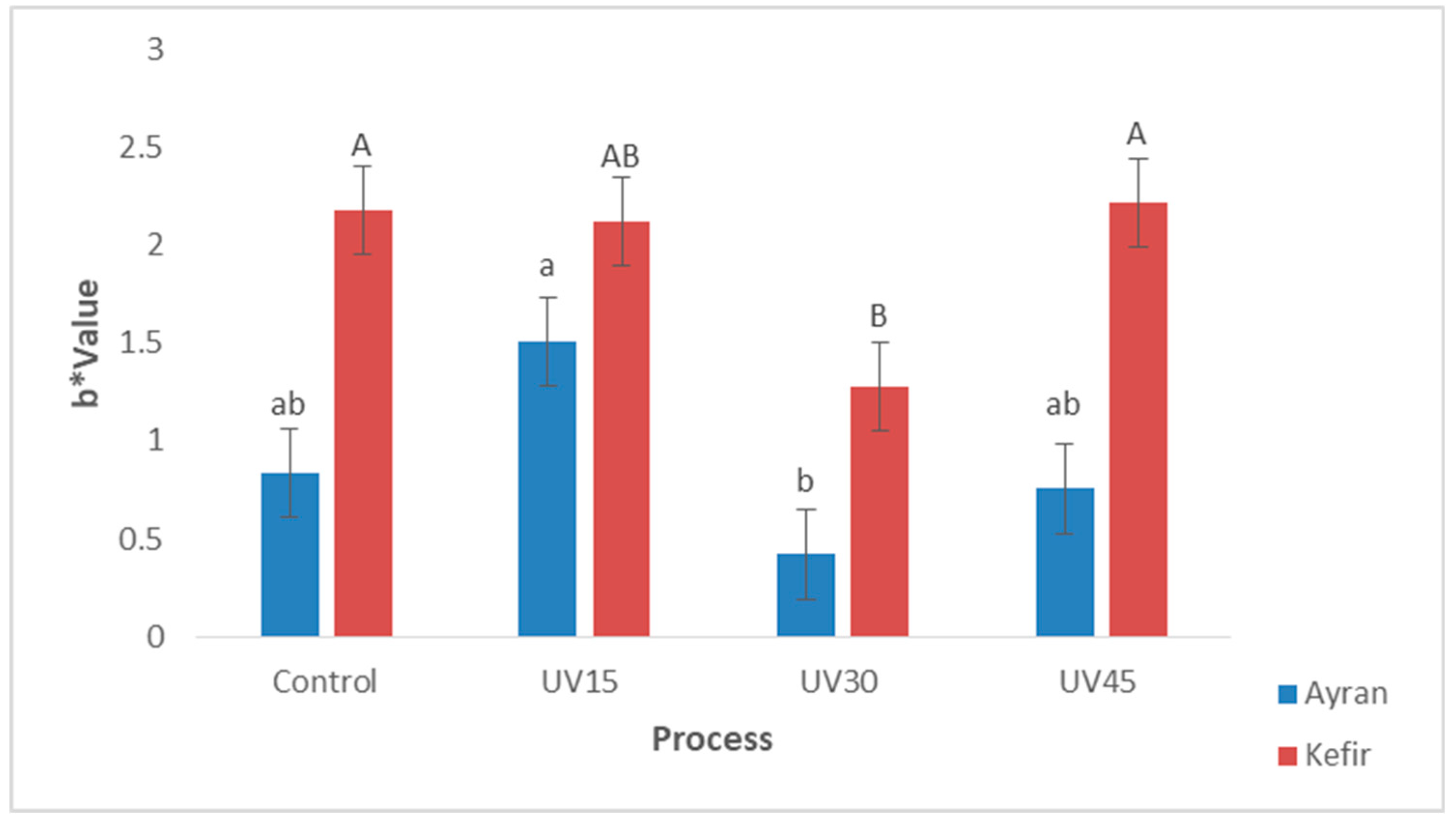

3.3. Colour Values

3.4. Textural Values

3.5. Organic Acid Content

3.6. Sensory Analysis

4. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Karakaya, E.; Akbay, C. Unpacked and Packed Milk Consumption Patterns of Consumers in Urban Area of Istanbul Province. Turk. J. Agric. Econ. 2014, 20, 17–27. [Google Scholar]

- Farimani, R.H.; Najafi, M.B.H.; Bazzaz, B.S.F.; Edalatian, M.R.; Bahrami, A.R.; Flórez, A.B.; Mayo, B. Identification, Typing and Functional Characterization of Dominant Lactic Acid Bacteria Strains from Iranian Traditional Yoghurt. Eur. Food Res. Technol. 2016, 242, 517–526. [Google Scholar] [CrossRef]

- Li, H.; Gao, J.; Chen, W.; Qian, C.; Wang, Y.; Wang, J.; Chen, L. Lactic Acid Bacteria Isolated from Kazakh Traditional Fermented Milk Products Affect the Fermentation Characteristics and Sensory Qualities of Yogurt. Food Sci. Nutr. 2022, 10, 1451–1460. [Google Scholar] [CrossRef] [PubMed]

- Rosa, D.D.; Dias, M.M.; Grześkowiak, Ł.M.; Reis, S.A.; Conceição, L.L.; Peluzio, M.D.C.G. Milk Kefir: Nutritional, Microbiological and Health Benefits. Nutr. Res. Rev. 2017, 30, 82–96. [Google Scholar] [CrossRef]

- Bourrie, B.C.; Willing, B.P.; Cotter, P.D. The Microbiota and Health Promoting Characteristics of The Fermented Beverage Kefir. Front. Microbiol. 2016, 7, 196946. [Google Scholar] [CrossRef]

- Salık, M.A.; Çakmakçı, S. Geographical Indication Ayran and Yogurts of Türkiye. In Proceedings of the 6th International Anatolian Agriculture, Food, Environment and Biology Congress, Kütahya, Türkiye, 7–9 October 2022; pp. 950–955. [Google Scholar]

- Leite, A.M.D.O.; Miguel, M.A.L.; Peixoto, R.S.; Rosado, A.S.; Silva, J.T.; Paschoalin, V.M.F. Microbiological, Technological and Therapeutic Properties of Kefir: A Natural Probiotic Beverage. Braz. J. Microbiol. 2013, 44, 341–349. [Google Scholar] [CrossRef] [PubMed]

- Barba, F.J.; Cortés, C.; Esteve, M.J.; Frígola, A. Study of Antioxidant Capacity and Quality Parameters in an Orange Juice–Milk Beverage After High-Pressure Processing Treatment. Food Bioprocess Technol. 2012, 5, 2222–2232. [Google Scholar] [CrossRef]

- Markakiou, S.; Gaspar, P.; Johansen, E.; Zeidan, A.A.; Neves, A.R. Harnessing the Metabolic Potential of Streptococcus thermophilus for New Biotechnological Applications. Curr. Opin. Biotechnol. 2020, 61, 142–152. [Google Scholar] [CrossRef]

- Mulaw, G.; Gebregziabher, T.; Tesfay, T. A Review on the Microbiology of Ethiopian Traditional Fermented Beverage Products. Front. Nutr. 2025, 12, 1519547. [Google Scholar] [CrossRef]

- Verardo, V.; Gómez-Caravaca, A.M.; Tabanelli, G. Bioactive Components in Fermented Foods and Food By-Products. Foods 2020, 9, 153. [Google Scholar] [CrossRef]

- Atik, A.; Gumus, T. The Effect of Different Doses of UV-C Treatment on Microbiological Quality of Bovine Milk. LWT 2021, 136, 110322. [Google Scholar] [CrossRef]

- Uysal Pala, Ç. Ultraviolet Light as an Alternative to Thermal Treatment in Fruit Juices. Ph.D. Thesis, Institute of Natural and Applied Sciences, Çanakkale Onsekiz Mart University,, Çanakkale, Türkiye, 2011. [Google Scholar]

- Cilliers, F.P.; Gouws, P.A.; Koutchma, T.; Engelbrecht, Y.; Adriaanse, C.; Swart, P. A Microbiological, Biochemical and Sensory Characterisation of Bovine Milk Treated by Heat and Ultraviolet (UV) Light for Manufacturing Cheddar Cheese. Innov. Food Sci. Emerg. Technol. 2014, 23, 94–106. [Google Scholar] [CrossRef]

- Gopisetty, V.V.S.; Patras, A.; Kilonzo-Nthenge, A.; Yannam, S.; Bansode, R.R.; Sasges, M.; Burns, S.M.; Vergne, M.J.; Pan, C.; Xiao, H. Impact of UV-C Irradiation on the Quality, Safety, and Cytotoxicity of Cranberry-Flavored Water Using a Novel Continuous Flow UV System. LWT 2018, 95, 230–239. [Google Scholar] [CrossRef]

- Atik, İ.; Atik, A.; Akarca, G.; Denizkara, A.J. Production of High-Mineral Content of Ayran and Kefir–Effect of The Fishbone Powder Obtained From Garfish (Belone belone). Int. J. Gastron. Food Sci. 2023, 33, 100786. [Google Scholar] [CrossRef]

- ISO 4833-2; Horizontal Method for The Enumeration of Microorganisms. Part 2: Colony count at 30 degrees C by The Surface Plating Technique. ISO: Geneva, Switzerland, 2013.

- Türköz-Bakırcı, G.; Kayaardı, S. Mikrobiological Analysis Methods (First Press); Sidas Media Co., Ltd.: İzmir, Turkey, 2017; p. 172. [Google Scholar]

- Öner, Z.; Karahan, A.G.; Çakmakçı, M.L. Effects of Different Milk Types and Starter Cultures on Kefir. J. Food 2010, 35, 177–182. [Google Scholar]

- AOAC. Official Methods of Analysis of the Association of Official Analytical Chemists, 18th ed.; The Association: Arlington, VA, USA, 2005. [Google Scholar]

- Wang, X.; Kong, X.; Zhang, C.; Hua, Y.; Chen, Y.; Li, X. Comparison of Physicochemical Properties and Volatile Flavor Compounds of Plant-Based Yoghurt and Dairy Yoghurt. Food Res Int. 2023, 164, 112375. [Google Scholar] [CrossRef]

- Akarca, G.; Denizkara, A.J. Changes of Quality in Yoghurt Produced under Magnetic Field Effect During Fermentation and Storage Processes. Int. Dairy J. 2024, 150, 105841. [Google Scholar] [CrossRef]

- Güzel-Seydim, Z.B.; Seydim, A.C.; Greene, A.K.; Bodine, A.B. Determination of Organic Acids and Volatile Flavor Substances in Kefir During Fermentation. J. Food Compos. Anal. 2000, 13, 35–43. [Google Scholar] [CrossRef]

- Aktas, A.H.; Sen, S.; Yılmazer, M.; Cubuk, E. Determination of Carboxylic Acids in Apple Juice by RP HPLC. Iran. J. Chem. Chem. Eng. 2005, 24, 1–6. [Google Scholar]

- Ercan, M.; Akbulut, M.; Çoklar, H.; Demirci, T. Impacts of Sonication on Fermentation Process and Physicochemical, Microbiological and Sensorial Characteristics of Fermented Black Carrot Juice. Fermentation 2025, 11, 475. [Google Scholar] [CrossRef]

- ISO 11132; Sensory Analysis—Methodology—Guidelines for Monitoring the Performance of a Quantitative Sensory Panel. ISO: Geneva, Switzerland, 2012.

- ISO 8589; Sensory Analysis—General Guidance for the Design of Test Rooms. ISO: Geneva, Switzerland, 2007.

- Diesler, K.; Golombek, P.; Kromm, L.; Scharfenberger-Schmeer, M.; Durner, D.; Schmarr, H.G.; Stahl, M.R.; Briviba, K.; Fischer, U. UV-C Treatment of Grape Must: Microbial Inactivation, Toxicological Considerations and Influence on Chemical and Sensory Properties of White Wine. Innov. Food Sci. Emerg. Technol. 2019, 52, 291–304. [Google Scholar] [CrossRef]

- Bandla, S.; Choudhary, R.; Watson, D.G.; Haddock, J. Impact of UV-C Processing of Raw Cow Milk Treated in a Continuous Flow Coiled Tube Ultraviolet Reactor. Agric. Eng. Int. CIGR J. 2012, 14, 86–93. [Google Scholar]

- Engin, F.B. Effects of Ultraviolet Light and Ultrasound Applications on Aroma-Active Components and Load of Microorganisms in Milk. Ph.D. Thesis, Institute of Natural and Applied Sciences, Çanakkale Onsekiz Mart University, Çanakkale, Türkiye, 2009. [Google Scholar]

- Koutchma, T. Preservation and Shelf Life Extension UV Applications for Fluid Foods, 1st ed.; Academic Press: San Diego, CA, USA, 2014. [Google Scholar]

- Molina-Menor, E.; Carlotto, N.; Vidal-Verdú, À.; Pérez-Ferriols, A.; Pérez-Pastor, G.; Porcar, M. Ecology and Resistance to UV Light and Antibiotics of Microbial Communities on UV Cabins in the Dermatology Service of a Spanish Hospital. Sci. Rep. 2023, 13, 14547. [Google Scholar] [CrossRef]

- Łopusiewicz, Ł.; Drozłowska, E.; Siedlecka, P.; Mężyńska, M.; Bartkowiak, A.; Sienkiewicz, M.; Zielińska-Bliźniewska, H.; Kwiatkowski, P. Development, Characterization, and Bioactivity of Non-Dairy Kefir-Like Fermented Beverage Based on Flaxseed Oil Cake. Foods 2019, 8, 544. [Google Scholar] [CrossRef] [PubMed]

- Yousefvand, A.; Huang, X.; Zarei, M.; Saris, P.E.J. Lacticaseibacillus rhamnosus GG Survival and Quality Parameters in Kefir Produced from Kefir Grains and natural Kefir Starter Culture. Foods 2022, 11, 523. [Google Scholar] [CrossRef]

- Cappozzo, J.C.; Koutchma, T.; Barnes, G. Chemical Characterization of Milk after Treatment with Thermal (HTST and UHT) and Nonthermal (Turbulent Flow Ultraviolet) Processing Technologies. J. Dairy Sci. 2015, 98, 5068–5079. [Google Scholar] [CrossRef]

- Guneser, O.N.U.R.; Yuceer, Y.K. Effect of ultraviolet light on water-and fat-soluble vitamins in cow and goat milk. J. Dairy Sci. 2012, 95, 6230–6241. [Google Scholar] [CrossRef]

- Urgu-Ozturk, M. Possibilities of Using the Continuous Type of UV Light on the Surface of Lor (Whey) Cheese: Impacts on Mould Growth, Oxidative Stability, Sensory and Colour Attributes During Storage. J. Dairy Res. 2022, 89, 335–341. [Google Scholar] [CrossRef]

- Pandiselvam, R.; Barut Gök, S.; Yüksel, A.N.; Tekgül, Y.; Çalişkan Koç, G.; Kothakota, A. Evaluation of the Impact of UV Radiation on Rheological and Textural Properties of Food. J. Texture Stud. 2022, 53, 800–808. [Google Scholar] [CrossRef]

- Bourrie, B.C.; Forgie, A.J.; Ju, T.; Richard, C.; Cotter, P.D.; Willing, B.P. Consumption of the Cell-Free or Heat-Treated Fractions of a Pitched Kefir Confers Some But Not All Positive İmpacts of The Corresponding Whole Kefir. Front. Microbiol. 2022, 13, 1056526. [Google Scholar] [CrossRef]

- Shalabi, O.M.; Hassan, A.M.; Ismail, M.M.; El-Menawy, R.K. Characterization of the Ayran Made with Commercial Probiotic Cultures for Fatty Acids, Cholesterol, Folic Acid Levels, and Anti-Oxidative Potential. Probiotics Antimicrob. Proteins 2024, 16, 1065–1075. [Google Scholar] [CrossRef] [PubMed]

- de Sainz, I.; Redondo-Solano, M.; Solano, G.; Ramírez, L. Effect of Different Kefir Grains on the Attributes of Kefir Produced with Milk from Costa Rica. J. Dairy Sci. 2020, 103, 215–219. [Google Scholar] [CrossRef] [PubMed]

- Biçer, Y.; Telli, A.E.; Sönmez, G.; Turkal, G.; Telli, N.; Uçar, G. Comparison of Commercial and Traditional Kefir Microbiota using Metagenomic Analysis. Int. J. Dairy Technol. 2021, 74, 528–534. [Google Scholar] [CrossRef]

- Gul, O.; Atalar, I.; Mortas, M.; Dervisoglu, M. Rheological, Textural, Colour and Sensorial Properties of Kefir Produced with Buffalo Milk Using Kefir Grains and Starter Culture: A Comparison with Cows’ Milk Kefir. Int. J. Dairy Technol. 2018, 71, 73–80. [Google Scholar] [CrossRef]

- Lu, Y.; Ishikawa, H.; Kwon, Y.; Hu, F.; Miyakawa, T.; Tanokura, M. Real-Time Monitoring of Chemical Changes in Three Kinds of Fermented Milk Products during Fermentation Using Quantitative Difference Nuclear Magnetic Resonance Spectroscopy. J. Agric. Food Chem. 2018, 66, 1479–1487. [Google Scholar] [CrossRef]

- Chen, H.L.; Tung, Y.T.; Chuang, C.H.; Tu, M.Y.; Tsai, T.C.; Chang, S.Y.; Chen, C.M. Kefir Improves Bone Mass and Microarchitecture in an Ovariectomized Rat Model of Postmenopausal Osteoporosis. Osteoporos. Int. 2015, 26, 589–599. [Google Scholar] [CrossRef]

- Li, Y.; Wang, Y.; Li, B.; Hou, B.; Hung, W.; He, J.; Jiang, Y.; Zhang, Y.; Man, C. Streptococcus thermophilus JM905—Strain Carbon Source Utilization and Its Fermented Milk Metabolic Profile at Different Fermentation Stages. Foods 2023, 12, 3690. [Google Scholar] [CrossRef]

- Atik, A.; Gümüs, T.; Karasu, S.; Sagdiç, O. Physicochemical and Sensory Properties of Bovine Milk Treated by Different UV-C Dose: The Effect on Vitamin D3, cholesterol, fatty acid, and formation of volatile compounds. Acta Sci. Technol. 2025, 47, e71447. [Google Scholar] [CrossRef]

- Menéndez-Carreño, M.; Ansorena, D.; Astiasarán, I. Stability of sterols in phytosterol-enriched milk under different heating conditions. J. Agric. Food Chem. 2008, 56, 9997–10002. [Google Scholar] [CrossRef] [PubMed]

- Stinson, L.; Ma, J.; Lai, C.; Rea, A.; Perrella, S.; Geddes, D. Milk Microbiome Transplantation: Recolonizing Donor Milk with Mother’s Own Milk Microbiota. Appl. Microbiol. Biotechnol. 2024, 108, 74. [Google Scholar] [CrossRef]

- Rossitto, P.V.; Cullor, J.S.; Crook, J.; Parko, J.; Sechi, P.; Cenci-Goga, B.T. Effects of UV Irradiation in a Continuous Turbulent Flow UV Reactor on Microbiological and Sensory Characteristics of Cow’s Milk. J. Food Prot. 2012, 75, 2197–2207. [Google Scholar] [CrossRef] [PubMed]

| Sample | TMAB | TCGB | TYM |

|---|---|---|---|

| Raw milk | 5.46 ± 0.01 a | 2.49 ± 0.03 | 5.18 ± 0.04 a |

| Pasteurised | 3.03 ± 0.01 d | <1 | <1 |

| UV15 | 4.15 ± 0.03 b | <1 | 4.22 ± 0.03 b |

| UV30 | 3.83 ± 0.04 b | <1 | 3.68 ± 0.06 bc |

| UV45 | 3.31 ± 0.02 c | <1 | 3.32 ± 0.07 c |

| Sample | Ayran | Kefir | |

|---|---|---|---|

| TMAB | Control | 4.38 ± 0.04 c | 6.85 ± 0.04 c |

| UV15 | 4.96 ± 0.02 b | 7.21 ± 0.09 b | |

| UV30 | 5.10 ± 0.03 a | 7.37 ± 0.05 ab | |

| UV45 | 5.16 ± 0.07 a | 7.48 ± 0.06 a | |

| Interaction | p Value | r | |

| Product type | <0.0001 | 0.972 ** | |

| Treatment | 0.001 | −0.019 | |

| Product type × Treatment | <0.0001 | -- | |

| Lactobacillus spp. | Control | 6.88 ± 0.04 b | 5.38 ± 0.05 c |

| UV15 | 6.84 ± 0.04 b | 5.50 ± 0.07 bc | |

| UV30 | 6.90 ± 0.03 ab | 5.57 ± 0.06 ab | |

| UV45 | 7.02 ± 0.06 a | 5.72 ± 0.06 a | |

| Interaction | p Value | r | |

| Product type | <0.0001 | −0.988 ** | |

| Treatment | 0.002 | 0.127 | |

| Product type × Treatment | 0.128 | -- | |

| Streptococcus/Lactococcus spp. | Control | 6.53 ± 0.03 c | 6.64 ± 0.01 b |

| UV15 | 6.59 ± 0.01 bc | 6.70 ± 0.01 b | |

| UV30 | 6.62 ± 0.02 ab | 6.75 ± 0.02 ab | |

| UV45 | 6.66 ± 0.04 a | 6.86 ± 0.08 a | |

| Interaction | p Value | r | |

| Product type | <0.0001 | 0.688 ** | |

| Treatment | <0.0001 | 0.655 ** | |

| Product type × Treatment | 0.282 | -- | |

| TYM | Control | 2.15 ± 0.05 a | 5.08 ± 0.04 c |

| UV15 | 2.05 ± 0.01 b | 5.18 ± 0.04 bc | |

| UV30 | 2.03 ± 0.01 b | 5.21 ± 0.03 ab | |

| UV45 | 1.99 ± 0.03 b | 5.30 ± 0.04 a | |

| Interaction | p Value | r | |

| Product type | <0.0001 | 0.999 * | |

| Treatment | 0.579 | 0.077 | |

| Product type × Treatment | <0.0001 | -- |

| Sample | Ayran | Kefir | |

|---|---|---|---|

| pH | Control | 3.87 ± 0.01 a | 3.90 ± 0.02 a |

| UV15 | 3.83 ± 0.09 a | 3.90 ± 0.01 a | |

| UV30 | 3.89 ± 0.01 a | 3.89 ± 0.02 a | |

| UV45 | 3.79 ± 0.07 a | 3.86 ± 0.03 a | |

| Interaction | p Value | r | |

| Product type | 0.107 | 0.459 | |

| Treatment | 0.619 | 0.850 | |

| Product type × Treatment | 0.512 | -- | |

| aw | Control | 0.960 ± 0.01 a | 0.955 ± 0.01 a |

| UV15 | 0.945 ± 0.01 a | 0.938 ± 0.01 b | |

| UV30 | 0.954 ± 0.01 a | 0.944 ± 0.01 ab | |

| UV45 | 0.955 ± 0.01 a | 0.949 ± 0.01 ab | |

| Interaction | p Value | r | |

| Product type | 0.037 | −0.474 | |

| Treatment | 0.070 | 0.008 | |

| Product type × Treatment | 0.439 | -- | |

| Dry Matter % | Control | 7.23 ± 0.35 a | 11.70 ± 0.45 a |

| UV15 | 7.79 ± 0.01 a | 11.62 ± 0.35 a | |

| UV30 | 7.59 ± 0.51 a | 11.24 ± 0.03 a | |

| UV45 | 7.23 ± 0.02 a | 11.27 ± 0.04 a | |

| Interaction | p Value | r | |

| Product type | 0.085 | 0.320 | |

| Treatment | 0.088 | 0.802 | |

| Product type × Treatment | 0.054 | -- | |

| Syneresis % | Control | 46.4 ± 7.91 b | 20.6 ± 1.41 a |

| UV15 | 47.6 ± 0.56 ab | 18.0 ± 1.69 a | |

| UV30 | 58.2 ± 1.41 a | 20.0 ± 1.13 a | |

| UV45 | 47.8 ± 0.58 ab | 20.6 ± 0.85 a | |

| Interaction | p Value | r | |

| Product type | <0.0001 | 0.966 ** | |

| Treatment | 0.064 | 0.060 | |

| Product type × Treatment | 0.072 | -- | |

| Titratable Acidity (% LA) | Control | 2.10 ± 0.28 a | 3.11 ± 1.19 a |

| UV15 | 2.19 ± 0.46 a | 3.21 ± 0.54 a | |

| UV30 | 2.23 ± 0.58 a | 3.45 ± 1.73 a | |

| UV45 | 2.19 ± 0.85 a | 3.96 ± 2.09 a | |

| Interaction | p Value | r | |

| Product type | 0.570 | 0.602 * | |

| Treatment | 0.938 | 0.507 | |

| Product type × Treatment | 0.959 | -- |

| Sample | Ayran | Kefir | |

|---|---|---|---|

| Firmness (g) | Control | 12.01 ± 0.65 a | 14.51 ± 0.14 b |

| UV15 | 12.14 ± 0.81 a | 14.97 ± 0.52 b | |

| UV30 | 11.71 ± 0.28 a | 15.49 ± 0.91 b | |

| UV45 | 11.82 ± 0.31 a | 18.77 ± 1.72 a | |

| Interaction | p Value | r | |

| Product type | <0.0001 | 0.835 ** | |

| Treatment | 0.029 | 0.283 | |

| Product type × Treatment | 0.018 | -- | |

| Consistency (g.sec) | Control | 110.14 ± 22.54 a | 375.38 ± 49.76 a |

| UV15 | 122.29 ± 21.29 a | 393.19 ± 56.69 a | |

| UV30 | 122.83 ± 17.17 a | 398.31 ± 69.26 a | |

| UV45 | 128.95 ± 22.55 a | 495.57 ± 44.33 a | |

| Interaction | p Value | r | |

| Product type | <0.0001 | 0.957 ** | |

| Treatment | 0.183 | 0.153 | |

| Product type × Treatment | 0.337 | -- | |

| Cohesiveness | Control | −5.89 ± 5.78 a | −9.37 ± 6.94 a |

| UV15 | −6.03 ± 5.93 a | −8.89 ± 7.13 a | |

| UV30 | −4.82 ± 3.07 a | −9.70 ± 6.01 a | |

| UV45 | −5.02 ± 5.64 a | −6.23 ± 4.06 a | |

| Interaction | p Value | r | |

| Product type | 0.309 | −0.349 | |

| Treatment | 0.955 | 0.564 | |

| Product type × Treatment | 0.974 | -- | |

| Index of Viscosity (g.sec) | Control | −1.12 ± 0.82 a | −2.46 ± 1.69 a |

| UV15 | −1.07 ± 0.88 a | −2.19 ± 1.50 a | |

| UV30 | −0.70 ± 0.25 a | −2.93 ± 1.92 a | |

| UV45 | −0.80 ± 0.47 a | −1.21 ± 0.16 a | |

| Interaction | p Value | r | |

| Product type | 0.057 | −0.563 * | |

| Treatment | 0.734 | 0.214 | |

| Product type × Treatment | 0.740 | -- |

| Sample | Ayran | Kefir | |

|---|---|---|---|

| Oxalic Acid | Control | 20.51 ± 0.87 b | 3.26 ± 0.30 b |

| UV15 | 22.91 ± 0.80 a | 4.38 ± 0.49 ab | |

| UV30 | 23.56 ± 0.54 a | 4.51 ± 0.43 a | |

| UV45 | 24.40 ± 0.56 a | 4.26 ± 0.30 ab | |

| Interaction | p Value | r | |

| Product type | <0.0001 | −0.992 ** | |

| Treatment | 0.001 | 0.736 | |

| Product type × Treatment | 0.042 | -- | |

| Tartaric Acid | Control | 9.55 ± 0.25 c | 28.11 ± 0.30 c |

| UV15 | 10.19 ± 0.41 bc | 29.45 ± 0.57 b | |

| UV30 | 10.99 ± 0.46 ab | 30.24 ± 0.48 b | |

| UV45 | 11.64 ± 0.34 a | 31.53 ± 0.45 a | |

| Interaction | p Value | r | |

| Product type | <0.0001 | −0.994 ** | |

| Treatment | <0.0001 | 0.105 | |

| Product type × Treatment | 0.256 | -- | |

| Formic Acid | Control | 772.15 ± 25.17 b | 1394.32 ± 31.19 a |

| UV15 | 860.86 ± 28.61 a | 1417.02 ± 31.06 a | |

| UV30 | 896.72 ± 23.03 a | 1440.79 ± 27.18 a | |

| UV45 | 906.46 ± 19.82 a | 1460.18 ± 16.82 a | |

| Interaction | p Value | r | |

| Product type | <0.0001 | 0.988 ** | |

| Treatment | 0.003 | 0.128 | |

| Product type × Treatment | 0.205 | -- | |

| Malic Acid | Control | 120.27 ± 1.71 b | 219.09 ± 0.19 c |

| UV15 | 122.51 ± 0.65 ab | 220.39 ± 0.47 bc | |

| UV30 | 123.13 ± 0.42 ab | 222.30 ± 0.98 ab | |

| UV45 | 124.62 ± 0.76 a | 224.10 ± 0.84 a | |

| Interaction | p Value | r | |

| Product type | <0.0001 | 0.999 ** | |

| Treatment | <0.0001 | 0.035 | |

| Product type × Treatment | 0.613 | -- | |

| Ascorbic Acid | Control | 9.23 ± 0.14 ab | 29.96 ± 0.92 c |

| UV15 | 9.915 ± 0.27 b | 31.65 ± 0.62 bc | |

| UV30 | 10.62 ± 0.51 a | 32.46 ± 0.77 ab | |

| UV45 | 10.99 ± 0.65 a | 34.18 ± 0.61 a | |

| Interaction | p Value | r | |

| Product type | <0.0001 | 0.994 ** | |

| Treatment | <0.0001 | 0.099 | |

| Product type × Treatment | 0.115 | -- | |

| Lactic Acid | Control | 9857.72 ± 73.95 c | 9050.23 ± 78.07 d |

| UV15 | 10,215.19 ± 49.83 b | 11,794.03 ± 77.71 c | |

| UV30 | 11,810.52 ± 84.19 a | 12,034.91 ± 55.12 b | |

| UV45 | 11,951.51 ± 75.13 a | 12,989.34 ± 35.41 a | |

| Interaction | p Value | r | |

| Product type | <0.0001 | 0.203 | |

| Treatment | <0.0001 | 0.888 ** | |

| Product type × Treatment | <0.0001 | -- | |

| Citric Acid | Control | 309.29 ± 8.93 b | 305.66 ± 16.89 c |

| UV15 | 394.07 ± 9.32 a | 329.19 ± 12.30 bc | |

| UV30 | 397.79 ± 6.09 a | 358.10 ± 10.00 b | |

| UV45 | 402.80 ± 0.81 a | 395.43 ± 13.54 a | |

| Interaction | p Value | r | |

| Product type | <0.0001 | −0.364 | |

| Treatment | <0.0001 | 0.821 ** | |

| Product type × Treatment | 0.011 | -- | |

| Shikimic Acid | Control | 8.99 ± 0.30 b | 11.75 ± 0.41 b |

| UV15 | 9.59 ± 0.36 ab | 12.84 ± 0.29 ab | |

| UV30 | 9.93 ± 0.38 ab | 13.31 ± 0.59 a | |

| UV45 | 10.48 ± 0.49 a | 13.69 ± 0.44 a | |

| Interaction | p Value | r | |

| Product type | <0.0001 | 0.912 ** | |

| Treatment | 0.003 | 0.359 | |

| Product type × Treatment | 0.753 | -- | |

| Succinic Acid | Control | 6716.49 ± 45.30 d | 7997.56 ± 15.65 d |

| UV15 | 6928.51 ± 41.88 c | 8764.37 ± 29.80 c | |

| UV30 | 7293.52 ± 17.02 b | 8970.95 ± 43.76 b | |

| UV45 | 7913.14 ± 25.46 a | 9137.83 ± 59.82 a | |

| Interaction | p Value | r | |

| Product type | <0.0001 | 0.860 ** | |

| Treatment | <0.0001 | 0.485 | |

| Product type × Treatment | <0.0001 | -- | |

| Fumaric Acid | Control | 1.60 ± 0.62 a | 2.56 ± 0.56 a |

| UV15 | 1.57 ± 0.39 a | 2.72 ± 0.60 a | |

| UV30 | 1.69 ± 0.43 a | 2.81 ± 0.45 a | |

| UV45 | 1.75 ± 0.70 a | 2.79 ± 0.59 a | |

| Interaction | p Value | r | |

| Product type | 0.005 | 0.799 ** | |

| Treatment | 0.956 | 0.679 | |

| Product type × Treatment | 0.994 | -- |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Atik, A. Non-Thermal UV-C Processing as an Alternative to Pasteurisation in Fermented Dairy Beverages: Ayran and Kefir. Fermentation 2025, 11, 557. https://doi.org/10.3390/fermentation11100557

Atik A. Non-Thermal UV-C Processing as an Alternative to Pasteurisation in Fermented Dairy Beverages: Ayran and Kefir. Fermentation. 2025; 11(10):557. https://doi.org/10.3390/fermentation11100557

Chicago/Turabian StyleAtik, Azize. 2025. "Non-Thermal UV-C Processing as an Alternative to Pasteurisation in Fermented Dairy Beverages: Ayran and Kefir" Fermentation 11, no. 10: 557. https://doi.org/10.3390/fermentation11100557

APA StyleAtik, A. (2025). Non-Thermal UV-C Processing as an Alternative to Pasteurisation in Fermented Dairy Beverages: Ayran and Kefir. Fermentation, 11(10), 557. https://doi.org/10.3390/fermentation11100557