Efficient Bioethanol Production from Spent Coffee Grounds Using Liquid Hot Water Pretreatment without Detoxification

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Washing of Spent Coffee Grounds

2.3. Liquid Hot Water (LHW) Pretreatment

2.4. Separate Enzymatic Hydrolysis and Fermentation

2.5. Analytical Methods

2.5.1. High-Performance Liquid Chromatography (HPLC)

2.5.2. X-ray Analysis

2.5.3. Fourier Transform Infrared (FT-IR) Analysis

2.5.4. Scanning Electron Microscope (SEM) Analysis

2.6. Statistical Analysis

3. Results and Discussion

3.1. Effects of LHW Pretreatment Conditions on Enzymatic Hydrolysis

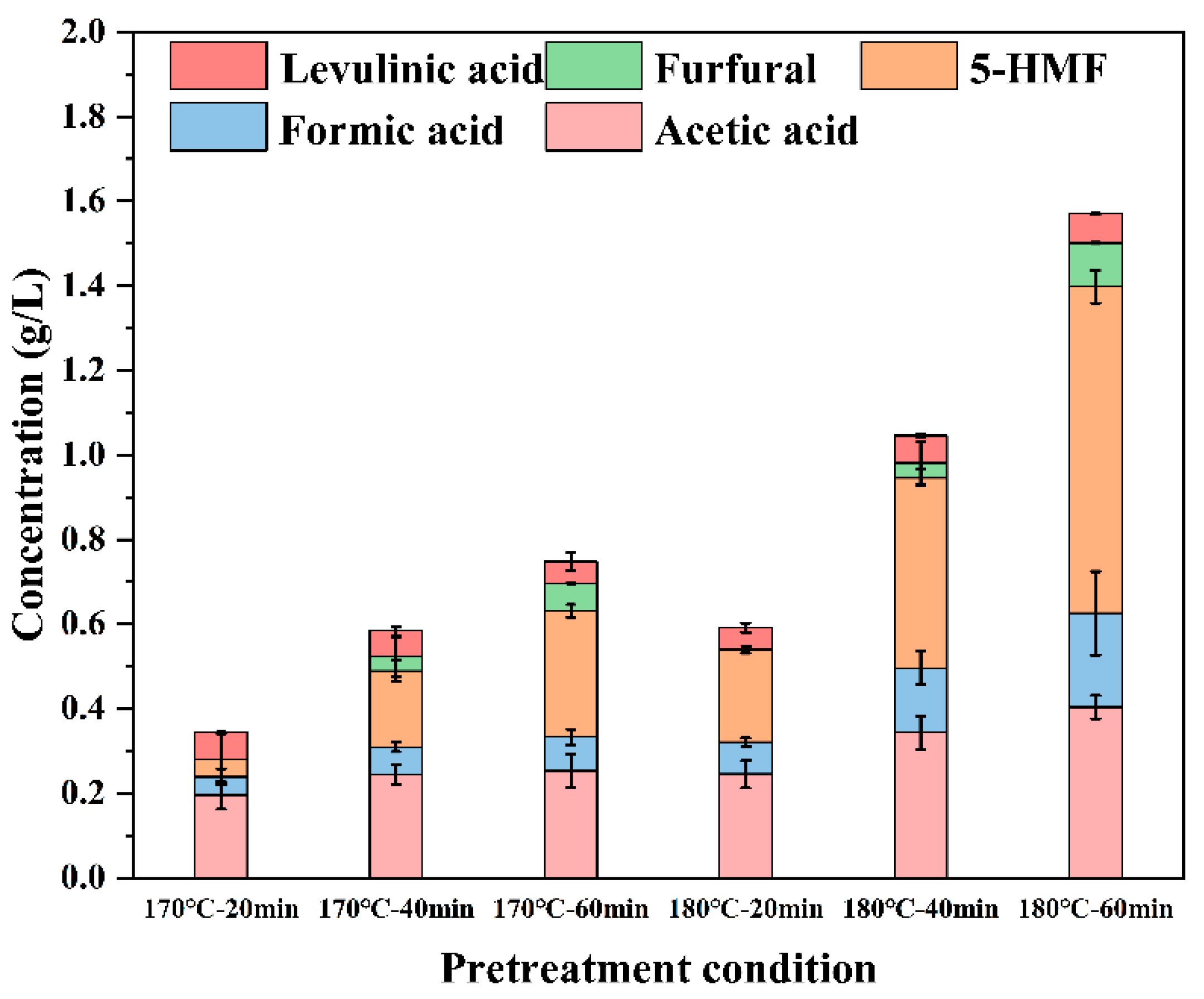

3.1.1. Pretreatment Temperature and Retention Time

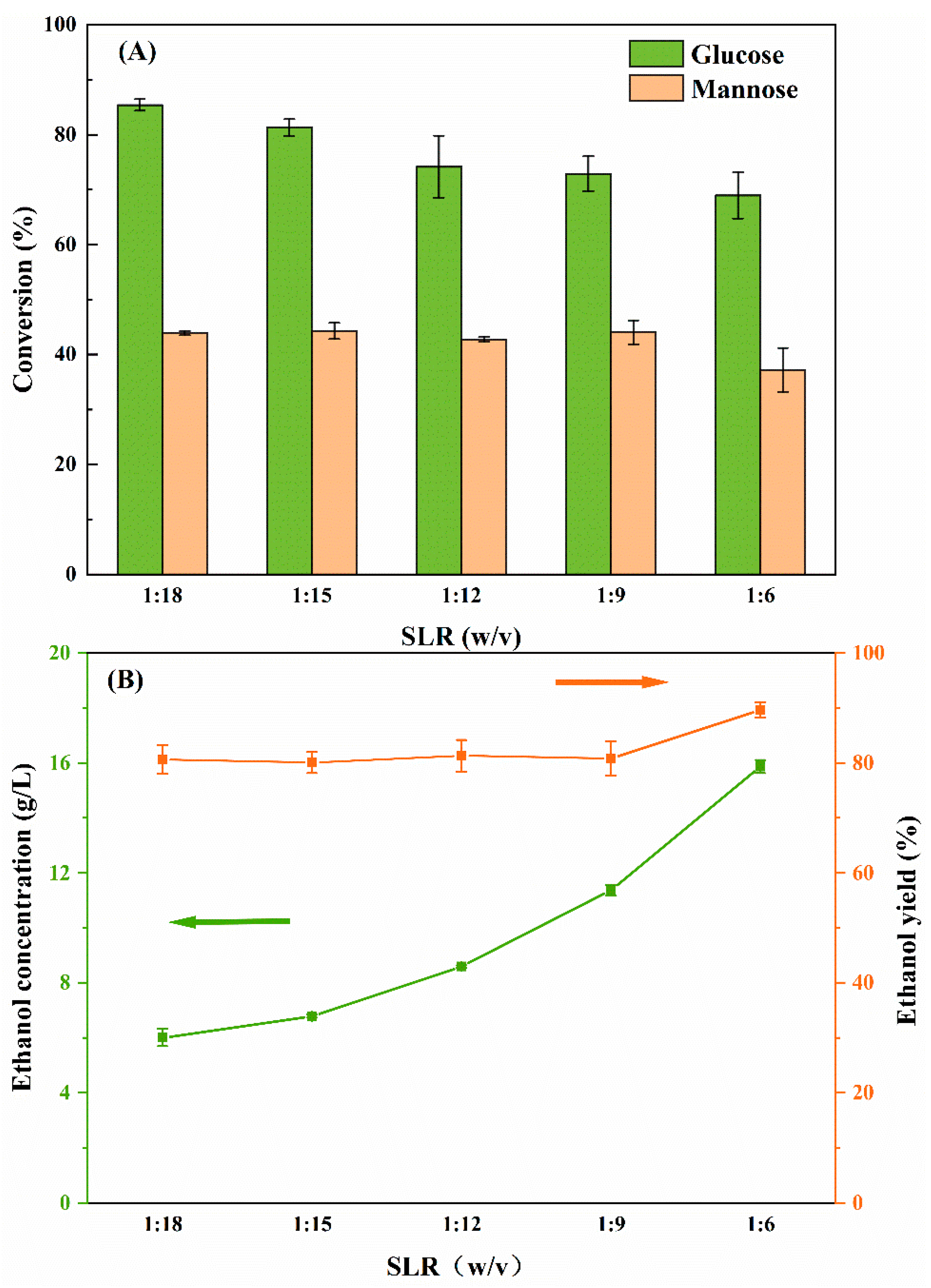

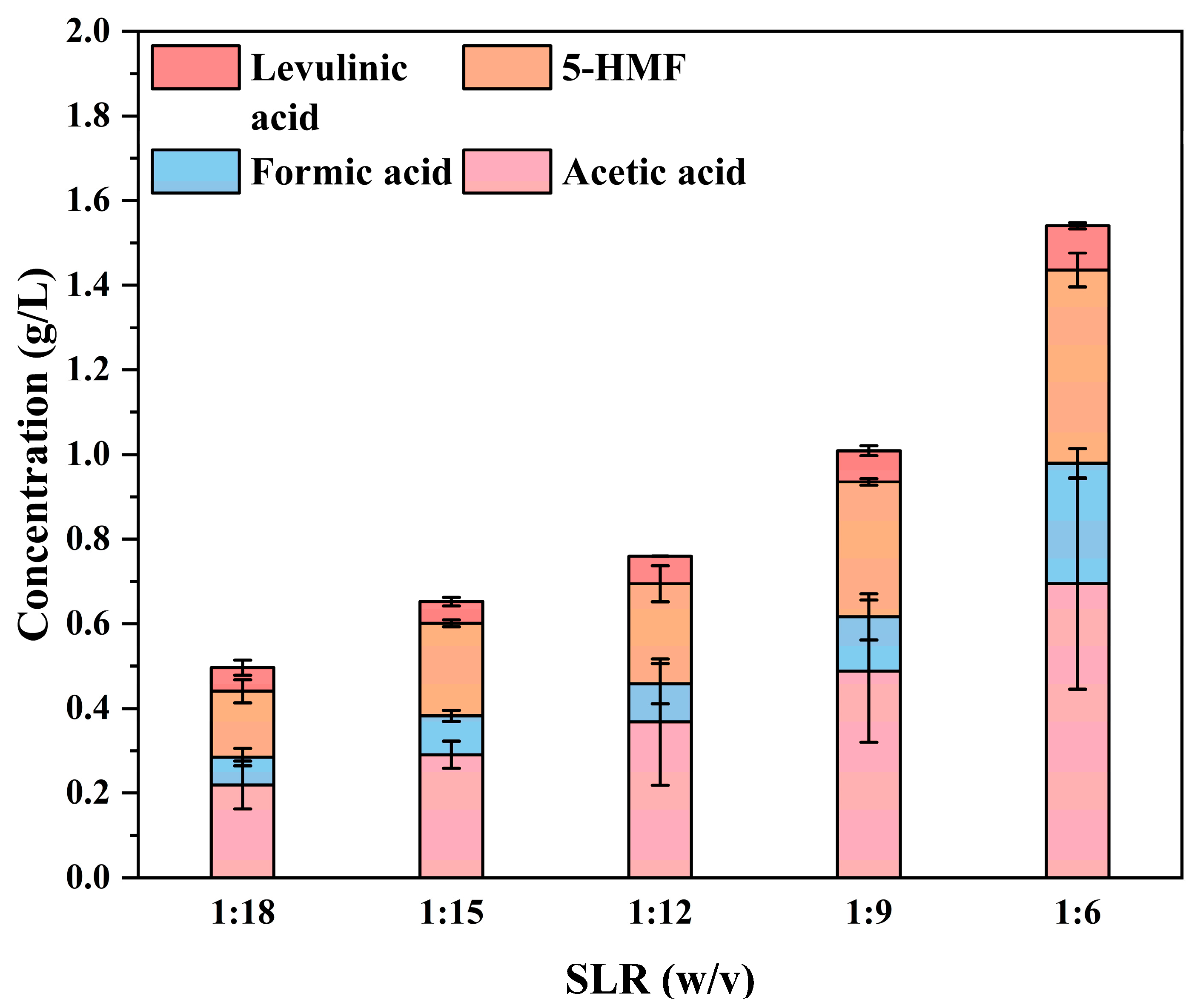

3.1.2. Solid-to-Liquid Ratio

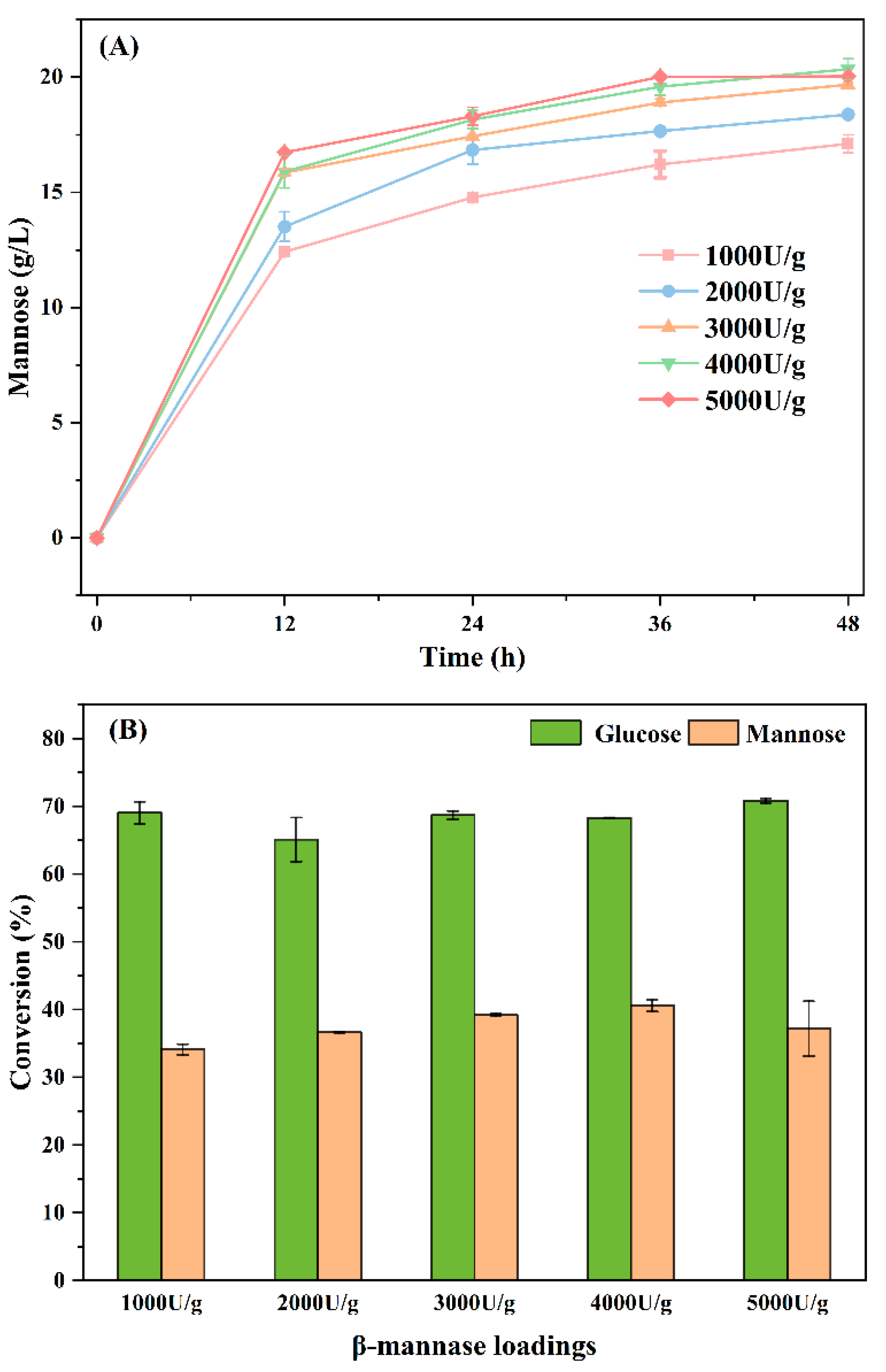

3.1.3. Optimization of Enzymatic Hydrolysis Process

3.2. Mass Balance

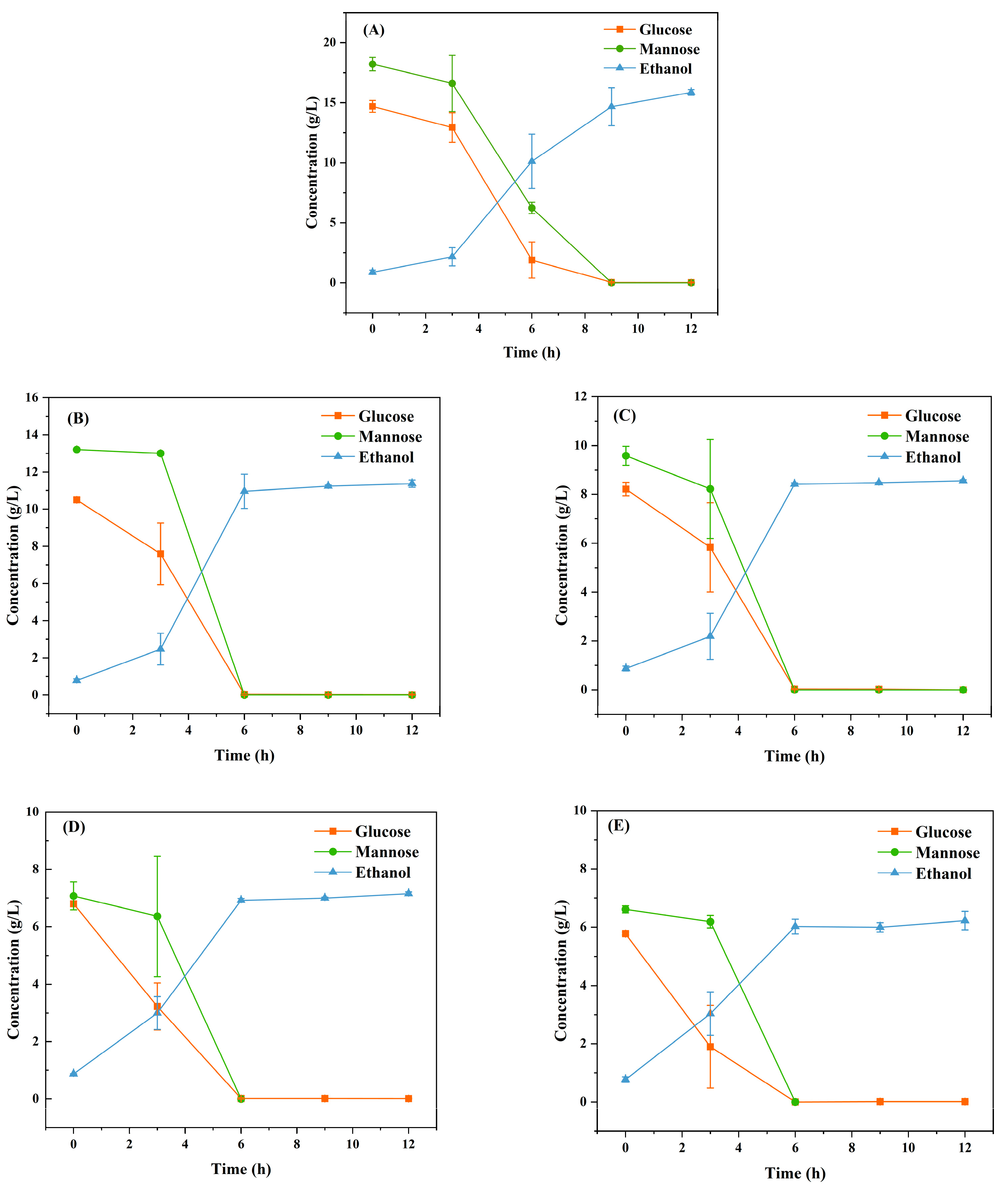

3.3. Bioethanol Generartion Analysis

3.4. Structural Characterization Studies

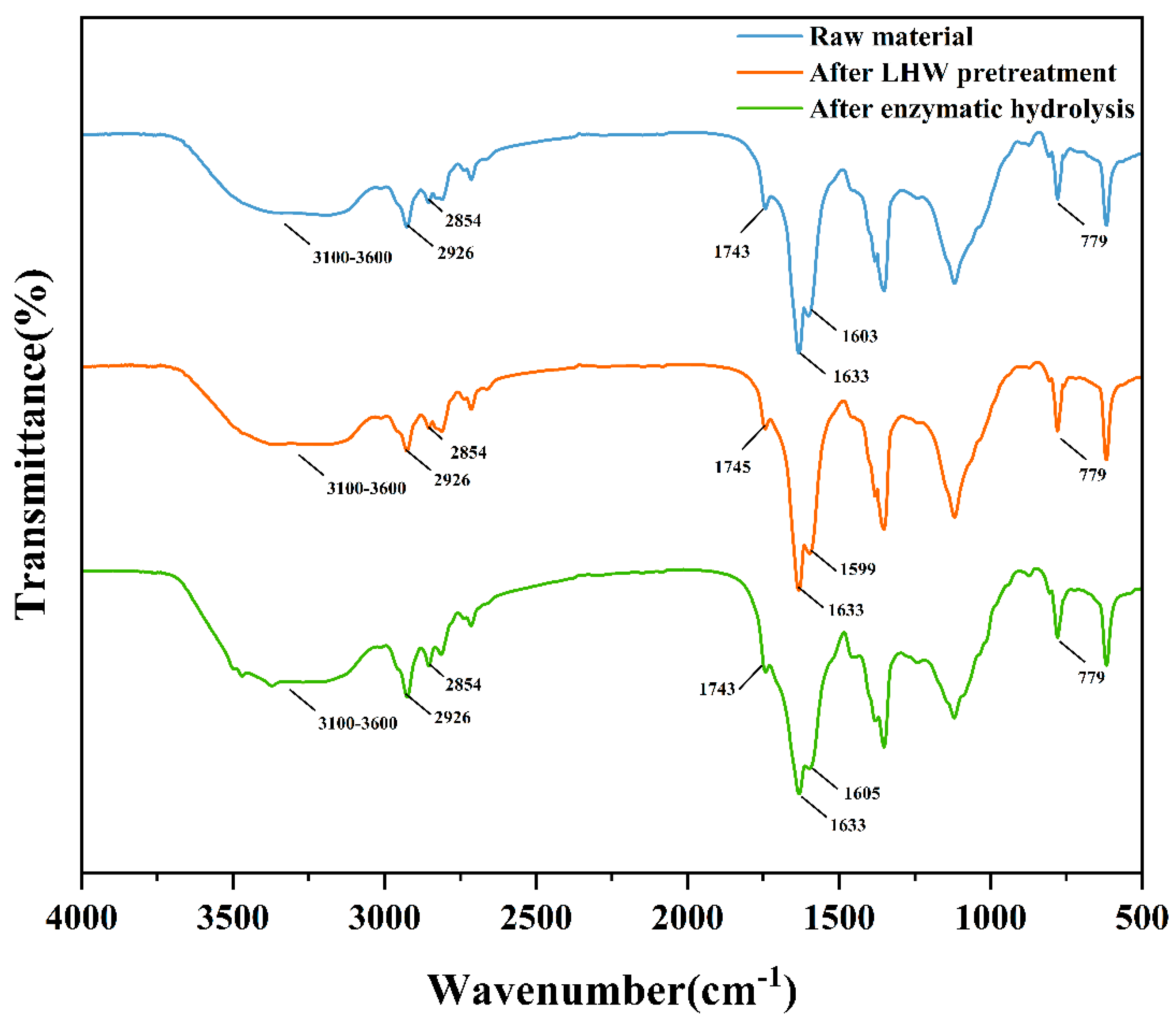

3.4.1. FT-IR Analysis

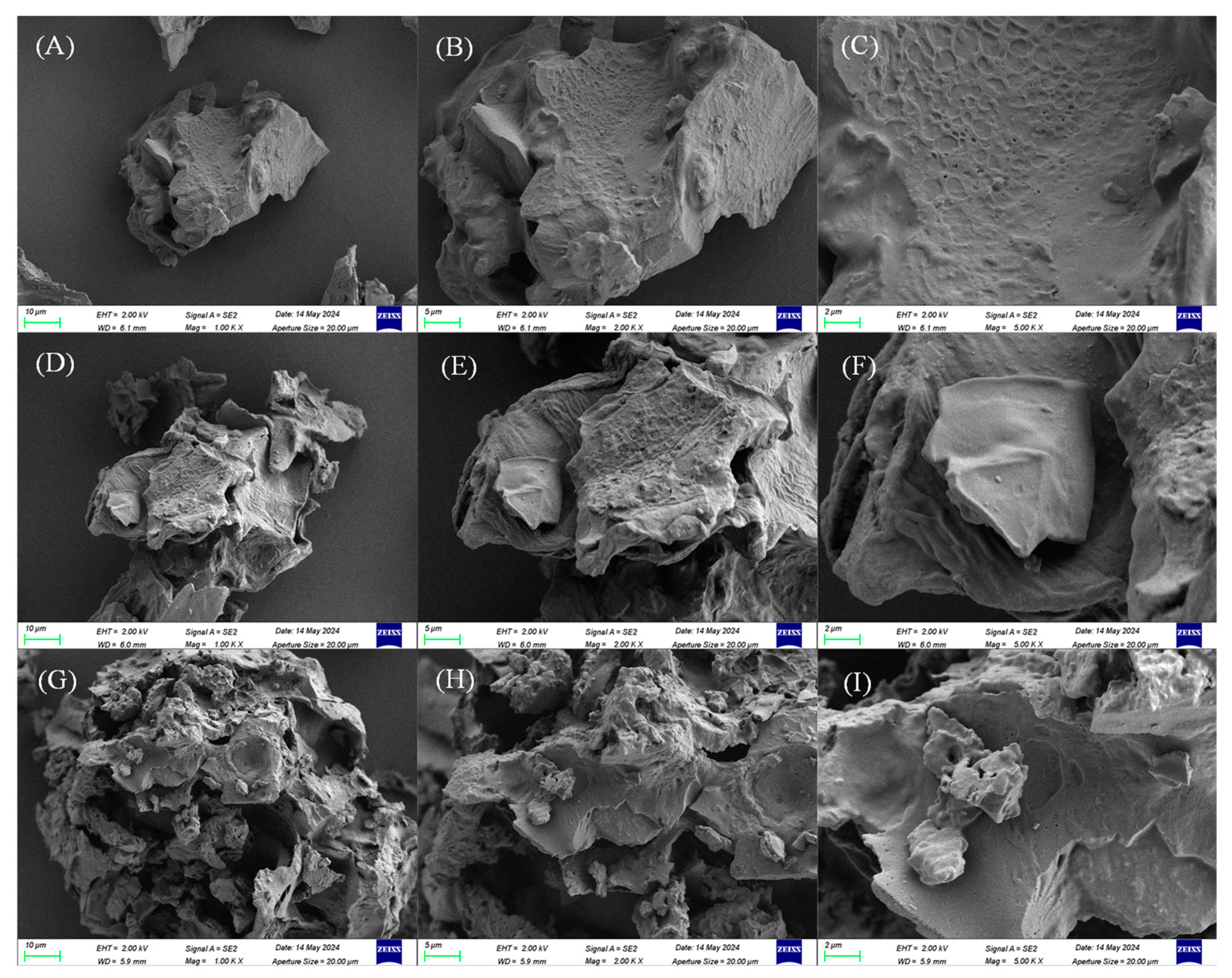

3.4.2. SEM Analysis

3.4.3. X-ray Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, Z.H.; Chen, L.; Khoo, K.S.; Gupta, V.K.; Sharma, M.; Show, P.L.; Yap, P.S. Exploitation of lignocellulosic-based biomass biorefinery: A critical review of renewable bioresource, sustainability and economic views. Biotechnol. Adv. 2023, 69, 36. [Google Scholar] [CrossRef]

- International Coffee Organization. December 2023 Coffee Report and Outlook. Available online: https://icocoffee.org/documents/cy2023-24/Coffee_Report_and_Outlook_December_2023_ICO.pdf (accessed on 11 June 2024).

- Murthy, P.S.; Naidu, M.M. Sustainable management of coffee industry by-products and value addition—A review. Resour. Conserv. Recycl. 2012, 66, 45–58. [Google Scholar] [CrossRef]

- Hardgrove, S.J.; Livesley, S.J. Applying spent coffee grounds directly to urban agriculture soils greatly reduces plant growth. Urban For. Urban Green. 2016, 18, 1–8. [Google Scholar] [CrossRef]

- Stylianou, M.; Agapiou, A.; Omirou, M.; Vyrides, I.; Ioannides, I.M.; Maratheftis, G.; Fasoula, D. Converting environmental risks to benefits by using spent coffee grounds (SCG) as a valuable resource. Environ. Sci. Pollut. Res. 2018, 25, 35776–35790. [Google Scholar] [CrossRef]

- McNutt, J.; He, Q. Spent coffee grounds: A review on current utilization. J. Ind. Eng. Chem. 2019, 71, 78–88. [Google Scholar] [CrossRef]

- Liu, Y.; Zheng, X.J.; Tao, S.H.; Hu, L.; Zhang, X.D.; Lin, X.Q. Process optimization for deep eutectic solvent pretreatment and enzymatic hydrolysis of sugar cane bagasse for cellulosic ethanol fermentation. Renew. Energy 2021, 177, 259–267. [Google Scholar] [CrossRef]

- Jesus, M.S.; Romani, A.; Genisheva, Z.; Teixeira, J.A.; Domingues, L. Integral valorization of vine pruning residue by sequential autohydrolysis stages. J. Clean. Prod. 2017, 168, 74–86. [Google Scholar] [CrossRef]

- Zhang, J.H.; Fu, Y.Z.; Dong, Y.Y.; Wang, D.W.; Deng, J.; Shi, Z.J.; Yang, J.; Yang, H.Y. Pretreatment of bamboo with choline chloride-lactic acid integrated with calcium chloride hydrates deep eutectic solvent to boost bioconversion for ethanol production. Ind. Crops Prod. 2023, 200, 9. [Google Scholar] [CrossRef]

- Qian, Q.; Luo, Z.Y.; Sun, H.R.; Wei, Q.; Shi, J.K.; Li, L.F. Life cycle assessment and techno-economic analysis of wood-based biorefineries for cellulosic ethanol production. Bioresour. Technol. 2024, 399, 11. [Google Scholar] [CrossRef]

- Xian, X.; Fang, L.; Zhou, Y.; Li, B.; Zheng, X.; Liu, Y.; Lin, X. Integrated Bioprocess for Cellulosic Ethanol Production from Wheat Straw: New Ternary Deep-Eutectic-Solvent Pretreatment, Enzymatic Saccharification, and Fermentation. Fermentation 2022, 8, 371. [Google Scholar] [CrossRef]

- Raj, T.; Singh, V. Natural deep eutectic solvents (NADES) assisted deconstruction of oilcane bagasse for high lipid and sugar recovery. Ind. Crops Prod. 2024, 210, 118127. [Google Scholar] [CrossRef]

- Xian, X.; Li, B.; Feng, S.; Huang, J.; Fu, X.; Wu, T.; Lin, X. Enhanced bioethanol production from sugarcane bagasse: Combination of liquid hot water and deep eutectic solvent pretreatment for optimized enzymatic saccharification. Front. Chem. Sci. Eng. 2024, 18, 85. [Google Scholar] [CrossRef]

- Ruchala, J.; Kurylenko, O.O.; Dmytruk, K.V.; Sibirny, A.A. Construction of advanced producers of first- and second-generation ethanol in Saccharomyces cerevisiae and selected species of non-conventional yeasts (Scheffersomyces stipitis, Ogataea polymorpha). J. Ind. Microbiol. Biotechnol. 2020, 47, 109–132. [Google Scholar] [CrossRef] [PubMed]

- Qureshi, N.; Lin, X.Q.; Tao, S.H.; Liu, S.Q.; Huang, H.B.; Nichols, N.N. Can Xylose Be Fermented to Biofuel Butanol in Continuous Long-Term Reactors: If Not, What Options Are There? Energies 2023, 16, 4945. [Google Scholar] [CrossRef]

- Mussatto, S.I.; Carneiro, L.M.; Silva, J.P.A.; Roberto, I.C.; Teixeira, J.A. A study on chemical constituents and sugars extraction from spent coffee grounds. Carbohydr. Polym. 2011, 83, 368–374. [Google Scholar] [CrossRef]

- Mussatto, S.I.; Machado, E.M.S.; Carneiro, L.M.; Teixeira, J.A. Sugars metabolism and ethanol production by different yeast strains from coffee industry wastes hydrolysates. Appl. Energy 2012, 92, 763–768. [Google Scholar] [CrossRef]

- Ruta, L.L.; Farcasanu, I.C. Coffee and Yeasts: From Flavor to Biotechnology. Fermentation 2021, 7, 9. [Google Scholar] [CrossRef]

- Petridis, L.; Smith, J.C. Molecular-level driving forces in lignocellulosic biomass deconstruction for bioenergy. Nat. Rev. Chem. 2018, 2, 382–389. [Google Scholar] [CrossRef]

- Periyasamy, S.; Isabel, J.B.; Kavitha, S.; Karthik, V.; Mohamed, B.A.; Gizaw, D.G.; Sivashanmugam, P.; Aminabhavi, T.M. Recent advances in consolidated bioprocessing for conversion of lignocellulosic biomass into bioethanol—A review. Chem. Eng. J. 2023, 453, 16. [Google Scholar] [CrossRef]

- Rocha, M.V.P.; de Matos, L.; de Lima, L.P.; Figueiredo, P.M.D.; Lucena, I.L.; Fernandes, F.A.N.; Goncalves, L.R.B. Ultrasound-assisted production of biodiesel and ethanol from spent coffee grounds. Bioresour. Technol. 2014, 167, 343–348. [Google Scholar] [CrossRef]

- Titiri, E.; Filippi, K.; Giannakis, N.; Vlysidis, A.; Koutinas, A.; Stylianou, E. Optimisation of alkaline pretreatment of spent coffee grounds for microbial oil production by Cryptococcus curvatus. Biochem. Eng. J. 2023, 193, 108841. [Google Scholar] [CrossRef]

- Choi, I.S.; Wi, S.G.; Kim, S.B.; Bae, H.J. Conversion of coffee residue waste into bioethanol with using popping pretreatment. Bioresour. Technol. 2012, 125, 132–137. [Google Scholar] [CrossRef] [PubMed]

- Ravindran, R.; Jaiswal, S.; Abu-Ghannam, N.; Jaiswal, A.K. Evaluation of ultrasound assisted potassium permanganate pre-treatment of spent coffee waste. Bioresour. Technol. 2017, 224, 680–687. [Google Scholar] [CrossRef] [PubMed]

- Ravindran, R.; Sarangapani, C.; Jaiswal, S.; Cullen, P.J.; Jaiswal, A.K. Ferric chloride assisted plasma pretreatment of lignocellulose. Bioresour. Technol. 2017, 243, 327–334. [Google Scholar] [CrossRef] [PubMed]

- Ravindran, R.; Jaiswal, S.; Abu-Ghannam, N.; Jaiswal, A.K. Two-step sequential pretreatment for the enhanced enzymatic hydrolysis of coffee spent waste. Bioresour. Technol. 2017, 239, 276–284. [Google Scholar] [CrossRef] [PubMed]

- Kwon, E.E.; Yi, H.; Jeon, Y.J. Sequential co-production of biodiesel and bioethanol with spent coffee grounds. Bioresour. Technol. 2013, 136, 475–480. [Google Scholar] [CrossRef] [PubMed]

- Lopez-Linares, J.C.; Teresa Garcia-Cubero, M.; Coca, M.; Lucas, S. Efficient biobutanol production by acetone-butanol-ethanol fermentation from spent coffee grounds with microwave assisted dilute sulfuric acid pretreatment. Bioresour. Technol. 2021, 320, 124348. [Google Scholar] [CrossRef]

- Lin, X.Q.; Liu, Y.; Zheng, X.J.; Qureshi, N. High-efficient cellulosic butanol production from deep eutectic solvent pretreated corn stover without detoxification. Ind. Crops Prod. 2021, 162, 8. [Google Scholar] [CrossRef]

- Sun, D.; Lv, Z.W.; Rao, J.; Tian, R.; Sun, S.N.; Peng, F. Effects of hydrothermal pretreatment on the dissolution and structural evolution of hemicelluloses and lignin: A review. Carbohydr. Polym. 2022, 281, 13. [Google Scholar] [CrossRef]

- Zheng, X.J.; Xian, X.L.; Hu, L.; Tao, S.H.; Zhang, X.D.; Liu, Y.; Lin, X.Q. Efficient short-time hydrothermal depolymerization of sugarcane bagasse in one-pot for cellulosic ethanol production without solid-liquid separation, water washing, and detoxification. Bioresour. Technol. 2021, 339, 125575. [Google Scholar] [CrossRef]

- Qiu, Z.; Han, X.; He, J.; Jiang, Y.; Wang, G.; Wang, Z.; Liu, X.; Xia, J.; Xu, N.; He, A.; et al. One-pot d-lactic acid production using undetoxified acid-pretreated corncob slurry by an adapted Pediococcus acidilactici. Bioresour. Technol. 2022, 363, 127993. [Google Scholar] [CrossRef]

- Sluiter, A.; Hames, B.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D.; Crocker, D. Determination of Structural Carbohydrates and Lignin in Biomass; National Renewable Energy Laboratory: Golden, CO, USA, 2008; pp. 1–16.

- Xian, X.L.; Zheng, X.J.; Huang, J.L.; Qureshi, N.; Li, B.Y.; Liu, J.K.; Zeng, Y.R.; Nichols, N.N.; Lin, X.Q. Detoxification of high solid-liquid hydrothermal pretreated sugar cane bagasse by chromatographic adsorption for cellulosic ethanol production. Ind. Crops Prod. 2023, 202, 10. [Google Scholar] [CrossRef]

- Ballesteros, L.F.; Teixeira, J.A.; Mussatto, S.I. Chemical, Functional, and Structural Properties of Spent Coffee Grounds and Coffee Silverskin. Food Bioprocess Technol. 2014, 7, 3493–3503. [Google Scholar] [CrossRef]

- Ji, G.Y.; Zhang, B.; Niu, Q.J.; Liu, Y.X.; Yang, Q.Z. Enhancement of Liquid Hot Water Pretreatment on Corn Stover with Ball Milling to Improve Total Sugar Yields. Sustainability 2023, 15, 16426. [Google Scholar] [CrossRef]

- Najafi, E.; Castro, E.; Karimi, K. Biorefining for olive wastes management and efficient bioenergy production. Energy Convers. Manag. 2021, 244, 114467. [Google Scholar] [CrossRef]

- Romero-García, J.M.; López-Linares, J.C.; Contreras, M.d.M.; Romero, I.; Castro, E. Exploitation of olive tree pruning biomass through hydrothermal pretreatments. Ind. Crops Prod. 2022, 176, 114425. [Google Scholar] [CrossRef]

- Zhou, Q.Q.; Ding, A.J.; Zhang, L.; Wang, J.W.; Gu, J.X.; Wu, T.Y.; Gu, X.H.; Zhang, L. Furfural production from the lignocellulosic agro-forestry waste by solvolysis method—A technical review. Fuel Process. Technol. 2024, 255, 20. [Google Scholar] [CrossRef]

- Heer, D.; Sauer, U. Identification of furfural as a key toxin in lignocellulosic hydrolysates and evolution of a tolerant yeast strain. Microb. Biotechnol. 2008, 1, 497–506. [Google Scholar] [CrossRef] [PubMed]

- Zhang, B.; Liu, X.C.; Bao, J. High solids loading pretreatment: The core of lignocellulose biorefinery as an industrial technology—An overview. Bioresour. Technol. 2023, 369, 12. [Google Scholar] [CrossRef]

- Burniol-Figols, A.; Cenian, K.; Skiadas, I.V.; Gavala, H.N. Integration of chlorogenic acid recovery and bioethanol production from spent coffee grounds. Biochem. Eng. J. 2016, 116, 54–64. [Google Scholar] [CrossRef]

- Koppram, R.; Tomás-Pejó, E.; Xiros, C.; Olsson, L. Lignocellulosic ethanol production at high-gravity: Challenges and perspectives. Trends Biotechnol. 2014, 32, 46–53. [Google Scholar] [CrossRef]

- Cao, G.; Ximenes, E.; Nichols, N.N.; Zhang, L.; Ladisch, M. Biological abatement of cellulase inhibitors. Bioresour. Technol. 2013, 146, 604–610. [Google Scholar] [CrossRef] [PubMed]

- Zhao, J.; Lee, J.; Wang, D. A Critical Review on Water Overconsumption in Lignocellulosic Biomass Pretreatment for Ethanol Production through Enzymic Hydrolysis and Fermentation. Energy Fuels 2023, 37, 2667–2680. [Google Scholar] [CrossRef]

- Statista. Production of Biofuels Worldwide in 2022, with a Forecast until 2030, by Product Type (in Billion Liters). Available online: https://www.statista.com/statistics/1440696/biofuel-production-forecast-by-product-type/ (accessed on 16 July 2024).

- Ballesteros, L.F.; Cerqueira, M.A.; Teixeira, J.A.; Mussatto, S.I. Characterization of polysaccharides extracted from spent coffee grounds by alkali pretreatment. Carbohydr. Polym. 2015, 127, 347–354. [Google Scholar] [CrossRef]

- Zarrinbakhsh, N.; Wang, T.; Rodriguez-Uribe, A.; Misra, M.; Mohanty, A.K. Characterization of Wastes and Coproducts from the Coffee Industry for Composite Material Production. Bioresources 2016, 11, 7637–7653. [Google Scholar] [CrossRef]

- Singh, B.R.; Wechter, M.A.; Hu, Y.H.; Lafontaine, C. Determination of caffeine content in coffee using Fourier transform infra-red spectroscopy in combination with attenuated total reflectance technique: A bioanalytical chemistry experiment for biochemists. Biochem. Educ. 1998, 26, 243–247. [Google Scholar] [CrossRef]

- Coelho, G.O.; Batista, M.J.A.; Avila, A.F.; Franca, A.S.; Oliveira, L.S. Development and characterization of biopolymeric films of galactomannans recovered from spent coffee grounds. J. Food Eng. 2021, 289, 10. [Google Scholar] [CrossRef]

- Figueiró, S.D.; Góes, J.C.; Moreira, R.A.; Sombra, A.S.B. On the physico-chemical and dielectric properties of glutaraldehyde crosslinked galactomannan–collagen films. Carbohydr. Polym. 2004, 56, 313–320. [Google Scholar] [CrossRef]

- Batista, M.; Torres, S.S.; Franca, A.S.; Oliveira, L.S. Effect of zinc chloride solution assisted by ultrasound on polysaccharides of spent coffee grounds. Carbohydr. Polym. Technol. Appl. 2023, 5, 10. [Google Scholar] [CrossRef]

- Jiang, X.; Jiang, T.; Gan, L.; Zhang, X.; Dai, H.; Zhang, X. The plasticizing mechanism and effect of calcium chloride on starch/poly(vinyl alcohol) films. Carbohydr. Polym. 2012, 90, 1677–1684. [Google Scholar] [CrossRef]

| Pretreatment | Conversion (%) | Ethanol | |||

|---|---|---|---|---|---|

| Glucose | Mannose | Concentration (g/L) | Yield b (%) | Mass Yield c (mg/g SCG) | |

| 170 °C—20 min | 73.52 ± 1.45 a | 42.64 ± 2.11 | 6.95 ± 0.15 | 93.80 ± 0.17 | 116.09 ± 0.10 |

| 170 °C—40 min | 80.78 ± 1.75 | 42.21 ± 0.28 | 7.00 ± 0.10 | 90.61 ± 2.19 | 117.53 ± 0.07 |

| 170 °C—60 min | 81.85 ± 2.20 | 41.04 ± 0.51 | 7.05 ± 0.36 | 91.31 ± 3.10 | 124.02 ± 0.08 |

| 180 °C—20 min | 81.05 ± 1.86 | 44.66 ± 1.34 | 7.25 ± 0.08 | 89.67 ± 4.13 | 124.81 ± 0.03 |

| 180 °C—40 min | 81.86 ± 1.27 | 38.98 ± 3.06 | 6.94 ± 0.07 | 91.49 ± 4.25 | 119.96 ± 0.03 |

| 180 °C—60 min | 83.15 ± 0.24 | 30.53 ± 0.50 | 6.32 ± 0.17 | 94.69 ± 3.20 | 112.80 ± 0.04 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, J.; Li, B.; Xian, X.; Hu, Y.; Lin, X. Efficient Bioethanol Production from Spent Coffee Grounds Using Liquid Hot Water Pretreatment without Detoxification. Fermentation 2024, 10, 436. https://doi.org/10.3390/fermentation10080436

Huang J, Li B, Xian X, Hu Y, Lin X. Efficient Bioethanol Production from Spent Coffee Grounds Using Liquid Hot Water Pretreatment without Detoxification. Fermentation. 2024; 10(8):436. https://doi.org/10.3390/fermentation10080436

Chicago/Turabian StyleHuang, Jiale, Biying Li, Xiaoling Xian, Yinan Hu, and Xiaoqing Lin. 2024. "Efficient Bioethanol Production from Spent Coffee Grounds Using Liquid Hot Water Pretreatment without Detoxification" Fermentation 10, no. 8: 436. https://doi.org/10.3390/fermentation10080436

APA StyleHuang, J., Li, B., Xian, X., Hu, Y., & Lin, X. (2024). Efficient Bioethanol Production from Spent Coffee Grounds Using Liquid Hot Water Pretreatment without Detoxification. Fermentation, 10(8), 436. https://doi.org/10.3390/fermentation10080436