1. Introduction

In recent years, microbial electrochemical systems (MESs) have shown increasing promise in a number of biotechnological applications, including waste treatment, chemical generation, and the production of renewable energy [

1,

2,

3,

4]. Microbial electrolysis cells (MECs) are a form of MESs that can utilize electrons within a cathode chamber in order to yield specific chemical compounds through the activity of specific electrochemically active microbes [

3]. Such MECs have been used to produce a range of chemical products, including alcohol, butanol, butyric acid, and succinic acid. In one study, researchers were able to achieve a 34% increase in

Clostridium tyrobutyricum BAS7-mediated butyric acid production by applying a −1.5 V cathodic potential to their MEC system while using neutral red (NR) as an electron carrier [

5]. Methyl viologen has been utilized in such MEC systems as well, being used to promote the reduction of acetate at a −0.55 V applied cathodic potential, leading to a 6-fold acceleration of ethanol production [

6]. When an MEC was subjected to a constant −1.8 V potential during a 60 h fermentation reaction, this was sufficient to yield 18 g/L succinic acid [

7]. While the increase in the product concentration was obvious, the electron utilization was inefficient due to the complex culture conditions and potentiostatic method. This meant that the extracellular electronic supplement using the potentiostatic method far exceeded the intracellular electronic requirements. As such, there is an urgent need to develop reliable methods suited to controlling MECs.

Redox reactions are essential mediators of a wide range of essential biological processes [

8]. The redox potential of a system is determined based upon factors including the pH equilibrium constant, concentrations of dissolved oxygen, and the amounts of particular compounds dissolved in a given medium [

9]. ORP measurements have been an increasing subject of focus. Liu et al., for example, found succinic acid yields from

Escherichia coli LL016 at a −400 mV ORP level to be 39% higher than at a −200 mV ORP level [

10]. Similarly, in a mixed-acid anaerobic

Corynebacterium crenatum fermentation system, a culture potential of −300 mV led to a 0.31 g/g succinic acid yield, which was 72% higher than when this ORP value was instead −40 mV [

11].

For ORP-controlled fermentation reactions, appropriately lower ORP levels lead to higher intracellular NADH levels and/or NADH/NAD

+ ratios [

10]. Intracellular NADH and NAD

+ are essential for many biological reactions, and as such, the use of ORP-controlled fermentation reactions that modulate this NADH/NAD

+ ratio and yield higher NADH concentrations lead to increased enzymatic activity and ATP synthesis, along with reductive metabolite production [

11,

12]. In MECs, the intracellular NADH levels have also been shown to be increased upon the application of an appropriate potential to the cathode [

13]. In these MECs, it is possible for electrons to be transferred to a given mediator and then to microbes, thereby compensating for any shortage in reducing power [

5]. As such, in MECs, these higher intracellular NADH levels are linked to increased enzymatic activity and ATP synthesis, along with reductive metabolite production [

7]. As such, modulating the ORP represents an attractive means of controlling MEC processes.

The redox potential of the extracellular environment plays a pivotal role in the regulation of cellular metabolism, as it influences metabolic flux, intracellular enzymatic activities, and the balance of redox cofactors, such as the NADH/NAD

+ ratio, which are essential for various metabolic pathways [

14,

15,

16]. As such, many different approaches have been employed to regulate the extracellular redox potential. For example, Liu et al. controlled the redox potential during succinic acid production by engineered

Escherichia coli through the use of dithiothreitol (DTT) and potassium ferricyanide (K

3Fe(CN)

6) as respective reducing and oxidizing agents [

10]. Additionally, the selection of carbon sources with varying oxidation states has been demonstrated to be a viable method for redox control. This strategy was effectively applied in the fermentation process of

A. succinogenes NJ113 to produce succinic acid, showcasing the versatility of redox management in bio-production systems [

12].

In the present investigation, we sought to implement a robust feedback control mechanism in MECs to augment the yield of succinic acid as well as to elevate the electron utilization efficiency. This encompassed the strategic selection of regulatory parameters, the meticulous design and refinement of the feedback control system, and the elucidation of the feedback regulation mechanism.

Therefore, in this study, we have explored the practicability of leveraging the ORP as a feedback regulatory parameter within MECs. In tandem, we examined the effects of NR, serving as an electron mediator within the MECs, on the efficacy of the control system. Furthermore, we refined the electron provisioning strategy by manipulating the applied electrical potentials, thereby elevating the regulatory system’s efficiency. This study also explores the use of a fed-batch fermentation approach, which could potentially enhance succinic acid production by providing a steady supply of substrates and maintaining optimal growth conditions throughout the fermentation process. The results from such research could have significant implications for industrial biotechnology. By demonstrating the feasibility of ORP manipulation to improve biochemical synthesis in a bioelectrochemical system, this work contributes to the development of more efficient and sustainable methods for producing valuable chemicals like succinic acid.

2. Results and Discussion

2.1. ORP-Controlled MEC System Development

In our previous research, within microbial electrolysis cells (MECs) operating without feedback control, a succinic acid concentration of 18.09 g/L was achieved using corn stover hydrolysate as the carbon source, while the utilization of molasses as the carbon source resulted in a succinic acid concentration of 83.67 g/L [

7,

17]. Existing research indicates that optimizing the startup cathode potentials, operating potential, and even polarity reversal has a significant impact on the electrosynthesis process, yet it does not result in effective feedback regulation [

7,

18,

19]. In the present study, an ORP-controlled MEC system was utilized to explore the impact on the extracellular redox potential, cell growth, and succinic acid production. The relative cell growth, succinic acid production, and ORP variability for

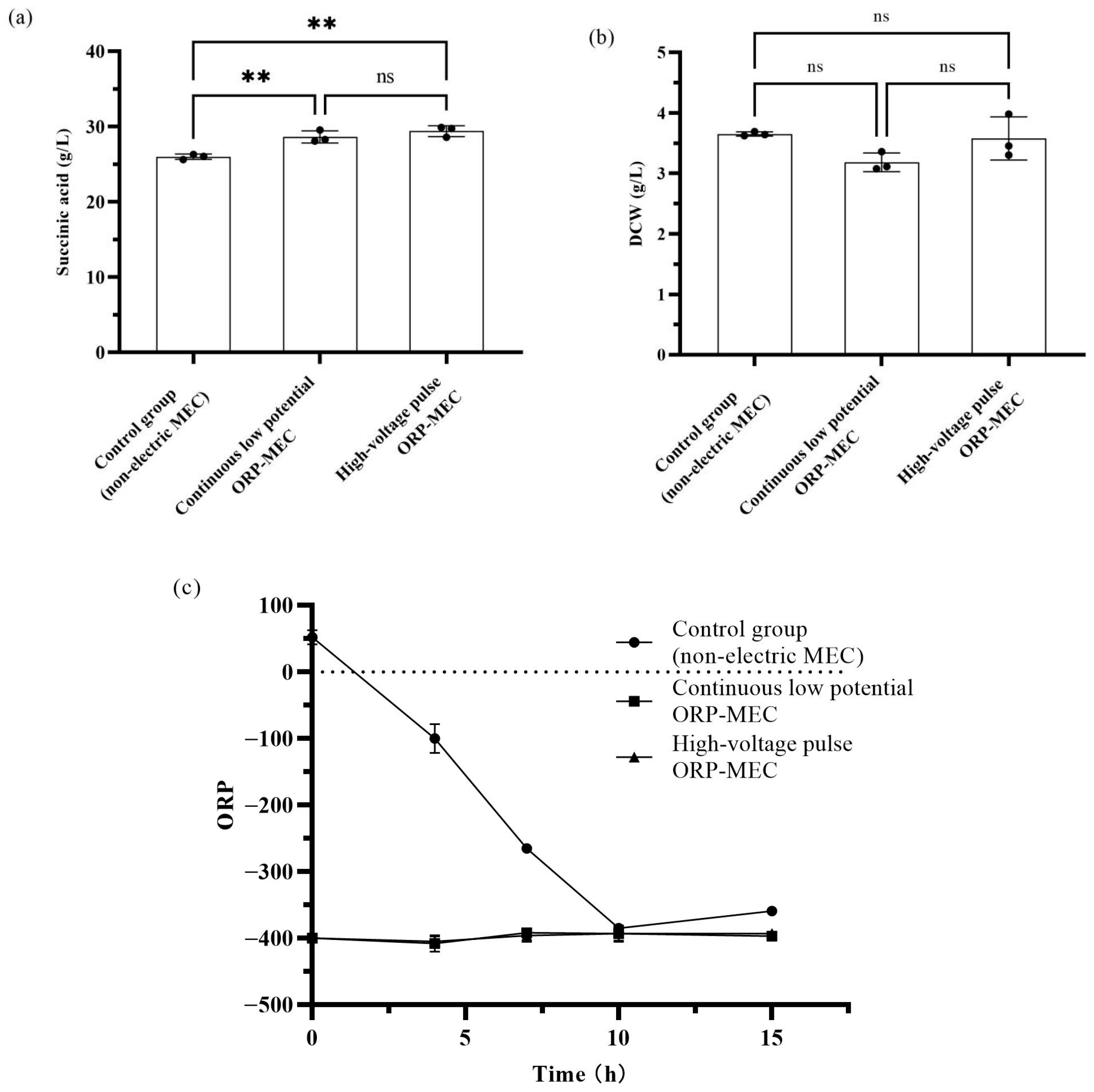

A. succinogenes in non-electric and ORP-controlled MEC systems are shown in

Figure 1.

The use of NR as an electronic mediator or electronophore was investigated in an effort to improve

A. succinogenes succinic acid production. The ORP-controlled MEC system with NR yielded a 17.21% increase in succinic acid production relative to the non-electric MEC system (non-NR) (

Figure 1a). When NR was added to a reaction mixture, the electricity delivered by the cathode could be used by

A. succinogenes to boost succinic acid production.

After 15 h of fermentation, there was a 20.44% increase in the cell growth for the electric MEC system when ORP was maintained at a constant −400 mV relative to the non-electric system (

Figure 1b). After 7 h of fermentation, the ORP in the non-electric MEC system decreased and remained stable at −350 mV (

Figure 1c). These results suggested that the use of a cathode to apply a potential was effective as a means of controlling the extracellular ORP values and that maintaining an appropriate ORP value led to improved

A. succinogenes growth in this MEC system.

In addition, the relatively low ORP regulatory sensitivity and the high applied voltage (≥−1.3 V) have the potential to limit the utility of this ORP-controlled MEC system, while a high ORP regulatory sensitivity and a relatively low applied voltage (−0.8 V) were obtained when NR was added to the ORP-controlled MEC system. With anaerobic conditions and pH control, the ORP of a system is determined based upon the amounts of particular compounds dissolved in the medium. As an electronic mediator, NR can effortlessly accept and release electrons. Therefore, when NR was added to the medium, a high ORP regulatory sensitivity and low applied voltage were obtained.

2.2. The Impact of Different Potential Applications on Succinic Acid Production

The exploration of various methodologies for the enhancement of fermentation reactions through the application of potential has yielded noteworthy findings. This study systematically evaluated the efficacy of different electrical strategies in augmenting the utility of MECs in producing valuable chemical compounds.

In the context of this research, the introduction of NR as a mediator in the MEC systems was a pivotal variable. NR’s role was to facilitate electron transfer, thus influencing the ORP within the system. By maintaining the ORP at a targeted level of −400 mV, two distinct approaches were employed: one involved the application of a continuous low potential, while the other involved intermittent high-voltage electric pulses. These strategies were compared against a baseline non-electric MEC system, serving as a control within the experimental design.

Both the continuous low-potential and the high-voltage pulse methods significantly outperformed the control in terms of the succinic acid production. Specifically, the continuous low-potential approach resulted in a 10.12% increase, achieving a concentration of 28.62 g/L, while the high-voltage pulse method saw a 13.08% increase, culminating in a concentration of 29.39 g/L of succinic acid after a 15 h fermentation period. These results were visually corroborated by

Figure 2a, which graphically represents the enhanced production levels.

Moreover, the impact of these electrical interventions on the metabolic directionality of the microbial consortia was profound. This was evidenced by the increased ratios of succinic to acetic acid, which were 33.34% and 8.14% higher in the continuous low-potential and high-voltage pulse systems, respectively, compared to the control. The peak ratios, occurring at the 10 h mark, were 2.44 for the continuous low-potential system and 1.98 for the high-voltage pulse system, indicating a more efficient biosynthetic conversion to succinic acid in the ORP-controlled environments.

Interestingly, despite the differences in electrical strategies, there was no discernible variance in the cell growth between the two systems at the 15 h mark, as illustrated in

Figure 2b. This suggests that the application of electrical potential, in this case, did not negatively impact the microbial proliferation.

This study also delved into the energy efficiency of the two systems. It was noted that the total electric charge applied in the high-voltage pulse system was 562.88 Coulombs, which was substantially less—only 82.28%—of that used in the continuous low-potential system. This parameter was crucial in determining the overall sustainability and practicality of the electrical enhancement strategies.

Given the superior succinic acid yields, favorable metabolic shifts, and lower energy input, the high-voltage electric pulse-based ORP-controlled MEC system (HPORP) emerged as the more advantageous approach. Consequently, it was selected for further experimentation, with the aim of refining the process and potentially scaling it for industrial applications.

2.3. Different ORP Value Impacts Succinic Acid Production

The extracellular ORP levels are recognized for their influential role in modulating organic acid fermentation processes. In light of this, our research delved into the correlation between the ORP levels and the biosynthesis of succinic acid within an ORP-regulated MEC framework.

Our study revealed that the optimized succinic acid concentration peaked at 29.39 g/L when the ORP was meticulously controlled at −400 mV, as delineated in

Table 1. This ORP level not only facilitated the highest yield of succinic acid but also delivered a remarkable electronic utilization efficiency of 177.58%. In contrast, the application of a potentiostatic method that maintained a constant potential of −1 V (referred to as CPMEC) did not yield a significant enhancement in succinic acid production when juxtaposed with the aforementioned −400 mV ORP level. This was a pivotal observation, especially considering that the CPMEC method resulted in a substantially higher energy consumption, tallying at 91.23% more than the −400 mV strategy.

The implications of these findings underscore the importance of the extracellular ORP as a critical parameter in fermentation reactions. By sustaining an optimal ORP level, the yields of succinic acid were markedly improved within the ORP-controlled MEC system. Notably, the electronic utilization efficiency of this system was found to be 113.85% higher than that of the conventional potentiostatic approach. It is particularly noteworthy that the electron utilization efficiency exceeded 100%, which suggests that the ORP-controlled MEC system might not only provide a sufficient supply of extracellular electrons but could also potentially enhance the enzymatic activity within the fermentation pathway under suitable ORP conditions.

This enhanced enzymatic activity could be attributed to the more favorable redox conditions created by the ORP-controlled environment, which may lead to a more efficient electron transfer process and thereby stimulate the metabolic pathways involved in succinic acid production. Consequently, the ORP-controlled MEC system emerges as a highly viable and energy-efficient alternative to traditional potentiostatic methods, paving the way for more sustainable and cost-effective biotechnological applications in organic acid production.

2.4. The Impact of Fed-Batch Fermentation on the ORP-Controlled MEC System

The fed-batch fermentation strategy is a widely acknowledged technique for achieving elevated concentrations of target metabolites in various bioprocesses. In our current study, we integrated the fed-batch methodology with an ORP-controlled MEC system to enhance the production of succinic acid.

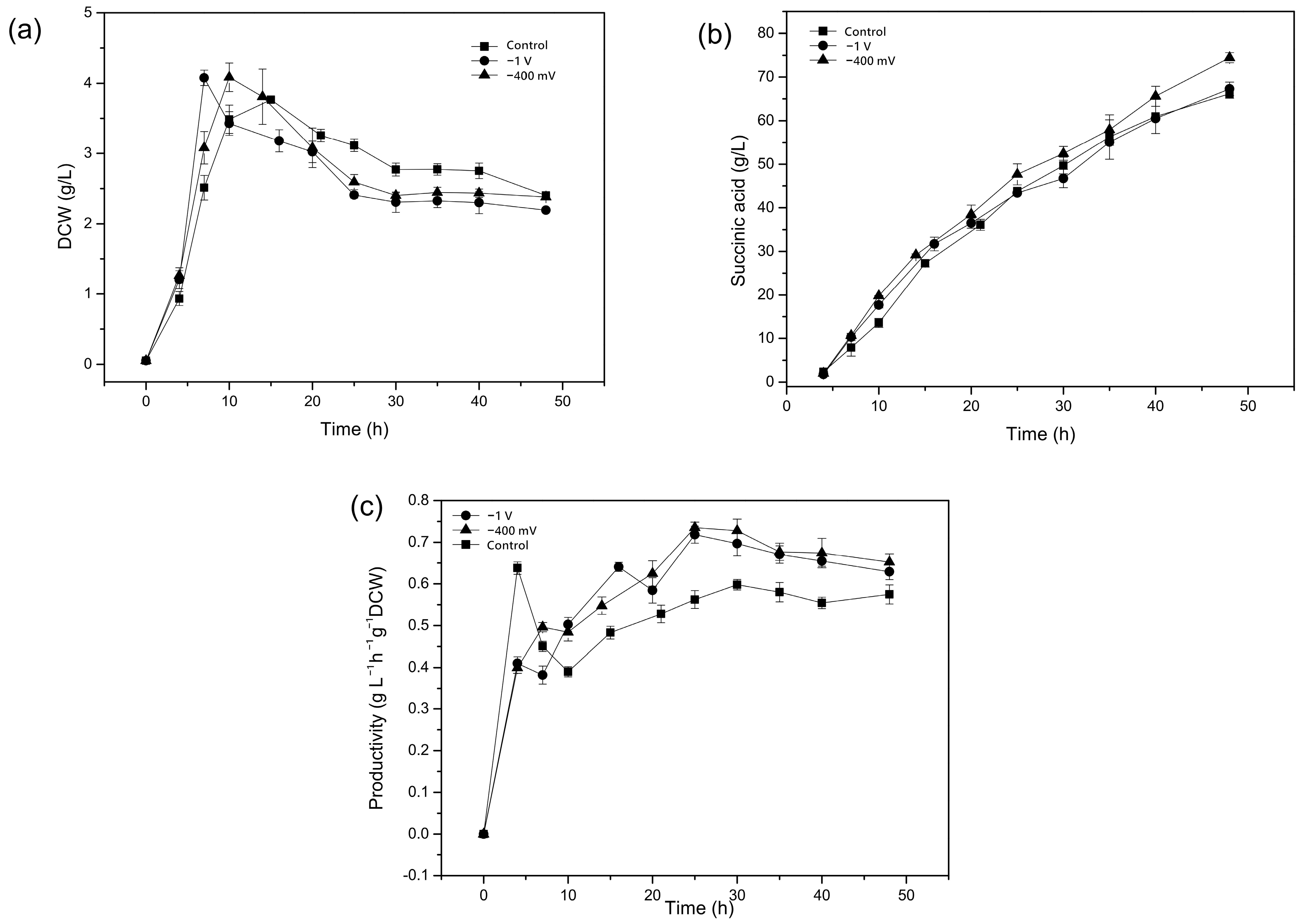

During the course of our 48 h fermentation period, the implementation of fed-batch fermentation in the ORP-controlled MEC system resulted in a substantial increase in the succinic acid concentration, reaching an impressive 74.43 g/L, as depicted in

Figure 3. This represents an increase of 10.81% and 12.44% over the succinic acid yields obtained from the non-electric and potentiostatic (constant −1 V) MEC systems, respectively. Notably, the application of a cathode-mediated potential in the ORP-controlled MEC system was correlated with accelerated microbial growth rates, whereas the continuous exposure to the potential was observed to have a detrimental effect on cell proliferation.

Further analysis, as illustrated in

Figure 3c, revealed that the ORP-controlled MEC system achieved a higher rate of succinic acid productivity, quantified at 0.735 g L

−1 h

−1 g

−1DCW, when compared to the control setup. This enhanced productivity can be attributed to the optimized extracellular conditions provided by the ORP control, which are conducive to microbial activity and succinic acid biosynthesis.

Comparative studies indicated that the potentiostatic (constant −1 V) system, which subjects the microbial culture to a sustained high voltage, led to lower succinic acid concentrations due to the inhibitory effects of prolonged high-voltage application on cell growth. Such conditions can negatively impact the bacterial cells, undermining their viability and metabolic capacity for succinic acid production [

7].

The superior performance of the fed-batch ORP-controlled MEC system was further substantiated by its energy consumption and electronic utilization efficiency. The system utilized 1748.62 coulombs of electricity, which was only 55.30% of the energy consumed by the potentiostatic system. Moreover, the electronic utilization efficiency of the ORP-controlled system reached 192.02%, a staggering 15.19-fold increase over the potentiostatic system.

In conclusion, our study demonstrates that the high-voltage pulse-based ORP-controlled MEC system is not only more effective in providing the necessary electrons for microbial metabolism but also does so with a greater energy efficiency, significantly boosting succinic acid production. These compelling findings highlight the practical applicability and advantages of an ORP-controlled MEC system in industrial-scale fermentation processes, offering a promising avenue for sustainable and cost-effective organic acid production.

3. Materials and Methods

3.1. Strain and Growth Media

A. succinogenes (130Z) was obtained from MBI International (Plaistow, NH, USA). Chemicals utilized in this study were from Aladdin (Shanghai, China), Fluka Chemical (Buchs, Switzerland), Oxoid Ltd. (Cambridge, UK), and Sinochem (Shanghai, China), and were of reagent-grade purity or higher. Carbon dioxide was obtained from the Nanjing Special Gases Factory (Nanjing, China). The media used for cellular growth were prepared as follows (per L): glucose, 10 g; yeast extract (YE), 5 g; NaH2PO4·2H2O, 9.6 g; K2HPO4·3H2O, 15.5 g; NaHCO3, 10 g; NaCl, 1 g; and corn steep liquor, 2.5 g. This culture media underwent a 15 min sterilization step at 121 °C. Sugars were separately sterilized and then added to the media following this autoclaving.

3.2. MEC System and Fed-Batch Fermentation

The Chemistry Department of Michigan State University (East Lansing, MI, USA) provided the MEC system used in this study, which contained anode and cathode compartments kept separate through the use of a cation-selective membrane (Nafion, NY, USA). Fine carbon felt was used for both anodes and cathodes, which were 70 mm × 50 mm × 5 mm, with 10.6 cm2/g total surface area. A 1 mm, 1.0 Ω/cm platinum wire (Sigma–Aldrich, St. Louis, MO, USA) was used to connect the anode and cathode. A power supply (PMC 1000/DC, AMETEK, Santiago, MN, USA) was used to provide potential to this MEC system. The volume in both the anode and cathode compartments was 280 mL. Inoculations before experimental fermentation were controlled at a 5% ratio in the cathode compartment. A. succinogenes cells and catholyte were added into the cathode compartment, with CO2 added at a rate of 25 mL/min. The catholyte was composed of (per L): glucose, 50 g; NaHPO4·12H2O, 31.5 g; NaHCO3, 10.0 g; NaH2PO4·2H2O, 8.5 g; and YE, 5.0 g. The anolyte was composed of (per L) 5.8 g NaCl, 15.6 g NaH2PO4·2H2O, and 35.8 g NaHPO4·12H2O. In addition, the catholyte was supplemented with 0.0288 g/L NR (determined by experiment) that had been subjected to 0.22 nm syringe filtration, and the anolyte was supplemented with 0.02% dithiothreitol that had been subjected to 0.22 nm syringe filtration. Prior to sterilization, 10 M NaOH was used to adjust the catholyte pH to 7.0. Once the fermentation reaction began, 1% alkaline magnesium carbonate was added to the catholyte in order to maintain pH balance. As a reference electrode, an Ag/AgCl electrode was used. The potential between the reference electrode and the cathode electrode was defined as a constant potential. No potential was supplied to the control non-electric MEC system, in which the open circuit voltage was monitored.

During fed-batch MEC, the catholyte initially contained the following (per L): NaHPO4·12H2O, 31.5 g; NaHCO3, 10.0 g; NaH2PO4·2H2O, 8.5 g; YE, 15.0 g; and NR, 0.0288 g. The initial glucose concentration was 50 g/L, and when the glucose concentration fell to <5 g/L, 50 g/L glucose was added, while alkaline magnesium carbonate served to maintain pH for the 48 h fermentation duration.

3.3. ORP-Controlled MEC System

A redox potential electrode (METTLER P14805-SC-DPAS-K8S/225, Zurich, Switzerland) was used to measure ORP, which was regulated via power supply (PMC 1000/DC, AMETEK). For the continuous low-potential strategy (LPORP), the potential was maintained from −0.4 V to −0.6 V. When the ORP levels rose above the set point, additional reductive potential was applied, whereas when these levels fell below the set point, additional oxidative potential was applied. For the high-voltage electric pulse strategy (HPORP), a 1-s periodic potential was employed, with a −1 V potential applied for 0.5 s and no potential applied for the remaining 0.5 s. Whenever ORP levels rose above the set point, a periodic potential was applied. No potential was applied when ORP levels fell below the set point, with open-circuit voltage instead being monitored. The −1 V constant potential MEC system (CPMEC) had a −1 V and was constantly applied throughout the 48 h fermentation reaction period (

Table 2).

3.4. Analytical Methods

High-performance liquid chromatography (Agilent 1290; Agilent Technologies, Santa Clara, CA, USA) was used to measure glucose and organic acid concentrations using an HPX-87H column (300 × 7.8 mm, Bio-Rad, Santa Clara, CA, USA). For detection, the column was warmed to 55 °C, with detection at 215 nm, a 20 µL injection volume, and a mobile phase composed of 8 mM sulfuric acid with a 0.6 mL/min flow rate. Succinic acid yields were defined based on the amount of succinic acid generated per gram of glucose.

3.5. Equation

Electronic utilization efficiency refers to the ratio of the theoretical charge required for the target metabolic product to the actual charge consumed by the MEC system.

∆MS: The molar quantity of succinic acid increased by MEC compared with non-electric MEC. NA: Avogadro’s constant. q: The charge of an electron. 2: The synthesis of 1 mol NADH requires 2 mol electrons. Q: The charges consumed by MEC.

4. Conclusions

The research undertaken in this study has provided a comprehensive analysis of the parameters that govern the efficiency of succinic acid production in an ORP-controlled MEC system, particularly focusing on the role of neutral red as an electron mediator, the application of voltage, and the optimization of ORP and fed-batch culture conditions.

The incorporation of NR into the MEC system has been a pivotal step in enhancing the production of succinic acid. NR, as an electron mediator, has improved the sensitivity of the system to ORP regulation. This heightened sensitivity allows for more precise control over the redox environment within the MEC, which is crucial for the metabolic processes of the microorganisms involved, particularly A. succinogenes (130Z).

This study found that the optimal approach to ORP level control was the use of a −400 mV high-voltage electric pulse-based strategy. This strategy not only provided the necessary extracellular electrons for the microbial metabolic processes but also seemed to stimulate enzyme activity related to succinic acid production. The result was an electronic utilization efficiency of 192.02%, an impressive figure that indicates the system’s ability to exceed the theoretical electron transfer efficiency. This could suggest that the ORP-controlled MEC system is capable of redirecting electron flow to enhance enzymatic pathways that are beneficial for succinic acid synthesis.

The efficiency over 100% indicates that the system may be capturing and utilizing electrons more effectively than anticipated, which could be due to several factors such as enhanced mediator performance, improved microbial metabolism, or more effective electron transfer mechanisms. This exceptional utilization efficiency also implies that the system can sustain a long-term fermentation process, providing a consistent and enhanced yield of succinic acid.

This research validates ORP control as a method to enhance succinic acid production in MEC systems, offering a pathway to more efficient and economical industrial fermentation with potential for commercial scaling, contingent on maintaining system performance. Future work in this area may focus on further refining the electron mediator system, perhaps by identifying new compounds that can perform better than NR, or by engineering microorganisms to more effectively interact with the existing mediators. Additionally, exploring the integration of this technology with other renewable energy sources or waste-to-energy systems could further improve the sustainability and economic viability of the process.

In summary, this research has not only provided insights into the effective management of the ORP in MEC systems but has also showcased the potential for these systems to revolutionize the production of valuable biochemicals like succinic acid, aligning with the principles of green chemistry and sustainable industrial processes.