Microbial Biocapsules as Generally Recognized-As-Safe Fungal-Based Immobilized Cell Technology for Precision Sequential Fermentations of Grape Must

Abstract

1. Introduction

2. Materials and Methods

2.1. Microorganisms, Media and Growth Conditions

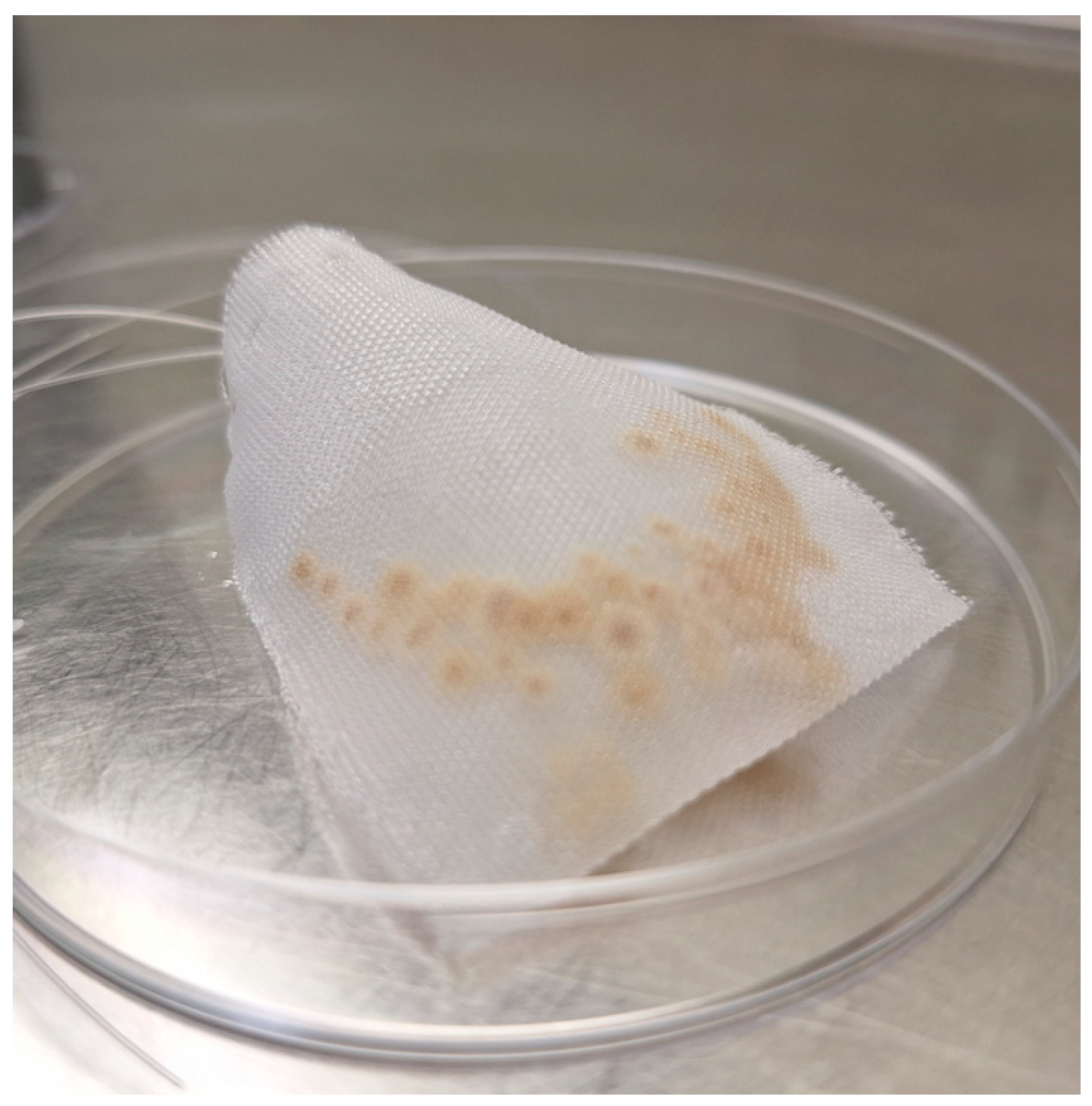

2.2. Yeast Immobilization Procedure

2.3. Fermentation Conditions

2.4. Microbiological Analysis

2.5. Measurement of Enological Parameters

2.6. Quantification of Major Aroma Compounds and Polyols

2.7. Quantification of Minor Aroma Compounds

2.8. Sensory Analyses

2.9. Statistical Analysis

3. Results and Discussion

3.1. Alcoholic Fermentation Rates

3.2. Microbiological Analysis

3.3. General Enological Parameters

3.4. Volatilome Analysis

3.5. Sensory Analyses

4. Conclusions

5. Patents

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Escribano-Viana, R.; González-Arenzana, L.; Portu, J.; Garijo, P.; López-Alfaro, I.; López, R.; Santamaría, P.; Gutiérrez, A.R. Wine Aroma Evolution throughout Alcoholic Fermentation Sequentially Inoculated with Non-Saccharomyces/Saccharomyces Yeasts. Food Res. Int. 2018, 112, 17–24. [Google Scholar] [CrossRef] [PubMed]

- Dutraive, O.; Benito, S.; Fritsch, S.; Beisert, B.; Patz, C.-D.; Rauhut, D. Effect of Sequential Inoculation with Non-Saccharomyces and Saccharomyces Yeasts on Riesling Wine Chemical Composition. Fermentation 2019, 5, 79. [Google Scholar] [CrossRef]

- Canonico, L.; Agarbati, A.; Comitini, F.; Ciani, M. Assessment of Spontaneous Fermentation and Non-Saccharomyces Sequential Fermentation in Verdicchio Wine at Winery Scale. Beverages 2022, 8, 49. [Google Scholar] [CrossRef]

- Canonico, L.; Comitini, F.; Oro, L.; Ciani, M. Sequential Fermentation with Selected Immobilized Non-Saccharomyces Yeast for Reduction of Ethanol Content in Wine. Front. Microbiol. 2016, 7, 278. [Google Scholar] [CrossRef] [PubMed]

- Clemente-Jimenez, J.M.; Mingorance-Cazorla, L.; Martínez-Rodríguez, S.; Las Heras-Vázquez, F.J.; Rodríguez-Vico, F. Influence of Sequential Yeast Mixtures on Wine Fermentation. Int. J. Food Microbiol. 2005, 98, 301–308. [Google Scholar] [CrossRef] [PubMed]

- Loira, I.; Vejarano, R.; Bañuelos, M.A.; Morata, A.; Tesfaye, W.; Uthurry, C.; Villa, A.; Cintora, I.; Suárez-Lepe, J.A. Influence of Sequential Fermentation with Torulaspora delbrueckii and Saccharomyces cerevisiae on Wine Quality. LWT-Food Sci. Technol. 2014, 59, 915–922. [Google Scholar] [CrossRef]

- Lapponi, M.J.; Méndez, M.B.; Trelles, J.A.; Rivero, C.W. Cell Immobilization Strategies for Biotransformations. Curr. Green Chem. 2022, 33, 100565. [Google Scholar] [CrossRef]

- Ciani, M.; Ferraro, L. Enhanced Glycerol Content in Wines Made with Immobilized Candida stellata Cells. Appl. Environ. Microbiol. 1996, 62, 128–132. [Google Scholar] [CrossRef]

- Ciani, M.; Ferraro, L. Combined Use of Immobilized Candida stellata Cells and Saccharomyces cerevisiae to Improve the Quality of Wines. J. Appl. Microbiol. 1998, 85, 247–254. [Google Scholar] [CrossRef]

- Genisheva, Z.; Mota, A.; Mussatto, S.I.; Oliveira, J.M.; Teixeira, J.A. Integrated Continuous Winemaking Process Involving Sequential Alcoholic and Malolactic Fermentations with Immobilized Cells. Process Biochem. 2014, 49, 1–9. [Google Scholar] [CrossRef]

- Lúquez-Caravaca, L.; Ogawa, M.; Rai, R.; Nitin, N.; Moreno, J.; García-Martínez, T.; Mauricio, J.C.; Jiménez-Uceda, J.C.; Moreno-García, J. Yeast Cell Vacuum Infusion into Fungal Pellets as a Novel Cell Encapsulation Methodology. Appl. Microbiol. Biotechnol. 2023, 107, 5715–5726. [Google Scholar] [CrossRef] [PubMed]

- Pastor-Vega, N.; Carbonero-Pacheco, J.; Mauricio, J.C.; Moreno, J.; García-Martínez, T.; Nitin, N.; Ogawa, M.; Rai, R.; Moreno-García, J. Flor Yeast Immobilization in Microbial Biocapsules for Sherry Wine Production: Microvinification Approach. World J. Microbiol. Biotechnol. 2023, 39, 271. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Ma, Z.; Meng, Q.; Li, D.; Ding, Z. Key Aroma Compounds and Metabolic Profiling of Debaryomyces hansenii L1-1-Fermented Flos Sophorae. J. Food Biochem. 2021, 45, e13711. [Google Scholar] [CrossRef] [PubMed]

- Capozzi, V.; Garofalo, C.; Chiriatti, M.A.; Grieco, F.; Spano, G. Microbial Terroir and Food Innovation: The Case of Yeast Biodiversity in Wine. Microbiol. Res. 2015, 181, 75–83. [Google Scholar] [CrossRef]

- García-Martínez, T.; de Lerma, N.L.; Moreno, J.; Peinado, R.A.; Millán, M.C.; Mauricio, J.C. Sweet Wine Production by Two Osmotolerant Saccharomyces cerevisiae Strains. J. Food Sci. 2013, 78, M874–M879. [Google Scholar] [CrossRef]

- He, B.; Tu, Y.; Jiang, C.; Zhang, Z.; Li, Y.; Zeng, B. Functional Genomics of Aspergillus oryzae: Strategies and Progress. Microorganisms 2019, 7, 103. [Google Scholar] [CrossRef]

- Muñoz-Castells, R.; Moreno-García, J.; García-Martínez, T.; Mauricio, J.C.; Moreno, J. Effect of Bentonite Addition to Pedro Ximénez White Grape Musts before Their Fermentation with Selected Yeasts on the Major Volatile Compounds and Polyols of Wines and Tentative Relationships with the Sensorial Evaluation. Molecules 2022, 27, 8057. [Google Scholar] [CrossRef]

- OIV. 2024. Available online: https://www.oiv.int/node (accessed on 31 March 2024).

- Peinado, R.A.; Moreno, J.A.; Muñoz, D.; Medina, M.; Moreno, J. Gas Chromatographic Quantification of Major Volatile Compounds and Polyols in Wine by Direct Injection. J. Agric. Food Chem. 2004, 52, 6389–6393. [Google Scholar] [CrossRef]

- Romano, P.; Braschi, G.; Siesto, G.; Patrignani, F.; Lanciotti, R. Role of Yeasts on the Sensory Component of Wines. Foods 2022, 11, 1921. [Google Scholar] [CrossRef]

- Ancín-Azpilicueta, C.; Jiménez-Moreno, N.; Moler, J.A.; Nieto-Rojo, R.; Urmeneta, H. Effects of Reduced Levels of Sulfite in Wine Production Using Mixtures with Lysozyme and Dimethyl Dicarbonate on Levels of Volatile and Biogenic Amines. Food Addit. Contam. Part A Chem. Anal. Control Expo. Risk Assess. 2016, 33, 1518–1526. [Google Scholar] [CrossRef]

- Hranilovic, A.; Gambetta, J.M.; Jeffery, D.W.; Grbin, P.R.; Jiranek, V. Lower-Alcohol Wines Produced by Metschnikowia pulcherrima and Saccharomyces cerevisiae Co-Fermentations: The Effect of Sequential Inoculation Timing. Int. J. Food Microbiol. 2020, 329, 108651. [Google Scholar] [CrossRef]

- Bely, M.; Sablayrolles, J.M.; Barre, P. Description of Alcoholic Fermentation Kinetics: Its Variability and Significance. Am. J. Enol. Vitic. 1990, 41, 319–324. [Google Scholar] [CrossRef]

- Callone, E.; Carturan, G.; Cavazza, A.; Guzzon, R. Immobilization of Yeast and Bacteria Cells in Alginate Microbeads Coated with Silica Membranes: Procedures, Physico-Chemical Features and Bioactivity. J. Mater. Chem. 2008, 18, 4839–4848. [Google Scholar] [CrossRef]

- Ramos-Moreno, L.; Ruiz-Pérez, F.; Rodríguez-Castro, E.; Ramos, J. Debaryomyces hansenii Is a Real Tool to Improve a Diversity of Characteristics in Sausages and Dry-Meat Products. Microorganisms 2021, 9, 1512. [Google Scholar] [CrossRef]

- Yanai, T.; Sato, M. Isolation and Properties of β-Glucosidase Produced by Debaryomyces hansenii and Its Application in Winemaking. Am. J. Enol. Vitic. 1999, 50, 231–235. [Google Scholar] [CrossRef]

- Contreras, A.; Hidalgo, C.; Henschke, P.A.; Chambers, P.J.; Curtin, C.; Varela, C. Evaluation of Non-Saccharomyces Yeasts for the Reduction of Alcohol Content in Wine. Appl. Environ. Microbiol. 2014, 80, 1670–1678. [Google Scholar] [CrossRef]

- Morata, A.; Loira, I.; Tesfaye, W.; Bañuelos, M.A.; González, C.; Suárez Lepe, J.A. Lachancea thermotolerans Applications in Wine Technology. Fermentation 2018, 4, 53. [Google Scholar] [CrossRef]

- Morata, A.; Loira, I.; Escott, C.; del Fresno, J.M.; Bañuelos, M.A.; Suárez-Lepe, J.A. Applications of Metschnikowia pulcherrima in Wine Biotechnology. Fermentation 2019, 5, 63. [Google Scholar] [CrossRef]

- Muñoz-Castells, R.; Moreno, J.; García-Martínez, T.; Mauricio, J.C.; Moreno-García, J. Chemometric Differentiation of White Wines from a Low-Aromatic Grape Obtained by Spontaneous Fermentation, Enriched with Non-Saccharomyces, or with a High-Glutathione-Producing Saccharomyces Yeast. Fermentation 2023, 9, 1023. [Google Scholar] [CrossRef]

- Ogawa, M.; Vararu, F.; Moreno-Garcia, J.; Mauricio, J.C.; Moreno, J.; Garcia-Martinez, T. Analyzing the Minor Volatilome of Torulaspora delbrueckii in an Alcoholic Fermentation. Eur. Food Res. Technol. 2021, 248, 613–624. [Google Scholar] [CrossRef]

- Wang, X.D.; Chen, J.W.; Ge, X.X.; Fu, X.F.; Dang, C.; Wang, J.; Liu, Y.Q. Sequential Fermentation with Indigenous Non-Saccharomyces Yeasts and Saccharomyces cerevisiae for Flavor and Quality Enhancement of Longyan Dry White Wine. Food Biosci. 2023, 55, 102952. [Google Scholar] [CrossRef]

- Sola, I.M.M.S.; Evers, L.D.; Wojeicchowski, J.P.; de Assis, T.M.; Marinho, M.T.; Demiate, I.M.; Alberti, A.; Nogueira, A. Impact of Pure, Co-, and Sequential Fermentations with Hanseniaspora Sp. and Saccharomyces cerevisiae on the Volatile Compounds of Ciders. Fermentation 2024, 10, 177. [Google Scholar] [CrossRef]

- Cioch-Skoneczny, M.; Grabowski, M.; Satora, P.; Skoneczny, S.; Klimczak, K. The Use of Yeast Mixed Cultures for Deacidification and Improvement of the Composition of Cold Climate Grape Wines. Molecules 2021, 26, 2628. [Google Scholar] [CrossRef]

- De-La-Fuente-Blanco, A.; Sáenz-Navajas, M.P.; Valentín, D.; Ferreira, V. Fourteen ethyl esters of wine can be replaced by simpler ester vectors without compromising quality but at the expense of increasing aroma concentration. Food Chem. 2020, 307, 125553. [Google Scholar] [CrossRef]

- Welke, J.E.; Zanus, M.; Lazzarotto, M.; Zini, C.A. Quantitative Analysis of Headspace Volatile Compounds Using Comprehensive Two-Dimensional Gas Chromatography and Their Contribution to the Aroma of Chardonnay Wine. Food Res. Int. 2014, 59, 85–99. [Google Scholar] [CrossRef]

- Chin, S.T.; Eyres, G.T.; Marriott, P.J. Identification of Potent Odourants in Wine and Brewed Coffee Using Gas Chromatography-Olfactometry and Comprehensive Two-Dimensional Gas Chromatography. J. Chromatogr. A 2011, 1218, 7487–7498. [Google Scholar] [CrossRef]

- Zea, L.; Moyano, L.; Moreno, J.A.; Medina, M. Aroma series as fingerprints for biological ageing in fino sherry-type wines. J. Sci. Food Agric. 2007, 87, 2319–2326. [Google Scholar] [CrossRef]

- Chen, H.; Liu, Y.; Chen, J.; Fu, X.; Suo, R.; Chitrakar, B.; Wang, J. Effects of Spontaneous Fermentation on Microbial Succession and Its Correlation with Volatile Compounds during Fermentation of Petit Verdot Wine. LWT 2022, 168, 113890. [Google Scholar] [CrossRef]

- Sam, F.E.; Ma, T.; Liang, Y.; Qiang, W.; Atuna, R.A.; Amagloh, F.K.; Morata, A.; Han, S. Comparison between Membrane and Thermal Dealcoholization Methods: Their Impact on the Chemical Parameters, Volatile Composition, and Sensory Characteristics of Wines. Membranes 2021, 11, 957. [Google Scholar] [CrossRef]

- Jiang, B.; Zhang, Z. Volatile Compounds of Young Wines from Cabernet Sauvignon, Cabernet Gernischet and Chardonnay Varieties Grown in the Loess Plateau Region of China. Molecules 2010, 15, 9184–9196. [Google Scholar] [CrossRef]

- Liu, C.; Yang, P.; Wang, H.; Song, H. Identification of Odor Compounds and Odor-Active Compounds of Yogurt Using DHS, SPME, SAFE, and SBSE/GC-O-MS. LWT 2022, 154, 112689. [Google Scholar] [CrossRef]

- Pueschel, V.A.; Schieberle, P. Changes in the Key Aroma Compounds of Matsutake Mushroom (Tricholoma matsutake Sing.) from Canada during Pan-Frying Elucidated by Application of the Sensomics Approach. Eur. Food Res. Technol. 2020, 247, 51–65. [Google Scholar] [CrossRef]

- Marín, J.; Ocete, R.; Pedroza, M.; Zalacain, A.; de Miguel, C.; López, M.A.; Salinas, M.R. Influence of the Mite Carpoglyphus lactis (L) on the Aroma of Pale and Dry Wines Aged under Flor Yeasts. J. Food Compost. Anal. 2009, 22, 745–750. [Google Scholar] [CrossRef]

- Janeš, D.; Kantar, D.; Kreft, S.; Prosen, H. Identification of Buckwheat (Fagopyrum esculentum Moench) Aroma Compounds with GC–MS. Food Chem. 2009, 112, 120–124. [Google Scholar] [CrossRef]

- Miller, G.C.; Barker, D.; Pilkington, L.I.; Deed, R.C. Synthesis of a Novel Isotopically Labelled Standard for Quantification of γ-Nonalactone in New Zealand Pinot Noir via SIDA-SPE-GC-MS. Anal. Bioanal. Chem. 2023, 415, 5035–5047. [Google Scholar] [CrossRef]

- Breuer, U.; Harms, H. Debaryomyces hansenii—An Extremophilic Yeast with Biotechnological Potential. Yeast 2006, 23, 415–437. [Google Scholar] [CrossRef]

- Moreno-García, J.; García-Martínez, T.; Mauricio, J.C.; Moreno, J. Yeast Immobilization Systems for Alcoholic Wine Fermentations: Actual Trends and Future Perspectives. Front. Microbiol. 2018, 9, 241. [Google Scholar] [CrossRef]

| Yeast Selected | Time Interval in Days at the Sequential Fermentation | Metabolic Feature | Wine Sensory Properties Expected | References |

|---|---|---|---|---|

| Debaryomyces hansenii LR1 | 1–3 | Production of phenethyl alcohol and α-terpineol. Low fermentative power | Floral aroma | [4,13] |

| Metschnikowia pulcherrima Primaflora | 3–6 | Low glycerol production, high ester production and production of pulcherrimine. High fermentative power | Low body, enhanced varietal aroma and wine microbial stability | [4,13,14] |

| Saccharomyces cerevisiae X5 | 6–14 | Low impact on grape compounds and highly fermentative | Varietal sensory profile, no residual sugars and high ethanol concentration | [4,15] |

| T0 | T3 | T6 | Tfinal | |

|---|---|---|---|---|

| SqFMB | 70 NS–30 S | 22 NS–78 S | 13 NS–87 S | 38 NS–62 S |

| SqF | 70 NS–30 S | 24 NS–76 S | 31 NS–69 S | 62 NS–38 S |

| SpF | 70 NS–30 S | 29 NS–71 S | 19 NS–81 S | 27 NS–73 S |

| Library/ID | Method of Detection | CAS | OT (mg/L) | Odor/Flavor Description | SqFMB | OAV | SqF | OAV | SpF | OAV |

|---|---|---|---|---|---|---|---|---|---|---|

| Ethanol (g/L) | Parameters measured according OIV | 64-17-5 | 10 | Alcoholic | 130.70 ± 0.05 a | 13,070 | 130.67 ± 0.49 a | 13,060 | 131.27 ± 0.25 a | 13,120 |

| Volatile acidity (acetic acid) (mg/L) | 64-19-7 | 200 | Vinegar | 200 ± 10 a | 1 | 200 ± 10 a | 1 | 210 ± 10 a | 1.05 | |

| pH | 3.13 ± 0.005 b | 3.13 ± 0.00 b | 3.11 ± 0.005 a | |||||||

| Fixed acidity (equiv/L) | 6.1 ± 0.026 a | 6.09 ± 0.035 a | 6.08 ± 0.005 a | |||||||

| Glucose (g/L) | 50-99-7 | 0.45 ± 0.06 a | 0.56 ± 0.07 a | 0.53 ± 0.05 a | ||||||

| Acetaldehyde (mg/L) | GC–FID | 75-07-0 | 10 | Over-ripe apple | 107.59 ± 10.23 a | 10.76 | 99.90 ± 4.78 a | 9.99 | 106.18 ± 2.93 a | 10.61 |

| Ethyl acetate (mg/L) | 141-78-6 | 7.5 | Pineapple, varnish, balsamic | 31.72 ± 0.84 a | 4.23 | 34.15 ± 1.27 a | 4.55 | 33.44 ± 1.84 a | 4.45 | |

| 1,1-Diethoxyethane (mg/L) | 105-57-7 | 1 | Green fruit, liquorice | 10.56 ± 0.65 b | 10.56 | 0.00 ± 0 a | 0 | 0 ± 0.00 a | 0 | |

| Methanol (mg/L) | 67-56-1 | 668 | Chemical, medicinal | 61.68 ± 4.64 a | 0.092 | 53.91 ± 4.22 a | 0.081 | 51.41 ± 6.85 a | 0.077 | |

| 1-Propanol (mg/L) | 71-23-8 | 830 | Ripe fruit, alcohol | 45.49 ± 0.92 a | 0.055 | 48.07 ± 1.78 a | 0.058 | 46.17 ± 1.11 a | 0.056 | |

| Isobutanol (mg/L) | 78-83-1 | 40 | Alcohol, wine-like, nail polish | 35.23 ± 0.45 a | 0.88 | 35.28 ± 1.28 a | 0.88 | 35.44 ± 1.82 a | 0.890 | |

| 2-Methylbutanol (mg/L) | 137-32-6 | N.f | Cooked roasted aroma with fruity or alcoholic undertones | 49.66 ± 1.97 a | - | 51.12 ± 1.45 a | - | 50.34 ± 0.99 a | - | |

| Isoamyl alcohol (mg/L) | 123-51-3 | 30 | Alcohol, nail polish | 243.05 ± 5.55 a | 8.10 | 257.55 ± 7.8 a | 8.59 | 248.78 ± 8.49 a | 8.29 | |

| Acetoin (mg/L) | 513-86-0 | 30 | Buttery, cream | 69.42 ± 8.61 b | 2.31 | 79.08 ± 4.51 b | 2.64 | 30.92 ± 15.40 a | 1.03 | |

| Ethyl lactate (mg/L) | 97-64-3 | 100 | Strawberry, raspberry, buttery | 15.88 ± 0.53 a | 0.16 | 16.08 ± 0.32 a | 0.16 | 15.8 ± 0.10 a | 0.16 | |

| Diethyl succinate (mg/L) | 123-25-1 | 100 | Over-ripe, lavender | 10.61 ± 1.76 a | 0.11 | 9.68 ± 2.63 a | 0.10 | 7.95 ± 1.14 a | 0.08 | |

| 2-Phenylethanol (mg/L) | 60-12-8 | 10 | Rose, honey | 56.98 ± 12.11 a | 5.70 | 49.19 ± 3.82 a | 4.92 | 43.3 ± 1.13 a | 4.33 | |

| 2,3-Butanediol l (mg/L) | 24347-58-8 | 668 | Buttery, creamy | 550.1 ± 218.87 a | 0.82 | 475.64 ± 147.38 a | 0.71 | 350.3 ± 81.47 a | 0.52 | |

| 2,3-Butanediol m (mg/L) | 5341-95-7 | 668 | Buttery, creamy | 168.04 ± 83.47 a | 0.25 | 116.45 ± 61.84 a | 0.17 | 79.42 ± 32.82 a | 0.12 | |

| Glycerol (g/L) | 56-81-5 | Confers body and smoothness and a sweet taste | 6.53 ± 0.11 a | - | 6.69 ± 0.1 a | - | 6.54 ± 0.06 a | - | ||

| Ethyl isobutyrate (mg/L) | SBSE-GCMS | 97-62-1 | 0.015 | Sweet, rubber | 0.013 ± 0.002 a | 0.84 | 0.014 ± 0.006 a | 0.97 | 0.015 ± 0.006 a | 1 |

| Ethyl butyrate (mg/L) | 105-54-4 | 0.02 | Fruity, sweet, apple | 0.10 ± 0.005 a | 5.24 | 0.11 ± 0.003 a | 5.55 | 0.11 ± 0.009 a | 5.50 | |

| Hexanal (mg/L) | 66-25-1 | 25 | Green | 0.006 ± 0.0008 a | 0.00024 | 0.0056 ± 0.0003 a | 0.00022 | 0.005 ± 0.0008 a | 0.00021 | |

| Butyl acetate (mg/L) | 123-86-4 | 4.6 | Banana, ripe pear, glue | 0.0021 ± 0.0002 a | 0.00046 | 0.0023 ± 0.0006 a | 0.00049 | 0.0024 ± 0.0006 a | 0.00053 | |

| Furfural (mg/L) | 98-01-1 | 0.77 | Burnt almond, incense, floral | 0.51 ± 0.2 a | 0.66 | 0.30 ± 0.19 a | 0.39 | 0.26 ± 0.23 a | 0.35 | |

| Ethyl 2-methylbutanoate (mg/L) | 7452-79-1 | 0.002 | Fruity, strawberry, apple, blackberry | ND | - | ND | 0 | 0.00088 ± 0.00028 a | 0.44 | |

| Ethyl 3-methylbutyrate (mg/L) | 108-64-5 | 0.0007 | Fruity, strawberry, apple | 0.0022 ± 0.00018 a | 3.14 | 0.0025 ± 0.00024 a | 3.51 | 0.0023 ± 0.00031 a | 3.29 | |

| 2-Furanmethanol (mg/L) | 98-00-0 | N.f. | Burnt sugar | 0.0035 ± 0.0017 a | - | ND | 0 | 0.0026 ± 0.00040 a | - | |

| Isoamyl acetate (mg/L) | 123-92-2 | 0.03 | Banana | 2.20 ± 0.13 a | 73.42 | 2.36 ± 0.080 a | 78.78 | 2.31 ± 0.25 a | 77.08 | |

| 3-Heptanone (mg/L) | 106-35-4 | N.f. | Fruity, green, fatty, sweet | 0.00019 ± 0.00005 a | - | 0.00068 ± 0.00028 b | - | 0.00032 ± 0.000035 a | - | |

| 2-Acetylfuran (mg/L) | 1192-62-7 | N.f. | Sweet, almondy, nutty, brown and toasted | 0.017 ± 0.0072 a | - | 0.014 ± 0.007 a | - | 0.0084 ±0.0047 a | - | |

| γ-Butyrolactone (mg/L) | 96-48-0 | 100 | Coconut, caramel | 20.69 ± 3.57 b | 0.21 | 12.66 ± 3.81 a | 0.13 | 7.82± 1.04 a | 0.078 | |

| 5-Methylfurfural (mg/L) | 620-02-0 | 1.1 | Toasted, bitter almond, spicy | 0.11 ± 0.060 b | 0.098 | ND | 0 | 0.051 ± 0.056 ab | 0.046 | |

| Ethyl hexanoate (mg/L) | 123-66-00 | 0.005 | Banana, green apple | 0.45 ± 0.0096 a | 89.48 | 0.48 ± 0.0085 a | 96.39 | 0.48 ± 0.031 a | 96.00 | |

| Hexyl acetate (mg/L) | 142-92-7 | 0.67 | Apple, cherry, pear, floral | 0.10 ± 0.0048 a | 0.15 | 0.11 ± 0.0022 a | 0.17 | 0.10 ± 0.010 a | 0.15 | |

| 2-Ethylhexanol (mg/L) | 104-76-7 | 8 | Fruity, floral | 0.052 ± 0.0056 a | 0.0065 | 0.052 ± 0.0088 a | 0.0065 | 0.039 ± 0.0047 a | 0.0049 | |

| 2-Phenylacetaldehyde (mg/L) | 122-78-1 | 0.001 | Flowery, rose | 0.013 ± 0.0018 a | 13.07 | 0.013 ± 0.0014 a | 12.98 | 0.014 ± 0.0017 a | 14.00 | |

| Octanol (mg/L) | 111-87-5 | 0.12 | Intense citrus, roses | 0.057 ± 0.016 a | 0.48 | 0.045 ± 0.011 a | 0.38 | 0.034 ± 0.011 a | 0.28 | |

| Acetophenone (mg/L) | 98-86-2 | 0.065 | Mildly sweet | 0.0028 ± 0.0025 a | 0.044 | 0.0019 ± 0.0021 a | 0.030 | 0.0025 ±0.0011 a | 0.038 | |

| Ethyl heptanoate (mg/L) | 106-30-9 | 0.0022 | Fruity, pineapple, sweet | 0.0006 ± 0.00003 a | 0.26 | 0.0006 ± 0.00003 a | 0.26 | 0.0005 ± 0.00007 a | 0.23 | |

| Nonanal (mg/L) | 124-19-6 | 0.0011 | Floral, orange–rose odor or waxy and green | 0.0037 ± 0.00095 b | 3.42 | 0.0014 ± 0.0013 a | 1.32 | ND | 0 | |

| Ethyl octanoate (mg/L) | 106-32-1 | 0.005 | Pineapple, pear, soapy | 0.31 ± 0.034 a | 62.33 | 0.37 ± 0.029 b | 74.45 | 0.36 ± 0.016 ab | 72.00 | |

| Decanal (mg/L) | 112-31-2 | 0.001 | Grassy, orange skin-like | 0.013 ± 0.00031 a | 12.86 | ND | 0 | ND | 0 | |

| Octyl acetate (mg/L) | 112-14-1 | 50 | Apple, mushroom, herbal | 0.0012 ± 0.0014 a | 0.000024 | 0.00035 ± 0.00015 a | 7.00 × 10−6 | ND | 0 | |

| B-Citronellol (mg/L) | 7540-51-4 | 0.1 | Floral | 0.039 ± 0.017 a | 0.39 | 0.040 ± 0.0039 a | 0.4 | 0.033 ± 0.0038 a | 0.33 | |

| 2-Phenethyl acetate (mg/L) | 103-45-7 | 0.25 | Fruity, rose, sweet, honey | 2.30 ± 0.15 a | 9.20 | 2.03 ± 0.16 a | 8.12 | 2.21 ± 0.086 a | 8.84 | |

| 1-Decanol (mg/L) | 112-30-1 | 0.4 | Fatty | 0.013 ± 0.00031 a | 0.032 | 0.01015 ± 0.0057 a | 0.025 | 0.0099 ± 0.0030 a | 0.025 | |

| E-Citral (mg/L) | 5392-40-5 | 0.03 | Citrus, Lemon | ND | 0 | ND | 0 | 0.0030 ± 0.0012 a | 0.1 | |

| 2,4-Decadienal (mg/L) | 25152-84-5 | 0.00007–0.01 | Fatty, Citrus | 0.00030 ± 0.00006 a | - | 0.00032 ± 0.00003 a | - | 0.00026 ± 0.000035 a | - | |

| 2-Methoxy-4-vinylphenol (mg/L) | 7786-61-0 | 0.004 | Apple, Spicy | 0.24 ± 0.011 a | 60 | 0.24 ± 0.023 a | 60 | 0.22 ± 0.031 a | 55 | |

| G-Nonalactone (mg/L) | 104-61-0 | 0.03 | Coconut, sweet, and stone fruit | 0.015 ± 0.0017 a | 0.51 | 0.016 ± 0.0017 a | 0.53 | 0.014 ± 0.0028 a | 0.46 | |

| Ethyl decanoate (mg/L) | 110-38-3 | 1.1 | Sweet, fruity, nuts and dried fruit | 0.44 ± 0.11 a | 0.40 | 0.51 ± 0.10 a | 0.46 | 0.54 ± 0.08 a | 0.49 | |

| E-Geranyl acetone (mg/L) | 3796-70-1 | 0.06 | Floral | ND | - | 0.00082 ± 0.00007 a | 0.014 | ND | 0 | |

| Z-Geranyl acetone (mg/L) | 3796-70-1 | 0.06 | Floral | 0.0026 ± 0.00013 a | 0.044 | 0.0026 ± 0.00006 a | 0.044 | 0.0025 ± 0.00012 a | 0.042 | |

| Dodecanol (mg/L) | 112-53-8 | 0.007 | Fatty | 0.012 ± 0.0016 ab | 1.67 | 0.013 ± 0.0031 c | 1.86 | 0.0054 ± 0.0048 a | 0.77 | |

| Ethyl undecanoate (mg/L) | 627-90-7 | N.f | N.f. | 0.00061 ± 0.00004 a | - | 0.00064 ± 0.00003 a | - | 0.00063 ± 0.000021 a | - | |

| Ethyl dodecanoate (mg/L) | 106-33-2 | 3.5 | Floral, fruity | 0.42 ± 0.049 a | 0.12 | 0.49 ± 0.074 a | 0.14 | 0.53 ± 0.063 a | 0.15 | |

| 2- Phenethyl hexanoate (mg/L) | 6290-37-5 | N.f | Fruity | 0.0013 ± 0.00014 a | - | 0.0015 ± 0.00019 a | - | 0.0014 ± 0.00022 a | - | |

| Trans-Methyl Dihydrojasmonate | 24851-98-7 | N.f | N.f. | 0.011 ± 0.0012 a | - | 0.013 ± 0.0052 a | - | 0.0084 ± 0.00059 a | - | |

| Ethyl myristate (mg/L) | 124-06-1 | 494 | Mild waxy, soapy | 0.039 ± 0.0029 a | 0.000078 | 0.040 ± 0.0038 a | 0.00008 | 0.040 ± 0.0020 a | 0 | |

| Phenethyl benzoate (mg/L) | 94-47-3 | N.f | N.f | 0.0015 ± 0.00011 a | - | 0.0018 ± 0.0004 a | - | 0.0015 ± 0.00018 a | - | |

| Ethyl hexadecanoate (mg/L) | 628-97-7 | 1.5 | Fatty, rancid, fruity, sweet | 0.13 ± 0.005 a | 0.086 | 0.13 ± 0.019 a | 0.086 | 0.12 ± 0.015 a | 0.080 |

| Attributes | SqFMB | Sqf | Spf |

|---|---|---|---|

| Visual | 6.10 ± 0.68 a | 6.11 ± 0.53 a | 6.10 ± 0.68 a |

| Smell | 8.77 ± 0.87 a | 8.55 ± 2.02 a | 8.48 ± 0.35 a |

| Taste | 8.90 ± 0.51 a | 8.49 ± 1.09 a | 9.16 ± 0.77 a |

| Overall quality | 9.55 ± 0.39 a | 9.33 ± 0.58 a | 9.89 ± 0.51 a |

| Total points | 83.85 ± 4.85 a | 81.2 ± 10.68 a | 84.19 ± 4.44 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Carbonero-Pacheco, J.; Constanta-Mustafa, F.; Muñoz-Castells, R.; Mauricio, J.C.; Moreno, J.; García-Martínez, T.; Moreno-García, J. Microbial Biocapsules as Generally Recognized-As-Safe Fungal-Based Immobilized Cell Technology for Precision Sequential Fermentations of Grape Must. Fermentation 2024, 10, 498. https://doi.org/10.3390/fermentation10100498

Carbonero-Pacheco J, Constanta-Mustafa F, Muñoz-Castells R, Mauricio JC, Moreno J, García-Martínez T, Moreno-García J. Microbial Biocapsules as Generally Recognized-As-Safe Fungal-Based Immobilized Cell Technology for Precision Sequential Fermentations of Grape Must. Fermentation. 2024; 10(10):498. https://doi.org/10.3390/fermentation10100498

Chicago/Turabian StyleCarbonero-Pacheco, Juan, Florina Constanta-Mustafa, Raquel Muñoz-Castells, Juan Carlos Mauricio, Juan Moreno, Teresa García-Martínez, and Jaime Moreno-García. 2024. "Microbial Biocapsules as Generally Recognized-As-Safe Fungal-Based Immobilized Cell Technology for Precision Sequential Fermentations of Grape Must" Fermentation 10, no. 10: 498. https://doi.org/10.3390/fermentation10100498

APA StyleCarbonero-Pacheco, J., Constanta-Mustafa, F., Muñoz-Castells, R., Mauricio, J. C., Moreno, J., García-Martínez, T., & Moreno-García, J. (2024). Microbial Biocapsules as Generally Recognized-As-Safe Fungal-Based Immobilized Cell Technology for Precision Sequential Fermentations of Grape Must. Fermentation, 10(10), 498. https://doi.org/10.3390/fermentation10100498