Abstract

Finishing coatings used in the wood-based composite industry play a key role in the final appearance of the finished product. However, the use of such coatings is not only for aesthetic purposes, but also to protect the product against surface damage and moisture or to minimize the emission of harmful substances. The latter is an extremely important factor in terms of safety for both the manufacturer and the user, which is why the emissivity test is one of the most important tests conducted in this case. Carbon-rich materials, such as those remaining from the extraction of birch bark, can fulfill the role of minimizing the emission of harmful substances. In this article, an attempt to create coatings in the form of a film by combining a biopolymer with suberinic acid residues (SARs) was made. Two types of biopolymers were used, polylactide (PLA) and polycaprolactone (PCL), in various polymer–SAR ratios. Suberinic acid as a residue is a raw material that can potentially contribute positively to the fixing of CO2 from the atmosphere, which creates the possibility for further use. As part of this study, the obtained coatings were tested in terms of scratch resistance, relative hardness, cold liquids, total volatile organic compounds (TVOCs), formaldehyde emission, surface absorption, etc. Differences between the polymers used and the effect of the SAR additive on selected surface properties were demonstrated. The addition of carbon-rich SAR significantly improves gas barrier properties of the PLA- and PCL-based surface finishing materials. The relative hardness and scratch resistance also increased with rising SAR content. However, the increasing content of SAR filler acts as a limiter in the depth of penetration of the deposited surface finishing materials onto the wood surface. It is possible to state that this innovative approach regarding (1) the utilization of biopolymers as a matrix, instead of conventional, crude oil-based resins, and (2) the incorporation of post-processed carbon-rich waste lignocellulosic materials to produce the surface finishing and/or protective films has been confirmed.

Keywords:

surface; emission; finishing; biopolymer; filler; bark; suberinic acid; residue; upcycling 1. Introduction

Wood finishes provide the desired appearance of products, protect wooden surfaces and provide an easy-to-clean surface [1]. Regarding traditional finishings, the biggest increase in wood gloss happens when a product is covered with acrylic lacquer or shellac [2], whereas drying oils provide exquisite bio-based finishes for wood [3], and wax fulfills the role of providing a protective coating for wood surfaces, although it is transparent to UV light [4]. According to EN 14342:2013, for wooden elements for indoor use, reaction to fire, formaldehyde content, tensile strength, thermal conductivity and biological sustainability are some important features [5]. Synthetic finishes still dominate the industry because they are the easiest to obtain, provide desirable properties and aesthetics and are economically profitable. Phenolic resins and saturating Kraft papers are raw materials used in the manufacture of decorative laminates [6]. The quality of decorative laminate boards depends on the impregnation process of Kraft papers with a phenolic resin [7,8]. Resins are applied to act as plasticizers and soften the wood cell wall [9]. Modifications involving resins to improve their properties are also well known. For example, with the addition of nano-silica content, the mechanical properties of composites finished with PF resin increase continuously, with a maximum modulus of rupture (MOR) by the mass fraction of nano-silica of 4% [10]. The use of paper impregnated with phenol-formaldehyde (PF) overlays significantly reduces discoloration, reaching the lowest color change in the case of using maple top veneers and the application of melamine-formaldehyde (MF). When applied to boards with top veneers from maple, they significantly reduce surface structuring and gloss reduction. However, the most promising effects were obtained by combining both MF and PF [11].

Apart from synthetic resins, another commonly used finishing can be lacquer coating. Samples treated with a combination of tannin and polyurethane coating change the color less than samples treated with a water-based coating and tannin [12]. The susceptibility of lacquer coatings to spotting in chemoresistance tests depends mainly on the kind of wood species used [13]. Two-component coatings (acrylate-polyurethane) have a greater hardness than one-component coatings (polyurethane-based) [14]. To increase the service life of wood flooring, a property, self-healing, is suggested by Landry [15], which actually increases crosslinking density while maintaining the self-healing behavior [16].

Other methods can be used when better surface properties are desired, and so, mechanically induced vibration fusion welding techniques can also be used to obtain a wood surface finish with increased hardness and improved surface properties [17]. Less roughness is observed for plane milling than for sanded surfaces [18].

The finishing coatings mentioned above have numerous benefits and provide desired properties. However, rising health concerns have led to an increasing focus on the use of wood finishing substances in the furniture industry based on vegetable oils instead of paints, pigments and lacquers [19], which is why the current trend is moving towards developing sustainable coating formulations that provide equivalent functionality while mitigating associated environmental impacts [20]. The use of formaldehyde-based adhesives and finishings in the wood-based composite industry represents a healthcare concern due to its toxic volatile compounds [21]. Results showed that the addition of cellulose nanofibers (CNCs) layers significantly reduced the emission of formaldehyde (26% less) [22]. The barrier performance of compatibilized CNCs compared with neat CNCs is higher; however, although the gains in oxygen barrier properties of nanocomposites are lower than that of CNC multilayer materials, their properties are more stable in service conditions [23]. The dispersion of xylan and alkyl ketene dimer was proven by obtaining coated paper with improved barrier properties [24]. A significant, linear reduction in formaldehyde emission has been observed by Kowaluk et al. [25] through the addition of charcoal. Bagasse-activated charcoal can be used for the removal of chromium [26] and the reduction in formaldehyde emission from particleboard. The emission value met the SNI 5008.2: 2016 standard [27]. Also, the alkali-soluble resin has been investigated by Jiang et al. [28,29] regarding its barrier properties. Applying a second coating layer covers the surface defects of the first coating layer, thereby improving the barrier performance. It was revealed that water-borne coating is dependent on relative humidity since absorbed water acts as a plasticizer and leads to decreased barrier performance.

When making an attempt to reduce the VOC emission from wood composites, another approach has also been employed, which is the usage of tree bark. Single-layer [28] and three-layer [29] particleboards were produced by replacing virgin wood particles with partially liquefied bark (PLB) in the core or surface layers. PLB was prepared by the acid-catalyzed liquefaction of industrial bark residues in polyhydric alcohol. Formaldehyde emissions from the analyzed particleboards remained below the E1 class limit mandated by the European Standard EN 13986:2004.

The valorization of tree bark through chemical treatment into valuable products, such as bark acid, leads to the formation of process residues with a high solids content [30]. Depolymerized suberinic acids (SA) offer a promising alternative resource to various feedstocks for acquiring value-added products [31,32,33]. For instance, they can be utilized in the development of bio-polyols, which in turn find application in the production of polymeric materials [34]. This approach contributes well both to the minimization approach of the CO2 emission from industries and to waste re-use [35]. The outer bark of birch (Betula spp.) is a valuable product rich in betulin, where suberin-containing tissues are left after removal of betulin extractives [36,37].

The aim of this research was to create and investigate the selected properties of film-forming coatings created through the amalgamation of a biopolymer with SAR, as a carbon-rich, alternative upcycled raw material. There were two types of biopolymers used, PLA and PCL, in various polymer–SAR ratios. SAR, as a residue, is a potential raw material that positively contributes to the sequestration of CO2 from the atmosphere and opens up possibilities for subsequent utilization. The innovative nature of this research lies not only in the utilization of biopolymers as matrices instead of conventional crude-oil-based resins, but also in the integration of post-processed, carbon-rich waste lignocellulosic materials for the production of surface finishing and/or protective films.

2. Materials and Methods

2.1. Materials

Surface finishing layers were fabricated using three distinct matrices: reference, phenol-formaldehyde (PF) resin (Silekol Sp. z o.o., Kędzierzyn-Koźle, Poland) with 66% dry matter content according to EN 827 [38]; and pure, laboratory-purpose PLA (Sigma-Aldrich, Saint Louis, MO, USA, product no. 38534) and PCL (Sigma-Aldrich, product no. 704105) in drops with a diameter of 3 mm. Suberinic acid residues used in the research that have been utilized to prepare the blends have been described in detail by Jeżo et al. [30]. The following are the basic chemical properties of SAR: acid number 95.8 mg/KOH, epoxy groups 0.61 mmol/g, cellulose 9.0 wt%, aromatic suberin, lignin 21.4 wt%, ω-hydroxy acids 17.5%, and α, ω-diacids 11.9%.

The following finishing layers have been produced:

- (1)

- Reference (hereafter called REF), which is a PF layer that has been created by manually spreading PF resin in the amount of 185 g m−2 onto the surface of industrial (Betula spp.) 3-layer, 5 mm thick, urea-formaldehyde (UF) birch plywood, then drying the spread PF resin at temperature of 70 °C for a duration of 2 h. After this, the finishing resin layer is cured in a hot press (AKE, Mariannelund, Sweden) under the following parameters: pressing time 420 s, temperature 180 °C, and pressure 0.8 MPa. The assumed resin surface spread (185 g m−2), with known dry matter content, has been selected to be able to ensure a consistent final thickness of 1 mm for all tested finishing layers.

- (2)

- PLA finishing layer, made by mixing methylene chloride (CH2Cl2) solution for PLA, 21% dry matter content, with SAR powder, 20% and 50% w/w, respectively, hereafter called “PLA20” and “PLA50”. A pure PLA surface finishing layer has also been tested (hereafter called “PLA”). All the prepared blends have been spread on PTFE sheets under a fume hood in order to evaporate the solvent, and then milled to attain a powder size smaller than 0.1 mm. Such a powder has been formed in a hot press (as mentioned above), as described by Gumowska et al. [39]. The prepared film has been pressed in a hot press (pressing time 75 s, temperature 185 °C, and pressure 0.8 MPa) onto the plywood surface described above.

- (3)

- PCL finishing layer, obtained by toluene (C7H8) solution for PCL, 25% dry matter content. The remaining steps of surface finishing preparation are the same as those described above for PLA. Using this method, the subsequent samples have been attained: PCL (hereafter called “PCL”; no SAR addition) “PCL20” and “PCL50”.

According to the research plan, the surface finishing layers created on the plywood base (Table 1) were exposed to ambient conditions (20 °C; 65% R.H.) until a constant weight was achieved over a span of seven days before tests.

Table 1.

Compositions of the tested surface finishing layers.

2.2. Density Profile

Density profiles of the tested samples were measured in 3 repetitions on a GreCon DAX 5000 device (Fagus-GreCon Greten GmbH and Co. KG, Alfeld/Hannover, Germany) using a sampling interval of 0.02 mm. The density profile measurement results were representative plots selected from the analysis of 3 individual plots for each tested finished surface. The plots illustrate a surface layer and half of the face veneer thickness density.

2.3. Resistance to Scratch and a Relative Hardness

Scratch resistance was measured according to the “A” procedure described in the EN 15186 standard [40]. As many as 5 repetitions per tested material type were conducted.

Relative hardness was measured according to the procedure described in ISO 1522 standard [41]. As many as 2 repetitions per tested sample type were performed.

2.4. Cold Liquids Resistance

Cold liquids resistance were measured according to the procedure described in the EN 12720+A1 standard [42]. As many as 5 repetitions per tested sample type were performed. The following cold liquids were employed: acetic acid 10%, acetone, citric acid, ethanol, and distilled water. The exposition time equaled 24 h. As many as 3 samples were used per finishing surface type.

2.5. Surface Water Absorption

Surface water absorption was measured according to the EN 382-2 standard [43] on 5 samples per finishing surface.

2.6. Contact Angle

Contact angle measurements were conducted using the contact angle analyzer PHOENIX 300 (SEO—Surface & Electro Optics Co., Gyeonggi-do, Ltd., Suwon City, Republic of Korea) equipment while using the method of distilled water sessile drop in 3 repetitions per finishing surface. The contact angle was measured directly after drop deposition, as well as 60 s after drop deposition for the same drop.

2.7. Total VOC and Formaldehyde Emission

The Total VOC and formaldehyde emission tests were completed in the emission test chamber at a temperature of 23 °C +/− 0.5 °C and relative air humidity of 44% +/− 1%. Other parameters of sample conditioning were performed following the EN 717-1 standard [44]. The TVOC and formaldehyde emission tests were carried out after 24 h of conditioning of the samples by analyzing the chamber air over three repetitions after 20 min each using a JD-3002 Air Quality Tester (Dongguan Jinlide Electronic Technology Co., Ltd., Dongguan City, Guangdong Province, China). We adhered to the standards regarding air conditioning conditions for samples during the emission test.

2.8. Statistical Analysis

Analysis of variance (ANOVA) and t-test calculations were performed to verify significant differences (α = 0.05) between factors and levels where appropriate using the IBM SPSS statistic base (IBM, SPSS 20, Armonk, NY, USA). A comparison of means was performed when the ANOVA indicated a significant difference.

3. Results and Discussion

3.1. Density Profile

The density profiles of the tested samples have been presented in Figure 1. Since the differences between the density profiles of pure biopolymers (PLA and PCL) were insignificant, the profiles of the main materials have been presented. Nevertheless, it was observed that the depth of penetration of the examined surface finishing materials decreased with the increasing amount of SAR added. The data depicted in Figure 1, excluding the density distribution, also represents the estimated boundary (adhesion line) between the surface finishing material (located on the left side of the Y axis) and the veneer material (situated on the right side of the Y axis). This estimated boundary has been indicated by the location of the Y axis. As depicted, the greatest depth of penetration, approximately 0.62 mm, has been attained with the reference PF resin. This can be attributed to the resin being spread onto the surface of plywood in its liquid state and subsequently cured. The PLA surface finishing material has penetrated wood only at a depth of approximately 0.36 mm. Results provided by Grigsby et al. [45] show that the penetration of semi-crystalline PLA is generally greater in outer bondlines of a plywood, with average penetration values of 40 to 70 µm compared to <50 µm for inner bondlines. The difference between these results and ours may be due to the fact that the authors tested PLA films with a thickness of 0.3 mm, while our coatings were about three times thicker. Also, the pressing parameters varied. For PCL, the penetration depth was only 0.2 mm. Such a low penetration of PCL can be explained by the high hydrophobicity of PCL, which was mentioned below. As depicted above, the contribution of SAR filler has slightly limited the depth of penetration of the tested surface finishing materials. The depth of penetration can impact the final properties of the wood surface covered, since the low penetration depth results in a weak anchoring force of the protective layer and, in the worst case, can lead to delamination. The greatest achieved density, about 1200 kg m−3,is comparable to the findings of Nemli et al. [46] for 0.55 mm thick continuous press laminates (CPL).

Figure 1.

Density profiles of the main tested surface finishing materials: reference (PF) (a), PLA (b), PCL (c). x-axis units: mm.

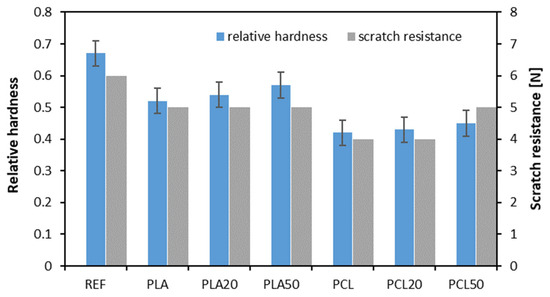

3.2. Resistance to Scratch and a Relative Hardness

Scratch resistance and relative hardness of the tested surface finishing layers are presented in Figure 2. The greatest hardness (0.67) and scratch resistance (6 N) have been demonstrated for the reference, PF surface layer. These results were statistically significantly different from those achieved for PLA and PCL. The highest scratch resistance and relative hardness for tested biopolymers have been revealed for pure PLA. The addition of SAR provoked a statistically insignificant increase in relative hardness and scratch resistance for both blends, PLA and PCL. However, the results of scratch resistance achieved for the tested materials are lower than for high-pressure laminates (HPL) where almost 9 N has been recorded [47]. The improvement of the stiffness and mechanical properties of PLA has been confirmed by Teymoorzadeh and Hedieh Rodrigue [48], whose study involved various additions of wood flour. Also, according to Němec et al. [49], the incorporation of 1% lignin HPL leads to a significant hardness improvement. The lower hardness of PCL has been noted by Quiles-Carrillo et al. [50], who modified blends of PLA and PCL using thermoplastic starch. This study has unveiled a promising avenue for enhancing the scratch resistance and hardness of surface finishing materials derived from renewable and upcycled raw materials through the addition of SAR-modified biopolymers.

Figure 2.

The relative hardness and scratch resistance of the tested surface finishing layers.

3.3. Cold Liquids Resistance

The cold liquids resistance evaluation results of the tested surface finishing layers have been depicted in Table 2. As demonstrated, the reference finishing layer appears to possess one of the highest resistances to the cold liquids applied. The results show that regarding PF resin, a slight turbidity after acetone and citric acid activity has been found. When it comes to pure PLA, there was slight cloudiness discovered only for acetone. There was no significant influence of the incorporation of SAR on PLA regarding the resistance to cold liquids. The pure PCL layer was less resilient when compared to PF and PLA. The changes in the surface have been indicated when acetone and ethanol have been implemented. The addition of SAR to PCL led to the lowering of the resistance of the tested blends to acetone and ethanol (C-grade for both liquids).

Table 2.

The grades of resistance of the tested surface finishing layers to cold liquids.

Comparing the obtained results to conclusions drawn from studies on various finishing coatings, it is worth mentioning the results provided by Prapruddivongs et al. [51] on the addition of organoclay to pure PLA. It has been proven that modification using organoclay led to the enhancement of water vapor permeability of the films examined. Regarding commercial waterborne coatings (acrylate-based and polyurethane-based), Pavlič et al. [14] confirmed that the best resilience to cold liquids was observed when exposed to water and citric acid, while the most rapid changes were observed after acetone application. The acrylic-based coatings showed better resistance compared to the polyurethane-based ones. It was also stated by Jelonek and Tomczak [52] that most of the agents had caused no changes on waterborne UV acrylic coatings even after 24 h. Only the ethyl alcohol negatively impacted the evaluated surfaces, resulting in slight changes.

3.4. Surface Water Absorption

While surface water absorption of the wood-based materials offers valuable insight into their surface characteristics when subjected to finishing or when in use, the results of the measurements conducted on the reference layer and those composed of PLA and PCL reveal no water uptake by the tested samples. The achieved results align with the margin of error for the method. This means that the tested surfaces, when exposed to 2 h of water influence, remain tight and impermeable. This provides promising insight regarding potential of the application of biopolymer/SAR blends as surface finishing layers.

Comparing SAR incorporation to other possible modifications, one can mention the results revealed by Nayak et al. [53]. It has been stated that the effect of the addition of 0.1 wt% nano TiO2 to glass fiber (GF) reinforced polymer reduces the moisture diffusion coefficient about 9%. According to Yang et al. [54], water absorption of the polyolefin-wood/rice flour blends slightly increased as the filler loading augmented, but to a negligible extent, while the study conducted by Gupta et al. [55] showed that jute- and sisal-reinforced epoxy resins showed satisfying water absorption properties when compared to non-reinforced polymer and enabled further improvement by alkali treatment.

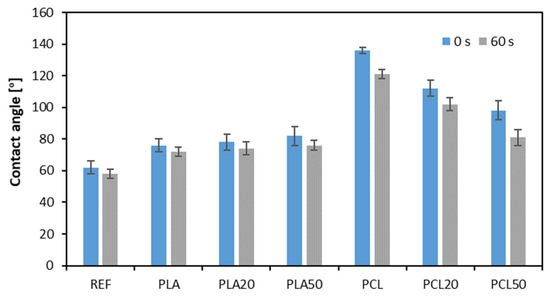

3.5. Contact Angle

The results of the measurements of contact angle on the tested surface finishing layers composed of different biopolymers with various content of SAR are depicted in Figure 3. As demonstrated, the lowest contact angle, 62°, were shown for the reference layer. After 60 s, this angle decreased to 58°. The contact angle for pure PLA equaled 76° and 72°, respectively, directly after deposition and 60 s after deposition. This contact angle indicated for PLA to attain the outcome was provided by Tümer et al. [56]. The values of water contact angle reported by Paragkumar et al. [57] for poly(D,L-lactide) without surface modification range from 87° to 69°. The subsequent addition of SAR, 20% and 50% to PLA, led to a statistically insignificant increase in contact angle values. A much higher contact angle, 136° and 121°, respectively, directly after deposition and 60 s after deposition, has been found for pure PCL. According to Dias and Bártolo [58], a contact angle of 17 wt% PCL dissolved in acetone equals 101° and of 11 wt% PCL dissolved in acetic acid with triethylamine at 84°. This indicates the influence of the type and the concentration of dissolvent on the contact angle values. The results obtained in this study confirm the strongly hydrophobic nature of PCL, which should remain an advantage when applied as a protective layer. The subsequent addition of SAR, 20% and 50%, to PCL resulted in a statistically significant reduction in the contact angle. As confirmed by Gumowska and Kowaluk [59]. The changes in the contact angle of biopolymers influence the properties of wood-based materials, including their use as a binder, especially when exposed to humidity or water.

Figure 3.

The contact angle of the tested surface finishing layers.

3.6. Total VOC and Formaldehyde Emission

The results of Total VOC and formaldehyde (HCHO) emissions from the tested surface finishing materials applied on plywood are displayed in Table 3. When comparing the achieved results of TVOC to those for laminated particleboards [60], it is obvious that the emission for reference panel (REF) remains lower than for particleboard. The reason can be a barrier layer of PF resin, as well as a lower content of VOC in deciduous species, such as Betula spp., which was the raw material for the plywood composition used [61]. A significant reduction in TVOC and HCHO emission was also reported when the investigated surface finishing layers were applied. The augmenting content of SAR significantly reduces the revealed emissions. The mentioned reduction in TVOC and formaldehyde emission from plywood covered with different surface finishing layers can be due to the scavenger nature of lignin, being the main component (over 21 wt%) of SAR. The SAR-containing surface finishing layers act as a bi-functional barrier layer, avoiding the gas transfer from the core of the composite to the environment, as well as fixing the formaldehyde and other emitted compounds in the finishing layer structure [62]. According to Aversa et al. [63] and Sousa et al. [64], the blends of PLA, as well as PCL, can be recognized as extremely promising for the development of bio-based and biodegradable polymeric materials with low oxygen permeation, that is, for the development of suitable alternatives to conventional and highly polluting oil-based plastics. In conclusion, the examined surface finishing materials, incorporating biopolymers with SAR, exhibit promising attributes in terms of creating an effective gas barrier layer on surfaces of wood-based materials.

Table 3.

The emission of TVOC and HCHO of the tested surface finishing layers.

4. Conclusions

The objective of this research was to develop and assess film-forming coatings, created by combining a biopolymer with SAR, as a carbon-rich, alternative upcycled raw material. There were two types of biopolymers employed, PLA and PCL, in various polymer–SAR ratios. SAR, as a residual material, presents as an opportunity for CO2 fixing from the atmosphere and creates a possibility of further use.

The findings indicate a positive influence of 20% and 50% addition of SAR into PLA and PCL blends regarding Total VOC and formaldehyde emission from plywood. This can be attributed to the high lignin content in SAR particles. Furthermore, SAR addition enhances the relative hardness and scratch resistance of PLA- and PCL-based surface finishing materials.

No significant differences between surface water absorption were revealed when testing the mentioned surface finishing materials.

The reduced features of resistance to selected cold liquids, such as acetone and ethanol, were noticed for PCL with a raising SAR content.

Based on the achieved results and aforementioned conclusions, it is possible to affirm that the innovative approach involving the use of biopolymers as matrices instead of traditional crude oil-based resins, along with the integration of post-processed carbon-rich waste lignocellulosic materials to create surface finishing and protective films, can be effectively developed and beneficial. One limitation of this approach is the necessity to expand the range of biopolymers utilized as matrices in order to enhance the mechanical properties of the tested films.

Author Contributions

Conceptualization, A.J. and G.K.; methodology, G.K.; validation, G.K.; formal analysis, A.J.; investigation, A.J.; resources, G.K.; data curation, G.K.; writing—original draft preparation, A.J.; writing—review and editing, A.J. and G.K.; visualization, A.J.; supervision, G.K.; project administration, G.K.; funding acquisition, G.K. All authors have read and agreed to the published version of the manuscript.

Funding

The research presented is a part of Project BarkBuild, which is funded by the ERA-NET Cofund ForestValue program through Vinnova (Sweden); Valsts izglītības attīstības aģentūra (Latvia); the Ministry of Education, Science and Sport (JIA) (Slovenia); the Academy of Finland; The Research Council of Norway; and the National Science Centre, Poland (agreement no. 2021/03/Y/NZ9/00038). The ForestValue program received funding from the Horizon 2020 Research and Innovation program of the European Union under grant agreement No. 773324.

Data Availability Statement

Not applicable.

Acknowledgments

The mentioned research has been completed with the support of the Student Furniture Scientific Group (Koło Naukowe Meblarstwa), Faculty of Wood Technology, Warsaw University of Life Sciences—SGGW. The authors would like to acknowledge Janis Rizhikovs, Latvian State Institute of Wood Chemistry, Riga, Latvia, for kindly providing the bark post-extraction residues (SAR).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Williams, R.S.; Railings, D.; Cleaners, W. Chapter 16—Finishing of Wood. In Wood Handbook Wood as an Engineering Material; USDA: Washington, DC, USA, 2010; pp. 1–39. [Google Scholar]

- Szczuka, M.; Różańska, A.; Koryciński, W. Selected Aesthetic Properties of Traditional Finish Coatings Used in Furniture Making. Ann. Wars. Univ. Life Sci. SGGW For. Wood Technol. 2016, 96, 168–175. [Google Scholar]

- Janesch, J.; Arminger, B.; Gindl-altmutter, W.; Hansmann, C. Progress in Organic Coatings Superhydrophobic Coatings on Wood Made of Plant Oil and Natural Wax. Prog. Org. Coat. 2020, 148, 105891. [Google Scholar] [CrossRef]

- Liu, X.Y.; Timar, M.C.; Varodi, A.M. A Comparative Study on the Artificial UV and Natural Ageing of Beeswax and Chinese Wax and Influence of Wax Finishing on the Ageing of Chinese Ash (Fraxinus Mandshurica) Wood Surfaces. J. Photochem. Photobiol. B Biol. 2019, 201, 111607. [Google Scholar] [CrossRef]

- Calatan, G.; Hegyi, A.; Dico, C.; Cazan, O. Comparative Study on the Physico-Mechanical Characteristics for Five Types of Wood Flooring. Constructii 2014, 15, 60–67. [Google Scholar]

- Ghorbani, M.; Mahendran, A.R.; van Herwijnen, H.W.G.; Liebner, F.; Konnerth, J. Paper-Based Laminates Produced with Kraft Lignin-Rich Phenol–Formaldehyde Resoles Meet Requirements for Outdoor Usage. Eur. J. Wood Wood Prod. 2018, 76, 481–487. [Google Scholar] [CrossRef]

- Thébault, M.; Kandelbauer, A.; Eicher, I.; Geyer, B.; Zikulnig-Rusch, E. Properties Data of Phenolic Resins Synthetized for the Impregnation of Saturating Kraft Paper. Data Br. 2018, 20, 345–352. [Google Scholar] [CrossRef] [PubMed]

- Thébault, M.; Li, Y.; Beuc, C.; Frömel-Frybort, S.; Zikulnig-Rusch, E.M.; Kutuzova, L.; Kandelbauer, A. Impregnated Paper-Based Decorative Laminates Prepared from Lignin-Substituted Phenolic Resins. J. Renew. Mater. 2020, 8, 1181–1198. [Google Scholar] [CrossRef]

- Shams, I.; Yano, H. Compressive Deformation of Wood Impregnated with Low Molecular Weight Phenol Formaldehyde (PF) Resin II: Effects of Processing Parameters. J. Wood Sci. 2004, 50, 343–350. [Google Scholar] [CrossRef]

- Ding, J.; Qin, Z.; Luo, H.; Yang, W.; Wang, Y.; Huang, Z. Nano-Silica Modified Phenolic Resin Film: Manufacturing and Properties. Nanotechnol. Rev. 2020, 9, 209–218. [Google Scholar] [CrossRef]

- Passauer, L.; Schubert, J.; Schulz, T.; Flade, P.; Weiß, B.; Burkhardt, H. Artificial Weathering of Surfaces from Laminated Phenol-Formaldehyde Resin Impregnated Compressed Wood: Impact of Top Veneer Type and Overlay Application. Eur. J. Wood Wood Prod. 2021, 79, 567–578. [Google Scholar] [CrossRef]

- Smardzewski, J.; Silvana, P. Modelling of Thin Paper Honeycomb Panels for Furniture; Zagreb University, Faculty of Forestry, Innovawood: Zagreb, Croatia, 2016; ISBN 9789532920260. [Google Scholar]

- Krystofiak, T.K.; Lis, B.L.; Muszyńska, M.M. The Effect of Aging Tests on Gloss and Adhesion of Lacquer Coatings on Window Elements from Pine Wood. Drew. Pr. Nauk. Doniesienia Komun. 2016, 59, 127–137. [Google Scholar] [CrossRef]

- Pavlič, M.; Petrič, M.; Žigon, J. Interactions of Coating and Wood Flooring Surface System Properties. Coatings 2021, 11, 91. [Google Scholar] [CrossRef]

- Landry, V. Self-Healing UV Curable Acrylate Coatings for Wood on Self-Healing Efficiency. Coatings 2020, 10, 770. [Google Scholar]

- White, S.R.; Sottos, N.R.; Geubelle, P.H.; Moore, J.S.; Kessler, M.R.; Sriram, S.R.; Brown, E.N.; Viswanathan, S. Autonomic Healing of Polymer Composites. Nature 2001, 409, 794. [Google Scholar] [CrossRef]

- Pizzi, A.; Leban, J.M.; Zanetti, M.; Pichelin, F.; Wieland, S.; Properzi, M. Surface Finishes by Mechanically Induced Wood Surface Fusion. Holz Als Roh-Und Werkst. 2005, 63, 251–255. [Google Scholar] [CrossRef]

- Karsznia, K.; Mankowski, P.; Krembuszewski, D. The use of a structural monitoring system in deformation surveying of a wooden beam during the destructive test. Ann. Wars. Univ. Life Sci. SGGW For. Wood Technol. 2018, 103, 114–122. [Google Scholar]

- Adegeye, A.O.; Ogunsanwo, O.Y.; Olajuyigbe, S.O.; Ogunsanwo, O.Y.; Adegeye, A.O.; Deniz, I.; Chavenetidou, M.; Birbilis, D.; Kakavas, K.V.; Sumthong, P.; et al. The Use of Some Vegetable Oils as Wood Finishing Substances in Furniture Industry the Use of Some Vegetable Oils as Wood Finishing Substances in Furniture Industry. IOP Conf. Ser. Mater. Sci. Eng. 2016, 18, 62–69. [Google Scholar]

- Montazeri, M.; Eckelman, M.J. Life Cycle Assessment of UV-Curable Bio-Based Wood Flooring Coatings. J. Clean. Prod. 2018, 192, 932–939. [Google Scholar] [CrossRef]

- Gonçalves, D.; Bordado, J.M.; Marques, A.C.; Dos Santos, R.G. Non-Formaldehyde, Bio-Based Adhesives for Use in Wood-Based Panel Manufacturing Industry—A Review. Polymers 2021, 13, 4086. [Google Scholar] [CrossRef]

- Gumowska, A.; Kowaluk, G.; Labidi, J.; Robles, E. Barrier Properties of Cellulose Nanofiber Film as an External Layer of Particleboard. Clean Technol. Environ. Policy 2019, 21, 2073–2079. [Google Scholar] [CrossRef]

- Faraj, H.; Follain, N.; Sollogoub, C.; Almeida, G.; Marais, S.; Tencé-girault, S.; Gouanvé, F.; Domenek, S. Gas Barrier Properties of Polylactide / Cellulose Nanocrystals Nanocomposites HAL Id: Hal-03794868. Polym. Test. 2022, 113, 107683. [Google Scholar] [CrossRef]

- Dimer, A.K.; Nechita, P.; Roman, M.; Ceoromila, A.C. Improving Barrier Properties of Xylan-Coated Food Packaging Papers with Sustainability Improving Barrier Properties of Xylan-Coated Food Packaging Papers with Alkyl Ketene Dimer. Sustainability 2022, 14, 16255. [Google Scholar] [CrossRef]

- Kowaluk, G.; Zając, M.; Czubak, E.; Auriga, R. Physical and Mechanical Properties of Particleboards Manufactured Using Charcoal as Additives. iForest Biogeosci. For. 2016, 10, 70–74. [Google Scholar] [CrossRef]

- Samadi, M.T.; Rahman, A.R.; Zarrabi, M.; Shahabi, E.; Sameei, F. Adsorption of Chromium (VI) from Aqueous Solution by Sugar Beet Bagasse-Based Activated Charcoal. Environ. Technol. 2009, 30, 1023–1029. [Google Scholar] [CrossRef]

- Indrayani, Y.; Septiani, E.; Setyawati, D.; Mariani, Y. Influence of Activated Charcoal Addition on the Adhesion, Emission, Physical, Mechanical, and Biological Properties of Particleboard. J. Sylva Lestari 2022, 10, 294–309. [Google Scholar] [CrossRef]

- Jiang, W.; Adamopoulos, S.; Hosseinpourpia, R.; Žigon, J.; Petrič, M.; Šernek, M.; Medved, S. Utilization of Partially Liquefied Bark for Production of Particleboards. Appl. Sci. 2020, 10, 5253. [Google Scholar] [CrossRef]

- Jiang, W.; Adamopoulos, S.; Hosseinpourpia, R. Properties and Emissions of Three-Layer Particleboards Liquefied Bark. Materials 2023, 16, 1855. [Google Scholar] [CrossRef]

- Jeżo, A.; Wronka, A.; Dębiński, A.; Kristak, L.; Reh, R.; Rizhikovs, J.; Kowaluk, G. Influence of Upcycled Post-Treatment Bark Biomass Addition to the Binder on Produced Plywood Properties. Forests 2023, 14, 110. [Google Scholar] [CrossRef]

- Makars, R.; Rizikovs, J.; Paze, A. Study of Catalysts for Suberinic Acid-Based Adhesive Polymerization. Mater. Sci. Forum 2022, 1071, 182–188. [Google Scholar] [CrossRef]

- Paze, A.; Rizhikovs, J.; Brazdausks, P.; Puke, M.; Grinins, J.; Tupciauskas, R.; Plavniece, A. Processing Possibilities of Birch Outer Bark into Green Bio-Composites. Vide. Tehnol. Resur. Environ. Technol. Resour. 2017, 3, 249–253. [Google Scholar] [CrossRef]

- Makars, R.; Godina, D.; Rizhikovs, J.; Paze, A.; Tupciauskas, R.; Berzins, R. Investigation of Furfural Formation and Mechanical Properties of Suberinic Acids-Bonded Particleboards Depending on Their Preparation Parameters. Key Eng. Mater. 2021, 903, 235–240. [Google Scholar]

- Godina, D.; Makars, R.; Abolins, A.; Paze, A.; Kirpluks, M.; Rizikovs, J. Suberinic Acid Isolation From Birch Outer Bark and Their Characterization. Mater. Sci. Forum 2022, 1071, 166–173. [Google Scholar] [CrossRef]

- Bahman, N.; Alalaiwat, D.; Abdulmohsen, Z.; Al Khalifa, M.; Al Baharna, S.; Al-Mannai, M.A.; Younis, A. A Critical Review on Global CO2 Emission: Where Do Industries Stand? Rev. Environ. Health 2022. [Google Scholar] [CrossRef] [PubMed]

- Makars, R.; Rizikovs, J.; Godina, D.; Paze, A. Utilization of Suberinic Acids Containing Residue as an Adhesive for Particle Boards. Polymers 2022, 14, 2304. [Google Scholar] [CrossRef] [PubMed]

- Jeżo, A.; Wronka, A. Post-Extraction Birch Bark Residues as a Potential Binder in Particleboards. Ann. Wars. Univ. Life Sci. SGGW For. Wood Technol. 2022, 47, 35–47. [Google Scholar] [CrossRef]

- EN 827; Adhesives—Determination of Conventional Solids Content and Constant Mass Solids Content. European Committee for Standardization: Brussels, Belgium, 2005.

- Gumowska, A.; Robles, E.; Bikoro, A.; Wronka, A.; Kowaluk, G. Selected Properties of Bio-Based Layered Hybrid Composites with Biopolymer Blends for Structural Applications. Polymers 2022, 14, 4393. [Google Scholar] [CrossRef] [PubMed]

- EN 15186; Furniture—Assessment of the Surface Resistance to Scratching. European Committee for Standardization: Brussels, Belgium, 2012.

- ISO 1522; Paints and Varnishes—Pendulum Damping Test. European Committee for Standardization: Brussels, Belgium, 2022.

- EN 12720+A1; Furniture—Assessment of Surface Resistance to Cold Liquids. European Committee for Standardization: Brussels, Belgium, 2013.

- EN 382-2; Fibreboards—Determination of Surface Absorption—Part 2: Test Method for Hardboards. European Committee for Standardization: Brussels, Belgium, 1993.

- EN 717-1; Wood-Based Panels—Determination of Formaldehyde Release—Part 1: Formaldehyde Emission by the Chamber Method. European Committee for Standardization: Brussels, Belgium, 2004.

- Grigsby, W.J.; Gaugler, M.; Torayno, D. Understanding the PLA–Wood Adhesion Interface for the Development of PLA-Bonded Softwood Laminates. Fibers 2022, 10, 51. [Google Scholar] [CrossRef]

- Nemli, G.; Örs, Y.; Kalaycioǧlu, H. The Choosing of Suitable Decorative Surface Coating Material Types for Interior End Use Applications of Particleboard. Constr. Build. Mater. 2005, 19, 307–312. [Google Scholar] [CrossRef]

- Nemli, G. Factors Affecting Some Quality Properties of the Decorative Surface Overlays. J. Mater. Process. Technol. 2008, 195, 218–223. [Google Scholar] [CrossRef]

- Teymoorzadeh, H.; Rodrigue, D. Biocomposites of Wood Flour and Polylactic Acid: Processing and Properties. J. Biobased Mater. Bioenergy 2015, 9, 252–257. [Google Scholar] [CrossRef]

- Němec, M.; Hájková, K.; Hýsek, Š. Paper-Based Laminates Impregnated with a Hybrid Lignin-Phenol-Formaldehyde Resin. Materials 2023, 16, 2669. [Google Scholar] [CrossRef] [PubMed]

- Quiles-Carrillo, L.; Montanes, N.; Pineiro, F.; Jorda-Vilaplana, A.; Torres-Giner, S. Ductility and Toughness Improvement of Injection-Molded Compostable Pieces of Polylactide by Melt Blending with Poly(ε-Caprolactone) and Thermoplastic Starch. Materials 2018, 11, 2138. [Google Scholar] [CrossRef] [PubMed]

- Prapruddivongs, C.; Sombatsompop, N.; Jayaraman, K. Effect of Organoclay Incorporation on Mechanical, Barrier and Thermal Properties and Anti-Bacterial Performance of PLA and PLA Composites with Triclosan and Wood Flour. Polym. Polym. Compos. 2014, 22, 643–652. [Google Scholar] [CrossRef]

- Jelonek, T.; Tomczak, A. Annals of Warsaw of Life Sciences–SGGW. Ann. Warsaw Agric. Univ. SGGW For. Wood Technol. 2010, 71, 328–335. [Google Scholar]

- Nayak, R.K.; Mahato, K.K.; Ray, B.C. Water Absorption Behavior, Mechanical and Thermal Properties of Nano TiO2 Enhanced Glass Fiber Reinforced Polymer Composites. Compos. Part A Appl. Sci. Manuf. 2016, 90, 736–747. [Google Scholar] [CrossRef]

- Yang, H.S.; Kim, H.J.; Park, H.J.; Lee, B.J.; Hwang, T.S. Water Absorption Behavior and Mechanical Properties of Lignocellulosic Filler-Polyolefin Bio-Composites. Compos. Struct. 2006, 72, 429–437. [Google Scholar] [CrossRef]

- Gupta, M.K.; Srivastava, R.K. Mechanical, Thermal and Water Absorption Properties of Hybrid Sisal/Jute Fiber Reinforced Polymer Composite. Indian J. Eng. Mater. Sci. 2016, 23, 231–238. [Google Scholar]

- Tümer, E.H.; Erbil, H.Y.; Akdoǧan, N. Wetting of Superhydrophobic Polylactic Acid Micropillared Patterns. Langmuir 2022, 38, 10052–10064. [Google Scholar] [CrossRef]

- Paragkumar, N.T.; Edith, D.; Six, J.L. Surface Characteristics of PLA and PLGA Films. Appl. Surf. Sci. 2006, 253, 2758–2764. [Google Scholar] [CrossRef]

- Dias, J.; Bártolo, P. Morphological Characteristics of Electrospun PCL Meshes—The Influence of Solvent Type and Concentration. Procedia CIRP 2013, 5, 216–221. [Google Scholar] [CrossRef]

- Gumowska, A.; Kowaluk, G. Physical and Mechanical Properties of High-Density Fiberboard Bonded with Bio-Based Adhesives. Forests 2023, 14, 84. [Google Scholar] [CrossRef]

- Wronka, A.; Kowaluk, G. The Influence of Multiple Mechanical Recycling of Particleboards on Their Selected Mechanical and Physical Properties. Materials 2022, 15, 8487. [Google Scholar] [CrossRef] [PubMed]

- Walker, H.; Jena, A.; McEwan, K.; Evans, G.; Campbell, S. Natural Volatile Organic Compounds (NVOCs) Are Greater and More Diverse in UK Forests Compared with a Public Garden. Forests 2023, 14, 92. [Google Scholar] [CrossRef]

- Eom, Y.-G.; Kim, J.-S.; Kim, S.; Kim, J.-A.; Kim, H.J. Reduction of Formaldehyde Emission from Particleboards by Bio Scavengers. Mokchae Konghak 2006, 34, 29–41. [Google Scholar]

- Aversa, C.; Barletta, M.; Puopolo, M.; Vesco, S. Cast Extrusion of Low Gas Permeability Bioplastic Sheets in PLA/PBS and PLA/PHB Binary Blends. Polym. Technol. Mater. 2020, 59, 231–240. [Google Scholar] [CrossRef]

- Sousa, F.M.; Cavalcanti, F.B.; Marinho, V.A.D.; Morais, D.D.S.; Almeida, T.G.; Carvalho, L.H. Effect of Composition on Permeability, Mechanical Properties and Biodegradation of PBAT/PCL Blends Films. Polym. Bull. 2022, 79, 5327–5338. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).