Graphene-Quantum-Dot-Mediated Semiconductor Bonding: A Route to Optoelectronic Double Heterostructures and Wavelength-Converting Interfaces

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

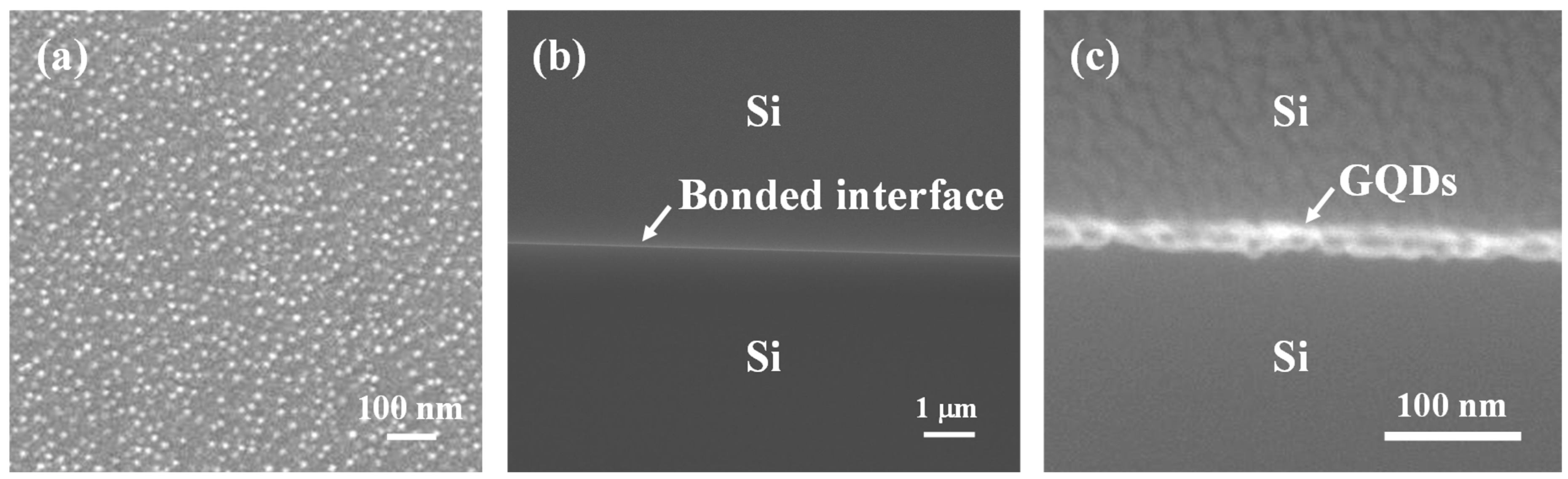

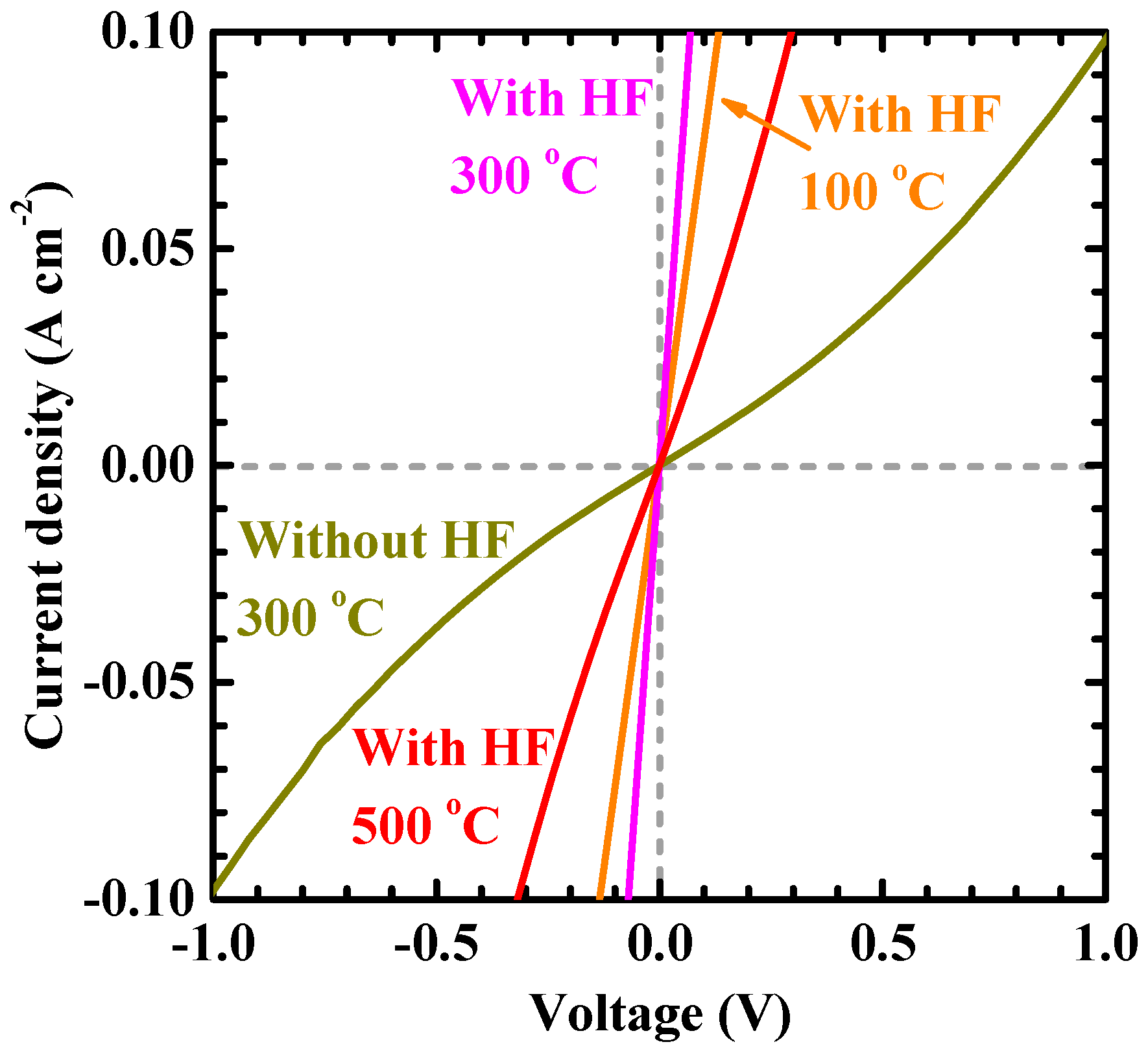

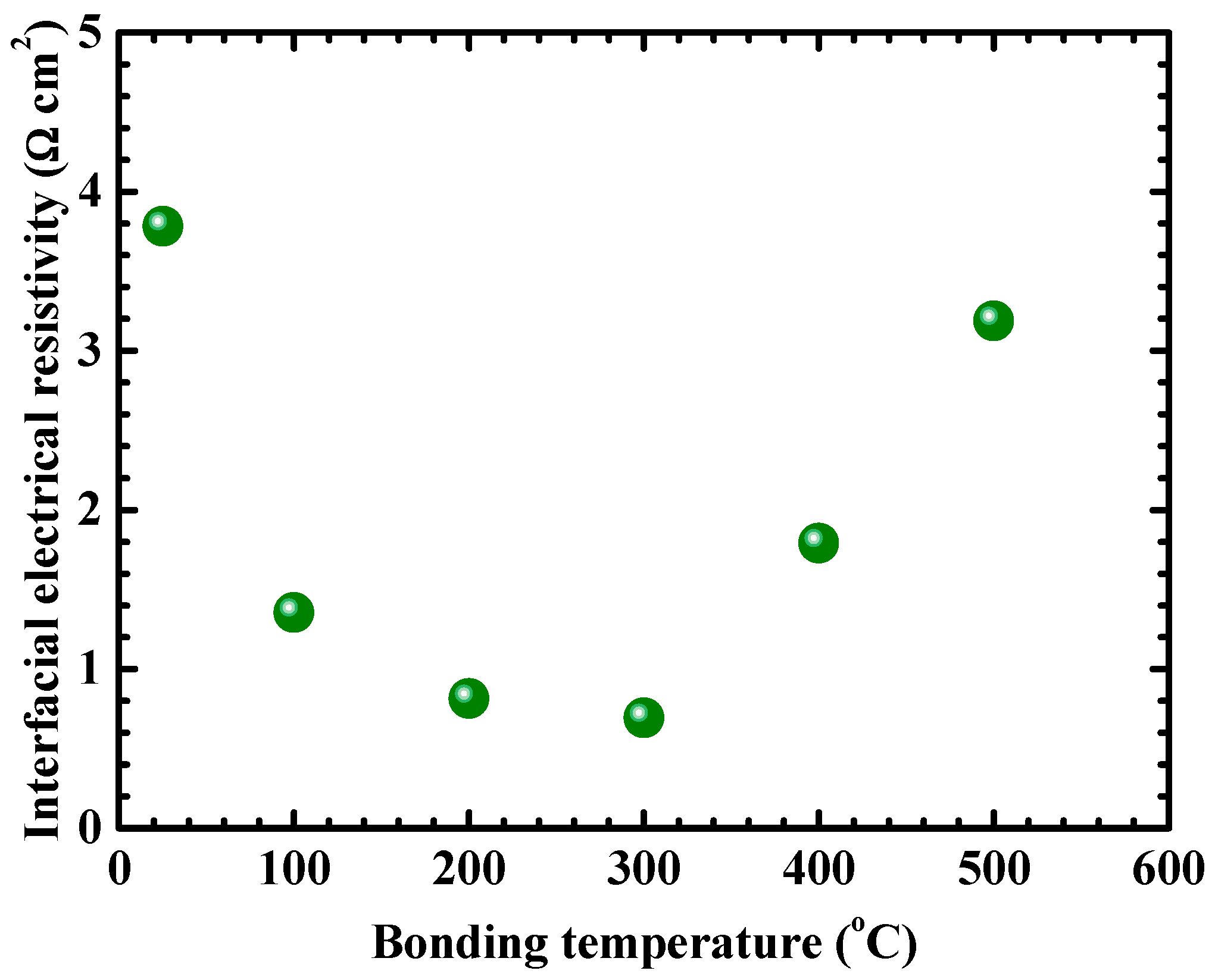

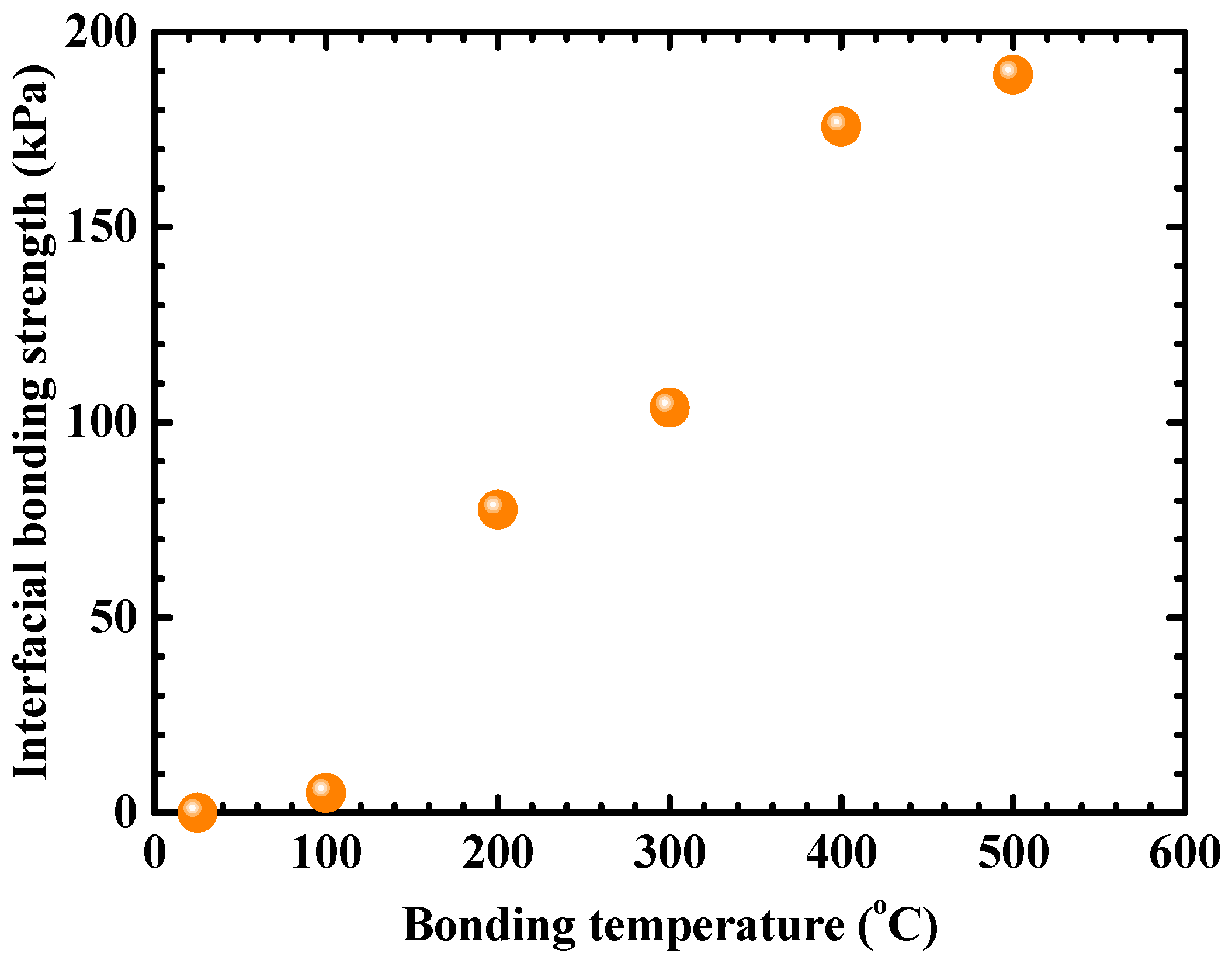

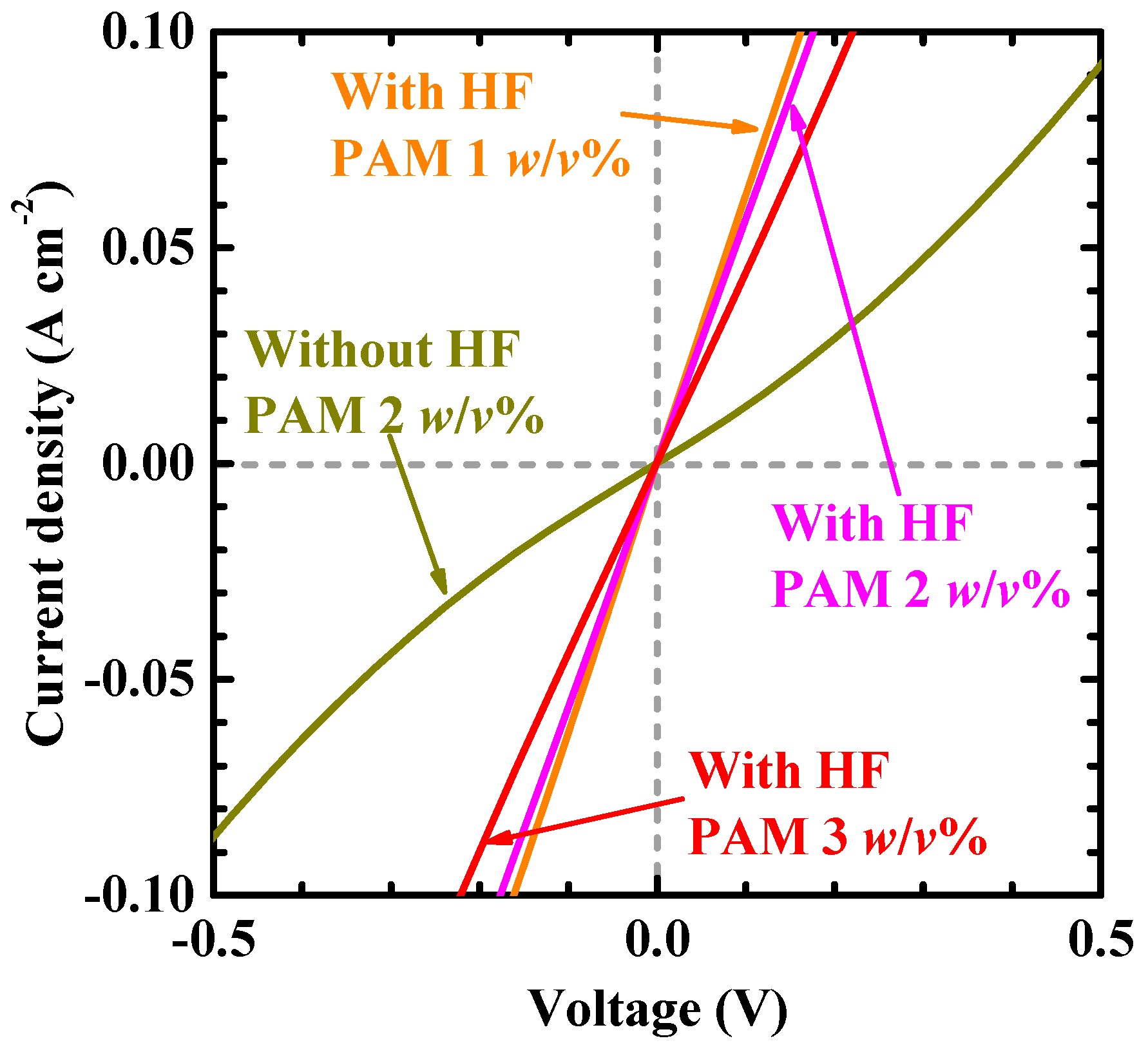

3.1. Bonding via Bare GQDs

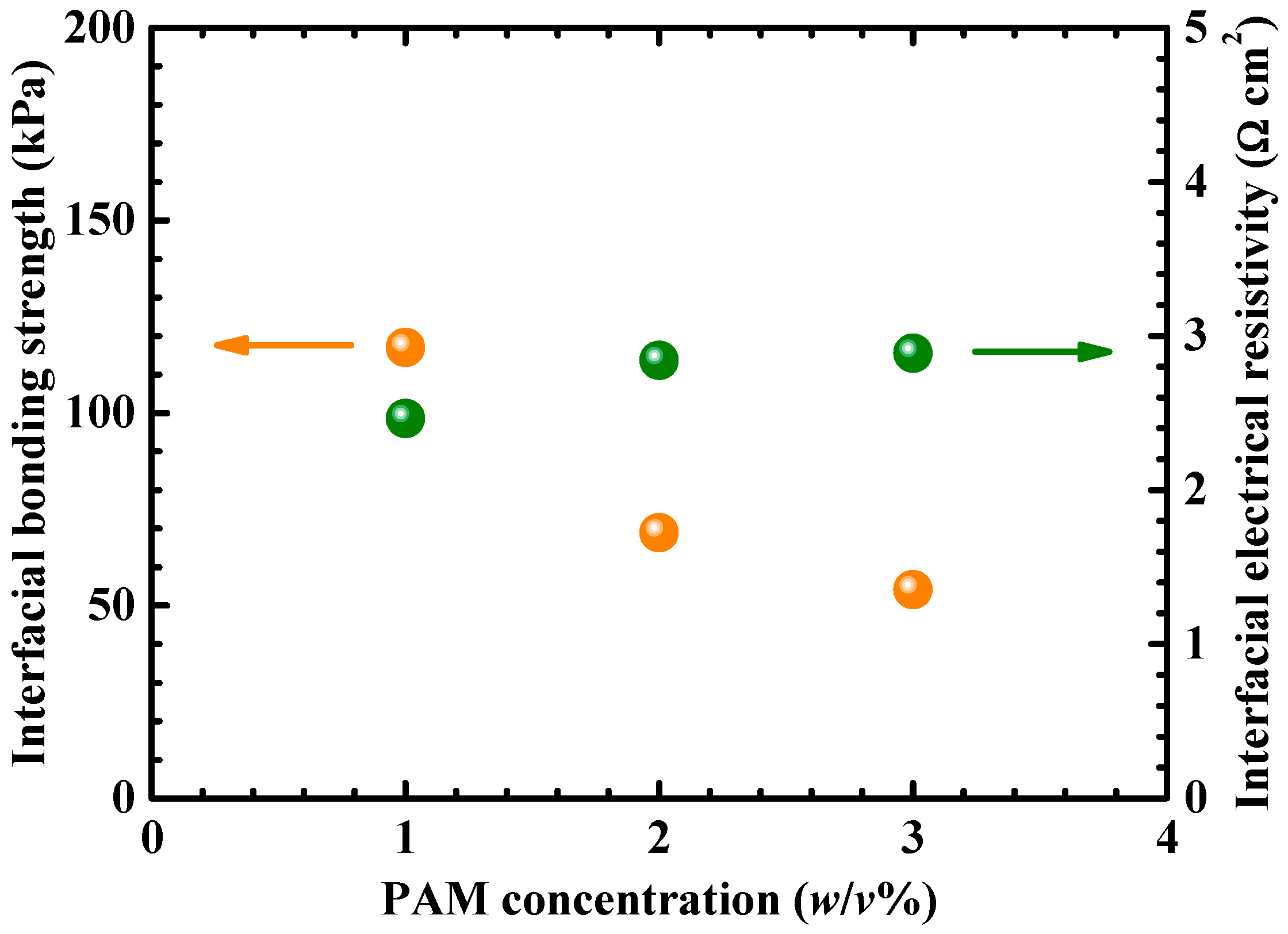

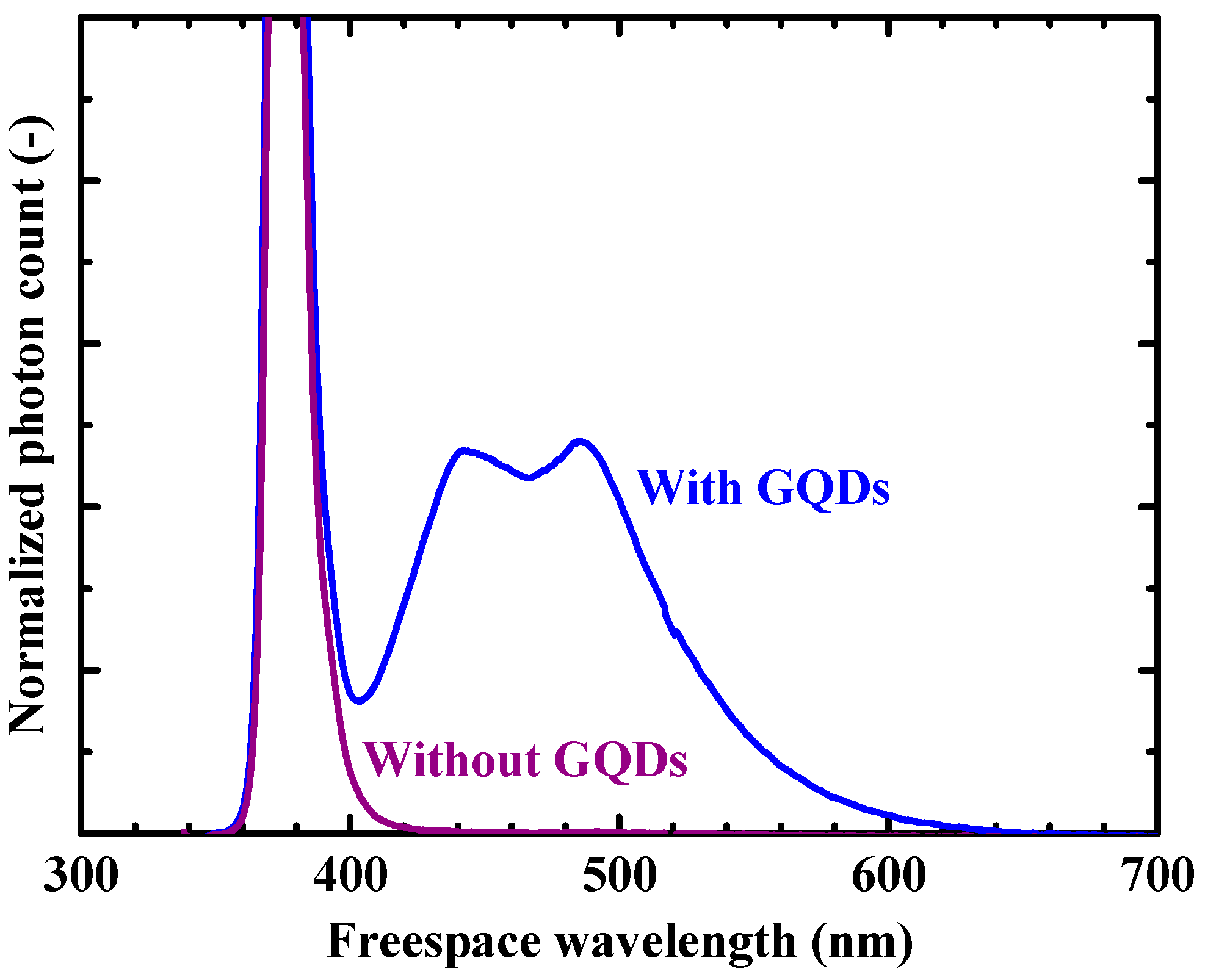

3.2. Bonding via Embedding GQDs in Hydrogel

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Arakawa, Y.; Sakaki, H. Multidimensional quantum well laser and temperature dependence of its threshold current. Appl. Phys. Lett. 1982, 40, 939–941. [Google Scholar] [CrossRef]

- Tessler, N.; Medvedev, V.; Kazes, M.; Kan, S.; Banin, U. Efficient near-infrared polymer nanocrystal light-emitting diodes. Science 2002, 295, 1506–1508. [Google Scholar] [CrossRef] [PubMed]

- Talapin, D.V.; Murray, C.B. PbSe nanocrystal solids for n- and p-channel thin film field-effect transistors. Science 2005, 310, 86–89. [Google Scholar] [CrossRef] [PubMed]

- Tanabe, K.; Nomura, M.; Guimard, D.; Iwamoto, S.; Arakawa, Y. Room temperature continuous wave operation of InAs/GaAs quantum dot photonic crystal nanocavity laser on silicon substrate. Opt. Express 2009, 17, 7036–7042. [Google Scholar] [CrossRef] [PubMed]

- Tanabe, K.; Guimard, D.; Bordel, D.; Arakawa, Y. High-efficiency InAs/GaAs quantum dot solar cells by metalorganic chemical vapor deposition. Appl. Phys. Lett. 2012, 100, 193905. [Google Scholar] [CrossRef]

- Bao, J.; Bawendi, M.G. A colloidal quantum dot spectrometer. Nature 2015, 523, 67–70. [Google Scholar] [CrossRef]

- Adinolfi, V.; Sargent, E.H. Photovoltage field-effect transistors. Nature 2017, 542, 324–327. [Google Scholar] [CrossRef]

- Won, Y.-H.; Cho, O.; Kim, T.; Chung, D.-Y.; Kim, T.; Chung, H.; Jang, H.; Lee, J.; Kim, D.; Jang, E. Highly efficient and stable InP/ZnSe/ZnS quantum dot light-emitting diodes. Nature 2019, 575, 634–638. [Google Scholar] [CrossRef]

- Ono, K.; Austing, D.G.; Tokura, Y.; Tarucha, S. Current rectification by Pauli exclusion in a weakly coupled double quantum dot system. Science 2002, 297, 1313–1317. [Google Scholar] [CrossRef]

- Fujisawa, T.; Hayashi, T.; Tomita, R.; Hirayama, Y. Bidirectional counting of single electrons. Science 2006, 312, 1634–1636. [Google Scholar] [CrossRef]

- Schaller, G.; Emary, C.; Kiesslich, G.; Brandes, T. Probing the power of an electronic Maxwell’s demon: Single-electron transistor monitored by a quantum point contact. Phys. Rev. B 2011, 84, 085418. [Google Scholar] [CrossRef]

- Tanabe, K. Coupled-double-quantum-dot environmental information engines: A numerical analysis. J. Phys. Soc. Jpn. 2016, 85, 064003. [Google Scholar] [CrossRef]

- Sun, H.; Wu, L.; Wei, W.; Qu, X. Recent advances in graphene quantum dots for sensing. Mater. Today 2013, 16, 433–442. [Google Scholar] [CrossRef]

- Minati, L.; Del Piano, A. Facile synthesis of water-soluble, highly-fluorescent graphene quantum dots from graphene oxide reduction for efficient cell labelling. C J. Carbon Res. 2019, 5, 77. [Google Scholar] [CrossRef]

- Yan, Y.; Gong, J.; Chen, J.; Zeng, Z.; Huang, W.; Pu, K.; Liu, J.; Chen, P. Recent advances on graphene quantum dots: From chemistry and physics to applications. Adv. Mater. 2019, 31, 1808283. [Google Scholar] [CrossRef]

- Liu, D.; Chen, X.; Hu, Y.; Sun, T.; Song, Z.; Zheng, Y.; Cao, Y.; Cai, Z.; Cao, M.; Peng, L.; et al. Raman enhancement on ultra-clean graphene quantum dots produced by quasi-equilibrium plasma-enhanced chemical vapor deposition. Nat. Commun. 2018, 9, 193. [Google Scholar] [CrossRef]

- Zhao, S.; Lavie, J.; Rondin, L.; Orcin-Chaix, L.; Diederichs, C.; Roussignol, P.; Chassagneux, Y.; Voisin, C.; Müllen, K.; Narita, A.; et al. Single photon emission from graphene quantum dots at room temperature. Nat. Commun. 2018, 9, 3470. [Google Scholar] [CrossRef]

- Alferov, Z.I. Nobel lecture: The double heterostructure concept and its applications in physics, electronics, and technology. Rev. Mod. Phys. 2001, 73, 767–782. [Google Scholar] [CrossRef]

- Kroemer, H. Nobel lecture: Quasielectric fields and band offsets: Teaching electrons new tricks. Rev. Mod. Phys. 2001, 73, 783–793. [Google Scholar] [CrossRef]

- Mi, Z.; Bhattacharya, P.; Fathpour, S. High-speed 1.3 μm tunnel injection quantum-dot lasers. Appl. Phys. Lett. 2005, 86, 153109. [Google Scholar] [CrossRef]

- Lasky, J.B. Wafer bonding for silicon-on-insulator technologies. Appl. Phys. Lett. 1986, 48, 78–80. [Google Scholar] [CrossRef]

- Tong, Q.-Y.; Goesele, U.M. Wafer bonding and layer splitting for microsystems. Adv. Mater. 1999, 11, 1409–1425. [Google Scholar] [CrossRef]

- Takigawa, R.; Higurashi, E.; Suga, T.; Kawanishi, T. Air-gap structure between integrated LiNbO3 optical modulators and micromachined Si substrates. Opt. Express 2011, 19, 15739–15749. [Google Scholar] [CrossRef]

- Matsumoto, K.; Zhang, X.X.; Kishikawa, J.; Shimomura, K. Current-injected light emission of epitaxially grown InAs/InP quantum dots on directly bonded InP/Si substrate. Jpn. J. Appl. Phys. 2015, 54, 030208. [Google Scholar] [CrossRef][Green Version]

- Kang, C.-M.; Lee, J.-Y.; Kong, D.-J.; Shim, J.-P.; Kim, S.-H.; Mun, S.-H.; Choi, S.-Y.; Park, M.-D.; Lee, J.; Lee, D.-S. Hybrid full-color inorganic light-emitting diodes integrated on a single wafer using selective area growth and adhesive bonding. ACS Photon. 2018, 5, 4413–4422. [Google Scholar] [CrossRef]

- Van Campenhout, J.; Rojo-Romeo, P.; Regreny, P.; Seassal, C.; Van Thourhout, D.; Verstuyft, S.; Di Cioccio, L.; Fedeli, J.M.; Lagahe, C.; Baets, R. Electrically pumped InP-based microdisk lasers integrated with a nanophotonic silicon-on-insulator waveguide circuit. Opt. Express 2007, 15, 6744–6749. [Google Scholar] [CrossRef]

- Tanabe, K.; Watanabe, K.; Arakawa, Y. III-V/Si hybrid photonic devices by direct fusion bonding. Sci. Rep. 2012, 2, 349. [Google Scholar] [CrossRef]

- Park, H.; Fang, A.W.; Jones, R.; Cohen, O.; Raday, O.; Sysak, M.N.; Paniccia, M.J.; Bowers, J.E. A hybrid AlGaInAs-silicon evanescent waveguide photodetector. Opt. Express 2007, 15, 6044–6052. [Google Scholar] [CrossRef]

- Chen, L.; Dong, P.; Lipson, M. High performance germanium photodetectors integrated on submicron silicon waveguides by low temperature wafer bonding. Opt. Express 2008, 16, 11513–11518. [Google Scholar] [CrossRef]

- Tanabe, K.; Fontcuberta i Morral, A.; Atwater, H.A.; Aiken, D.J.; Wanlass, M.W. Direct-bonded GaAs/InGaAs tandem solar cell. Appl. Phys. Lett. 2006, 89, 102106. [Google Scholar] [CrossRef]

- Shigekawa, N.; Hara, T.; Ogawa, T.; Liang, J.; Kamioka, T.; Araki, K.; Yamaguchi, M. GaAs/indium tin oxide/Si bonding junctions for III-V-on-Si hybrid multijunction cells with low series resistance. IEEE J. Photovolt. 2018, 8, 879–886. [Google Scholar] [CrossRef]

- Shen, J.; Zhu, Y.; Chen, C.; Yang, X.; Li, C. Facile preparation and upconversion luminescence of graphene quantum dots. Chem. Commun. 2011, 47, 2580–2582. [Google Scholar] [CrossRef]

- Zhuo, S.; Shao, M.; Lee, S.-T. Upconversion and downconversion fluorescent graphene quantum dots: Ultrasonic preparation and photocatalysis. ACS Nano 2012, 6, 1059–1064. [Google Scholar] [CrossRef]

- Zhu, S.; Zhang, J.; Tang, S.; Qiao, C.; Wang, L.; Wang, H.; Liu, X.; Li, B.; Li, Y.; Yu, W.; et al. Surface chemistry routes to modulate the photoluminescence of graphene quantum dots: From fluorescence mechanism to up-conversion bioimaging applications. Adv. Funct. Mater. 2012, 22, 4732–4740. [Google Scholar] [CrossRef]

- Ge, J.; Lan, M.; Zhou, B.; Liu, W.; Guo, L.; Wang, H.; Jia, Q.; Niu, G.; Huang, X.; Zhou, H.; et al. A graphene quantum dot photodynamic therapy agent with high singlet oxygen generation. Nat. Commun. 2014, 5, 4596. [Google Scholar] [CrossRef]

- Kishibe, K.; Hirata, S.; Inoue, R.; Yamashita, T.; Tanabe, K. Wavelength-conversion-material-mediated semiconductor wafer bonding for smart optoelectronic interconnects. Nanomaterials 2019, 9, 1742. [Google Scholar] [CrossRef]

- Sharps, P.R.; Timmons, M.L.; Hills, J.S.; Gray, J.L. Wafer bonding for use in mechanically stacked multi-bandgap cells. In Proceedings of the 26th IEEE Photovolt. Specialists Conference, Anaheim, CA, USA, 29 September–3 October 1997; pp. 895–898. [Google Scholar] [CrossRef]

- Yoshidomi, S.; Furukawa, J.; Hasumi, M.; Sameshima, T. Mechanical stacking multi junction solar cells using transparent conductive adhesive. Energy Procedia 2014, 60, 116–122. [Google Scholar] [CrossRef]

- Sun, M.; Qu, S.; Hao, Z.; Ji, W.; Jing, P.; Zhang, H.; Zhang, L.; Zhao, J.; Shen, D. Towards efficient solid-state photoluminescence based on carbon-nanodots and starch composites. Nanoscale 2014, 6, 13076–13081. [Google Scholar] [CrossRef]

- Yuk, H.; Zhang, T.; Lin, S.; Alberto Parada, G.; Zhao, X. Tough bonding of hydrogels to diverse non-porous surfaces. Nat. Mater. 2016, 15, 190–196. [Google Scholar] [CrossRef]

- Wirthl, D.; Pichler, R.; Drack, M.; Kettlguber, G.; Moser, R.; Gerstmayr, R.; Hartmann, F.; Bradt, E.; Kaltseis, R.; Siket, C.M.; et al. Instant tough bonding of hydrogels for soft machines and electronics. Sci. Adv. 2017, 3. [Google Scholar] [CrossRef]

- Kishibe, K.; Tanabe, K. Hydrogel-mediated semiconductor wafer bonding. Appl. Phys. Lett. 2019, 115, 081601. [Google Scholar] [CrossRef]

- Nam, H.G.; Nam, M.G.; Yoo, P.J.; Kim, J. Hydrogen bonding-based strongly adhesive coacervate hydrogels synthesized using poly(N-vinylpyrrolidone) and tannic acid. Soft Matter 2019, 15, 785–791. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Liu, X.; Duan, L.; Gao, G. Ultra-stretchable wearable strain sensors based on skin-inspired adhesive, tough and conductive hydrogels. Chem. Eng. J. 2019, 365, 10–19. [Google Scholar] [CrossRef]

- Javanbakht, S.; Namazi, H. Solid state photoluminescence thermoplastic starch film containing graphene quantum dots. Carbohydr. Polym. 2017, 176, 220–226. [Google Scholar] [CrossRef]

- Naito, T.; Tanabe, K. Fabrication of Si/graphene/Si double heterostructures by semiconductor wafer bonding towards future applications in optoelectronics. Nanomaterials 2018, 8, 1048. [Google Scholar] [CrossRef]

- Song, S.H.; Jang, M.; Chung, J.; Jin, S.H.; Kim, B.H.; Hur, S.; Yoo, S.; Cho, Y.; Jeon, S. Highly efficient light-emitting diode of graphene quantum dots fabricated from graphite intercalation compounds. Adv. Opt. Mater. 2014, 2, 1016–1023. [Google Scholar] [CrossRef]

- Kumar, G.S.; Thupakula, U.; Sarkar, P.K.; Acharya, S. Easy extraction of water-soluble graphene quantum dots for light emitting diodes. RSC Adv. 2015, 5, 27711–27716. [Google Scholar] [CrossRef]

- Lee, S.H.; Kim, D.Y.; Lee, J.; Lee, S.B.; Young, H.H.; Kim, Y.; Mun, S.C.; Im, S.H.; Kim, T.; Park, O.O. Synthesis of single-crystalline hexagonal graphene quantum dots from solution chemistry. Nano Lett. 2019, 19, 5437–5442. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nishigaya, K.; Kishibe, K.; Tanabe, K. Graphene-Quantum-Dot-Mediated Semiconductor Bonding: A Route to Optoelectronic Double Heterostructures and Wavelength-Converting Interfaces. C 2020, 6, 28. https://doi.org/10.3390/c6020028

Nishigaya K, Kishibe K, Tanabe K. Graphene-Quantum-Dot-Mediated Semiconductor Bonding: A Route to Optoelectronic Double Heterostructures and Wavelength-Converting Interfaces. C. 2020; 6(2):28. https://doi.org/10.3390/c6020028

Chicago/Turabian StyleNishigaya, Kosuke, Kodai Kishibe, and Katsuaki Tanabe. 2020. "Graphene-Quantum-Dot-Mediated Semiconductor Bonding: A Route to Optoelectronic Double Heterostructures and Wavelength-Converting Interfaces" C 6, no. 2: 28. https://doi.org/10.3390/c6020028

APA StyleNishigaya, K., Kishibe, K., & Tanabe, K. (2020). Graphene-Quantum-Dot-Mediated Semiconductor Bonding: A Route to Optoelectronic Double Heterostructures and Wavelength-Converting Interfaces. C, 6(2), 28. https://doi.org/10.3390/c6020028