Air Flow Monitoring in a Bubble Column Using Ultrasonic Spectrometry

Abstract

1. Introduction

2. Materials and Methods

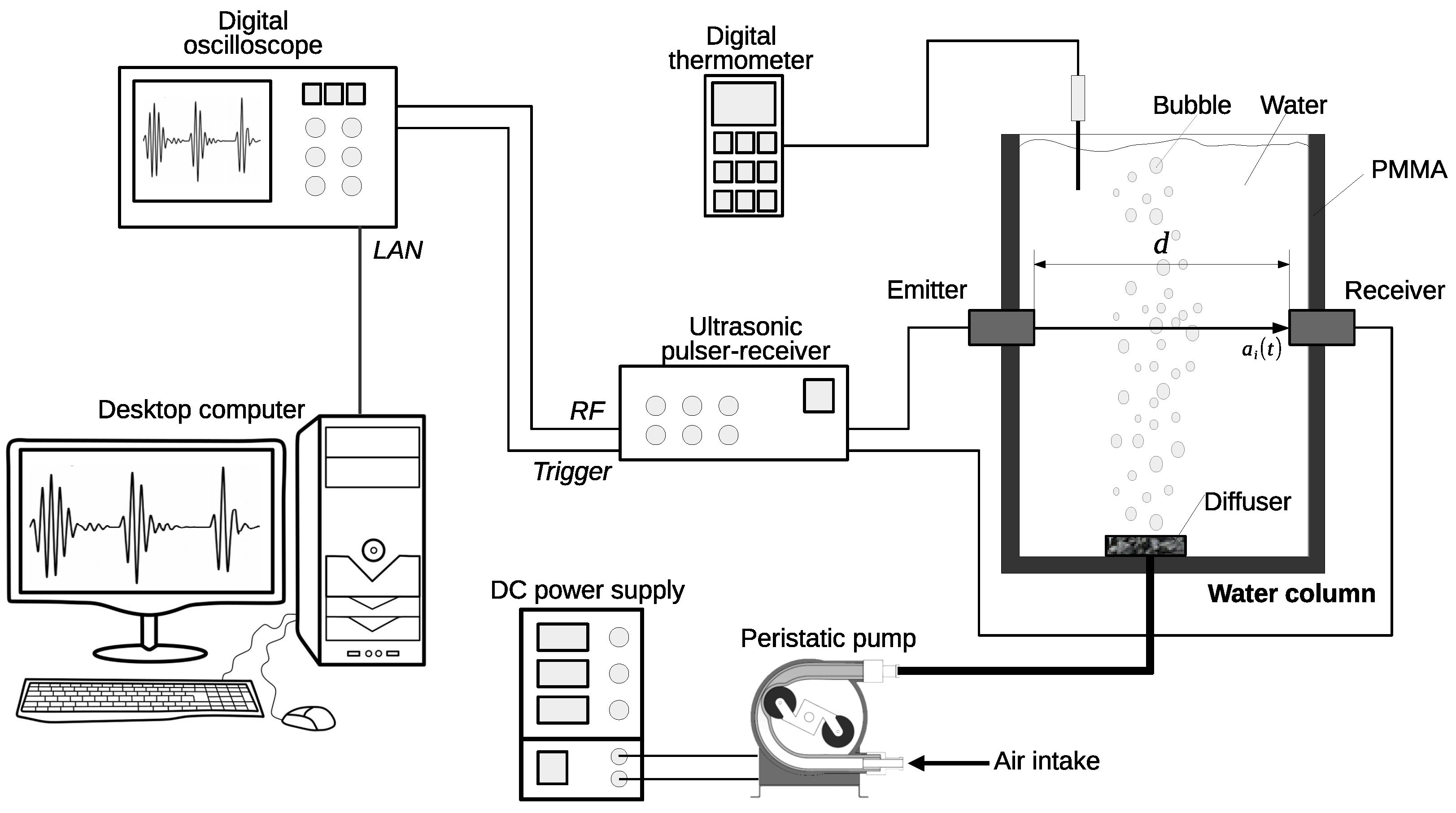

2.1. Experimental Setup

2.2. Signal Processing

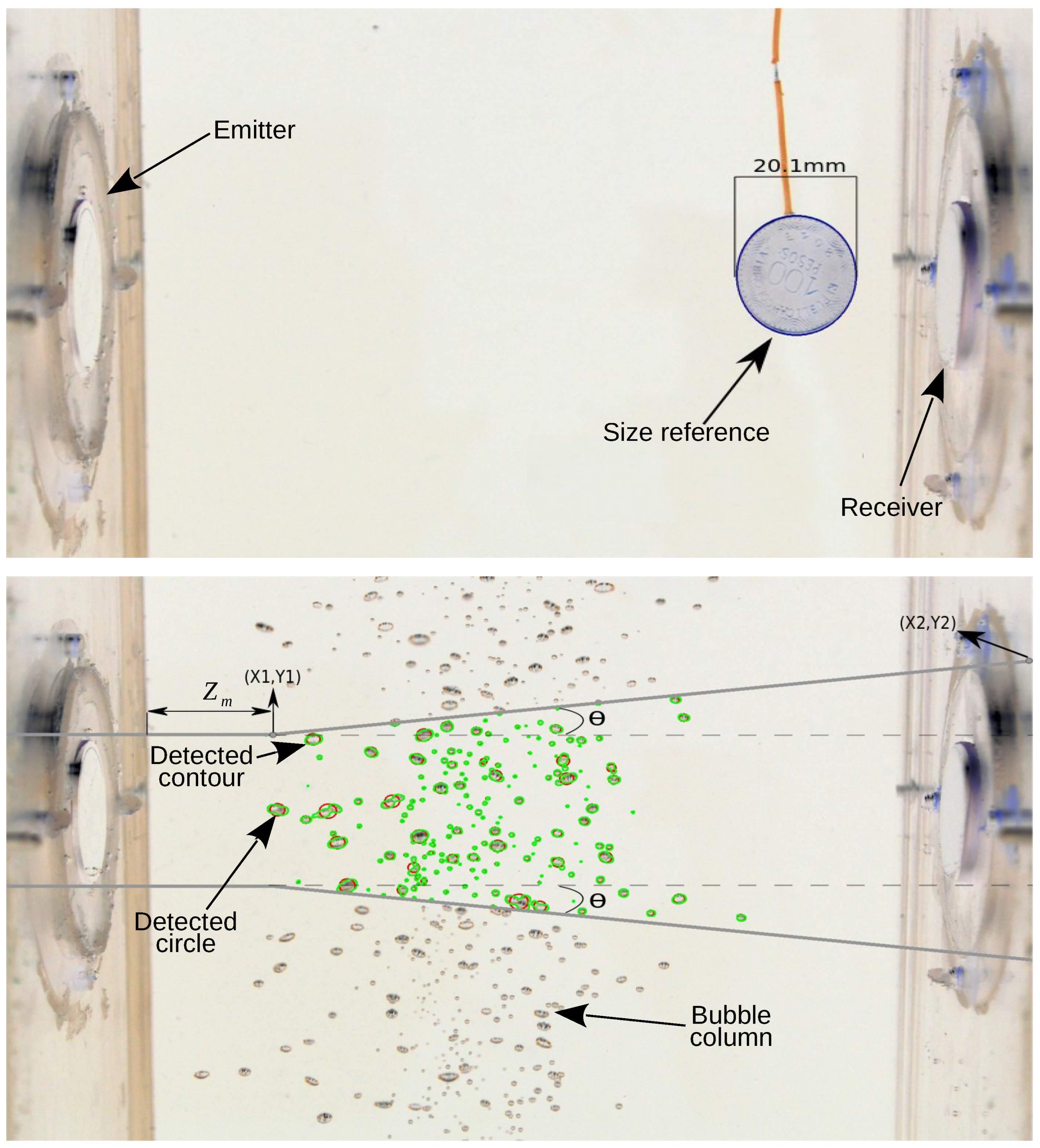

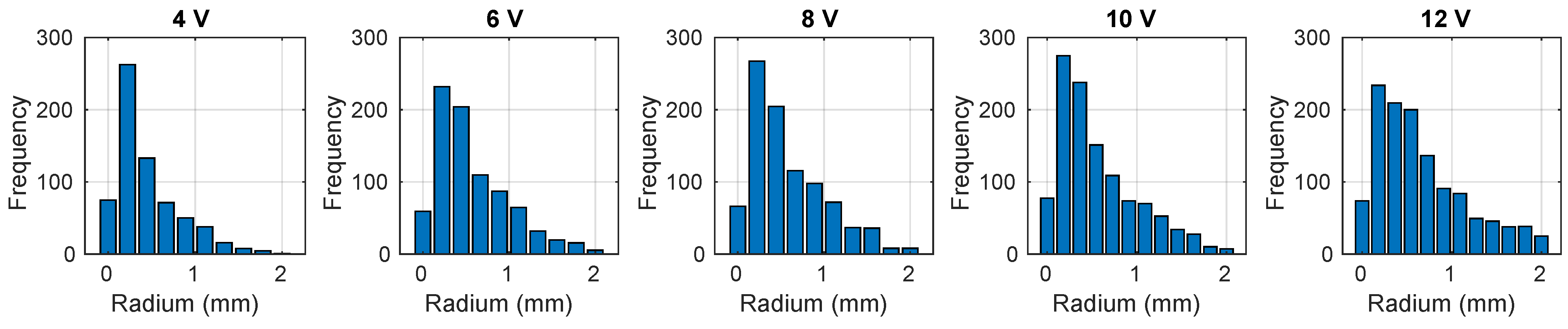

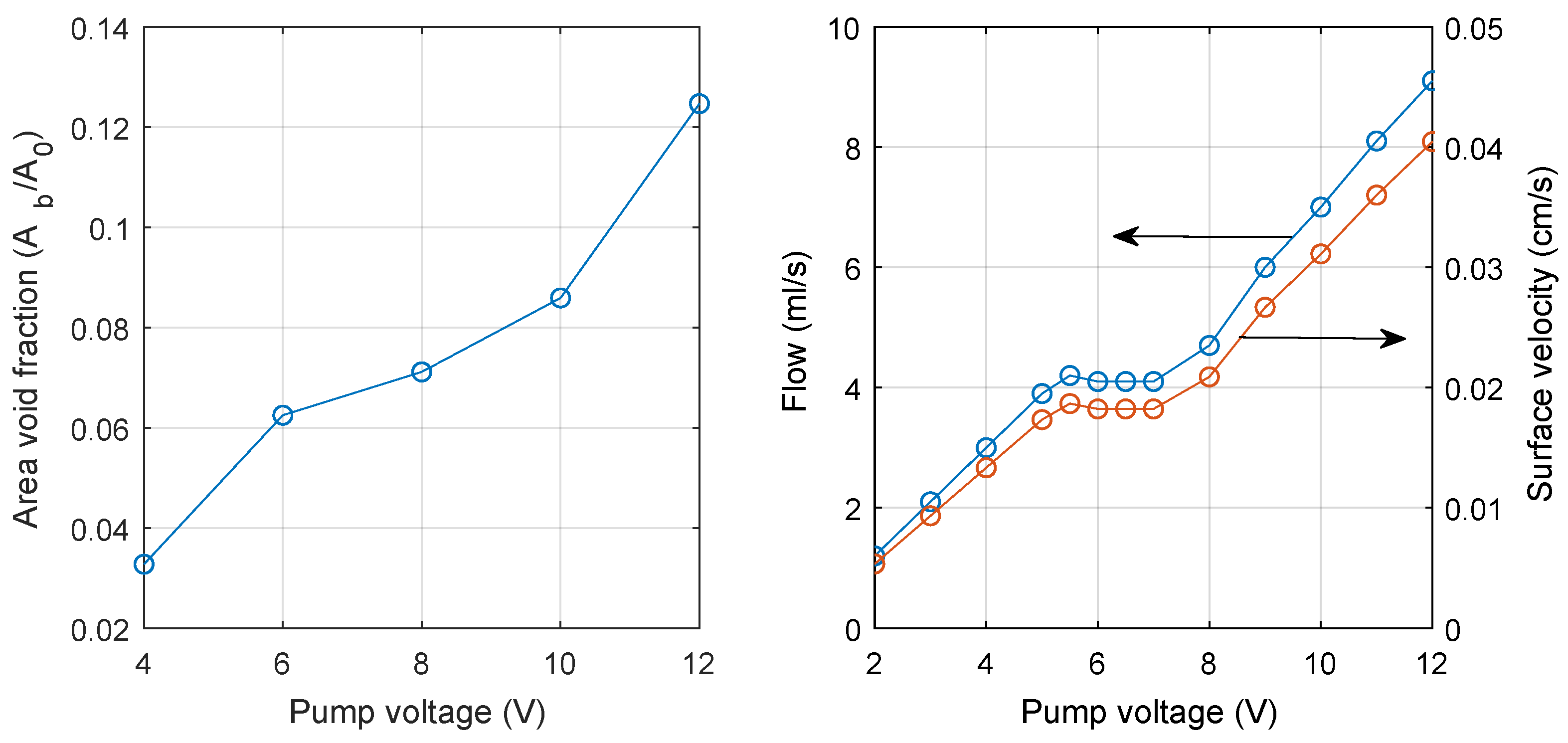

2.3. Characterization of the Bubble Column

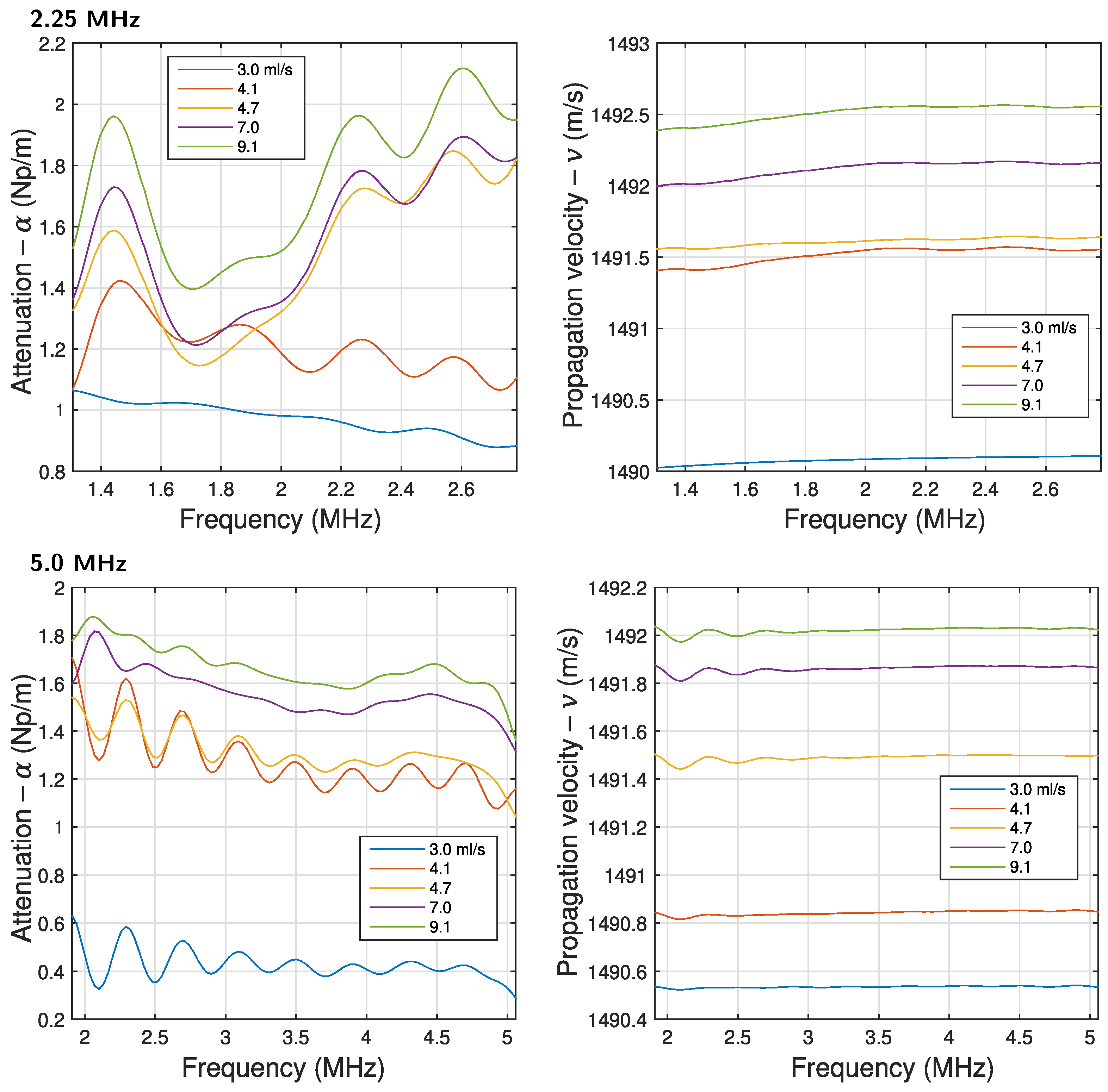

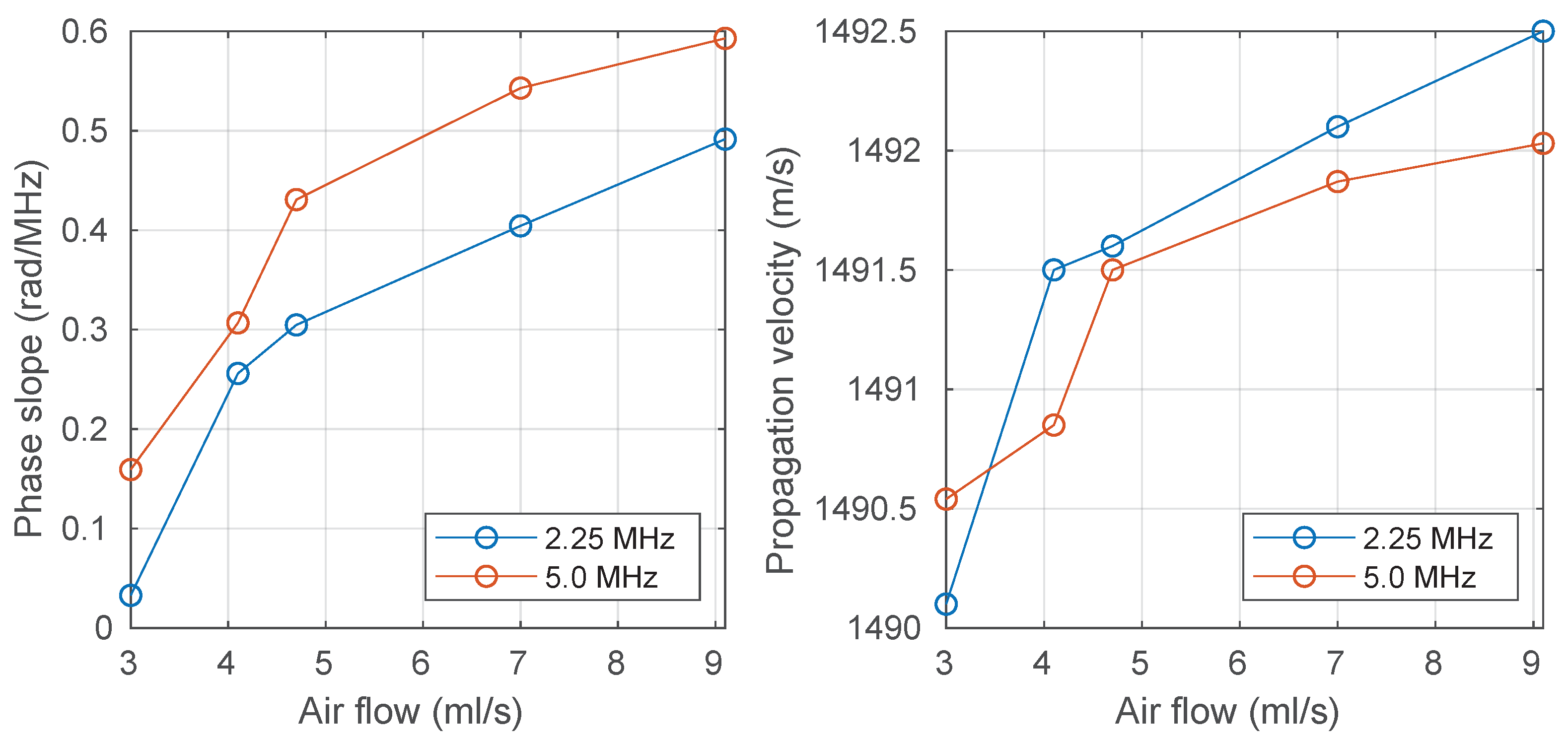

3. Results

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sokolichin, A.; Eigenberger, G.; Lapin, A. Simulation of buoyancy driven bubbly flow: Established simplifications and open questions. AIChE J. 2004, 50, 24–45. [Google Scholar] [CrossRef]

- Lain, S.; Bröder, D.; Sommerfeld, M. Experimental and numerical studies of the hydrodynamics in a bubble column. Chem. Eng. Sci. 1999, 54, 4913–4920. [Google Scholar] [CrossRef]

- Göz, M.; Laín, S.; Sommerfeld, M. Study of the numerical instabilities in Lagrangian tracking of bubbles and particles in two-phase flow. Comput. Chem. Eng. 2004, 28, 2727–2733. [Google Scholar] [CrossRef]

- Krishna, R.; van Baten, J. Mass transfer in bubble columns. Catal. Today 2003, 79–80, 67–75. [Google Scholar] [CrossRef]

- Laín, S.; Bröder, D.; Sommerfeld, M.; Göz, M. Modelling hydrodynamics and turbulence in a bubble column using the Euler–Lagrange procedure. Int. J. Multiph. Flow 2002, 28, 1381–1407. [Google Scholar] [CrossRef]

- Ambrose, S.; Hargreaves, D.M.; Lowndes, I.S. Numerical modeling of oscillating Taylor bubbles. Eng. Appl. Comput. Fluid Mech. 2016, 10, 578–598. [Google Scholar] [CrossRef]

- Etminan, A.; Muzychka, Y.S.; Pope, K. A Review on the Hydrodynamics of Taylor Flow in Microchannels: Experimental and Computational Studies. Processes 2021, 9, 870. [Google Scholar] [CrossRef]

- Asiagbe, K.S.; Fairweather, M.; Njobuenwu, D.O.; Colombo, M. Large Eddy Simulation of Microbubble Transport in Vertical Channel Flows. In Computer Aided Chemical Engineering; Espuña, A., Graells, M., Puigjaner, L., Eds.; Elsevier: Amsterdam, The Netherlands, 2017; Volume 40, pp. 73–78. [Google Scholar] [CrossRef]

- Dabiri, S.; Tryggvason, G. Heat transfer in turbulent bubbly flow in vertical channels. Chem. Eng. Sci. 2015, 122, 106–113. [Google Scholar] [CrossRef]

- Takimoto, R.Y.; Matuda, M.Y.; Oliveira, T.F.; Adamowski, J.C.; Sato, A.K.; Martins, T.C.; Tsuzuki, M.S. Comparison of Optical and Ultrasonic Methods for Quantification of Underwater Gas Leaks. IFAC-PapersOnLine 2020, 53, 16721–16726. [Google Scholar] [CrossRef]

- Abbaszadeh, M.; Alishahi, M.M.; Emdad, H. A new bubbly flow detection and quantification procedure based on optical laser-beam scattering behavior. Meas. Sci. Technol. 2020, 32, 025202. [Google Scholar] [CrossRef]

- Alméras, E.; Cazin, S.; Roig, V.; Risso, F.; Augier, F.; Plais, C. Time-resolved measurement of concentration fluctuations in a confined bubbly flow by LIF. Int. J. Multiph. Flow 2016, 83, 153–161. [Google Scholar] [CrossRef]

- Ma, Y.; Muilwijk, C.; Yan, Y.; Zhang, X.; Li, H.; Xie, T.; Qin, Z.; Sun, W.; Lewis, E. Measurement of Bubble Flow Frequency in Chemical Processes Using an Optical Fiber Sensor. In Proceedings of the 2018 IEEE SENSORS, New Delhi, India, 28–31 October 2018; pp. 1–4. [Google Scholar] [CrossRef]

- Bröder, D.; Sommerfeld, M. Planar shadow image velocimetry for the analysis of the hydrodynamics in bubbly flows. Meas. Sci. Technol. 2007, 18, 2513. [Google Scholar] [CrossRef]

- Shamoun, B.; Beshbeeshy, M.E.; Bonazza, R. Light extinction technique for void fraction measurements in bubbly flow. Exp. Fluids 1999, 26, 16–26. [Google Scholar] [CrossRef]

- Fu, Y.; Liu, Y. Development of a robust image processing technique for bubbly flow measurement in a narrow rectangular channel. Int. J. Multiph. Flow 2016, 84, 217–228. [Google Scholar] [CrossRef]

- Karn, A.; Ellis, C.; Arndt, R.; Hong, J. An integrative image measurement technique for dense bubbly flows with a wide size distribution. Chem. Eng. Sci. 2015, 122, 240–249. [Google Scholar] [CrossRef]

- Lau, Y.; Möller, F.; Hampel, U.; Schubert, M. Ultrafast X-ray tomographic imaging of multiphase flow in bubble columns—Part 2: Characterisation of bubbles in the dense regime. Int. J. Multiph. Flow 2018, 104, 272–285. [Google Scholar] [CrossRef]

- Cabrera-López, J.J.; Velasco-Medina, J. Structured Approach and Impedance Spectroscopy Microsystem for Fractional-Order Electrical Characterization of Vegetable Tissues. IEEE Trans. Instrum. Meas. 2020, 69, 469–478. [Google Scholar] [CrossRef]

- George, D.L.; Iyer, C.O.; Ceccio, S.L. Measurement of the Bubbly Flow Beneath Partial Attached Cavities Using Electrical Impedance Probes. J. Fluids Eng. 1999, 122, 151–155. [Google Scholar] [CrossRef]

- Huang, C.; Lee, J.; Schultz, W.W.; Ceccio, S.L. Singularity image method for electrical impedance tomography of bubbly flows. Inverse Probl. 2003, 19, 919. [Google Scholar] [CrossRef][Green Version]

- de Moura, B.F.; Martins, M.F.; Palma, F.H.S.; da Silva, W.B.; Cabello, J.A.; Ramos, R. Nonstationary bubble shape determination in Electrical Impedance Tomography combining Gauss–Newton Optimization with particle filter. Measurement 2021, 186, 110216. [Google Scholar] [CrossRef]

- Zhu, Z.; Li, G.; Luo, M.; Zhang, P.; Gao, Z. Electrical Impedance Tomography of Industrial Two-Phase Flow Based on Radial Basis Function Neural Network Optimized by the Artificial Bee Colony Algorithm. Sensors 2023, 23, 7645. [Google Scholar] [CrossRef] [PubMed]

- Prasser, H.M.; Böttger, A.; Zschau, J. A new electrode-mesh tomograph for gas–liquid flows. Flow Meas. Instrum. 1998, 9, 111–119. [Google Scholar] [CrossRef]

- Hampel, U.; Babout, L.; Banasiak, R.; Schleicher, E.; Soleimani, M.; Wondrak, T.; Vauhkonen, M.; Lähivaara, T.; Tan, C.; Hoyle, B.; et al. A Review on Fast Tomographic Imaging Techniques and Their Potential Application in Industrial Process Control. Sensors 2022, 22, 2309. [Google Scholar] [CrossRef] [PubMed]

- Durán, A.L.; Franco, E.E.; Reyna, C.A.B.; Pérez, N.; Tsuzuki, M.S.G.; Buiochi, F. Water Content Monitoring in Water-in-Crude-Oil Emulsions Using an Ultrasonic Multiple-Backscattering Sensor. Sensors 2021, 21, 5088. [Google Scholar] [CrossRef] [PubMed]

- Allegra, J.R.; Hawley, S.A. Attenuation of Sound in Suspensions and Emulsions: Theory and Experiments. J. Acoust. Soc. Am. 1972, 51, 1545–1564. [Google Scholar] [CrossRef]

- Wu, X.; Chahine, G.L. Development of an acoustic instrument for bubble size distribution measurement. J. Hydrodyn. Ser. B 2010, 22, 330–336. [Google Scholar] [CrossRef]

- Pinfield, V.J. Advances in ultrasonic monitoring of oil-in-water emulsions. Food Hydrocoll. 2014, 42, 48–55. [Google Scholar] [CrossRef]

- de Jong, N.; Emmer, M.; van Wamel, A.; Versluis, M. Ultrasonic characterization of ultrasound contrast agents. Med. Biol. Eng. Comput. 2009, 47, 861–873. [Google Scholar] [CrossRef] [PubMed]

- Kremkau, F.W.; Gramiak, R.; Carstensen, E.L.; Shah, P.M.; Kramer, D.H. Ultrasonic detection of cavitation at catheter tips. Am. J. Roentgenol. 1970, 110, 177–183. [Google Scholar] [CrossRef]

- Nishi, R. Ultrasonic detection of bubbles with doppler flow transducers. Ultrasonics 1972, 10, 173–179. [Google Scholar] [CrossRef]

- Baroni, D.B.; Filho, J.S.C.; Lamy, C.A.; Bittencourt, M.S.Q.; Pereira, C.M.N.A.; Motta, M.S. Determination of size distribution of bubbles in a ubbly column two-phase flows by ultrasound and neural networks. In Proceedings of the 2011 International Nuclear Atlantic Conference—INAC 2011, Brazzilian Asiciation of Nuclear Engineering—ABEN, Belo Horizonte, MG, Brazil, 24–28 October 2011. [Google Scholar]

- Cents, A.H.G. Mass Transfer and Hydrodynamics in Stirred Gas-Liquid-Liquid Contactors. Ph.D. Thesis, Universiteit Twente, Enschede, The Netherlands, 2003. [Google Scholar]

- Djekoune, A.O.; Messaoudi, K.; Amara, K. Incremental circle hough transform: An improved method for circle detection. Optik 2017, 133, 17–31. [Google Scholar] [CrossRef]

- Lubbers, J.; Graaff, R. A simple and accurate formula for the sound velocity in water. Ultrasound Med. Biol. 1998, 24, 1065–1068. [Google Scholar] [CrossRef] [PubMed]

- Del Grosso, V.A.; Mader, C.W. Speed of Sound in Pure Water. J. Acoust. Soc. Am. 1972, 52, 1442–1446. [Google Scholar] [CrossRef]

- Reyna, C.A.; Franco, E.E.; Tsuzuki, M.S.; Buiochi, F. Water content monitoring in water-in-oil emulsions using a delay line cell. Ultrasonics 2023, 134, 107081. [Google Scholar] [CrossRef]

- Franco, E.E.; Reyna, C.A.B.; Durán, A.L.; Buiochi, F. Ultrasonic Monitoring of the Water Content in Concentrated Water–Petroleum Emulsions Using the Slope of the Phase Spectrum. Sensors 2022, 22, 7236. [Google Scholar] [CrossRef]

| Transducer | (MHz) | (mm) | BW ( dB) | (mm) | (degree) |

|---|---|---|---|---|---|

| Krautkrame 242–280 | |||||

| Krautkrame 254–360 | 24 | 486 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Franco, E.E.; Henao Santa, S.; Cabrera, J.J.; Laín, S. Air Flow Monitoring in a Bubble Column Using Ultrasonic Spectrometry. Fluids 2024, 9, 163. https://doi.org/10.3390/fluids9070163

Franco EE, Henao Santa S, Cabrera JJ, Laín S. Air Flow Monitoring in a Bubble Column Using Ultrasonic Spectrometry. Fluids. 2024; 9(7):163. https://doi.org/10.3390/fluids9070163

Chicago/Turabian StyleFranco, Ediguer Enrique, Sebastián Henao Santa, John Jairo Cabrera, and Santiago Laín. 2024. "Air Flow Monitoring in a Bubble Column Using Ultrasonic Spectrometry" Fluids 9, no. 7: 163. https://doi.org/10.3390/fluids9070163

APA StyleFranco, E. E., Henao Santa, S., Cabrera, J. J., & Laín, S. (2024). Air Flow Monitoring in a Bubble Column Using Ultrasonic Spectrometry. Fluids, 9(7), 163. https://doi.org/10.3390/fluids9070163