Fully Coupled Fluid–Structure Interaction with Heat Transfer Effects in an Adaptive NACA Airfoil

Abstract

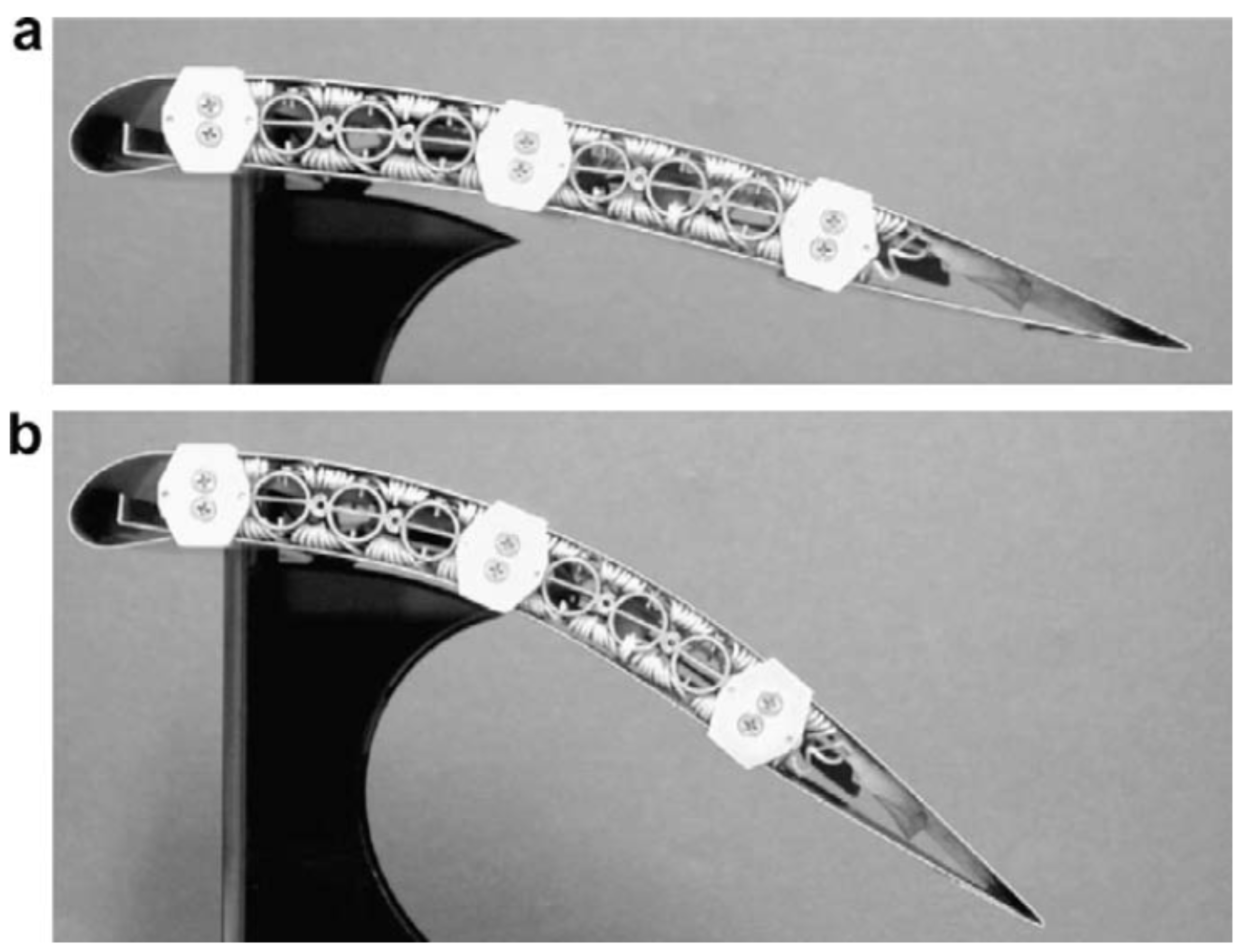

1. Introduction

2. Materials and Methods

2.1. Assumptions

2.2. Sequence of Phenomena Coupling

2.3. Governing Equations

2.3.1. Solid Mechanics

2.3.2. Fluid Flow

2.3.3. Energy

- Fluid phase f:

- Solid phase s:with representing the temperature of the s phase, representing the averaged temperature of the f phase (see Figure 2), representing the nominal power feed to the SMA wire, representing the power related to latent heat due to the martensite-to-austenite transformation, representing the volume of the s phase 1, and and with the usual meanings.

2.4. Boundary Conditions and Couplings

- SMA wire, or solid phase s1: prescribed power determining the volumetric force :

- Embedding airfoil, or solid phase s2: the solid phase is structurally free everywhere, with the exception of the leading edge, which has a fixed constraint:Additionally, the volumetric force in the embedding airfoil is given by the inherent external force or aerodynamic force (due to FSI effects) supplied to , the volume of the s phase 2 (see Figure 2):implying that .

- Air–free-stream boundary: the control volume of fluid phase is very long along x and wide along y with respect to the airfoil length and thickness, respectively (see Figure 2). Therefore, the air is issued to the control volume with prescribed conditionsalong with a 15% free-stream turbulence intensity exercised for the application at stake.

- Solid–fluid interface: thermal continuity and no-slip, requiringrespectively, along with the usual conditions for the chosen turbulence paradigm, again left unreported here for the sake of brevity. The thermal continuity condition allows to solve the temperature field simultaneously in both the solid and fluid phases in a conjugate fashion, i.e., with no need to impose a convective heat flux (based on a simplistic heat transfer coefficient at the solid–fluid interface).

- Outflow boundaries: outlet conditions requiringalong with the usual conditions for the chosen turbulence paradigm, again left unreported here for the sake of brevity.

- Thermal FSI coupling: coupling between solid mechanics and fluid mechanics meshes is imposed through the mutual geometry change, whose numerical treatment is presented next. The structural and fluid problems are defined and solved in their respective phases only, whereas the thermal problem is solved in both phases.

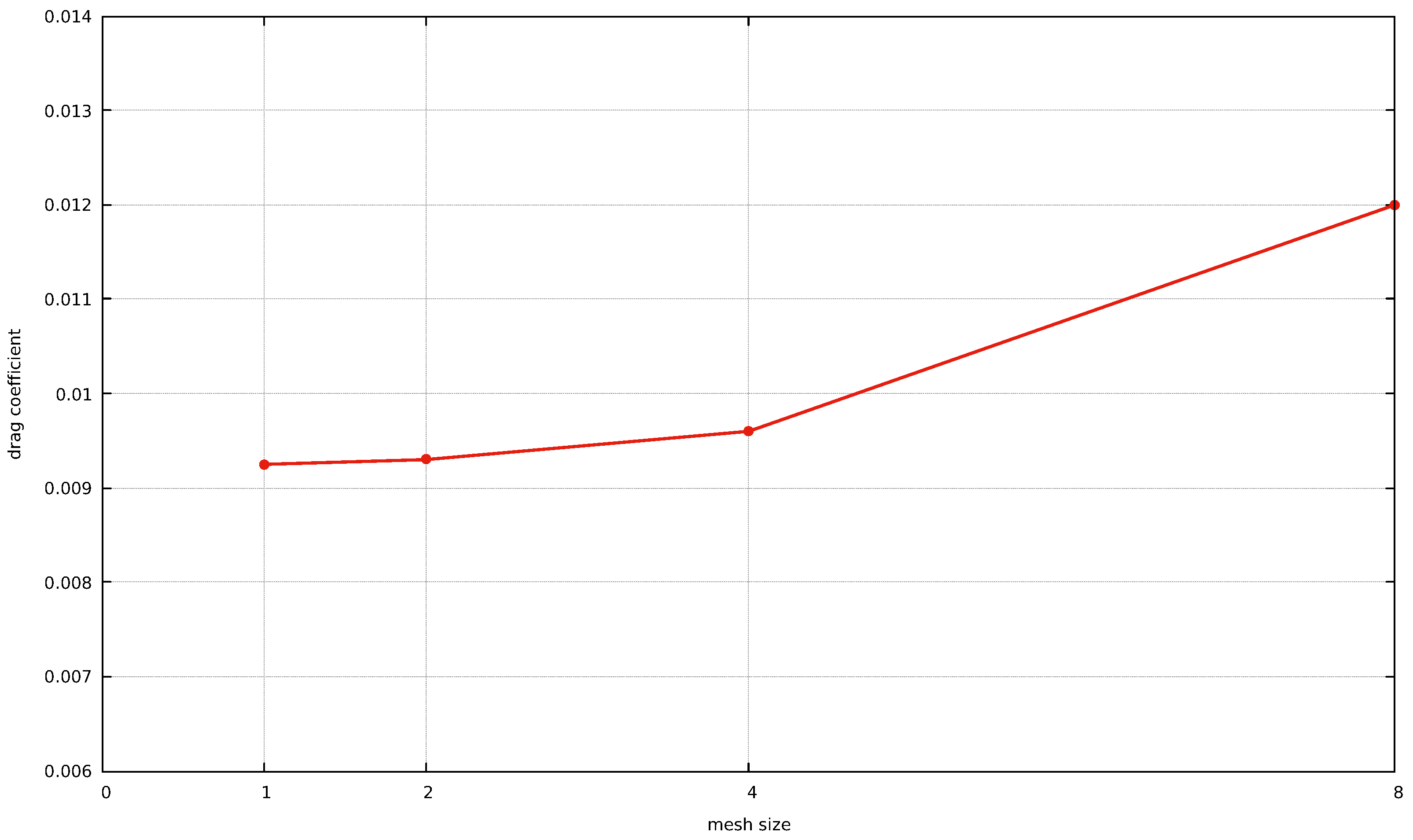

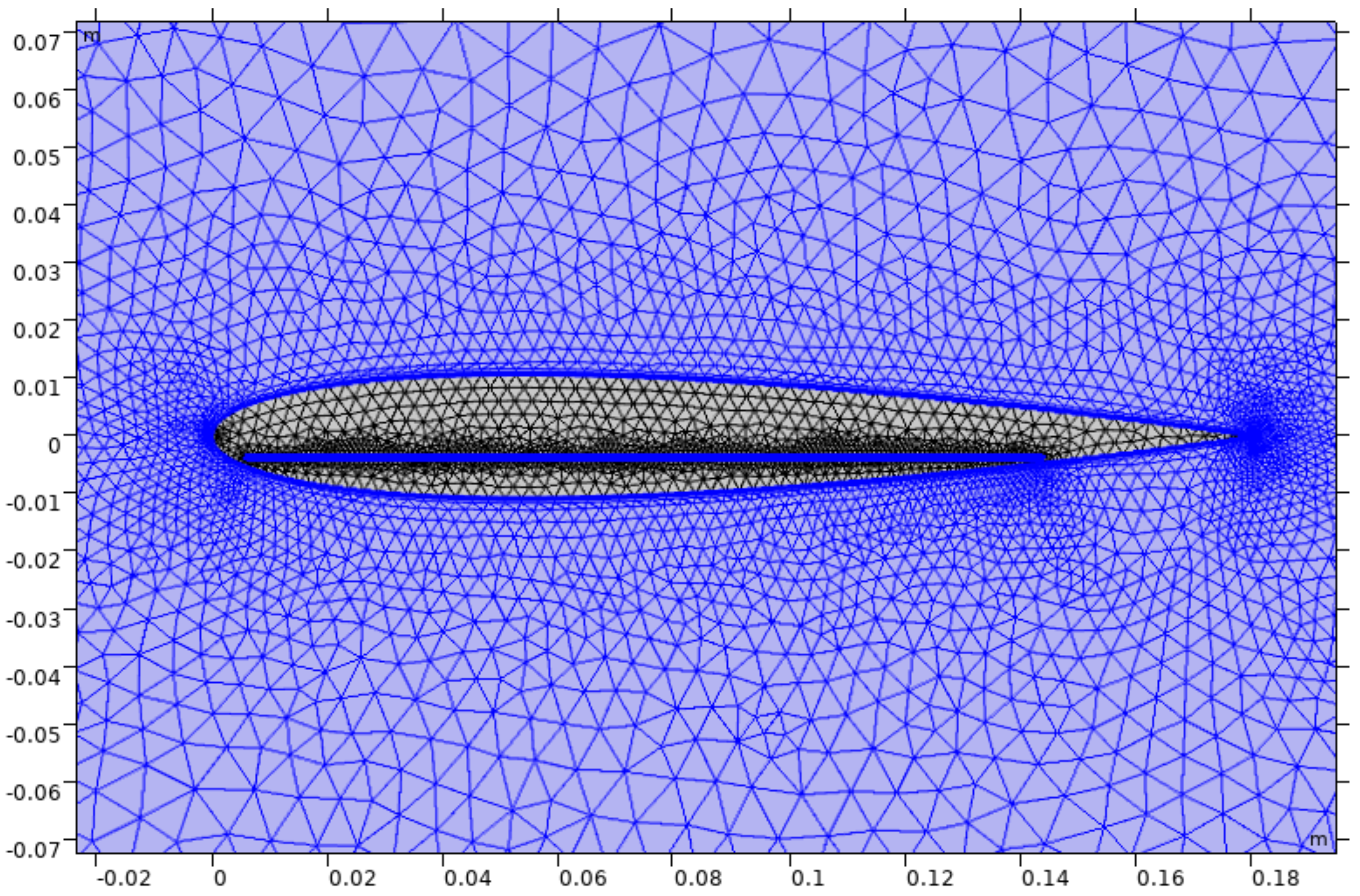

2.5. Numerical Method

2.6. FSI Treatment

2.7. Overall Computational Remarks

3. Results and Discussion

3.1. Explored Variables Space and Auxiliary Definitions

3.2. Comparison with the Available Literature for an Airfoil with No Power Feed

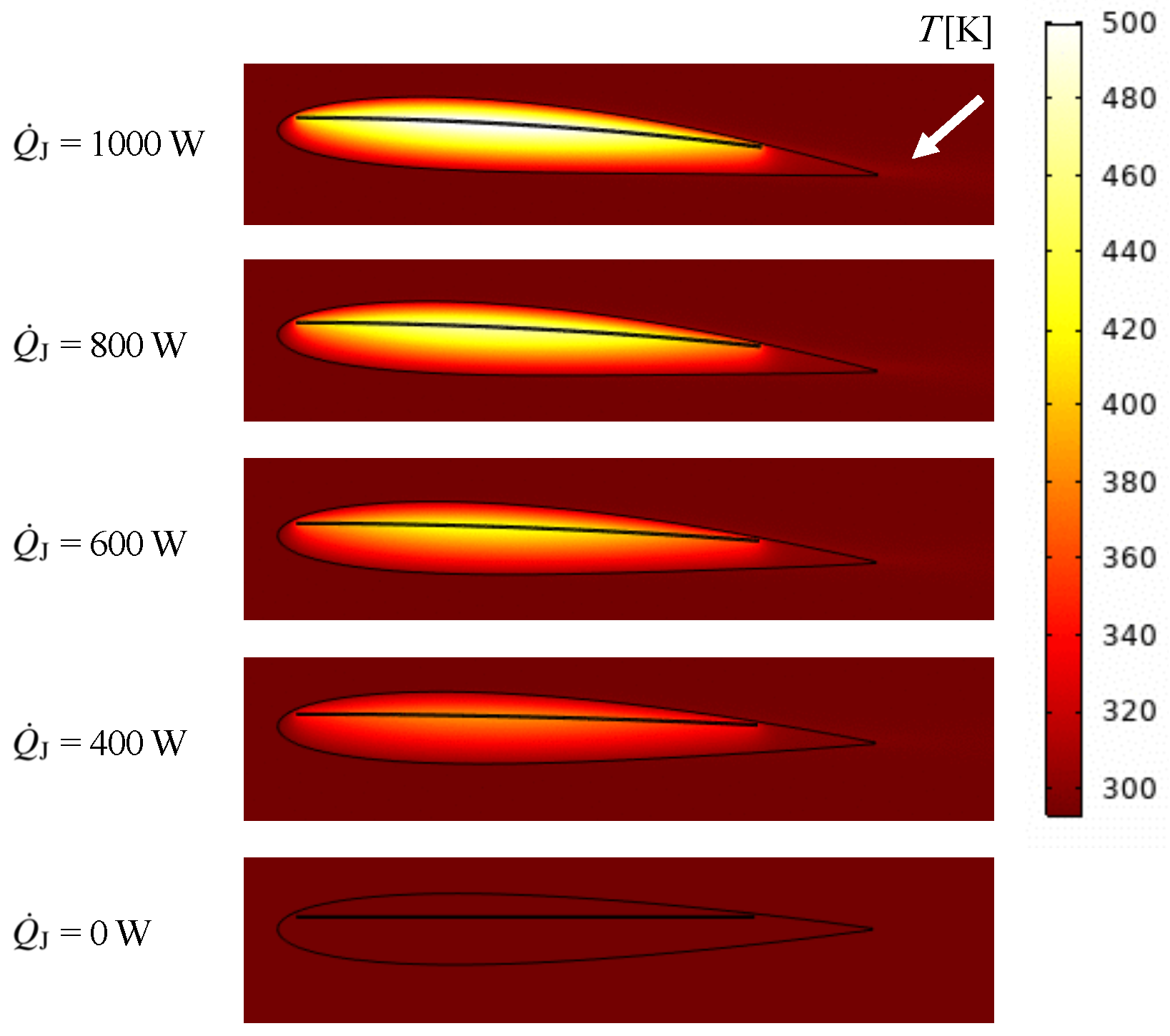

3.3. Temperature Distributions

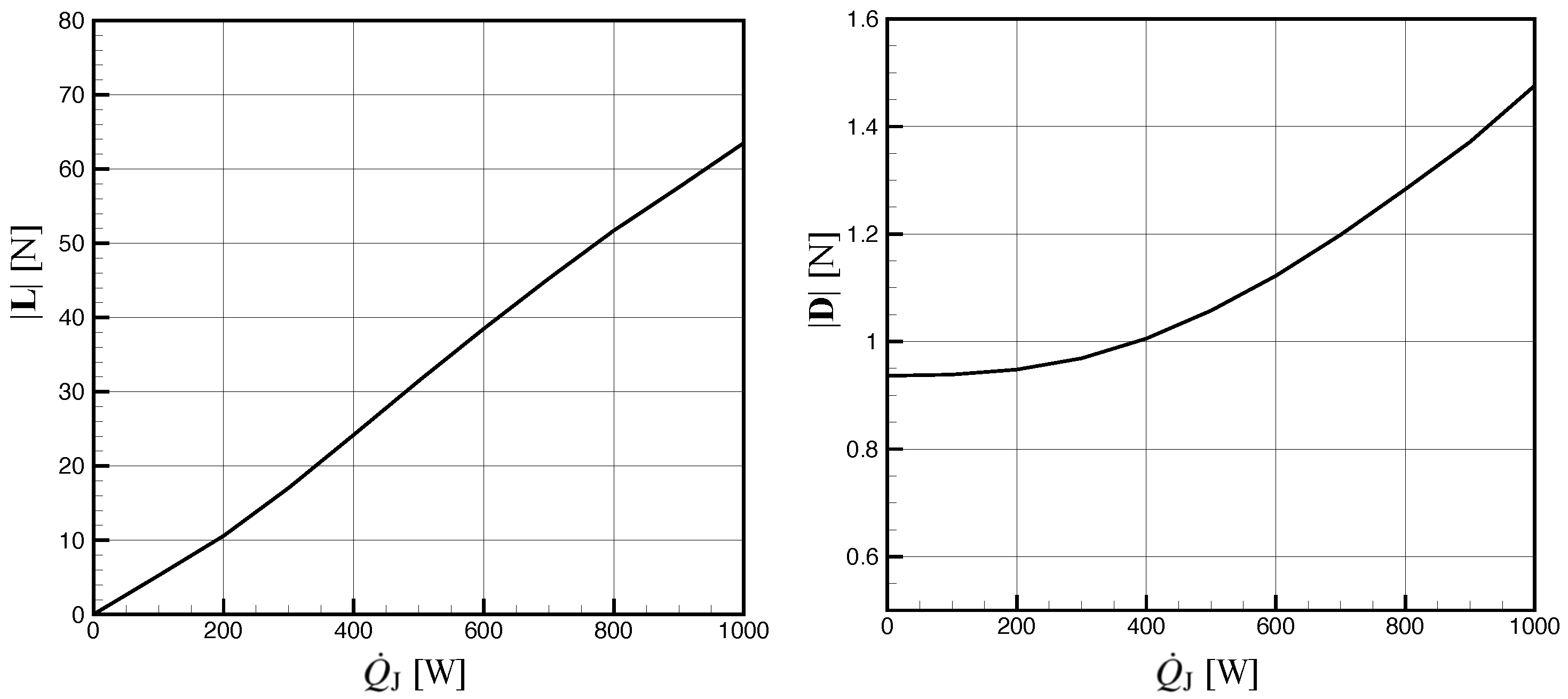

3.4. Air Velocity Distributions, Lift and Drag

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| ALE | Arbitrary Lagrangian–Eulerian |

| FEM | Finite element method |

| FSI | Fluid–structure interaction |

| NACA | National Advisory Committee for Aeronautics |

| PP–PE | polypropylene–polyethylene |

| SMA | Shape memory alloy |

| TASC | Thermally activated shape-changing |

References

- Pern, N.J.; Jacob, J.D. Aerodynamic flow control using shape adaptive surfaces. In Proceedings of the 1999 ASME Design Engineering Technical Conferences; ASME: New York, NY, USA, 1999; pp. 1–8. [Google Scholar]

- Li, D.; Zhao, S.; Da Ronch, A.; Xiang, J.; Drofelnik, J.; Li, Y.; Zhang, L.; Wu, Y.; Kintscher, M.; Monner, H.P.; et al. A review of modelling and analysis of morphing wings. Prog. Aerosp. Sci. 2018, 100, 46–62. [Google Scholar] [CrossRef]

- Barbarino, S.; Flores, E.S.; Ajaj, R.M.; Dayyani, I.; Friswell, M.I. A review on shape memory alloys with applications to morphing aircraft. Smart Mater. Struct. 2014, 23, 063001. [Google Scholar] [CrossRef]

- Daynes, S.; Weaver, P.M. Review of shape-morphing automobile structures: Concepts and outlook. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2013, 227, 1603–1622. [Google Scholar] [CrossRef]

- Sofla, A.Y.N.; Meguid, S.A.; Tan, K.T.; Yeo, W.K. Shape morphing of aircraft wing: Status and challenges. Mater. Des. 2010, 31, 1284–1292. [Google Scholar] [CrossRef]

- Mayda, E.A.; Van Dam, C.P.; Nakafuji, D. Computational investigation of finite width microtabs for aerodynamic load control. In Proceedings of the 43rd AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 10–13 January 2005; pp. 1185–1198. [Google Scholar]

- Bashir, M.; Lee, C.F.; Rajendran, P. Shape memory materials and their applications in aircraft morphing: An introspective study. J. Eng. Appl. Sci. 2017, 12, 50–56. [Google Scholar]

- Bashir, M.; Rajendran, P.; Sharma, C.; Smrutiranjan, D. Investigation of smart material actuators & aerodynamic optimization of morphing wing. Mater. Today Proc. 2018, 5, 21069–21075. [Google Scholar]

- Kumar, P.K.; Lagoudas, D.C. Introduction to shape memory alloys. In Shape Memory Alloys; Springer: Berlin/Heidelberg, Germany, 2008; pp. 1–51. [Google Scholar]

- Cross, W.B.; Kariotis, A.H.; Stimler, F.J. Nitinol Characterization Study; Technical report; NASA: Pasadena, CA, USA, 1969.

- Memory Metals are Shaping the Evolution of Aviation. Available online: www.nasa.gov/feature/glenn/2019/memory-metalsare-shaping-the-evolution-of-aviation (accessed on 15 December 2022).

- Scalet, G.; Niccoli, F.; Garion, C.; Chiggiato, P.; Maletta, C.; Auricchio, F. A three-dimensional phenomenological model for shape memory alloys including two-way shape memory effect and plasticity. Mech. Mater. 2019, 136, 103085. [Google Scholar] [CrossRef]

- Elzey, D.M.; Sofla, A.Y.N.; Wadley, H.N.G. A shape memory-based multifunctional structural actuator panel. Int. J. Solids Struct. 2005, 42, 1943–1955. [Google Scholar] [CrossRef]

- Sellitto, A.; Riccio, A. Overview and future advanced engineering applications for morphing surfaces by shape memory alloy materials. Materials 2019, 12, 708. [Google Scholar] [CrossRef] [PubMed]

- Hou, G.; Wang, J.; Layton, A. Numerical methods for fluid-structure interaction – a review. Commun. Comput. Phys. 2012, 12, 337–377. [Google Scholar] [CrossRef]

- Ismail, N.I.; Zulkifli, A.H.; Talib, R.J.; Zaini, H.; Yusoff, H. Drag performance of twist morphing MAV wing. In Proceedings of the MATEC Web of Conferences; EDP Sciences: Les Ulis, France, 2016; Volume 82, p. 01004. [Google Scholar]

- MacPhee, D.W.; Beyene, A. Fluid–structure interaction analysis of a morphing vertical axis wind turbine. J. Fluids Struct. 2016, 60, 143–159. [Google Scholar] [CrossRef]

- Machairas, T.; Kontogiannis, A.; Karakalas, A.; Solomou, A.; Riziotis, V.; Saravanos, D. Robust fluid-structure interaction analysis of an adaptive airfoil using shape memory alloy actuators. Smart Mater. Struct. 2018, 27, 105035. [Google Scholar] [CrossRef]

- Barbarino, S. SMAs in Commercial Codes. In Shape Memory Alloy Engineering; Elsevier: Amsterdam, The Netherlands, 2015; pp. 193–212. [Google Scholar]

- Scholten, W.; Hartl, D.J. An Uncoupled Method for Fluid-Structure Interaction Analysis with Application to Aerostructural Design. In Proceedings of the AIAA Scitech 2020 Forum, Orlando, FL, USA, 6–10 January 2020; p. 1635. [Google Scholar]

- Caccavale, P.; Mele, B.; De Bonis, M.V.; Ruocco, G. Analysis of thermally activated fluid-structure interaction for a morphing plate immersed in turbulent flow. Int. J. Heat Mass Transf. 2022, 194, 123081. [Google Scholar] [CrossRef]

- Machado, L.G.; Lagoudas, D.C. Thermomechanical constitutive modeling of SMAs. In Shape Memory Alloys; Springer: Berlin/Heidelberg, Germany, 2008; pp. 121–187. [Google Scholar]

- Abe, K.; Kondoh, T.; Nagano, Y. A new turbulence model for predicting fluid flow and heat transfer in separating and reattaching flows – I. Flow field calculations. Int. J. Heat Mass Transf. 1994, 37, 139–151. [Google Scholar] [CrossRef]

- Lagoudas, D.C. Shape Memory Alloys: Modeling and Engineering Applications; Springer: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- COMSOL Multiphysics v.5.6; COMSOL AB: Stockholm, Sweden, 2020.

- Renaud, C.; Cros, J.M.; Feng, Z.Q.; Yang, B. The Yeoh model applied to the modeling of large deformation contact/impact problems. Int. J. Impact Eng. 2009, 36, 659–666. [Google Scholar] [CrossRef]

- Abbott, I.H.; Von Doenhoff, A.E. Theory of Wing Sections: Including a Summary of Airfoil Data; Courier Corporation: North Chelmsford, MA, USA, 2012. [Google Scholar]

- Gregory, N.; O’reilly, C.L. Low-Speed Aerodynamic Characteristics of NACA 0012 Aerofoil Section, including the Effects of Upper-Surface Roughness Simulating Hoar Frost; Number 3726; Ministry of Defence, Aeronautical Research Council: London, UK, 1970.

| [kg/m] | [W/(m K)] | E [GPa] | ||

|---|---|---|---|---|

| NiTi SMA wire (s1 phase) | 6500 | 10.8 | 0.33 | , |

| PP/PE airfoil (s2 phase) | 900 | 0.15 | 0.40 | 2.37 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Caccavale, P.; Mele, B.; Brandizzi, M.; Ruocco, G. Fully Coupled Fluid–Structure Interaction with Heat Transfer Effects in an Adaptive NACA Airfoil. Fluids 2023, 8, 39. https://doi.org/10.3390/fluids8020039

Caccavale P, Mele B, Brandizzi M, Ruocco G. Fully Coupled Fluid–Structure Interaction with Heat Transfer Effects in an Adaptive NACA Airfoil. Fluids. 2023; 8(2):39. https://doi.org/10.3390/fluids8020039

Chicago/Turabian StyleCaccavale, Paolo, Benedetto Mele, Marco Brandizzi, and Gianpaolo Ruocco. 2023. "Fully Coupled Fluid–Structure Interaction with Heat Transfer Effects in an Adaptive NACA Airfoil" Fluids 8, no. 2: 39. https://doi.org/10.3390/fluids8020039

APA StyleCaccavale, P., Mele, B., Brandizzi, M., & Ruocco, G. (2023). Fully Coupled Fluid–Structure Interaction with Heat Transfer Effects in an Adaptive NACA Airfoil. Fluids, 8(2), 39. https://doi.org/10.3390/fluids8020039