Abstract

Fluid/fluid interfaces are ubiquitous in science and technology, and hence, the understanding of their properties presents a paramount importance for developing a broad range of soft interface dominated materials, but also for the elucidation of different problems with biological and medical relevance. However, the highly dynamic character of fluid/fluid interfaces makes shedding light on fundamental features guiding the performance of the interfaces very complicated. Therefore, the study of fluid/fluid interfaces cannot be limited to an equilibrium perspective, as there exists an undeniable necessity to face the study of the deformation and flow of these systems under the application of mechanical stresses, i.e., their interfacial rheology. This is a multidisciplinary challenge that has been evolving fast in recent years, and there is currently available a broad range of experimental and theoretical methodologies providing accurate information of the response of fluid/fluid interfaces under the application of mechanical stresses, mainly dilational and shear. This review focused on providing an updated perspective on the study of the response of fluid/fluid interfaces to dilational stresses; to open up new avenues that enable the exploitation of interfacial dilational rheology and to shed light on different problems in the interest of science and technology.

1. Introduction

Complex fluid/fluid interfaces are ubiquitous, be it in nature, industry, or academia. For instance, they can be exploited to provide structure to different products, including foam and emulsion-based items. Moreover, they are present in a broad range of chemical processes, including liquid-liquid extraction, froth flotation, wastewater treatment, or tertiary oil recovery. On the other hand, fluid/fluid interfaces can be exploited as platforms for nanostructured material fabrication, or as models to elucidate problems with biological and medical relevance [1,2,3,4,5]. Therefore, it may be expected that most of the fluid/fluid interfaces with technological or scientific relevance involve systems operating under dynamic conditions, and hence, the understanding of the dynamic and mechanical properties of interfacial layers laden at fluid/fluid interfaces is of paramount importance for living systems, foods, personal care products, and the environment [6].

The rheological performance of fluid/fluid interfaces can be modulated almost at will, to design soft interface-dominated materials for specific applications [7,8]. This makes understanding the deformation and flow of fluid/fluid interfaces under the application of mechanical stresses, i.e., the rheological properties of the interface, a matter of key importance for science and technology [9,10]. For instance, the understanding and control of the rheological response of fluid/fluid interfaces plays a very important role in the control of emulsion stability [11,12], foamability and foam stability (resistance against drainage) [13], lung surfactant performance [4,14], aerosol formation [15], tear film stability [16,17], encapsulation process [18], coffee ring formation [19], tertiary oil recovery [20], or remote sensing [21,22].

The description of the rheological response of 2D systems (or more correctly, quasi-2D systems), i.e., layers of surface-active compounds confined at fluid/fluid interfaces, is not always trivial. In fact, interfacial rheology relies on the confinement of the applied deformation within the xy plane, which requires to introduce specific modification to the classical rheological formalism used for the study of the mechanical response of bulk systems. This is of a paramount importance because, in most of the cases, the small thickness of fluid/fluid interfaces makes it difficult to decouple the pure interfacial rheological response from the contribution associated with the response of the adjacent bulk phases to the applied stress. Therefore, it is necessary to develop suitable experimental and theoretical methodologies enabling such decoupling [23,24]. This is significant because the combination of experimental and theoretical tools may significantly contribute to the impact of the stress boundary conditions on the behavior and breakup of thin films [25].

Despite the importance of the mechanical properties of fluid/fluid interfaces for many technological and scientific purposes, there is a broad range of features that yet remains unclear, and deserving of additional research effort. Therefore, this review is focused on providing an updated perspective of the current understanding of the performance of fluid/fluid interfaces under the application of dilational stresses. This is important because dilational rheology plays an essential role in a broad range of scientific and technological features, ranging from the formation and stability of foams to the respiratory cycle, and from tertiary oil recovery to demulsification processes [20,26,27,28]. However, the study of the performance of interfaces under dilational stresses is particularly challenging because it requires one to deconvolute the changes in thermodynamic properties associated with the changes in the interfacial concentration and the intrinsic compressional viscoelasticity, which is not always easy [29]. To effectively conduct a study of the dilational rheology of fluid/fluid interfaces, the first part of the review is focused on the description of the physical bases governing the response of fluid/fluid interfaces upon the application of different mechanical stresses. Then, the most fundamental aspects of the interfacial behavior under the application of a dilational stress are discussed. Afterward, a discussion of the available experimental and theoretical tools for studying the dilational rheology of fluid/fluid interfaces is included. Finally, the effect of the non-linear character of the dilational deformation on the rheological response of fluid/fluid interfaces is briefly discussed.

2. Interfacial Rheology: Foundations

The adsorption of soluble species to the interface of a bulk solution, or the direct deposition of insoluble surface-active species at the interface, leads to the formation of the so-called Gibb and Langmuir monolayers, respectively. The formation of an interfacial layer at the fluid/fluid interface leads to the decrease of the interfacial tension, γ, in relation to that corresponding to the bare interface, γ0. However, the use of the interfacial tension only provides an equilibrium description of the true picture of the interface and, as previously mentioned, this is not enough in most practical applications of fluid/fluid interfaces. In fact, fluid/fluid interfaces with technological and scientific relevance are commonly subject to external mechanical perturbations that result in a modification of their size or shape [30]. The understanding of the response of fluid/fluid interfaces to mechanical processes is essential, because even the simplest deformation processes can yield to very complex responses, including multiple dynamic processes or deformation mixing different interfacial modes [31].

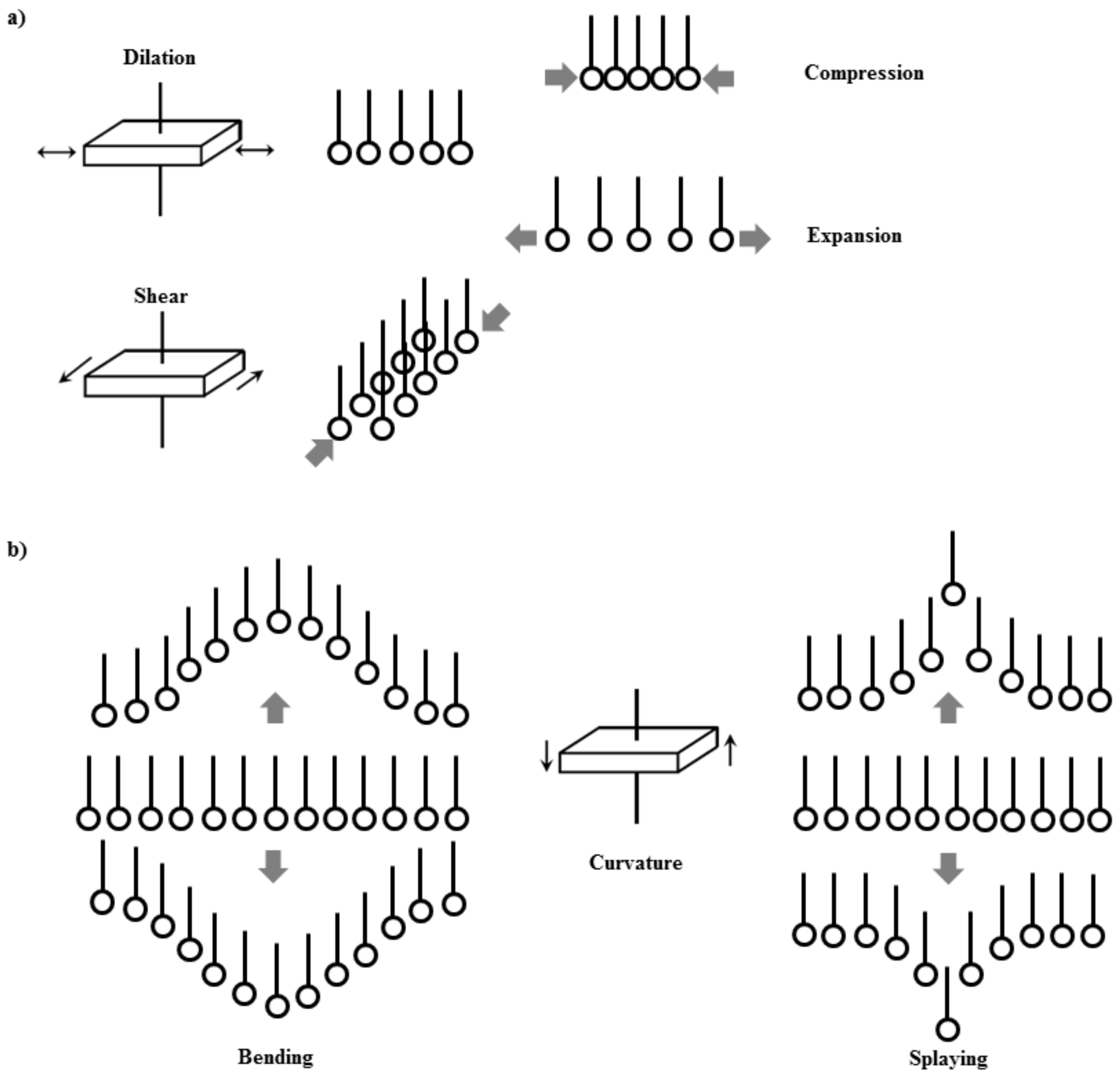

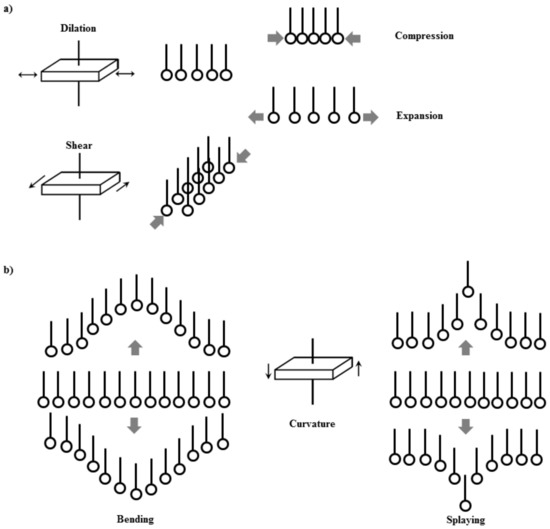

The interfacial response against perturbations that modify the size of the interface, without affecting its shape, can be defined in terms of the dilational elasticity and viscosity; whereas, the modification of the interfacial shape without varying the dimensions of the interface, i.e., at constant size, is described in terms of the shear elasticity and viscosity [30,32]. Moreover, under specific stress conditions, fluid/fluid interface can undergo out-of-plane deformations. These out-of-plane deformation modes lead to a displacement of the whole monolayer, or parts of the monolayer, in relation to the equilibrium position of the interfacial plane (splaying or bending), resulting in the emergence of different phenomena, e.g., buckling of the monolayer, expulsion of material into the bulk, or the formation of multilayers [33]. These transverse out-of-plane deformations are restored under the action of interfacial-tension-driven forces, whereas in-plane modes (shear and dilation) are directly restored by interfacial tension gradients associated with the interfacial concentration [24,34]. The interfacial tension gradients can emerge due to different factors, including the interfacial convection of adsorbed species or the heterogeneity of the adsorbed layers. However, the origin of the interfacial tension gradients occurring during interfacial rheology experiments is found in the externally triggered modification of properties, e.g., interfacial concentration, directly affecting the interfacial tension. This drives the Marangoni flows trying to restore interfacial equilibrium [31]. Figure 1 shows a sketch representing the in-plane and out-of-plane deformation modes that can occur in fluid/fluid interfaces under the action of mechanical stresses.

Figure 1.

Sketch of different surface relaxation modes: (a) in-plane-modes (dilation and shear) and (b) out-of-plane modes (bending and splaying). Reprinted from Maestro and Guzmán [34], with permission under Open access CC BY 4.0 license, https://creativecommons.org/licenses/by/4.0/ (accessed 22 August 2022).

It should be noted that, in most of cases, the out-of-plane deformations can be rigorously modeled, whereas the in-plane modes have been commonly analyzed for long time using very simplified models that may be considered generalizations of the bulk behavior to the interface, which neglects some subtle aspects of the interfacial rheology, e.g., the existence of a finite dilational modulus, which is not considered in bulk models, designed for incompressible fluids or the role of the curvature modes [10,35]. Moreover, in most cases, the different rheological modes are coupled, and hence, the determination of the real (storage modulus) and imaginary (loss modulus) components of the corresponding viscoelastic moduli is not always trivial. This can be understood considering that the origin on the interfacial property gradient can arise from different processes; e.g., interfacial tension gradients can be originated by a gradient of the interfacial concentration, or by the convective transport that generates a concentration gradient. This makes it difficult, in some cases, to independently obtain the different modes of the rheological response from a single experiment [31]. However, this coupling is of interest in specific cases, e.g., for obtaining dilational moduli from experiments involving capillary waves [36]. Moreover, the coupling between the interfacial response and the mechanical properties of the adjacent fluids or their structure may introduce additional problems for a proper evaluation of the viscoelastic moduli [23].

The rheological analysis of interfaces requires the use of a continuum mechanical approach. This assumes that bulk flows can be described in terms of the conservation equations for mass, momentum, and energy, and specific coupling conditions. This leads to the definition of the interface as a 2D dividing surface located between two adjacent fluid phases (“sharp interface” framework) [10]. Considering the above picture, it is possible to define the Cauchy interfacial stress tensor σs as a combination of two contributions: (i) the interfacial energy, which accounts for the energetic cost associated with the presence of a fluid interface of a fixed area, and provides information of any process changing the interfacial concentration and affecting the interfacial tension, and (ii) the Marangoni stresses emerging as a result of spatial interfacial tension gradients [9,10]. Thus, it is possible to define the interfacial stress tensor according to the following expression.

where δs is the surface unit tensor, and is the interfacial tension, which is a state variable depending on the interfacial concentration and temperature. The second contribution to the interfacial stress tensor is the anisotropic tensor or interfacial extra stress (Τij), and accounts for the energy required to deform the interface [1,37]. The surface stress tensor can be considered as a 2D second-order symmetric and tangential tensor embedded in 3D space [9].

Considering a purely viscous fluid/fluid interface, it is possible to provide a definition of the anisotropic tensor in terms of the Boussinesq–Scriven model [9]:

where and are the interfacial dilational and shear viscosities, respectively. is the interfacial gradient operator, v is the velocity vector on the interface, and is the interfacial rate-of-deformation tension [38]. In general, the Boussinesq–Scriven model is used for defining the rheological properties of fluid/fluid interfaces due to the viscoelastic character of most fluid/fluid interfaces [39].

In the case of a purely elastic fluid/fluid interface, it is possible to define the anisotropic tensor by a linear elastic model, according to the following expression (only valid for infinitely small deformations) [10]:

with and being the interfacial dilational and shear elasticity, respectively; the displacement vector on the interface; and the interfacial infinitesimal strain tensor. It should be noted that bending stresses can also play a very important role under specific conditions, e.g., densely packed particle-laden fluid/fluid interfaces. However, for simplicity they are commonly not included [9].

The description of elastic interfaces against larger stresses requires the introduction of a finite strain tensor. This is possible by separating the dilational and shear contributions in an interfacial elastic stress described by the following expression [40]:

where the deformations are defined by the left-Cauchy-Green interfacial strain tensor , and is the relative area deformation, i.e., the ratio between the instantaneous interfacial area and the interfacial area in a reference state. The combination of the two limit cases, i.e., the Newtonian and the quasi-linear neo-Hookean, is essential for a realistic description of real fluid/fluid interfaces, where viscoelasticity is of a paramount importance [9].

3. Interfacial Dilational Rheology: General Aspects

The determination of the response of interfaces against dilation offers different experimental and theoretical challenges that are not present when the properties against shear stresses are evaluated. In fact, the application of isotropic dilational stresses to the interface, without any shear influence, is very difficult [9,41]. Moreover, the change in the interfacial area is associated with the change in the interfacial concentration of the surface-active molecules existing at the interface, which yields a change in the state variable, i.e., the interfacial tension. On the other hand, when soluble surface active molecules are concerned, the modification of the interfacial concentration may be accompanied by exchange processes involving the transference of molecules between the interface and the bulk, which introduces, in many cases, additional relaxation processes to the problem [9]. In fact, the ability of surface molecules and active soluble molecules to diffuse (diffusivity) from the adjacent fluid phases to the interface, and from the interface into the adjacent fluid phases as result of the modification of the interfacial area, can originate surface tension changes which are counteracted by the Marangoni flows, aimed toward re-establishing the interfacial equilibrium.

The application of an infinitesimal uniaxial mechanical perturbation to a fluid/fluid interface leads to a small change of the surface area, δA, which induces a time dependence modification of the interfacial pressure by a δΠ quantity (with Π being the interfacial pressure defined as , and the interfacial tension of a fluid/fluid interface loaded with surface active molecules). This change strongly emerges dependent on the timescale probed during the specific experiment, and can be approximated according to the following expression:

where u(t) and E(t) account for the temporal dependence of the compressional strain and dilational viscoelastic modulus, respectively, and Π(t) and Π0 account for the temporal evolution of the interfacial pressure and the initial interfacial pressure, respectively. Thus, it possible to define the time evolution of the viscoelastic dilational modulus in terms of the following expression:

and that corresponding to the compressional strain as:

From an experimental perspective, the dilational rheology measurements rely on the application of a time-dependent stress to the interface, and the evaluation of the time-dependent change of the interfacial tension. These type of measurements allow for the evaluation of the ratio between the temporal evolution of the interfacial tension and the time-dependent stress, which is defined as the complex dilational viscoelastic modulus [42]:

where is the Fourier transform function, is the time evolution of the interfacial tension, is the time evolution surface area, and ω is the angular frequency. The complex modulus can be split into its real (Es) and imaginary components (Ev), which correspond to the storage and loss moduli, respectively [43,44]. Assuming an oscillatory deformation of small amplitude and a fixed frequency ω, it is possible to define the complex dilational viscoelastic modulus as complex magnitude according to the following expression:

with the loss moduli allowing one to calculate the dilational viscosity , and the storage modulus defining the dilational elasticity. It should be stressed that the constitutive viscoelastic parameters and are functions of ω. Therefore, they provide information about the time-dependent response of the system subject to small perturbations of the interfacial area, playing a central role in probing the interfacial dynamics of adsorbed films.

The definition of the viscoelastic interfacial dilational modulus accounts for a change in the applied stress as a result of the adsorption/desorption state of the molecules and the interfacial structure. Thus, interfacial area changes can promote different relaxation processes, with different characteristic timescales, that are associated with the different mechanisms involved in reestablishing the equilibrium state of the interface after the dilational deformation [45,46,47].

For fluid layers under equilibrium condition, or when the layers are disturbed following a quasi-static path (), the interfacial dilation forces an instantaneous modification of the interfacial concentration (, and it is possible to define a limit value for the dynamic modulus at zero frequency. This is the so-called static modulus, which is given by the Gibbs elasticity ε0, defined as:

Hence, this apparent elasticity can be considered a result of the deformation-induced change in the interfacial concentration (), which in turn modifies the interfacial tension. This magnitude can be obtained from the relative slope of the equilibrium isotherm [30]. According to the above discussion, it is possible to define a dilational viscosity at zero frequency in terms of the frequency independent Newtonian limit:

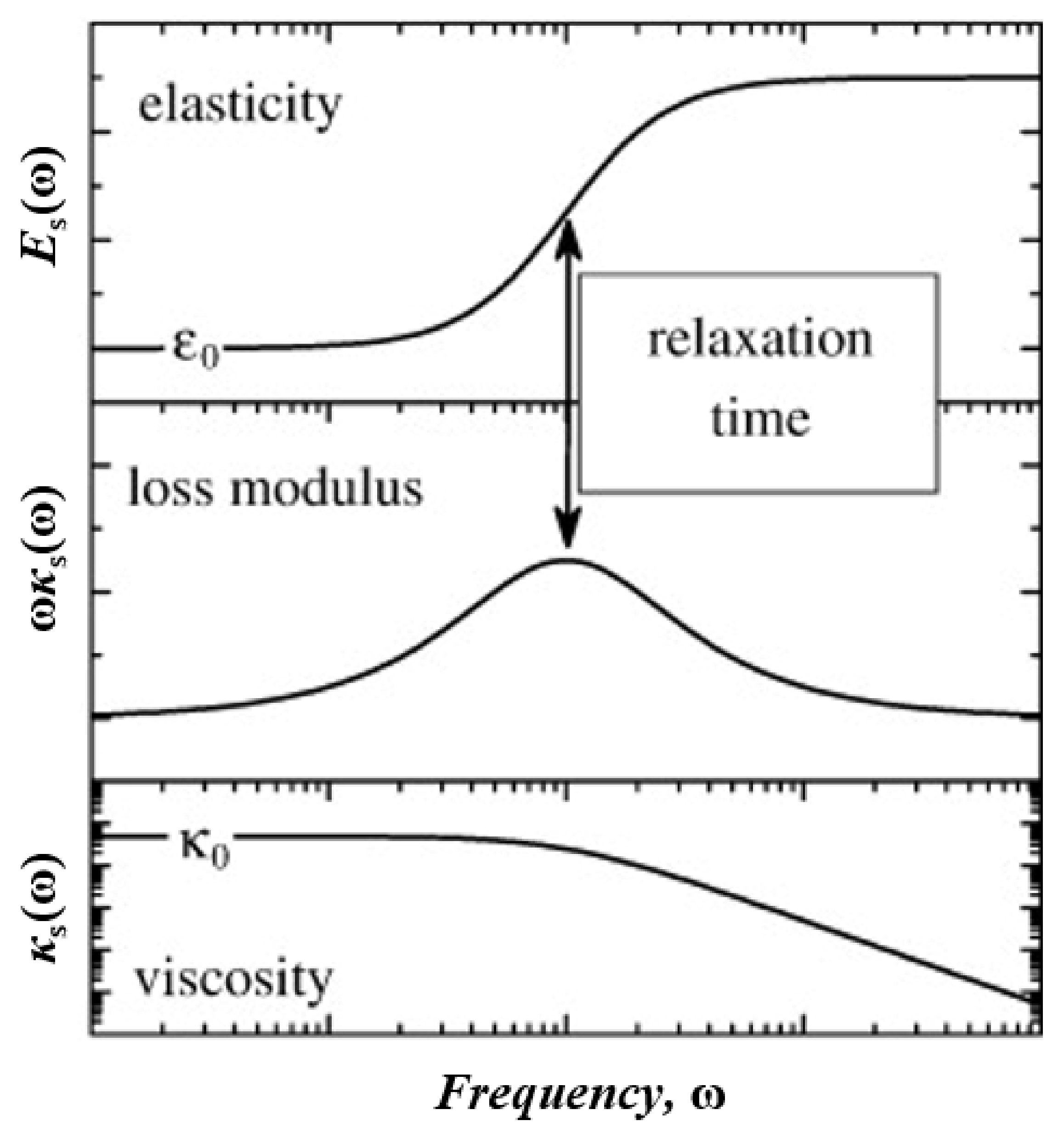

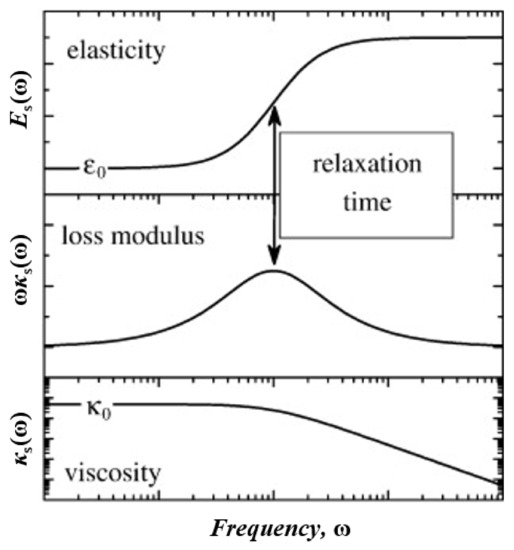

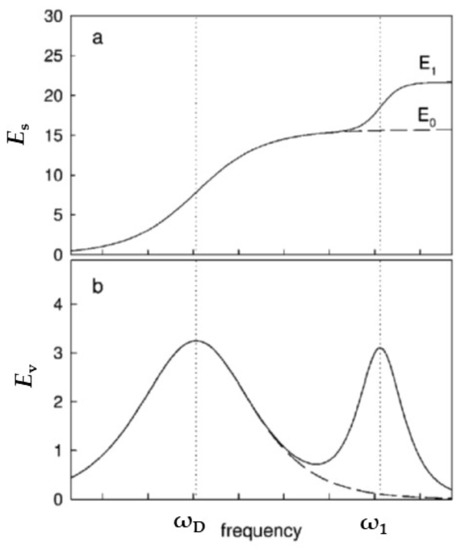

Figure 2 summarizes the typical material response expected for a viscoelastic layer undergoing a single relaxation process as a result of the dilational deformation.

Figure 2.

Sketch of the typical material response for a viscoelastic layer undergoing a single relaxation process upon the application of a dilational stress. Adapted from Mendoza et al. [30], with permission from Elsevier, Copyright (2014).

4. Rheological Tools for Evaluating the Response of Planar Fluid/Fluid Interfaces against Dilation

The last few years have been very fruitful in terms of the development of suitable tools to measure the response of planar fluid/fluid interfaces against dilational deformation [48,49]. Unfortunately, many of such tools provide information of the response against deformations within the linear response regime, which does not provide, in most cases, a suitable representation of some of the phenomena occurring in complex fluid/fluid interfaces, which are of technological and scientific interest [6,9]. However, these tools provide important information regarding the relaxation mechanism driving the re-equilibration of the interface upon dilational deformations. In fact, the experimental and theoretical tools of the interfacial dilational rheology provide information about the exchange mechanisms of material between the interface and the adjacent fluid phases, as well as the different reorientation and exchange process occurring between molecules confined within the interface [50,51,52]. This section focuses on the description of the most fundamental methodological features of the determination of the dilational response of planar fluid/fluid interfaces. However, it should be stressed that even the description of the mechanical response of curved interfaces is not discussed in this work. The understanding of the rheological response of curved interfaces has gained importance due to their recognized role in terms of its technological importance, including the stability of emulsions and foams, or coffee-ring formations upon the evaporation of liquid droplets deposited on solid substrates [19,53,54].

4.1. Experimental Tools

The characterization of the dilational response of interfacial layers requires careful selection of the most suitable technique, as well as appropriate experimental conditions. Several experimental techniques can be applied for evaluating the response of fluid/fluid interfaces to dilational stresses, offering different sensitivities and measurement ranges [50]. This section provides a brief overview of the types of experiments and experimental techniques that are currently available for studying fluid/fluid interfaces subjected to dilational deformations.

4.1.1. Experimental Techniques

This section includes a brief overview of the most common methodologies used for evaluating the dilational properties of fluid/fluid interfaces. A more detailed discussion about the experimental techniques used for this purpose may be found in references [9,50].

Drop/Bubble Shape Tensiometers

The use of drop/bubble shape tensiometers on the evaluation of the dilational viscoelasticity of fluid/fluid interfaces relies on the determination of the time evolution of the interfacial tension during harmonic changes of the area at a fixed frequency. This information can be extracted from an analysis of the changes occurring in the drop/bubble shape profile during the process, and is achieved by applying the Young–Laplace equation. This approach provides a framework to calculate the interfacial tension, by assuming that the contributions associated with shear are negligible. Therefore, the analysis of the drop/bubble shape profile can be only exploited for rheological simple interfaces characterized by an isotropic and constant stress along the whole interface.

where and are the curvature radius of the drop/bubble, p is the pressure difference across the interface, g is the gravitational acceleration, the fluid density, and z the vertical coordinate. It is worth noting that the deformation of drops/bubbles cannot be always assumed as purely radial. Moreover, the drop/bubble requires an instantaneous mechanical equilibrium for a correct evaluation of the interfacial tension, which limits the applicability of drop/bubble shape tensiometers for the evaluation of the interfacial dilational modulus for deformation frequencies in the range 10−3–0.2 Hz [55].

It is worth mentioning that the evaluation of the interfacial tension by applying Equation (12) is not always straightforward, especially because it is often difficult to obtain accurate values of the curvature radius. This can be commonly solved, considering that drops/bubbles undergo an axisymmetric deformation under the application of an external force. This condition is not fulfilled when densely coated drops and bubbles are considered [56,57].

In general, the use of drop/bubble shape tensiometers for evaluating the dilational properties assumes the existence of a single isotropic and constant tension for the entire interface. This allows for the application of the generalized Young–Laplace equation [58]:

with and defining the principal curvature and stress in circumferential direction, respectively, whereas and account for the principal curvature and stress in meridional direction, respectively. The interfacial stresses are magnitudes that depend on the interfacial deformation; hence, its evaluation should be locally performed because the deformation may not be constant within the whole drop/bubble. On the other hand, when the deformations are non-isotropic, the principal interfacial stresses become equal [9].

Capillary Pressure Tensiometers

An alternative approach for evaluating the dilational rheological properties of fluid/fluid interfaces relies on the determination of the capillary pressure inside droplets or bubbles, together with their dimensions. In this case, the determination of the interfacial tension does not require a strong gravitational deformation of the drops/bubbles, which was necessary with conventional shape tensiometers [59]. This allows a reduction in the size of the drops/bubbles used (in the range 20–200 μm). Thus, it is possible to reduce capillary and inertial relaxation times, enabling an extension of the probed frequencies up to 100 Hz [45]. Moreover, this approach reduces the role of the shear contributions on the deformation, making acceptable the isotropic assumption for the resolution of the Young–Laplace equation to determine the interfacial tension [9,10,60].

In recent years, methods using oscillating drops/bubbles have been further developed to extend the frequency range that can be probed. One of the most popular alternatives for this purpose is to design a device consisting of a closed cell, a pressure sensor, and a piezo translator, which monitors the time evolution of the capillary pressure during the experiments. Thus, it is possible to determine the rheological properties of fluid/fluid interfaces in the 0.5–450 Hz range. Moreover, this type of device allows for the measurement of the rheological properties of interfaces formed for two fluids with very similar densities [56,61].

Langmuir Troughs

The Langmuir trough is a common experimental setup used for studies dealing with the dilational properties of fluid/fluid interfaces [62,63]. It consists of two barriers, arranged parallel at opposite extremes of the trough, that can be used to compress or expand the area available for the interface under controlled conditions. During the compression/expansion of the interface, the interfacial tension is monitored by using a surface balance fitted with a contact probe; generally, a Wilhelmy plate. This reduces the interfacial stress for specific deformation conditions [4].

It is worth mentioning that the interfacial stress measured in the Langmuir trough, as a result of a uniaxial deformation, in many cases, includes both dilational and shear components [64]. Moreover, special care is required for interpreting the rheological properties of solid-like layers obtained using Langmuir troughs, because in many cases the deformation field cannot be defined as homogeneous, and hence, it depends on the specific geometric constraints of the used trough [40,65]. The inability to apply a purely isotropic stress, which leads to rheological responses containing dilational and shear contributions, is a very important problem when interfaces with a complex microstructure are analyzed. The application of anisotropic stresses to such complex systems results in a rheological response characterized by the change of the area and the shape under compression [10,40]. This can be solved by introducing several modifications to the Langmuir trough to ensure a purely dilational deformation of fluid/fluid interfaces [40].

The most useful design of Langmuir trough to ensure a pure dilational deformation of planar fluid/fluid interfaces is the proposed by Pepicelli et al. [40]. This relies on a radial trough which is isotropically deformed by an elastic band held by twelve “fingers”. The interfacial pressure is determined by using a Wilhelmy rod, ensuring radial symmetry. This type of device allows for the application of isotropic deformation, avoiding any shear effect on the interfacial deformation [66].

Wave Damping

A traditional approach exploited for the evaluation of the mechanical response of fluid/fluid interfaces against high frequency dilational deformations relies on the study of the damping of capillary waves. These can be generated upon the application of mechanically, thermally, or electrically driven perturbations of the interface, when their propagation happens along the fluid/fluid interface. During their propagation, the waves are dampened by the action of surface forces that try to restore the flatness of the interface [22,67,68,69,70,71].

The study of the rheological properties by the evaluation of the dampening of surface waves allows the study of information of the dilational properties of fluid/fluid interfaces up to frequencies of about 100 kHz [72]. Information about dilation properties of fluid/fluid interfaces can be also obtained from the longitudinal wave dampening. These are propagated mainly by interfacial tension gradients, allowing one to probe the dilational rheology of fluid/fluid interfaces at lower values of deformation frequencies than when capillary waves are used [50,73,74,75].

Despite the broad range of frequencies (0.1–105 Hz) that can be probed by the evaluation of the damping of waves generated at fluid/fluid interfaces, and the contactless character of this type of technique, the interpretation of the data is not straightforward, which limits their applicability [72,76]. Recently, Slavchov et al. [68] reviewed the most fundamental aspects of capillary wave damping as a tool for evaluating the mechanical response of fluid/fluid interfaces and other of its potential applications. Moreover, they analyzed some recent theoretical developments on the use of capillary waves. Rajan [77] has recently solved the problems associated with the use of the damping of interfacial waves for the determination of the rheological properties of liquid/liquid interfaces, providing results of the interfacial elasticity and viscosity of water/oil interfaces.

The use of Faraday waves can be an alternative for studying the properties of fluid/fluid interfaces for systems with very low values of this property [78,79]. Henderson [80] used the analysis of Faraday waves to evaluate the mechanical response of interfaces with monolayers of different insoluble molecules, and found that the effectiveness of wave damping was enhanced as the interfacial packing of the interfacial film increased. Similar results were found for monolayers of wheat storage proteins [81].

4.1.2. Experimental Methods

The experimental methods used for studying the dilational rheological response of fluid/fluid interfaces rely on the mechanical perturbation of the interfacial area, and the measurement of the response.

Stress Relaxation Experiments

Relaxation experiments of fluid/fluid interfaces can be performed by applying a sudden perturbation of a controllable parameter defining the equilibrium state of a monolayer at a fluid/fluid interface, e.g., interfacial area, or interfacial concentration, among others. This type of perturbation takes the system to an out-equilibrium situation, and hence, the system undergoes a relaxation process to reestablish the equilibrium state [82]. Stress relaxation experiments can be performed using Langmuir troughs or drop/bubble shape tensiometers [83].

In a stress relaxation experiment, the time evolution of the interfacial tension γ(t) or the interfacial pressure Π(t) are recorded, after a sudden change (compression or expansion) of the interfacial area. This change of the interfacial area takes the interfacial pressure far from its equilibrium value, inducing a change of the interfacial pressure ΔΠ that defines the interfacial stress. This acts as a restoring force which tries to recover the equilibrium state of the interface once the strain ceases [84].

Creep Experiments

Creep experiments are commonly performed by using Langmuir troughs. In this type of experiment, an equilibrated interface characterized by its equilibrium interfacial pressure Π0 is suddenly compressed, i.e., as fast as possible, until it reaches a desired interfacial pressure value; then, the surface pressure is constantly maintained by changing the interfacial area. Thus, the excess of interfacial pressure is adjusted by considering the area relaxation process, allowing one to define the creep compliance as [85]:

The creep compliance is a phenomenological function, providing information on how the structure of the film resists the application of a controlled stress [85,86].

Oscillatory Area Experiments

Oscillatory area experiments rely on the application of a sinusoidal perturbation to the interface, at a constant frequency ω, which is a profile described as . The deformation of drops or bubbles at low frequencies almost guarantees a pure dilational deformation of the interface. However, for planar films studied in Langmuir troughs, the in-plane shear components can appear coupled to the dilational ones in both the applied strain and the response stress, which makes it difficult to extract true information of the dilational viscoelastic moduli. This may also occur in relaxation and creep experiments. It should be noted that the shear contributions present for films at fluid/fluid interface values are smaller values than those obtained for the dilational contributions, and hence, it can be neglected in oscillatory area experiments [30,87].

If the deformation allows the monolayer response within the linear regime to be maintained, this will follow a sinusoidal function with the same frequency of the strain.

with . introduces a phase factor that includes the contribution associated with any delay in the response, due to viscous contributions in the rheological response of the interface. From oscillatory area experiments, within the linear regime, it is possible to obtain the elastic modulus and the dilational viscosity

and

with .

Surface Waves Experiments

Interfacial rheology experiments using surface waves are possible following two different strategies. The first takes advantage of the waves originated as a result of the “natural” thermal fluctuations of the surface position, which can be explained in terms of the second law of thermodynamics. The second strategy is based on the production of “artificial” surface waves upon the application of external stimuli, e.g., electrical or mechanical perturbations. Independently of the nature of the used waves, the features of the fluctuations (amplitude, frequency, damping, etc.) can be related to the interfacial rheological properties of the probed systems [88,89,90]. In fact, any displacement of the fluid/fluid interface in relation to their flat level shape can be interpreted as an interfacial motion guided by an external force, and restored as result of the viscoelastic properties of the fluid phases and the interface itself [36,91].

One of the most common techniques based on the study of surface waves is the surface quasi-elastic light scattering (SQELS) technique, which relies on the light scattered by transverse surface waves. These provide a measurement of the dynamics associated with the thermal induced roughness of the interface [36,91,92]. Thus, it is possible to evaluate the interfacial dynamics under equilibrium conditions by observing the dynamics of thermal fluctuations around the equilibrium state. These fluctuations present a very small length scale (a few Angstrom), allowing one to probe the interfacial rheology in the linear regime. SQELS experiments can be based on the determination of the heterodyne autocorrelation function or the power spectrum of the scattered light P(ω).

where kB is the Boltzmann constant and η the subphase viscosity. q and m define the wave-vector and the diffraction order, respectively. E is the complex dilational modulus (compression+shear), and D(ω) the surface wave dispersion relation defined by the following expression [36]:

with . The dilational elasticity and viscosity can be determined by measuring P(ω) and the interfacial tension. SQELS allows probing of the dilational viscoelastic properties of interfaces in the frequency range 103–106 Hz [93].

A second example of experiments based on surface waves relies on the excitation of surface waves with higher amplitudes than those obtained in SQELS experiments (~1μm). This is possible under the application of an external physical stimulus, commonly mechanical or electrical, as an excitation force. In general, electrical stimuli are preferred to mechanical ones because they present a non-invasive character, allowing for an easier experimental design [30].

Electrically excited surface waves are so-called electrocapillary waves (ECW), and they can be evaluated by measuring the spatial profile of the generated waves by using spatially resolved laser reflectometry. Thus, it is possible to obtain a spatial profile that follows a damped wave function, defined as:

where λ accounts for the capillary wavelength and β for the spatial damping constant of the capillary wave oscillations. ϕ defines a phase term obtained as a function of the excitation frequency. ECW experiments are required to perform measurements at different frequencies to obtain the group velocity, and to transform the results obtained from the space domain to the time domain. Then, by combining the frequency of the independently measured interfacial tension and the values of λ and β obtained in the fitting of the spatial profile of the damped wave, it is possible to calculate the interfacial dilational elasticity and viscosity by solving numerically the dispersion equation for each measured frequency (in the range 20–103 Hz) [30].

It should be noted that the above wave damping considers a sharp fluid/fluid interface, which is coated by a thin monomolecular film. However, the situation becomes more complicated when thick films are adsorbed at the fluid/fluid interface. A detailed discussion of the role of the interface thickness on the ability of fluid/fluid interfaces for dampening waves can be found in the literature [94,95,96].

4.2. Theoretical Models

The use of suitable theoretical models for analyzing the frequency dependence of the dilational viscoelastic properties of fluid/fluid interfaces can shed light on the relaxation mechanism involved in the reestablishment of the interfacial equilibrium after a dilational deformation [45,97]. The Lucassen-Van den Tempel model assumes that the adsorption-desorption equilibrium occurs freely, and no adsorption barriers are present; thus, the material exchange between the bulk and the interface is governed by diffusion [45,98,99]. This is only possible assuming that the formation of an interfacial layer of the interface requires the equilibrium between the interface and the species existing in the bulk, i.e., the formation of a soluble or Gibbs monolayers. Thus, it is possible to define the complex viscoelastic modulus according to the following relationship:

where , with being the characteristic frequency of the exchange process, D the diffusion coefficient, and c the bulk concentration. From the above definition, it is possible to assume two limits. In the first limit, and , which results in and , and the monolayer behaves as an insoluble one (Langmuir monolayer), i.e., there are no possibilities for material exchange between the interface and the adjacent fluid phases. The opposite situation occurs when and , which results in , leading to a situation where the resistance to the compression is negligible, and the equilibrium between the bulk and the interface can occur during the compression process. For those cases in which the frequency assumes intermediate values, the condition and is fulfilled.

The above model assumes that the interfacial concentration only changes as a result of the exchange of molecules between the fluid/fluid interface and the adjacent bulk phases (Gibb monolayers). However, this is not possible when insoluble layers are considered. In these cases, it can be only expected relaxation processes that are circumscribed to the fluid/fluid interface. This type of relaxation mechanism can also appear in soluble monolayers. There are several possible interfacial tension relaxation processes that can directly affect the interface upon a dilational deformation [100]. These correspond to the internal reorganization of the adsorption layer, which can occur according to different mechanisms, e.g., phase transitions, molecular reorientation, and molecular folding/unfolding [17,45,101,102,103].

The existence of a relaxation mechanism involving only the interface requires introducing a generic thermodynamic variable X, which gives a description of the advancement of the relaxation process. This new variable, combined with the interfacial tension and the interfacial concentration, permits a description of the state of the interface. Thus, it is possible to define a state equation for the interface according to the following expression:

Assuming a relaxation process following a first order kinetics, it is possible to define the kinetic equation as:

where k is the characteristic constant of the process and is the value of the thermodynamic variable under equilibrium conditions [45,104]. The above framework allows a description of the dependence of the viscoelastic modulus in terms of the frequency as:

where and provide information about the characteristic frequency of the j-th relaxation processes, and and are thermodynamic parameters related to the limit elasticities. For insoluble systems, stands for the limit elasticity when the deformation tends to zero.

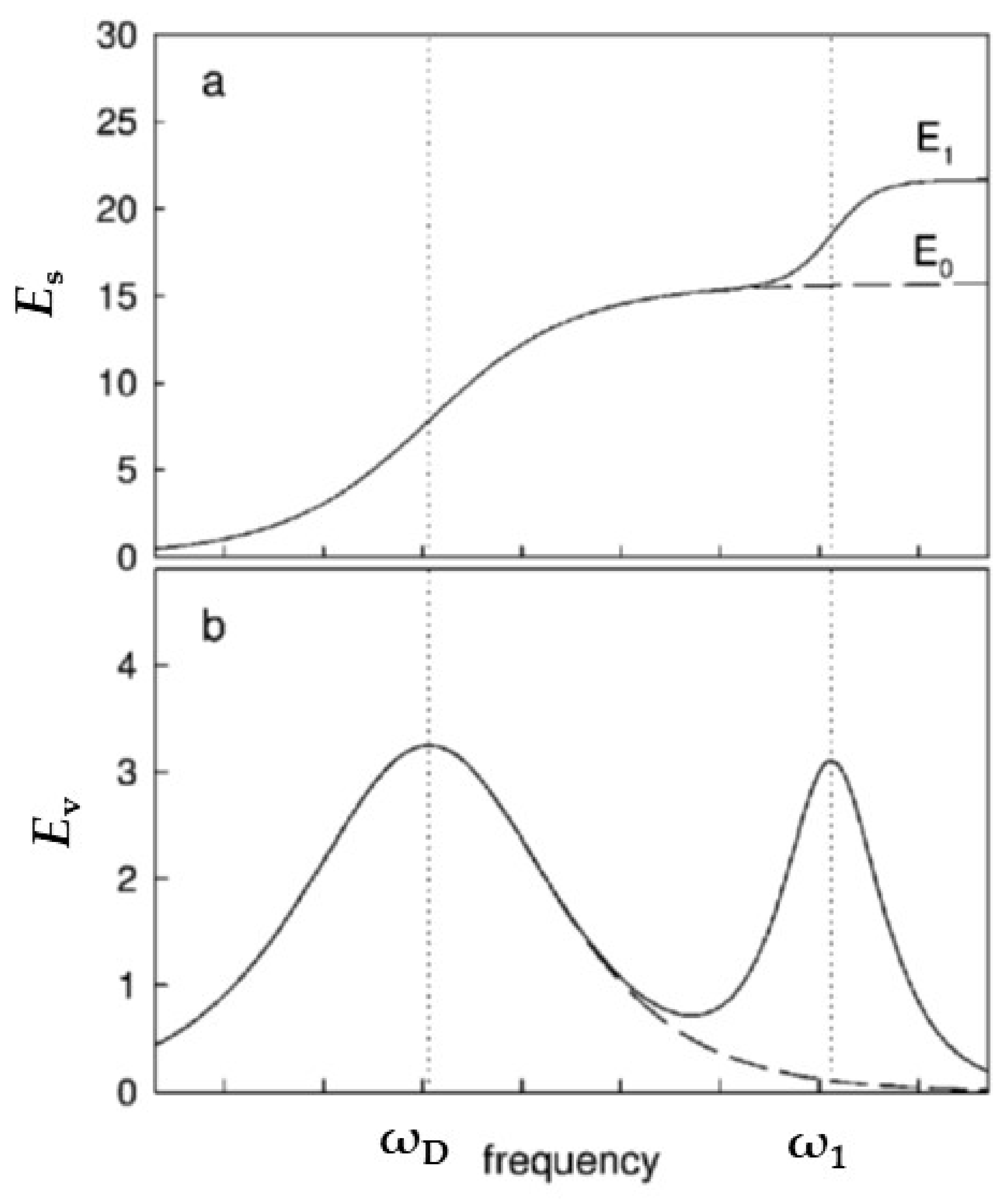

The frequency dependence of the imaginary part of the dilational viscoelastic modulus is characterized by peaks, with their maximum corresponding to the characteristic frequency of the involved relaxation processes. The maxima of the peaks in the imaginary part correspond to the inflection points in the real part curves. Figure 3 represents the frequency dependence of the real or imaginary parts of the dilational viscoelastic modulus for fluid/fluid interfaces presenting different relaxation processes.

Figure 3.

Sketch of the typical dependences of the (a) real and (b) imaginary parts of the viscoelastic modulus for fluid/fluid interfaces presenting different relaxation processes. The dashed lines correspond to a system presenting a relaxation process characterized by a relaxation process defined in terms of the Lucassen-van der Tempel model, and the continuous lines represent the typical behavior of a fluid/fluid interfaces where a relaxation process affecting only the interface is coupled to a Lucassen-van der Tempel-like relaxation. Reprinted from Liggieri et al. [104], with permission from Royal Society of Chemistry, Copyright (2011).

For systems presenting several relaxation processes, it is possible to superimpose them following a linear combination scheme to fabricate an expression for the frequency dependence of the dilational viscoelastic modulus containing an arbitrary number of processes [45,46,103,105].

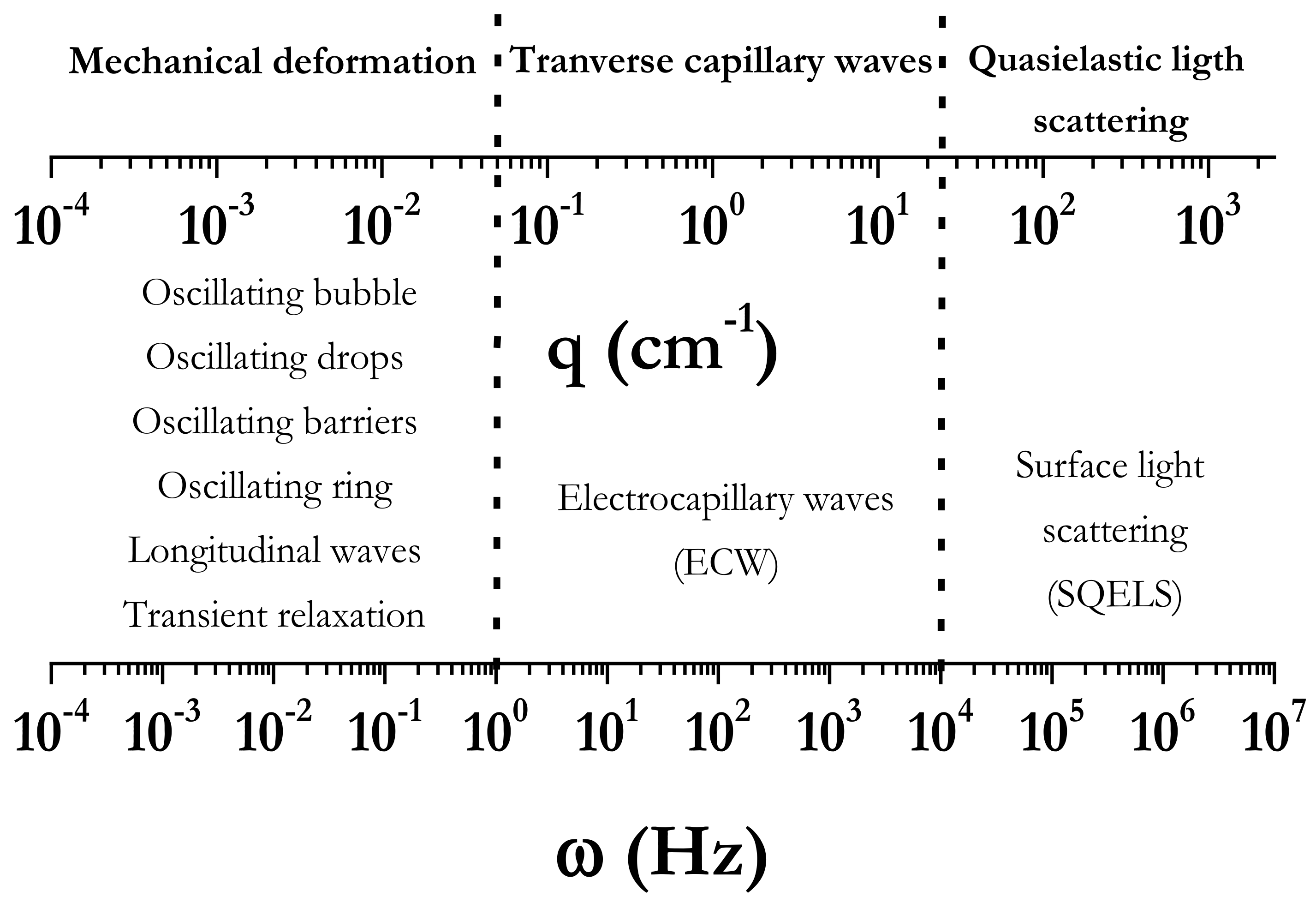

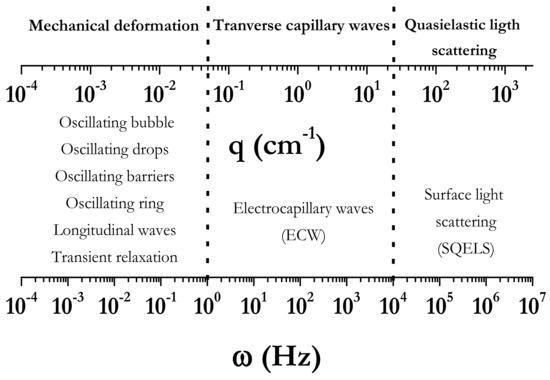

5. Evaluation of the Mechanical Relaxation Spectrum from Dilational Rheology Experiments

One of the main challenges when dilational rheology experiments are performed is related to the evaluation of the mechanical response of fluid/fluid interfaces in a broad range of frequencies. Unfortunately, this requires a combination of techniques, which introduces two main issues: (i) the accessibility to the different techniques is not always easy; and (ii) some devices cannot be used for studying both soluble and insoluble interfacial layers. Figure 4 presents a summary of some of the experimental techniques accessible for evaluating the dilational response of fluid/fluid interfaces, as well as the frequency range in which they can be used.

Figure 4.

Summary of some of the most extended methodologies for evaluating the dilational response of fluid/fluid interface, together with the accessible frequency ranges for such techniques.

Presently, there has been only one study concerning the whole relaxation spectrum in the frequency range 10−3–103 Hz [104]. This required combining an oscillatory drop tensiometer, a capillary pressure tensiometer, and an electrocapillary wave instrument to access the whole frequency range. Moreover, there are several studies where the combination of different techniques has provided information about the mechanical relaxation spectrum, and information regarding the real and imaginary part of the viscoelastic modulus values from the whole frequency range is not available [106,107,108].

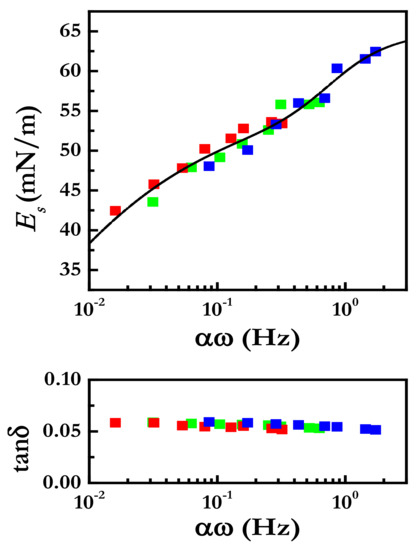

Assuming the difficulties associated with performing dilational rheology experiments in a broad frequency range, it is necessary to adapt classical approaches of conventional rheology to the study of fluid/fluid interfaces. One example of these approaches is to adapt the widely used time-temperature superposition principle for extending the range of frequencies accessible for the analysis of data [109]. The applicability of this type of superposition is limited to the thermo-rheologically simple, which are characterized by the presence of a single relaxation mechanism over the whole temperature and frequency range explored. Despite the proved effectiveness of the superposition principle for describing the bulk rheology of different systems, its application to the study of fluid/fluid interfaces is recent [52]. Bae et al. [52] proposed to describe dilational interfacial rheology by using a concentration-frequency superposition methodology. Thus, it was possible to expand the explored frequency range, even though the accessible data were acquired in a limited region. The concentration-frequency superposition can be defined in terms of the following set of expressions:

and

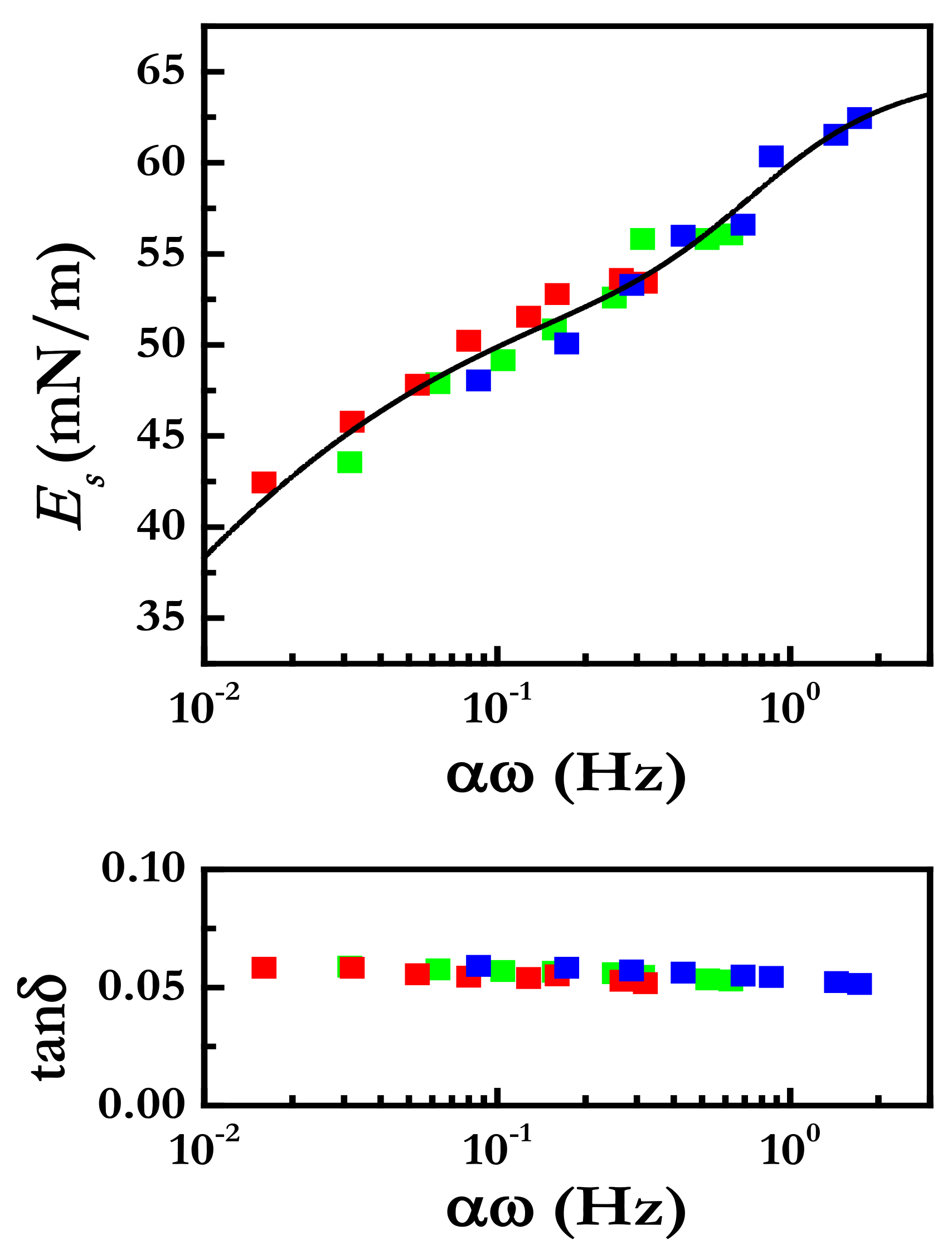

where and represent the dilational elastic and viscous moduli, respectively, as were obtained at the experimental frequency for a fixed value of the bulk concentration which is fixed at reference, and and correspond to the elastic and viscous moduli, respectively, at a certain bulk concentration , in which the deformation frequency has been re-scaled by a shift factor α enabling the superposition of the real and imaginary parts of the viscoelastic dilational modulus. is a shifting factor for ensuring the perfect overlapping between the data. When , the frequency-concentration superposition method provides information related to the concentration dependence of the rheological response, which provides the basis for enlarging the frequency window accessible for the experiments. Figure 5 shows, for the sake of example, the superposition of the curves corresponding to the dilational elasticity modulus and the loss tangent () for mixtures of chitosan and an anionic surfactant with increasing surfactant concentrations. The introduction of the shift factors to the rheological results allows for the establishment of master curves for the elastic modulus and the loss tangent.

Figure 5.

Re-scaled frequency dependences of the elastic modulus and loss tangent for chitosan-anionic surfactant mixtures with different surfactant concentrations (symbols of different color represents the set of data for solutions with different concentrations) and a fixed chitosan concentration of 2 g/L (pH 4.5 and ionic strength 120 mM NaCl). The symbols are the experimental results, and the solid lines represent the best fit of the experimental curves to a model, including a Lucassen-Van der Tempel-like relaxation process and a relaxation process affecting the interface. Adapted from Akanno et al. [51], with permission from Royal Society of Chemistry, Copyright (2020).

6. Non-Linear Dilational Interfacial Rheology

The above discussion has so far dealt with the dilational response of fluid/fluid interfaces to small amplitude deformations. However, the situation significantly changes when the amplitude of the deformation is large enough to push the response of interfacial films far from the linear regime. It should be noted that, in some systems, the onset in the region of a non-linear response is reached even with deformations of very small amplitude [110,111,112].

The analysis of the non-linear response in dilational rheology is not straightforward, mainly due to the difficulties associated with providing a suitable definition of the applied deformation [113]. This may be understood by considering axisymmetric drop shape analysis as an example. In many cases, this type of experiment relies on inhomogeneous deformation, which depends on the position [114]. This is a very critical issue because the stretching can be very different depending on the interface area, even though this is not considered in most cases for data analysis. Moreover, the interference of time-dependent and deformation-dependent rheological properties also complicates the analysis of non-linear behavior of fluid/fluid interfaces.

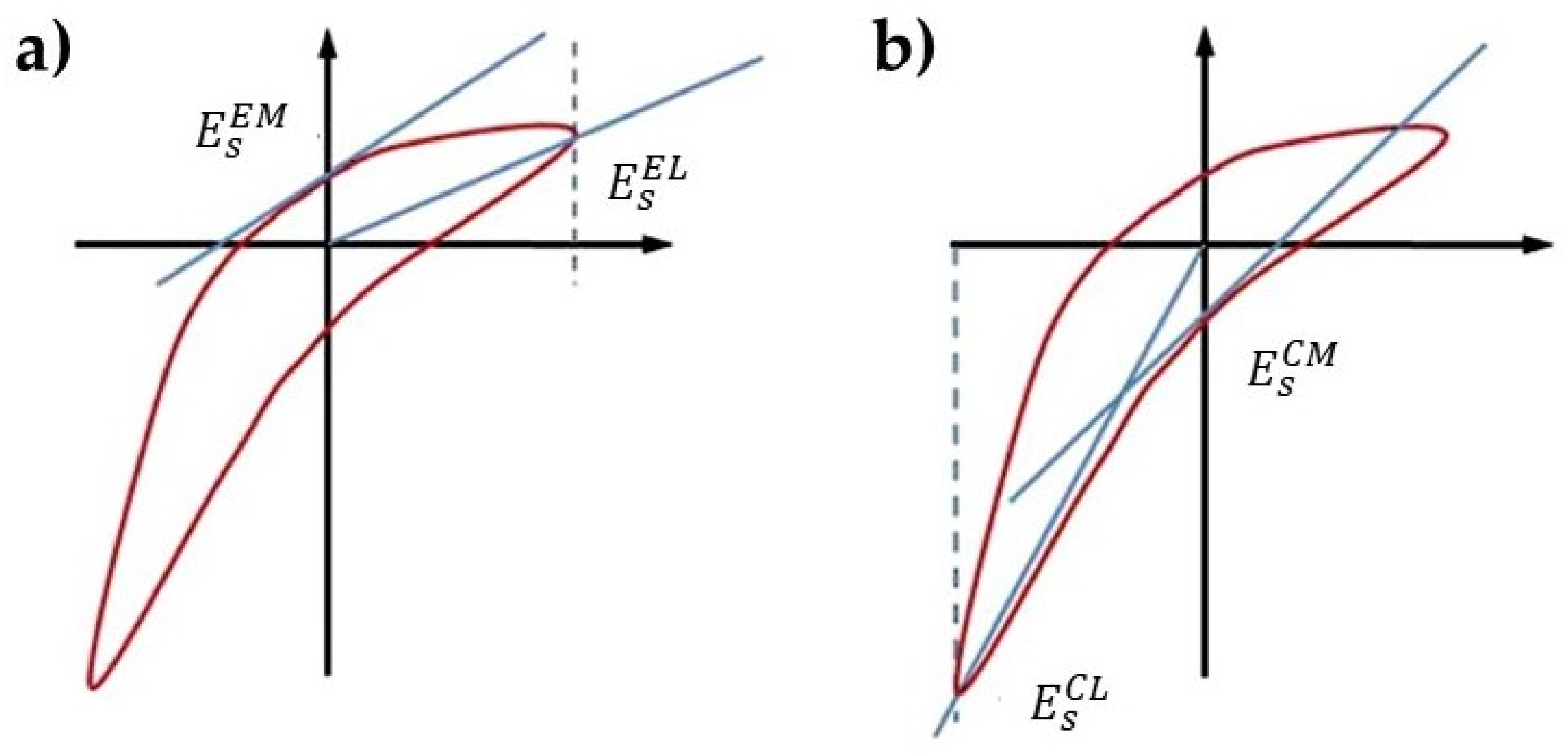

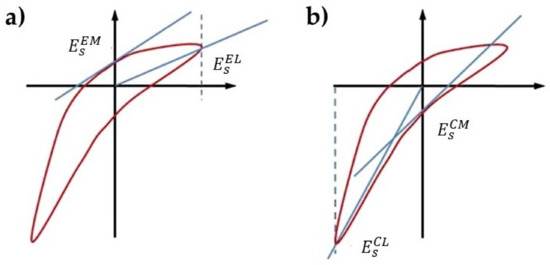

The study of the Lissajous curves is very useful for evaluating the properties of fluid/fluid interfaces under non-linear conditions. The asymmetry of the Lissajous plots results in four different contributions: two defining the extension part of the cycle (the dilational moduli at minimum and large extension), and two providing information of the compression part of the cycle (the dilational moduli at minimum and large compression) [113,115]. Figure 6 shows a schematic representation of the stress decomposition to obtain the four contributions.

Figure 6.

Definition of minimum and large-strain moduli. (a) Minimum and large deformation dilational moduli in extension. (b) Minimum and large deformation dilational moduli in compression. Adapted from Sagis and Fischer [113], with permission from Elsevier, Copyright (2014).

Using the abovementioned four contributions, it is possible to define two parameters defining the non-linearity; the first defining the compression part of the cycle:

and the second accounting for the extension part of the cycle:

The evaluation of the S factors as a function of the applied strain provides quantitative information on the non-linearity of the interface [113].

As an alternative to the graphical analysis in terms of a stress decomposition, the non-linear rheological response of interfaces can also be analyzed by representing the stress by using Fourier series, making use of the Fourier-transform rheology [111]. This relies on defining the stress response in terms of a Fourier expansion:

where defines the amplitude of the stress response defined with respect to the initial interfacial pressure, and , , etc., correspond to the amplitudes of the harmonic terms of the non-linear response. The use of Fourier transform rheology for modelling the non-linear dilational response of fluid/fluid interfaces presents an important limitation associated with the definition of the stress as an expansion around a zero-interface deformation rate, which can provide information only for systems with small deviations from the linearity. A very useful methodology for quantifying the non-linearity of the rheological response of fluid/fluid interfaces is by introducing the concept of the Total Harmonic Distortion (THD), defined as [116]:

where corresponds to the amplitudes of the harmonic terms of the non-linear response. The above definition of the THD indicates that when this parameter assumes a null value, the systems present a linear rheological response, while larger values of this parameter show the emergence of a non-linear response of the fluid/fluid interface. Another alternative to decomposing the stress response in non-linear systems is the Volterra series [117].

7. Concluding Remarks

The study of the dilational properties of fluid/fluid interfaces has been extensively developed in recent years due to their recognized importance in different features of science and technology. In this review, an updated overview of the currently available theoretical and experimental strategies for evaluation of the dilational properties of fluid/fluid interfaces has been presented.

The more recently available knowledge on the interpretation of rheological data is based on constitutive models. However, a more detailed understanding of the rheological properties of fluid/fluid interfaces is required to introduce information about structural features, allowing the establishment of a link between the mechanical response of the interface and its structure. Therefore, it is necessary to advance the development of more suitable models, enabling a better description of the dilational rheology of fluid/fluid interfaces. Unfortunately, there are several challenges to overcome with regard to the evaluation of the mechanical performance of fluid/fluid interfaces, with the separation of the bulk effects and the response of the interface being one of the most important issues identified in the experimental and theoretical development of the study of the dilational rheology of fluid/fluid interfaces.

Author Contributions

The manuscript was written with the input at all authors. All authors have read and agreed to the published version of the manuscript.

Funding

This work was funded in part by MICINN under Grant PID2019-106557GB-C21 and by E.U. on the framework of the European Innovative Training Network—Marie Sklodowska-Curie Action Nano Paint (Grant Agreement 955612).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not Applicable.

Data Availability Statement

This manuscript has not contributed to the generation of any new data.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Forth, J.; Kim, P.Y.; Xie, G.; Liu, X.; Helms, B.A.; Russell, T.P. Building Reconfigurable Devices Using Complex Liquid–Fluid Interfaces. Adv. Mater. 2019, 31, 1806370. [Google Scholar] [CrossRef] [PubMed]

- Guzmán, E. Current Perspective on the Study of Liquid–Fluid Interfaces: From Fundamentals to Innovative Applications. Coatings 2022, 12, 841. [Google Scholar] [CrossRef]

- Guzmán, E.; Martínez-Pedrero, F.; Calero, C.; Maestro, A.; Ortega, F.; Rubio, R.G. A broad perspective to particle-laden fluid interfaces systems: From chemically homogeneous particles to active colloids. Adv. Colloids Interface Sci. 2022, 302, 102620. [Google Scholar] [CrossRef] [PubMed]

- Guzmán, E. Fluid Films as Models for Understanding the Impact of Inhaled Particles in Lung Surfactant Layers. Coatings 2022, 12, 277. [Google Scholar] [CrossRef]

- Guzmán, E.; Santini, E. Lung surfactant-particles at fluid interfaces for toxicity assessments. Curr. Opin. Colloid Interface Sci. 2019, 39, 24–39. [Google Scholar] [CrossRef]

- Klein, C.O.; Theodoratou, A.; Rühs, P.A.; Jonas, U.; Loppinet, B.; Wilhelm, M.; Fischer, P.; Vermant, J.; Vlassopoulos, D. Interfacial Fourier transform shear rheometry of complex fluid interfaces. Rheol. Acta 2019, 58, 29–45. [Google Scholar] [CrossRef]

- Masuda, T.; Takai, M. Design of biointerfaces composed of soft materials using controlled radical polymerizations. J. Mater. Chem. B 2022, 10, 1473–1485. [Google Scholar] [CrossRef]

- Sagis, L.M.C.; Liu, B.; Li, Y.; Essers, J.; Yang, J.; Moghimikheirabadi, A.; Hinderink, E.; Berton-Carabin, C.; Schroen, K. Dynamic heterogeneity in complex interfaces of soft interface-dominated materials. Sci. Rep. 2019, 9, 2938. [Google Scholar] [CrossRef]

- Jaensson, N.; Vermant, J. Tensiometry and rheology of complex interfaces. Curr. Opin. Colloid Interface Sci. 2018, 37, 136–150. [Google Scholar] [CrossRef]

- Jaensson, N.O.; Anderson, P.D.; Vermant, J. Computational interfacial rheology. J. Non-Newton. Fluid Mech. 2021, 290, 104507. [Google Scholar] [CrossRef]

- Wei, Y.; Xie, Y.; Cai, Z.; Guo, Y.; Zhang, H. Interfacial rheology, emulsifying property and emulsion stability of glyceryl monooleate-modified corn fiber gum. Food Chem. 2021, 343, 128416. [Google Scholar] [CrossRef]

- Botti, T.C.; Hutin, A.; Quintella, E.; Carvalho, M.S. Effect of interfacial rheology on drop coalescence in water–oil emulsion. Soft Matter 2022, 18, 1423–1434. [Google Scholar] [CrossRef]

- Wang, H.; Wei, X.; Du, Y.; Wang, D. Experimental investigation on the dilatational interfacial rheology of dust-suppressing foam and its effect on foam performance. Process. Saf. Environ. Prot. 2019, 123, 351–357. [Google Scholar] [CrossRef]

- Thai, L.P.A.; Mousseau, F.; Oikonomou, E.K.; Berret, J.F. On the rheology of pulmonary surfactant: Effects of concentration and consequences for the surfactant replacement therapy. Colloids Surf. B 2019, 178, 337–345. [Google Scholar] [CrossRef]

- Haslbeck, K.; Schwarz, K.; Hohlfeld, J.M.; Seume, J.R.; Koch, W. Submicron droplet formation in the human lung. J. Aerosol Sci. 2010, 41, 429–438. [Google Scholar] [CrossRef]

- Svitova, T.F.; Lin, M.C. Tear lipids interfacial rheology: Effect of lysozyme and lens care solutions. Optom. Vis. Sci. 2010, 87, 10–20. [Google Scholar] [CrossRef]

- Rubio, R.G.; Guzmán, E.; Ortega, F.; Liggieri, L. Monolayers of Cholesterol and Cholesteryl Stearate at the Water/Vapor Interface: A Physico-Chemical Study of Components of the Meibum Layer. Colloids Interfaces 2021, 5, 30. [Google Scholar] [CrossRef]

- Zhang, H.; Lamnawar, K.; Maazouz, A. Fundamental studies of interfacial rheology at multilayered model polymers for coextrusion process. AIP Conf. Proc. 2015, 1664, 100008. [Google Scholar] [CrossRef]

- Perrin, L.; Akanno, A.; Guzman, E.; Ortega, F.; Rubio, R.G. Pattern Formation upon Evaporation of Sessile Droplets of Polyelectrolyte/Surfactant Mixtures on Silicon Wafers. Int. J. Mol. Sci. 2021, 22, 7953. [Google Scholar] [CrossRef]

- Sun, H.-Q.; Zhang, L.; Li, Z.-Q.; Zhang, L.; Luo, L.; Zhao, S. Interfacial dilational rheology related to enhance oil recovery. Soft Matter 2011, 7, 7601–7611. [Google Scholar] [CrossRef]

- Gade, M.; Byfield, V.; Ermakov, S.; Lavrova, O.; Mitnik, L. Slicks as Indicators for Marine Processes. Oceanography 2013, 26, 138–149. [Google Scholar] [CrossRef]

- Ermakov, S.A.; Khazanov, G.E. Resonance damping of gravity–capillary waves on water covered with a visco-elastic film of finite thickness: A reappraisal. Phys. Fluids 2022, 34, 092107. [Google Scholar] [CrossRef]

- Sánchez-Puga, P.; Tajuelo, J.; Pastor, J.M.; Rubio, M.A. Flow field-based data analysis in interfacial shear rheometry. Adv. Colloids Interface Sci. 2021, 288, 102332. [Google Scholar] [CrossRef]

- Guzmán, E.; Tajuelo, J.; Pastor, J.M.; Rubio, M.Á.; Ortega, F.; Rubio, R.G. Shear rheology of fluid interfaces: Closing the gap between macro- and micro-rheology. Curr. Opin. Colloid Interface Sci. 2018, 37, 33–48. [Google Scholar] [CrossRef]

- Wong, W.-H.B.; Hulsen, M.A.; Anderson, P.D. A numerical model for the development of the morphology of disperse blends in complex flow. Rheol. Acta 2019, 58, 79–95. [Google Scholar] [CrossRef]

- Nilsson, M.A.; Kulkarni, R.; Gerberich, L.; Hammond, R.; Singh, R.; Baumhoff, E.; Rothstein, J.P. Effect of fluid rheology on enhanced oil recovery in a microfluidic sandstone device. J. Non-Newton. Fluid Mech. 2013, 202, 112–119. [Google Scholar] [CrossRef]

- Perez, P.L.; Zaragoza, J.N.; Patel, N.K.; Dion, M.A. Impact of Asphaltene Stabilizers on the Elasticity of a Crude Oil–Water Interface and Its Correlation to Demulsification under Desalting Conditions. Energy Fuels 2022, 36, 275–289. [Google Scholar] [CrossRef]

- Guzmán, E.; Santini, E.; Ferrari, M.; Liggieri, L.; Ravera, F. Evaluating the Impact of Hydrophobic Silicon Dioxide in the Interfacial Properties of Lung Surfactant Films. ACS Environ. Sci. Technol. 2022, 56, 7308–7318. [Google Scholar] [CrossRef] [PubMed]

- Nagel, M.; Tervoort, T.A.; Vermant, J. From drop-shape analysis to stress-fitting elastometry. Adv. Colloids Interface Sci. 2017, 247, 33–51. [Google Scholar] [CrossRef] [PubMed]

- Mendoza, A.J.; Guzmán, E.; Martínez-Pedrero, F.; Ritacco, H.; Rubio, R.G.; Ortega, F.; Starov, V.M.; Miller, R. Particle laden fluid interfaces: Dynamics and interfacial rheology. Adv. Colloids Interface Sci. 2014, 206, 303–319. [Google Scholar] [CrossRef] [PubMed]

- Manikantan, H.; Squires, T.M. Surfactant dynamics: Hidden variables controlling fluid flows. J. Fluid Mech. 2020, 892, P1. [Google Scholar] [CrossRef]

- Krotov, V.V. Basics of Interfacial rheology. In Interfacial Rheology; Miller, R., Liggieri, L., Eds.; Brill: Leiden, The Netherlands, 2009; pp. 1–37. [Google Scholar]

- Garbin, V. Collapse mechanisms and extreme deformation of particle-laden interfaces. Curr. Opin. Colloid Interface Sci. 2019, 39, 202–211. [Google Scholar] [CrossRef]

- Maestro, A.; Guzmán, E. Colloids at Fluid Interfaces. Processes 2019, 7, 942. [Google Scholar] [CrossRef]

- Nitschke, I.; Voigt, A. Observer-invariant time derivatives on moving surfaces. J. Geom. Phys. 2022, 173, 104428. [Google Scholar] [CrossRef]

- Langevin, D. Light scattering by liquid surfaces, new developments. Adv. Colloids Interface Sci. 2021, 289, 102368. [Google Scholar] [CrossRef]

- Fuller, G.G.; Vermant, J. Complex Fluid-Fluid Interfaces: Rheology and Structure. Annu. Rev. Chem. Biomol. Eng. 2012, 3, 519–543. [Google Scholar] [CrossRef]

- Stone, H.A.; Leal, L.G. The effects of surfactants on drop deformation and breakup. J. Fluid Mech. 1990, 220, 161–186. [Google Scholar] [CrossRef]

- De Kinkelder, E.; Sagis, L.; Aland, S. A numerical method for the simulation of viscoelastic fluid surfaces. J. Comput. Phys. 2021, 440, 110413. [Google Scholar] [CrossRef]

- Pepicelli, M.; Verwijlen, T.; Tervoort, T.; Vermant, J. Characterization and modelling of Langmuir interfaces with finite elasticity. Soft Matter 2017, 13, 5977–5990. [Google Scholar] [CrossRef]

- Sagis, L. Dynamic surface tension of complex fluid-fluid interfaces: A useful concept, or not? Eur. Phys. J. Spec. Top. 2013, 222, 39–46. [Google Scholar] [CrossRef]

- Reichert, M.D.; Alvarez, N.J.; Brooks, C.F.; Grillet, A.M.; Mondy, L.A.; Anna, S.L.; Walker, L.M. The importance of experimental design on measurement of dynamic interfacial tension and interfacial rheology in diffusion-limited surfactant systems. Colloids Surf. A 2015, 467, 135–142. [Google Scholar] [CrossRef]

- Miller, R.; Ferri, J.; Javadi, A.; Krägel, J.; Mucic, N.; Wüstneck, R. Rheology of interfacial layers. Colloid Polym. Sci. 2010, 288, 937–950. [Google Scholar] [CrossRef]

- Karbaschi, M.; Lotfi, M.; Krägel, J.; Javadi, A.; Bastani, D.; Miller, R. Rheology of interfacial layers. Curr. Opin. Colloid Interface Sci. 2014, 19, 514–519. [Google Scholar] [CrossRef]

- Ravera, F.; Ferrari, M.; Santini, E.; Liggieri, L. Influence of surface processes on the dilational visco-elasticity of surfactant solutions. Adv. Colloids Interface Sci. 2005, 117, 75–100. [Google Scholar] [CrossRef]

- Guzmán, E.; Liggieri, L.; Santini, E.; Ferrari, M.; Ravera, F. Influence of silicananoparticles on dilational rheology of DPPC–palmitic acid Langmuir monolayers. Soft Matter 2012, 8, 3938–3948. [Google Scholar] [CrossRef]

- Guzmán, E.; Liggieri, L.; Santini, E.; Ferrari, M.; Ravera, F. Mixed DPPC–cholesterol Langmuir monolayers in presence of hydrophilic silica nanoparticles. Colloids Surf. B 2015, 105, 284–293. [Google Scholar] [CrossRef]

- Omari, Y.E.; Yousfi, M.; Duchet-Rumeau, J.; Maazouz, A. Recent Advances in the Interfacial Shear and Dilational Rheology of Polymer Systems: From Fundamentals to Applications. Polymers 2022, 14, 2844. [Google Scholar] [CrossRef]

- Ravera, F.; Miller, R.; Zuo, Y.Y.; Noskov, B.A.; Bykov, A.G.; Kovalchuk, V.I.; Loglio, G.; Javadi, A.; Liggieri, L. Methods and models to investigate the physicochemical functionality of pulmonary surfactant. Curr. Opin. Colloid Interface Sci. 2021, 55, 101467. [Google Scholar] [CrossRef]

- Firouzi, M.; Kovalchuk, V.I.; Loglio, G.; Miller, R. Salt effects on the dilational viscoelasticity of surfactant adsorption layers. Curr. Opin. Colloid Interface Sci. 2022, 57, 101538. [Google Scholar] [CrossRef]

- Akanno, A.; Guzmán, E.; Ortega, F.; Rubio, R.G. Behavior of the water/vapor interface of chitosan solutions with an anionic surfactant: Effect of polymer–surfactant interactions. Phys. Chem. Chem. Phys. 2020, 22, 23360–23373. [Google Scholar] [CrossRef]

- Bae, J.-E.; Jung, J.B.; Kim, K.; Lee, S.-M.; Kang, N.-G. A study on time-concentration superposition of dilatational modulus and foaming behavior of sodium alkyl sulfate. J. Colloid Interface Sci. 2019, 55, 704–716. [Google Scholar] [CrossRef]

- Suja, V.C.; Rodríguez-Hakim, M.; Tajuelo, J.; Fuller, G.G. Single bubble and drop techniques for characterizing foams and emulsions. Adv. Colloids Interface Sci. 2020, 286, 102295. [Google Scholar] [CrossRef]

- Akanno, A.; Perrin, L.; Guzmán, E.; Llamas, S.; Starov, V.M.; Ortega, F.; Rubio, R.G.; Velarde, M.G. Evaporation of Sessile Droplets of Polyelectrolyte/Surfactant Mixtures on Silicon Wafers. Colloids Interfaces 2021, 5, 12. [Google Scholar] [CrossRef]

- Noskov, B.A. Dilational surface rheology of polymer and polymer/surfactant solutions. Curr. Opin. Colloid Interface Sci. 2010, 15, 229–236. [Google Scholar] [CrossRef]

- Javadi, A.; Krägel, J.; Makievski, A.V.; Kovalchuk, V.I.; Kovalchuk, N.M.; Mucic, N.; Loglio, G.; Pandolfini, P.; Karbaschi, M.; Miller, R. Fast dynamic interfacial tension measurements and dilational rheology of interfacial layers by using the capillary pressure technique. Colloids Surf. A 2012, 407, 159–168. [Google Scholar] [CrossRef]

- Saad, S.; Neumann, A. Axisymmetric drop shape analysis (ADSA): An outline. Adv. Colloids Interface Sci. 2016, 238, 62–87. [Google Scholar] [CrossRef]

- Danov, K.; Stanimirova, R.; Kralchevsky, P.; Marinova, K.; Alexandrov, N.; Stoyanov, S.; Blijdenstein, T.; Pelan, E. Capillary meniscus dynamometry—method for determining the surface tension of drops and bubbles with isotropic and anisotropic surface stress distributions. J. Colloid Interface Sci. 2015, 440, 168–178. [Google Scholar] [CrossRef]

- Ravera, F.; Loglio, G.; Kovalchuk, V.I. Interfacial dilational rheology by oscillating bubble/drop methods. Curr. Opin. Colloid Interface Sci. 2010, 15, 217–228. [Google Scholar] [CrossRef]

- Kotula, A.P.; Anna, S.L. Regular perturbation analysis of small amplitude oscillatory dilatation of an interface in a capillary pressure tensiometer. J. Rheol. 2014, 59, 85–117. [Google Scholar] [CrossRef]

- Kovalchuk, V.I.; Krägel, J.; Makievski, A.V.; Loglio, G.; Ravera, F.; Liggieri, L.; Miller, R. Frequency characteristics of amplitude and phase of oscillating bubble systems in a closed measuring cell. J. Colloid Interface Sci. 2002, 252, 433–442. [Google Scholar] [CrossRef]

- Guzmán, E.; Santini, E.; Ferrari, M.; Liggieri, L.; Ravera, F. Evaluation of the impact of carbonaceous particles in the mechanical performance of lipid Langmuir monolayers. Colloids Surf. A 2022, 634, 127974. [Google Scholar] [CrossRef]

- Guzmán, E.; Santini, E.; Ferrari, M.; Liggieri, L.; Ravera, F. Interaction of Particles with Langmuir Monolayers of 1,2-Dipalmitoyl-Sn-Glycero-3-Phosphocholine: A Matter of Chemistry? Coatings 2020, 10, 469. [Google Scholar] [CrossRef]

- Petkov, J.; Gurkov, T.; Campbell, B.; Borwankar, R. Dilatational and shear elasticity of gel-like protein layers on air/water interface. Langmuir 2000, 16, 3703–3711. [Google Scholar] [CrossRef]

- Vora, S.; Bognet, B.; Patanwala, H.; Young, C.; Chang, S.; Daux, V.; Ma, A. Global strain field mapping of a particle-laden interface using digital image correlation. J. Colloid Interface Sci. 2018, 509, 94–101. [Google Scholar] [CrossRef]

- Alicke, A.; Simon, S.; Sjöblom, J.; Vermant, J. Assessing the interfacial activity of insoluble asphaltene layers: Interfacial rheology versus interfacial tension. Langmuir 2020, 36, 14942–14959. [Google Scholar] [CrossRef]

- Duncan, J.H.; Waxman, A.M.; Tulin, M.P. The dynamics of waves at the interface between a viscoelastic coating and a fluid flow. J. Fluid Mech. 1985, 158, 177–197. [Google Scholar] [CrossRef]

- Slavchov, R.I.; Peychev, B.; Ismail, A.S. Characterization of capillary waves: A review and a new optical method. Phys. Fluids 2021, 33, 101303. [Google Scholar] [CrossRef]

- Sergievskaya, I.; Ermakov, S.; Lazareva, T.; Guo, J. Damping of surface waves due to crude oil/oil emulsion films on water. Mar. Pollut. Bull. 2019, 146, 206–214. [Google Scholar] [CrossRef]

- Ermakov, S.A. Damping of gravity-capillary waves on water surface covered with a visco-elastic film of finite thickness. Izv. Atmos. Ocean. Phys. 2003, 39, 624–628. [Google Scholar]

- Ermakov, S.A.; Kijashko, S.V. Laboratory study of the damping of parametric ripples due to surfactant films. In Marine Surface Films. Chemical Characteristics, Influence on Air-Sea Interactions and Remote Sensing; Gade, M., Hühnerfuss, H., Korenowski, G.M., Eds.; Springer: Berlin, Germany, 2006; pp. 113–128. [Google Scholar]

- Langevin, D. Rheology of adsorbed surfactant monolayers at fluid surfaces. Annu. Rev. Fluid Mech. 2014, 46, 47–65. [Google Scholar] [CrossRef]

- Liu, X.; Duncan, J.H.; Korenowski, G.M.; Kelly, J.S. A laboratory study of longitudinal waves in surfactant films in a water wave tank. J. Geophys. Res. Oceans 2007, 122, C06005. [Google Scholar] [CrossRef]

- Rajan, G.K. Dissipation of interfacial Marangoni waves and their resonance with capillary-gravity waves. Int. J. Eng. Sci. 2020, 154, 103340. [Google Scholar] [CrossRef]

- Rajan, G.K. Solutions of a comprehensive dispersion relation for waves at the elastic interface of two viscous fluids. Eur. J. Mech. B Fluids 2021, 89, 241–258. [Google Scholar] [CrossRef]

- Derkach, S.R.; Krägel, J.; Miller, R. Methods of measuring rheological properties of interfacial layers (Experimental methods of 2D rheology). Colloid J. 2009, 71, 1–17. [Google Scholar] [CrossRef]

- Rajan, G.K. Damping rate measurements and predictions for gravity waves in an air–oil–water system. Phys. Fluids 2022, 34, 022113. [Google Scholar] [CrossRef]

- Lau, Y.M.; Westerweel, J.; Van De Water, W. Using Faraday Waves to Measure Interfacial Tension. Langmuir 2020, 36, 5872–5879. [Google Scholar] [CrossRef]

- Kharbedia, M.; Caselli, N.; Herráez-Aguilar, D.; López-Menéndez, H.; Enciso, E.; Santiago, J.A.; Monroy, F. Moulding hydrodynamic 2D-crystals upon parametric Faraday waves in shear-functionalized water surfaces. Nat. Commun. 2021, 12, 1130. [Google Scholar] [CrossRef]

- Henderson, D.M. Effects of surfactants on Faraday-wave dynamics. J. Fluid Mech. 1998, 365, 89–107. [Google Scholar] [CrossRef]

- Henderson, D.M.; Larsson, K.; Rao, Y.K. A study of wheat storage protein monolayers by Faraday wave damping. Langmuir 1991, 7, 2731–2736. [Google Scholar] [CrossRef]

- Monroy, F.; Ortega, F.; Rubio, R.G. Dilatational rheology of insoluble polymer monolayers: Poly(vinylacetate). Phys. Rev. E 1998, 58, 7629. [Google Scholar] [CrossRef]

- Guzmán, E.; Ritacco, H.; Ortega, F.; Svitova, T.; Radke, C.J.; Rubio, R.G. Adsorption Kinetics and Mechanical Properties of Ultrathin Polyelectrolyte Multilayers: Liquid-Supported versus Solid-Supported Films. J. Phys. Chem. B 2009, 113, 7128–7137. [Google Scholar] [CrossRef]

- Alexandrov, N.A.; Marinova, K.G.; Gurkov, T.D.; Danov, K.D.; Kralchevsky, P.A.; Stoyanov, S.D.; Blijdenstein, T.B.J.; Arnaudov, L.N.; Pelan, E.G. Interfacial layers from the protein HFBII hydrophobin: Dynamic surface tension, dilatational elasticity and relaxation times. J. Colloid Interface Sci. 2012, 376, 296–306. [Google Scholar] [CrossRef]

- Hilles, H.; Monroy, F. Dilational creep compliance in Langmuir polymer films. Soft Matter 2011, 7, 7790–7796. [Google Scholar] [CrossRef]

- Findley, W.N.; Lai, J.S.; Onaran, K. Creep and Relaxation of Nonlinear Viscoelastic Materials; Dover Publications, Inc.: New York, NY, USA, 1976. [Google Scholar]

- Ravera, F.; Liggieri, L.; Loglio, G. Dilational rheology of adsorbed layers by oscillating drops and bubbles. In Interfacial Rheology; Miller, R., Liggieri, L., Eds.; Brill: Leiden, The Netherlands, 2009; pp. 138–173. [Google Scholar]

- Lombardini, P.P.; Piazzese, F.; Cini, R. The Marangoni wave in ripples on an air-water interface covered by a spreading film. Il Nuovo Cimento C 1982, 5, 256–263. [Google Scholar] [CrossRef]

- Ghia, P.L.; Trivero, P. On the vibration modes of the air-water interface in the presence of surface films. Il Nuovo Cimento C 1988, 11, 305–315. [Google Scholar] [CrossRef]

- Fiscella, B.; Lombardini, P.P.; Trivero, P.; Cini, R. Ripple damping on water surface covered by a spreading film: Theory and experiment. Il Nuovo Cimento C 1985, 8, 491–500. [Google Scholar] [CrossRef]

- Monroy, F.; Ortega, F.; Rubio, R.G.; Velarde, M.G. Surface rheology, equilibrium and dynamic features at interfaces, with emphasis on efficient tools for probing polymer dynamics at interfaces. Adv. Colloids Interface Sci. 2007, 134–135, 175–189. [Google Scholar] [CrossRef]

- Cicuta, P.; Hopkinson, I. Recent developments of surface light scattering as a tool for optical-rheology of polymer monolayers. Colloids Surf. A 2004, 233, 97–107. [Google Scholar] [CrossRef]

- Sutherland, G.; Halsne, T.; Rabault, J.; Jensen, A. The attenuation of monochromatic surface waves due to the presence of an inextensible cover. Wave Motion 2017, 68, 88–96. [Google Scholar] [CrossRef]

- Jenkins, A.D.; Jacobs, S.J. Wave damping by a thin layer of viscous fluid. J. Fluid Mech. 1997, 9, 1256. [Google Scholar] [CrossRef]

- Monroy, F. Surface hydrodynamics of viscoelastic fluids and soft solids: Surfing bulk rheology on capillary and Rayleigh waves. Adv. Colloid Interface Sci. 2017, 247, 4–22. [Google Scholar] [CrossRef]

- Muñoz, M.G.; Monroy, F.; Hernández, P.; Ortega, F.; Rubio, R.G.; Langevin, D. Anomalous Damping of the Capillary Waves at the Air−Water Interface of a Soluble Triblock Copolymer. Langmuir 2003, 19, 2147–2154. [Google Scholar] [CrossRef]

- Baidakov, V.G.; Protsenko, S.P.; Bryukhanov, V.M. Relaxation processes at liquid-gas interfaces in one- and two-component Lennard-Jones systems: Molecular dynamics simulation. Fluid Ph. Equilibria 2019, 481, 1–14. [Google Scholar] [CrossRef]

- Lucassen, J.; Van Den Tempel, M. Dynamic measurements of dilational properties of a liquid interface. Chem. Eng. Sci. 1972, 27, 1283–1291. [Google Scholar] [CrossRef]

- Van den Tempel, M.; Lucassen-Reynders, E. Relaxation processes at fluid interfaces. Adv. Colloid Interface Sci. 1983, 18, 281–301. [Google Scholar] [CrossRef]

- Liggieri, L.; Miller, R. Interfacial rheology—The response of two-dimensional layers on external perturbations. Curr. Opin. Colloid Interface Sci. 2010, 15, 256–263. [Google Scholar] [CrossRef]

- Muñoz-López, R.; Guzmán, E.; Velázquez, M.M.; Fernández-Peña, L.; Merchán, M.D.; Maestro, A.; Ortega, F.; Rubio, R.G. Influence of Carbon Nanosheets on the Behavior of 1,2-Dipalmitoyl-sn-glycerol-3-phosphocholine Langmuir Monolayers. Processes 2020, 8, 94. [Google Scholar] [CrossRef]

- Guzmán, E.; Fernández-Peña, L.; Akanno, A.; Llamas, S.; Ortega, F.; Rubio, R.G. Two Different Scenarios for the Equilibration of Polycation—Anionic Solutions at Water–Vapor Interfaces. Coatings 2019, 9, 438. [Google Scholar] [CrossRef]

- Llamas, S.; Guzmán, E.; Akanno, A.; Fernández-Peña, L.; Ortega, F.; Campbell, R.A.; Miller, R.; Rubio, R.G. Study of the Liquid/Vapor Interfacial Properties of Concentrated Polyelectrolyte–Surfactant Mixtures Using Surface Tensiometry and Neutron Reflectometry: Equilibrium, Adsorption Kinetics, and Dilational Rheology. J. Phys. Chem. C 2018, 122, 4419–4427. [Google Scholar] [CrossRef]

- Liggieri, L.; Santini, E.; Guzmán, E.; Maestro, A.; Ravera, F. Wide-frequency dilational rheology investigation of mixed silica nanoparticle–CTAB interfacial layers. Soft Matter 2011, 7, 7699–7709. [Google Scholar] [CrossRef]

- Akanno, A.; Guzmán, E.; Fernández-Peña, L.; Llamas, S.; Ortega, F.; Rubio, R.G. Equilibration of a Polycation–Anionic Surfactant Mixture at the Water/Vapor Interface. Langmuir 2018, 34, 7455–7464. [Google Scholar] [CrossRef] [PubMed]

- Llamas, S.; Mendoza, A.J.; Guzmán, E.; Ortega, F.; Rubio, R.G. Salt effects on the air/solution interfacial properties of PEO-containing copolymers: Equilibrium, adsorption kinetics and surface rheological behavior. J. Colloid Interface Sci. 2013, 400, 49–58. [Google Scholar] [CrossRef] [PubMed]

- Maestro, A.; Kotsmar, C.; Javadi, A.; Miller, R.; Ortega, F.; Rubio, R.G. Adsorption of β-Casein–Surfactant Mixed Layers at the Air–Water Interface Evaluated by Interfacial Rheology. J. Phys. Chem. B 2012, 116, 4898–4907. [Google Scholar] [CrossRef] [PubMed]

- Maestro, A.; Ortega, F.; Rubio, R.G.; Rubio, M.A.; Krägel, J.; Miller, R. Rheology of poly(methyl methacrylate) Langmuir monolayers: Percolation transition to a soft glasslike system. J. Chem. Phys. 2011, 134, 104704. [Google Scholar] [CrossRef]

- Riande, E.; Diaz-Calleja, R.; Prolongo, M.G.; Masegosa, R.; Salom, C. Polymer Viscoelasticity: Stress and Strain in Practice; CRC Press: Boca Raton, FL, USA, 2000. [Google Scholar]

- Hilles, H.; Maestro, A.; Monroy, F.; Ortega, F.; Rubio, R.G. Polymer monolayers with a small viscoelastic linear regime: Equilibrium and rheology of poly(octadecyl acrylate) and poly(vinyl stearate). J. Chem. Phys. 2007, 126, 124904. [Google Scholar] [CrossRef]

- Hilles, H.; Monroy, F.; Bonales, L.J.; Ortega, F.; Rubio, R.G. Fourier-transform rheology of polymer Langmuir monolayers: Analysis of the non-linear and plastic behaviors. Adv. Colloid Interface Sci. 2006, 122, 67–77. [Google Scholar] [CrossRef]

- Guzmán, E.; Santini, E.; Ferrari, M.; Liggieri, L.; Ravera, F. Effect of the Incorporation of Nanosized Titanium Dioxide on the Interfacial Properties of 1,2-Dipalmitoyl-sn-glycerol-3-phosphocholine Langmuir Monolayers. Langmuir 2017, 33, 10715–10725. [Google Scholar] [CrossRef]

- Sagis, L.M.C.; Fischer, P. Nonlinear rheology of complex fluid–fluid interfaces. Curr. Opin. Colloid Interface Sci. 2014, 19, 520–529. [Google Scholar] [CrossRef]