On an Exact Step Length in Gradient-Based Aerodynamic Shape Optimization—Part II: Viscous Flows

Abstract

1. Introduction

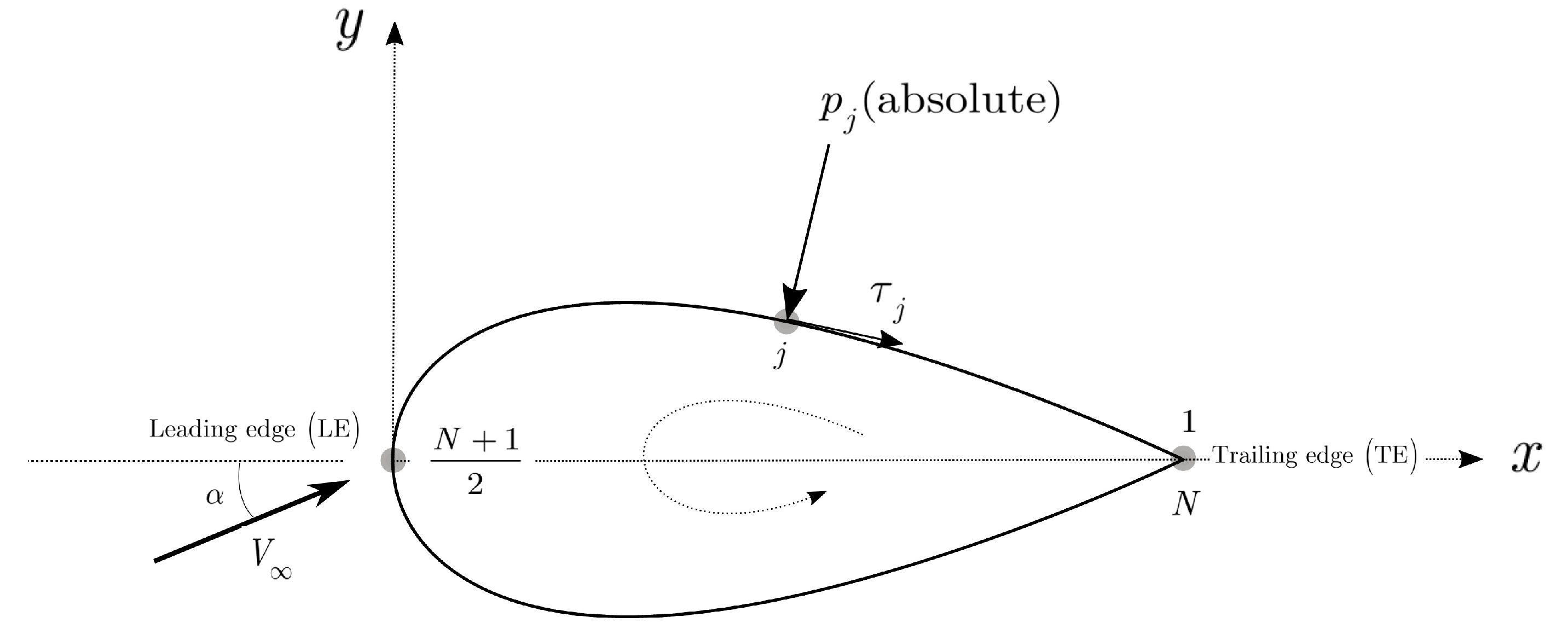

2. Governing Equations

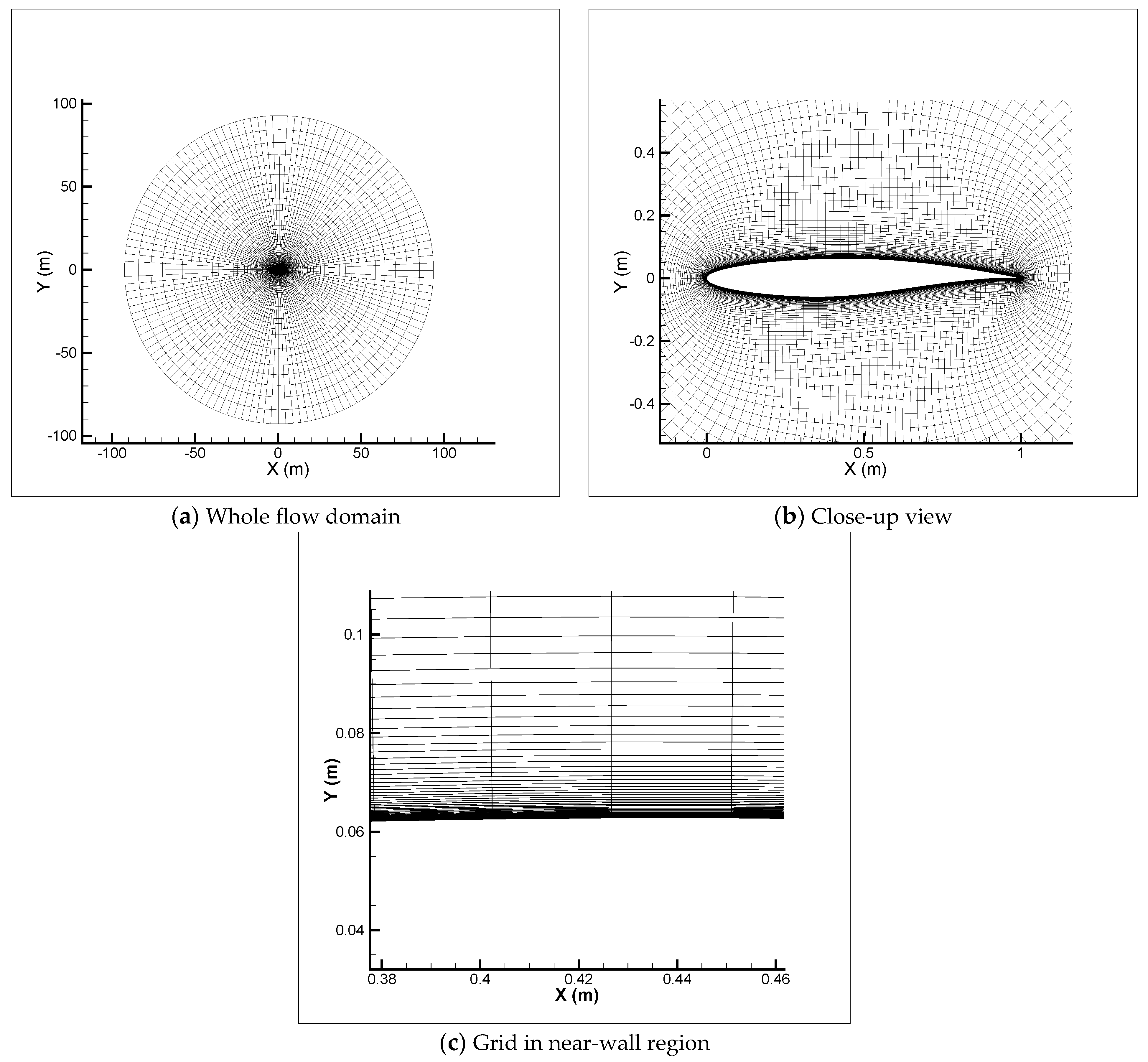

3. Aerodynamic Shape Optimization

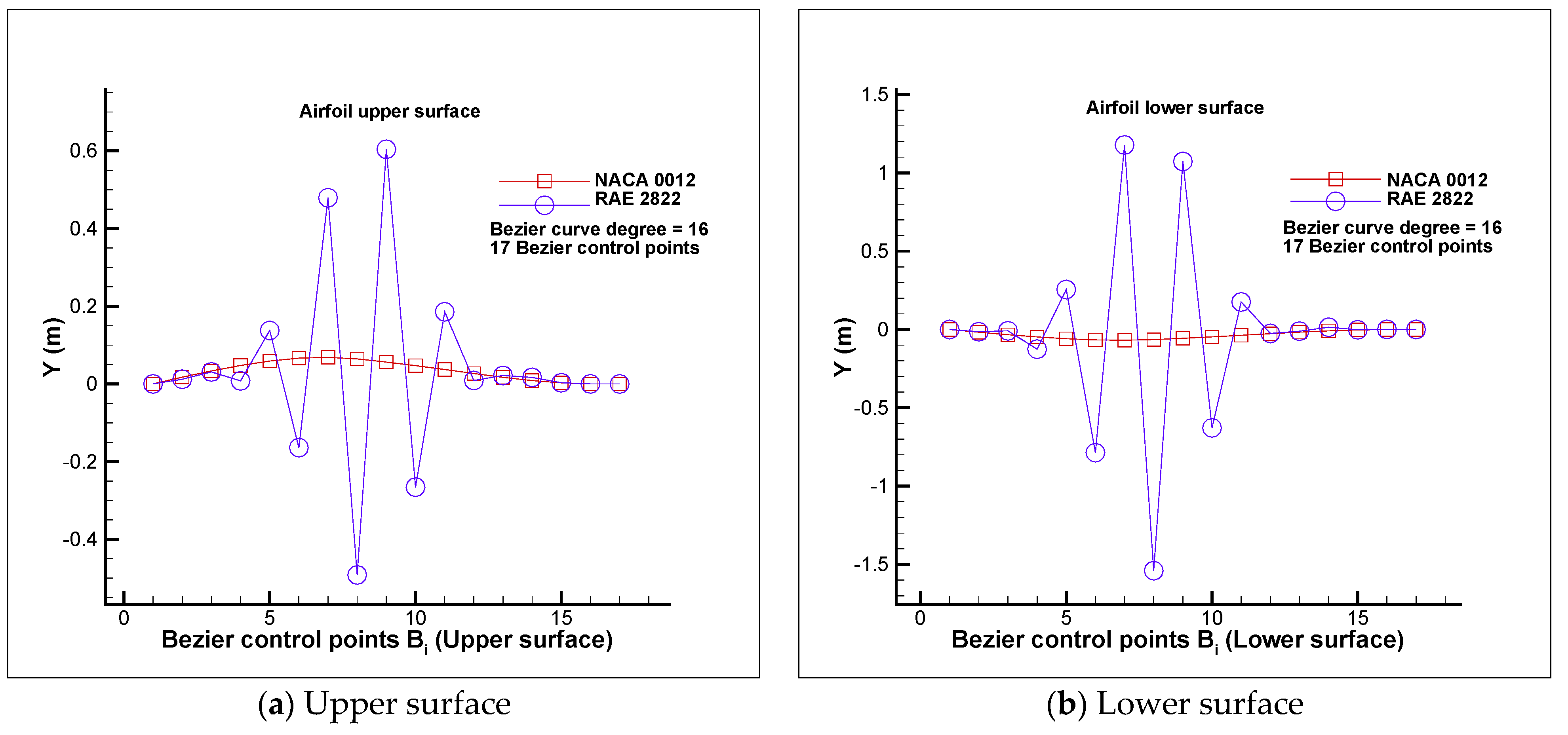

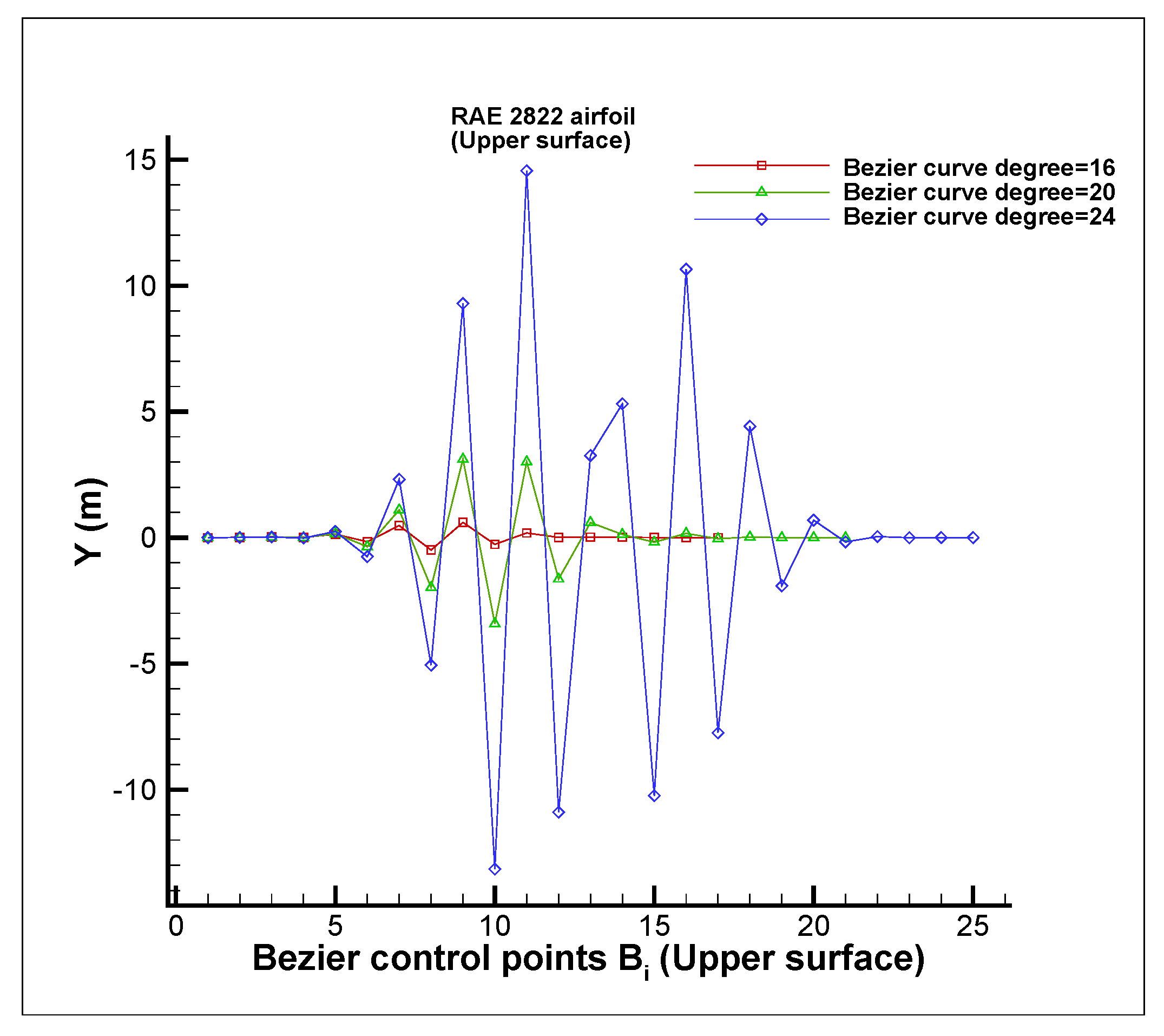

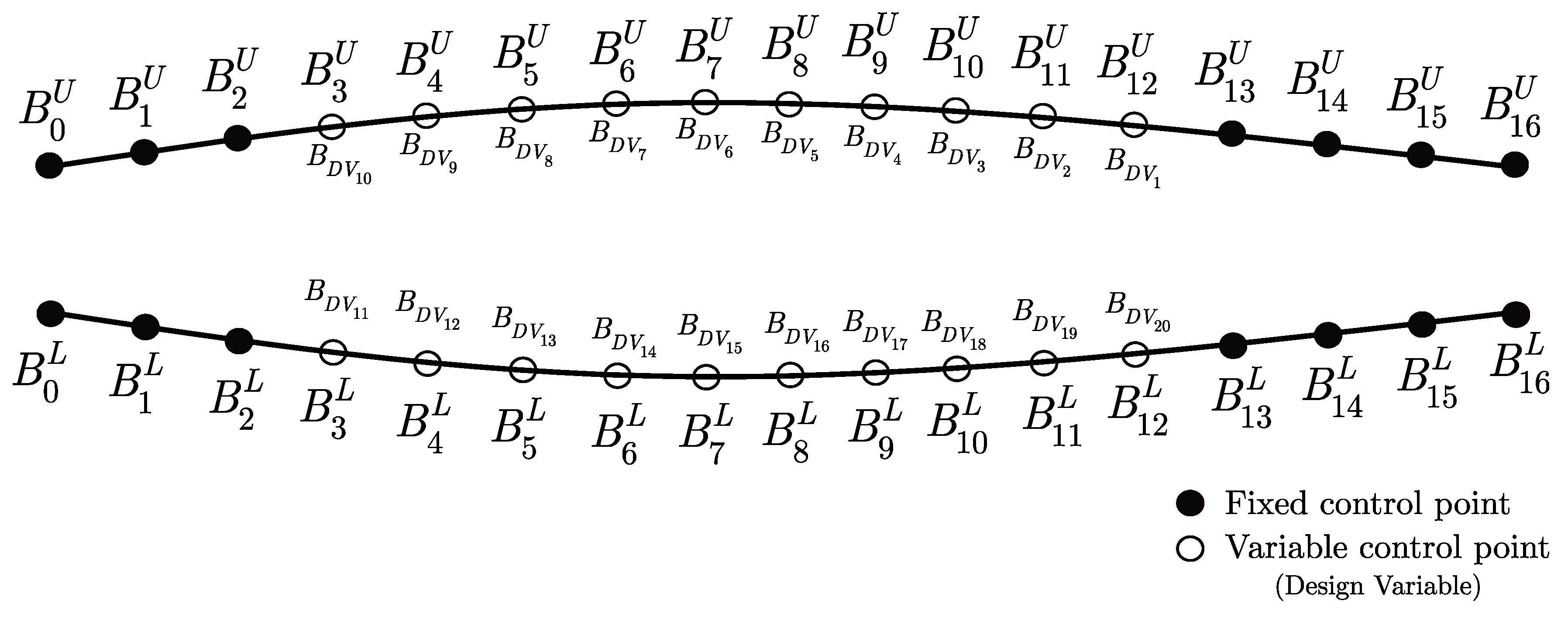

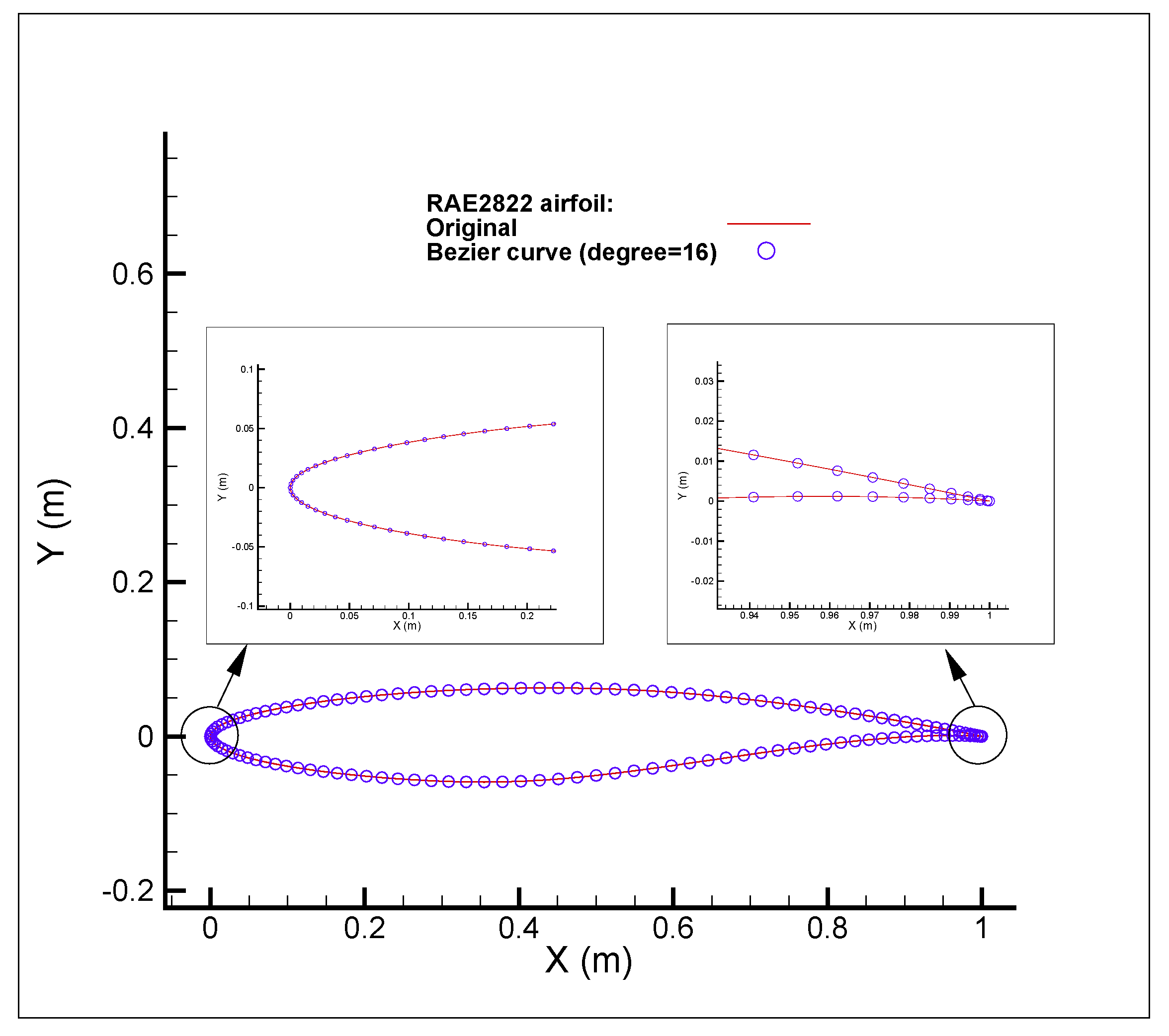

3.1. Airfoil Parameterization

3.2. Optimization Method

3.3. Exact Step Length

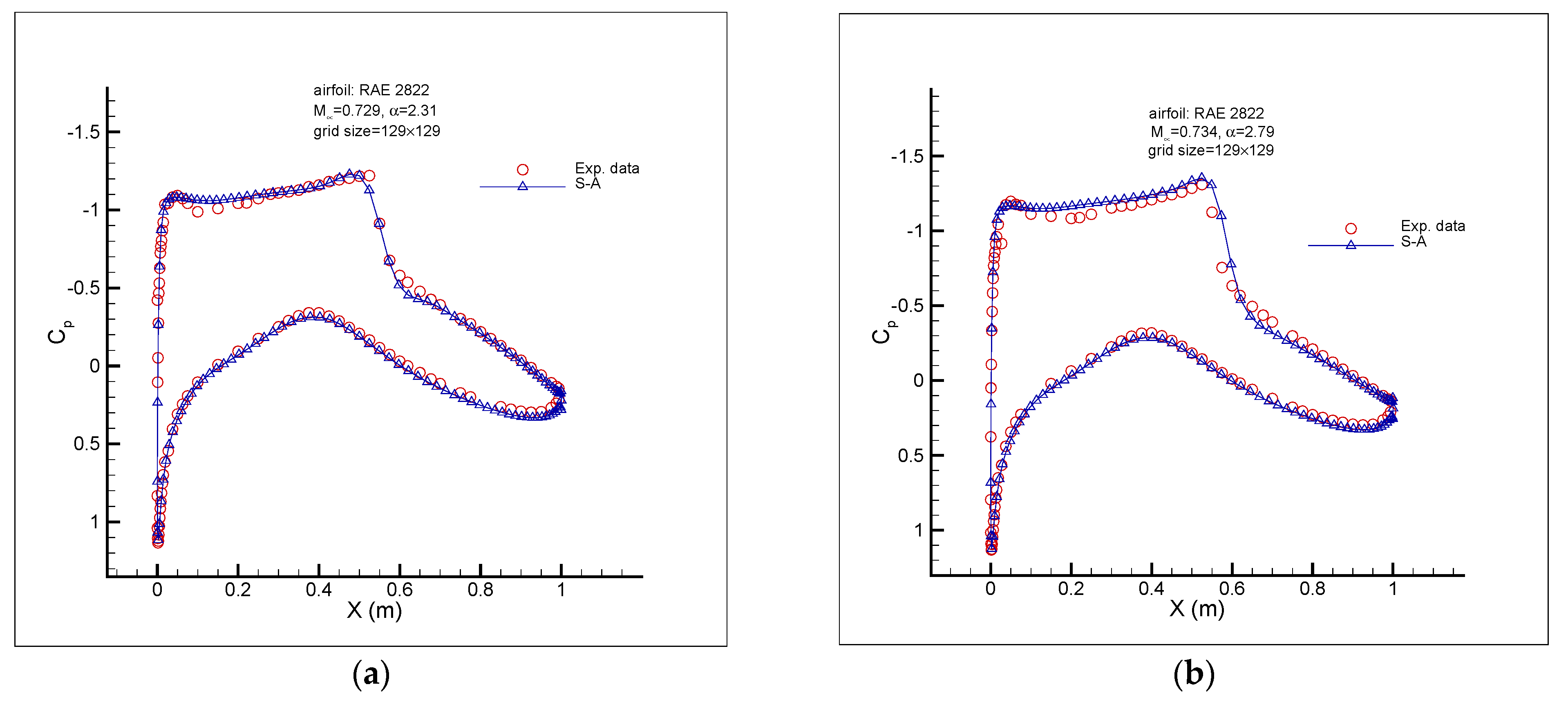

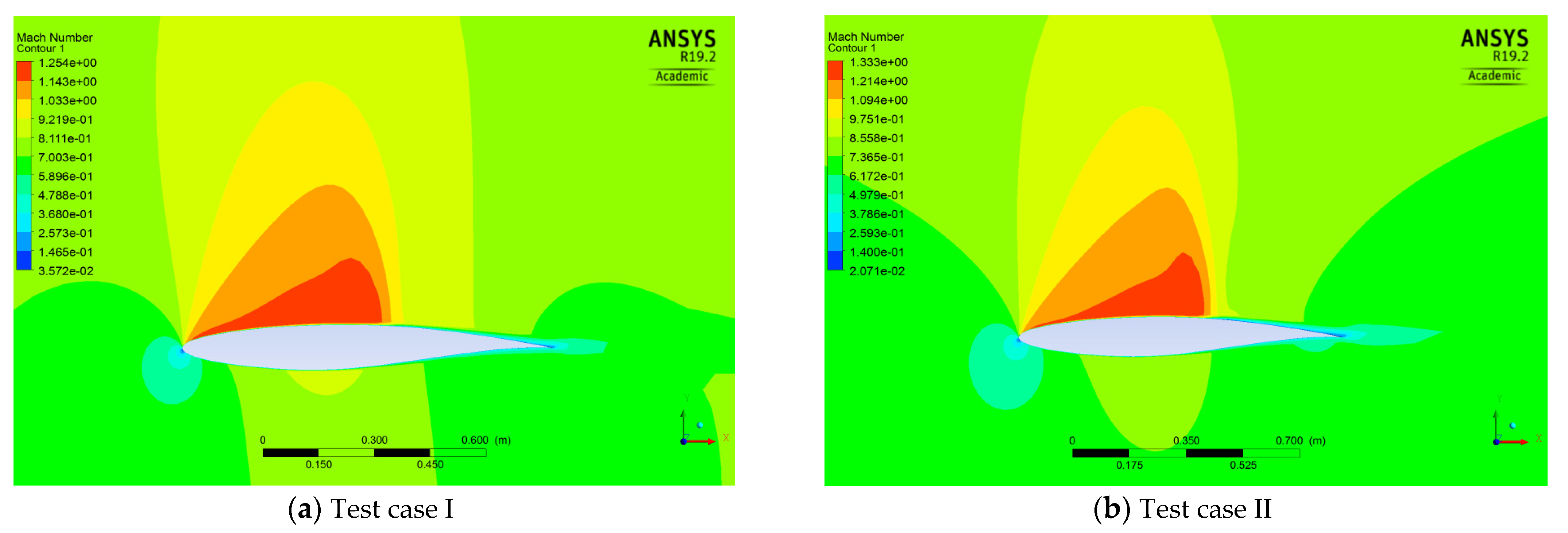

4. Results

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Mohebbi, F.; Evans, B. On an exact step length in gradient-based aerodynamic shape optimization. Fluids 2020, 5, 70. [Google Scholar] [CrossRef]

- He, X.; Li, J.; Mader, C.A.; Yildirim, A.; Martins, J.R. Robust aerodynamic shape optimization—From a circle to an airfoil. Aerosp. Sci. Technol. 2019, 87, 48–61. [Google Scholar] [CrossRef]

- Carrier, G.; Destarac, D.; Dumont, A.; Meheut, M.; El Din, I.S.; Peter, J.; Ben Khelil, S.; Brezillon, J.; Pestana, M. Gradient-based aerodynamic optimization with the elsA software. In Proceedings of the 52nd Aerospace Sciences Meeting, National Harbor, MD, USA, 13–17 January 2014; p. 0568. [Google Scholar]

- Anderson, G.R.; Nemec, M.; Aftosmis, M.J. Aerodynamic shape optimization benchmarks with error control and automatic parameterization. In Proceedings of the 53rd AIAA Aerospace Sciences Meeting, Kissimmee, FL, USA, 5–9 January 2015; p. 1719. [Google Scholar]

- Bisson, F.; Nadarajah, S.; Shi-Dong, D. Adjoint-based aerodynamic optimization of benchmark problems. In Proceedings of the 52nd Aerospace Sciences Meeting, National Harbor, MD, USA, 13–17 January 2014; p. 0412. [Google Scholar]

- Zhang, Y.; Han, Z.-H.; Shi, L.; Song, W.-P. Multi-round surrogate-based optimization for benchmark aerodynamic design problems. In Proceedings of the 54th AIAA Aerospace Sciences Meeting, San Diego, CA, USA, 4–8 January 2016; p. 1545. [Google Scholar]

- Lee, C.; Koo, D.; Telidetzki, K.; Buckley, H.; Gagnon, H.; Zingg, D.W. Aerodynamic Shape Optimization of Benchmark Problems Using Jetstream. In Proceedings of the 53rd AIAA Aerospace Sciences Meeting, Kissimmee, FL, USA, 5–9 January 2015; p. 0262. [Google Scholar]

- Poole, D.J.; Allen, C.B.; Rendall, T. Control point-based aerodynamic shape optimization applied to AIAA ADODG test cases. In Proceedings of the 53rd AIAA Aerospace Sciences Meeting, Kissimmee, FL, USA, 5–9 January 2015; p. 1947. [Google Scholar]

- Zhang, M.; Rizzi, A.W.; Nangia, R.K. Transonic airfoils and wings design using inverse and direct methods. In Proceedings of the 53rd AIAA Aerospace Sciences Meeting, Kissimmee, FL, USA, 5–9 January 2015. [Google Scholar]

- Spalart, P.; Allmaras, S. A one-equation turbulence model for aerodynamic flows. Rech. Aerosp. 1994, 1, 5–21. [Google Scholar]

- Blazek, J. Computational Fluid Dynamics: Principles and Applications; Butterworth-Heinemann: Oxford, UK, 2015. [Google Scholar]

- Cook, P.; McDonald, M.; Firmin, M. Aerofoil RAE 2822-Pressure Distributions, and Boundary Layer and Wake Measurements, Experimental Data Base for Computer Program Assessment; AGARD Report AR 138; Research and Technology Organisation (NATO): Neuilly-sur-Seine, France, 1979. [Google Scholar]

- Cobb, S.M.; Gill, P.E.; Murray, W.; Wright, M.H. Practical optimization. Math. Gaz. 1982, 66, 252. [Google Scholar] [CrossRef][Green Version]

- RAE 2822 AIRFOIL (rae2822-il). Available online: http://airfoiltools.com/airfoil/details?airfoil=rae2822-il (accessed on 20 December 2020).

- Fluent Users Guide; Version 19.2; ANSYS Inc.: Canonsburg, PA, USA, 2018.

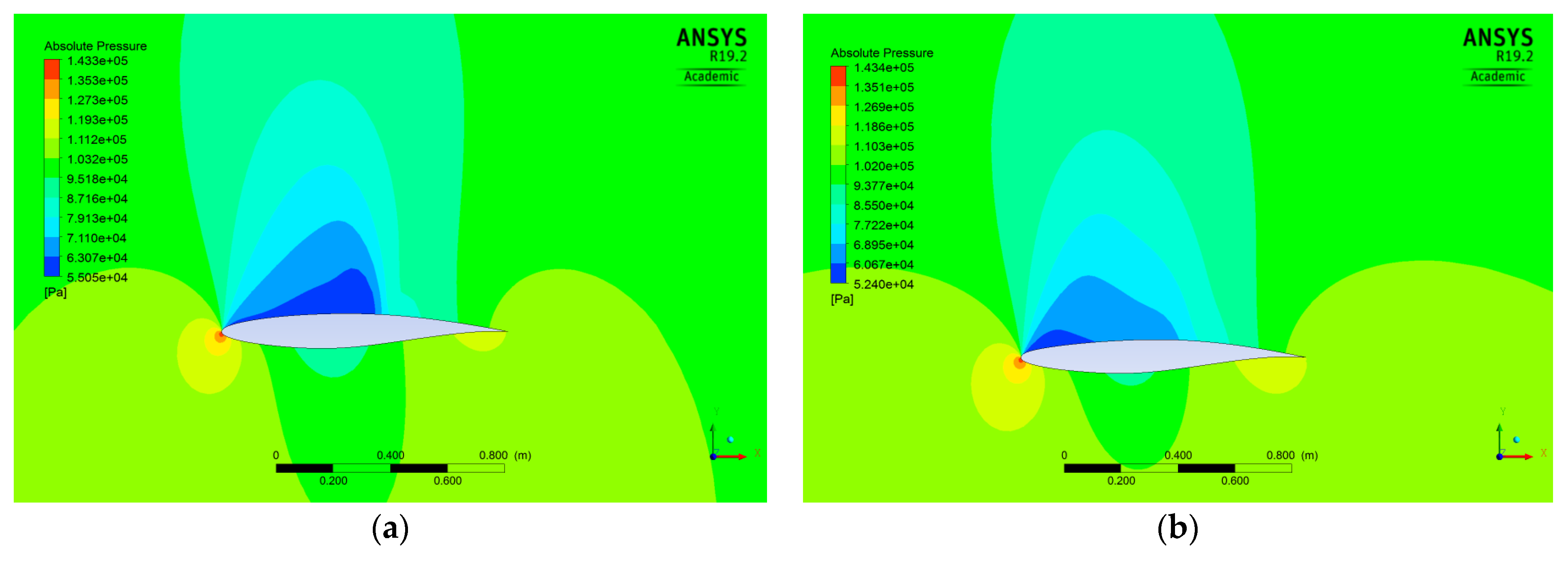

| Test Case | Grid Size | Wall Spacing | Turbulence Model | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 1 | 0.729 | 2.31 | 129 × 129 | 5 × 10−5 m | S-A | 478.215 N | 0.0127 | 28,861.262 N | 0.766 |

| Experimental results ([12]: Case 6 (corrected): | 0.0127 | 0.743 | |||||||

| 2 | 0.734 | 2.79 | 129 × 129 | 5 × 10−5 m | S-A | 780.363 N | 0.0204 | 32,671.037 N | 0.856 |

| Experimental results ([12]: Case 9 (corrected): | 0.0168 | 0.803 | |||||||

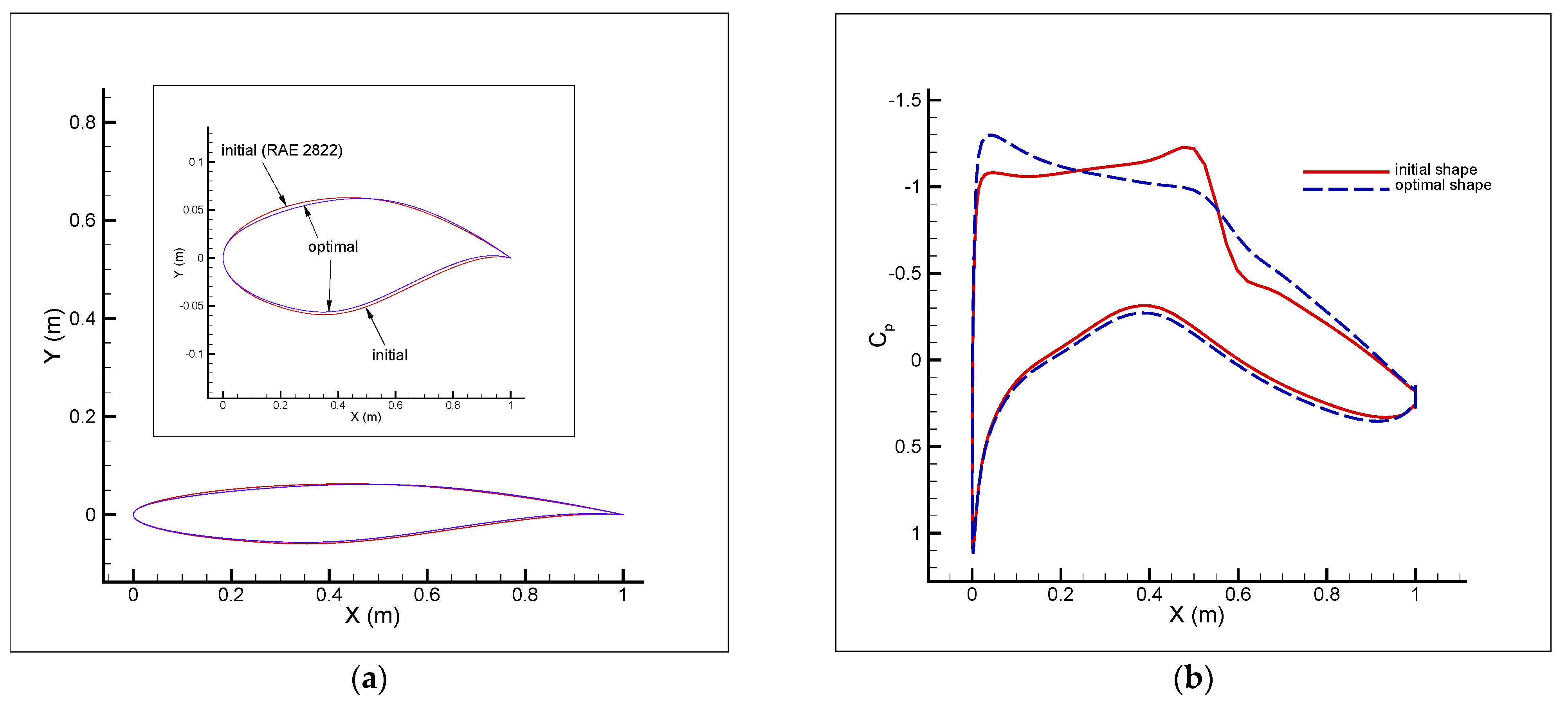

| Airfoil Shape | ||||

|---|---|---|---|---|

| Initial | 0.00753 (75.3 counts) | 0.00515 (51.5 counts) | 0.766 | Negligible |

| Optimal | 0.00478 (47.8 counts) | 0.00521 (52.1 counts) | 0.827 | Negligible |

| Variation | −27.5 counts (−36.5%) | +0.6 counts (+1.2%) | +7.9% | - |

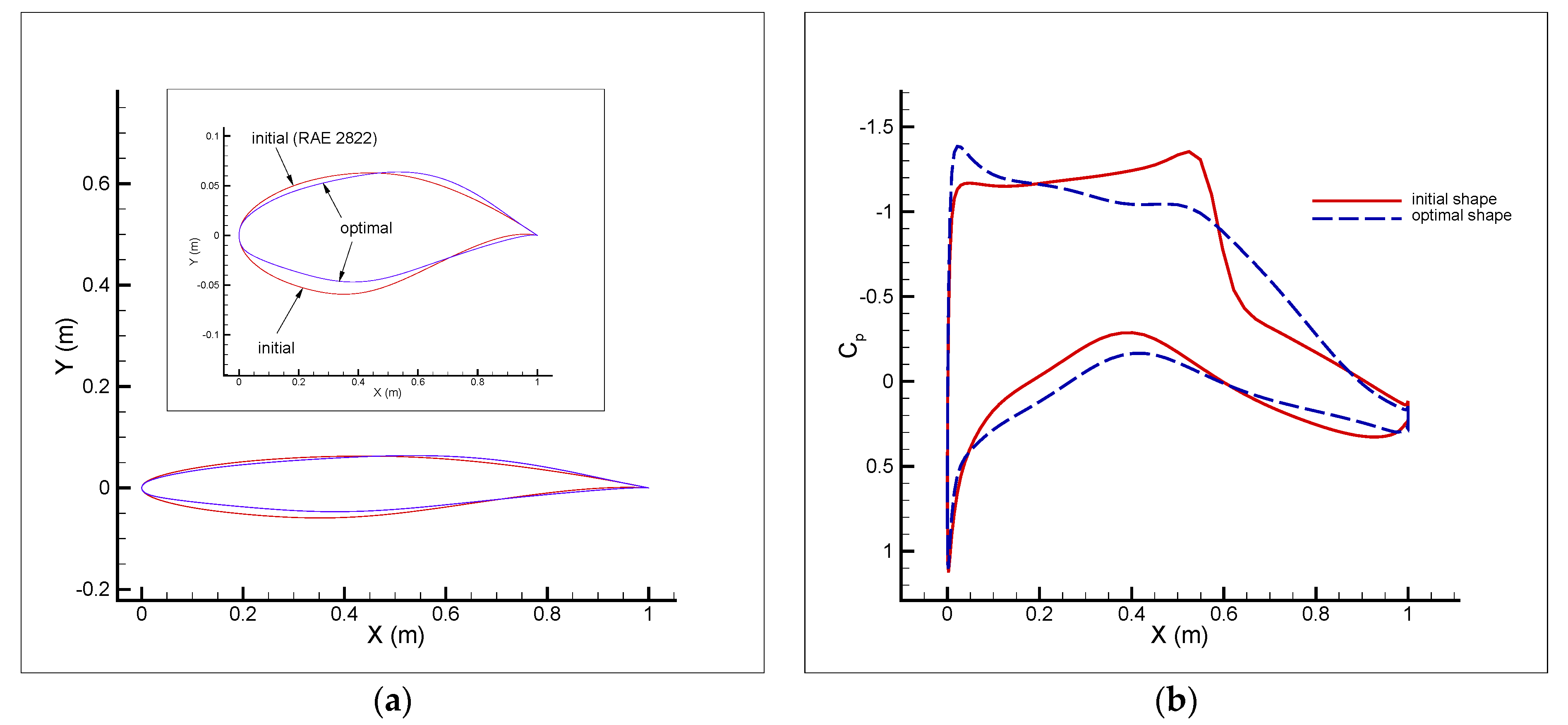

| Airfoil Shape | ||||

|---|---|---|---|---|

| Initial | 0.01551 (155.1 counts) | 0.00492 (49.2 counts) | 0.856 | negligible |

| Optimal | 0.00584 (58.4 counts) | 0.00519 (51.9 counts) | 0.893 | negligible |

| Variation | −96.7 counts (−62.3%) | +2.7 counts (+5.5%) | +4.3% | - |

| Iteration Number (k) | ||||||

|---|---|---|---|---|---|---|

| 0 (initial shape) | 2.745 × 10−4 | - | 478.215 | 0.01270 | 28,861.262 | 0.766 |

| 1 | 1.646 × 10−4 | 0.617 | 365.337 | 0.00970 | 28,471.807 | 0.756 |

| 2 | 1.605 × 10−4 | 0.380 | 362.635 | 0.00963 | 28,623.569 | 0.760 |

| 3 | 1.574 × 10−4 | 0.478 | 363.709 | 0.00966 | 28,993.749 | 0.770 |

| 4 | 1.541 × 10−4 | 0.527 | 365.979 | 0.00972 | 29,479.790 | 0.783 |

| 5 | 1.464 × 10−4 | 1.023 | 376.658 | 0.01000 | 31,132.061 | 0.827 |

| Variation: | −46.68% | −21.24% | +7.87% |

| Iteration Number (k) | ||||||

|---|---|---|---|---|---|---|

| 0 (initial shape) | 5.705 × 10−4 | - | 780.363 | 0.02044 | 32,671.037 | 0.856 |

| 1 | 1.922 × 10−4 | 0.649 | 452.707 | 0.01186 | 32,650.360 | 0.855 |

| 2 | 1.732 × 10−4 | 1.020 | 424.828 | 0.01113 | 32,278.523 | 0.845 |

| 3 | 1.704 × 10−4 | 2.892 | 422.808 | 0.01107 | 32,387.967 | 0.848 |

| 4 | 1.676 × 10−4 | 0.472 | 419.205 | 0.01098 | 32,382.375 | 0.848 |

| 5 | 1.651 × 10−4 | 0.194 | 416.252 | 0.01090 | 32,391.880 | 0.848 |

| 6 | 1.630 × 10−4 | 0.159 | 414.045 | 0.01084 | 32,427.214 | 0.849 |

| 7 | 1.613 × 10−4 | 0.071 | 412.262 | 0.01080 | 32,458.909 | 0.850 |

| 8 | 1.600 × 10−4 | 0.191 | 411.515 | 0.01078 | 32,531.610 | 0.852 |

| 9 | 1.589 × 10−4 | 0.204 | 411.136 | 0.01077 | 32,618.635 | 0.854 |

| 10 | 1.579 × 10−4 | 0.130 | 411.253 | 0.01077 | 32,725.537 | 0.857 |

| 11 | 1.570 × 10−4 | 0.176 | 411.640 | 0.01078 | 32,847.427 | 0.860 |

| 12 | 1.563 × 10−4 | 0.166 | 412.425 | 0.01080 | 32,987.541 | 0.864 |

| 13 | 1.557 × 10−4 | 0.135 | 413.322 | 0.01082 | 33,129.353 | 0.868 |

| 14 | 1.551 × 10−4 | 0.060 | 414.412 | 0.01085 | 33,274.957 | 0.871 |

| 15 | 1.546 × 10−4 | 0.135 | 415.624 | 0.01088 | 33,428.423 | 0.875 |

| 16 | 1.541 × 10−4 | 0.128 | 416.984 | 0.01092 | 33,589.964 | 0.880 |

| 17 | 1.536 × 10−4 | 0.129 | 418.408 | 0.01096 | 33,758.836 | 0.884 |

| 18 | 1.531 × 10−4 | 0.131 | 419.861 | 0.01100 | 33,937.661 | 0.889 |

| 19 | 1.526 × 10−4 | 0.023 | 421.374 | 0.01103 | 34,112.008 | 0.893 |

| Variation: | −73.25% | −46.00% | +4.41% |

| Initial Shape | Optimal Shape | Reduction |

|---|---|---|

| 1.90 × 10−2 | 2.3 × 10−3 | 87.99% |

| Initial Shape | Optimal Shape | Reduction |

|---|---|---|

| 3.33 × 10−2 | 1.5 × 10−3 | 95.46% |

| Airfoil Shape | |

|---|---|

| Initial | 60.35 |

| Optimal | 82.65 |

| Variation | +36.95% |

| Airfoil Shape | |

|---|---|

| Initial | 41.87 |

| Optimal | 80.95 |

| Variation | +93.34% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohebbi, F.; Evans, B.; Sellier, M. On an Exact Step Length in Gradient-Based Aerodynamic Shape Optimization—Part II: Viscous Flows. Fluids 2021, 6, 106. https://doi.org/10.3390/fluids6030106

Mohebbi F, Evans B, Sellier M. On an Exact Step Length in Gradient-Based Aerodynamic Shape Optimization—Part II: Viscous Flows. Fluids. 2021; 6(3):106. https://doi.org/10.3390/fluids6030106

Chicago/Turabian StyleMohebbi, Farzad, Ben Evans, and Mathieu Sellier. 2021. "On an Exact Step Length in Gradient-Based Aerodynamic Shape Optimization—Part II: Viscous Flows" Fluids 6, no. 3: 106. https://doi.org/10.3390/fluids6030106

APA StyleMohebbi, F., Evans, B., & Sellier, M. (2021). On an Exact Step Length in Gradient-Based Aerodynamic Shape Optimization—Part II: Viscous Flows. Fluids, 6(3), 106. https://doi.org/10.3390/fluids6030106