Numerical Bifurcation Analysis of a Film Flowing over a Patterned Surface through Enhanced Lubrication Theory

Abstract

:1. Introduction

2. Mathematical Model

3. Results and Discussion

3.1. Numerical Setup

- First, the stability and dynamics of a 1D falling film down an inclined plate was investigated. A uniform substrate wettability was considered. Symmetry condition, and , was applied through the lateral boundaries, and , meaning that an infinitely wide plate is simulated. and were imposed through the inlet section, located at , while fully developed flow, and , was assumed through . was set far all the 1D computations.

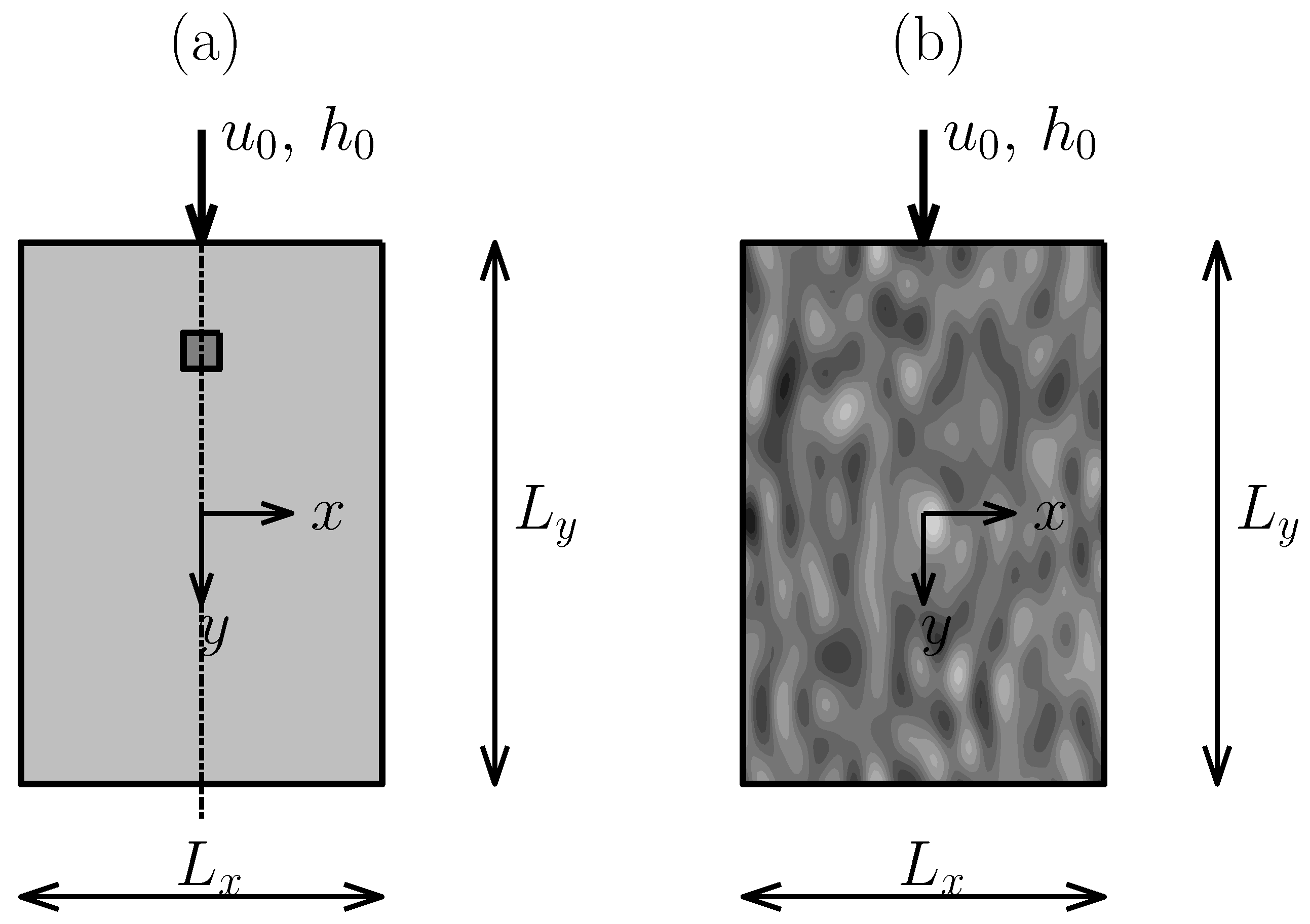

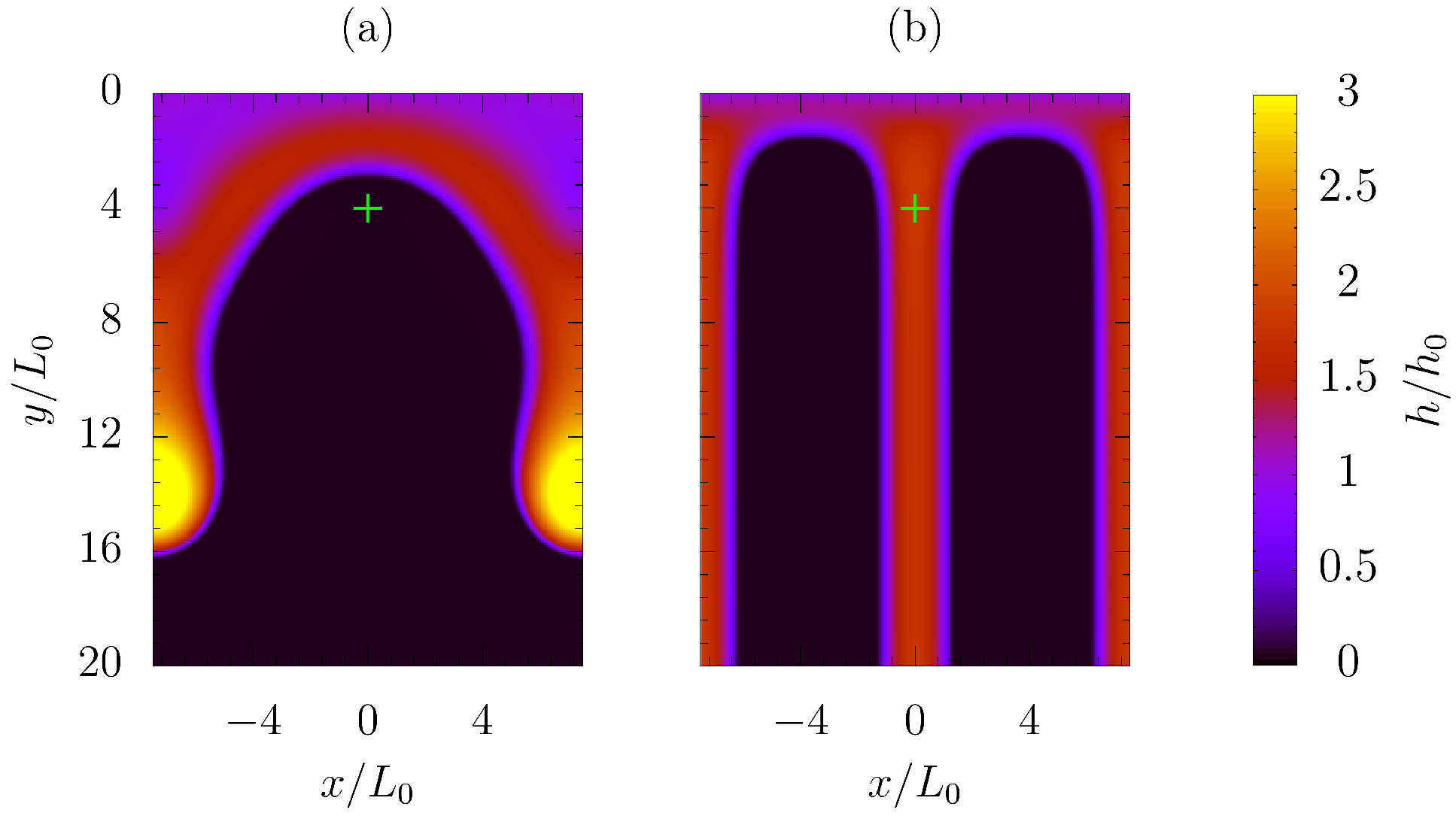

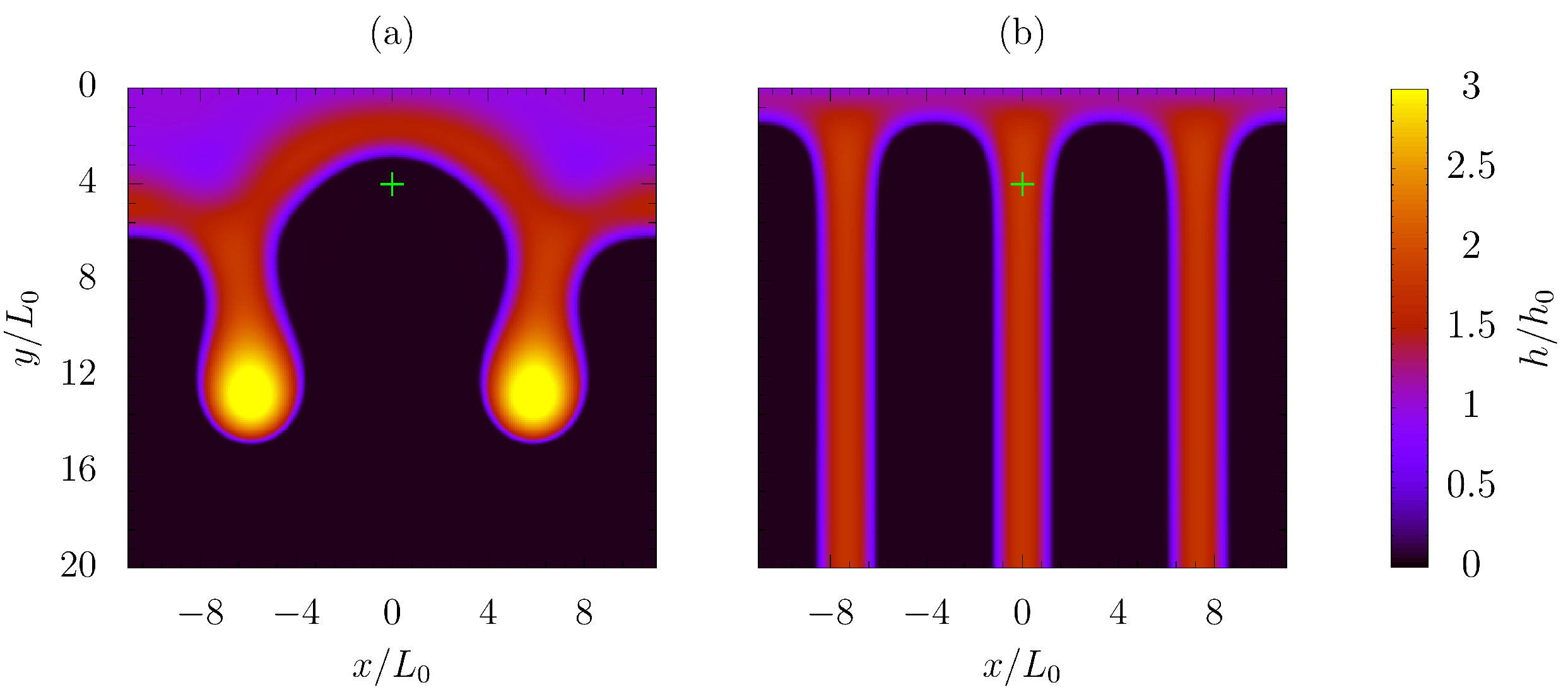

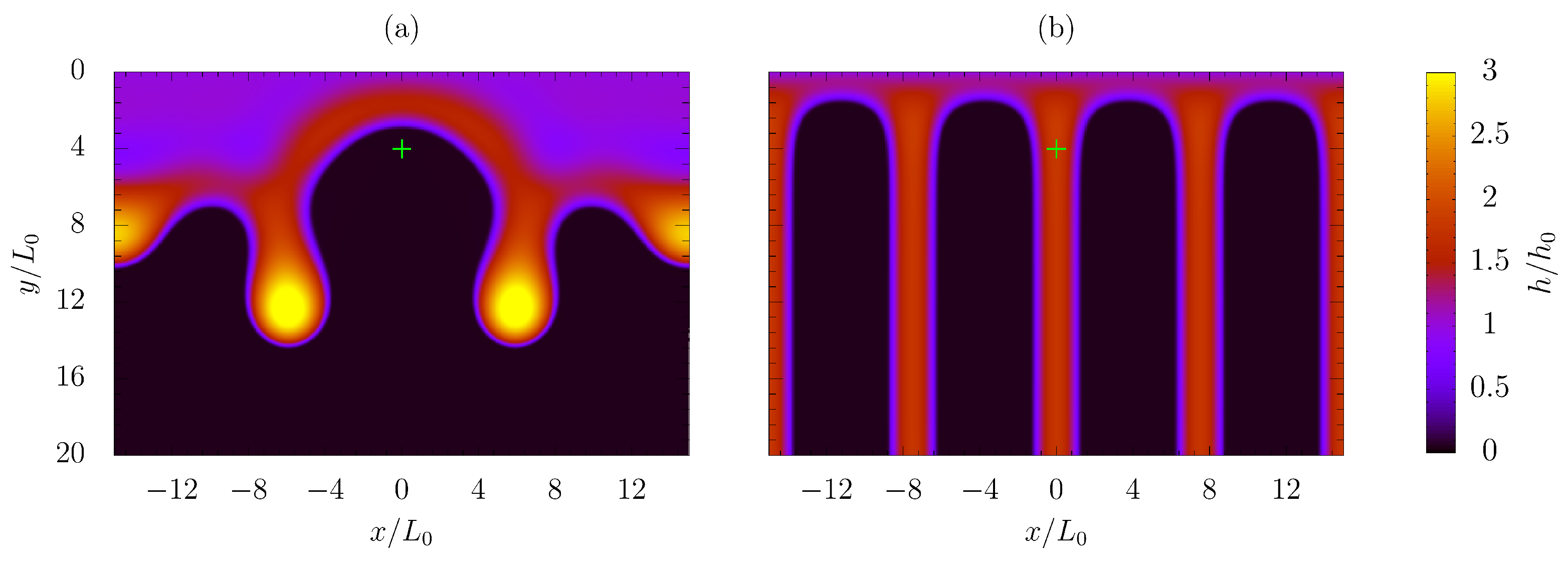

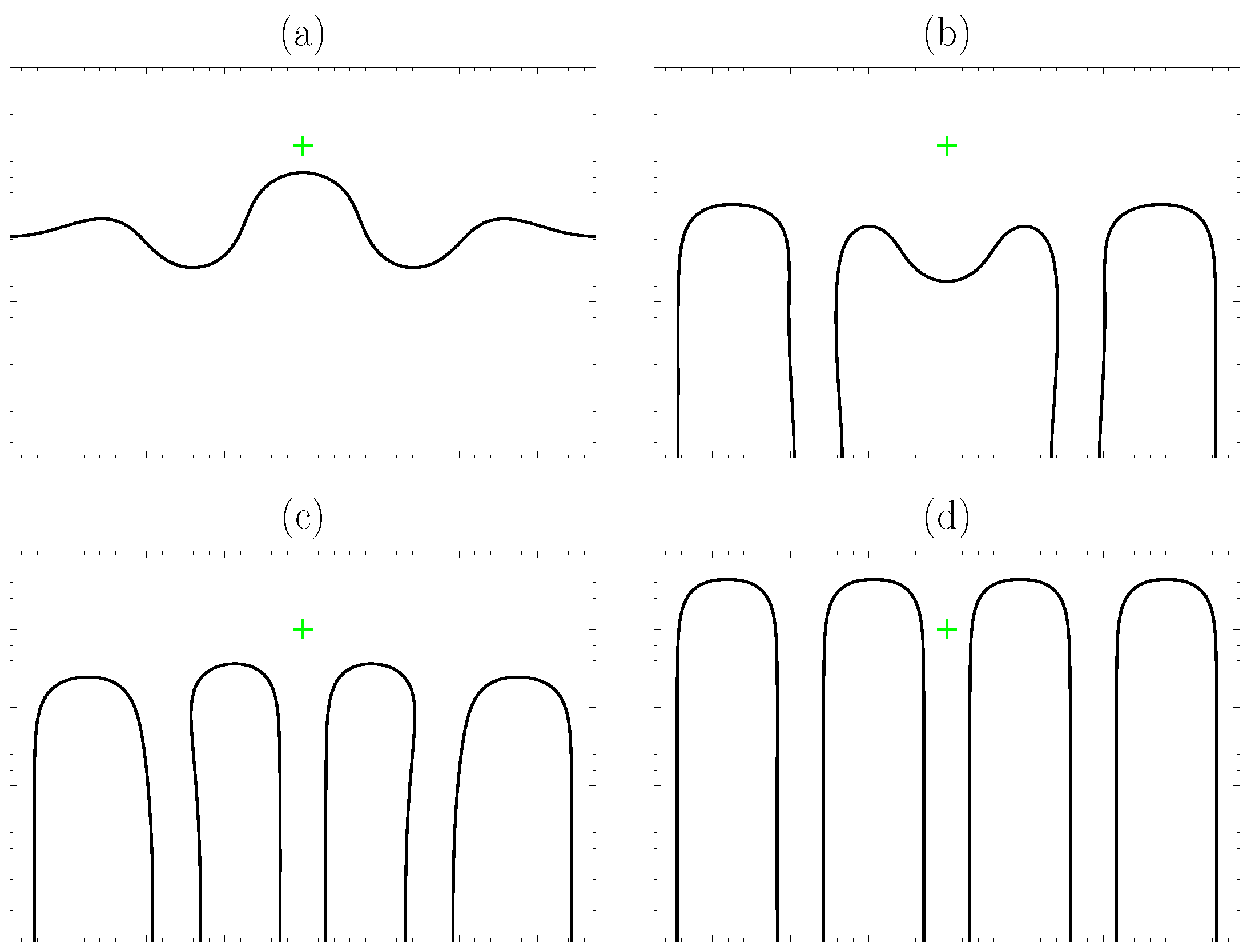

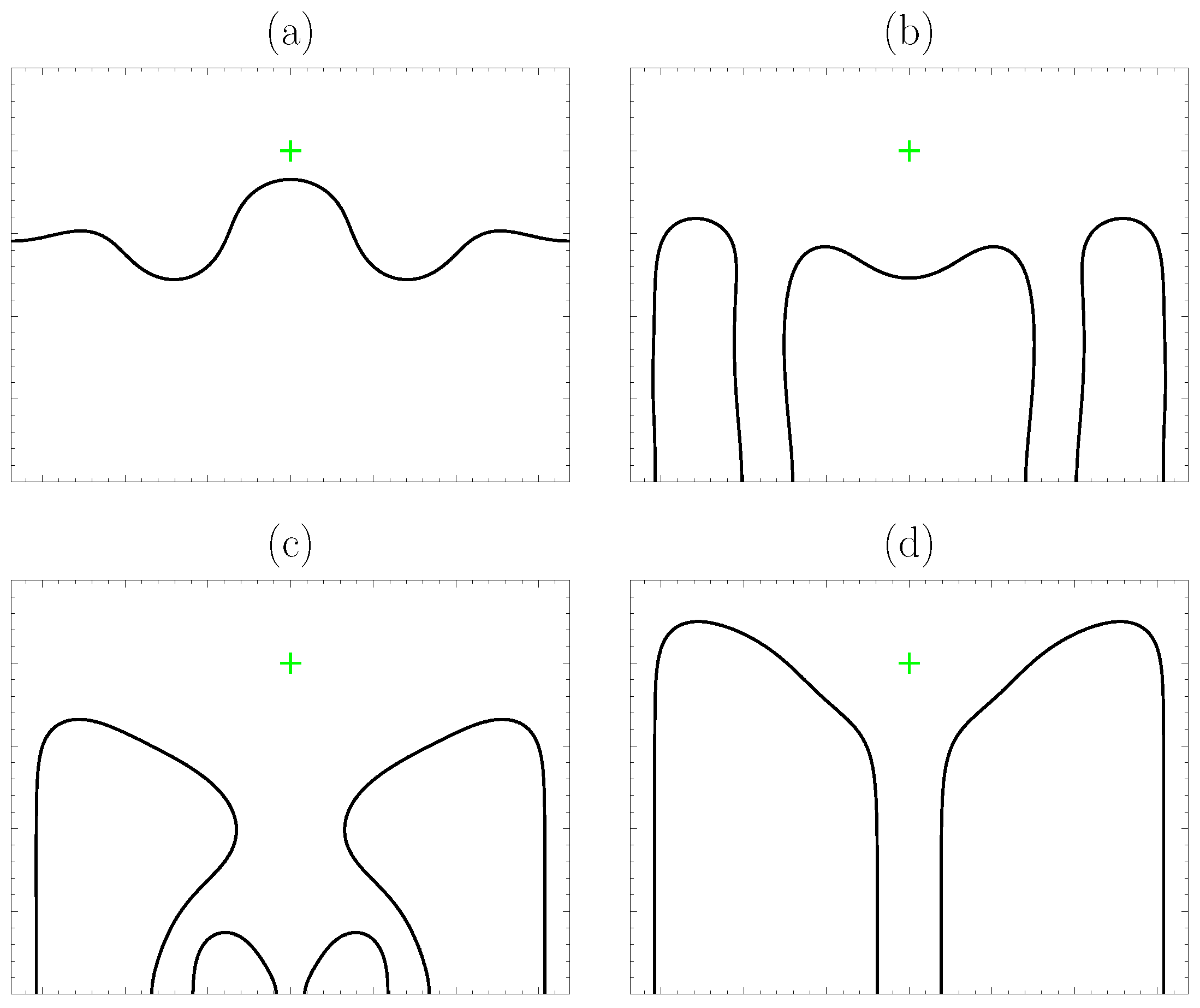

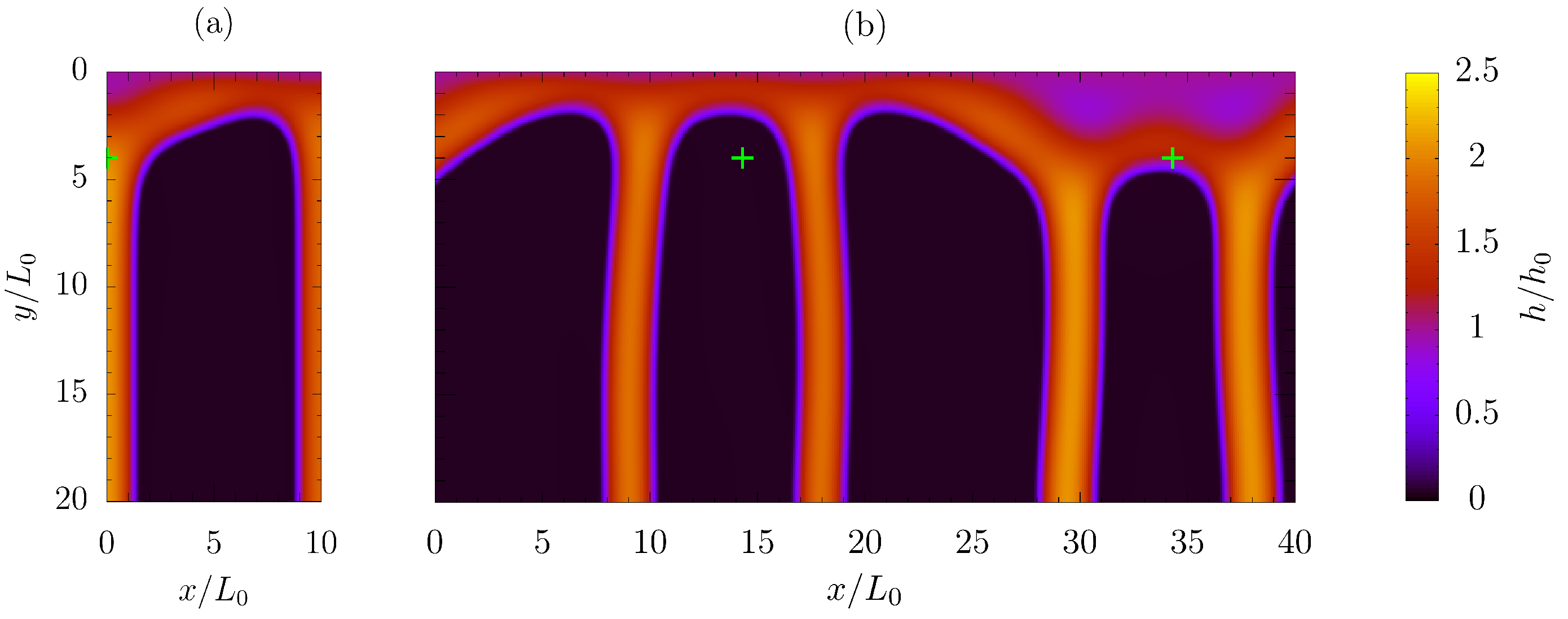

- Second, a 2D film flowing down an inclined plate, characterized by a single array of equally spaced contamination spots with decreased surface wettability, was simulated, Figure 1a. Defining as the distance between adjacent contamination spots, only a portion of width was considered, due to the problem symmetry. Thus, symmetry condition was imposed through and , while inlet condition and fully developed flow were applied at (top-most section) and (bottomest section) respectively. The low-wettable square patch of dimension defining the contamination spot was located at , far enough from the inlet section () to avoid boundary effects.

- Finally, the hybrid surface shown in Figure 1b, characterized by the following periodic, isotropic smooth random wettability distribution from [26], was investigated,with being random coefficients falling inside a given range, being the random phase of cosine function, and being the number of harmonics over x and y. In order to ensure physical consistency, periodic conditions were applied through and . Inlet condition and fully developed flow were again applied through and .

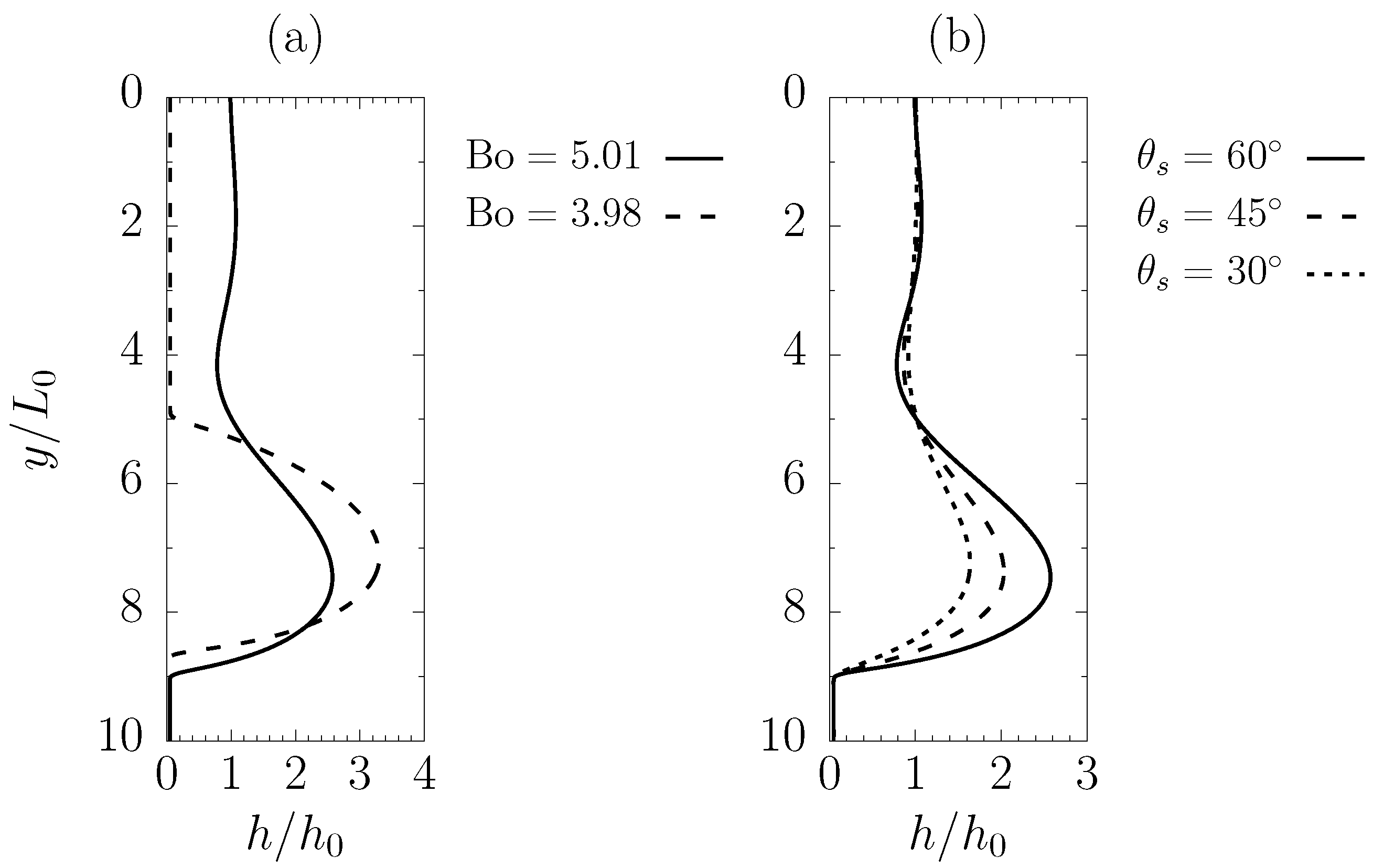

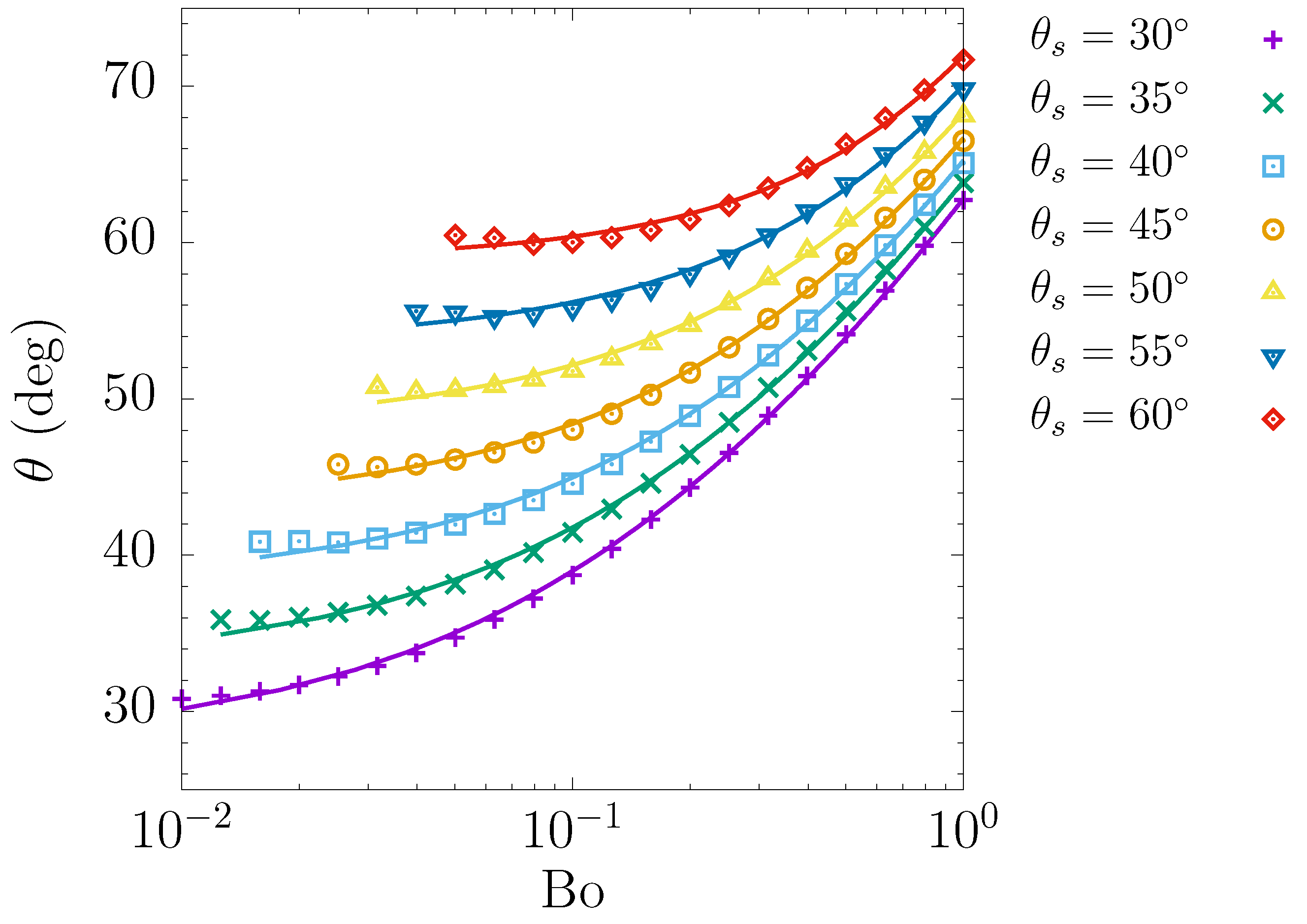

3.2. Dynamic Contact Angle

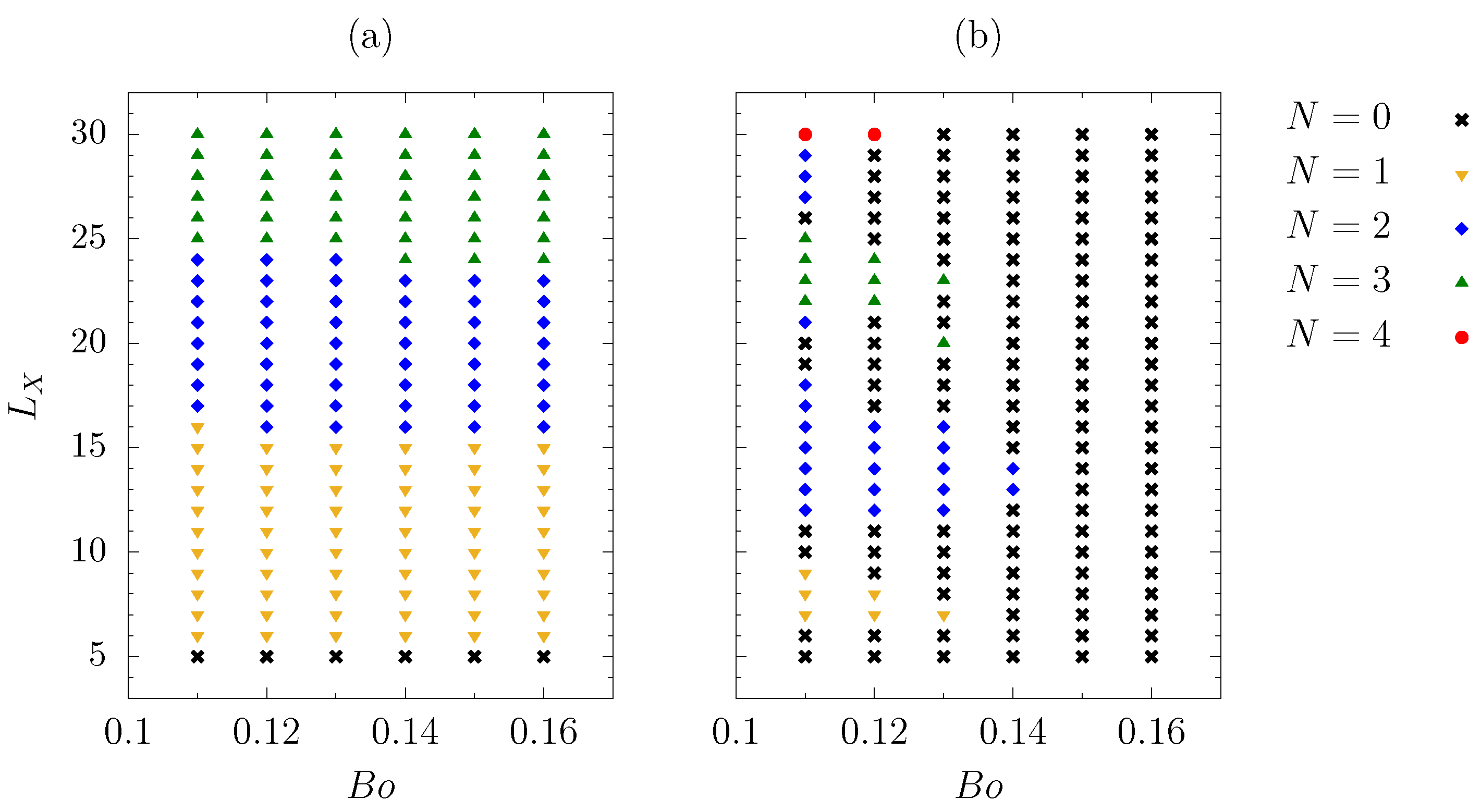

3.3. Single Array of Contamination Spots

3.4. Randomly Generated Heterogeneous Surface

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Croce, G.; De Candido, E.; Habashi, W.G.; Munzar, J.; Aube, M.; Baruzzi, G.S.; Aliaga, C. FENSAP-ICE: Analytical model for spatial and temporal evolution of in-flight icing roughness. J. Aircr. 2010, 47, 1283–1289. [Google Scholar] [CrossRef]

- Schweizer, P.M.; Kistler, S.F. Liquid Film Coating: Scientific Principles and Their Technological Implications; Springer: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Rocha, J.A.; Bravo, J.L.; Fair, J.R. Distillation Columns Containing Structured Packings: A Comprehensive Model for Their Performance. 1. Hydraulic Models. Ind. Eng. Chem. Res. 1993, 32, 641–651. [Google Scholar] [CrossRef]

- Rocha, J.A.; Bravo, J.L.; Fair, J.R. Distillation Columns Containing Structured Packings: A Comprehensive Model for Their Performance. 2. Mass-Transfer Model. Ind. Eng. Chem. Res. 1996, 35, 1660–1667. [Google Scholar] [CrossRef]

- Xie, Z.; Zhu, W. Theoretical and experimental exploration on the micro asperity contact load ratios and lubrication regimes transition for water-lubricated stern tube bearing. Tribol. Int. 2021, 164, 107105. [Google Scholar] [CrossRef]

- Xie, Z.; Zhang, Y.; Zhou, J.; Zhu, W. Theoretical and experimental research on the micro interface lubrication regime of water lubricated bearing. Mech. Syst. Signal Process. 2021, 151, 107422. [Google Scholar] [CrossRef]

- Wen, J.; Zhang, W.Y.; Ren, L.Z.; Bao, L.Y.; Dini, D.; Xi, H.D.; Hu, H.B. Controlling the number of vortices and torque in Taylor-Couette flow. J. Fluid Mech. 2020, 901, A30. [Google Scholar] [CrossRef]

- Elmaboud, Y.A.; Abdelsalam, S.I. DC/AC magnetohydrodynamic-micropump of a generalized Burger’s fluid in an annulus. Phys. Scr. 2019, 94, 115209. [Google Scholar] [CrossRef]

- Diez, J.A.; Kondic, L. Computing Three-Dimensional Thin Film Flows Including Contact Lines. J. Comput. Phys. 2002, 183, 274–306. [Google Scholar] [CrossRef] [Green Version]

- Thiele, U.; Brusch, L.; Bestehorn, M.; Bar, M. Modelling thin-film dewetting on structured substrates and templates: Bifurcation analysis and numerical simulations. Eur. Phys. J. E 2003, 11, 255–271. [Google Scholar] [CrossRef]

- Shkadov, V.Y.; Sisoev, G.M. Numerical bifurcation analysis of the travelling waves on a falling liquid film. Comput. Fluids 2005, 34, 151–168. [Google Scholar] [CrossRef]

- Zhao, Y.; Marshall, J.S. Dynamics of driven liquid films on heterogeneous surfaces. J. Fluid Mech. 2006, 559, 355–376. [Google Scholar] [CrossRef]

- Sellier, M. Modelling the wetting of a solid occlusion by a liquid film. Int. J. Multiph. Flow 2015, 71, 66–73. [Google Scholar] [CrossRef]

- Wilson, S.K.; Duffy, B.R.; Davis, H. On a slender dry patch in a liquid film draining under gravity down an inclined plane. Eur. J. Appl. Math. 2001, 12, 233–252. [Google Scholar] [CrossRef] [Green Version]

- Yatim, Y.M.; Duffy, B.R.; Wilson, S.K. Travelling-wave similarity solutions for a steadily translating slender dry patch in a thin fluid film. Phys. Fluids 2013, 25, 052103. [Google Scholar] [CrossRef] [Green Version]

- Rio, E.; Limat, L. Wetting hysteresis of a dry patch left inside a flowing film. Phys. Fluids 2006, 18, 032102. [Google Scholar] [CrossRef]

- Podgorski, T.; Flesselles, J.M.; Limat, L. Dry arches within flowing films. Phys. Fluids 1999, 11, 845. [Google Scholar] [CrossRef]

- Schwartz, L.W.; Eley, R.R. Simulation of Droplet Motion on Low-Energy and Heterogeneous Surfaces. J. Colloid Interface Sci. 1998, 202, 173–188. [Google Scholar] [CrossRef]

- Suzzi, N.; Croce, G. Numerical simulation of rivulet build up via lubrication equations. J. Phys. Conf. Ser. 2017, 923, 012020. [Google Scholar] [CrossRef]

- Suzzi, N.; Croce, G. Numerical simulation of film instability over low wettability surfaces through lubrication theory. Phys. Fluids 2019, 31, 122106. [Google Scholar] [CrossRef]

- Suzzi, N.; Croce, G. Bifurcation analysis of liquid films over low wettability surfaces. J. Phys. Conf. Ser. 2021, 1868, 012010. [Google Scholar] [CrossRef]

- Nusselt, W. Die oberflächenkondensation des wasserdampfes. Z. Ver. Deutsch. Ing. 1916, 60, 569–575. [Google Scholar]

- Perazzo, C.A.; Gratton, J. Navier-Stokes solutions for parallel flow in rivulets on an inclined plane. J. Fluid Mech. 2004, 507, 367–379. [Google Scholar] [CrossRef]

- Do Carmo, M.P. Differential Geometry of Curves and Surfaces; Pearson: New York, NY, USA, 1976; p. 163. [Google Scholar]

- Witelski, T.P.; Bowen, M. ADI schemes for higher-order nonlinear diffusion equations. Appl. Numer. Math. 2003, 45, 331–351. [Google Scholar] [CrossRef]

- Filip, S.I.; Javeed, A.; Trefethen, L.N. Smooth random functions, random ODEs, and Gaussian processes. SIAM Rev. 2019, 61, 185–205. [Google Scholar] [CrossRef] [Green Version]

- Blake, T.D. The physics of moving wetting lines. J. Colloid Interface Sci. 2006, 299, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Ajaev, V.S. Coating Flows and Contact Line Models. In Interfacial Fluid Mechanics: A Mathematical Modeling Approach; Springer: Berlin/Heidelberg, Germany, 2012; pp. 39–69. [Google Scholar]

| 200 | 250 | 4 | 0 | |

| 80 | 100 | 3 | 0 | |

| 1 | 40 | 50 | 3 | 0 |

| 2 | 20 | 25 | 3 | 0 |

| 5 | 8 | 10 | 3 | 0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Suzzi, N.; Croce, G. Numerical Bifurcation Analysis of a Film Flowing over a Patterned Surface through Enhanced Lubrication Theory. Fluids 2021, 6, 405. https://doi.org/10.3390/fluids6110405

Suzzi N, Croce G. Numerical Bifurcation Analysis of a Film Flowing over a Patterned Surface through Enhanced Lubrication Theory. Fluids. 2021; 6(11):405. https://doi.org/10.3390/fluids6110405

Chicago/Turabian StyleSuzzi, Nicola, and Giulio Croce. 2021. "Numerical Bifurcation Analysis of a Film Flowing over a Patterned Surface through Enhanced Lubrication Theory" Fluids 6, no. 11: 405. https://doi.org/10.3390/fluids6110405

APA StyleSuzzi, N., & Croce, G. (2021). Numerical Bifurcation Analysis of a Film Flowing over a Patterned Surface through Enhanced Lubrication Theory. Fluids, 6(11), 405. https://doi.org/10.3390/fluids6110405