Recycled Cellulose Aerogels from Paper Waste for a Heat Insulation Design of Canteen Bottles

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Recycled Cellulose Aerogels from Paper Waste

2.3. Heat Insulation Static Tests of the Water Canteen Bottle and the FLOE Bottle

2.4. Heat Insulation Dynamic Tests of the Water Canteen Bottle and the FLOE Bottle

3. Results and Discussion

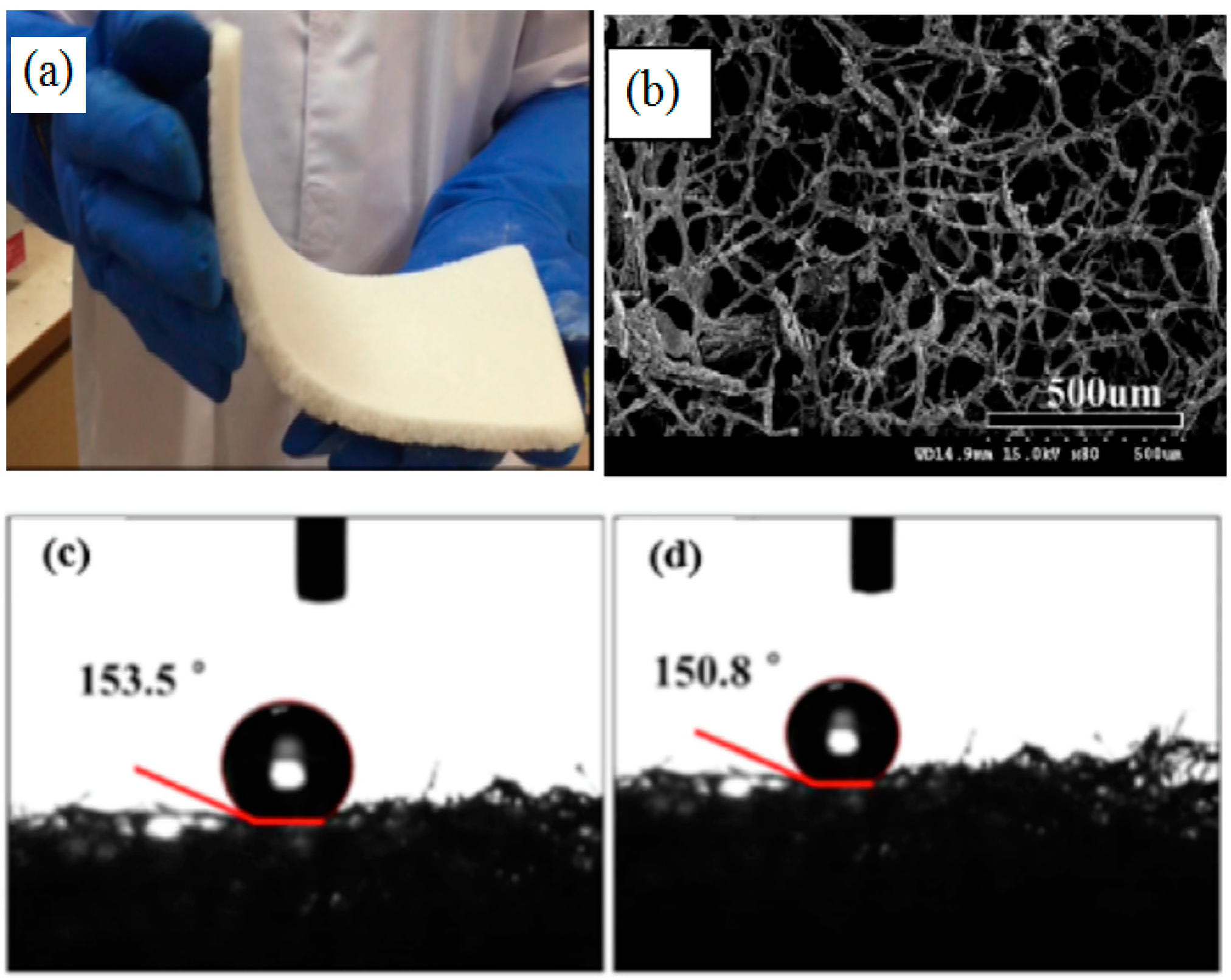

3.1. Morphology of the Cellulose Aerogels

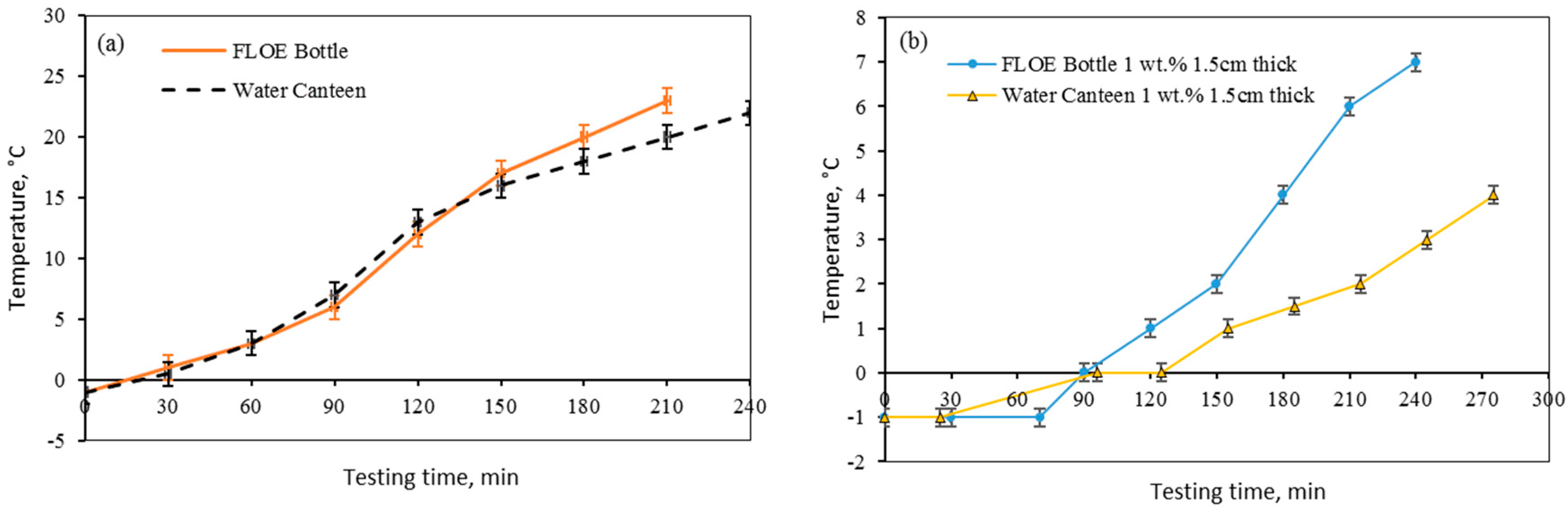

3.2. Heat Insulation Performance of the Water Canteen Bottle and the Commercial FLOE Bottle With and Without the Wrapped Cellulose Aerogel

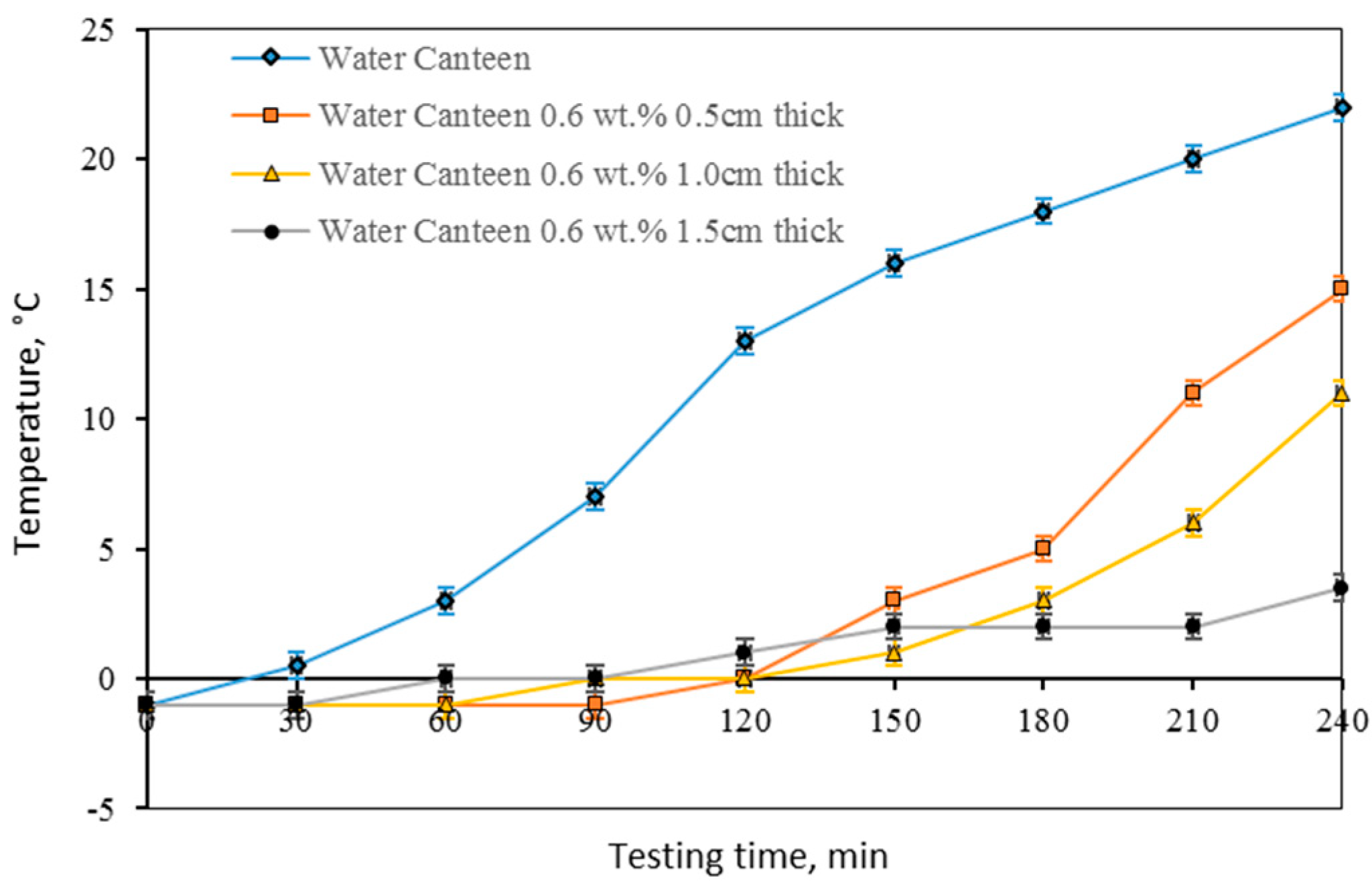

3.3. Effects of the Aerogel Thickness on the Heat Insulation Performance of the Water Canteen Bottle

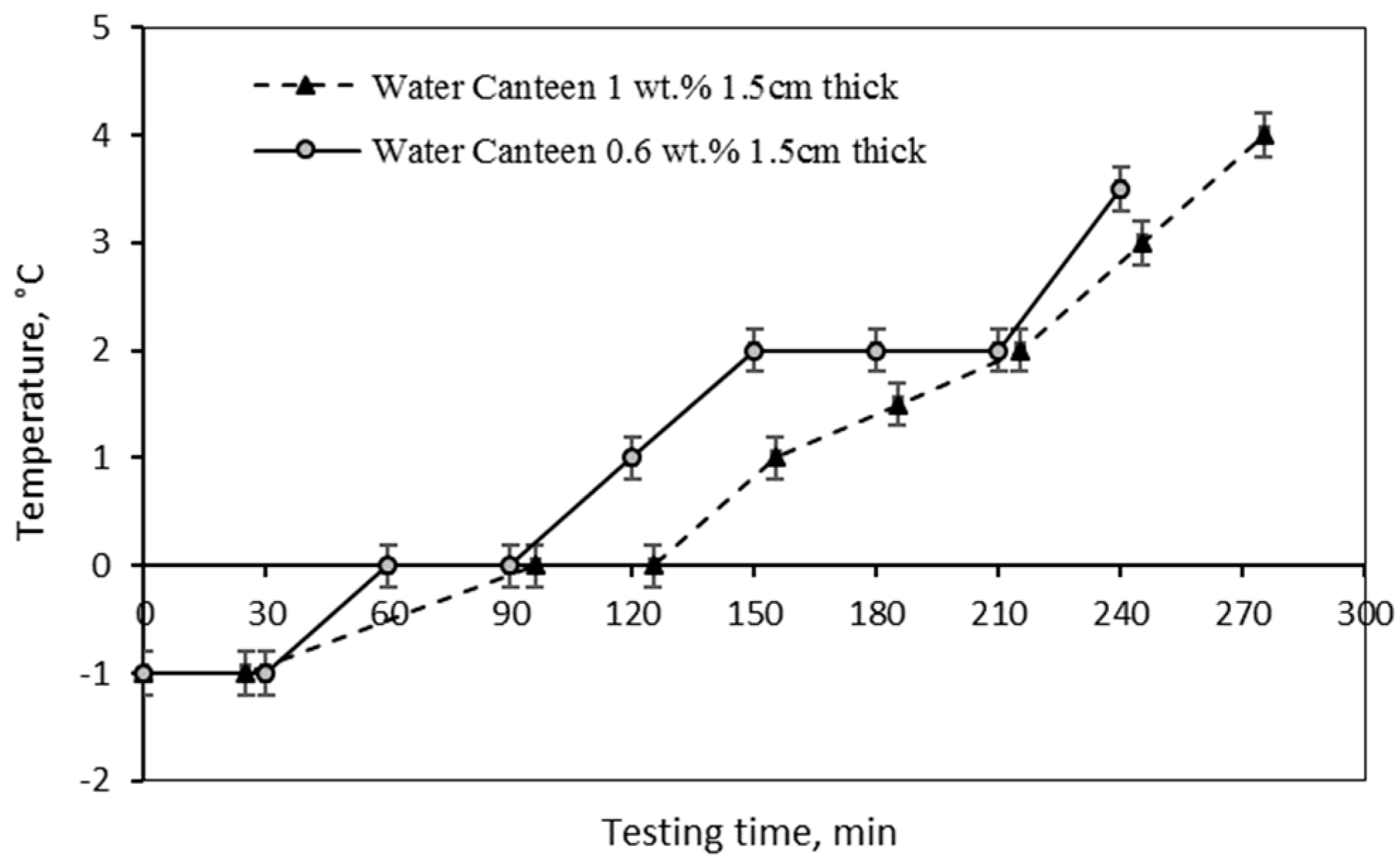

3.4. Effects of the Various Aerogel Compositions on the Heat Insulation Performance of the Water Canteen Bottle

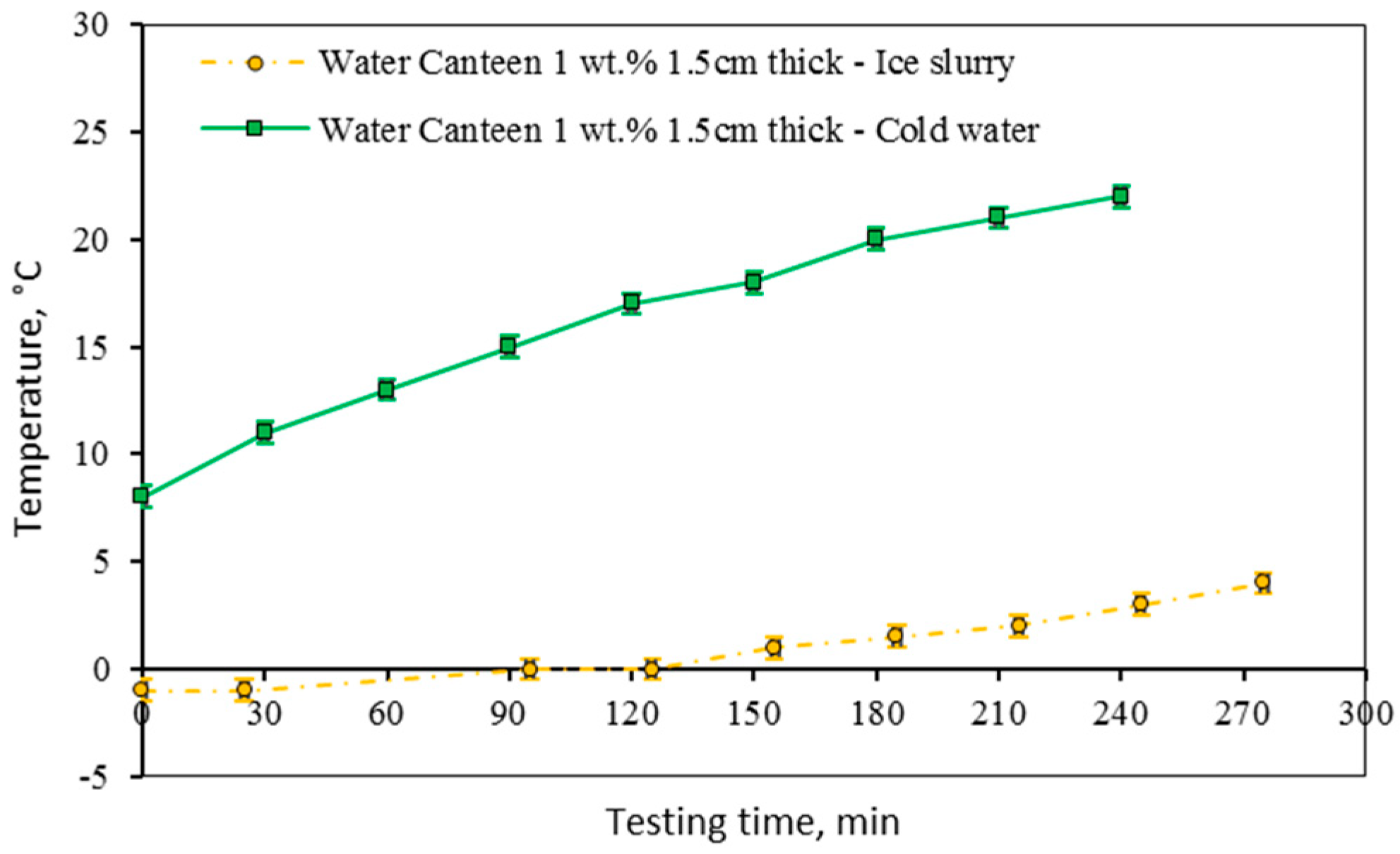

3.5. Effects of Internal Temperature

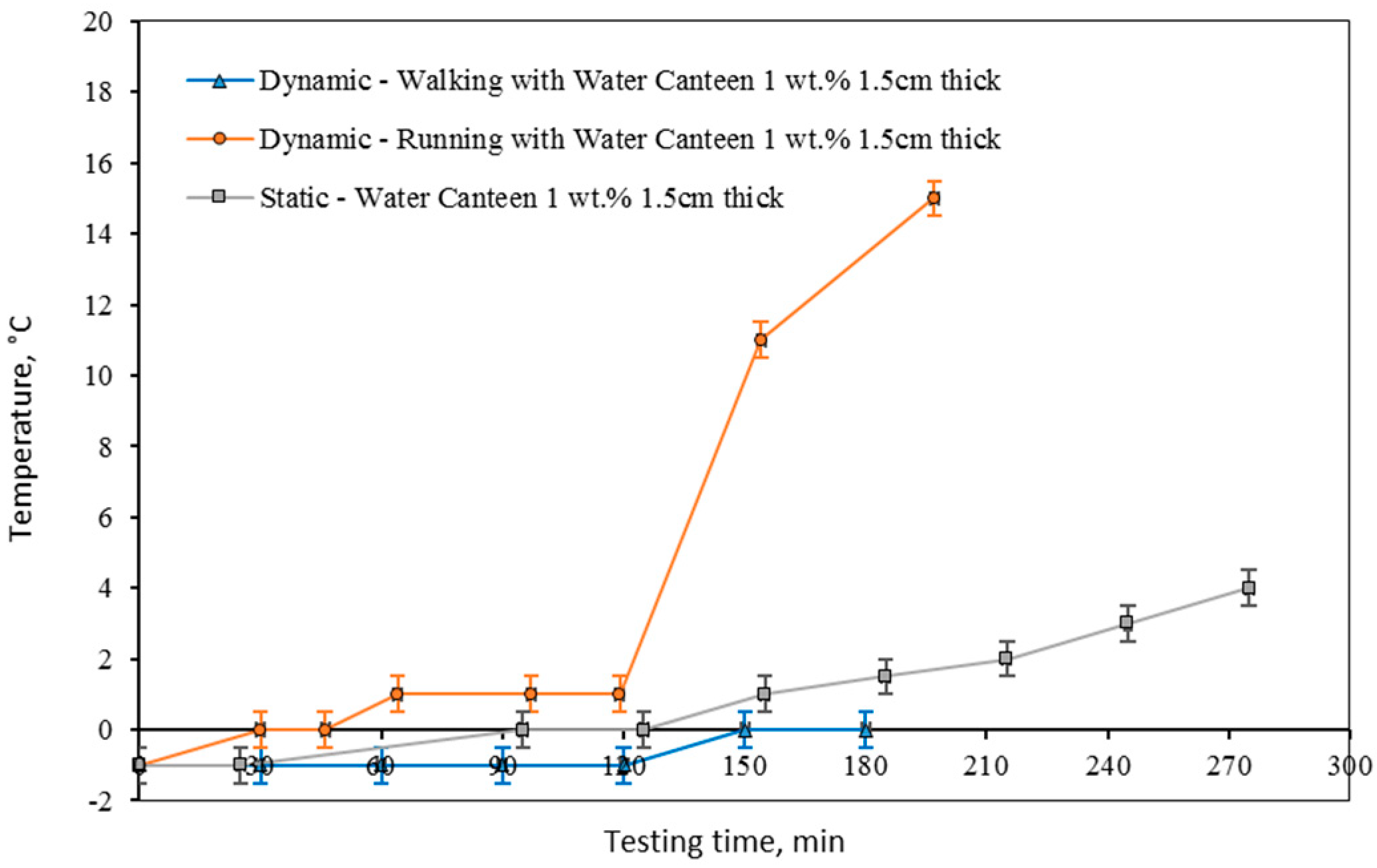

3.6. Effects of the Static and Synamic Conditions

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Mindef Singapore. Available online: https://www.mindef.gov.sg/web/portal/pioneer/article/regular-article-detail/ops-and-training/2018-dm/12Jun2014_00671 (accessed on 24 May 2019).

- Lee, J.K.W.; Kennefick, R.W.; Cheuvront, S.N. Novel cooling strategies for military training and operations. J. Stren. Cond. Res. 2015, 29, S77–S81. [Google Scholar] [CrossRef] [PubMed]

- Dugas, J. Ice slurry ingestion increases running time in the heat. Clin. J. Sport Med. 2011, 21, 541–542. [Google Scholar] [CrossRef] [PubMed]

- Tan, P.M.; Lee, J.K. The role of fluid temperature and form on endurance performance in the heat. Scand. J. Med. Sci. Sports 2015, 25, 39–51. [Google Scholar] [CrossRef] [PubMed]

- Teknicool, FLOE bottle. Available online: https://procreate.co.nz/floe-bottle-graphic (accessed on 24 May 2019).

- Thermaxx Jackets. Available online: https://www.thermaxxjackets.com/5-most-common-thermal-insulation-materials/ (accessed on 24 May 2019).

- Shekdar, A.V. Sustainable solid waste management: An integrated approach for Asian countries. Waste Manag. 2009, 29, 1438–1448. [Google Scholar] [CrossRef] [PubMed]

- Pokhrel, D.; Viraraghavan, T. Treatment of pulp and paper mill wastewater-a review. Sci. Total Environ. 2014, 333, 37–58. [Google Scholar] [CrossRef] [PubMed]

- Feng, J.; Nguyen, S.T.; Fan, Z.; Duong, H.M. Advanced fabrication and oil absorption properties of super-hydrophobic recycled cellulose aerogels. Chem. Eng. J. 2015, 270, 168–175. [Google Scholar] [CrossRef]

- Duong, H.M.; Nguyen, S.T. Nanocellulose Aerogels as Thermal Insulation Materials. In Nano and Biotech Based Materials for Energy Building Efficiency; Pacheco Torgal, F., Buratti, C., Kalaiselvam, S., Granqvist, C.G., Ivanov, V., Eds.; Springer International Publishing: Cham, Switzerland, 2016; pp. 411–427. [Google Scholar]

- Nguyen, S.T.; Feng, J.; Le, N.; Le, A.T.; Hoang, N.; Duong, H.M. Cellulose aerogel from paper waste for crude oil spill cleaning. Ind. Eng. Chem. Res. 2013, 52, 18386–18391. [Google Scholar] [CrossRef]

- Nguyen, S.T.; Duong, H.M.; Tan, V.B.C.; Ng, S.K.; Wong, J.P.W.; Feng, J. Advanced thermal insulation and absorption properties of recycled cellulose aerogels. Col. Surf. A. 2014, 445, 128–134. [Google Scholar] [CrossRef]

- Lyu, J.; Liu, Z.; Wu, X.; Li, G.; Fang, D.; Zhang, X. Nanofibrous Kevlar Aerogel Films and Their Phase-Change Composites for Highly Efficient Infrared Stealth. ACS Nano 2019, 13, 2236–2245. [Google Scholar] [CrossRef] [PubMed]

- Parale, V.G.; Han, W.; Lee, K.Y.; Mahadik, D.B.; Cho, H.H.; Park, H.H. Improvement in the high temperature thermal insulation performance of Y2O3 opacified silica aerogels. J. Alloy. Compd. 2017, 727, 871–878. [Google Scholar] [CrossRef]

- Rudaz, C. Cellulose and Pectin Aerogels: Towards their nano-structuration. Ph.D. Thesis, Paris Institute of Technology, Paris, France, 2013. [Google Scholar]

- Kobayashi, Y.; Saito, T.; Isogai, A. Aerogels with 3D Ordered Nanofiber Skeletons of Liquid-Crystalline Nanocellulose Derivatives as Tough and Transparent Insulators. Angew. Chem. Int. Ed. 2014, 53, 10394–10397. [Google Scholar] [CrossRef] [PubMed]

- Jiménez-Saelices, C.; Seantier, B.; Cathala, B.; Grohens, Y. Effect of freeze-drying parameters on the microstructure and thermal insulating properties of nanofibrillated cellulose aerogels. J. Sol. Gel. Sci. Technol. 2017, 84, 475–485. [Google Scholar] [CrossRef]

- Ebert, H.P. Thermal Properties of Aerogels. In Aerogels Handbook; Aegerter, M.A., Leventis, N., Koebel, M.M., Eds.; Springer: New York, NY, USA, 2011; pp. 537–564. [Google Scholar]

- The Engineering ToolBox. Available online: http://www.engineeringtoolbox.com/thermal-conductivity-d_429.html (accessed on 24 May 2019).

- Wu, Z.Y.; Li, C.; Liang, H.W.; Chen, J.F.; Yu, S.H. Ultralight, flexible, and fire-resistant carbon nanofiber aerogels from bacterial cellulose. Agnew. Chem. Int. Ed. 2013, 52, 2925–2929. [Google Scholar] [CrossRef] [PubMed]

- Chen, W.; Yu, H.; Li, Q.; Liu, Y.; Li, J. Ultralight and highly flexible aerogels with long cellulose I nanofibers. Soft Matter 2011, 7, 10360–10368. [Google Scholar] [CrossRef]

- Lin, R.; Li, A.; Zheng, T.; Lu, L.; Cao, Y. Hydrophobic and flexible cellulose aerogel as an efficient, green and reusable oil sorbent. RSC Adv. 2015, 5, 82027–82033. [Google Scholar] [CrossRef]

- Seah, K.H. Fundamental Principles of Manufacturing; Cobee Publishing House: Singapore, 2017. [Google Scholar]

- Hydration Anywhere. Available online: https://hydrationanywhere.com/best-insulated-water-bottle-our-top-picks/ (accessed on 14 August 2017).

- Floe Bottle. Available online: https://www.floebottle.com/ (accessed on 14 August 2017).

- Solenis. Available online: https://solenis.com/en/industries/tissue-towel/innovations/kymene-wet-strength-additives/ (accessed on 24 May 2019).

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wen Zhen, L.; Thai, Q.B.; Nguyen, T.X.; Le, D.K.; Kai Wei Lee, J.; Qing Xiang, Y.; Duong, H.M. Recycled Cellulose Aerogels from Paper Waste for a Heat Insulation Design of Canteen Bottles. Fluids 2019, 4, 174. https://doi.org/10.3390/fluids4030174

Wen Zhen L, Thai QB, Nguyen TX, Le DK, Kai Wei Lee J, Qing Xiang Y, Duong HM. Recycled Cellulose Aerogels from Paper Waste for a Heat Insulation Design of Canteen Bottles. Fluids. 2019; 4(3):174. https://doi.org/10.3390/fluids4030174

Chicago/Turabian StyleWen Zhen, Lim, Quoc B. Thai, Thanh X. Nguyen, Duyen K. Le, Jason Kai Wei Lee, Yee Qing Xiang, and Hai M. Duong. 2019. "Recycled Cellulose Aerogels from Paper Waste for a Heat Insulation Design of Canteen Bottles" Fluids 4, no. 3: 174. https://doi.org/10.3390/fluids4030174

APA StyleWen Zhen, L., Thai, Q. B., Nguyen, T. X., Le, D. K., Kai Wei Lee, J., Qing Xiang, Y., & Duong, H. M. (2019). Recycled Cellulose Aerogels from Paper Waste for a Heat Insulation Design of Canteen Bottles. Fluids, 4(3), 174. https://doi.org/10.3390/fluids4030174