1. Introduction

Hydropower, a clean and renewable energy resource, has been developed worldwide for the economic growth and improvement of people’s living standards. It has also been frequently used to improve the stability and safety of smart power grids.

Depending on the water head available at hydropower plants, various types of hydraulic turbines such as Francis, Kaplan and Pelton can be selected to maximize energy conversion efficiency. Francis turbines, which combine radial and axial flows, are the most common type in use nowadays because they can operate in a quite wide water head range. In order to meet the ever-changing power requirements of the electrical grid, Francis turbines have to work under various operating conditions from no-load to maximum load. At a given water head, the power output of Francis turbines can be controlled by adjusting the flow discharge with the wicket gate opening. However, this changes the flow pattern dramatically within the runner blade channels. Furthermore, extreme hydrodynamic conditions, provoking strong pressure reductions, are found by the irregular flow inside the runner channels when the turbine operates both at low part loads and over loads, below and above the best efficiency point, respectively. Consequently, both at off-design and at design operation conditions, two-phase flows with large scale cavitation forms may occur inside the Francis runners [

1]. Cavitation is the condition when local pressure reaches vapor pressure, causing vapor cavities to form and grow within a liquid. Within flowing water, cavitation can take the form of bubbles, macro-cavities that develop and attach to the solid walls or vortices. Moreover, the plant cavitation number or Thoma number [

2] can change due to unavoidable variations of the tail water level during operation at a given condition, which can increase the risk of cavitation.

Cavitation phenomena in Francis runners have been well investigated with model tests and site measurement campaigns [

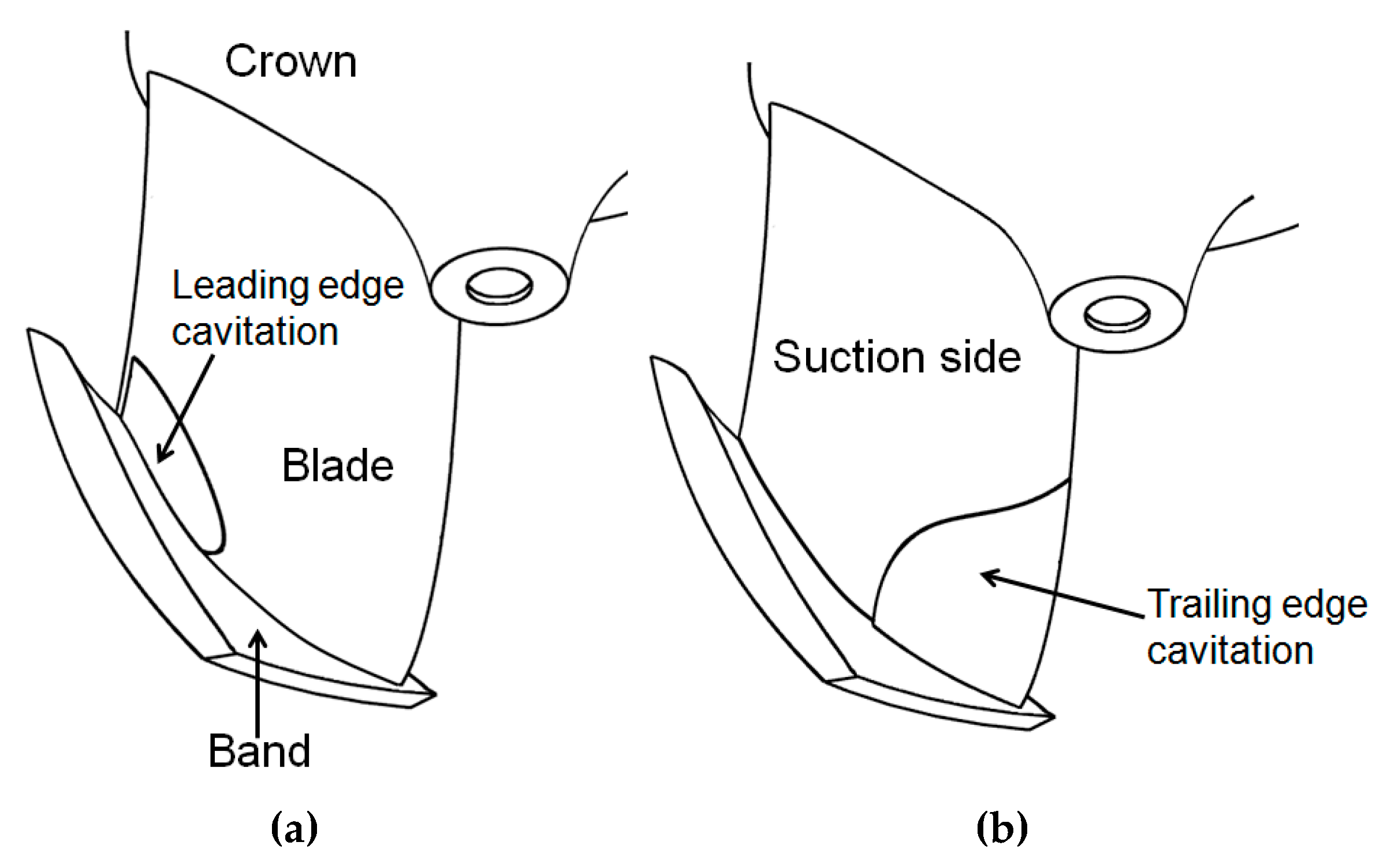

3]. The typical blade-attached forms of cavitation in a Francis runner are leading edge cavitation (LEC) and trailing edge cavitation (TEC). LEC appears on the suction side of runner blades due to operation at a higher head than the machine design head when the incidence angle of the inlet flow is positive and largely deviated from the design value. TEC appears as separated bubbles attached to the blade suction side, located near the mid-chord next to the trailing edge. These travelling bubbles appear due to a low plant cavitation number reaching their maximum when the machine operates in overload condition with the highest flow rate.

In order to avoid damages provoked by vibration resonances and material fatigues due to hydraulic excitations [

4,

5], the structural behavior of the turbine runner has to be carefully investigated during the design phase. Extensive research has been carried out to measure and characterize the vibrations and dynamic stresses induced by pressure fluctuations in Francis turbines [

6,

7] and pump-turbines [

8,

9]. Many research works have been carried out to predict the dynamic behavior of Francis runners in air and still water based on both measurements and simulations in reduced scale models of Francis runners [

10,

11] and pump-turbines [

12,

13]. The final objective is to identify the natural frequencies and the damping ratios of the runner, taking into account the added mass and damping of the surrounding water, because it has been demonstrated that these effects can considerably affect the results [

14]. Moreover, additional boundary conditions such as the proximity of walls can also influence the added mass effects, which have been investigated from simple structures like disks [

15] to actual prototype structures [

16,

17,

18].

However, the possible effect of cavitation inside hydraulic turbines has not been sufficiently addressed, and only one recent work has numerically investigated the possibility that inter-blade cavitation vortices are responsible for multiple fractures that have appeared on the trailing edge of full-scale Francis runner blades [

19]. For example, the added mass effects of the presence of attached cavitation on the runner blades have not been calculated yet. Under this condition, a significant region of the surrounding fluid in contact with the structure is occupied by vapor instead of water, meaning that the density is locally reduced. In particular, only limited research has been performed on hydrofoil to investigate the added mass effects under partial cavitation, and the significance of this [

20,

21] has not been demonstrated in comparison with the no cavitation condition. However, hydrofoil is only a very simple structure compared with the complex Francis runner. Therefore, it is necessary to consider the geometry of an actual Francis runner with all its complexity.

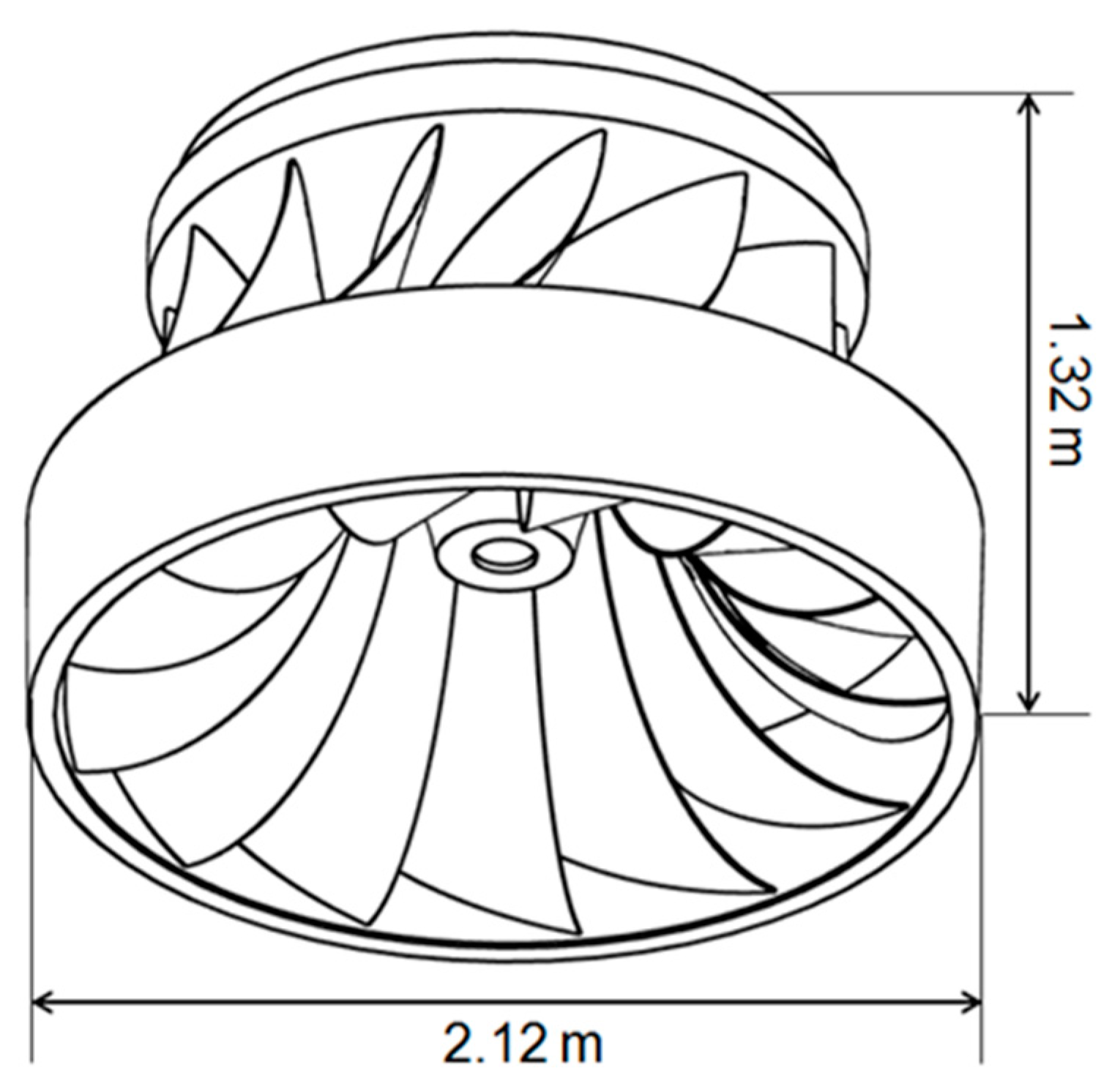

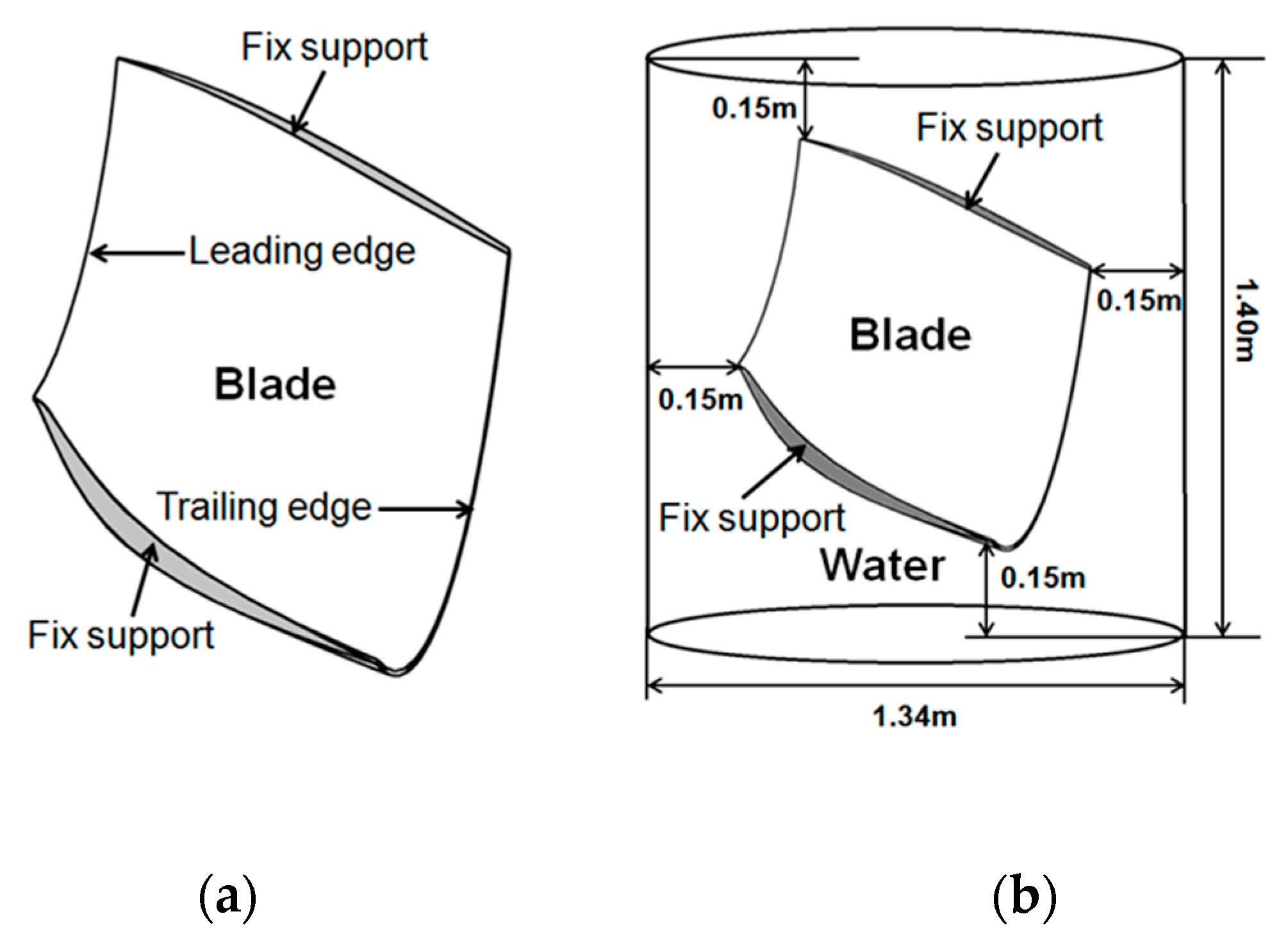

Consequently, a Francis runner with 13 blades and a diameter of 2.12 m (

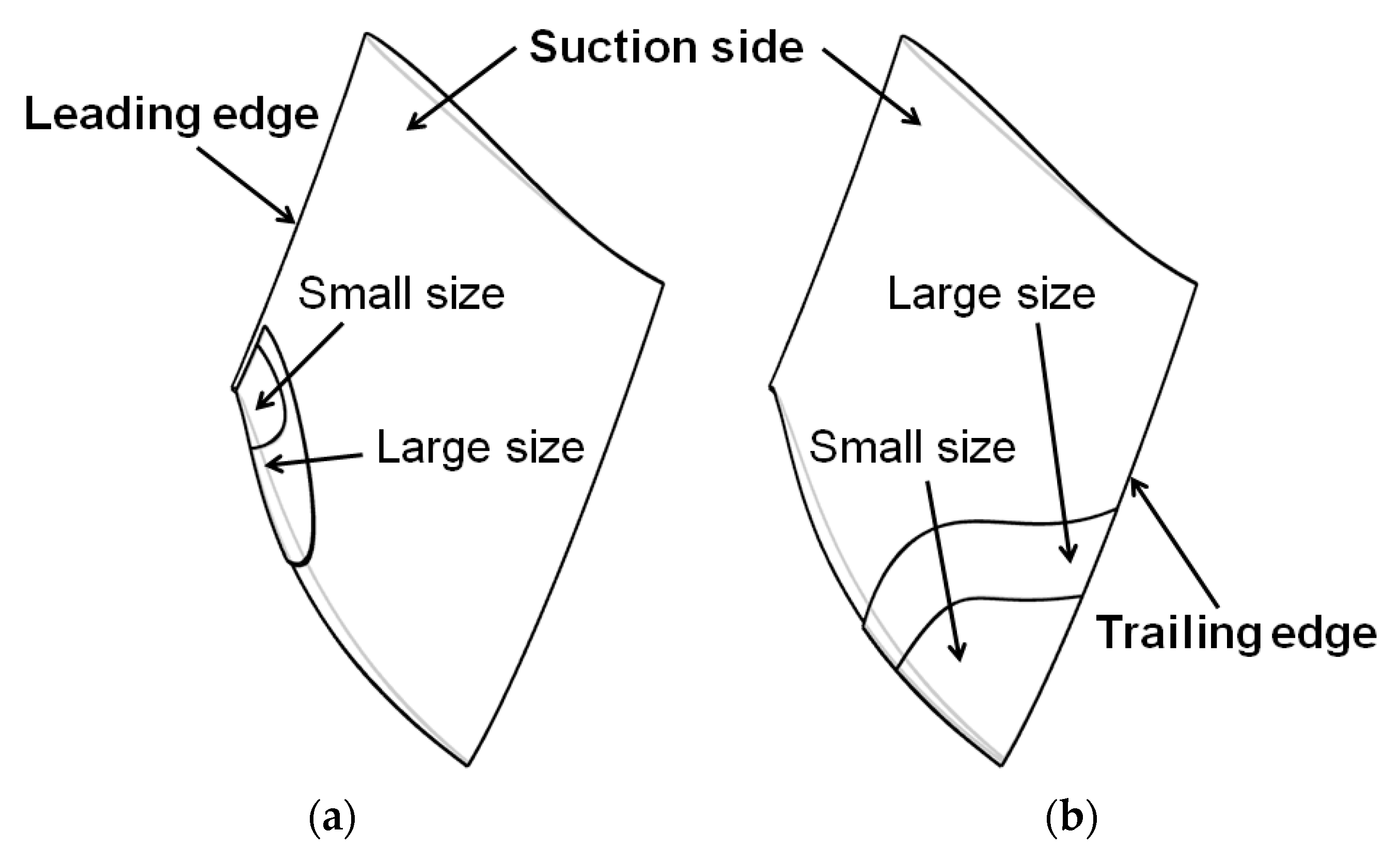

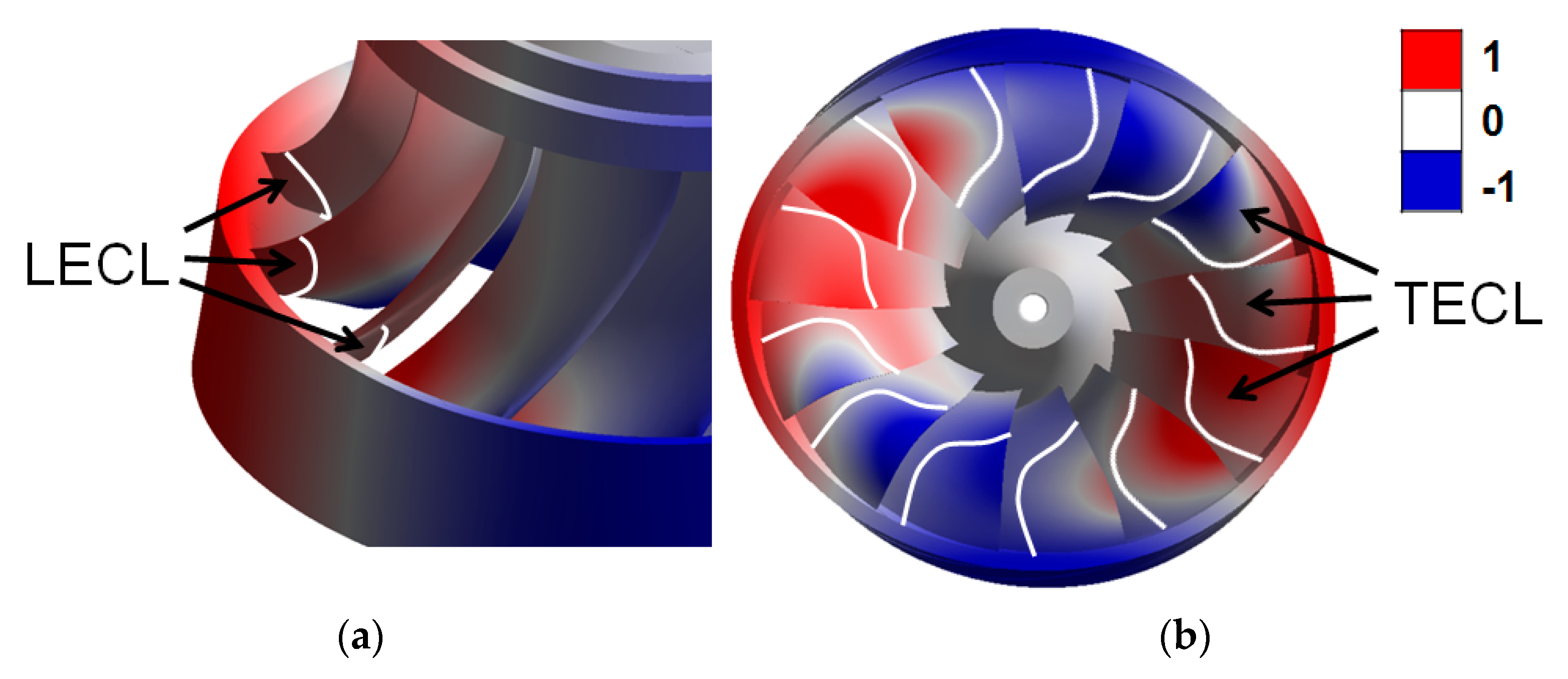

Figure 1) has been selected to carry out the structural behavior analysis by numerical simulation. The objective of the current work is to quantify the influence that the presence of cavitation might have on the modal behavior of the runner. For that, both LEC and TEC of different sizes have been considered, and the added mass effects have been compared with those corresponding to the pure water condition without cavitation. A review of the numerical results of cavitation in Francis turbine runners [

22] and the visual observations from reduced scale models [

23] and full-scale Francis prototypes [

24] has permitted us to determine the most probable locations and sizes of cavitation, as shown in

Figure 2. First of all, a single blade has been investigated to evaluate the level of significance for the proposed cavity shapes and dimensions. Furthermore, based on the results obtained, the complete runner structure has been considered with similar cavity shapes and locations on all the blades.

2. Added Mass and Frequency Reduction Ratio

The concept of added mass was developed by several authors like Lamb [

25] and Milne-Thomson [

26] for the two-dimensional case of a circular cylinder of radius

a moving forward in liquid with velocity

U and density

. In this case, the kinetic energy per unit thickness of the fluid is given by

Let , then is the mass of the liquid (per unit thickness) displaced by the cylinder.

If

is the mass of the cylinder (per unit thickness), the total kinetic energy of the fluid and the cylinder is

Let

be the external force in the direction of motion of the cylinder necessary to maintain the motion. Then, the rate at which

does work must be equal to the rate of increase of the total kinetic energy, and therefore

Thus, the cylinder experiences a resistance to its motion due to the presence of the liquid, and the amount of resistance per unit thickness equals

Therefore, the presence of the liquid effectively increases the mass of a moving circular cylinder from to that is called the “virtual mass” of the liquid displaced. The virtual mass is obtained by adding the mass and the added mass or hydrodynamic mass .

As analogously explained by Brennen [

27], whenever acceleration is imposed on a fluid flow by acceleration of a body, additional fluid forces will act on the surfaces in contact with the fluid due to the added mass. These inertial fluid forces can be of considerable importance in many engineering problems if a structure is submerged in water. For example, the added mass of the cylinder with potential flow for rectilinear motion is equal to the mass of the fluid displaced by the cylinder, as previously expressed in Equation (1). However, this should be regarded as coincidental, because there is no general correlation between the added mass and displaced fluid mass. Furthermore, in general, the value of the added mass depends on the direction of acceleration. Therefore, the added mass must be characterized with the added mass matrix.

The added mass matrix provides a method of expressing the relationship between the six force components imposed on the body by the inertial effects of the fluid due to the three translation accelerations in three perpendicular directions and the three angular accelerations. Unfortunately for complex geometry, the added mass matrix cannot be theoretically predicted with sufficient accuracy.

If a solid body is vibrated, the general equation of a motion is

where

Ms is the mass,

Cs is the damping,

Ks is the stiffness,

F is the force applied to the body and

,

and

are displacement, velocity and acceleration, respectively. When this body is surrounded by a still fluid then the equation of motion is

where

Mf is the added mass,

Cf is the added damping and

Kf is the added stiffness.

When the body is considered to be lightly damped to vibrate in-vacuum conditions without any surrounding fluid, the natural frequency of a mode of vibration is expressed as

where

k and

m are the modal stiffness and modal mass, respectively. However, its dynamic response is significantly changed when it is submerged in a fluid with high density, such as water. The added modal mass,

mf, then reduces the new natural frequency to

The frequency reduction ratio (FRR) of a vibration mode can be calculated relative to in-vacuum conditions as expressed with

3. Acoustic Fluid–Structural Coupling Method and Numerical Model

The acoustic fluid–structural coupling method (AFSCM) is commonly used to calculate the added mass effects of fluid on structures submerged in dense fluids like water. In our study, we used the finite element analysis tool available in ANSYS Mechanical, which takes into account the fluid–structure interaction phenomena, as described in [

28].

Using the finite element method (FEM), the structural dynamic equilibrium equation is expressed as

where

Ms,

Cs and

Ks are the structure mass, damping and stiffness matrices, respectively;

u,

,

are nodal displacement, velocity and acceleration vectors, respectively;

fs(

t) represents the externally applied force vector and

t is time.

With consideration of the acoustic fluid pressure acting at the interface, Equation (11) can be described as

where

ffs(

t) = −

Kfsp is the acoustic fluid pressure load vector at the interface,

Kfs is the equivalent coupling stiffness matrix and

p is the acoustic pressure vector.

In AFSCM, it is assumed that the fluid is compressible (density changes due to pressure variations) and that there is no mean flow of the fluid. To describe the fluid effect on the submerged structures, the discretized Helmholtz acoustic equation is adopted as

where

Mf,

Cf and

Kf are the acoustic fluid equivalent mass, damping and stiffness matrices, respectively, and

fsf(

t) = −

Mfs is the fluid load produced by the structure displacement at the interface and

Mfs is the equivalent coupling mass matrix.

Finally, the complete finite element discretized equations with assembled form expressed in Equation (14) can be used to solve acoustic fluid–structural coupling problems by considering Equations (12) and (13) simultaneously:

Several works devoted to investigating the modal behavior and dynamic responses of hydraulic turbine runners both in air and water can be found in the literature based on FEM and AFSCM [

4,

5,

6,

7,

8,

9,

10,

11,

12,

13,

14,

15]. In all cases, the numerical results have shown a good agreement with the corresponding measured ones, which fully validates the feasibility of FEM and AFSCM for the current study.

The single blade and the whole runner structure domains are built with high order tetrahedral structural elements that are suitable for modelling complex geometries. The fluid domains comprising the cavities and surrounding water have been meshed with tetrahedral acoustic elements, which are also typically used to solve fluid–structure coupling problems.

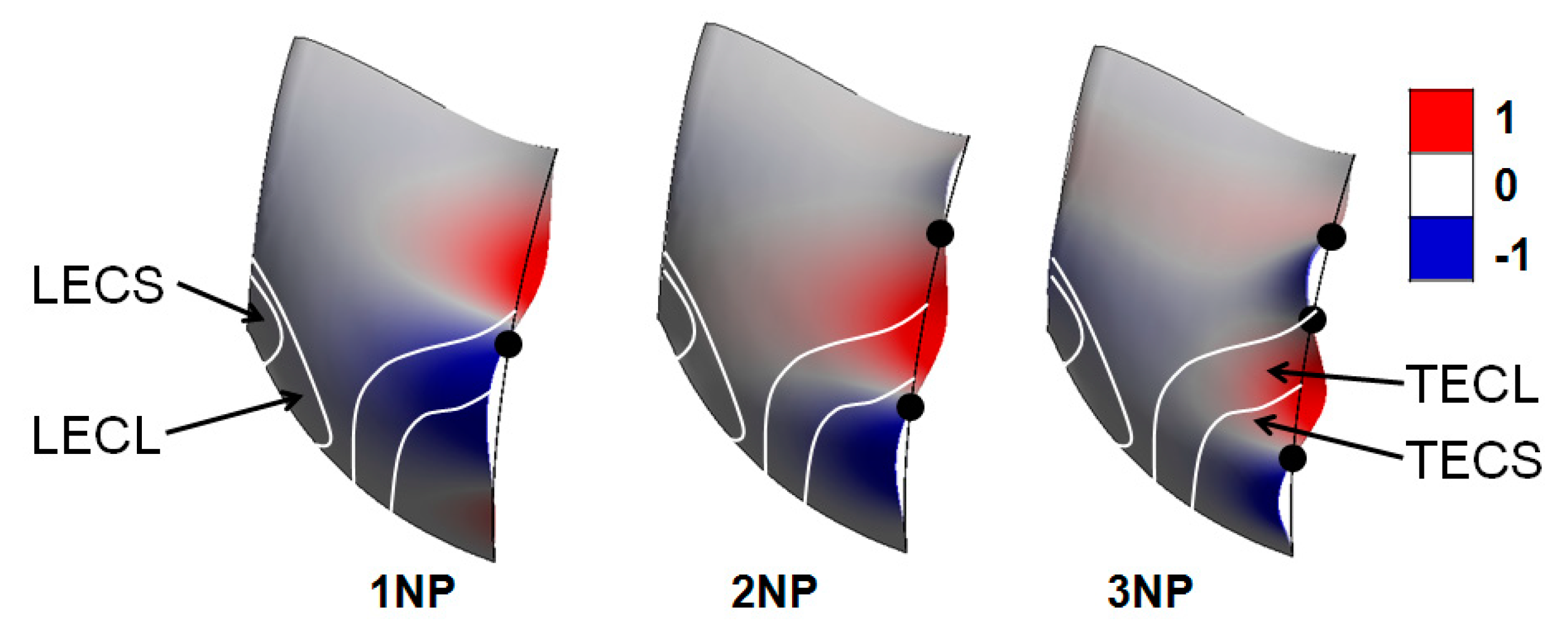

The proposed attached cavities with different dimensions and locations are modelled on the suction side of the runner blade (

Figure 2). The thickness of attached cavities is assumed to be 0.0225 m, which is three times the blade trailing edge thickness.

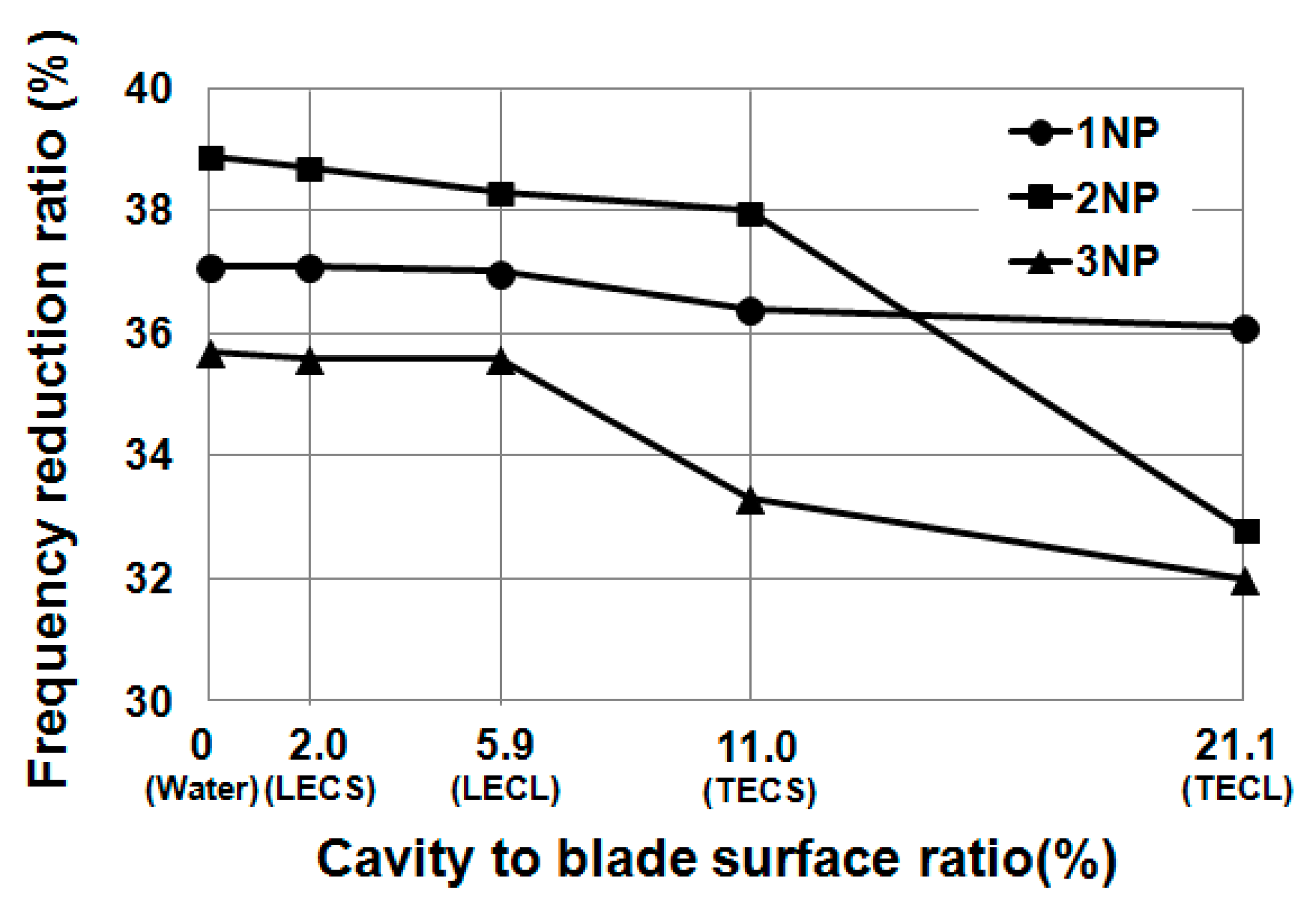

The dimensions of the attached cavities have been calculated relative to the surface of the blade suction side in percentage and presented as the cavity to blade surface ratio (CSR), which is defined by

where

SCavity is the area of the cavity, and

SSuction_side is the area of the blade suction side. These results are listed in

Table 1, where LECS and LECL indicate small (S) and large (L) sizes of leading edge cavitation, respectively, and TECS and TECL indicate small (S) and large (L) sizes of trailing edge cavitation, respectively.

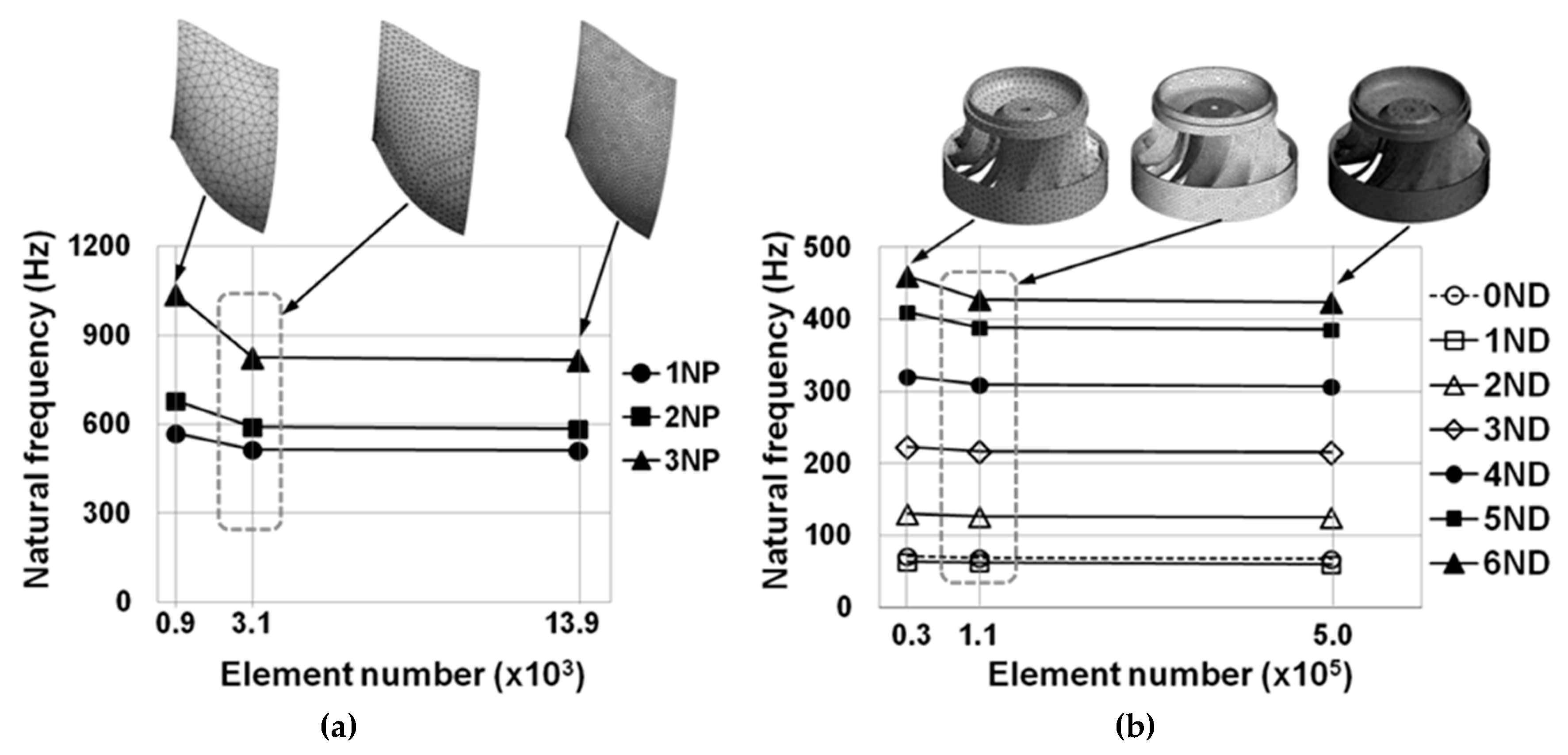

To guarantee the accuracy and convergence of the numerical model, results sensitivity to mesh size and density was analyzed based on previous experience first [

9]. For that, three meshes with increasing numbers of elements were constructed for both the single blade and entire turbine runner, as shown at the top of

Figure 3. The graphs present the evolutions of the predicted natural frequencies when the element number increases, as well as how they converge towards constant values. The meshes providing the results marked with dashed line boxes were finally selected to perform the simulations. The corresponding numbers of elements for the structures and fluid domains are indicated in

Table 2.

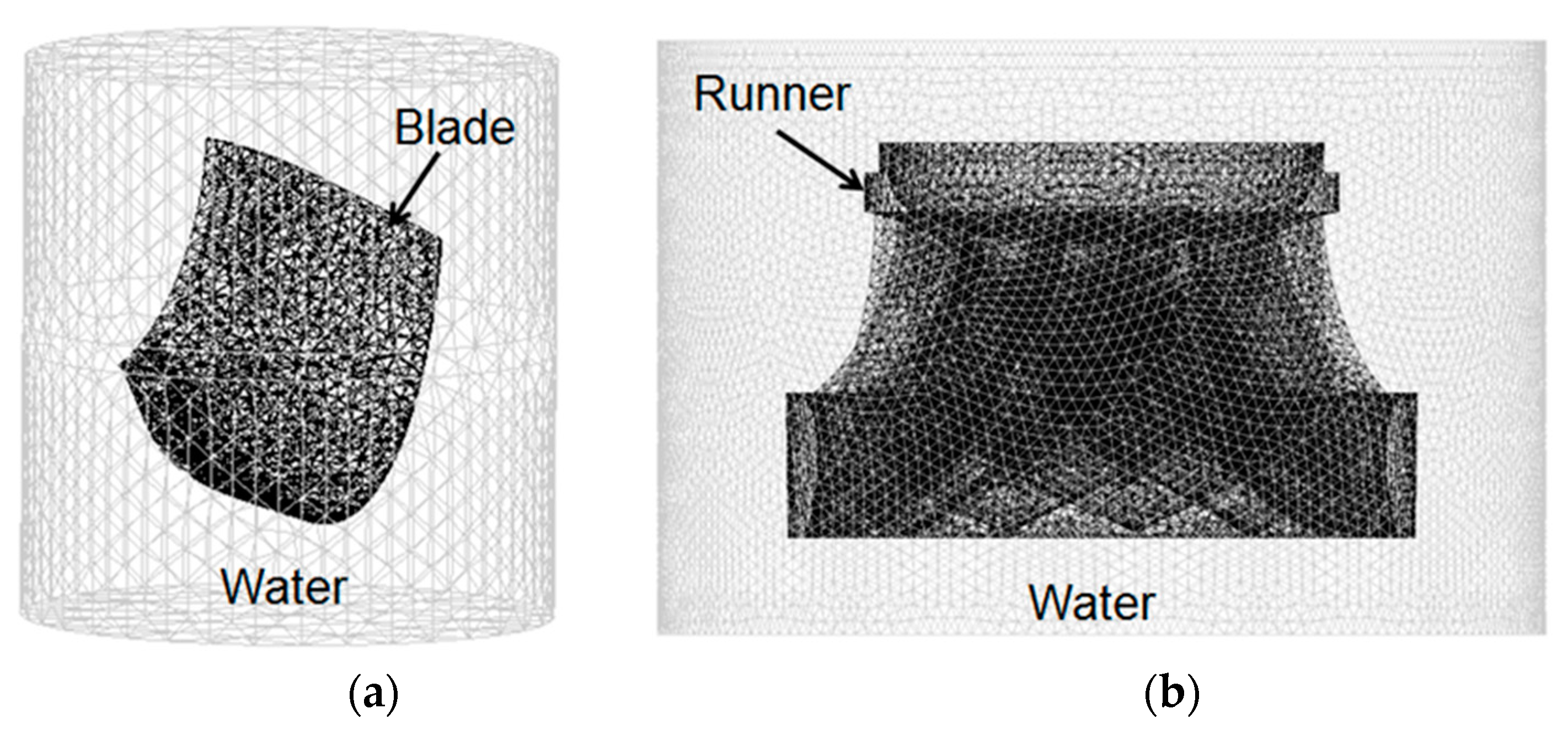

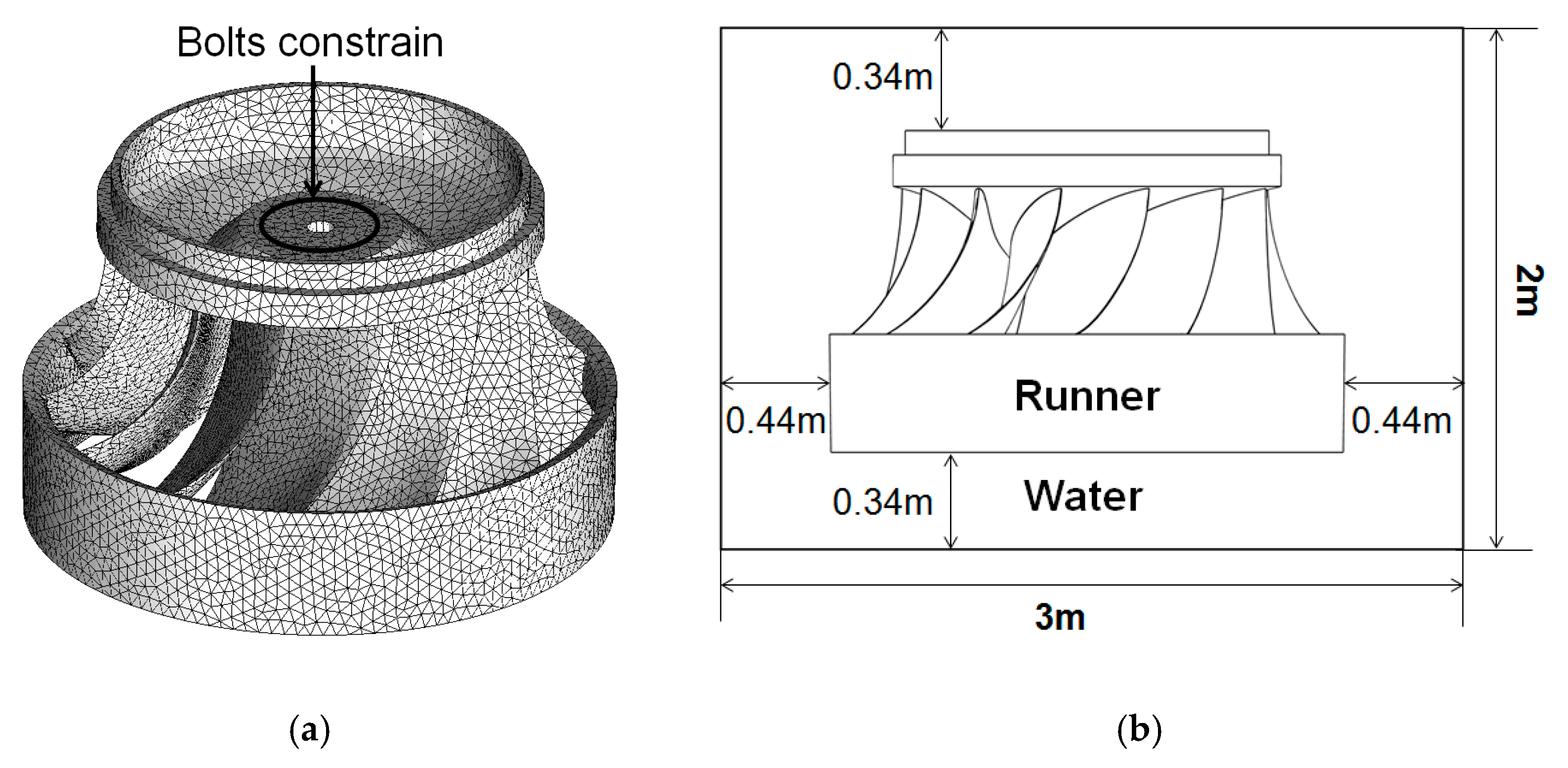

Moreover, based on the results obtained by Rodriguez et al. [

10] with a similar runner geometry, and in order to have a sufficiently large fluid domain, the surfaces of the fluid domain where located at a distance around 1/3 to 1/4 of the runner height relative to the runner outer surfaces as shown at the right of

Figure 4. And the fluid domain for the single blade is shown at the left of

Figure 4.

The material properties of the cavitation domains are the corresponding ones to pure saturated vapor, assuming a vapor volume fraction of 1. As a summary, the material properties of the structure and both fluids, water and vapor, used in the numerical calculations are tabulated in

Table 3.

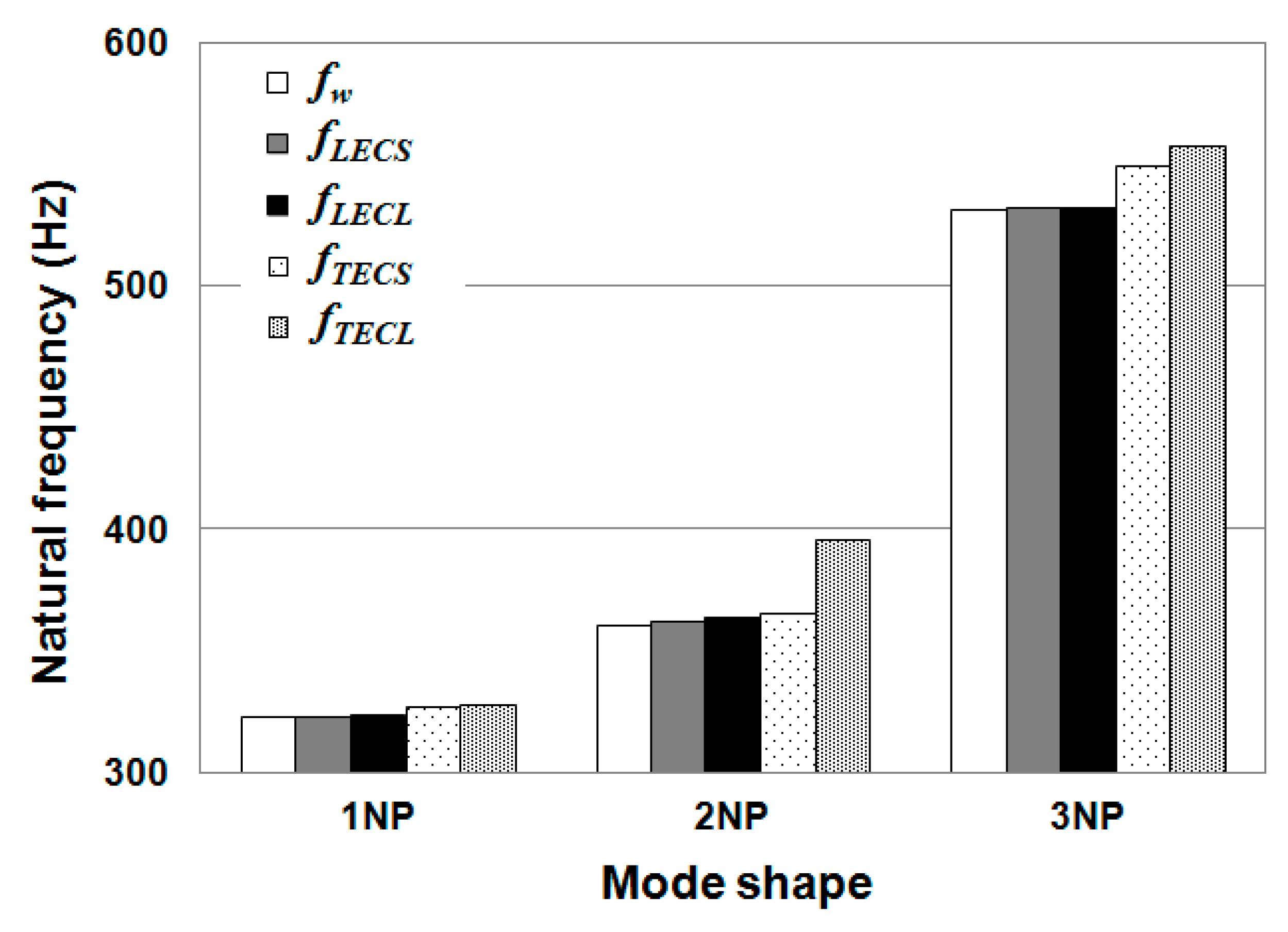

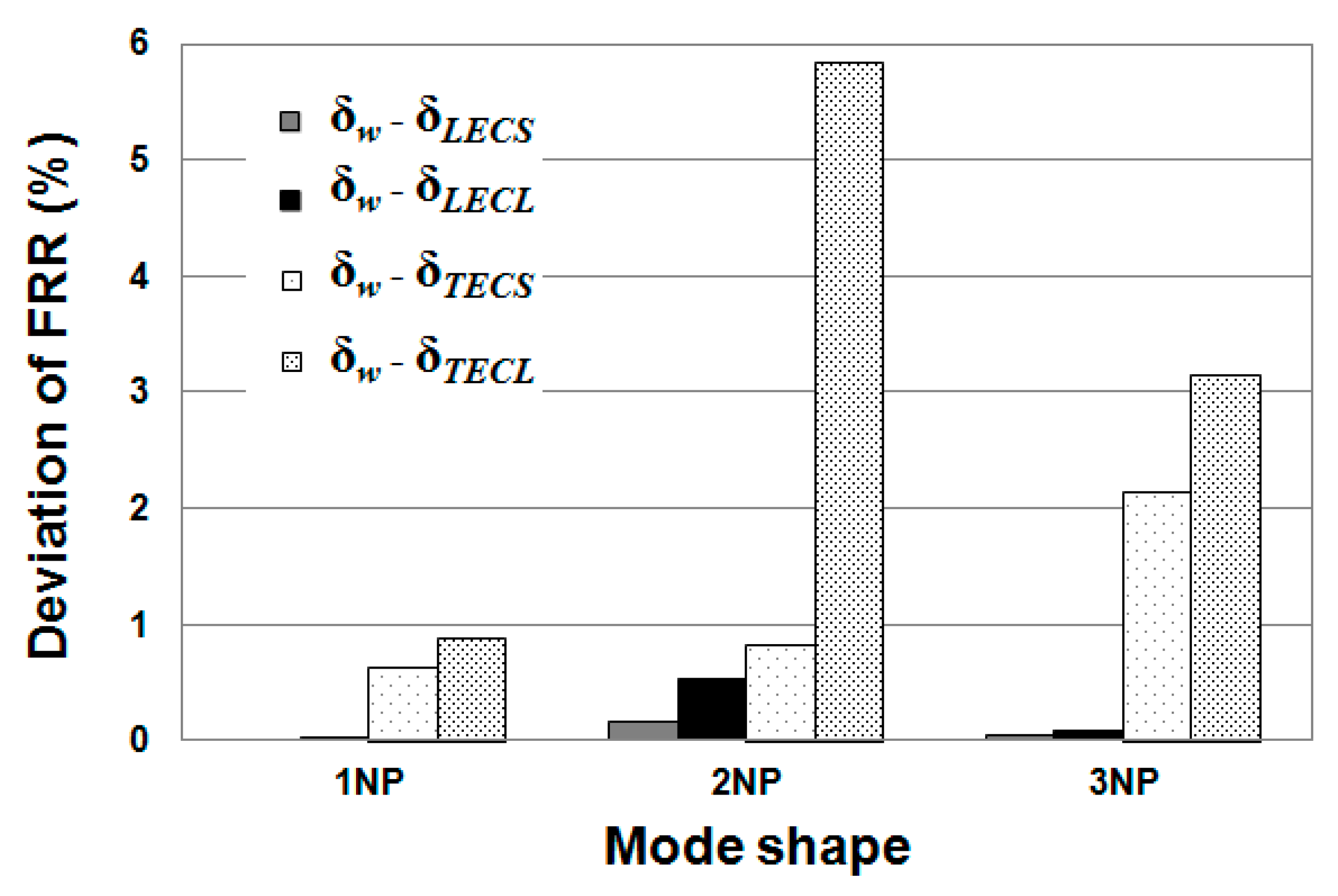

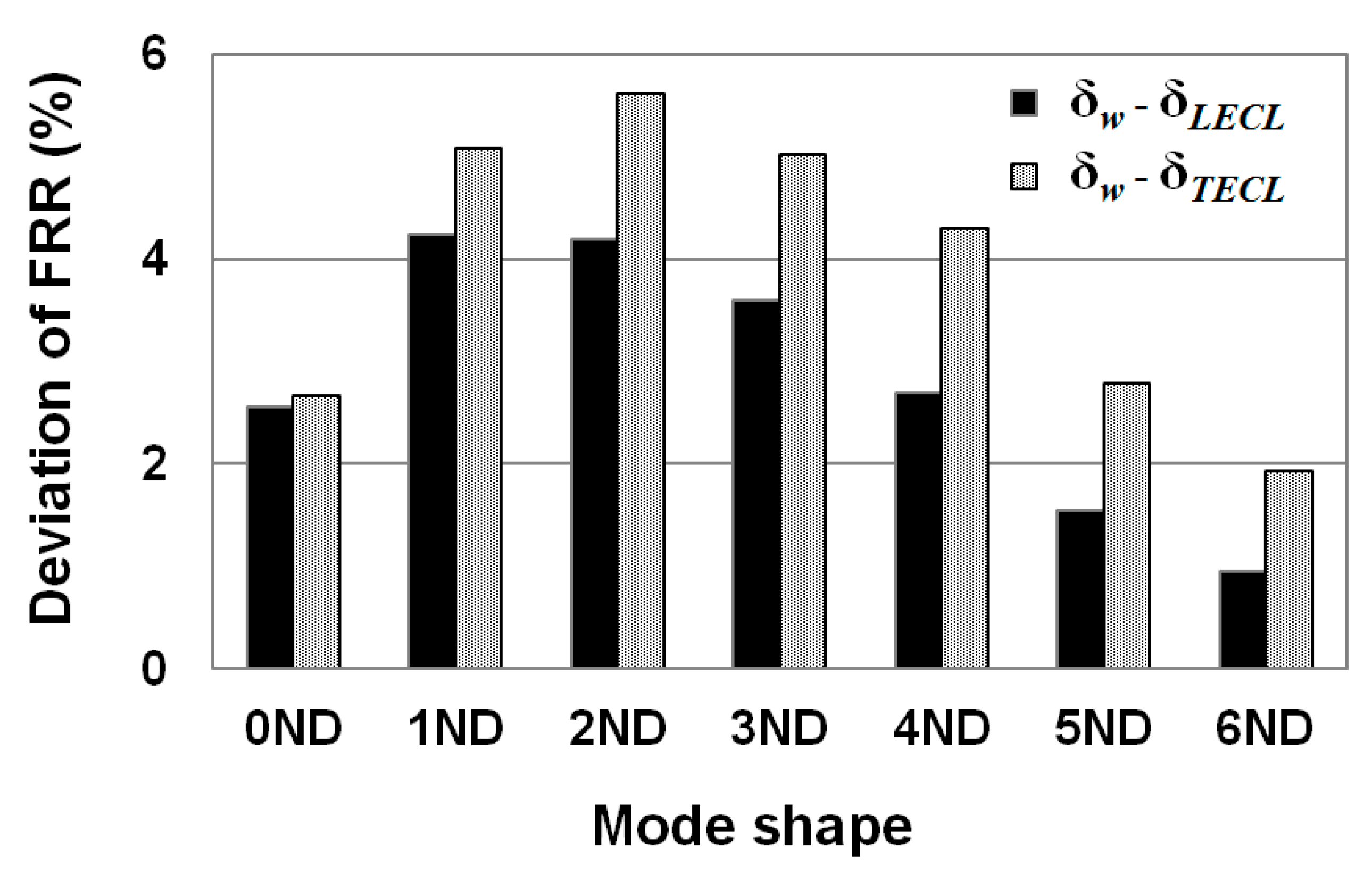

In order to quantitatively evaluate the added mass effects on the structures, the FRR of each mode either submerged in pure water (

δw) or with various cavities (

δcavity) has been calculated based on Equation (10). The deviation of FRRs of a specified mode due to the presence of different types of cavitation has been calculated with

where the frequency

fcavity can correspond to any of the cavitation types

fLECS,

fLECL,

fTECS and

fTECL.

As the added mass effect of air on the modal behavior of structures has been experimentally and numerically proved to be negligible in similar studies [

5,

6,

7,

8,

9,

10], the numerical simulation to obtain the reference values will be performed in-vacuum conditions instead of air.

The procedure will consist of solving first the air condition, then the same case with water and finally with both water and attached pockets of vapor. This will be done first for a single blade to quantify the level of significance on the structure response. Then, the entire Francis runner will be simulated with air, water and water with cavitation. To conclude, the whole set of results will be compared among all the cases.

6. Conclusions

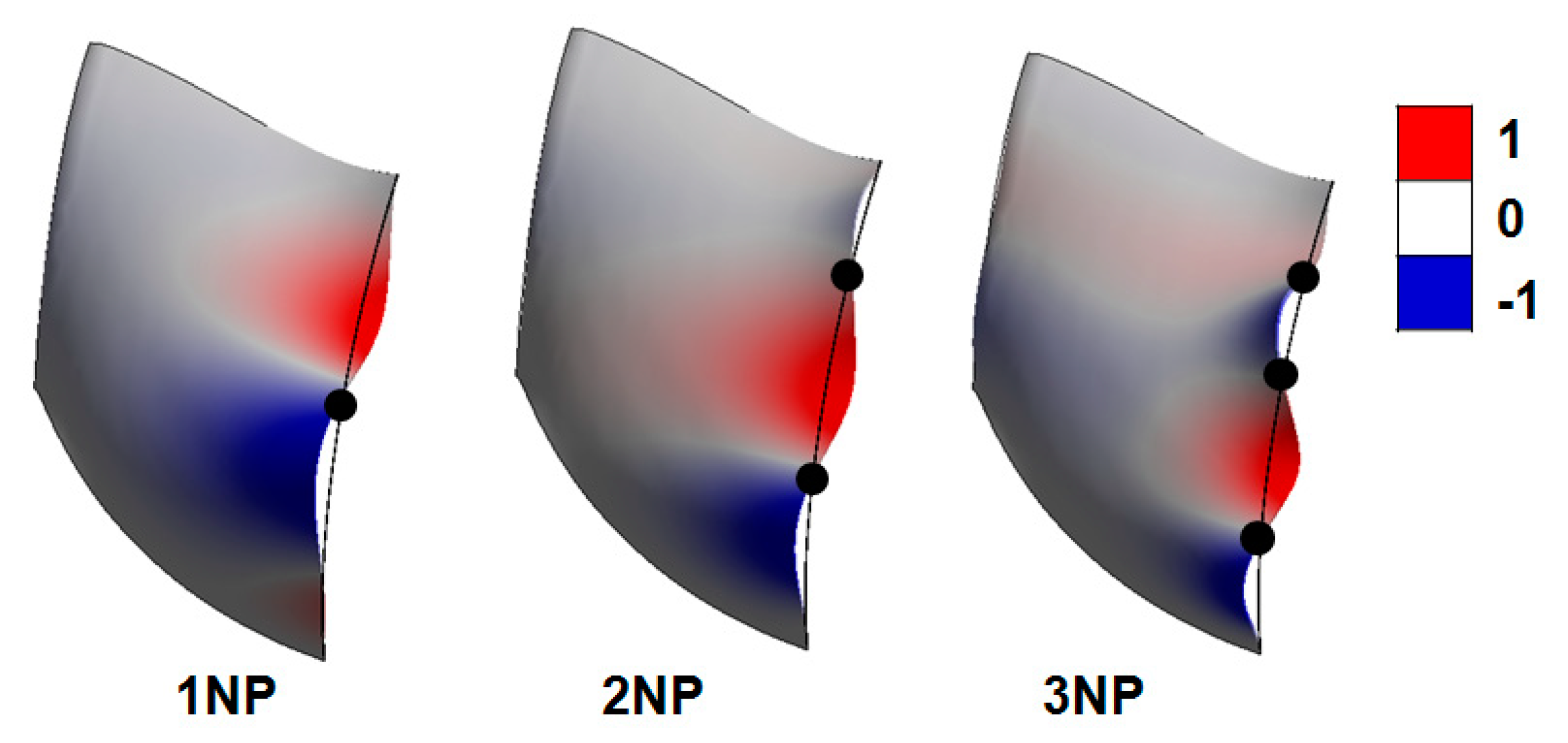

The added mass effects of attached blade cavitation on the structural behavior of a single blade and of a complete Francis runner have been investigated numerically. The acoustic–structural coupling method was applied to calculate the natural frequencies and mode shapes of the structure surrounded by a fluid. The study compared the results of a single-phase fluid, water, with those of a two-phase fluid, vapor and water, by reproducing the typical leading edge or trailing edge attached blade cavitation.

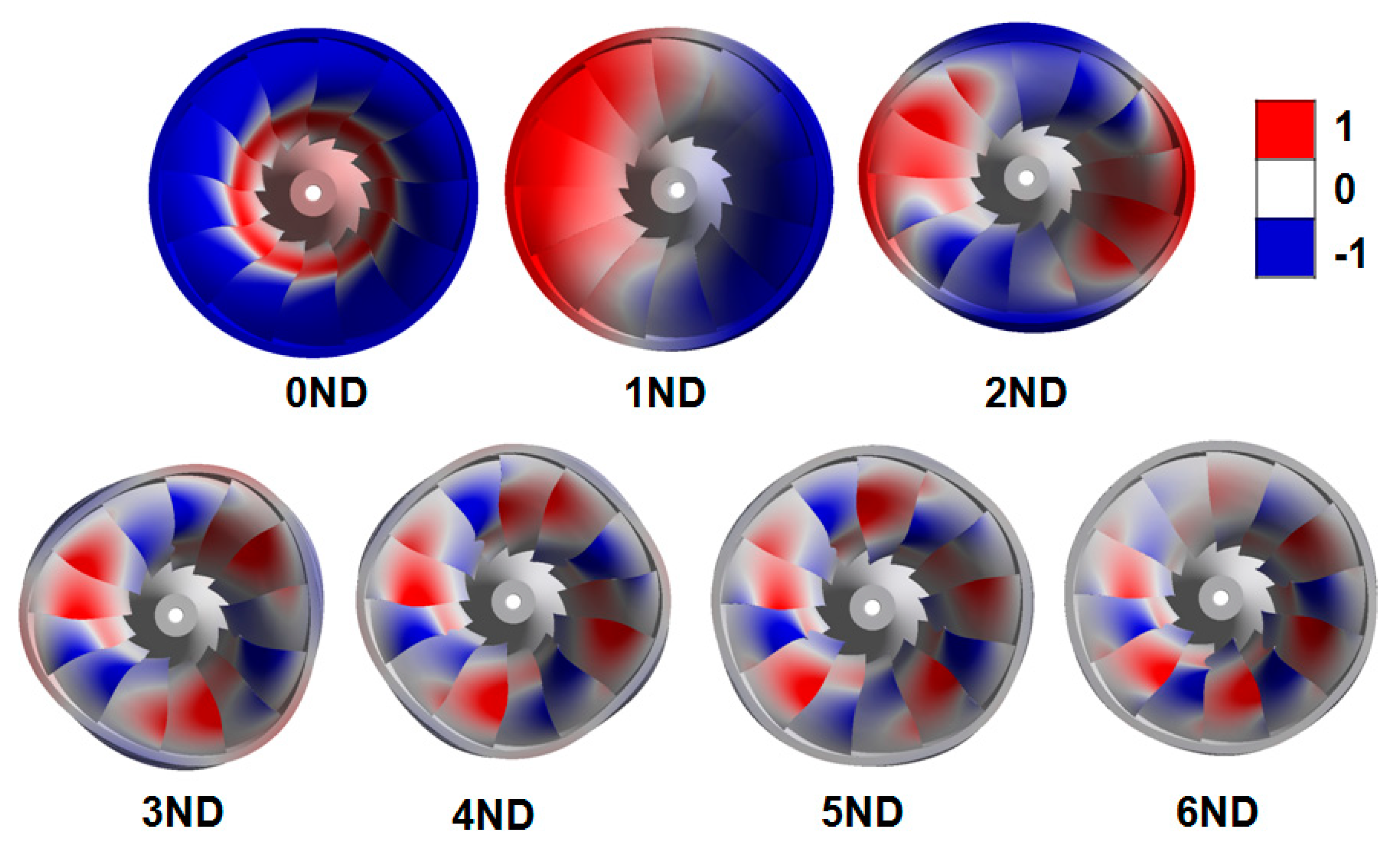

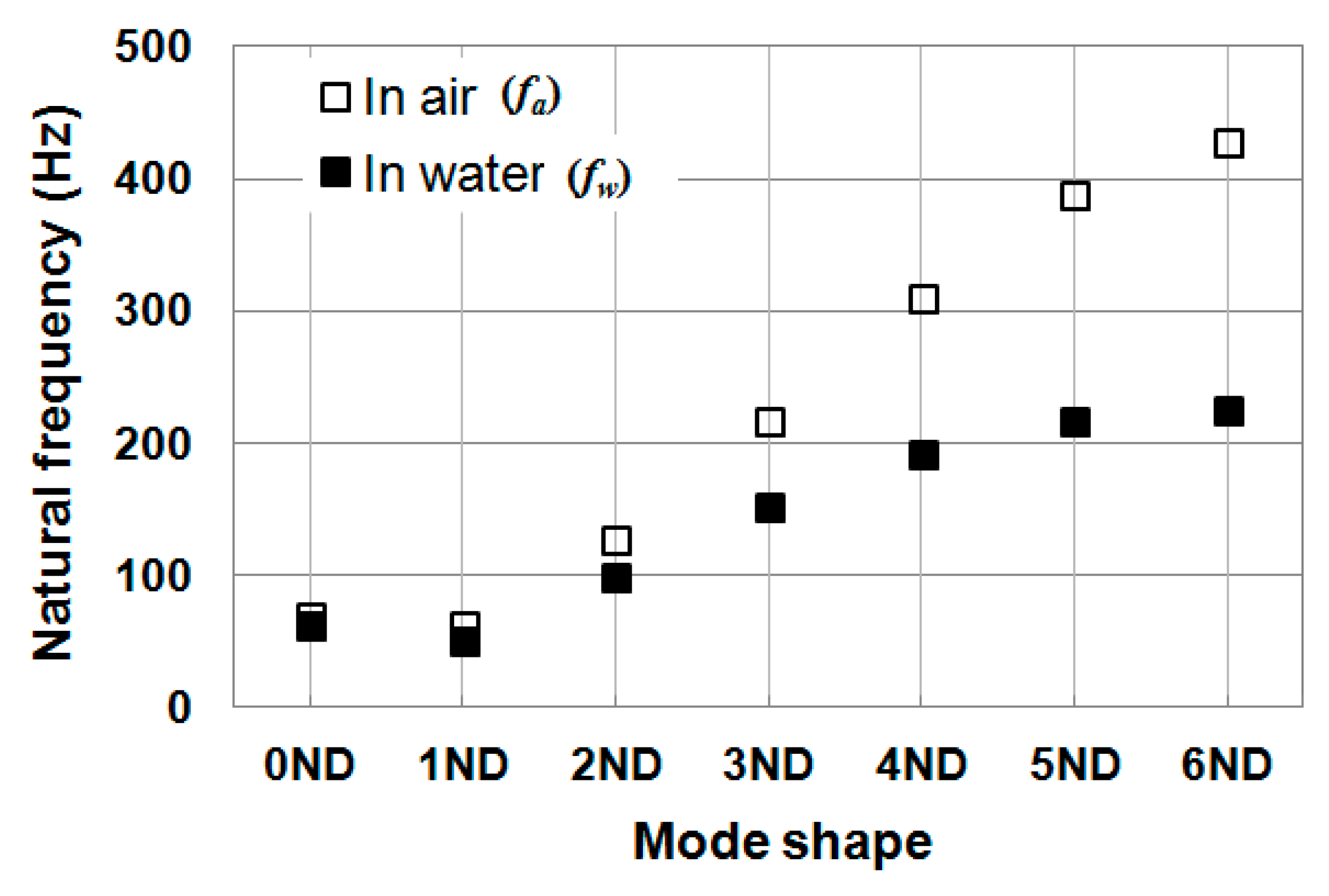

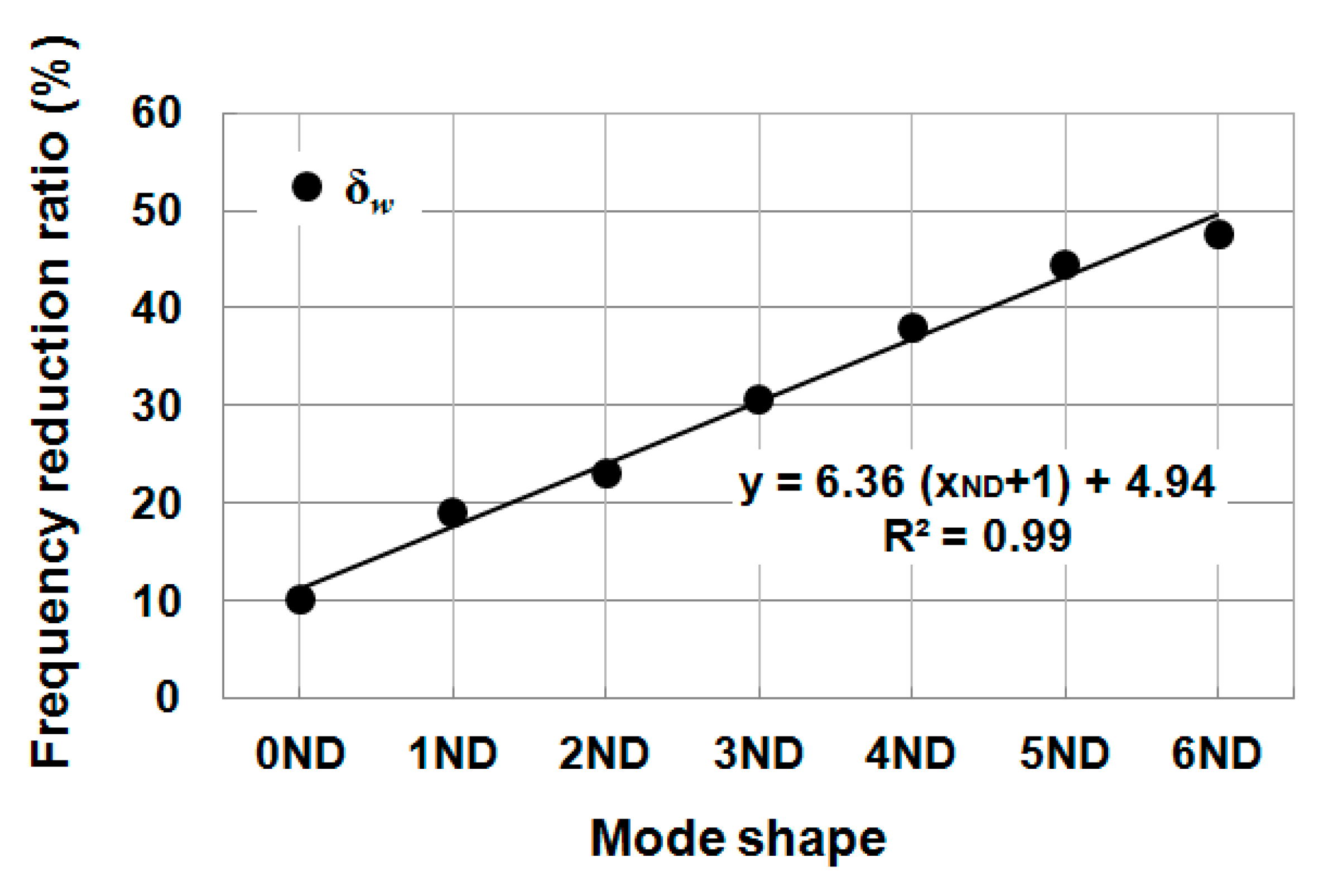

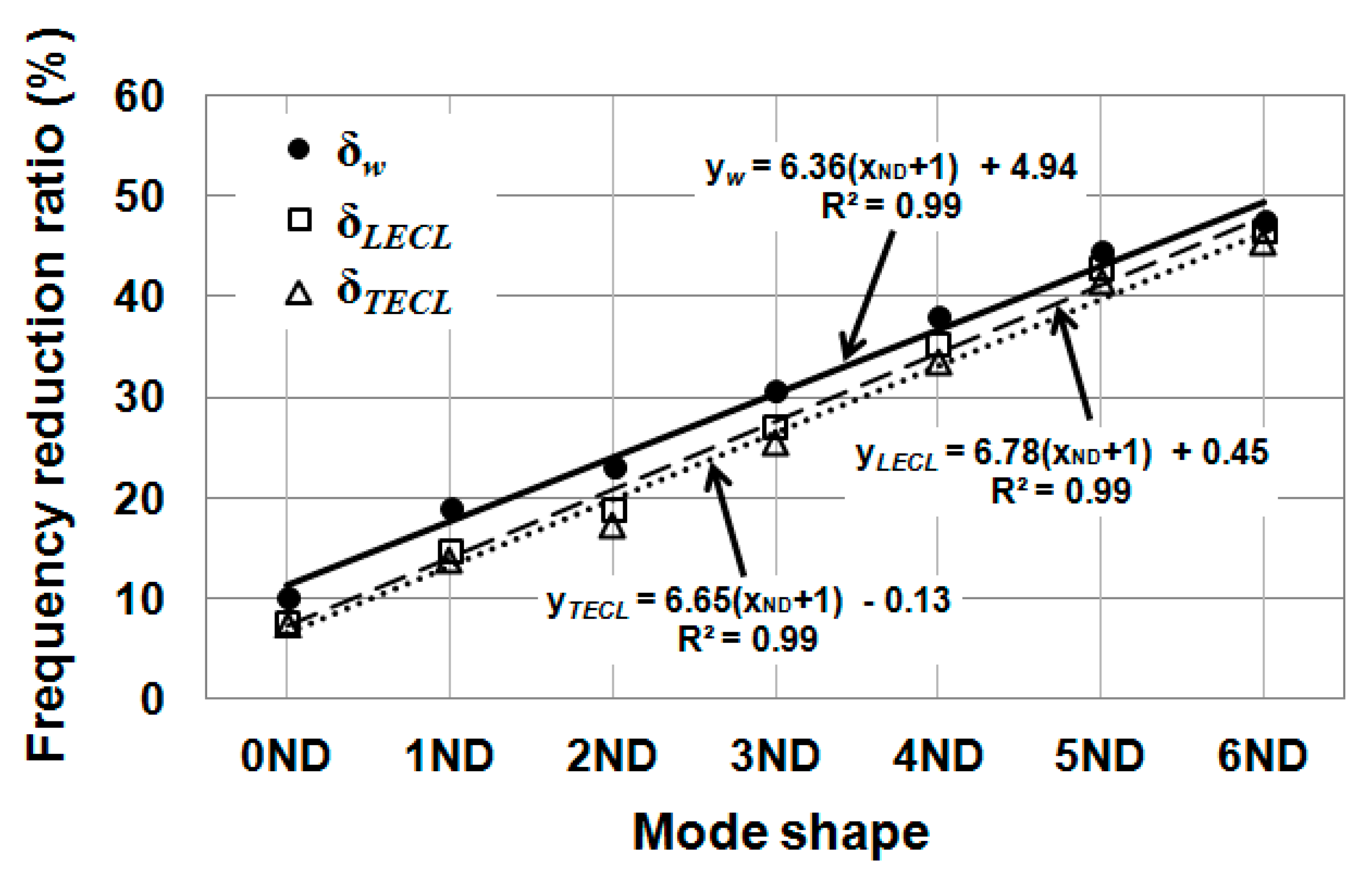

Surrounding water led to a significant reduction of natural frequencies. For the single blade, the first three natural frequencies were reduced by around 37%. For the whole runner, the first seven natural frequencies were reduced from around 10% to 48%, following a growing linear trend with the nodal diameter number. Therefore, added water mass effects depend on mode shape. The modes that present more deformation in the direction normal to the blade surface have larger added water mass effects because they accelerate more surrounding fluid.

In general, the presence of vapor cavities on the blades provoked an increase of natural frequencies due to a reduction of added mass for both the single blade and the whole runner.

For the single blade, only trailing edge cavitation presented more than 1% effect for the second and third modes. The largest influence was found for the second mode, at about 6% for the large cavity size. This behavior was determined by the effective normal deformation of the blade at the cavity location as well as the size of the cavity. For the same reason, the effects of leading edge cavitation were lower than 1% due to the low deformation of the blade and smaller size.

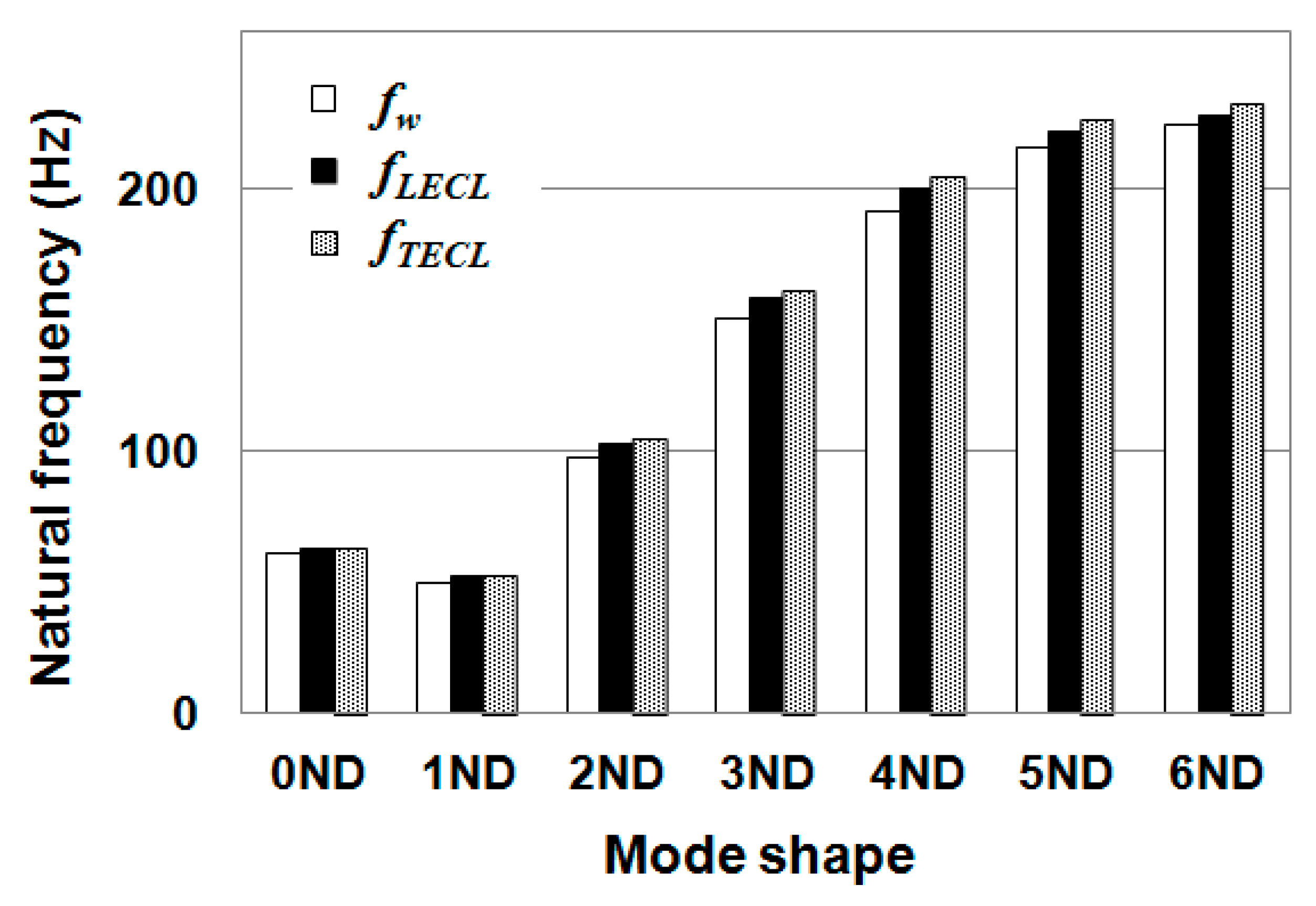

For the entire runner, both leading and trailing edge cavities induced effects higher than 1% in all modes because the mode shapes of the blades differed in relation to the single blade case. As a result, the maximum effects were found between 4% and 6% for modes 1ND and 2ND with both types of cavitation. Starting from 2ND, the effects decreased with nodal number. Again, trailing edge cavitation always had a larger effect than leading edge cavitation for any given mode.

In summary, added mass effects with cavitation attached to blades was determined by the coincidence between the mode shape of the structure and the location and size of the cavities. However, the main features of the mode shape were similar in all the cases considered. In reality, a Francis runner is mounted inside a spiral case in a hydropower plant, and the added mass effects of attached cavitation on a submerged runner with nearby boundaries should be further investigated.