Resistance Reduction Mechanism in Slurry Pipeline Transportation Under the Action of the Swirler

Abstract

1. Introduction

2. Test Methods

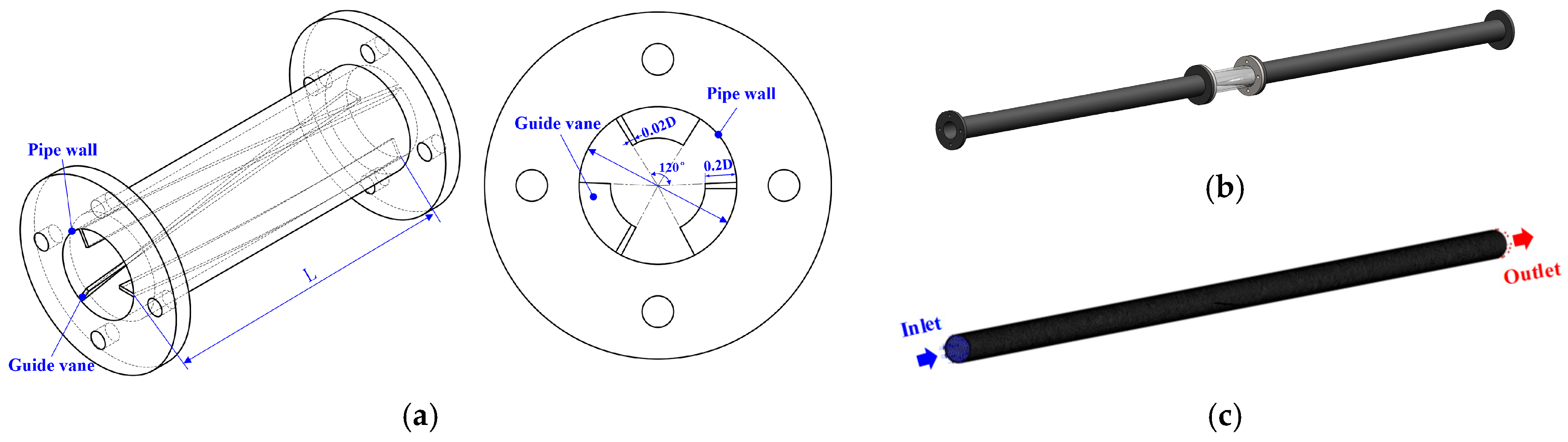

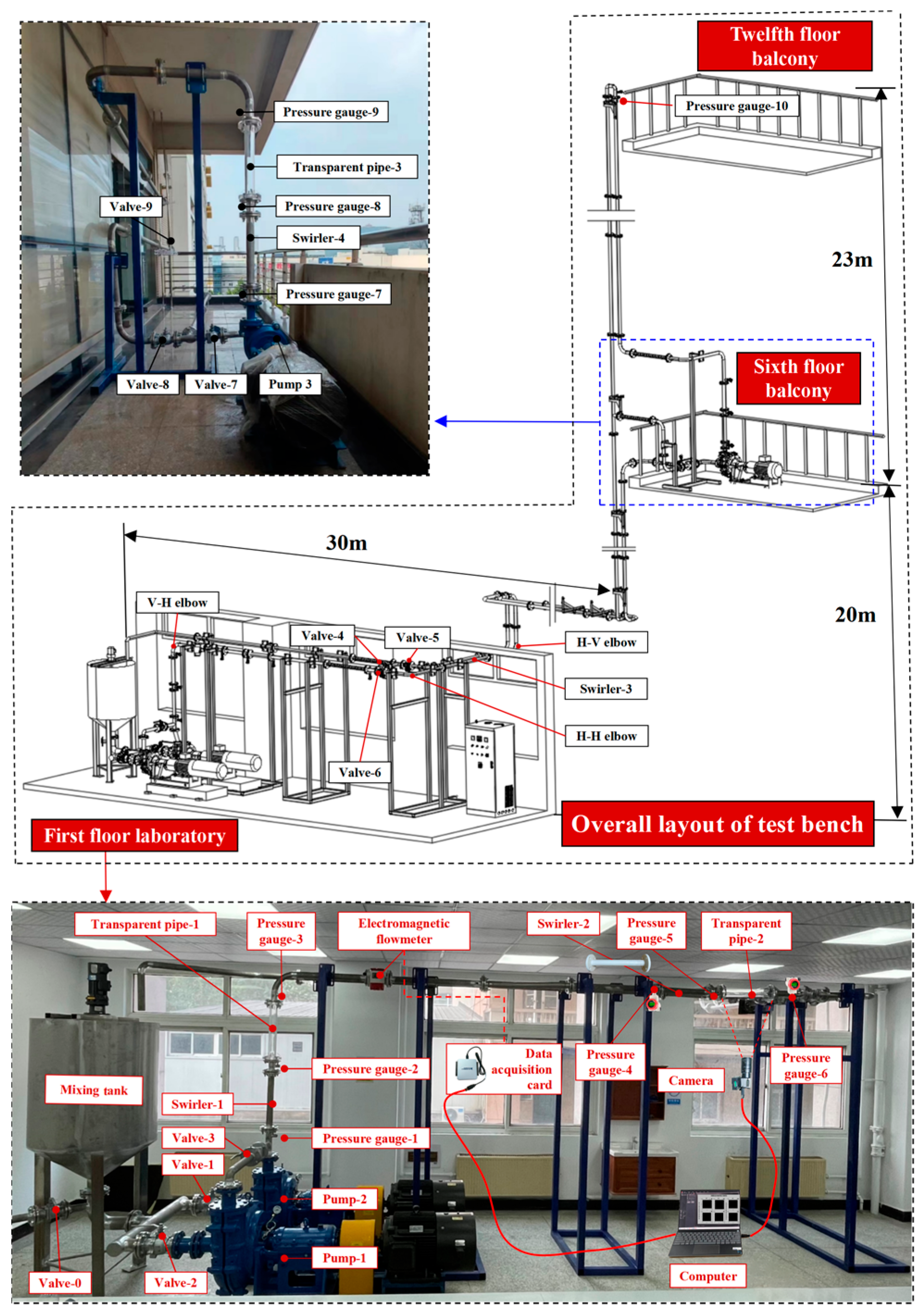

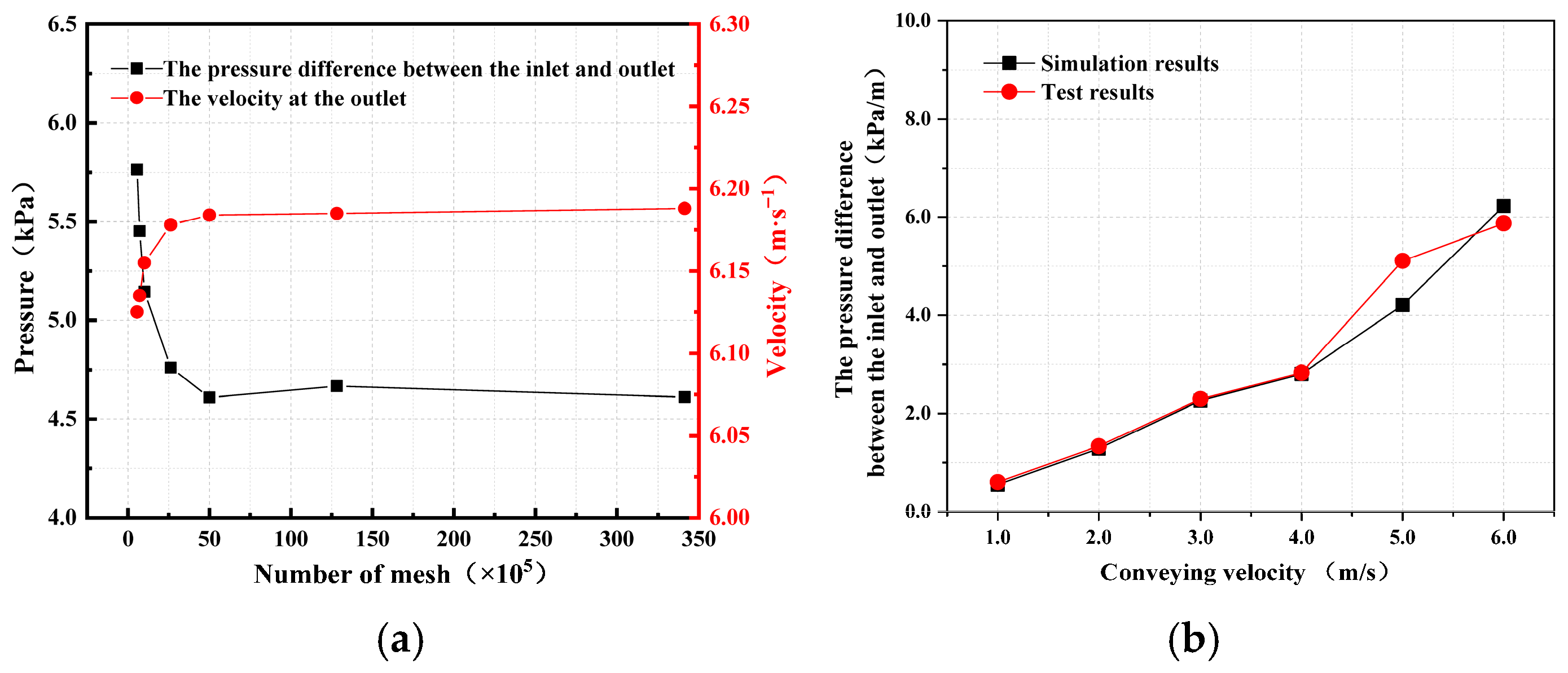

2.1. Numerical Simulation Method

2.2. Bench Test Method

3. Simulation and Test Results

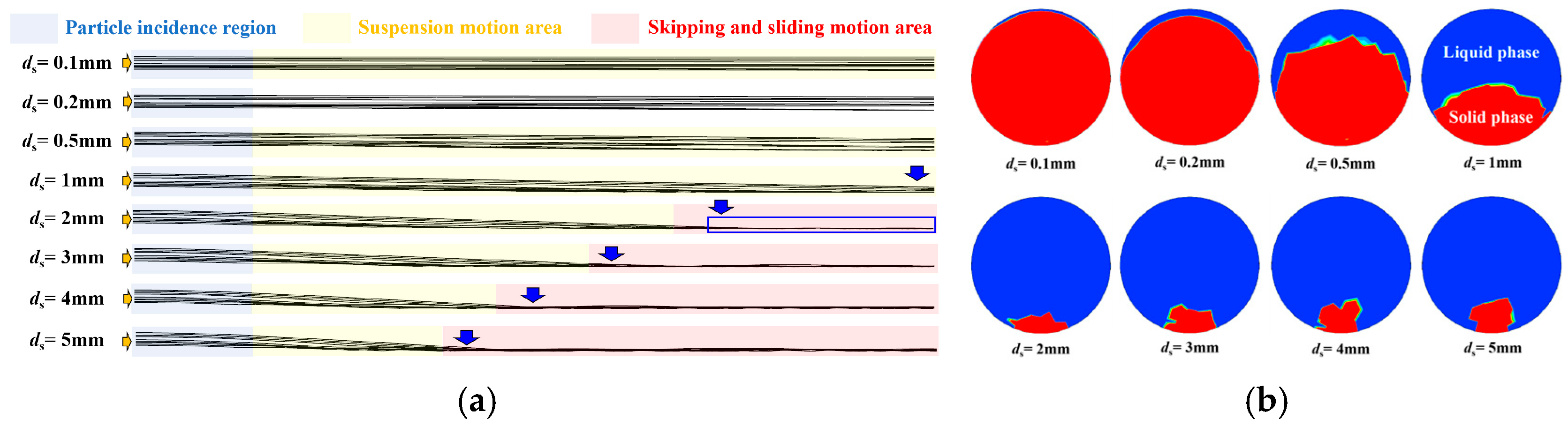

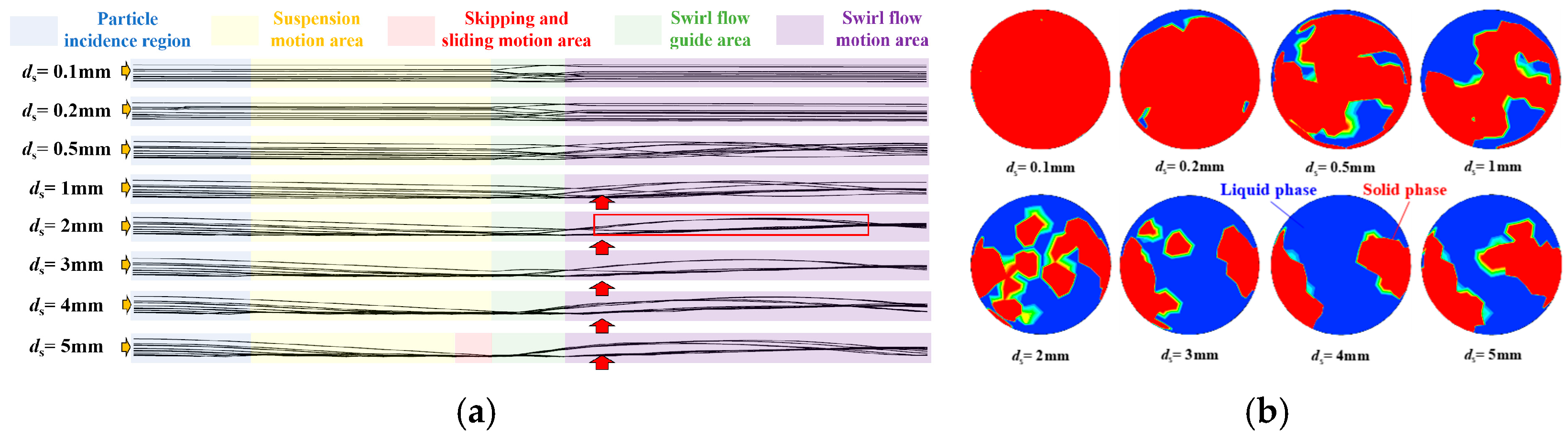

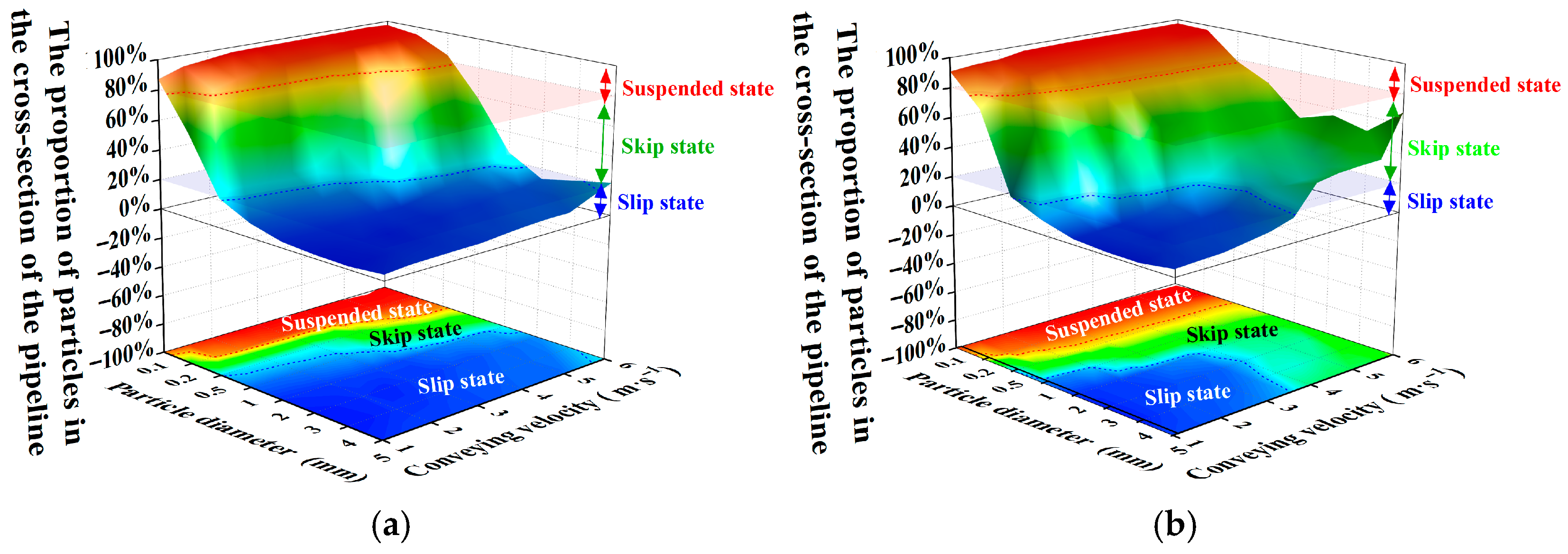

3.1. Particle Settlement in the Pipeline with and Without a Swirler

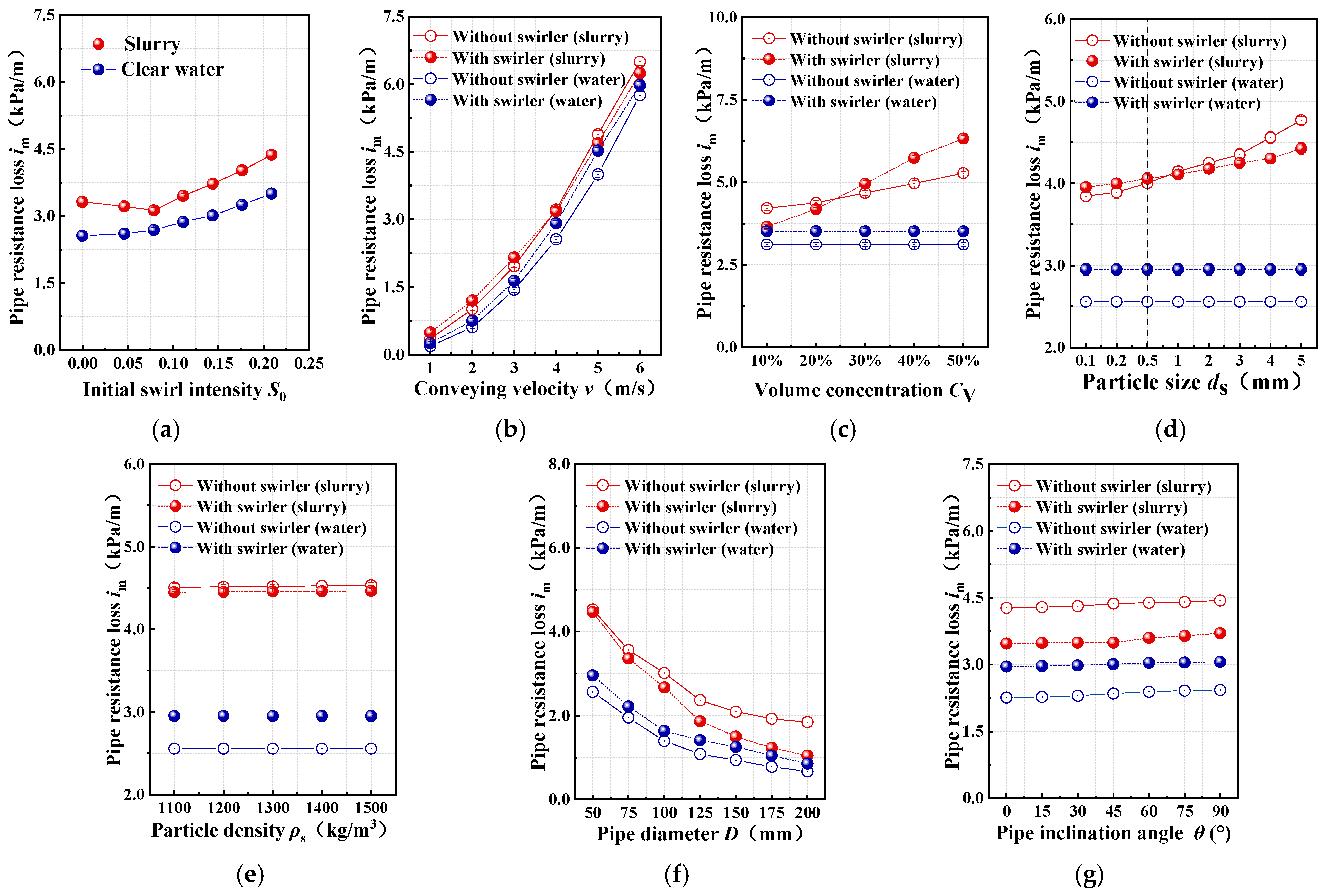

3.2. The Variation Law of Resistance Loss in the Pipeline with and Without a Swirler

3.2.1. The Influence of Swirl Intensity on Resistance Loss

3.2.2. The Influence of Conveying Velocity on Resistance Loss

3.2.3. The Influence of Volume Concentration on Resistance Loss

3.2.4. The Influence of Particle Diameter on Resistance Loss

3.2.5. The Influence of f Particle Density on Resistance Loss

3.2.6. The Influence of f Pipe Diameter on Resistance Loss

3.2.7. The Influence of f Pipe Inclination Angle on Resistance Loss

3.3. Comparative Analysis of Drag Reduction Methods for Slurry Transport

4. Calculation Model of Resistance Loss Considering the Swirl Characteristics

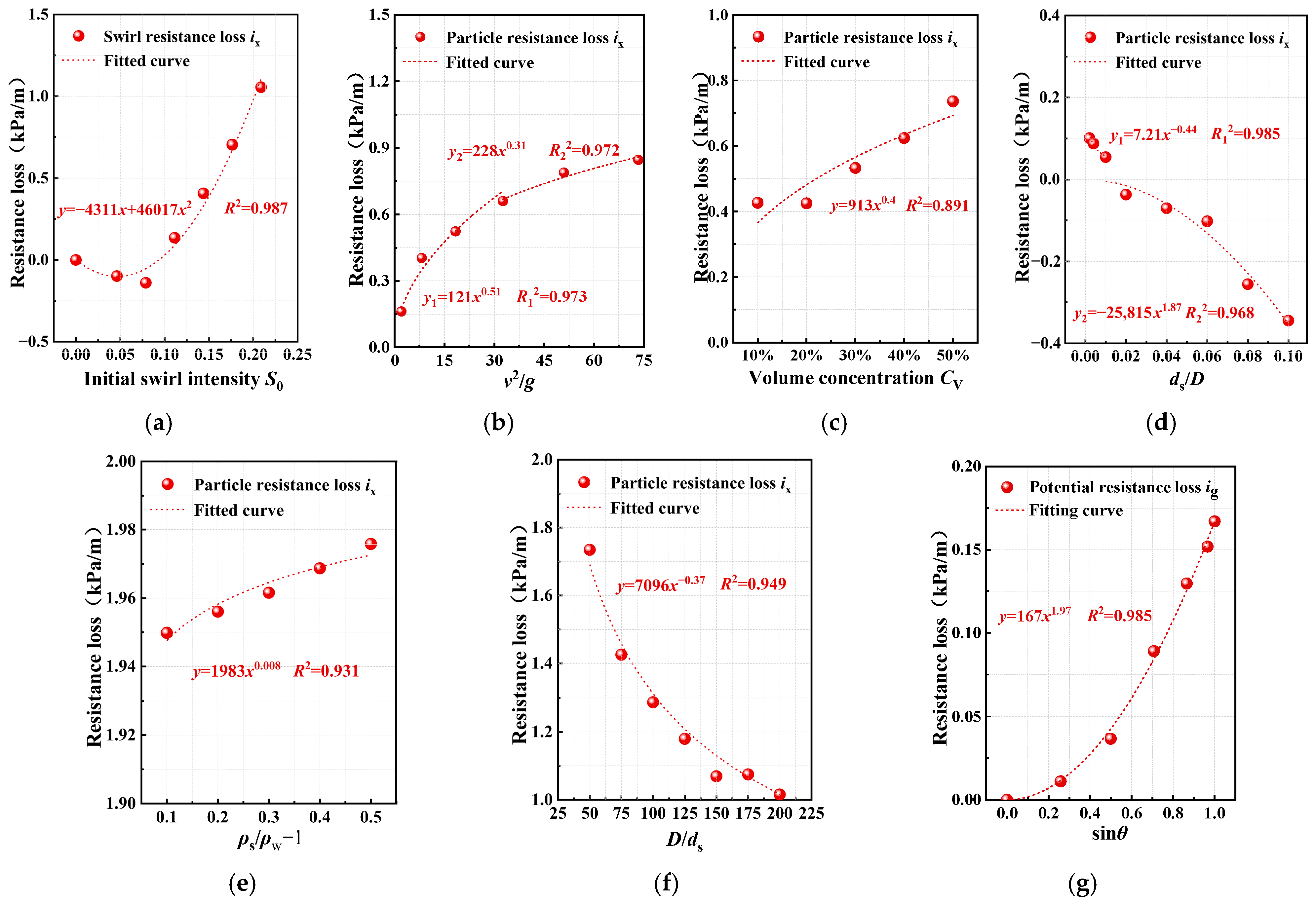

4.1. The Functional Relationship Between Resistance Loss and Its Influencing Factors

4.2. The Calculation Model of Slurry Resistance Loss Based on Swirling Characteristics

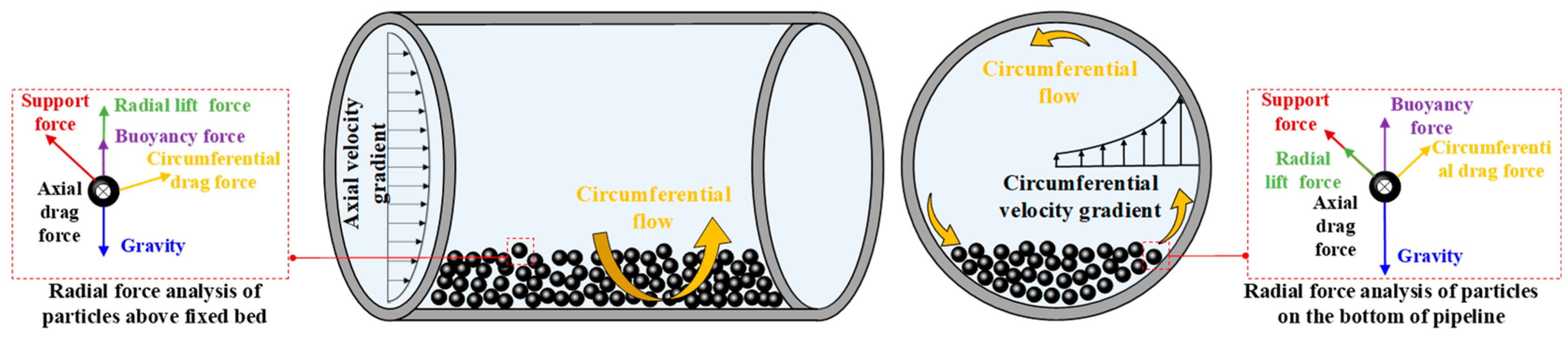

4.2.1. Suspended State

4.2.2. Skip State

4.2.3. Slip State

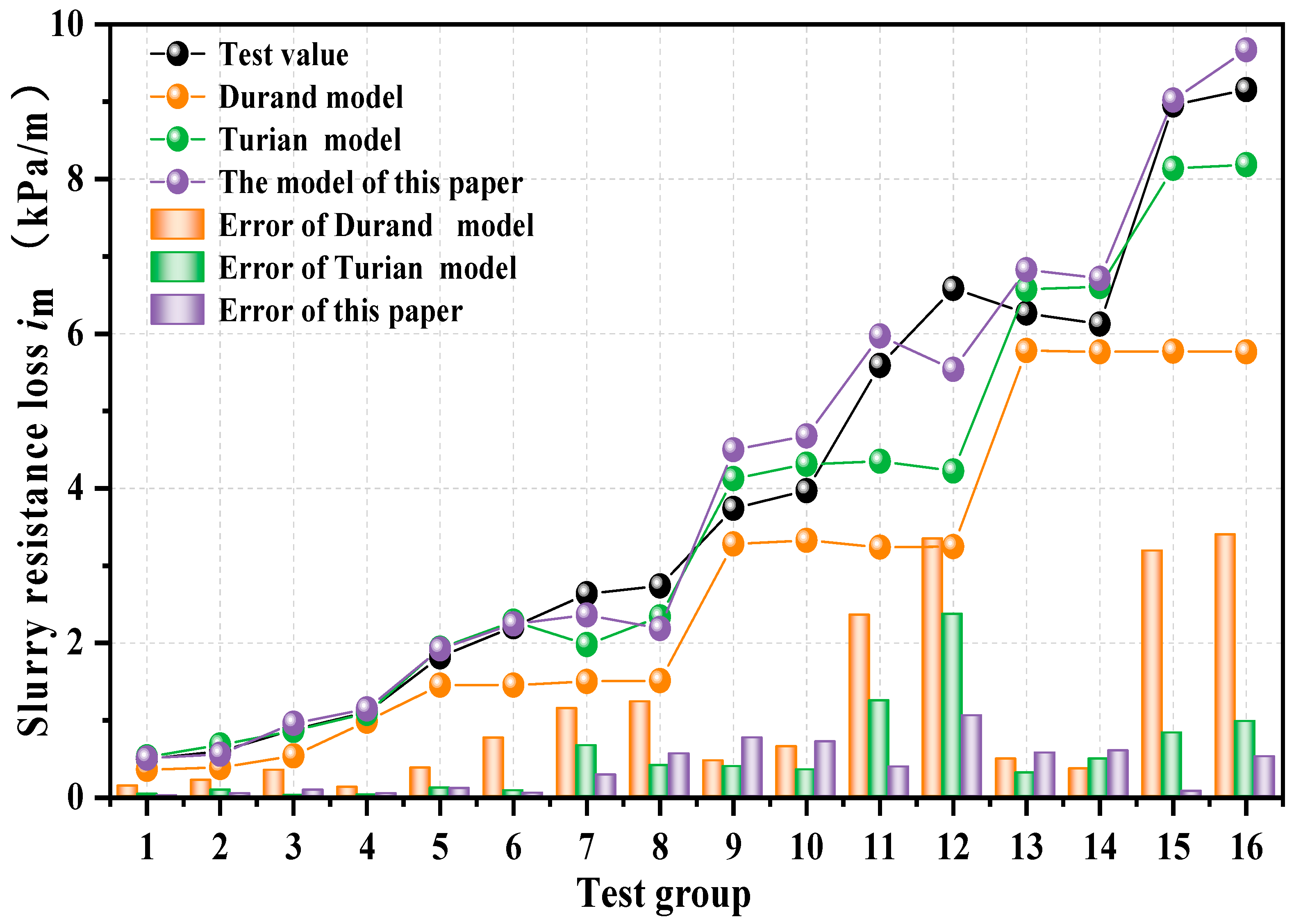

4.3. Verification Test of the Slurry Resistance Loss Calculation Model

5. Conclusions

- (1)

- The addition of the swirler transforms the axial flow field in the conveying pipeline into a spiral flow field. The dragging force of the circumferential water flow can cause the large particles that have settled at the bottom of the pipeline to rise, making the particles easier to suspend. As a result, the slurry changes from a slip state to a skip state, thereby reducing the resistance loss.

- (2)

- Under the action of the swirler, the slurry resistance loss first decreases and then increases with the increase in the swirling intensity. It increases with the increase in conveying velocity, volume concentration, particle diameter, particle density, and pipe inclination angle, and decreases with the increase in pipe diameter. Only under the conditions where the conveying velocity exceeds 4 m/s, the particle diameter is larger than 0.5 mm, and the volume concentration remains below 25%, does the pressure loss become lower than that without the swirler.

- (3)

- Considering the relationship between the flow state of the slurry in the conveying pipeline and the resistance loss, resistance loss calculation models for the suspended state, skip state, and slip state based on the swirl characteristics were established, respectively. The average error is 9.04% and the maximum error is 19.38%.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| αg | the volume fraction of the fluid |

| ρg | the fluid density, kg/m3 |

| ug | the fluid velocity, m/s |

| g | the fluid velocity vector, m/s |

| ▽ | the horizontal and vertical gradient operator, 1/m |

| μg | the fluid viscosity, Pa·s |

| ex | the solid–liquid interaction force, N |

| the pressure, Pa | |

| k | the turbulent kinetic energy, m2/s2 |

| ε | the dissipation rate, m2/s3 |

| xj | the Cartesian coordinate component in tensor notation |

| ug,j | the Cartesian component of the fluid velocity vector in tensor notation |

| σk | the turbulent Prandtl numbers of the k equation |

| μt | the turbulent viscosity coefficient, Pa·s |

| σt | the turbulent Prandtl numbers of the ε equation |

| Gk | the turbulent kinetic energy caused by velocity, kg/(m·s3) |

| Sk | the turbulent energy term, m2/s3 |

| C1ε, C2 | the constant coefficients for the turbulence model |

| YM | the influence of turbulent pulsation on the total dissipation rate, m2/s3 |

| Sε | the turbulent dissipation source term, m2/s4 |

| C1 | the equation correction coefficient |

| Gb | the turbulent kinetic energy caused by buoyancy, kg/(m·s3) |

| p | the particle velocity vector, m/s |

| C3ε | the uncertain constant affecting buoyancy |

| ds | the particle diameter, mm |

| mp | the mass of the particle, kg |

| Cd | the drag coefficient |

| ρs | the particle density, kg/m3 |

| r | the distance from a point on the section of the pipe to the center of the pipeline, mm |

| R | the radius of the pipe, mm |

| uc | the circumferential velocity of the liquid phase, m/s |

| ua | the axial velocity of the liquid phase, m/s |

| im | the slurry resistance loss, Pa/m |

| iw | the clear water resistance loss, Pa/m |

| ig | the potential resistance loss, Pa/m |

| ix | the swirl resistance loss, Pa/m |

| S0 | the initial swirl intensity |

| CV | the volume concentration |

| D | the pipe diameter, mm |

| θ | the pipe inclination angle, rad |

| χ(Zsd) | the spiral flow attenuation function |

| Zsd | the distance from the outlet of the swirler, mm |

| KTGF | the particle fluid dynamics used in the DDPM model to consider the interaction between particles (such as particle collision, translation, etc.), N |

References

- Zhang, Q.H.; Wang, X.R.; Yuan, L. Development of a multi-field coupled numerical simulation program for underground coal gasification and multi-field evolution laws. J. China Coal Soc. 2023, 48, 2506–2518. [Google Scholar] [CrossRef]

- Chen, S.D.; Tang, D.Z.; Hou, W.; Li, Y.Z.; Tao, S.; Xu, H.; Li, S.; Tang, S.L.; Pu, Y.F.; Zhang, B. Geological particularity and reservoir engineering response of deep coalbed methane. Acta Pet. Sin. 2023, 44, 1993–2006. [Google Scholar] [CrossRef]

- Xie, H.P.; Gao, F.; Ju, Y.; Zhang, R.; Gao, M.Z.; Deng, J.H. Novel idea and disruptive technologies for the exploration and research of deep earth. Adv. Eng. Sci. 2017, 49, 1–8. [Google Scholar] [CrossRef]

- Xie, H.P.; Gao, F.; Ju, Y.; Ge, S.R.; Wang, G.F.; Zhang, R.; Gao, M.Z.; Wu, G.; Liu, J.Z. Theoretical and technological conception of the fluidization mining for deep coal resources. J. China Coal Soc. 2017, 42, 547–556. [Google Scholar] [CrossRef]

- Xie, H.P.; Ju, Y.; Gao, M.Z.; Gao, F.; Liu, J.Z.; Ren, H.W.; Ge, S.R. Theories and technologies for in-situ fluidized mining of deep underground coal resources. J. China Coal Soc. 2018, 43, 1210–1219. [Google Scholar] [CrossRef]

- Xie, H.P.; Ju, Y.; Ren, S.H.; Gao, F.; Liu, J.; Zhu, Y. Theoretical and technological exploration of deep in situ fluidized coal mining. Front. Energy 2019, 13, 603–611. [Google Scholar] [CrossRef]

- Singh, R.P.; Mallick, M.; Verma, M.K. Studies on failure behaviour of wire rope used in underground coal mines. Eng. Fail. Anal. 2016, 70, 290–304. [Google Scholar] [CrossRef]

- Wang, D.G.; Zhang, J.; Ge, S.R.; Zhang, D.K.; Shi, G.Y. Mechanical behavior of hoisting rope in 2 km ultra deep coal mine. Eng. Fail. Anal. 2019, 106, 104185. [Google Scholar] [CrossRef]

- Galy, B.; Giraud, L. Risk mitigation strategies for automated current and future mine hoists. Saf. Sci. 2023, 167, 106267. [Google Scholar] [CrossRef]

- Das, S.N.; Biswal, S.K.; Mohapatra, R.K. Recent advances on stabilization and rheological behaviour of iron ore slurry for economic pipeline transportation. Mater. Today Proc. 2020, 33, 5093–5097. [Google Scholar] [CrossRef]

- Das, D.; Das, S.K.; Parhi, P.K.; Dan, A.K.; Mishra, S.; Misra, P.K. Green strategies in formulating, stabilizing and pipeline transportation of coal water slurry in the framework of WATER-ENERGY NEXUS: A state of the art review. Energy Nexus 2021, 4, 100025. [Google Scholar] [CrossRef]

- Bao, J.S.; Zhao, S.D.; Wang, Z.B.; Ge, S.R.; Yin, Y.; Huang, C.G.; Zhou, H. A Deep Coal Fluidized Pipeline Transportation System. CN202110715365.2. 18 February 2022. Available online: https://kns.cnki.net/kcms2/article/abstract?v=29aDaWKg40GLx-CVGG35OkGpkvaQYG7YrPDBKcWU_7BjN2PvCu-tXfp4YGLIC3WcdexAWLm_qaiygr_UmUIvQQpDIaVJ9tASXL5qQkN14nFHflz20Kg266bITRQ5mNBsAs_s2U96dNB0qSDLy-7LHAvUhiCSWrB-_XnKxYuPEJAC6UXBaT3xjfjmpyoZNiyA&uniplatform=NZKPT (accessed on 22 December 2025).

- He, C.; Han, W.; Li, R.; Dong, Y.; Zhang, Y. Multi-objective optimization and performance analysis of the splitter blades in a multiphase pump. Int. J. Fluid Eng. 2024, 2, 013501. [Google Scholar] [CrossRef]

- Chang, L.; Yang, C.; Su, X.; Dai, X.; Xu, Q.; Guo, L. Investigations on affinity law under gas–liquid conditions in multistage radial and mixed-flow multiphase pumps. Int. J. Fluid Eng. 2024, 1, 013503. [Google Scholar] [CrossRef]

- Sun, X.; Lin, Z.; Li, L.; Zhu, Z. Motion characteristics of multi-scale particles in periodic lifting pipes. Ocean Eng. 2025, 327, 120952. [Google Scholar] [CrossRef]

- Ma, Y.; Chen, J.Q.; Men, Z.M.; Ruan, Z.Y.; Zou, D.Z.; Zuo, H.Q.; Han, W.L. Optimization of coal pipeline transportation parameters. Coal Eng. 2017, 49, 107–111. [Google Scholar] [CrossRef]

- Li, Y.G.; Pang, Y.Q.; Song, X.T.; Jia, X.M.; Lu, Y.F.; Sun, X.H.; Zhang, X.L. Influence of setting angle for guide bar on velocity characteristics of spiral flow in cross-sections between piped carriages. Trans. Chin. Soc. Agric. Eng. 2021, 37, 87–94. [Google Scholar] [CrossRef]

- Lu, Y. Application status and development direction of coal slurry pipeline transportation technology. Guangdong Chem. Ind. 2020, 47, 67–68. [Google Scholar]

- Singh, M.K.; Kumar, S.; Ratha, D.; Kaur, H. Improvement in head loss characteristics of fine particulate coal water suspension with addition of coarser particulate. Int. J. Coal Prep. Util. 2019, 42, 305–314. [Google Scholar] [CrossRef]

- Sun, X.H.; Yan, Q.F.; Li, Y.Y. Study on Hydraulic Characteristics of Pipe Helical Flow Transportation; China Water and Power Press: Beijing, China, 2012. [Google Scholar]

- Hawkins, E.K.; Cheng, J.S.; Abbate, J.A.; Pilegard, T.; Stellmach, S.; Julien, K.; Aurnou, J.M. Laboratory Models of Planetary Core-Style Convective Turbulence. Fluids 2023, 8, 106. [Google Scholar] [CrossRef]

- Chen, X.; Chen, Y.; Wu, X.; Zhu, P.; Yang, L. Optimizing Energy Efficiency in Deep-Sea Mining: A Study on Swirling Flow Transportation of Double-Size Mineral Particles. Energies 2024, 17, 4240. [Google Scholar] [CrossRef]

- Klinzing, G.E.; Rizk, F.; Marcus, R.; Leung, L.S. Chapter 8, Flow Aids and Their Applications. In Pneumatic Conveying of Solids: A Theoretical and Practical Approach; Springer: Dordrecht, The Netherlands, 2010. [Google Scholar] [CrossRef]

- Thakur, R.K.; Vial, C.; Nigam, K.D.P.; Nauman, E.B.; Djelveh, G. Static Mixers in the Process Industries—A Review. Chem. Eng. Res. Des. 2004, 82, 155–164. [Google Scholar] [CrossRef]

- Nan, J.H.; Luo, H.; Ma, K.N.; Gao, H.; Wang, C.Q. Orthogonal numerical experiment method and application for shape optimization of desilting channel with swirling flow. J. Hydroelectr. Eng. 2022, 41, 160–169. [Google Scholar] [CrossRef]

- Zhao, S.D.; Bao, J.S.; Ge, S.R.; Wang, Z.B.; Yin, Y.; Li, Y.F. Influence of solid-liquid two-phase flow conveying parameters on the elbow wear with and without the swirler. Tribol. Int. 2023, 186, 108635. [Google Scholar] [CrossRef]

- Gao, R.J.; Tang, J.; Lin, T. Resistance loss of transportation derivation on high-speed spiral flow in lifting pipe for deep-sea mining. Mach. Des. Manuf. 2017, 2, 153–156. [Google Scholar] [CrossRef]

- Zhao, S.D.; Bao, J.S.; Ge, S.R.; Wang, Z.B.; Yin, Y.; Huang, C.G. Influence and optimization of swirler parameters on elbow wear of deep coal fluidization pipeline transportation system. Friction 2024, 12, 1408–1433. [Google Scholar] [CrossRef]

- Saad, I.; Baria, S. Guide vane swirl and tumble device to improve in-cylinder air flow of CI engine using vegetable oil. Procedia Eng. 2014, 90, 425–430. [Google Scholar] [CrossRef][Green Version]

- Baria, S.; Saad, I. CFD modelling of the effect of guide vane swirl and tumble device to generate better in-cylinder air flow in a CI engine fuelled by biodiesel. Comput. Fluids 2013, 84, 262–269. [Google Scholar] [CrossRef]

- Kim, I.; Kim, J.; Choe, Y.; Ryu, K.; Cha, J.; Ri, J. Effect of vane angle on combustion characteristics of premixed H2/air in swirl micro-combustors with straight vane or twisted vane. Appl. Therm. Eng. 2023, 228, 120528. [Google Scholar] [CrossRef]

- Singh, M.K.; Kumar, S.; Ratha, D. Computational analysis on disposal of coal slurry at high solid concentrations through slurry pipeline. Int. J. Coal Prep. Util. 2020, 40, 116–130. [Google Scholar] [CrossRef]

- Li, Y.; Liu, D.X.; Cui, B.L.; Lin, Z.; Zheng, Y.H.; Ishnazarov, O. Studying particle transport characteristics in centrifugal pumps under external vibration using CFD-DEM simulation. Ocean Eng. 2024, 301, 117538. [Google Scholar] [CrossRef]

- Fagbade, A.; Heinz, S. Continuous Eddy Simulation vs. Resolution-Imposing Simulation Methods for Turbulent Flows. Fluids 2024, 9, 22. [Google Scholar] [CrossRef]

- Jeong, S.-J.; Lee, S.-J.; Moon, S.-J. CFD Thermo-Hydraulic Evaluation of a Liquid Hydrogen Storage Tank with Different Insulation Thickness in a Small-Scale Hydrogen Liquefier. Fluids 2023, 8, 239. [Google Scholar] [CrossRef]

- Dehghanghadikolaei, A.; Abdul Halim, B.; Khoshbakhtnejad, E.; Sojoudi, H. Dynamics of a Water Droplet Impacting an Ultrathin Layer of Oil Suspended on a Pool of Water. Fluids 2024, 9, 82. [Google Scholar] [CrossRef]

- Bao, J.S.; Zhao, S.D.; Yin, Y.; Wang, Z.B.; Liu, S.; Ge, S.R. Non-silting transport characteristics of coal slurry in a deep underground fluidization conveying pipeline under the action of a guide vane swirler. Deep Undergr. Sci. Eng. 2025, 1–17. [Google Scholar] [CrossRef]

- Paolillo, G.; Greco, C.S.; Cardone, G.; Astarita, T. A semi-empirical correlation for the swirl number of swirling jets generated by a radial-type swirler. Exp. Therm. Fluid Sci. 2023, 144, 110874. [Google Scholar] [CrossRef]

- Besagni, G.; Varallo, N.; Mereu, R. Computational Fluid Dynamics Modelling of Two-Phase Bubble Columns: A Comprehensive Review. Fluids 2023, 8, 91. [Google Scholar] [CrossRef]

- Li, T.; Yang, T.; Liu, J.; Gao, H.; Ma, H. Study on suspension state stability of coal-based solid waste filling slurry of long-distance pipeline transportation. Coal Sci. Technol. 2025, 53, 444–456. [Google Scholar] [CrossRef]

- Hall, T.D.; Weerasekara, N.S. ARTERRATM ultra-high molecular weight polyethylene: A sustainable solution for slurry pipeline transportation. In Proceedings of the 27th International Conference on Paste, Thickened and Filtered Tailings, Swakopmund, Namibia, 8–10 April 2025; pp. 249–262. [Google Scholar] [CrossRef]

| Experimental Group | Swirl Intensity | Conveying Velocity | Volume Concentration | Particle Size | Particle Density | Pipe Diameter | Pipe Inclination Angle |

|---|---|---|---|---|---|---|---|

| a | 0~0.21 | 4 m/s | 20% | 5 mm | 1400 kg/m3 | 50 mm | 0° |

| b | 0.08 | 1~6 m/s | 20% | 5 mm | 1400 kg/m3 | 50 mm | 0° |

| c | 0.08 | 4 m/s | 10~50% | 5 mm | 1400 kg/m3 | 50 mm | 0° |

| d | 0.08 | 4 m/s | 20% | 0.1~5 mm | 1400 kg/m3 | 50 mm | 0° |

| e | 0.08 | 4 m/s | 20% | 5 mm | 1100~1500 kg/m3 | 50 mm | 0° |

| f | 0.08 | 4 m/s | 20% | 5 mm | 1400 kg/m3 | 50~200 mm | 0° |

| g | 0.08 | 4 m/s | 20% | 5 mm | 1400 kg/m3 | 50 mm | 0~90° |

| Method | Core Principle | Typical Drag Reduction | Key Advantage | Key Limitation |

|---|---|---|---|---|

| Installation of the swirler (in this study) | Active flow control: suspends particles via swirling flow to reduce wall contact. | −10% to −40% (optimal at high velocity, large particles). | Targeted solution for particle sedimentation, facilitating modularization transformation. | Adds energy; less effective for fine particles. |

| Pipe Liner/Coating | Passive wall modification: reduces surface friction. | −5% to −20% (degrades with abrasive wear). | No active energy input. | Poor durability in abrasive slurry; high installation cost. |

| Polymer Additives | Alters fluid rheology: suppresses turbulence. | −20% to −70% (in compatible fluids). | High effectiveness in compatible systems. | Chemical dependency; shear degradation; may contaminate product |

| Larger Pipe Diameter | System redesign: reduces velocity and shear stress. | Theoretically high (depends on design). | Fundamental, permanent solution. | Very high capital cost; not viable for existing systems. |

| Flow Regulation | Operational optimization: avoids high-drag regimes. | −5% to −15% (often reduces capacity). | Low cost, easy to implement. | Limited potential; may sacrifice throughput. |

| Test Group | v/m·s−1 | CV | ds/mm | ρs/mm |

|---|---|---|---|---|

| 1 | 1.5 | 20% | 0.2 | 1200 |

| 2 | 1.5 | 30% | 0.5 | 1300 |

| 3 | 1.5 | 40% | 2 | 1400 |

| 4 | 1.5 | 50% | 5 | 1500 |

| 5 | 3 | 20% | 0.5 | 1400 |

| 6 | 3 | 30% | 0.2 | 1500 |

| 7 | 3 | 40% | 5 | 1200 |

| 8 | 3 | 50% | 2 | 1300 |

| 9 | 4.5 | 20% | 2 | 1500 |

| 10 | 4.5 | 30% | 5 | 1400 |

| 11 | 4.5 | 40% | 0.2 | 1300 |

| 12 | 4.5 | 50% | 0.5 | 1200 |

| 13 | 6 | 20% | 5 | 1300 |

| 14 | 6 | 30% | 2 | 1200 |

| 15 | 6 | 40% | 0.5 | 1500 |

| 16 | 6 | 50% | 0.2 | 1400 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Zhao, S.; Bao, J.; Ji, J.; Li, Y.; Zhang, X.; Ma, Y.; Yin, Y. Resistance Reduction Mechanism in Slurry Pipeline Transportation Under the Action of the Swirler. Fluids 2026, 11, 3. https://doi.org/10.3390/fluids11010003

Zhao S, Bao J, Ji J, Li Y, Zhang X, Ma Y, Yin Y. Resistance Reduction Mechanism in Slurry Pipeline Transportation Under the Action of the Swirler. Fluids. 2026; 11(1):3. https://doi.org/10.3390/fluids11010003

Chicago/Turabian StyleZhao, Shaodi, Jiusheng Bao, Jinjie Ji, Yutan Li, Xing Zhang, Yansong Ma, and Yan Yin. 2026. "Resistance Reduction Mechanism in Slurry Pipeline Transportation Under the Action of the Swirler" Fluids 11, no. 1: 3. https://doi.org/10.3390/fluids11010003

APA StyleZhao, S., Bao, J., Ji, J., Li, Y., Zhang, X., Ma, Y., & Yin, Y. (2026). Resistance Reduction Mechanism in Slurry Pipeline Transportation Under the Action of the Swirler. Fluids, 11(1), 3. https://doi.org/10.3390/fluids11010003