Laminar Pipe Flow Instability: A Theoretical-Experimental Perspective

Abstract

1. Introduction

- Diffusion frequency: , where = the kinematic viscosity of fluid and D = the pipe diameter;

- Convection frequency: , where = the spatial mean velocity of the pipe flow and L = the pipe length;

- Acoustic frequency: , where c = fluid speed of sound;

- Exit vortex frequency: , where = Strouhal number.

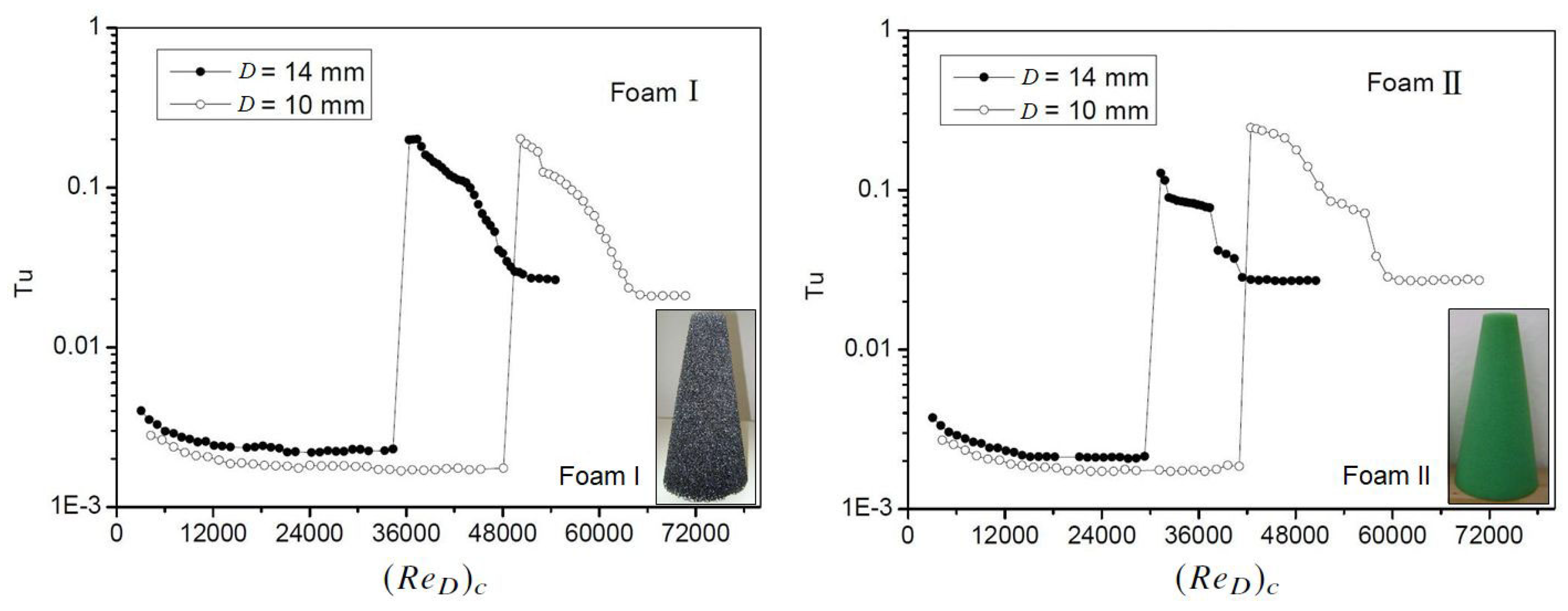

- Instability triggered by the flow through the test-rig components of the experimental setup, leading to the transition to turbulence = forced transition.

- Instability inherent to the pipe flow itself, independent of any test section components = natural transition.

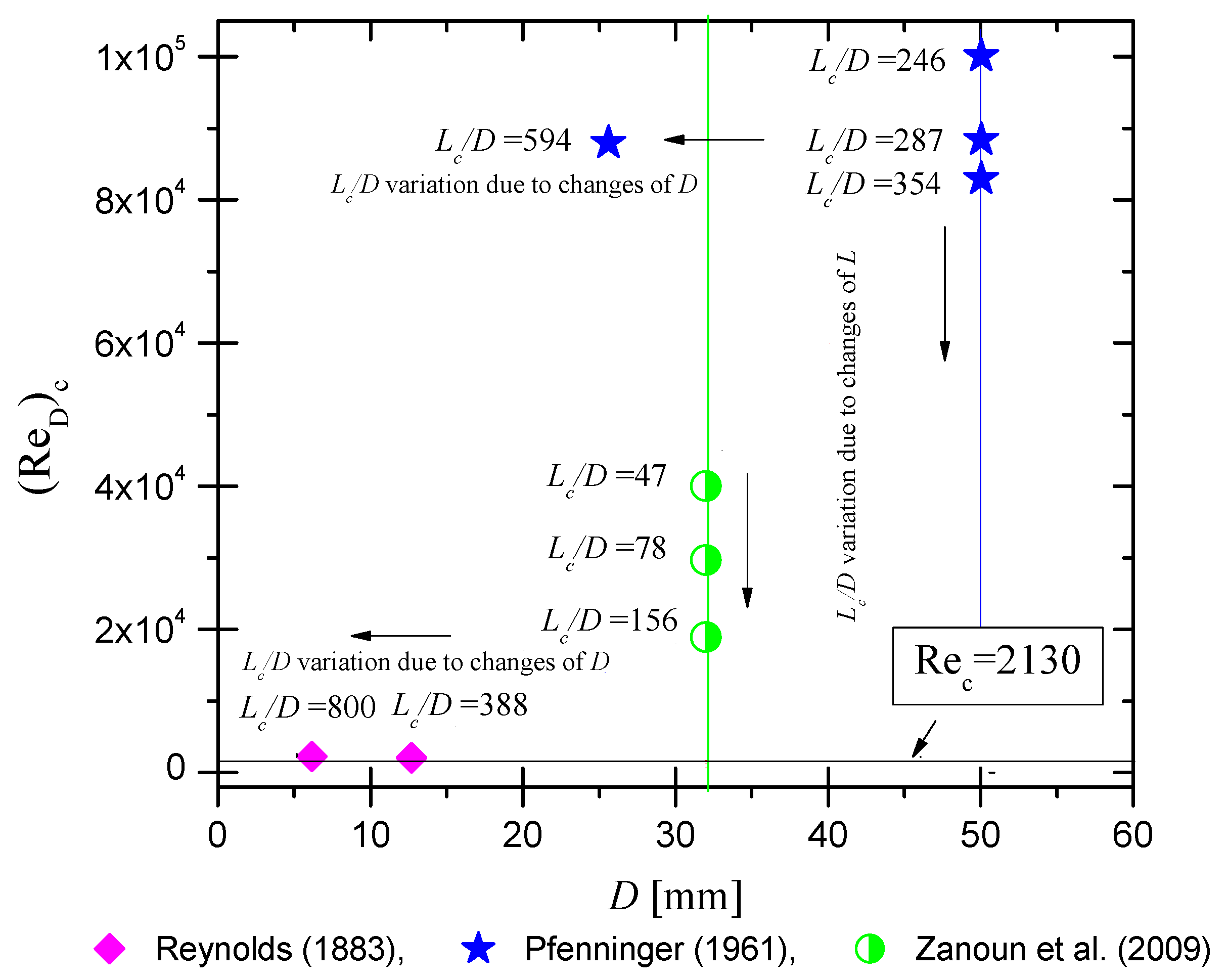

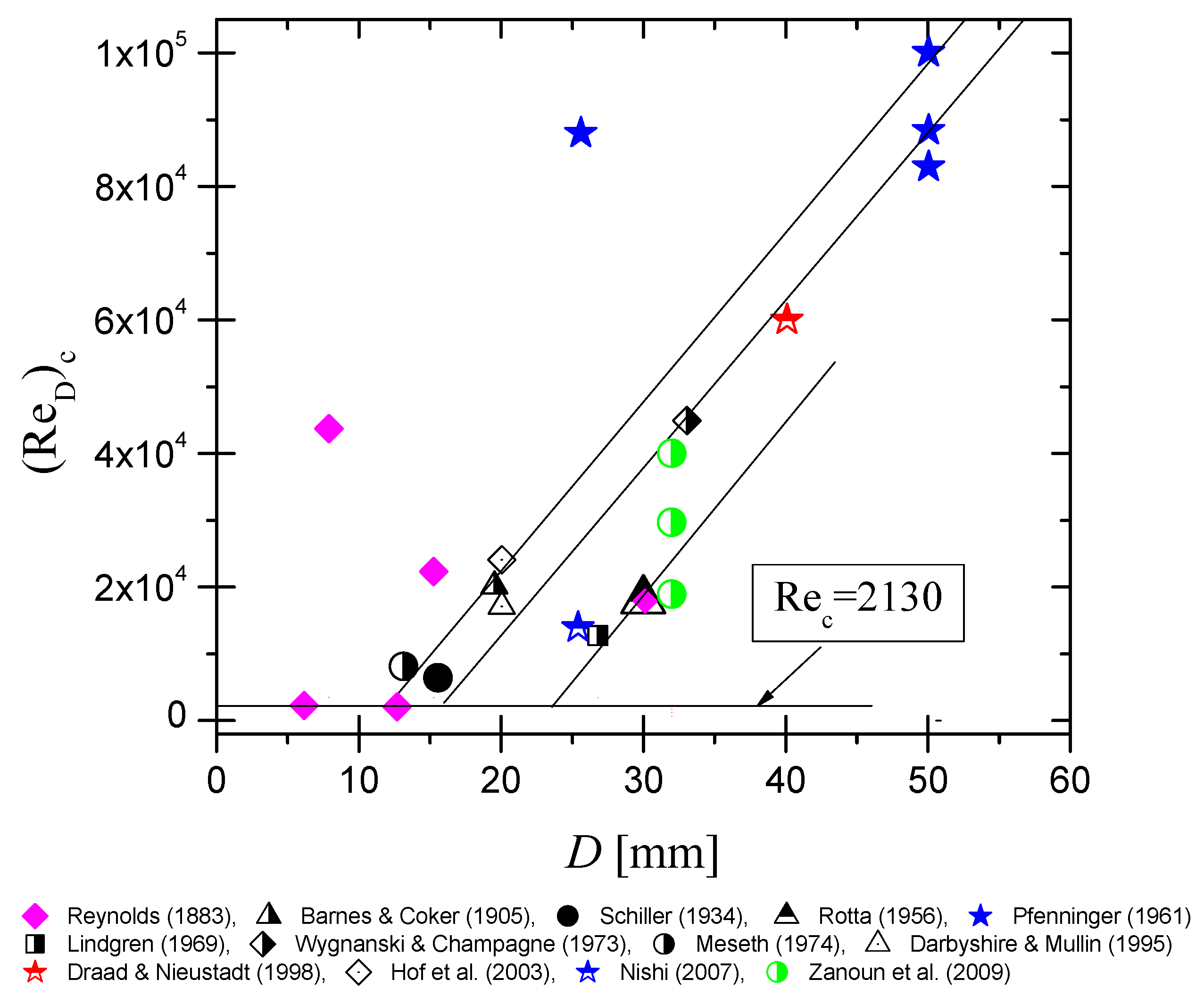

- In their paper, in pages 970 and 971, Reynolds [11] reported results for laminar pipe flow transition in pipes with diameters mm and mm, both occurring at approximately similar critical Reynolds numbers: 2073 and 2278, respectively. These values are in close agreement with the critical Reynolds number 2130, recently proposed by [3] and earlier by Fox et al. [12]. They reported two key findings: flow stability depends on both disturbance frequency and Reynolds number, and instability begins at a critical Reynolds number of about 2130 for the first azimuthal mode. Note that is defined as and , where is the critical velocity of the pipe flow and is the critical pipe diameter.

- In Table 1, on page 954, Reynolds (1883) reported also, for one set of experiments, about critical velocities at which the steady flow motion breaks down for three different pipe diameters (), yielding average critical Reynolds numbers of , respectively, i.e., the smaller the pipe diameters, the higher the critical Reynolds numbers.

- Experiments show that laminar pipe flows stay stable up to a critical Reynolds number.

- Theoretical Investigations show that fully developed laminar pipe flows are inherently stable even for .

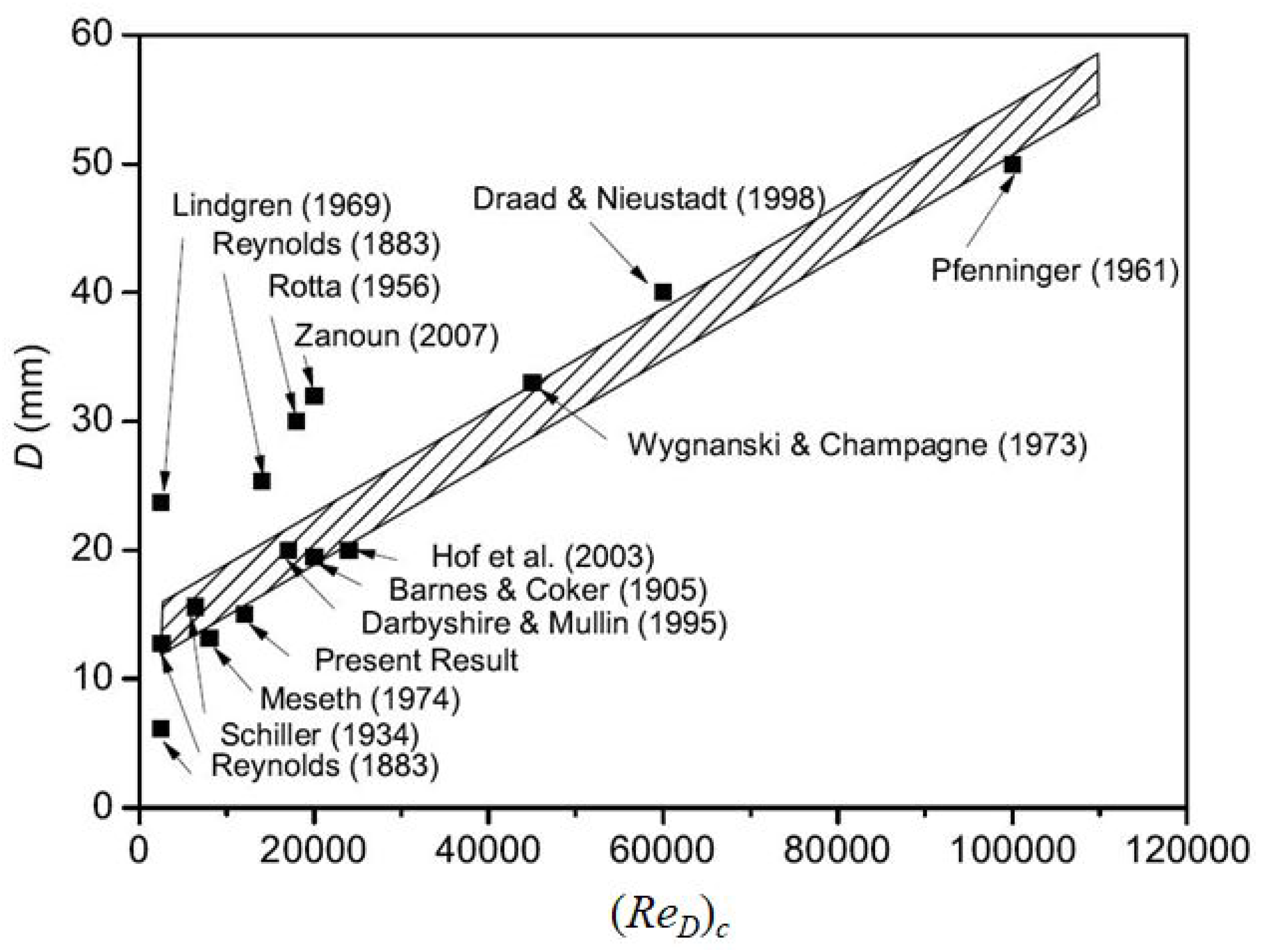

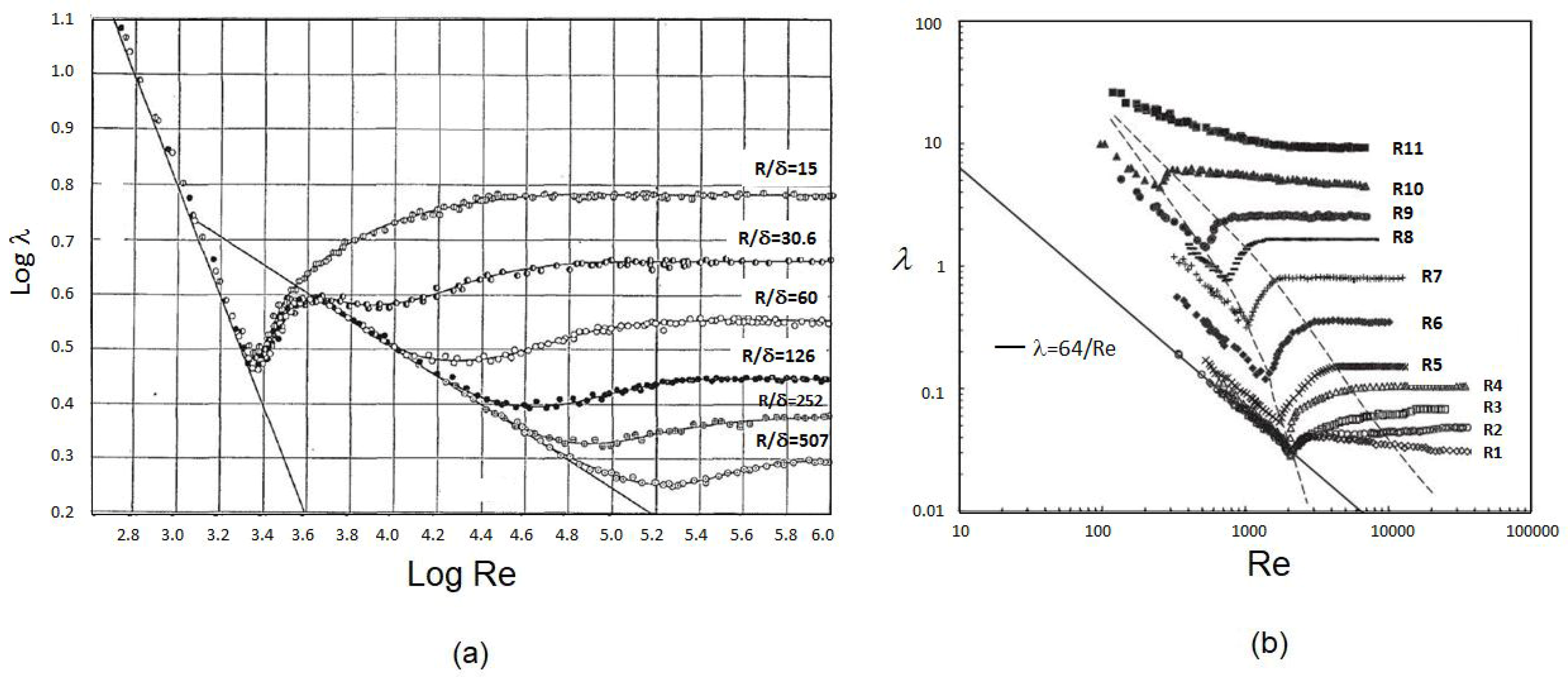

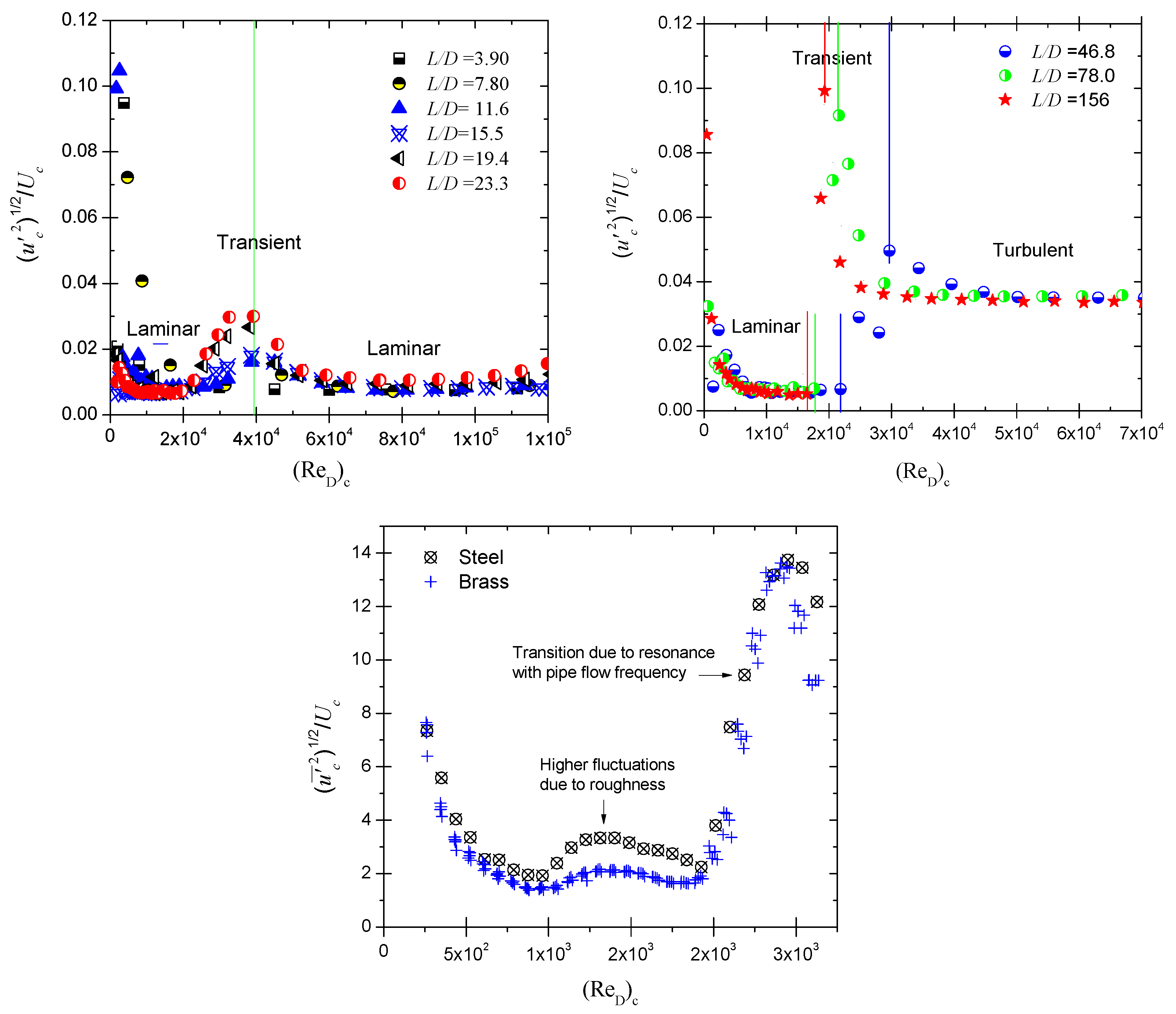

- There are laminar pipe flow experiments available that show a stability dependence on the pipe diameter and the pipe length.

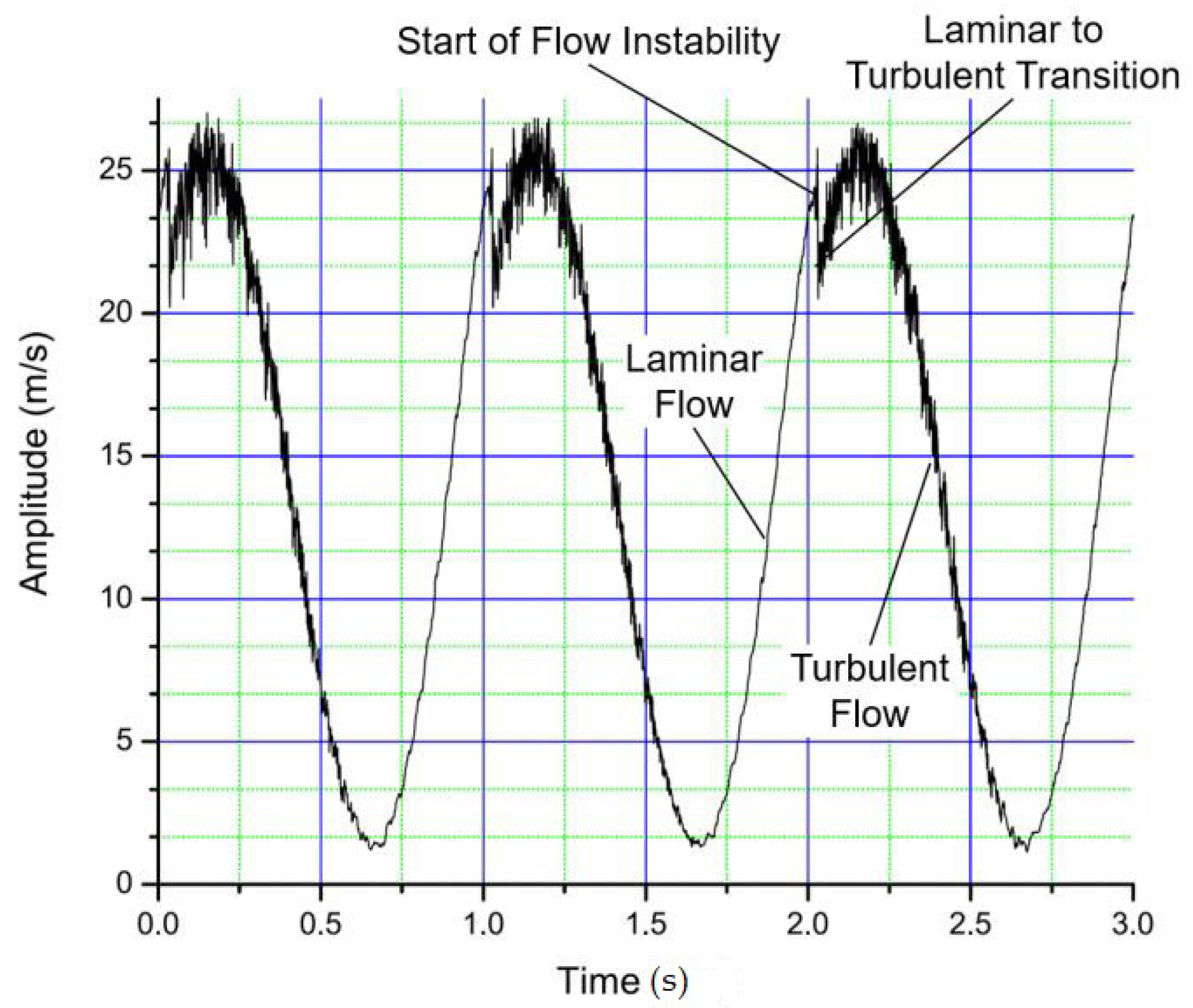

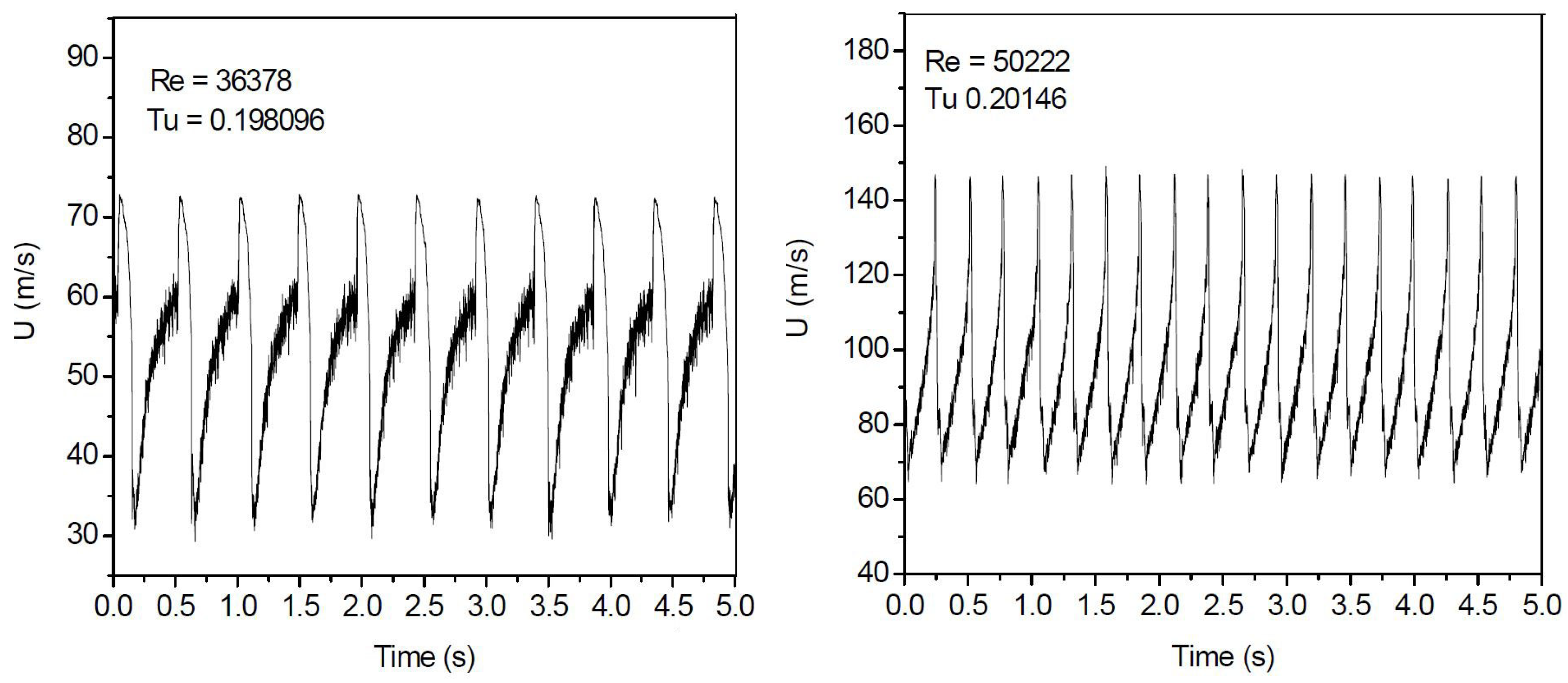

- Available experiments have shown that turbulent pipe flow can instantly become laminar, i.e., reverse transition occurs.

- A new theory, predicting the instability of fully developed laminar pipe flow, see [27], is applied to analyze the dependence of flow transition on pipe diameter and pipe length.

- Comparisons are made with relevant experimental studies from the literature. To facilitate references, diagrams are presented alongside citations of the corresponding papers, eliminating the need for the reader to search for them separately.

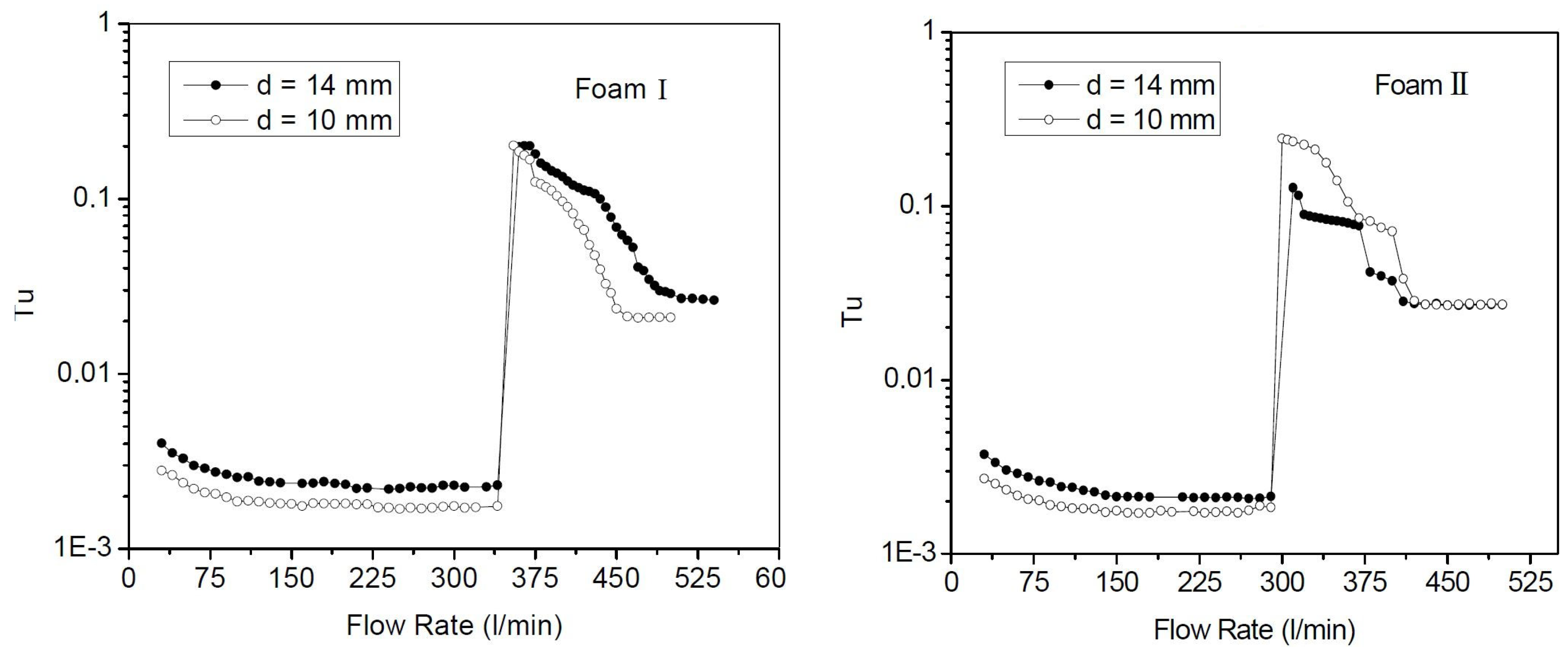

- Using the theoretical framework of [27], we analyze fully developed laminar pipe flow instability, yielding results that closely match experimental data from [12], yielding a critical Reynolds number of = 2130. Fox et al. [12] introduced oscillatory disturbances at preferred frequencies to investigate how such excitations interacted with the natural frequencies of the pipe flow and influenced its stability.

2. Theoretical Treatments of Dependence of Pipe Flow Transition on Pipe Diameter and Length

2.1. General Remarks and Short Literature Survey

2.2. Theory of Durst Revisited

2.2.1. Dependence on the Pipe Diameter

- = maximum permeability at [m2];

- = thickness of roughness layer [m];

- = critical pipe diameter [m].

- This indicates that the stability of the pipe flow and, hence, the laminar-to-turbulent transition of pipe flow, is characterized by a critical pipe diameter , which is entirely defined by wall roughness properties only.

- When , it yields a stability parameter and transition occurs at constant Reynolds number being given by Equation (20). This is in alignment with [27], who verified similar results shown in Figure 9 of their paper. As shown above, the laminar pipe flow remains stable for at all pipe lengths and Reynolds numbers.

- For pipe diameters , i.e., , the system reaches the critical case where laminar pipe flow becomes unstable, with the critical Reynolds number remaining constant at = 2130. [27] demonstrated that velocity profiles for have no inflection point, where represents the lower limit for unstable laminar pipe flows.

- When , it yields a stability parameter and unstable laminar pipe flow. However, if , the laminar pipe flow remains stable, as experimentally verified and derived in Section 2.2.2. For pipe diameters , results are often presented as a function of the Reynolds number. However, they should be based on the critical velocity . Equation (20) relates to D and . Although Figure 6 suggests a linear dependence of on D, this is artificial, arising from normalizing the critical pipe diameter by the nominal diameter D, to yield .

2.2.2. Dependence on the Pipe Length

- In addition to the convective flow in a pipe (flow with mass transport), wave motions (flows without mass transport) also influence the pipe flow transition.

- For turbulent flow to exist at constant Reynolds numbers, it is necessary to have a pipe length larger than a critical length, see Figure 9.

- for all pipe lengths.

- but also for:

- and for pipe lengths

- At low Reynolds numbers, i.e., , the laminar flow turns turbulent if . On the other hand, as the pipe length is getting shorter than the critical length, i.e., , the flow turns back to its laminar state even for higher value of , see Figure 9(top-left). This repeatability occurs at the same velocity that corresponds to the same Reynolds number, as Equation (22) suggests.

- Case 1: D = 0.0268 m, L = 5 ft = 1.524 m, = 12,694;

- Case 2: D = 0.01527 m, L = 5 ft = 1.524 m, = 22,337;

- Case 3: D = 0.007886 m, L = 5 ft = 1.524 m, = 43,705.

- For all three cases of Reynolds’ experiments, the above considerations suggest that n should yield the same value for all three cases given above:

- Case 1: ;

- Case 2: ;

- Case 3: .

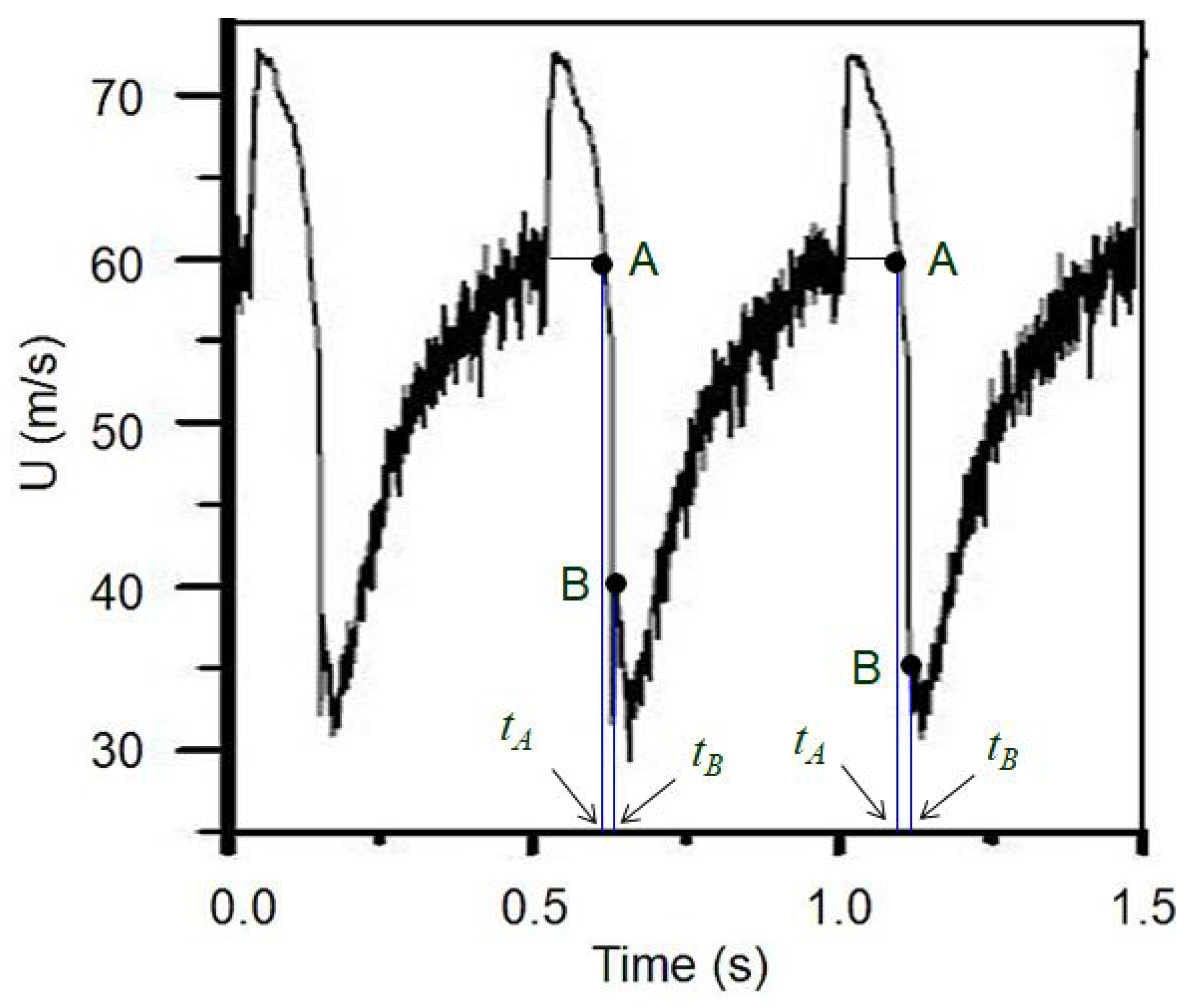

3. Other Resonance Conditions

4. Conclusions, Final Remarks, and Outlook

- Ensure that the pipe diameter D is smaller than the critical diameter based on the wall material and roughness properties.

- For cases where , maintain the pipe length L below the critical length , given by , to avoid transition.

- Avoid resonance conditions between system components (e.g., plenum chambers) and the natural frequencies of the flow, which can promote instability even in otherwise stable configurations.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Durst, F.; Al-Zoubi, A. Numerical treatments of laminar-to-turbulent transitions of pipe flows with moderate rough walls. J. Phys. Fluids. 2024. under consideration for publication. [Google Scholar]

- Durst, F.; Breuer, M.; Ünsal, B.; Haddad, K. Laminar-to-turbulent transition of pipe flows triggered by wall-mounted, ring-type obstacles. J. Turbul. 2022, 23, 382. [Google Scholar] [CrossRef]

- Durst, F.; Biswas, G.; Haddad, K. Laminar to turbulent transitions of pipe flows by resonances of natural frequencies of components of test sections. J. Turbul. 2024, 25, 62–82. [Google Scholar] [CrossRef]

- Sexl, T.R. Zur Stabilitätfrage der Poiseuilischen und de Couette-Strömung. Irmalen Phys. 1927, 83, 835. [Google Scholar]

- Sexl, T.H.; Spielberg, K. Zum Stabilitätproblem der Poiseu Mromung Heta. Phys. Aust. 1958, 12, 9. [Google Scholar]

- Avila, M.; Barkley, D.; Hof, B. Transition to turbulence in pipe flow. Annu. Rev. Fluid Mech. 2023, 55, 575–602. [Google Scholar] [CrossRef]

- Schlichting, H.; Kestin, J. Boundary Layer Theory, 7th ed.; McGraw-Hill: New York, NY, USA, 1979. [Google Scholar]

- Kerswell, R.R. Recent progress in understanding the transition to turbulence in a pipe. Nonlinearity 2005, 18, R17. [Google Scholar] [CrossRef]

- Manneville, P. Transition to turbulence in wall bounded flows: Where do we stand. Mech. Eng. Rev. 2016, 3. [Google Scholar] [CrossRef]

- White, F.M. Viscous Fluid Flow, Section Transition to Turbulence, 3rd ed.; McGraw Hill: New York, NY, USA, 2009. [Google Scholar]

- Reynolds, O. An experimental investigation of the circumstances which determine whether the motion of water shall be direct of sinuous, and the law of resistance in parallel channels. Philos. Trans. R. Soc. Lond. Ser. A 1883, 174, 935–982. [Google Scholar]

- Fox, J.A.; Lessen, M.; Bhat, W.V. Experimental Investigation of the Stability of Hagen-Poiseuille Flow. Phys. Fluids 1968, 11, 1–4. [Google Scholar] [CrossRef]

- Nishi, M. Laminar-to-Turbulent Transition in Pipe Flow Through Puffs and Slugs. Ph.D. Thesis, University of Erlangen-Nuremberg, Erlangen, Germany, 2009. [Google Scholar]

- Selvam, K.; Öngüner, E.; Peixinho, J.; Zanoun, E.-S.; Egbers, C. Wall pressure in developing turbulent pipe flows. J. Fluids Eng. ASME 2018, 140, 081203. [Google Scholar] [CrossRef]

- Zanoun, E.-S.; Kito, M.; Egbers, C. A study on flow transition and development in circular and rectangular ducts. J. Fluids Eng. 2009, 131, 061204. [Google Scholar] [CrossRef]

- Zanoun, E.-S.; Egbers, C. Flow transition and development in pipe facilities. J. Eng. Appl. Sci. 2016, 63, 141–159. [Google Scholar]

- Barnes, H.T.; Coker, E.G. The flow of water through pipes—Experiments on streamline motion and the measurement of critical velocity. R. Soc. 1905, 3, 497–506. [Google Scholar] [CrossRef]

- Darbyshire, A.G.; Mullin, T. Transition to turbulence in constant-mass-flux pipe flow. J. Fluid Mech. 1995, 289, 83–114. [Google Scholar] [CrossRef]

- Draad, A.A.; Kuiken, G.D.C.; Nieuwstadt, F.T.M. Laminar–turbulent transition in pipe flow for Newtonian and Non- Newtonian fluids. J. Fluid Mech. 1998, 377, 267–312. [Google Scholar] [CrossRef]

- Hof, B.; Juel, A.; Mullin, T. Scaling of the turbulence transition threshold in a pipe. Phys. Rev. Lett. 2003, 91, 244502. [Google Scholar] [CrossRef]

- Lindgren, E.R. Propagation velocity of turbulent slugs and streaks in transition pipe flow. Phys. Fluids 1969, 12, 418–425. [Google Scholar] [CrossRef]

- Meseth, J. Experimentelle Untersuchung der Übergangszonen Zwischen Laminaren und Turbulenten Strömungsgebieten in Intermittenter Rohrströmung; Mitteilungen aus dem Max–Planck–Institut für Strömungsforschung und der Aerodynamischen Versuchsanstalt, Nr. 58; Max–Planck–Ges. z. Forderung d. Wiss., Max–Planck–Inst. f. Stromungsforschung: Gottingen, Germany, 1974; pp. 1–114. [Google Scholar]

- Pfeninger, W. Boundary layer suction experiments with laminar flow at high Reynolds numbers in the inlet length of a tube by various suction methods. In Boundary Layer and Flow Control; Lachman, G.V., Ed.; Pergamon Press: Oxford, UK, 1961; pp. 961–980. [Google Scholar]

- Rotta, J.C. Experimenteller Beitrag zur Entstehung turbulenter Ströung im Röhr. Ingeniieur-Arch. 1956, 24, 258–281. [Google Scholar] [CrossRef]

- Schiller, L. Neu berichte zur turbulenzentwicklung. Z. Angew.-Mathe-Matik Mech. (ZAMM) 1934, 14, 36–42. [Google Scholar] [CrossRef]

- Wygnanski, I.J.; Champagne, F.H. On Transition in a Pipe—Part 1: The Origin of Puffs and Slugs and the Flow in a Turbulent Slug. J. Fluid Mech. 1973, 59, 281–335. [Google Scholar] [CrossRef]

- Durst, F. Theoretical treatment of the instability of fully developed laminar pipe flow taking wall roughness into account. Phys. Fluids 2024, 36, 104109. [Google Scholar] [CrossRef]

- Haddad, K.E. Development of Special Flow Test Rigs and their Application for Pulsating and Transitional Flow Investigations. Ph.D. Thesis, Universität Erlangen Nürnberg, Erlangen, Germany, 2009. [Google Scholar]

- Ünsal, B. Time-Dependent Laminar, Transitional and Turbulent Pipe Flows. Ph.D. Thesis, University of Erlangen-Nuremberg, Erlangen, Germany, 2008. [Google Scholar]

- Zanoun, E.-S. Flow characteristics in low-speed wind tunnel contractions: Simulation and testing. AEJ-Alex. Eng. J. 2017, 57, 2265–2277. [Google Scholar] [CrossRef]

- McKeon, B.J.; Zagarola, M.V.; Smits, A.J. A new friction factor relationship for fully developed pipe flow. J. Fluid Mech. 2005, 538, 429–443. [Google Scholar] [CrossRef]

- Peixinho, J.; Mullin, T. Finite-amplitude thresholds for transition in pipe flow. J. Fluid Mech. 2007, 582, 169–178. [Google Scholar] [CrossRef]

- Nikuradse, J. Gesetzmssigkeiten der turbulenten Strömung in glatten Röhren, Forschungsh. Ver Deutsch. Ing. 1932, 356. [Google Scholar]

- Haung, K.; Wan, J.W.; Chen, C.X. Experimental investigation on friction factor in pipes with large roughness. Exp. Therm. Fluid Sci. 2013, 50, 147–153. [Google Scholar] [CrossRef]

- Churchill, S.W.; Usagi, R. A general expression for the correlation rates of transfer and other phenomena. AIChE J. Wol. 1972, 18, 1121–1128. [Google Scholar] [CrossRef]

- Millikan, C.M. A critical discussion of turbulent flows in channels and circular tubes. Int. Congr. Appl. Mech. 1938, 386–392. [Google Scholar]

- Tennekes, H. Outline of a second-order theory of turbulent pipe flow. AIAA J. 1968, 6, 1735. [Google Scholar] [CrossRef]

- Tennekes, H.; Lumley, J.L. A First Course in Turbulence; MIT Press: Cambridge, MA, USA, 1972. [Google Scholar]

- Jovanovic, J. (LSTM-Erlangen, FAU Erlangen-Nuremberg, Erlangen, Germany). Priviate communication, 2024.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Durst, F.; Zanoun, E.-S. Laminar Pipe Flow Instability: A Theoretical-Experimental Perspective. Fluids 2025, 10, 216. https://doi.org/10.3390/fluids10080216

Durst F, Zanoun E-S. Laminar Pipe Flow Instability: A Theoretical-Experimental Perspective. Fluids. 2025; 10(8):216. https://doi.org/10.3390/fluids10080216

Chicago/Turabian StyleDurst, Franz, and El-Sayed Zanoun. 2025. "Laminar Pipe Flow Instability: A Theoretical-Experimental Perspective" Fluids 10, no. 8: 216. https://doi.org/10.3390/fluids10080216

APA StyleDurst, F., & Zanoun, E.-S. (2025). Laminar Pipe Flow Instability: A Theoretical-Experimental Perspective. Fluids, 10(8), 216. https://doi.org/10.3390/fluids10080216