Abstract

The flow of viscous and highly viscous fluids in straight and bent pipes and channels is a fundamental process in a wide variety of industrial applications and is, therefore, of great interest in science and engineering. Understanding the physics behind such flows has a direct impact on the design of efficient, safe and reliable systems. The type of fluid, which can be viscous or even highly viscous, and the pipe geometry can affect the flow dynamics, the pressure loss and the overall efficiency of the process. In this paper, we provide an extensive review of the state-of-the-art research concerning the flow of Newtonian and non-Newtonian, single-phase fluids in straight and bent pipes. Since a big amount of work in the literature is devoted to the study of Newtonian pipe flows, the paper starts with a brief outline of the nonlinear theory of viscous Newtonian fluid flow in pipes, including a survey of early and recent analytical solutions to the Navier–Stokes equations. The central part of the paper deals with an extensive overview of existing experimental and numerical research work on viscous Newtonian pipe flows. Separate sections are devoted to non-Newtonian fluid flows, the problem of entropy generation due to irreversible processes in the flow and hydromagnetic Newtonian and non-Newtonian pipe flow. The review closes with a brief survey of machine learning and artificial intelligence modeling applied to pipe flow along with future trends and challenges in pipe flow research.

1. Introduction

The movement of fluids in pipes and pipeline components, as well as its physical description in terms of the flow regimes encountered, is of fundamental importance in science and engineering. Several applications, such as household water and gas supply, sewage flows and numerous industrial processes, require the transportation of fluids through pipes. Although all fluids in nature are viscous, highly viscous liquids offer higher resistance to flow because of their stronger intermolecular forces, resulting in higher internal friction. This slows the movement of liquid layers past one another compared to low-viscosity liquids, which flow much more easily because of their corresponding lower friction forces. In spite of this difference between low- and high-viscosity fluids, a review of highly viscous fluid flows in pipes must in general cover the topic of viscous fluid flows in pipes and ducts.

Although the transport of water through pipes dates back to Roman times, the first scientific studies of flow through a pipe began in 1839, when Hagen [1] and then Poiseuille [2] performed the first experiments (reported in the literature) of laminar flow of water through straight pipes of various sizes to determine pressure losses. This flow is known today as the Hagen–Poiseuille flow. In particular, Hagen [1] first observed that above a certain pressure head the flow becomes unstable, undergoing a transition from laminar to turbulent state. Later, similar studies were carried out by Darcy [3], who also considered the effects of pipe roughness on pressure drop, and Reynolds [4], who observed that the transition to turbulent flow occurs above a certain critical value, known today as the critical Reynolds number. The Reynolds number (Re) measures the relationship between the inertial forces and the viscous forces present in the fluid and is used to indicate whether the flow is laminar or turbulent. On the other hand, the friction factor, which relates the pressure drop to the flow velocity and the roughness of the pipe, and the energy losses have an important impact on flow efficiency and performance. Early studies also focused on investigating the flow through curved pipes [5,6,7,8,9,10,11], revealing that (1) the curvature balance between pressure and centrifugal forces in a bend leads to the formation of a secondary flow there, often in the form of two symmetrical vortices, (2) the maximum flow velocity due to this imbalance in fluid motion occurs toward the outer pipe wall at the outlet of the bend, (3) the pressure losses are greater than in straight pipes and (4) the critical Reynolds number for transition to turbulent flow increases compared to straight pipes. In addition, Dean [12,13] studied the centrifugal instabilities in curved pipes and showed by analytical means that the emerging secondary flow is characterized by two counter-rotating vortex cells, which are known today as Dean vortices. In particular, these early studies have provided the basis for the current theory of pipe flow. The emergence of turbulence in straight and curved pipe flows has been thoroughly reviewed by Kalpakli Vester et al. [14], while a comprehensive review of advances in experiments and simulations of fluid flow in helically coiled pipes has been recently presented by Sigalotti et al. [15].

Single-phase viscous flow in pipes can be laminar (i.e., smooth and steady) at low Re, in a transition state from laminar to turbulent at intermediate Re values, and turbulent (i.e., fluctuating) at high Re. The type of regime encountered will depend on the pipe geometry (i.e., the pipe bending, which can be sharp or moderate, and the cross-sectional area, which can be circular, square, elliptical, rectangular, etc.), the fluid properties and the flow parameters of the system as well as the roughness and rigidity of the pipe wall. In addition to the need to redirect the flow through curved sections, many pipeline systems may have branches and junctions that serve to distribute the flow. This is the case of the transportation of oil and gas in pipelines from the production well to the refining plant, cold water in the refrigeration system of nuclear reactors, air in the respiratory system and blood in the cardiovascular system of mammals, non-Newtonian fluids during food processing operations, among many other processes. Whereas liquids are in general incompressible, the transportation of gas (and air) will require to consider the effects of compressibility. The above discussion shows how the flow regime depends on several conditions, which in general complicates the correct description of the flow in pipes and pipeline systems and components.

The flow of viscous fluids in straight and curved pipes has been the subject of extensive theoretical and experimental research since the early investigations carried out by Hagen [1] and Poiseuille [2]. There are several books and review articles and a huge amount of research articles dealing with the flow of viscous fluids through straight and curved pipes under various conditions that have been published during the last ninety years, spanning from 1938 to 2024 [14,15,16,17,18,19,20,21,22,23,24,25,26]. Citations to a large number of research articles dealing with laminar and turbulent viscous flow through pipes and ducts will be made throughout the text in the following sections. The focus of the present review article will be on viscous and highly viscous single-phase flows through straight and curved pipes, including only pipe bends and elbows, based on experiments and numerical simulations. For a recent review of flow through helically coiled pipes, the interested reader is referred to Ref. [15]. As mentioned above, the turbulent flow through straight and curved pipes along with a historical background spanning from 1839 to 2016 has been reviewed by Kalpakli Vester [14]. Therefore, in addition to a short review of the material covered by Kalpakli Vester et al. [14], we will expand more on the experimental and numerical work performed over the last two decades.

For reasons of space, the flow in micro-devices, such as channels and heat pipes, as well as in nanotubes, was not considered in the present review. In the last 20 years, the research in the field of micro-fluidic has been constantly increasing due to the very rapid growth of technological applications that require heat transfer in miniature volumes. In the same way, the transport of nanofluids in mini- and micro-channels has been pointed out as a promising candidate for a disproportionate enhancement of heat transfer in important engineering applications, including energy storage, electronics cooling and the thermal processing of materials. This has generated a huge amount of published papers that a comprehensive review of the subject will require writing a separate paper. However, the interested reader is referred to recent comprehensive reviews by Singh and Myong [27], Kavokine et al. [28] and Zhang et al. [29] of flow in nano-, micro- and mini-channels. In passing, we note that Inamdar and Lawankar [30] have also published a recent review dealing with flow boiling in micro- and mini-channels.

The paper is organized as follows. The basic parameters, definitions and friction factor correlations for the prediction of frictional pressure losses that characterize the flow of Newtonian fluids through a pipe are described in Section 2. A brief outline of the nonlinear theory of viscous Newtonian fluid flow in pipes is given in Section 3. Section 4 and Section 5 deal with an overview of experimental work and results obtained from numerical simulations of Newtonian fluid flows in pipes, respectively. The flow of non-Newtonian fluids in pipes and ducts is reviewed in Section 6. The problem of entropy generation in pipe flows is discussed in Section 7. Section 8 provides a brief survey on hydromagnetic flows in pipes. Section 9 contains a brief overview of the rapid development of machine learning and artificial intelligence in pipe flow research, while Section 10 contains a brief outline of possible directions for future research and challenges. Finally, Section 11 summarizes the main conclusions.

2. Useful Parameters and Friction Factor Correlations for Newtonian Fluid Flow in Pipes

2.1. Basic Parameters

A fundamental parameter in fluid mechanics is the dimensionless Reynolds number defined as

where is the fluid density, v is the mean flow velocity, l is some characteristic length scale related to the flow and is the shear viscosity coefficient of the fluid. This parameter measures the importance of inertial forces over viscous forces. For fluid flow in a pipe, the Reynolds number is often written in terms of the pipe diameter, D, and the kinematic viscosity, , as

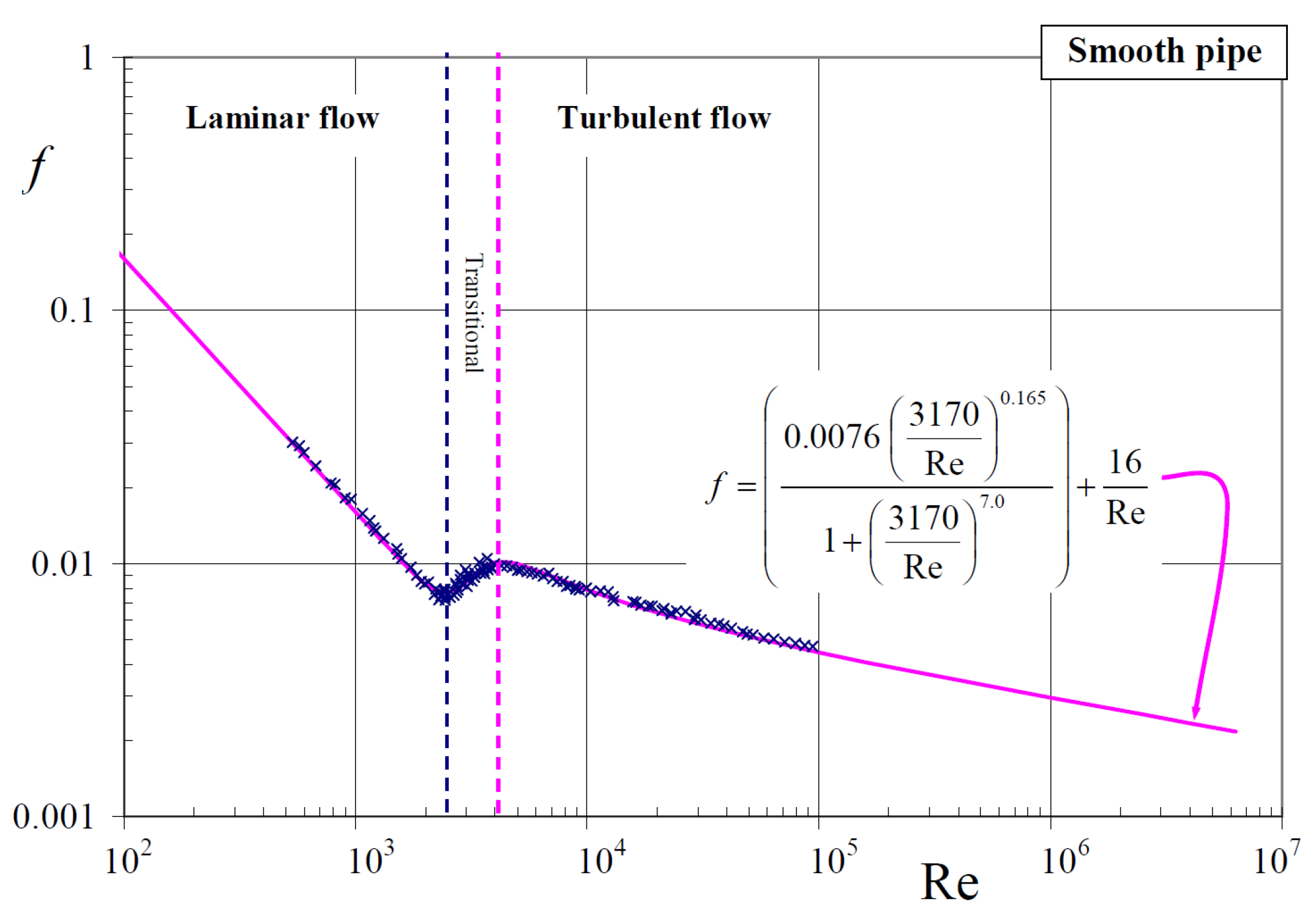

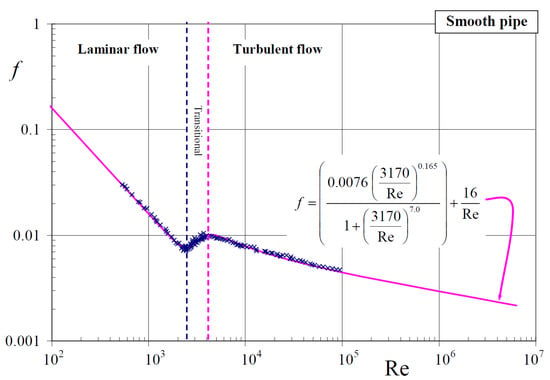

In particular, Reynolds [4] showed experimentally that the transition from laminar (low Re) to turbulent (high Re) flow in a pipe of circular cross-sectional area occurs at a critical Re-value of . In the laminar regime small disturbances in the flow are quickly damped, while at the transitional regime, the flow is characterized by intermittent bursts of turbulence. It is frequently found in the literature that the approximate range is characteristic of the (creeping) motion of highly viscous fluids, while for , the flow is still laminar but with a rather strong Re-dependence. In the interval, a transition to turbulence can be observed, and, only for , the flow becomes turbulent. However, these ranges are only representative and can vary depending on the flow geometry, the pipe wall roughness and the level of fluctuations in the inlet stream.

For curved pipe flows, a relevant dimensionless parameter is the Dean number [12,13]

where is the curvature ratio, R is the pipe radius and is the radius of curvature, defined as the distance from the center of curvature to the centerline of the pipe. For straight pipes, ; therefore, , while for sharp bends (i.e., elbows), since, in this case, . From the entrance region of a pipe, there is a finite distance beyond which the flow becomes fully developed; that is to say, the flow streamwise velocity profile becomes invariant. For fully developed laminar flow, this finite distance can be estimated using the empirical correlation

For turbulent flow, this distance is relatively shorter and can be estimated from the correlation

2.2. Friction Factor Correlations

A dimensionless quantity that relates the pressure losses to the square of the streamwise velocity is the so-called Fanning friction factor given by

where is the pressure gradient along the pipe. As a fluid flows through a pipe, its interaction with the pipe walls produces friction, which in addition to reducing the pressure along the pipe slows down the flow. Therefore, the Fanning friction factor is a key parameter used to estimate pressure losses in a pipe. The Darcy–Weisbach factor, defined as , is often used to describe friction losses in laminar and turbulent flows in pipes and open channels. From now on, we will refer to the Darcy–Weisbach friction factor simply as the friction factor and use F rather than to denote it. For laminar (smooth) flow in a circular pipe of diameter D, the friction factor is . Note that for pipes with non-circular cross-sections, D is replaced by the hydraulic diameter, , in the definition of Re, where A is the cross-sectional area of the flow and P is the wet perimeter of the pipe cross-section.

The dependence of the friction factor on Re has been used as an indicator of whether the flow is laminar, transitional or turbulent. Therefore, the friction factor is not a constant, and, in the same way as Re, it depends on the pipe characteristics, the flow velocity and the type of fluid. In general, it can be estimated from empirical correlations or it can be read from Moody diagrams [31], where the friction factor is plotted as a function of Re. In the turbulent regime, the friction factor varies slowly with Re between and 0.06, and the flow can be divided into sub-regimes depending on whether the pipe wall is smooth or rough. For turbulent flow in smooth pipes, the transfer of momentum from the bulk of the fluid to the pipe wall is governed by many small eddies; therefore, the friction factor can be estimated solving the transcendental equation, referred to as the Kármán–Prandtl resistance equation [32]

where the constant factors are chosen to provide a fairly good fit to the data [33]. Using the Lambert W function, Equation (7) can be written in the more compact form

For flow through a pipe with rough walls, the friction factor differs from the smooth pipe curve and approaches an asymptotic value, known as the rough pipe regime. When the height of the wall roughness, , is important, a number of existing correlations for the friction factor are given in terms of the modified Reynolds number [34]

which is often referred to in the literature as the roughness friction Reynolds number.

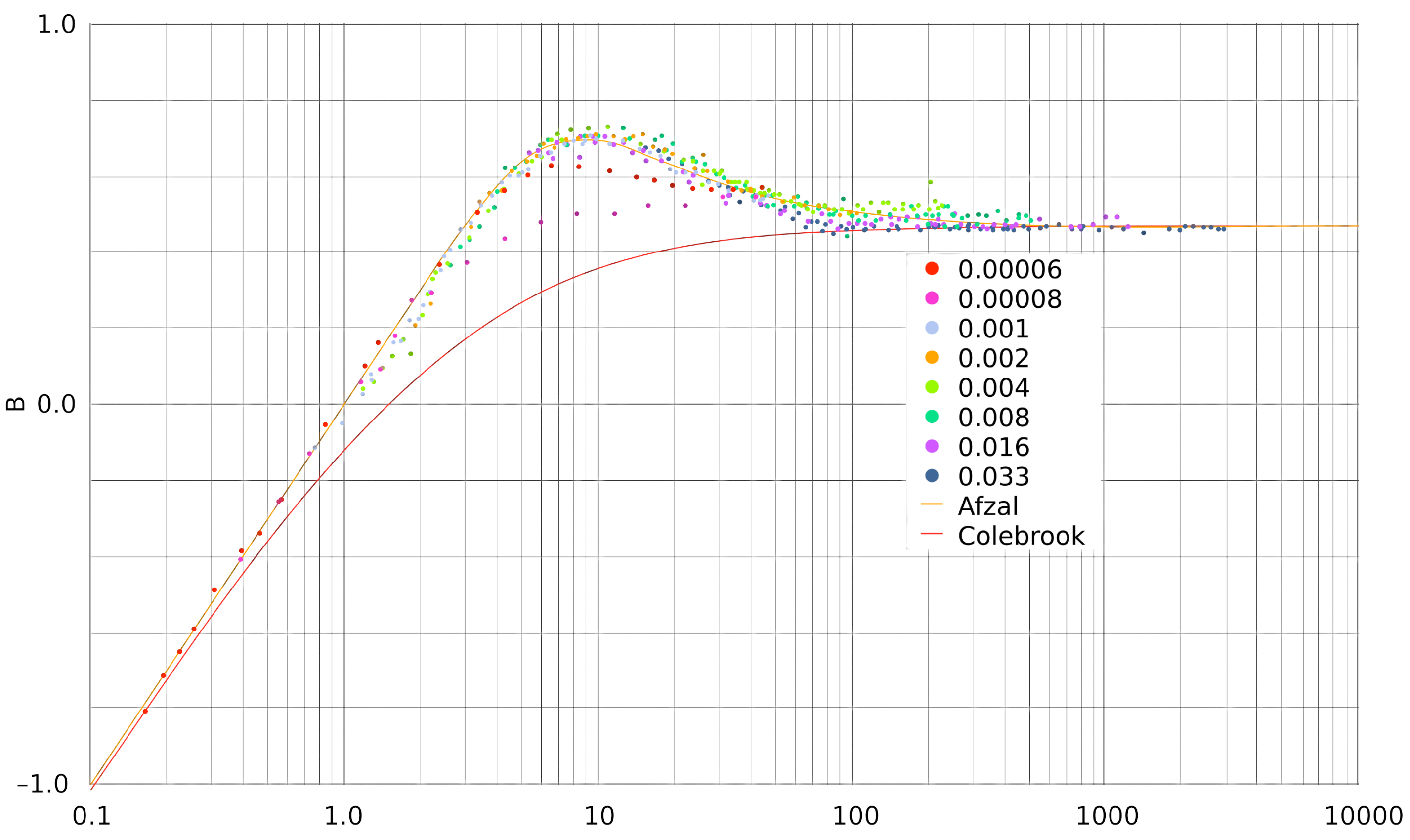

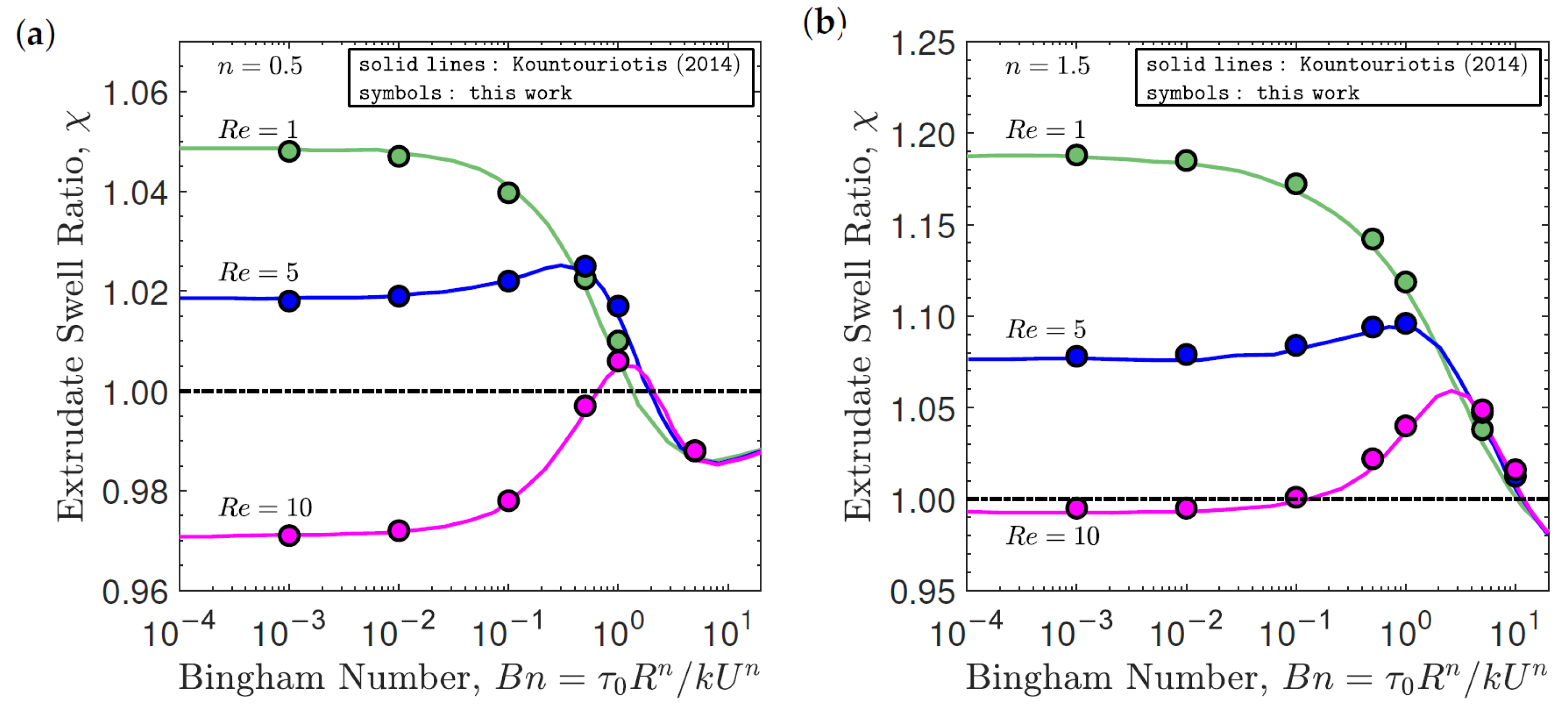

Figure 1 shows the roughness function B as a function of for different values of the roughness ratio between 0.00006 and 0.033 (colored dots) and the functions predicted by Colebrook [35] and Afzal [36] (solid lines). The dots include data flow measurements reported by Nikuradse [34], Shockling et al. [37] and Langelandsvik et al. [38] for a commercial steel pipe. In the region , the roughness function varies linearly with . This region describes the smooth pipe regime. In the interval , the data slowly deviate from linear, reaching a maximum value around and then monotonically decreasing to a constant value at . This interval describes the transition from smooth to rough pipe flow. At , the roughness function approaches asymptotically a constant value and becomes almost independent of and .

Figure 1.

Dependence of the roughness function B on the friction Reynolds number . The solid lines depict the functions predicted by Colebrook [31] and Afzal [32]. Figure credit: Arthur Ogawa. Figure adapted from https://commons.wikimedia.org/wiki/File:Figure3(BvsR*).svg#file (accessed on 7 February 2025).

For turbulent flow in transitional rough pipes, Afzal and Seena [39] have introduced the inner rough wall variable , where is a transitional roughness scale such that all mean relative motions and energy components of the turbulent flow are independent of the surface roughness. In terms of , the roughness Reynolds number can be defined as [36,39]. Note that for , . For transitional roughness in pipes, Afzal [36] reports the friction factor relation in terms of

which has been adjusted to match Prandtl’s [40] smooth wall relation. In the range , this relation describes very well the fully smooth pipe data of Nikuradse [34]. Based on Princeton’s superpipe data of McKeon [41] for , the alternate correlation for transitional pipe roughness is given by [36]

For inflectional roughness, the friction factor in terms of and based on Prandtl’s [40] smooth wall relation becomes [36]

while based on smooth pipe constants from McKeon [41], the friction factor in terms of becomes

In relations (12) and (13), the value of j is set to 11 to better describe the transition from a smooth to a rough pipe regime [36,39]. For transitional rough pipes, alternate forms of Equations (12) and (13) are listed in Table 1 of Ref. [36] for different roughness parameters. Since these equations are implicit in nature, they must be solved iteratively. However, each of them can be manipulated in an explicit expression that allows one to calculate the friction factor approximately (see Table 1 of Ref. [36]). Alternative formulas to Equations (12) and (13) due to machine honed surface roughness in fully developed turbulent flow were further proposed by Afzal et al. [42] to be

where was used to fit the data of Nikuradse [34].

The correct behavior at can be reproduced using the Colebrook–White relation [35]

According to Figure 1, this relationship approximates the behavior for the smooth pipe regime at and substantially underestimates the friction factor in the transitional domain [37]. Several authors have proposed approximations to Equation (14) for turbulent flow through circular pipes [43,44,45,46,47,48]. A list of available Colebrook–White based explicit friction factor relations can be found in Ref. [48]. In particular, Serghides’s [45] solution was found to be one of the most accurate, matching the Colebrook–White implicit solution within an error of about 0.0023%. More recently, Niazkar [48] developed a modified version of the Serghides’s solution, which is known to be the most accurate approximation to the Colebrook–White implicit formula. For fully rough pipes, Afzal [36] proposed the following explicit counterpart relations to Equations (14) and (15), respectively:

Friction factor correlations for laminar and turbulent viscous flows in helical pipes have been reviewed recently by Sigalotti et al. [15]; therefore, they will not be repeated here. Other parameters of interest in the description of certain flow cases will be introduced in conjunction with their discussion in the next sections.

3. Theory of Viscous Newtonian Fluid Flow in Pipes

3.1. Governing Equations

The motion of a viscous fluid in a pipe is described by the physical laws of mass, momentum and energy conservation. These can be written in terms of a set of coupled nonlinear differential equations, which in Lagrangian coordinates have the form

where is the fluid density, is the fluid velocity vector, U is the fluid specific internal energy, is the gravitational acceleration vector, is the stress tensor given by

and is the heat flux vector, defined as

In Equations (21) and (22), p denotes the pressure, the shear viscosity coefficient, the bulk viscosity, d the dimension factor, the unit tensor, the heat conductivity and T the fluid temperature. Sometimes requiring that the second law of thermodynamics be satisfied, the entropy balance equation

must be solved coupled to Equations (18)–(20), where S is the specific entropy and

is the entropy production due to the irreversible processes of frictional viscous dissipation and heat transfer. Under non-isothermal effects, the above differential equations must be solved coupled to pressure, , and caloric, , equations of state. In general, appropriate boundary conditions require setting at the pipe wall.

For incompressible fluids, such as most liquids, Equation (18) simplifies to , and Equation (19) takes the form of the Navier–Stokes equations

In the presence of heat transfer, the specific internal energy equation becomes

Sometimes Equation (26) is converted into a temperature equation by setting , where is the specific heat at constant pressure.

3.2. Analytical and Semi-Analytical Approaches

In their very recent comprehensive review of 2023, Urbanowicz et al. [49] classified the analytical solutions to the Navier–Stokes equations for the laminar accelerated flow of viscous Newtonian fluids in a pipe into two main groups, where the first group, which is made up of classical (earlier) solutions, deals with models of flow acceleration driven by a step pressure gradient along the length of the pipe, while in the second group of solutions, which appeared in the literature more recently, the flow motion is forced by imposition of a flow rate. These latter models include solutions for the laminar flow of viscous fluids in a porous pipe. However, in the next sections, we will refer to “classical solutions” as those that were reported in the literature before the end of the last century, which may include both groups of solutions, and to “more recent solutions” as those solutions that were reported later.

3.2.1. Classical Exact Solutions

Complete exact solutions to the Navier–Stokes equations for fluid flow in a pipe can be derived only for cases in which the non-linear terms can be neglected. As quoted by Urbanowicz et al. [49], the first known analytical solution to the Navier–Stokes equations for the accelerated flow of an incompressible viscous fluid in a vertical hydraulic pipe was presented in 1871 by the Italian physicist Antonio Roiti [50] at the University of Pisa. On the other hand, a similar analytical solution for horizontal pipes was obtained by the Russian physicist Ippolit S. Gromeka in 1882 [51]. As was pointed out by Urbanowicz et al. [49], these two solutions were not noticed for a long time until they were revealed to the scientific community in relatively recent times. Examples of classical solutions for the velocity field, which are described in many introductory books on Fluid Mechanics, are the several variants of laminar Poiseuille flow [52], including the famous time-dependent plane Poiseuille and Hagen–Poiseuille flow in a pipe [53], the steady-state Poiseuille flow in an annular section [54] and through pipes of non-circular cross-sectional area [5,55,56,57], the unsteady Poiseuille flow with an oscillating pressure gradient [58,59], the Couette flow of a viscous fluid between two surfaces when one slides over the other [60] and the Taylor–Couette flow between two rotating and infinitely long coaxial cylinders [61]. A steady-state solution also exists for the Taylor–Couette flow between two finite-length rotating cylinders [62]. A further notorious exact solution of the Navier–Stokes equation is the so-called Stokes problem or Stokes boundary layer, which consists in finding a solution for the flow induced by an oscillating solid surface [63].

Possibly the most celebrated flow solution is the time-dependent Hagen–Poiseuille flow, which describes the movement of a viscous fluid along a cylindrical pipe of constant inner diameter driven by a step pressure gradient. In this case, the solution can be derived for initial conditions, corresponding to a fluid initially at rest (i.e., ), and no-slip boundary conditions at the pipe wall due to the effects of viscosity. After a transient, a steady-state solution, corresponding to a parabolic velocity profile, is achieved, where the peak velocity occurs along the axis of symmetry () of the pipe. Using cylindrical coordinates () to represent the flow and leaving aside the details of the derivation, the exact solution for the Hagen–Poiseuille flow through a pipe of radius R is given by

where is the maximum asymptotic velocity, which is proportional to the hydrostatic pressure difference () between the two ends of the pipe of length L, is the kinematic viscosity, the (with ) are the Bessel functions of the first kind of integral order n, and (for are the roots of . A generalization of the above solution for a non-vanishing initial velocity, starting with a steady-state Hagen–Poiseuille profile, and a step change pressure gradient was reported by Ito [64]. This author also developed an exact solution for a time-varying pressure gradient (see Ref. [64]).

Almost all analytical solutions of the Hagen–Poiseuille type assume that the pressure gradient varies steeply from an initial to a final value. This differs from real systems where the pressure gradient does not vary steeply since it depends on the valve opening time [49]. In particular, Avula [65] and Avula and Young [66] demonstrated by experimental means that, in real systems, the flow velocity varies with time differently as stated by the classical Hagen–Poiseuille theory and provided a modified semi-analytical solution for the velocity profile. The discrepancy in the velocity profiles with the classical theory is greater at the beginning of the transient stage and becomes considerably smaller at larger times. A further generalization of the Hagen–Poiseuille flow for a time-varying pressure gradient of the form was obtained in 1997 by Smith [67], where k and b are positive constants, and r and z are cylindrical coordinates. For a pipe of radius and taken the fluid at rest for with the pressure gradient turned on at , Smith’s [67] exact solution reads as follows

where (with ) are the roots of . In passing, we note that universal solutions for arbitrary pressure gradients were obtained by a number of authors [68,69,70,71,72,73,74,75,76] and more recently by Lee [77], which include flows under sinusoidal pressure gradients.

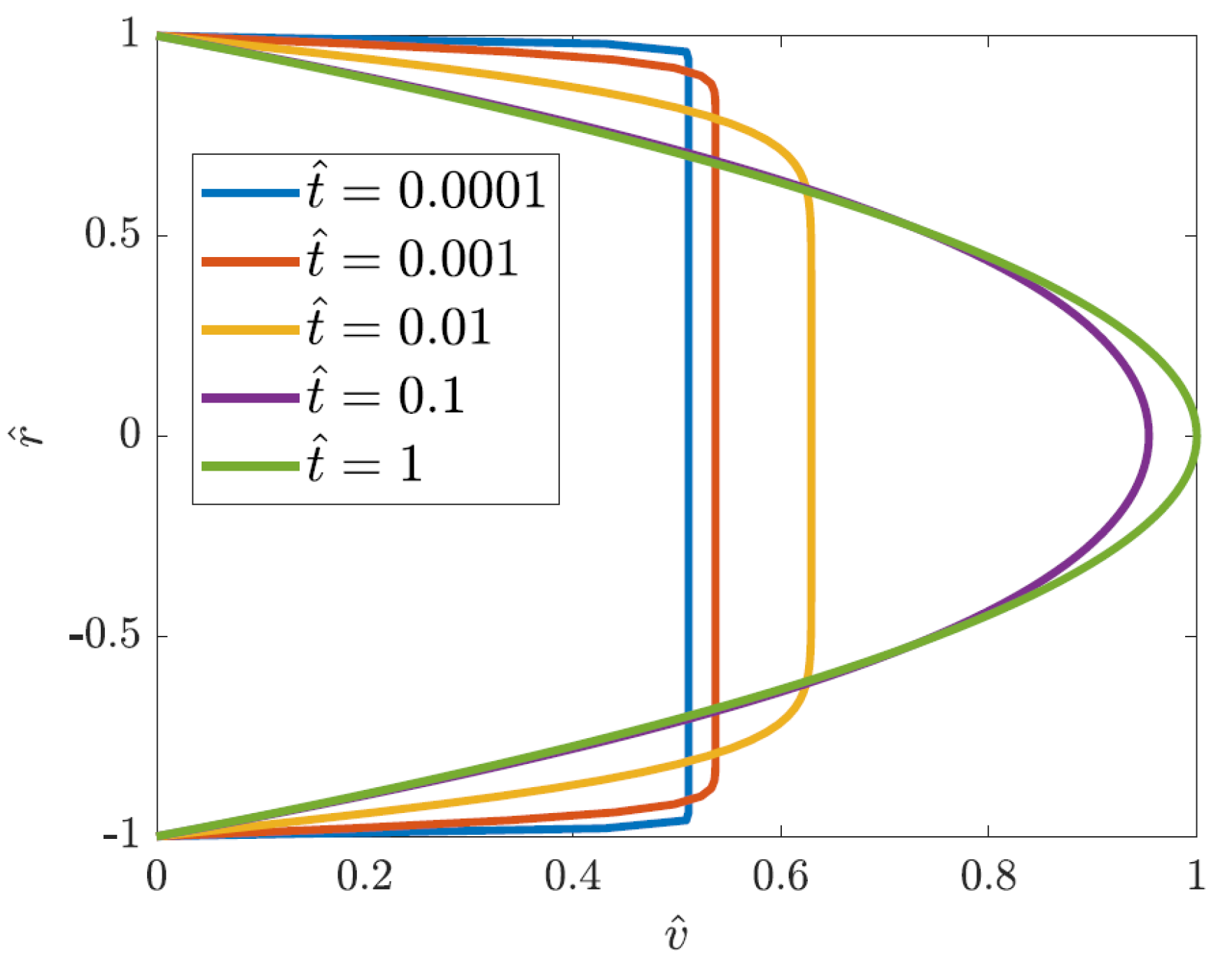

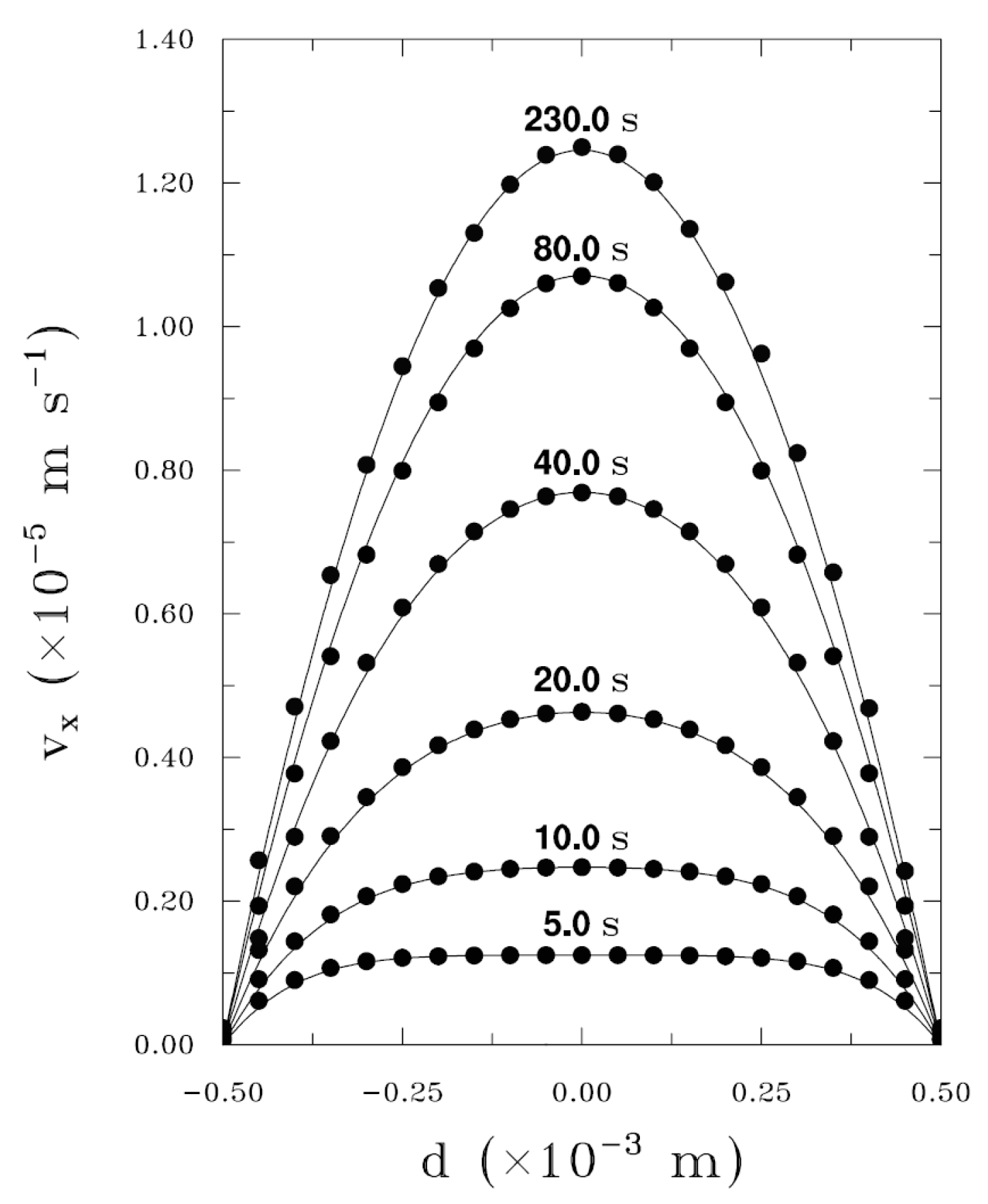

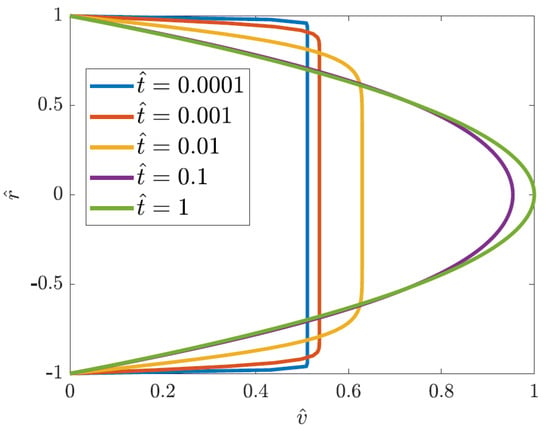

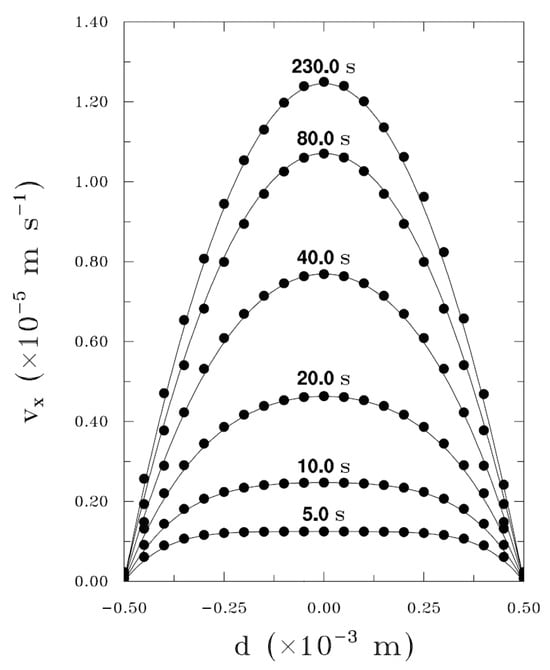

Analytical solutions to the Navier–Stokes equations for laminar flow in a long pipe can also be obtained by imposing a flow rate. The idea of assuming a constant flow rate was first considered by Andersson and Tiseth [78], who obtained the exact solution for laminar flow along a cylindrical pipe of radius a

where , and are dimensionless variables defined by , and , is twice the final mean flow velocity and is the mth zero of the Bessel function for . Figure 2 shows the temporal evolution of the velocity profiles as calculated from Equation (29). A parabolic velocity profile is established at , much earlier than for the Hagen–Poiseuille flow given by Equation (27) for the same pipe configuration. A solution identical in form to Equation (29) was previously derived by Sparrow et al. [79] by assuming a pressure inlet from a reservoir at the pipe entrance. The only difference is that the dimensionless time, , in Equation (29) is replaced by a dimensionless distance , where is a stretched axial coordinate, a is the radius of the cylindrical pipe and is the mean velocity. Das and Arakeri [80] derived an analytical solution for the case when the imposed flow rate is caused by a piston motion at the entrance of the pipe. In this case, the solution for the flow velocity is a piecewise function: (a) for flow acceleration from rest, (b) for flow driven by a constant piston velocity, (c) for flow during piston deceleration and (d) for flow to rest when the piston is stopped. Figure 12 of Ref. [49] shows the course of Das and Arakeri’s [80] solution over time as compared to Andersson and Tiseth’s [78] model solution for a constant flow rate.

Figure 2.

Streamwise velocity profiles at selected times as predicted by Equation (29) for the accelerated laminar flow driven by a suddenly imposed constant flow rate. Figure taken from Urbanowicz et al. [49].

An analytical axisymmetric solution for laminar flow in a porous cylindrical tube was obtained by Terrill [81] by superposing potential flow on the Poiseuille flow. In order to overcome the difficulty that sometimes a fully developed velocity profile cannot be achieved due to a fluid long memory of the inlet velocity profile for constant suction (or mass injection) at the wall [82], he introduced a solution for the case of variable mass transfer at the pipe wall. Later, this solution was extended to the case of flow along pipes with impermeable walls and varying circular cross-sectional area by Terrill and Colgan [83]. In this case, analytical solutions to the Navier–Stokes equations with appropriate boundary conditions were obtained by expanding the potential function into a power-series expansion of the cylindrical coordinates z and r up to quadratic and cubic order. An analytical solution for fully turbulent, incompressible flow in smooth pipes was also reported by Zagustin and Zagustin [84]. As these authors themselves commented, a remarkable property of this solution is that it depends only on the von Kármán universal constant. They reported solution curves for the mixing length, velocity and eddy viscosity distributions that are in excellent agreement with experimental data everywhere within the pipe. A particular class of flow solutions, i.e., the generalized Beltrami flows, which satisfy the condition , where is the vorticity, have been reviewed by Wang [85] for several types of flows, including the axisymmetric flow in a cylindrical porous pipe. Second-order solutions for the velocity, pressure and temperature, corresponding to flow of high viscosity in a long cylindrical tube, were obtained by Thomann [86] as functions of increasing powers of the Mach number for small shear wave numbers, , and the Prandtl number

where R is the pipe radius, is the frequency, and is the specific heat at constant pressure. These solutions were used to show that thermal effects (i.e., heat transferred to the pipe wall) in an incompressible liquid are an order of magnitude larger than in a gas.

3.2.2. Recent Analytical Solutions

The generalization of the Hagen–Poiseuille flow for vertical and sloping pipes was developed by Urbanowicz et al. [87]. They presented a universal solution that works for horizontal as well as for vertical and sloping (upward and downward) pipe flows. In terms of piezometric heads, the solution for the velocity reads as follows

where R is the inner pipe radius, L is the pipe length, is the inclination pipe angle measured with respect to an horizontal axis () and is the mth zero of the Bessel function . In this case, the shear stress on the pipe wall, , and the instantaneous coefficient of resistance, F, obey the exact expressions

where with . For , Equations (31)–(33) reduce to the Gromeka–Szymański solution [51] for flow in a horizontal pipe, while for and , they reduce to the form derived by Roiti [50] for upward and downward flow in a vertically oriented pipe. For , upward flow occurs when and downward flow otherwise. For angles in the interval , there will always be downward flow.

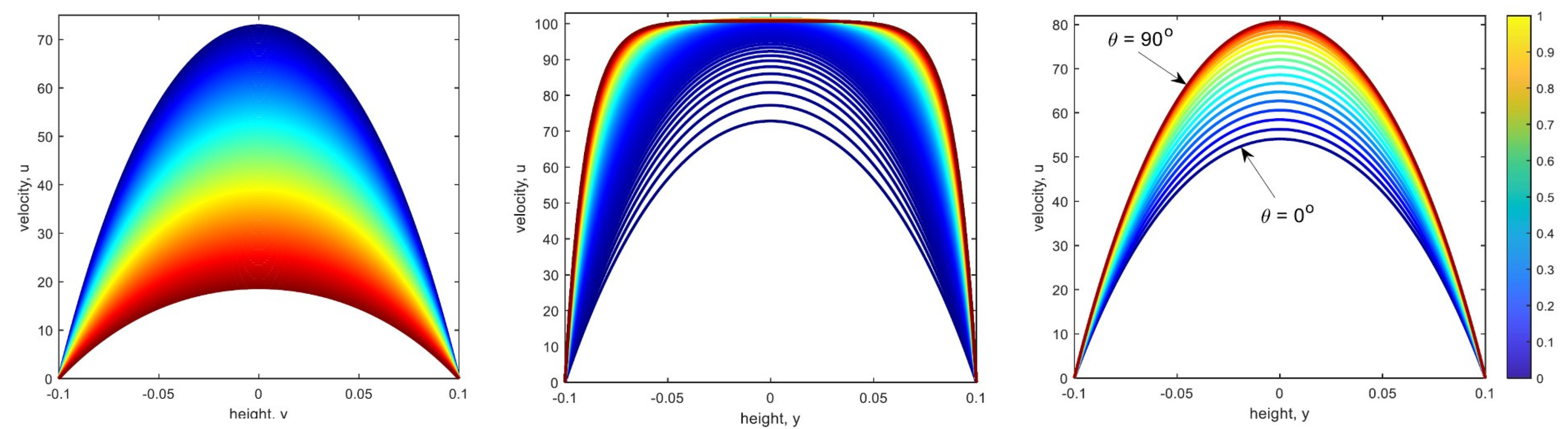

In a very recent study, Kanuri et al. [88] explored the interaction between the Poiseuille flow, the Coriolis force and the channel inclination in the fully developed flow of an incompressible viscous fluid for the case when the channel rotates with angular velocity perpendicular to the main flow. They found an analytical solution for the steady-state flow velocity given by

where the mainstream flow is along the x-direction, is the width of the channel, is the inclination angle of the channel measured with respect to an horizontal axis and . This solution describes a parabolic velocity profile with the maximum velocity along the centerline of the channel (). Figure 3 shows the response of the velocity to decreasing pressure gradient (left plot), to increasing rotation (middle plot) and to increasing inclination angle (right plot) from (perfectly horizontal) to (perfectly vertical). In the core of the channel, the mainstream velocity increases with decreasing pressure gradient and increasing rotation and inclination angle. The analytical solution for the axial and circumferential velocity of the unsteady flow of a viscous incompressible fluid as induced by the sudden swirling of a cylindrical pipe wall and starting with an axial velocity component was presented by Bocci et al. [89]. Moreover, Pillai and Manu [90] obtained time-dependent velocity profiles and pressure gradient for laminar flow in cylindrical pipes driven by an arbitrary flow rate with slip boundary conditions at the wall. In particular, they presented exact solutions for starting, oscillatory and arbitrary inflows.

Figure 3.

Streamwise velocity profiles as predicted by the steady-state solution given by Equation (34) for incompressible flow of a viscous fluid in a rotating inclined channel. Response of the flow velocity with decreasing pressure gradient (left), increasing rotation (middle) and increasing inclination angle (right). Figure taken from Kanuri et al. [88]. http://creativecommons.org/licenses/by/4.0/ (accessed on 8 February 2025).

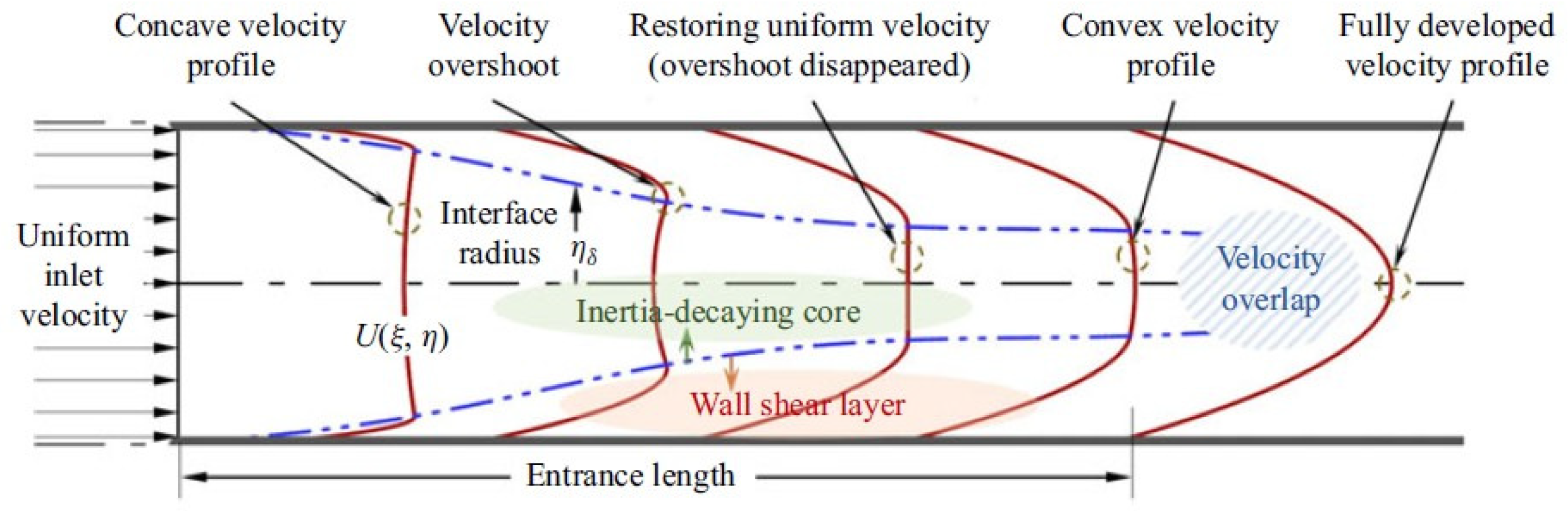

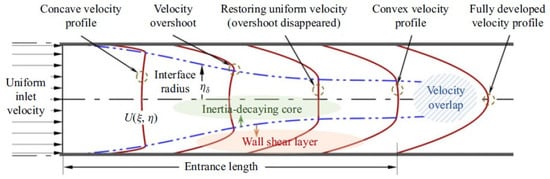

A standard problem in fluid dynamics concerns the laminar entrance flow in a cylindrical pipe, which precedes the fully developed Poiseuille flow. Recently, Kim [91] identified for the first time by analytical means the existence of velocity overshoot at a short distance from the pipe inlet, which is characterized by the maximum inflow velocity appearing near the pipe wall instead of the central symmetry axis as was corroborated by experimental measurements. Figure 4 shows a schematic drawing of the velocity evolution as predicted by Kim’s [91] analytical solution. The velocity overshoot is evident at the pipe entrance and progressively disappears as the velocity profile approaches a fully parabolic shape. Their Figures 3 and 4 show how well their predicted axial variation of the central axial velocity and pressure drop fits published experimental data. Based on the assumption of constant flow, , and a linear Navier slip boundary condition, , through the wall of a cylindrical pipe of radius oriented along the z-coordinate axis, where is the slip length, Cox and Hill [92] derived two approximate analytical solutions for the radial and axial velocity fields, namely, and

respectively, for fully developed laminar flow, where is a constant factor. They found that a second flow arises, which gives rise to enhanced flow rates compared to the conventional Poiseuille flow that occurs for an injected radial flow velocity across the permeable pipe wall boundary. However, as Cox and Hill [92] pointed out, such high flow rates do not explain the much higher rates that have been reported for carbon nanotubes.

Figure 4.

Schematic drawing showing the development of the laminar entrance flow in a cylindrical long pipe as predicted by Kim’s [91] analytical solution. The presence of a velocity overshooting is evident near the pipe entrance. The velocity profiles are depicted in red, while the dash-double-dotted blue lines indicate how the the velocity overshooting is disappearing as the flow becomes fully developed. Figure taken from Kim [91].

As an additional interesting case, Kannaiyan et al. [93] derived an analytical solution for unsteady incompressible laminar flow in a cylindrical pipe subjected to arbitrary change in flow rate. They found solutions for the main velocity, pressure gradient, wall shear stress and skin friction factor when the flow rate changes in a step-like fashion from an initial value to a final value at an arbitrary time. Recently, Dunnimit et al. [94] obtained an approximate analytical solution for the time-fractional Navier–Stokes equations using the generalized Laplace residual power series method. They showed that by increasing the fractional order of the Katugampola fractional derivative of the Caputo type, the velocity of the fluid flow in a pipe is reduced. However, an increase in the radius of the pipe or the duration of the flow over time will increase the flow velocity. An explicit expression for the flow velocity was derived by Lyberg and Tryggeson [95] by considering the generation of vorticity at the boundaries of the system. They reformulated the Navier–Stokes equations in a divergence form that permitted immediate integration, allowing the velocity to be explicitly calculated and depend on boundary conditions only. Analytical solutions that aim to describe the flow of incompressible peristaltic viscous fluid in a horizontal tube were also presented by Mohammadein et al. [96,97].

Fatsis et al. [98] reported a new class of analytical solutions to the Navier–Stokes equations for unsteady swirling flow along a porous cylindrical tube rotating about its axis of symmetry. They found that the axial velocity peaks at the center of the pipe and decays toward its porous wall. In a more recent work, Manopoulos et al. [99] derived a generalized analytical solution for the laminar, oscillatory, creeping flow of an incompressible Newtonian fluid in a leaky pipe. In this case, suction and injection through the permeable wall of a cylindrical pipe of radius and aligned with the z-axis are represented by a spatiotemporal radial velocity of the form with period and amplitude . Using no-slip boundary conditions for the axial velocity, i.e., , Manopoulos et al. [99] obtained the following analytical solutions for the radial and axial velocities

where , , , and and are the zeroth- and first-order modified Bessel functions of the first kind, respectively. They examined their analytical solutions for varying Womersley numbers,

and ejection/suction parameters, , finding that the flow velocity decreases with increasing for all values of , while for small , the pressure increases. The same occurs when the ejection/suction frequency, , increases, which also leads to a shift of the peak velocity toward the leaky pipe wall. This mathematical model has important applications to the study of biofluidic systems, such as the renal tubules and the glymphatic system in the brain, where the leakage of fluids takes place across permeable interfaces.

Exact and approximate analytical solutions for the turbulent flow in a pipe are based on the idea that the flow velocity can be treated as the superposition of a turbulent (fluctuating) component on a laminar (parabolic) solution [100]. This kind of pipe flow was studied by García García and Alvariño [101], who solved analytically the Reynolds-averaged Navier–Stokes (RANS) equations for unsteady incompressible flow of a viscous fluid in a cylindrical pipe. In this approach, the mean field velocity is the sum of two components, namely, a laminar component, which is the result of a Poiseuille-type flow driven by the pressure gradient, and a turbulent one due to the Reynolds shear stress gradient developing within the pipe. A third component related to a transient response to the initial conditions disappears quickly. More recently, Fedoseyev [102] derived an approximate analytical solution to the so-called Generalized Hydrodynamic Equations (GHEs) for incompressible viscous flow. These equations are [103]: the continuity equation

and the momentum equation

where , is a scale velocity, L is the hydrodynamic length scale, is a body force and is a dimensionless time scale. The right-hand side of Equation (40) is the divergence of the fluctuating component of the velocity. The solution of Equations (39) and (40) allows explaining the nature of turbulence as the linear superposition of a laminar and a turbulent (super-exponential) solution

where is a parameter to be determined from experimental data, and . This analytical solution was found to compare well with experimental data for water flow in a horizontal pipe at and provided a complete structure of the turbulent boundary layer for experiments with distilled water flow at . A basic theory of viscous fluid flow in straight and curved pipes of circular and elliptical cross-section, which is valid for both incompressible and compressible linear viscous fluids, has been developed by Green and Naghdi [104] and Green et al. [105]. Explicit formulations of the mass flow rate per unit area, , for the compressible laminar and turbulent flow through a pipe were derived by Hullender et al. [106] in terms of empirical friction factors for both types of flow.

4. Experimental Studies: Flow of Newtonian Fluids in Pipes

In this section, we first perform a survey of early experimental studies, spanning the period from 1839 to 2000, whose results form the foundations on which the current theory of pipe flow is based. Experimental studies from the year 2000 onward will be reviewed separately in the following subsection.

4.1. Early Experimental Studies

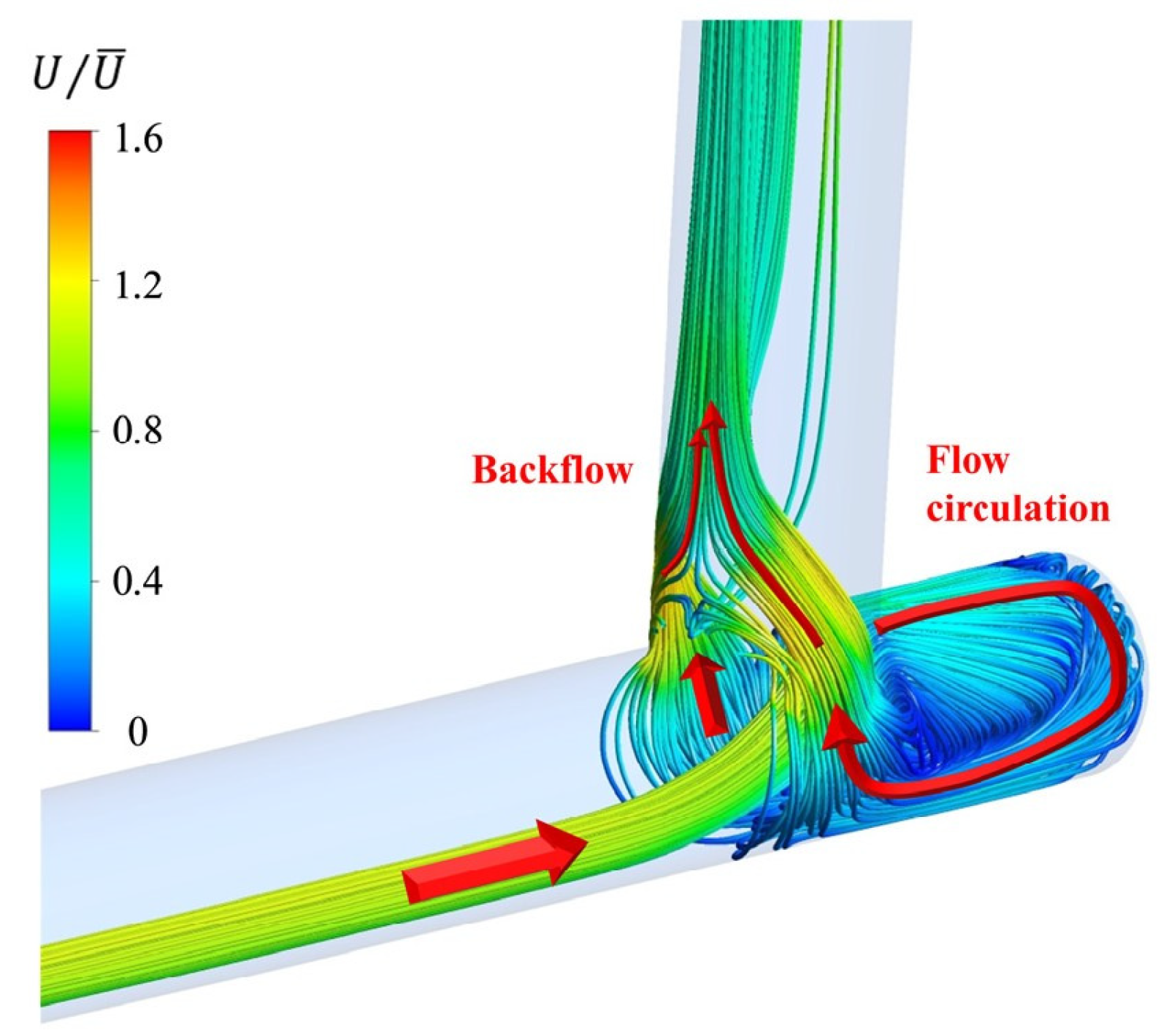

The first experiments of fluid flow in pipes were largely restricted to measurements of pressure losses and to a very minor extent to flow visualization [1,2,3,4,6,7]. Two important conclusions were drawn from these early experiments, namely, that the laminar flow in a straight pipe becomes turbulent above a certain pressure head and that a secondary (circulatory) flow arises in a pipe bend, which occupies its entire cross-sectional area. Experiments mainly on water flow in curved pipes were continued in the early 1900s, with the work of Williams [8], who demonstrated for the first time that the point of maximum mean velocity at the exit of a bend shifts toward the outer wall of the pipe. Later, Eustice [9,10] found from similar experiments that the pressure drop in curved pipes was always greater than in straight pipes. However, Eustice also observed that the pressure changes in straight pipes at the transition point from laminar to turbulent flow did not occur so abruptly. Similar experiments were later taken up by White [11], who demonstrated by pressure drop measurements that the critical Reynolds number is generally much higher for curved pipes than for straight pipes. On the other hand, experiments by Taylor [107] showed that with increasing curvature, the transition from laminar flow to turbulent flow occurred for ever larger Reynolds numbers. The fully developed turbulent flow in a curved channel of constant curvature and cross-section was then experimentally studied by Wattendorf [108]. Measurement techniques include mainly laser Doppler velocimetry (LDV), hot-wire anemometry (HWA) and, in minor extent wall shear gauges, Pitot tubes and pressure taps. In particular, HWA measurements of velocity distributions downstream of pipe bends of circular, elliptical, square and rectangular cross-sectional area were presented by Weske [109]. In spite of differences in the cross-sectional shape, he found that the velocity distributions are quite similar and that the secondary flow arises as a consequence of the upstream flow converging asymmetrically with respect to the plane of the bend curvature. In addition, Detra [110] performed measurements of the mean axial velocity at through pipe bends of and , corresponding to curvature ratios and 0.04, respectively. Moreover, Tunstall and Harvey [111] found experimentally that turbulent flow through an L-shaped bend of circular cross-section produces a downstream secondary flow that is dominated by a single circulation instead of two counter-rotating Dean vortices, as usually found in pipe bends. For experimental data on measurements of pressure wall and pressure probe surveys prior to 1970, the interested reader is referred to the thorough review by Ward Smith [112] and references therein.

The development of the laser-Doppler anemometer has allowed for more detailed measurements of complex flows in pipes, including those occurring in bends and elbows. Therefore, after 1970, most experimental research has focused mainly on studying laminar and turbulent flows through curved pipes, in general. Humphrey et al. [113] studied experimentally the developing laminar flow of water through a bend of mm2 square section with smooth walls and long upstream and downstream ducts attached. They used laser-Doppler anemometry to provide measurements of longitudinal velocity and flow visualization for a qualitative analysis of the flow characteristics. Later, this study was extended to the analysis of turbulent flow using the same experimental setup used in the laminar flow analysis [114]. In this case, detailed measurements of the longitudinal and radial velocity components along with the corresponding components of the Reynolds stress tensor were provided using LDV techniques. Similar measurements of laminar and turbulent flows with thin inlet boundary layers using LDV methods were contemporaneously reported by Taylor et al. [115]. Other authors have performed experimental work on the development of turbulent flow in curved ducts with square and rectangular cross-sections [116,117,118,119]. In particular, Enayet et al. [117] found that for moderately curved ducts of square cross-section, the secondary cross-stream velocities are only one-half of those measured in strongly curved bends.

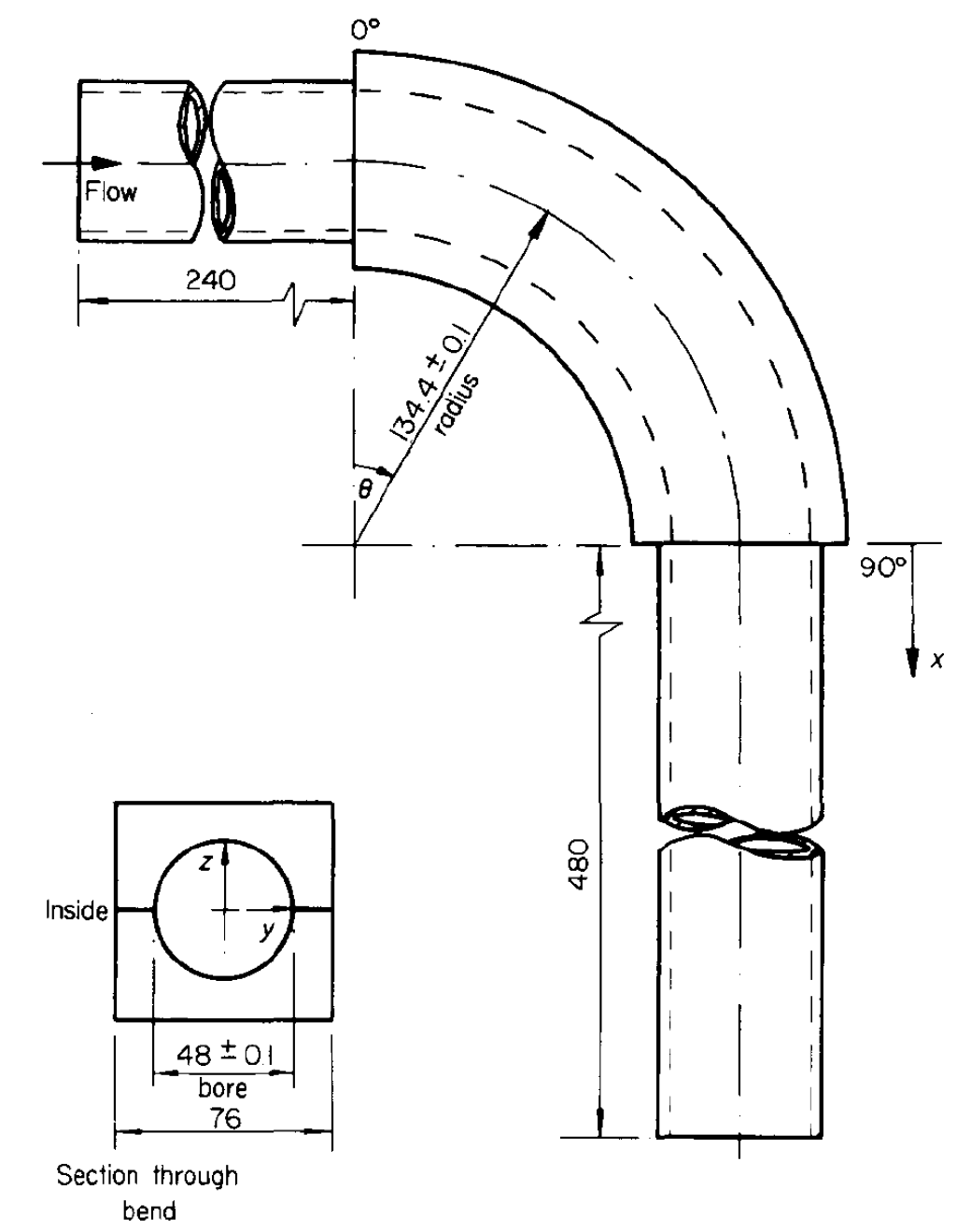

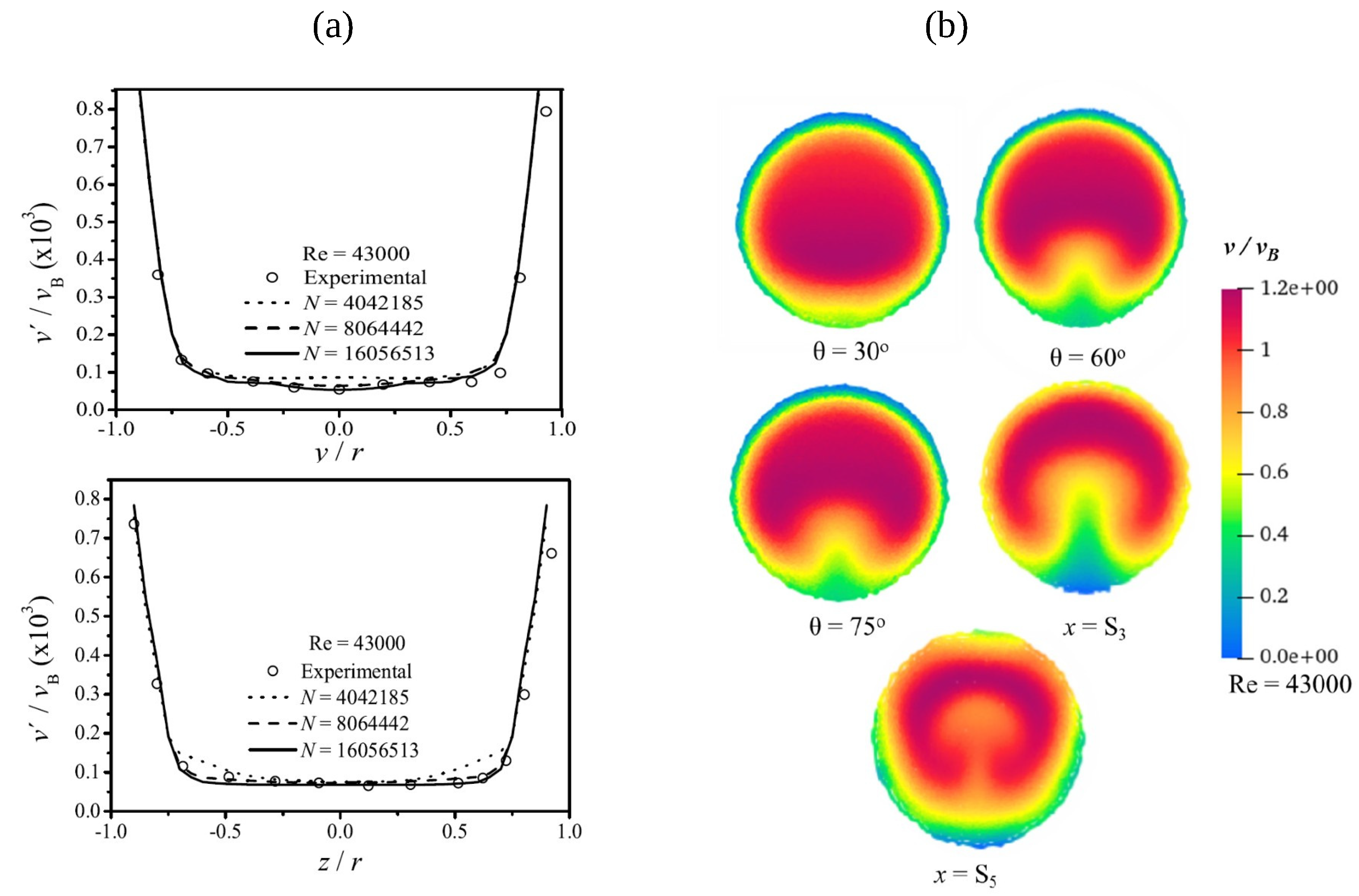

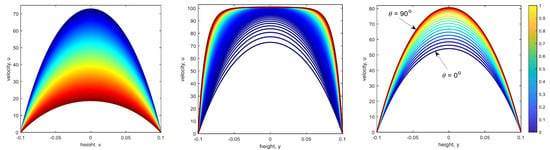

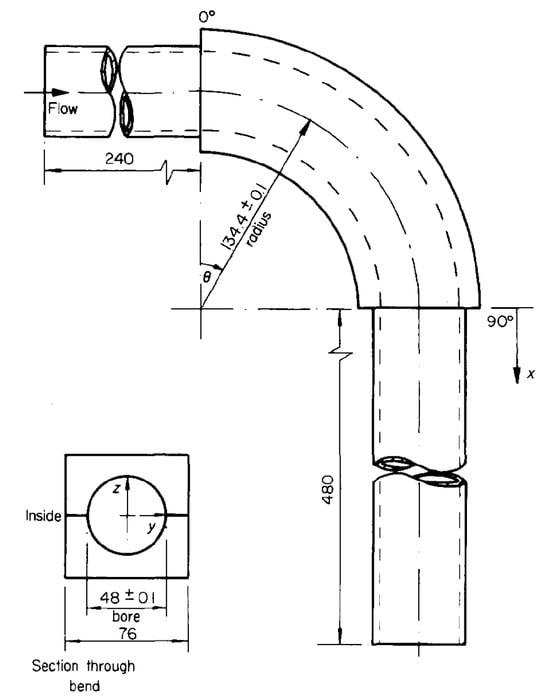

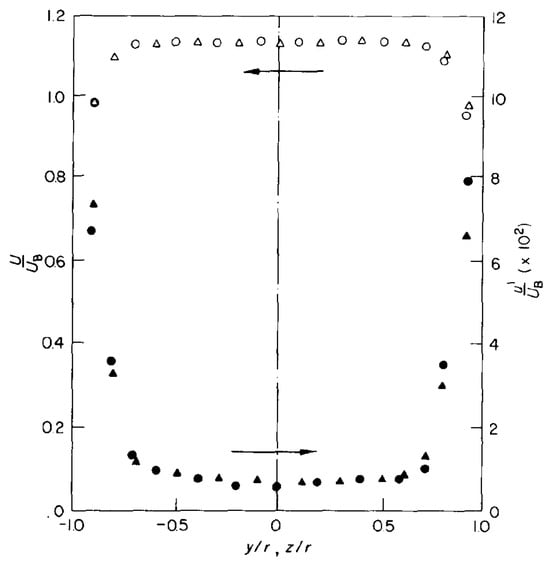

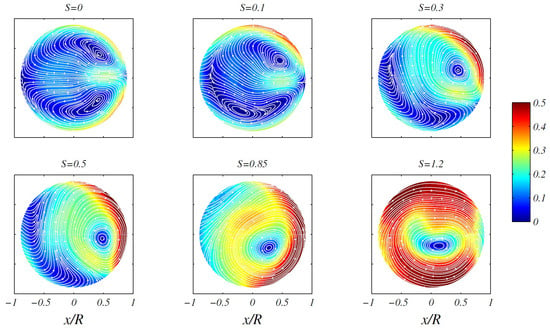

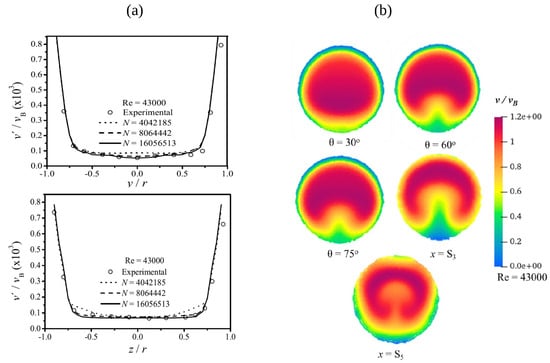

Further LDV measurements of laminar (at and 1093) and turbulent (at = 43,000) water flow in a circular cross-sectional bend were reported by Enayet et al. [120]. A schematic of their experimental test bend is shown in Figure 5. Their experimental model and results represent a benchmark for testing the accuracy of numerical simulations of laminar and turbulent flow in pipe bends. Long straight pipes of length 240 mm and 480 mm were attached upstream and downstream of the bend, respectively, and the entire system fitted to a closed-loop water flow rig. For flow field visualization, they used a laser light beam focused onto a radial diffraction grating. The beam was collimated to reduce spherical aberration and focused to form the scattering volume at the measurement point in the bend. Measurements were made by turning the light beam through using an optically flat mirror. The forward scattered light that was collected by an objective lens was focused on and passed through a pinhole to a photomultiplier. The output signal from the photomultiplier was then processed in a frequency tracking demodulator. The optical details of the laser-Doppler anemometer employed by Enayet et al. [120] are given in their Table 1. They measured horizontal (along the y-coordinate in Figure 5) and vertical (along the z-coordinate) velocity profiles in a cross-stream plane 0.58 pipe diameters upstream of the bend inlet and cross-sectional contours of the mean velocity at different stations within the bend and downstream of the bend exit plane. In all experiments, they observed the development of a strong pressure-driven secondary flow in the form of two counter-rotating vortices in the streamwise direction, which persisted downstream of the bend exit. There is a more or less general consensus that the vortical motion arises as the flow from the straight section entering the bend must adjust itself to counter centrifugal forces. In this way, the flow meets the outer pipe wall farther from the center of curvature where the pressure is consequently greater. At the bend inlet, the outer wall boundary layer experiences a positive streamwise pressure gradient that is strong enough to cause local flow separation, while the inner wall boundary layer is accelerated as a result of a much lower pressure there. In the side wall boundary layers, the fluid moves slowly and is eventually forced toward the center of curvature and the high speed flow near the axis is driven outward by continuity. This process results in a secondary flow superimposed to the main flow. The experimentally observed horizontal and vertical mean velocity and rms fluctuations (turbulence intensity) are depicted in Figure 6. From knowledge of the mean velocity, , the turbulent fluctuation in the streamwise direction is . The turbulence intensity is defined as the root mean square (rms) of the square of the fluctuating part

where is a sufficiently long time interval, which can be set equal to the time required to achieve a steady-state flow. The turbulence intensity in the streamwise direction is given by

Figure 5.

Schematic of the experimental test 90° bend and coordinate system used by Enayet et al. [120] in their LDV flow measurements. Figure taken from Enayet et al. [120].

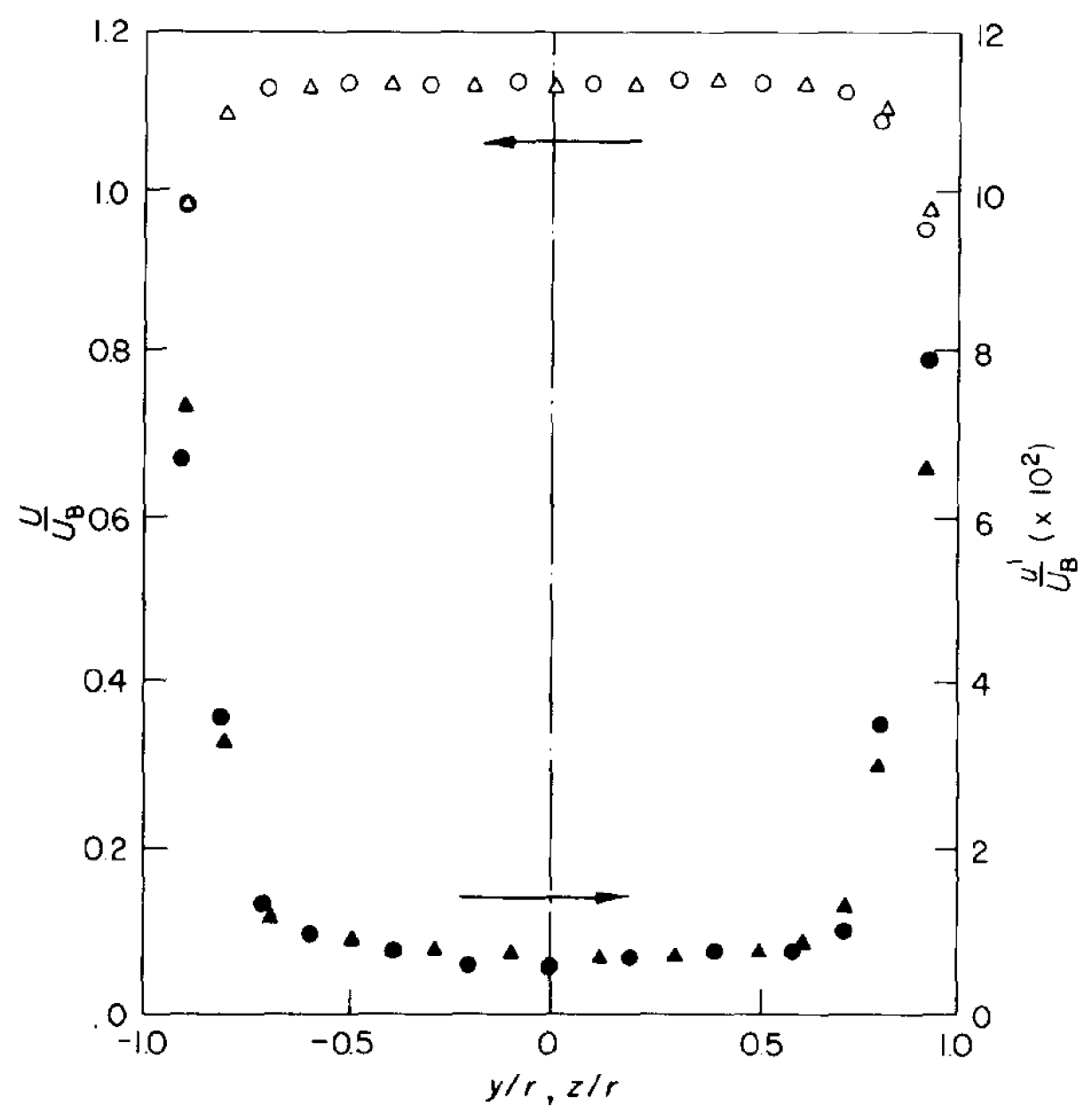

Figure 6.

Horizontal and vertical profiles for the mean velocity and turbulence intensity for turbulent flow at = 43,000 in the cross-sectional plane 0.58 diameters upstream of the bend inlet. Open circles and triangles correspond to horizontal and vertical velocity profile data, respectively, while filled circles and triangles refer to horizontal and vertical turbulence intensity profile data, respectively. Figure taken from Enayet et al. [120].

For the turbulent case ( = 43,000), Enayet et al. [120] found that the secondary flow that formed persisted six pipe diameters downstream of the bend outlet. Compared to the laminar flow at , the inlet boundary layers appear to be much thinner, and, as shown in Figure 6, the region of maximum velocity is characterized by a much larger central uniform plateau. This plays a significant role in the development of secondary flow downstream of the bend outlet.

LDV measurements of water flow at = 57,400 and 110,000 in a U-bend pipe were presented by Azzola et al. [121]. They provided profiles for the longitudinal and circumferential velocity components and for the longitudinal and circumferential turbulence intensity components at different stations within the U-bend and in the straight tangents upstream and downstream of the U-bend. As the flow enters the bend, the streamwise flow accelerates toward the outer wall and slows down in the central core, while a strong secondary flow develops during the first half of the U-bend. This cross-stream circumferential velocity pattern arises as a consequence of the transverse pressure gradient that sets in between the outer and inner bend walls. In the second half section of the U-bend, the cross-stream flow reverts its sense of motion and is directed toward the inner wall. Downstream of the U-bend outlet, the secondary flow gradually dissipates. Azzola et al.’s [121] compared their experimental results with additional numerical simulations for = 65,000, finding a reasonably good agreement between the experimental and numerical velocity profiles and circumferential turbulence intensity (see their Figures 2 and 3). However, Lee et al. [122] reported hot-wire measurements of the same flow parameters as Azzola et al. [121]. In particular, they were unable to reproduce the rms velocity fluctuation profiles reported by Azzola et al. [121], concluding that the profiles reported by these authors were erroneous.

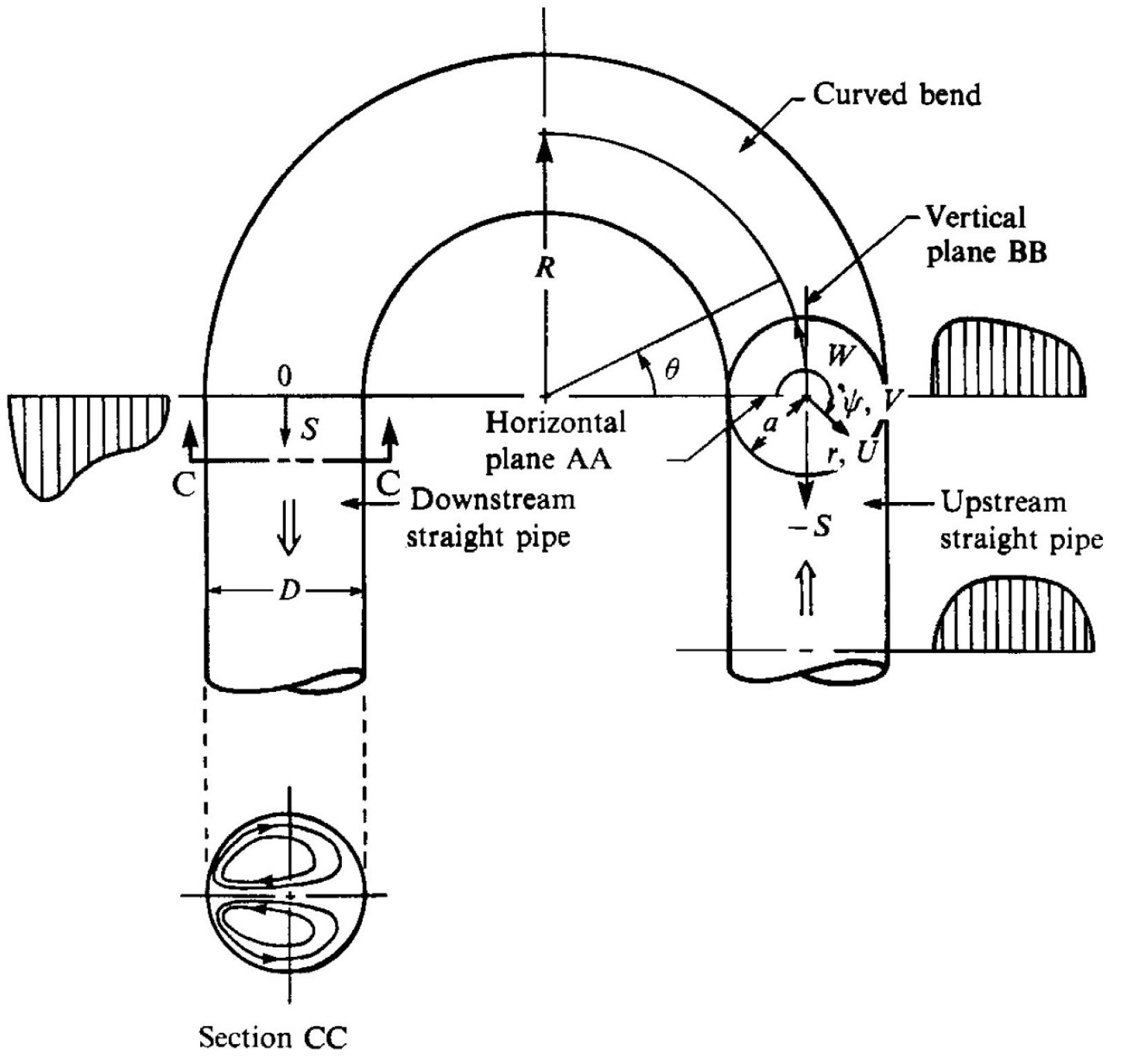

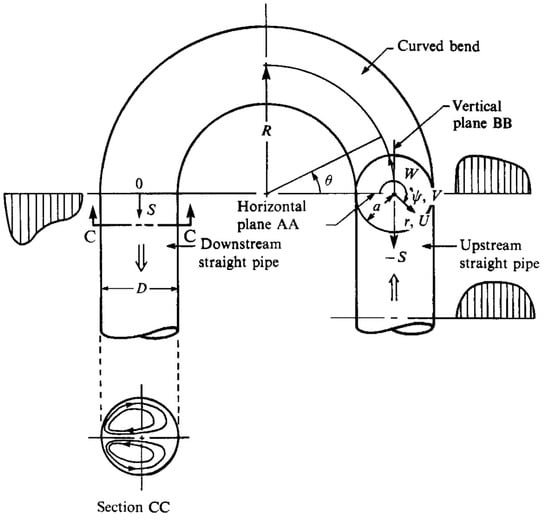

Miniature hot-wire and wall-static pressure techniques were used by Anwer et al. [123] to investigate a fully developed turbulent flow at = 50,000 in a U-bend with . They measured the three components of the mean velocity and the six components of Reynolds stress along a horizontal and in a perpendicular plane in different pipe stations from 18 pipe diameters upstream to 18 pipe diameters downstream of the U-bend. Figure 7 shows a schematic drawing of the U-bend geometry along with the shape of the streamwise velocity profiles at selected stations and the form of the cross-stream (secondary) flow in the straight tangent downstream of the pipe bend. They found that a Dean-type secondary flow (i.e., two counter-rotating cell vortices) is established in the bend. However, the second cell disappears about one pipe diameter downstream of the U-bend exit, while complete flow recovery will take distances from the bend exit greater than 18 pipe diameters. In a follow-up investigation using the same experimental set-up of Anwer et al. [123], Anwer and So [124] used a variable interval time averaging technique to detect sublayer bursting in turbulent flow through a U-bend. They found that the measured circumferential wall shear stress distribution along with the spectral content of the wall shear signal and the associated bursting frequency confirm the previous finding that downstream of the bend return of the main flow to an unperturbed parabolic shape will take long distances.

Figure 7.

Schematic drawing of the U-bend geometry used in Anwer et al.’s [123] and Anwer and So’s [124] experimental set up. Figure taken from Anwer and So [124].

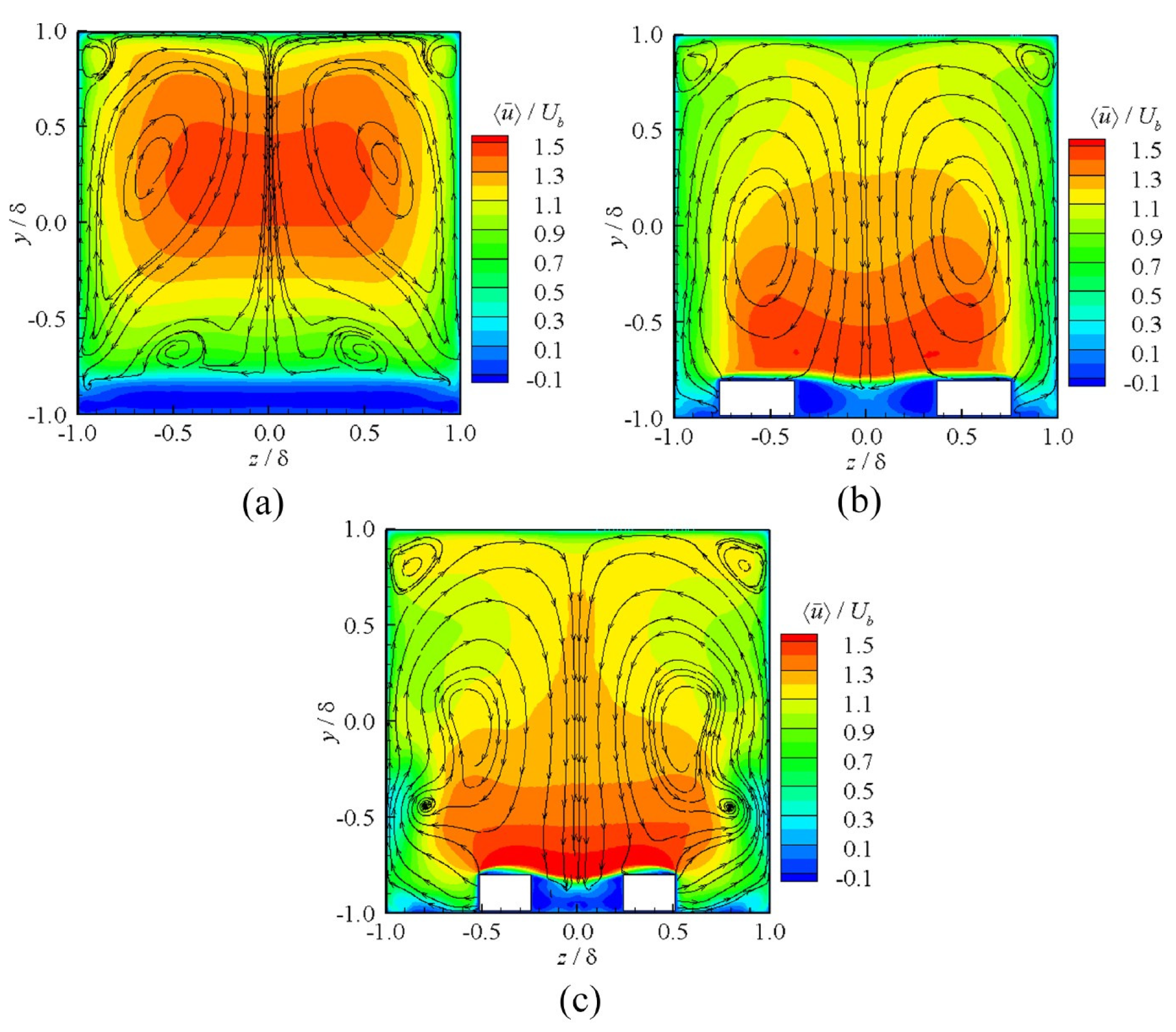

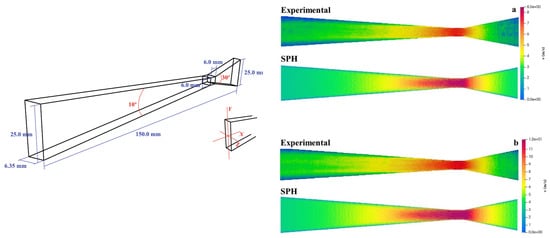

4.2. Recent Experimental Studies

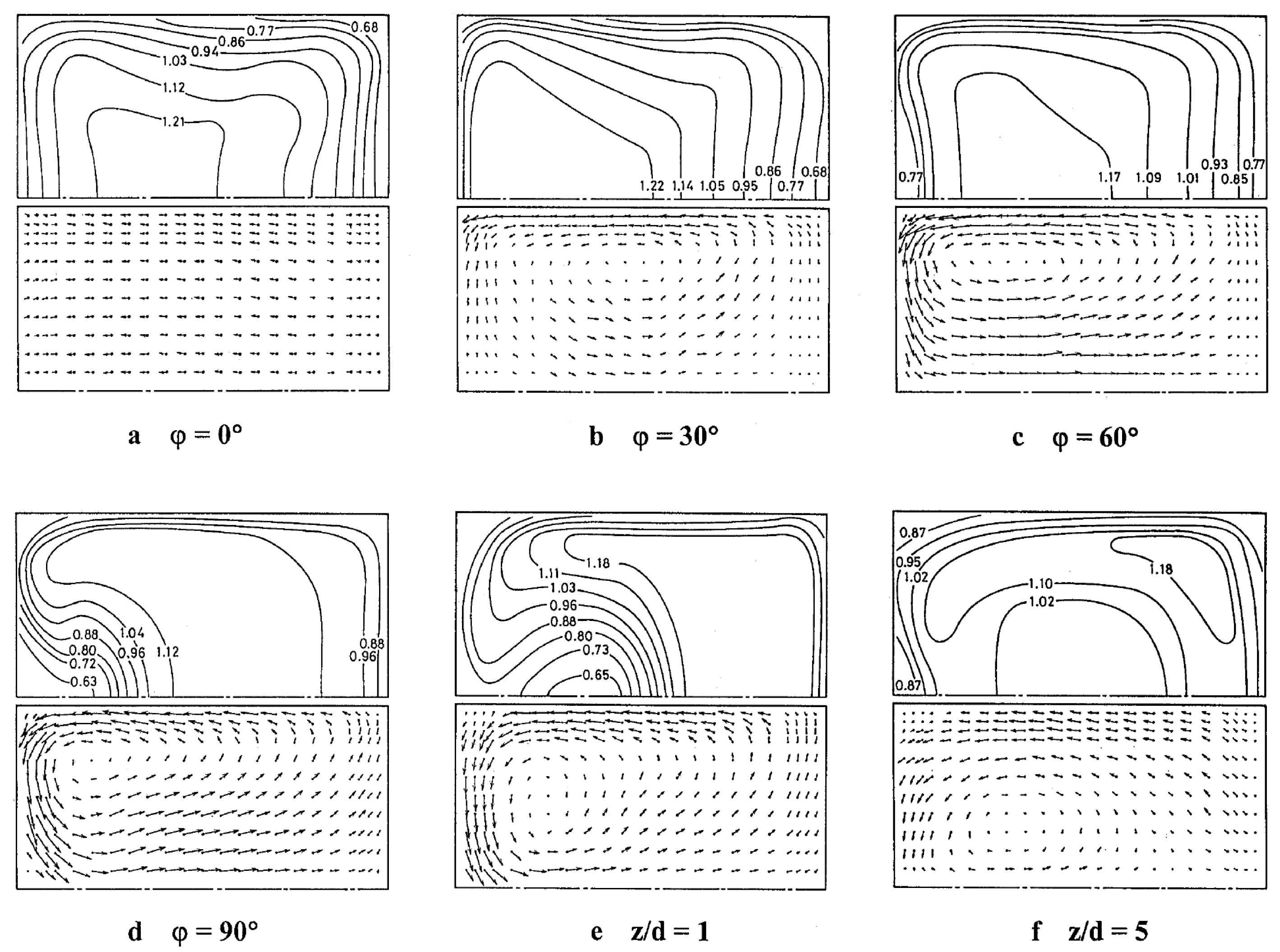

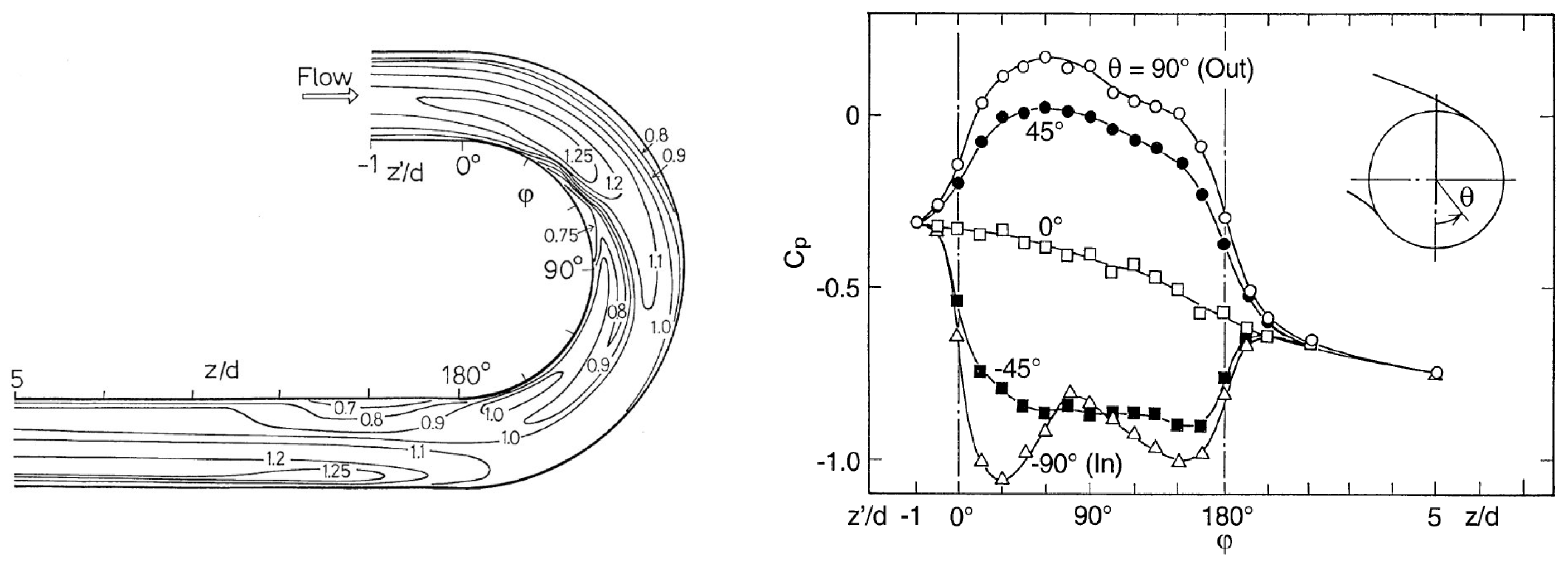

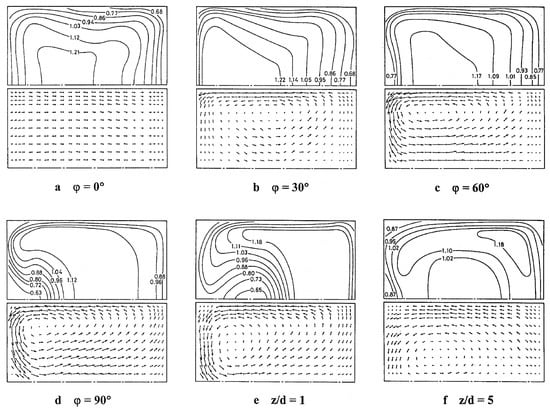

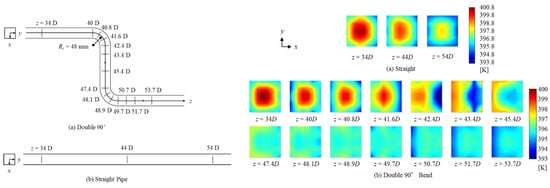

As was outlined by Kalpakli Vester et al. [14], the classical papers by Sudo et al. [125,126,127] are probably the most well cited and extensive experimental studies on the development of turbulent flow through and pipe bends. In particular, Sudo et al. [126] studied the steady turbulent flow in a circular bend with long upstream and downstream tangents. Using the innovative technique of rotating a probe with an inclined hot wire at = 60,000, they measured the three components of the mean and fluctuating velocities and Reynolds stresses at different pipe stations. In these experiments, a hot wire stem was mounted to a slip moving ring in the circumferential direction. In this method, the probe had to rotate several times at a prescribed point to obtain the velocity there. This technique is better suited than LDV to measure time-averaged and fluctuating velocity components in the three directions as well as their corresponding Reynolds stresses. This visualization of the velocity field was obtained by processing the signals from the hot wire probe in a computer, where they were transformed into mean and fluctuating velocities. The results indicate that as the primary flow enters the bend, it accelerates near the inner wall and soon forms a secondary flow, which in an angular section develops into a pair of vortices. At this stage, the Reynolds stresses are greater in the outer part of the cross-section. Toward the bend exit, the primary flow becomes greatly distorted, and both the turbulence intensity and the Reynolds stresses increase in the inner part of the bend cross-section. Downstream of the bend exit, the primary flow becomes progressively smoother, while the secondary flow weakens and the vortices break down. Later, Sudo et al. [125] performed similar experiments for turbulent flow in a square cross-section bend using a hot wire anemometer at = 40,000. In this case, the longitudinal and lateral components of the mean and fluctuating velocities were measured along with the turbulent intensity and components of the Reynolds stresses. As in the circular bend, after the flow enters the bend, it is accelerated near the inner bend wall and decelerated near the outer wall. At , a secondary flow of a vortex type arises, which gets stronger at larger angles. Toward the bend exit and about two pipe diameters downstream of the bend outlet (i.e., at in Sudo et al.’s notation), the primary flow looks quite distorted. Figure 8 shows contour plots of the longitudinal velocity component and secondary flow velocity vectors at different angular stations within the bend and along the downstream tangent. At and , a depression in the primary velocity contours is evident in the inner part of the bend cross-section. Owing to this large velocity gradient, the turbulence intensity and the Reynolds stresses increase around the velocity depression. As the main flow leaves the bend, the secondary flow attenuates beyond .

Figure 8.

Primary flow velocity contours (top panels) and secondary flow velocity vectors (bottom panels) for turbulent flow at = 40,000 (a–d) at different angular stations within a square-sectioned 90°-bend and (e,f) along the downstream tangent. Figure taken from Sudo et al. [125].

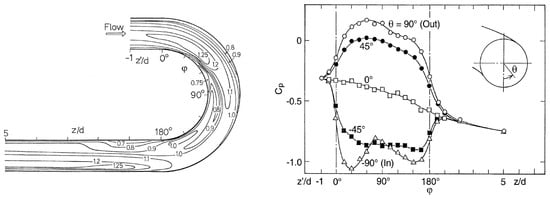

These experiments were also extended by Sudo et al. [127] to investigate the turbulent flow through a circular-sectioned U-bend. Longitudinal velocity contours through the bend and in the downstream section are shown in the left plot of Figure 9. Similarly to flow in a bend between and , the flow accelerates near the inner bend wall. At about , a secondary vortical flow forms as a result of the action of the strong pressure gradients between the outer and inner walls and the centrifugal force working on the fluid. Due to the transverse pressure gradients, the secondary flow still persists for and beyond the bend exit, although gradually weakening. In the downstream tangent, the flow returns slowly to its parabolic form, but it needs much longer distances than in the bend for full recovery. The distribution of the wall static pressure, defined as

is shown in the right plot of Figure 9. Here, is the pressure coefficient, is the pressure at in the straight pipe station upstream of the bend inlet and m s−1 is the bulk velocity, forming a flow with = 60,000.

Figure 9.

(Left) Longitudinal velocity contours on the horizontal plane along a U-bend and its downstream tangent, normalized to the bulk velocity m s−1 for turbulent flow at = 60,000. (Right) Variation of the wall static pressure within the U-bend at different angles along the circular arc of the bend. Figures taken from Sudo et al. [127].

All previously discussed experimental investigations of laminar and turbulent pipe flow were performed under isothermal conditions. Under non-isothermal conditions, Wada et al. [128] constructed an experimental apparatus to study the convective heat transfer in the laminar pipe flow of highly viscous fluids ( Pa s) with and a temperature-dependent viscosity during cooling. The working viscous fluids consisted of solutions containing 80 wt% (with Pa s), 90 wt% (with Pa s) and 95 wt% (with Pa s) syrup. They performed an analysis of the pipe flow in terms of the dimensionless parameters and , where L is the pipe length, D is the pipe diameter, is the Péclet number and and are the fluid shear viscosities based on the inlet and wall temperatures, respectively. It was found that the thermal boundary layer is fully developed at , and, at this value, the maximum fluid velocity is observed to deviate significantly from Poiseuille flow. For , the deviations of the velocity profiles from Poiseuille flow are very small for the whole range of between 0.0005 and 0.05, while for close to zero, the velocity profile deviates from Poiseuille flow in the flow direction after heat transfer starts, and the deviation is seen to increase with increasing in the thermal entrance region. Based on numerically calculated Nusselt numbers (), a semi-empirical correlation was proposed to predict for highly viscous fluids (see Wada et al.’s [128] Equations (5)–(9)). In a more recent investigation, McNeil and Stuart [129] performed a series of experiments of highly viscous flow in pipeline components using a purpose-built test facility. For aqueous glycerin solutions with nominal viscosities between 1 and 550 mPa s, they obtained variations in the friction factor of the pipe as a function of , which fit very well the theoretical value for laminar flow in a circular cross-section pipe, . They also provided variations of the discharge coefficient for orifice plates and nozzles and loss coefficients for different systems, including a nozzle, an orifice plate, an abrupt enlargement and a globe valve for values between 10 and 200. They concluded that while existing methods appear to be quite adequate for prediction of friction factors and discharge coefficients for highly viscous flows, they are rather inaccurate for predicting loss coefficients.

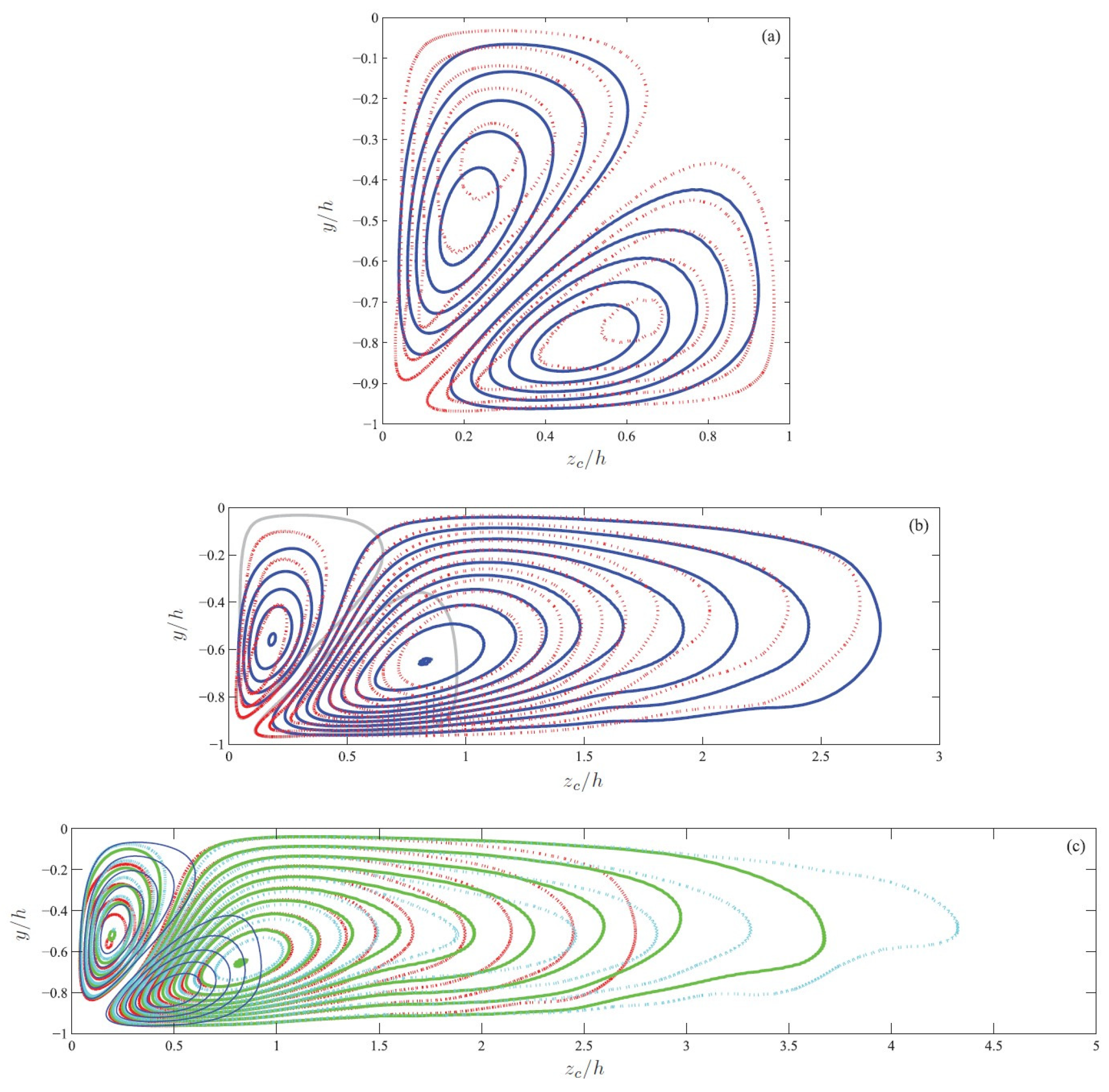

Curvature-induced flow structures downstream of a bend exit at = 20,000 and 115,000 were investigated by Hellström et al. [130] using time-resolved stereoscopic particle image velocimetry (PIV). They performed snapshot proper orthogonal decomposition (POD) analysis of the flow at three different stations in the downstream tangent, finding that the most energetic flow structure does not conform with the usual Dean cell vortices, but, instead, it resembles a single-cell circulatory motion with an alternating direction of rotation, which they called the “swirl switching” mode. However, Dean vortices formed downstream of a circular bend were observed by Sakakibara and Machida [131] by synchronizing two sets of a PIV system.

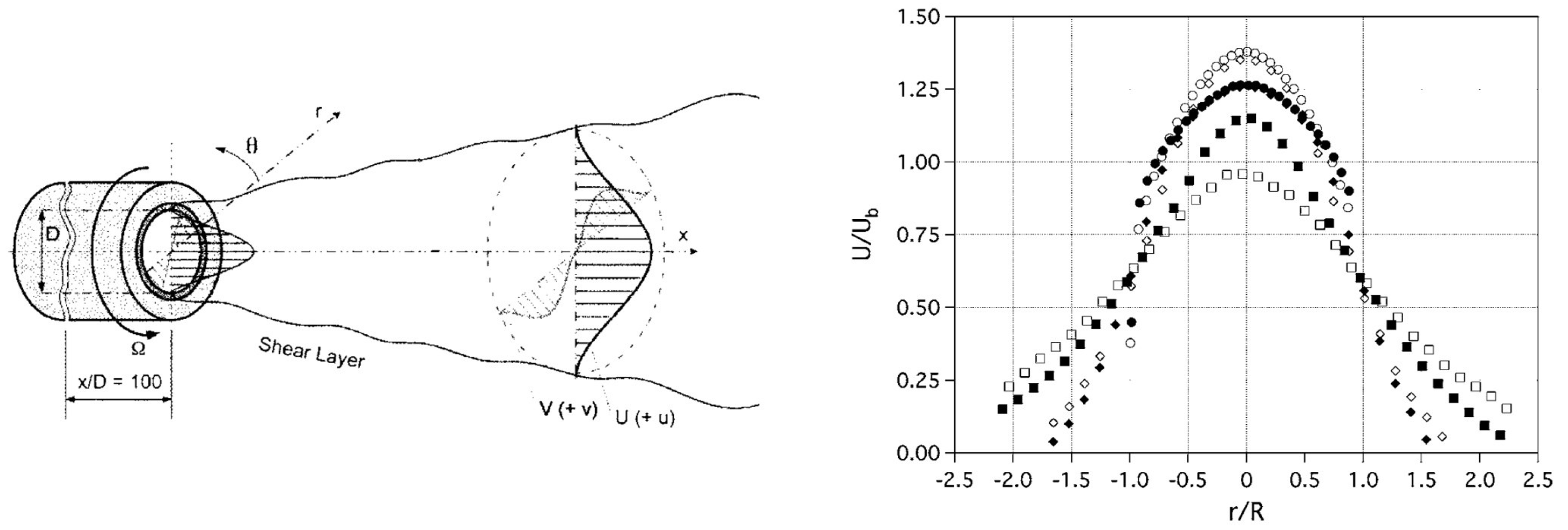

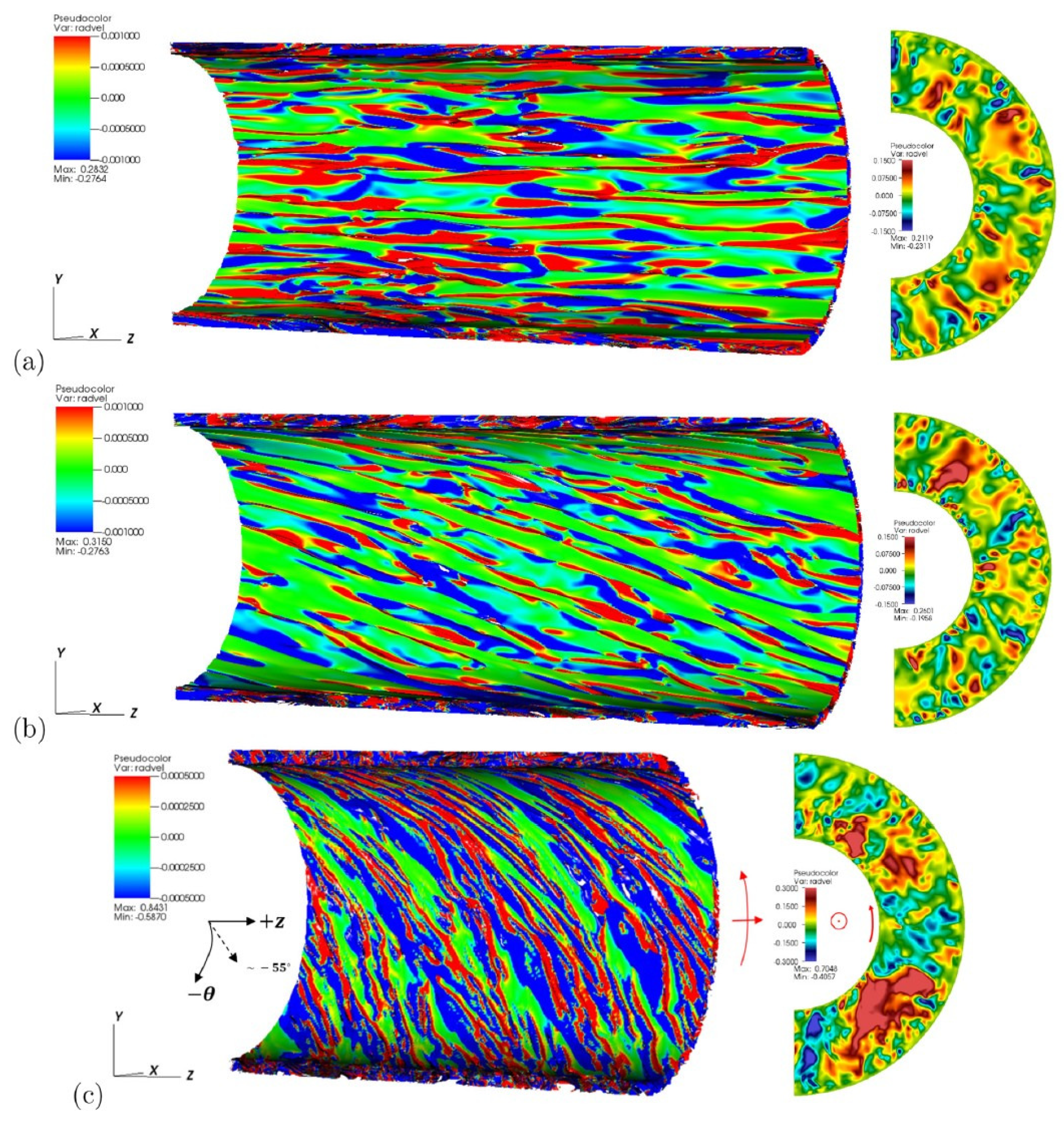

Swirling turbulent flow in straight pipes was studied experimentally by a number of authors [132,133,134,135,136,137,138,139]. When a viscous fluid flows through a pipe rotating about its axis of symmetry, the tangential forces acting between the pipe wall and the fluid causes the latter to rotate with the pipe, giving rise to a flow pattern that differs from the one observed in conventional stationary pipes. Possibly, the first flow experiments in rotating straight tubes were carried out by White [132], who observed that in an axially rotating tube the laminar flow destabilizes, while the turbulent flow shows a clear tendency to stabilize. He also demonstrated that in a turbulent flow regime, the pressure losses decrease with an increasing rotation rate of the pipe. Flow velocity profiles in a rotating pipe were subsequently analyzed by Lavan et al. [133] for the case when a fully developed laminar flow is introduced into the pipe. Depending on the magnitude of the swirl number, defined as

where is the tangential velocity of the pipe wall, is the mean axial (or bulk) velocity and is the rotational Reynolds number, they observed a reverse flow in the wall region near the pipe inlet, which occurs for large values of S. The flow patterns and resistance in an axially rotating pipe were also investigated by Murakami and Kikuyama [134] for turbulent flow with and . Rotating pipes of lengths between and having a hydraulically smooth surface were used in the experiments. For rotating pipe lengths greater than , the hydraulic head loss was found to decrease for S increasing from 0.35 to 1.2. For , the suppression of the turbulence saturates and the head loss remains essentially unaltered. At pipe lengths , the velocity profiles were seen to become almost independent of the distance from the inlet. With a constant value of S, the axial velocity profile changes from turbulent to laminar. However, the ultimate shape of the axial velocity distribution was found to depend on the degree of turbulence suppression. These results were further confirmed by measurements with a three-hole pressure probe by Reich and Beer [136]. From measurements with hot-wire probes, Kikuyama et al. [135] confirmed previous findings obtained by White [132] that the pipe rotation destabilizes the flow in the inlet region due to a large shear induced by the rotating pipe wall and stabilizes the turbulent flow downstream due to the centrifugal force of the swirling velocity flow component.

Velocity measurements for water flow at = 20,000 through a 30 mm diameter pipe at a distance of from the inlet were performed by Imao et al. [137], using a single-component LDV operated in forward scatter. They observed that the turbulence intensity decreases gradually with increasing swirling S due to the increasing stabilizing effects of the centrifugal force. Measurements of the Reynolds shear stresses show that they experience a greater decrease compared to the turbulent kinetic energy, which results in the suppression of the momentum transfer by turbulent motion in the rotating pipe. Similar measurements by Rocklage-Marliani et al. [138] of turbulent flow in an axially rotating pipe at showed that the Reynolds shear stresses are reduced in the core flow region due to swirling, which, in addition, enhances the level of anisotropy in the fluctuating motion. In a relatively more recent work, Facciolo et al. [139] carried out LDV measurements of swirling turbulent flow in a rotating pipe and the initial development of a swirling jet, which arises when the turbulent swirling flow leaves the axially rotating pipe. The left graph of Figure 10 shows a schematic drawing of the swirling jet issuing from the rotating pipe. In agreement with previous observations by Murakami and Kikuyama [134], they found that within the rotating pipe, the cross-stream Reynolds stress impedes the flow to be in perfect solid body rotation. This appears to be true independently of how long is the rotating pipe. The measured streamwise velocity distribution was found to compare well with the scalings derived by Oberlack [140,141] for the azimuthal and axial mean fluid velocity components. A more complex flow situation involves the issuing swirling jet, whose core rotates in the opposite sense of the pipe relative to the laboratory reference frame. The right graph of Figure 10 shows the evolution of the mean axial velocity profile at three different positions downstream of the rotating pipe outlet with (no swirl) and (swirl). A more peaked profile is evident in the swirling flow case. At a short distance from the pipe exit (), the axial velocity of the jet is fairly unaffected, while further away from the pipe exit (at ), the jet velocity appears to be significantly larger for the case.

Figure 10.

(Left) Schematic drawing showing the development of a swirling jet as it leaves an axially rotating pipe. (Right) Measured mean axial velocity profiles showing the developing swirling jet at = 24,000 at varying streamwise positions from the rotating pipe outlet: (circles), (rhombuses), (squares) for (open symbols) and (filled symbols), where D is the rotating pipe diameter. Figures taken from Facciolo et al. [139].

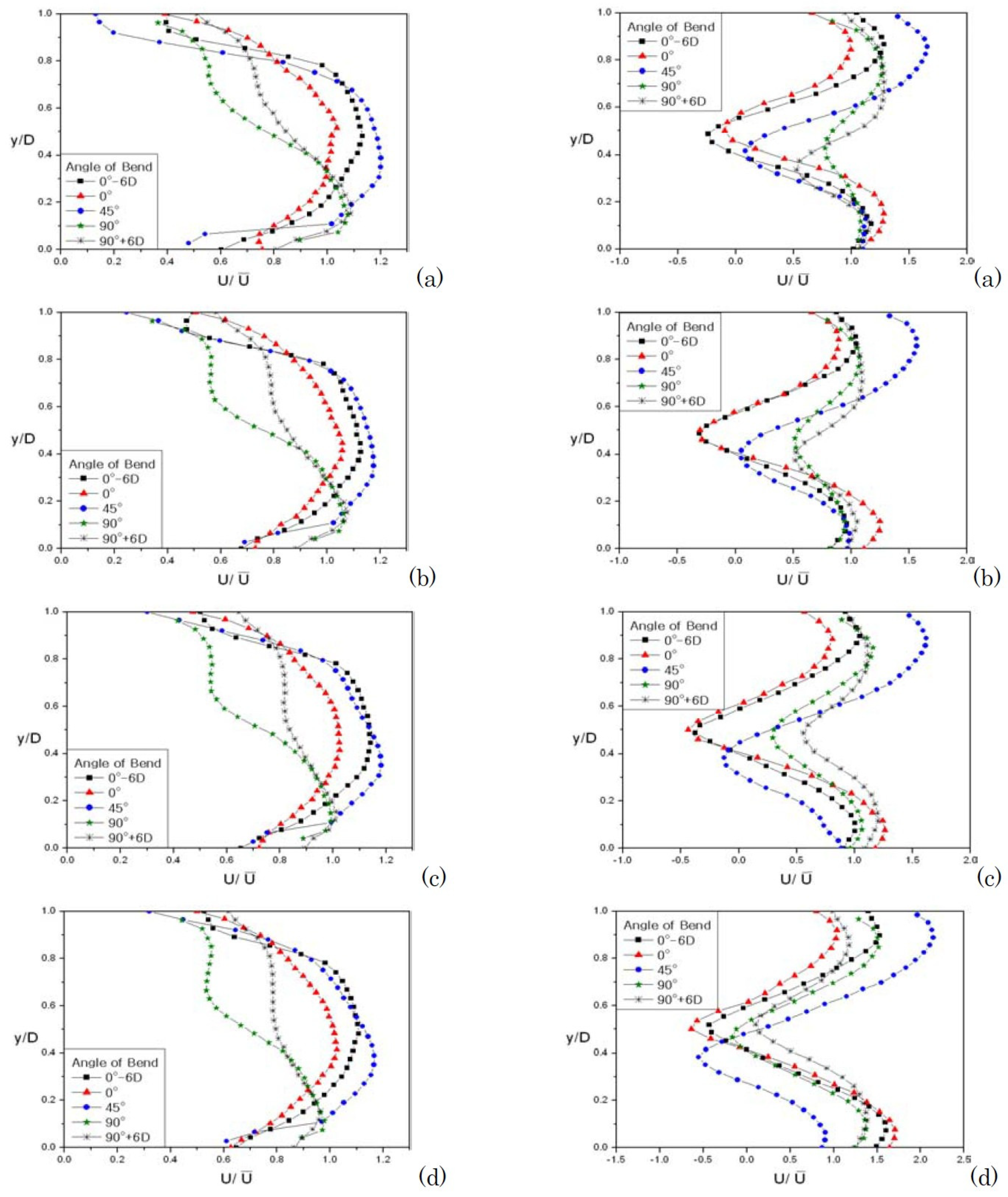

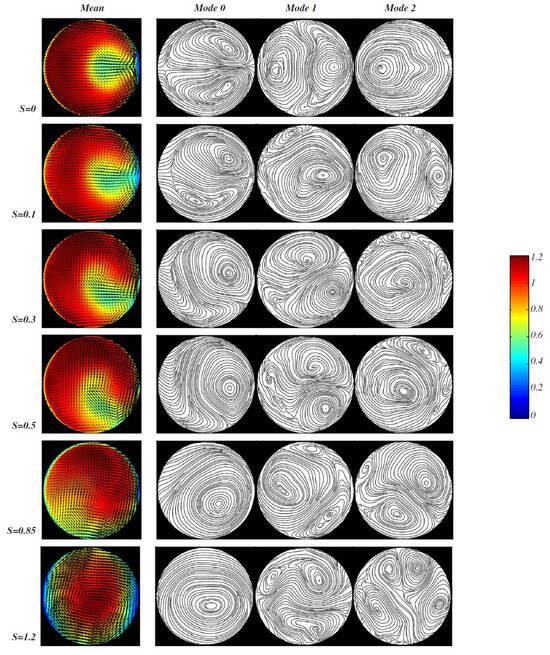

Early experimental measurements of swirling flow in pipe bends were reported by Shimizu and Sugino [142], Anwer and So [143] and So and Anwer [144]. In particular, Shimizu and Sugino [142] investigated the flow patterns and the hydraulic losses in swirling flow through U-bends. They found that the swirling flow patterns in the U-bend are affected by the curvature and wall roughness of the bend, while the total energy losses depend on the strength of the swirl at the bend inlet, the bend curvature and the pipe wall roughness. Further experiments of swirling turbulent flow in a U-bend were performed by Anwer and So [143]. In their experiments, the rotating section was placed six pipe diameters upstream of the bend inlet for flow at = 50,000. They provided measurements of the wall static pressure, mean flow velocity components, Reynolds stresses and wall shear distribution around the pipe using pressure transducers, rotating-wires and surface hot-film gauges. The secondary flow pattern that forms consists of a single, off-center vortical cell that follows a wavy path along the bend. The measured wall static pressure was seen to be higher at the inner pipe bend contrary to what is expected in the case. This finding conforms with previous measurements by Kitoh [145] for flow through a curved pipe with large swirling. In addition, the wall shear was found to be the same at the inner and outer bend for . The superimposed pipe solid-body rotation leads to an increased turbulent production of the normal stresses near the pipe wall in both the radial and tangential directions. This, in turn, gives rise to more uniform and symmetric distributions of the normal stresses across the bend, which are then responsible for the generated insufficient vorticity to maintain a sustained secondary flow as in the case. In a follow-up paper, So and Anwer [144] investigated the flow recovery in the downstream tangent using the same experimental setup of Anwer and So [143], finding that full recovery of the mean flow occurs at approximately 74 pipe diameters downstream of the rotating section. They concluded that this recovery length is shorter than that observed in straight pipes, and, as a consequence, the effect of the bend curvature is to accelerate the swirl decay in the downstream section. Using a PIV method, Chang and Lee [146] investigated the swirling flow through a pipe bend of circular cross-section. They measured time-averaged velocity and turbulence intensity profiles with swirl and without swirl for 10,000 ≤ Re ≤ 25,000 at different stations within the bend and along the upstream and downstream tangents. Figure 11 shows the measured mean axial velocity profiles without swirl (the left column of plots) and with swirl (the right column of plots) at different values and pipe stations. In the non-swirl case, within the bend, the maximum velocity shifts toward the concave bend wall due to the influence of centrifugal forces. The shape of the velocity profiles remains unchanged even when is increased, consistently with previous findings. However, under pipe swirling conditions, the profiles look quite different, and again they remain almost the same regardless of the value. In contrast with the non-swirl case, the axial velocity in the upstream tangent and in the bend inlet is higher toward the concave bend wall. However, as a consequence of the tangential pipe wall velocity, the peak velocity within the bend and in the downstream tangent moves toward the convex bend wall.

Figure 11.

Experimentally measured mean axial flow velocity with no-swirl (left column) and with swirl (right column) at different stations within a 90° circular bend and along the upstream and downstream tangents. In both columns, the flow is at (a) = 10,000, (b) 15,000, (c) 20,000 and (d) 25,000. Figures taken from Chang and Lee [146].

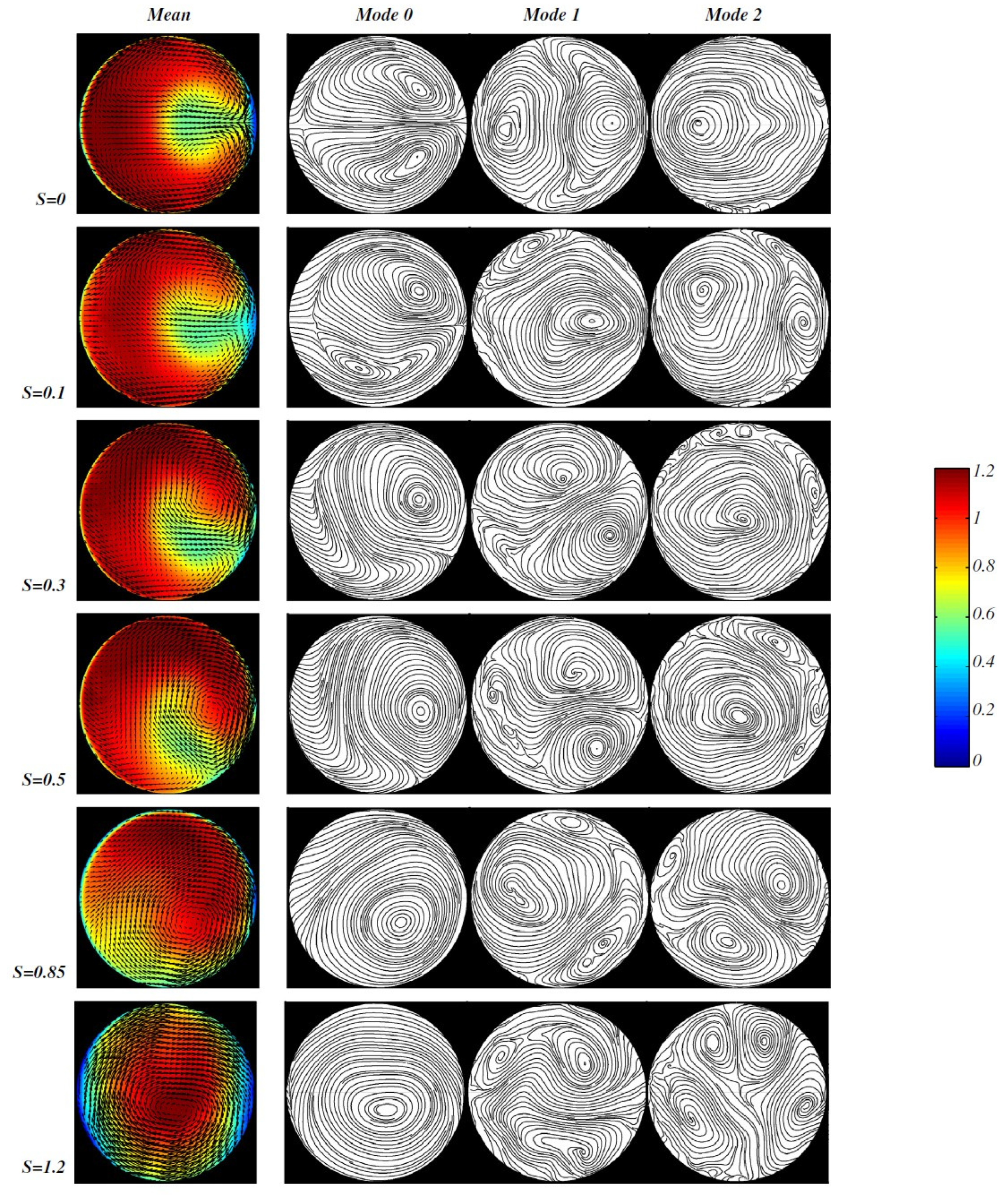

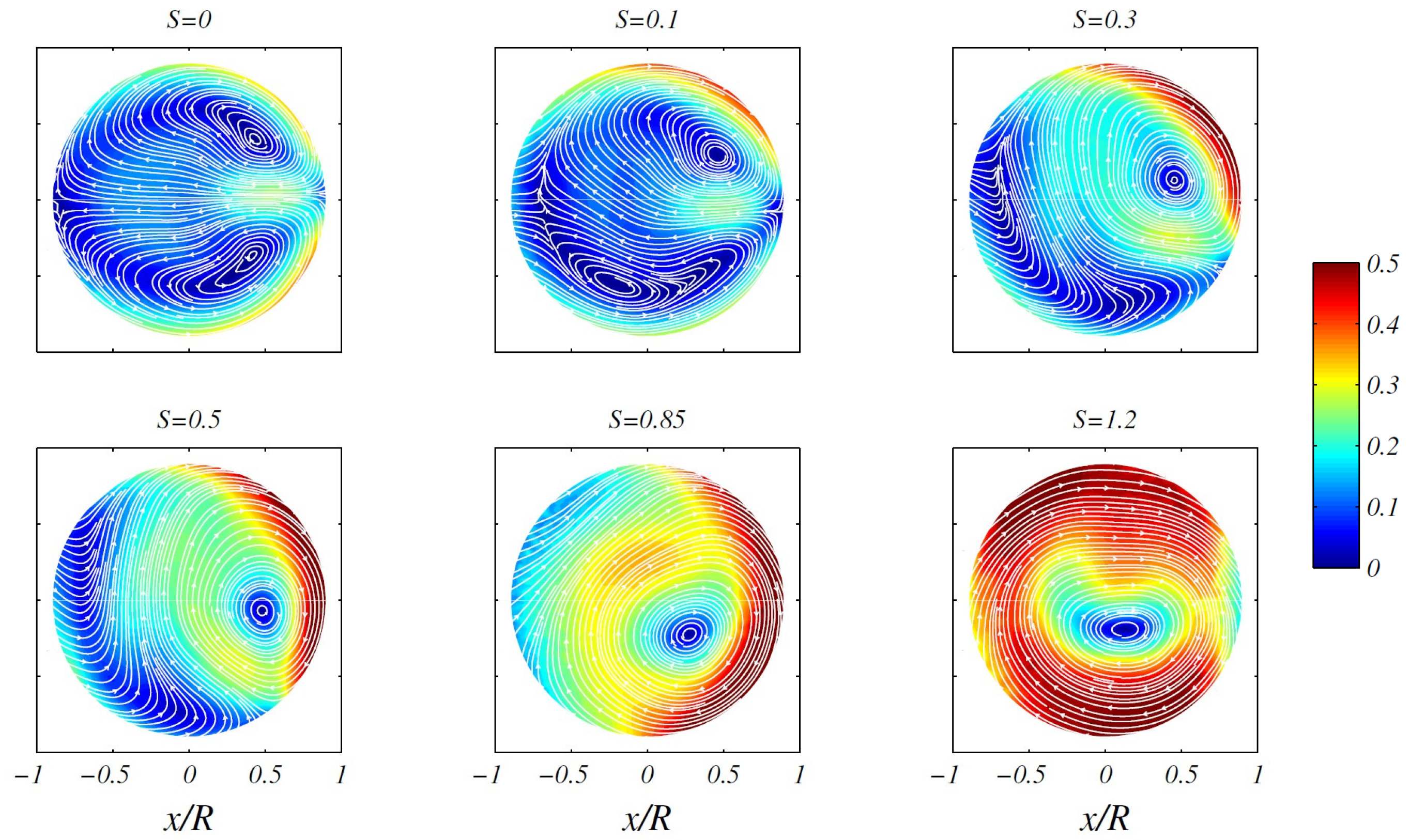

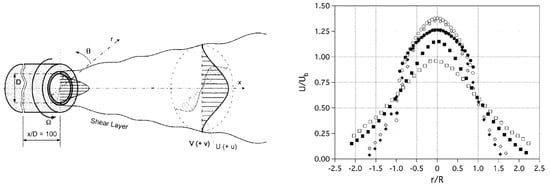

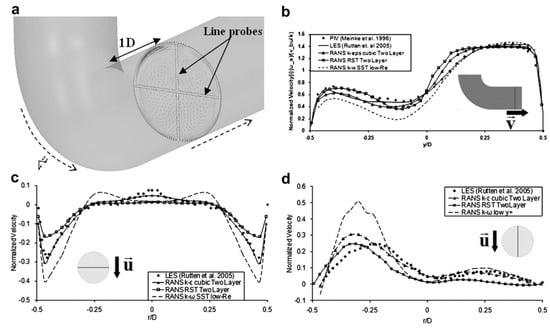

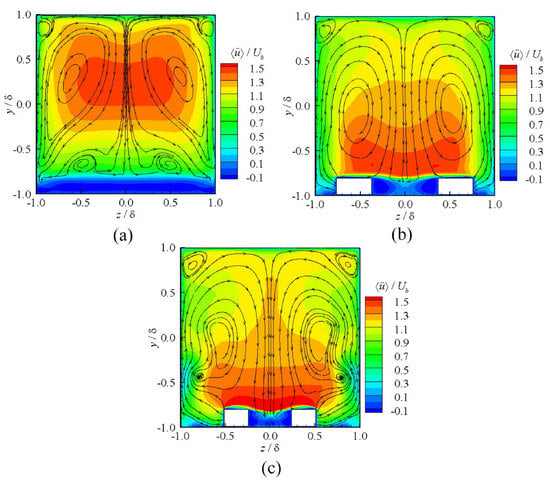

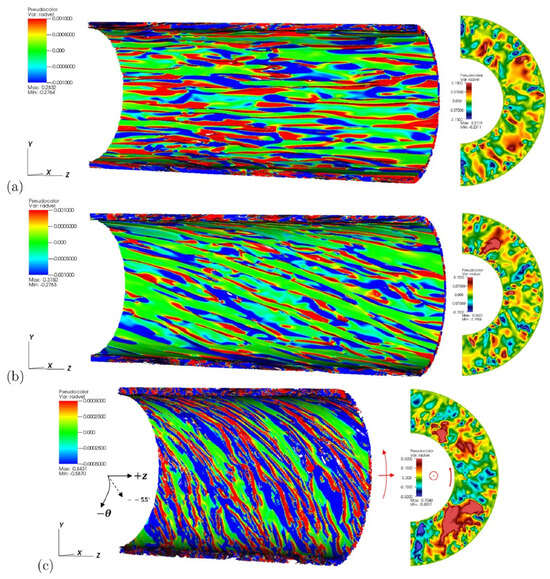

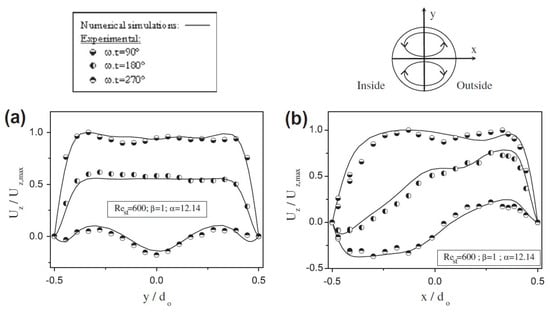

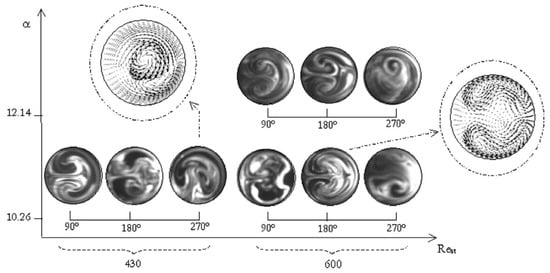

Experiments on flow downstream a pipe bend were later performed by Kalpakli and Örlü [147] using stereoscopic (TS) PIV for non-swirling and swirling flow conditions. The pipe facility consisted of a rotating straight upstream section connected to a still bend of curvature ratio and inner diameter mm. The flow medium consisted of air with = 14,000, 24,000 and 34,000. To acquire the three-dimensional flow field using TS-PIV, they used two high-speed C-MOS cameras, which were positioned at an angle of in backward–forward scattering. A laser light sheet of thickness mm was aligned at a distance 0.5 mm downstream of the bend exit, and raw images with a resolution of px were acquired from the measurements, which were then post-processed to obtain the velocity vectors. motion of the Dean vortices were additionally examined through snapshot proper orthogonal decomposition (POD), which is a powerful tool to ease visualization of the flow vorticity. They examined the turbulent flow structure at swirl numbers between and . The background color maps in the first column of Figure 12 shows the main velocity field scaled by the bulk velocity in a cross-sectional plane at downstream of the bend with a superimposed swirl from to , while the vectors visualize the secondary flow motion. The following three columns depict the zeroth, the first and the second POD spatial modes corresponding to each case. Mode zero represents the field averaged over time, while the other two modes represent the fluctuating part of the flow field. These plots illustrate the interplay between the swirling motion and the Dean vortical cells, as evidenced by the more energetic first and second POD modes.

Figure 12.

Cross-stream mean velocity field at downstream of the bend exit for increasing swirl numbers from to (first column). The next three columns depict the zeroth, first and second POD modes, which are shown as cross-sectional streamlines to ease visualization of the secondary flow. The color-scale bar and numbers on the right border indicate the velocity contrast scaled by the bulk velocity. Figure taken from Kalplaki and Örlü [147].

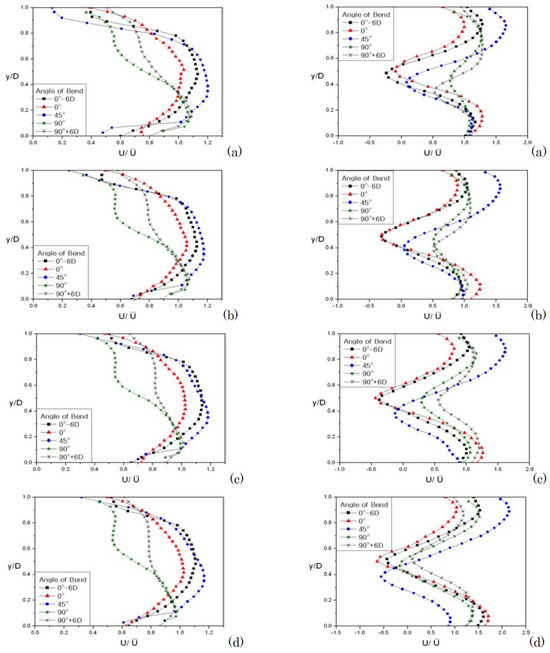

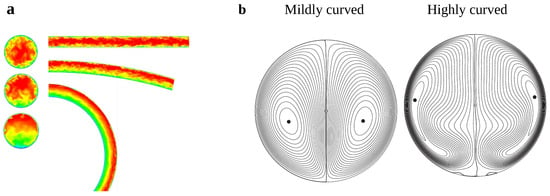

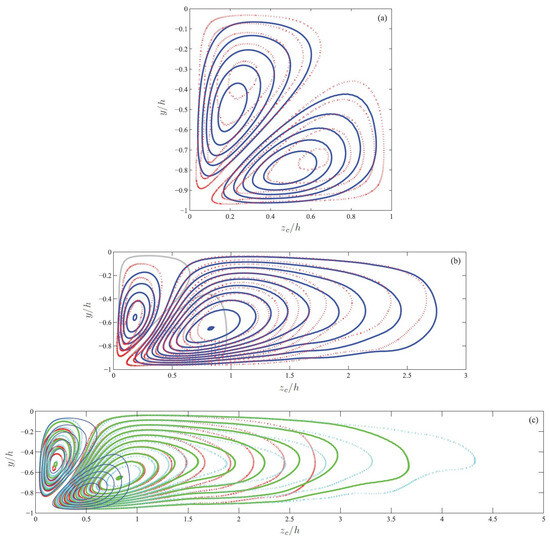

Using the same experimental facility, Kalpakli Vester et al. [148] performed HWA and time-resolved stereoscopic PIV measurements of swirling turbulent flow at varying swirling intensities at a distance downstream of a bend outlet. In this case, a Platinum wire of nominal diameter 5 micron and length 1 mm soldered on straight prongs was used to perform the HWA measurements. A micro-manometer was used to calibrate the hot-wire ex situ. The hot-wires were operated in constant temperature anemometry mode at an overheat resistance ratio of 80%, while converged statistics was obtained by setting the sampling frequency to 20 kHz. They found that both experimental techniques produce results for the mean axial flow velocity that are in fairly good agreement. However, the single hot-wire method was found to provide a satisfactory estimate of the axial velocity when , while the agreement between the hot-wire and PIV data improves when , i.e., for the highest swirl intensity. Figure 13 illustrates the effect of the swirl number on the flow at = 24,000 downstream of the pipe bend from the PIV data. At , two bean-like shaped symmetrical Dean vortices form around the pipe horizontal axis. In this case, the two symmetrical cells persist even when is decreased to 14,000 or increased to 34,000. However, a slight increase in the swirl intensity to is enough to perturb the flow and break the symmetry of the Dean vortical cells. Since the upper vortex rotates in the same direction as the superimposed pipe wall rotation, it grows and dominates the flow as S is increased. In fact, at , the lower vortex has already disappeared. At higher swirl intensities the single vortex spans the whole pipe cross-section. At , the vortex is slightly off-center and is on the lower side of the wall of the pipe. Therefore, by gradually increasing the swirl number, a transition from a pair of vortices to a single vortex is observed.

Figure 13.

Contour maps and sectional streamlines of the mean cross-stream flow velocity at a distance downstream of a 90° circular bend for = 24,000 and varying cross-stream swirl intensities between and . The color-scale bar and numbers on the right border indicate the cross-stream velocity contrast scaled by the bulk velocity. Figure taken from Kalpakli Vester et al. [148].

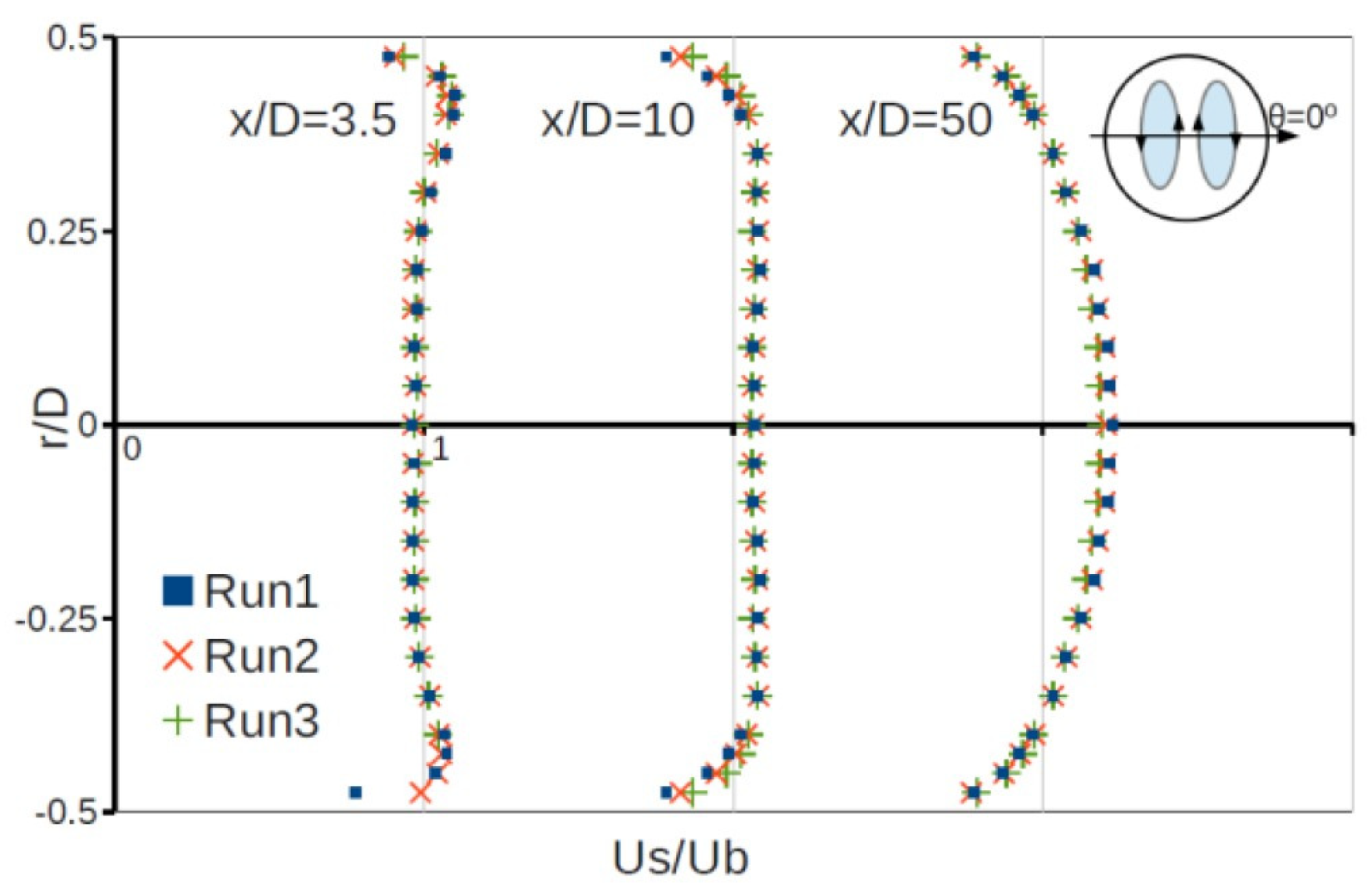

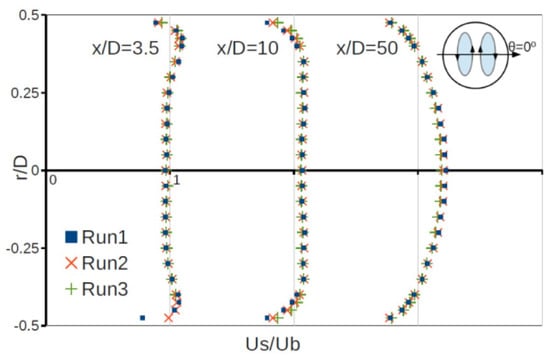

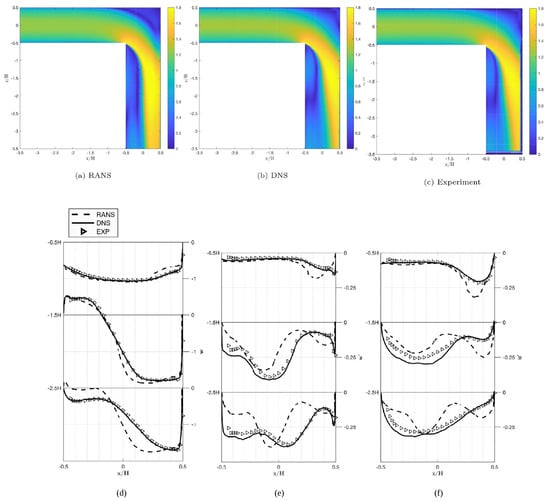

Laser-Doppler anemometry measurements of the no-swirl, secondary flow of water induced by a bend was also performed by Kim et al. [149]. Their experimental facility consists of upstream and downstream sections of acrylic pipes connected to a glass elbow. They tested three different flow conditions, corresponding to = 50,800 (their Run1), 101,600 (their Run2) and 203,200 (their Run3), and measured the mean axial flow velocity at distances of , and downstream of the bend exit. Figure 14 displays the measured axial velocity profiles in the downstream section. For the three values tried, the profiles are all coincident, implying that there exists a similarity in the flow structure at least for Reynolds numbers between 50,000 and 200,000. Sufficiently far from the bend exit, i.e., at , the flow looks parabolic. However, at = 203,200, the velocity profile appears to be slightly flatter compared to Run1 and Run2 working at lower values. Kim et al. [149] pointed out that this feature is consistent with previous experimental measurements of turbulent pipe flow by Zaragola and Smits [150]. Wang et al. [151] performed additional experiments on the flow of water through a elbow at = 44,805.

Figure 14.

Measured axial velocity profiles at three different stations downstream of a 90° bend for turbulent flow at = 50,800 (Run1), 101,600 (Run2) and 203,200 (Run3). Figure taken from Kim et al. [149] (Characteristics of secondary flow induced by 90-degree elbow in turbulent pipe flow, Kim, J.; Yadav, M.; Kim, S., Engineering Applications of Computational Fluid Mechanics, copyright © Department of Civil & Environmenal Engineering, The Hong Kong Polytechnic University, reprinted by permission of Informa UK Limited, trading Taylor & Francis Group, https://www.tandfonline.com (accessed on 16 February 2025) on behalf of Department of Civil & Environmental Engineering, The Hong Kong Polytechnic University).

Recently, Synowiec et al. [152] provided measurements of velocities and flow rates downstream of a bend using an ultrasonic flowmeter with clamp-on sensors for water flow at = 70,000 and 100,000. Axial velocity profiles and cross-stream velocity fields were measured at the exit plane of the bend and downstream of the bend at every 1 pipe diameter until 15 diameters are reached. They found that at a distance from the bend exit, it is possible to perform correct measurements with errors less than 2% of the flow stream value. At distances , the errors drop to about 1.3%. However, in all downstream stations, the level of error is larger for the = 100,000 flow. On the other hand, it is well known that curved pipes may represent a device for enhanced heat transfer with the outside because the emerging secondary flow can promote mixing in the main flow and break the thermal boundary layer. In particular, Guo et al. [153] performed recent experiments to investigate turbulent flow and heat transfer through a straight pipe and a pipe bend. A hot-air generator was used to produce high-temperature airflow. The streamwise velocity and temperature field on the pipe wall were measured using hot-wire anemometers and thermal couples, respectively. At the pipe inlet, the airflow is set to 402 K with a bulk velocity corresponding to 60,000. For flow in a straight pipe, they found that the cross-sectional mean temperature decreases monotonically in the streamwise direction, while in a sharp bend, the temperature first increases and then decreases to increase again.

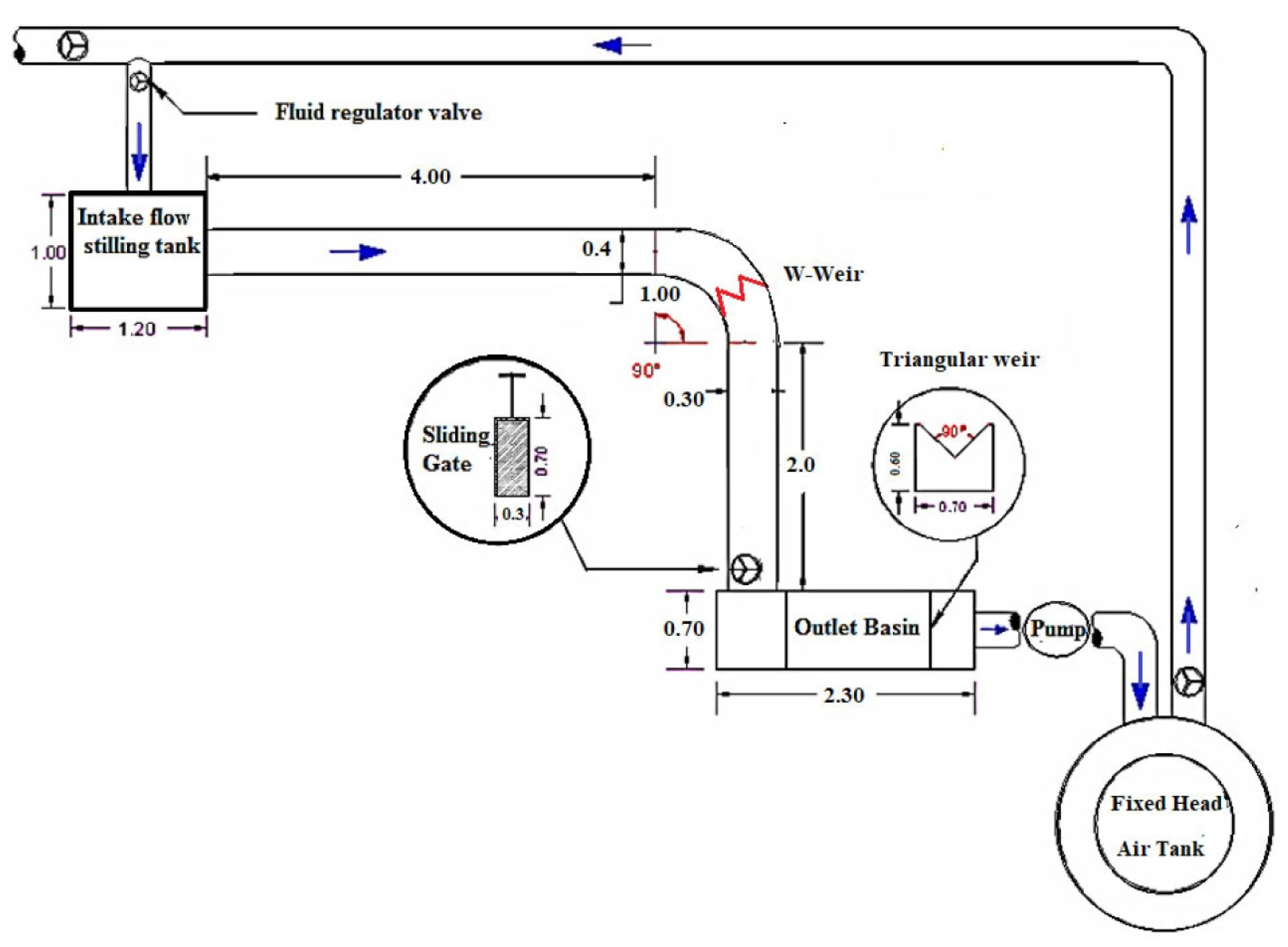

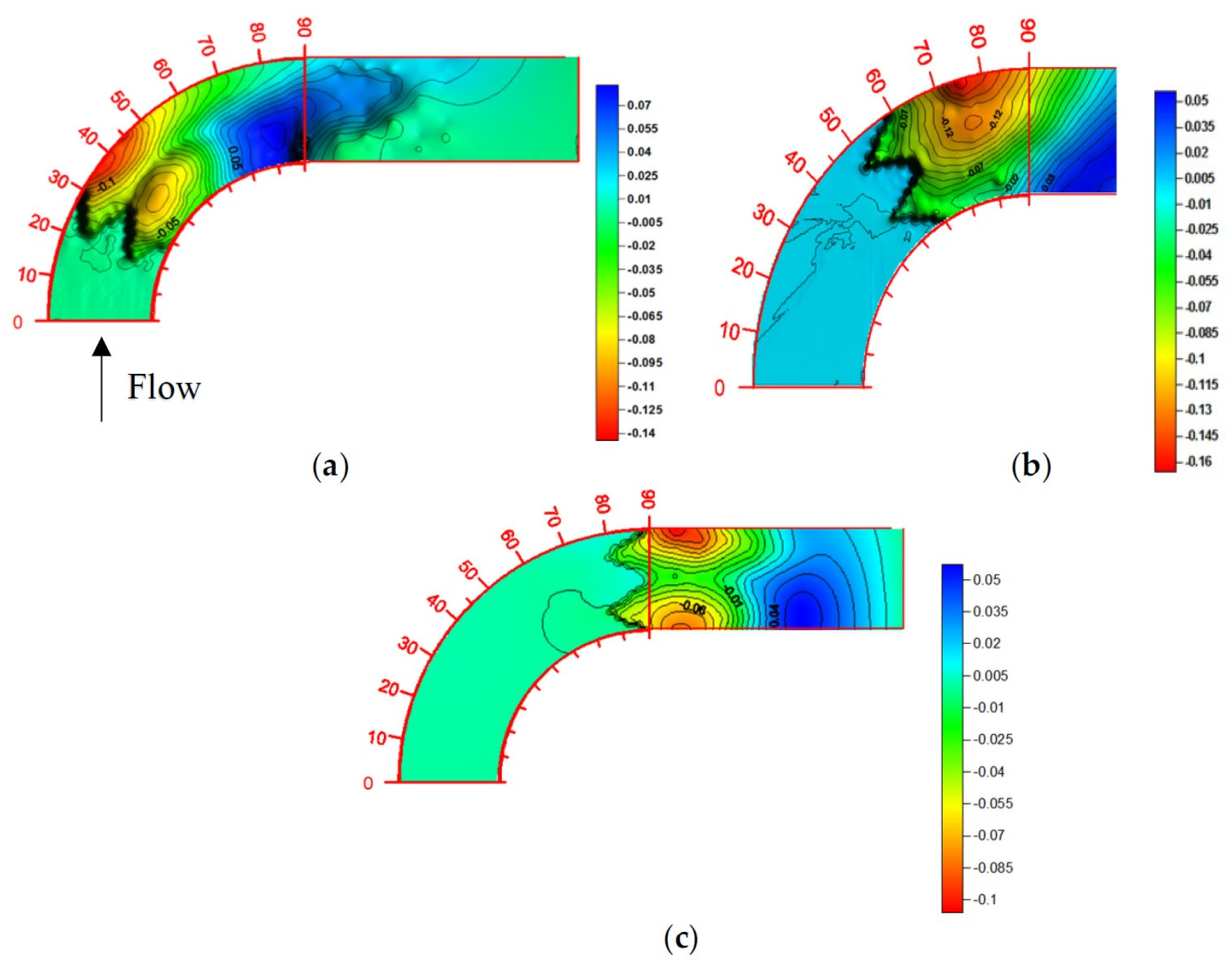

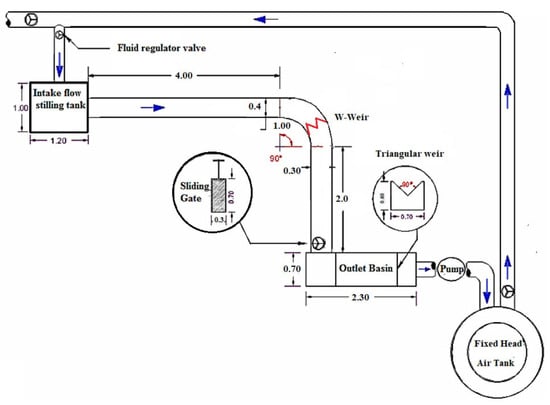

In a very recent paper, Atashi et al. [154] conducted an experimental investigation of the scour geometry downstream of a W-Weir in a bent channel. In particular, they measured the flow pattern and shear stress changes in different discharges and positions along the inner and outer bends. Figure 15 shows a schematic view of their laboratory flume and test bend. The W-Weir (in red) was constructed using a 1 mm thick galvanized sheet and was installed at angles , and within the bend. They considered two Froude numbers, and 0.28, where

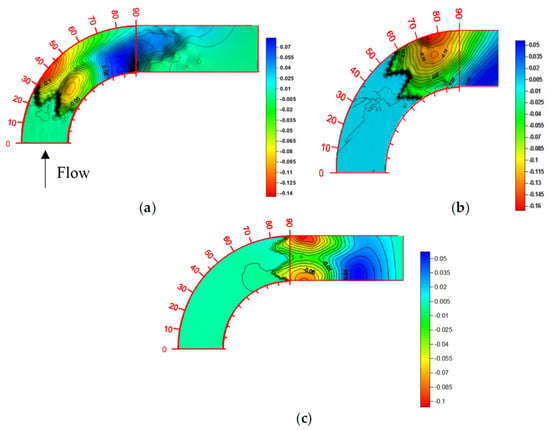

with v being the main flow velocity, g the acceleration of gravity and L a characteristic length scale. The experimental results showed that there was a lower depth of scour and a lower volume of sediment removal when the weir was placed at the bend exit (see Figure 16, where a topography of the bend is displayed for at three installation angles). These results corroborated previous findings by Bhuiyan et al. [155], who observed that the best place to install the W-Weir was just immediately downstream of the bend, where the flow pattern exhibits severe turbulence. Furthermore, compared to installation of the W-Weir at and , erosion on the outer bend wall was reduced by 39% and 37%, respectively, when the W-Weir was placed at .

Figure 15.

Schematic view of the laboratory flume and test bend used by Atashi et al. [154] for their measurements of the flow pattern and erosion in a sharp bend around a W-Weir. All numbers express dimensions in meters. The arrows indicate the flow direction. Figure taken from Atashi et al. [154].

Figure 16.

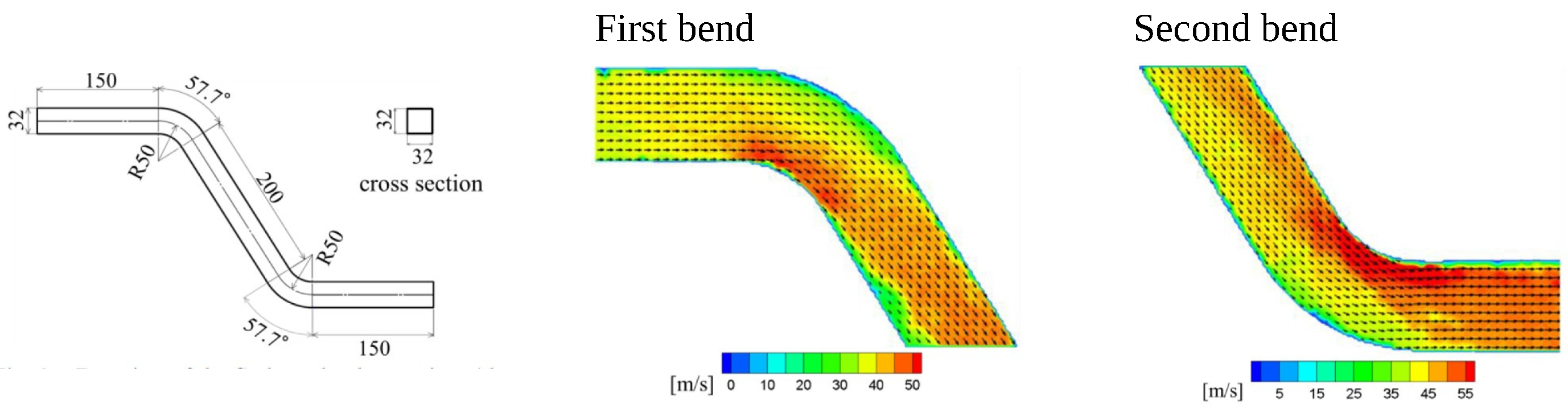

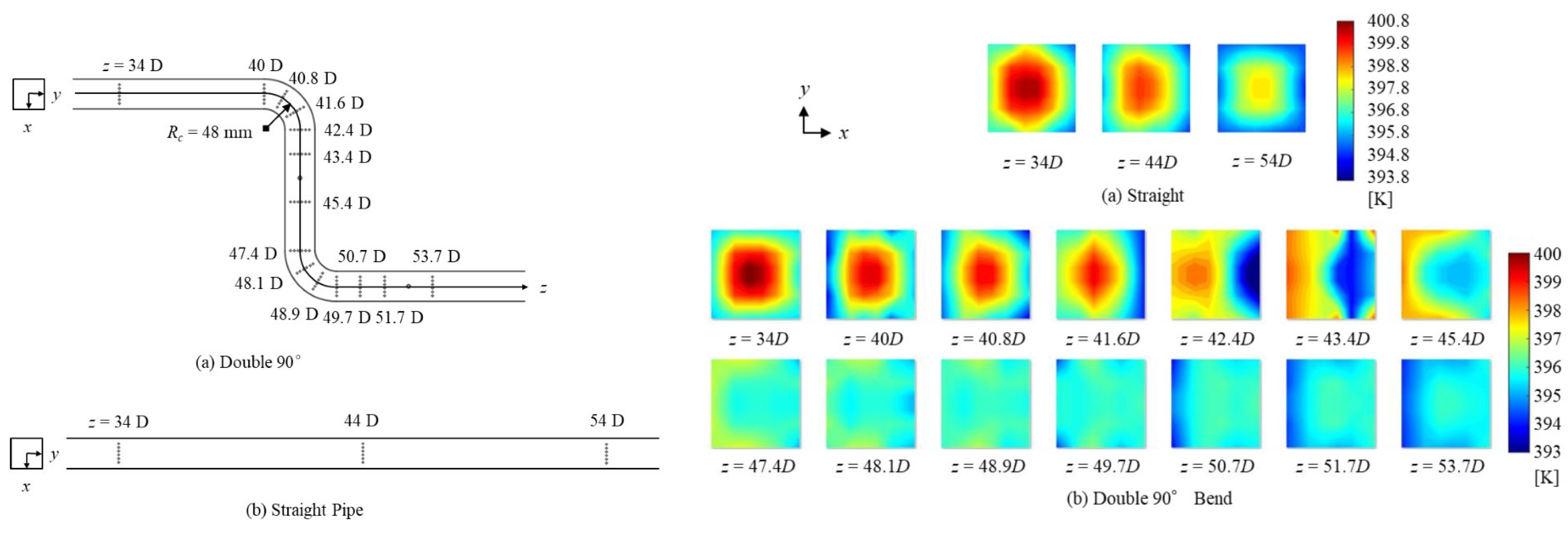

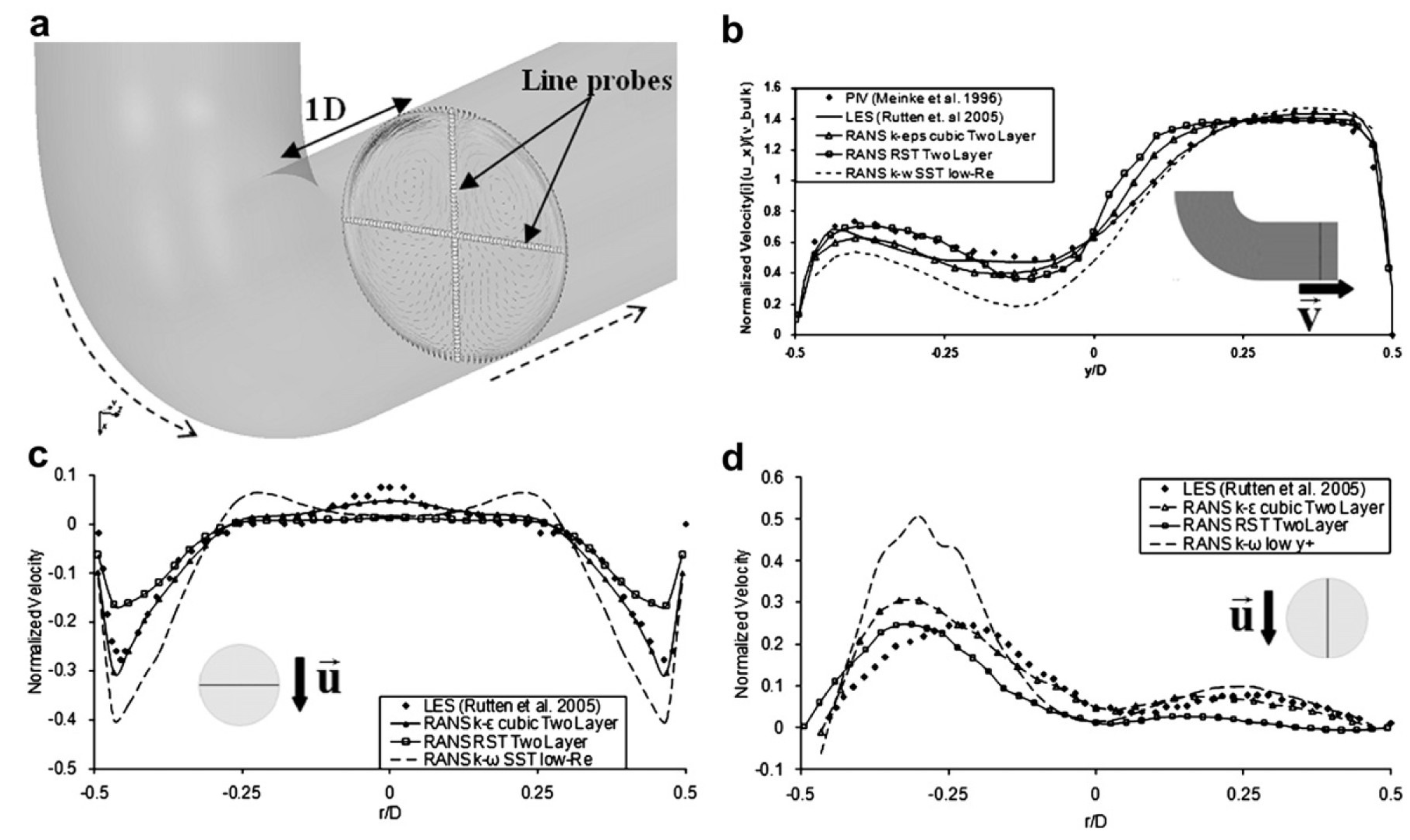

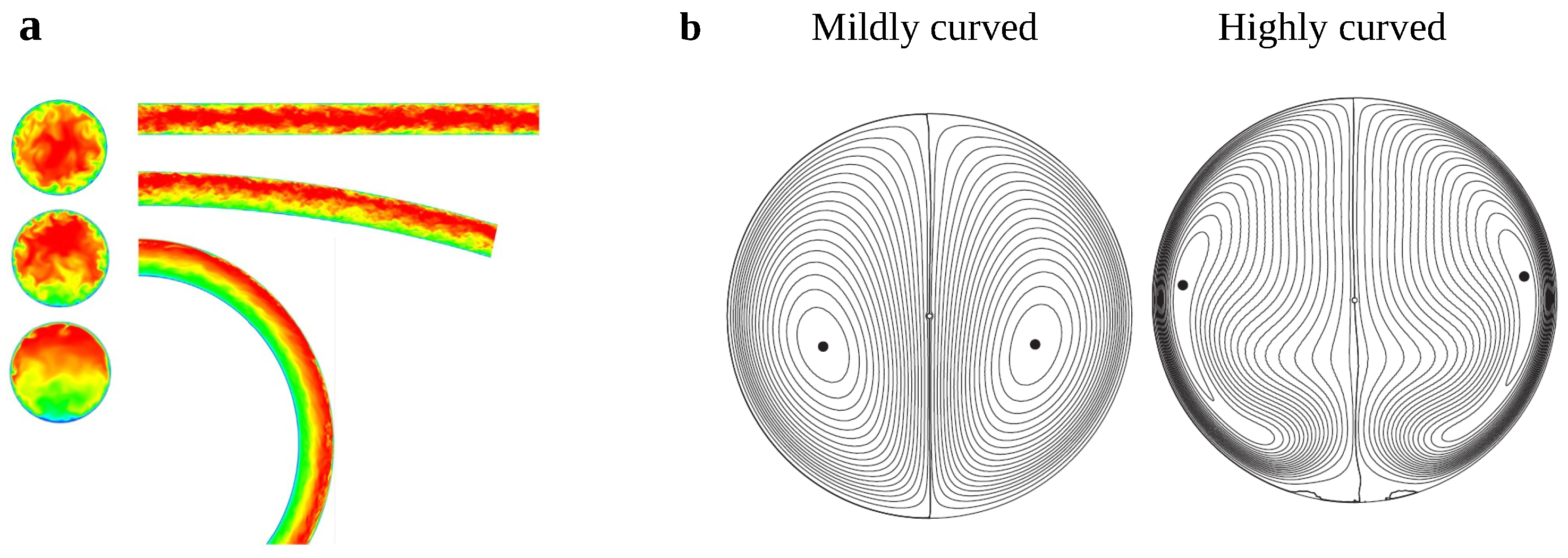

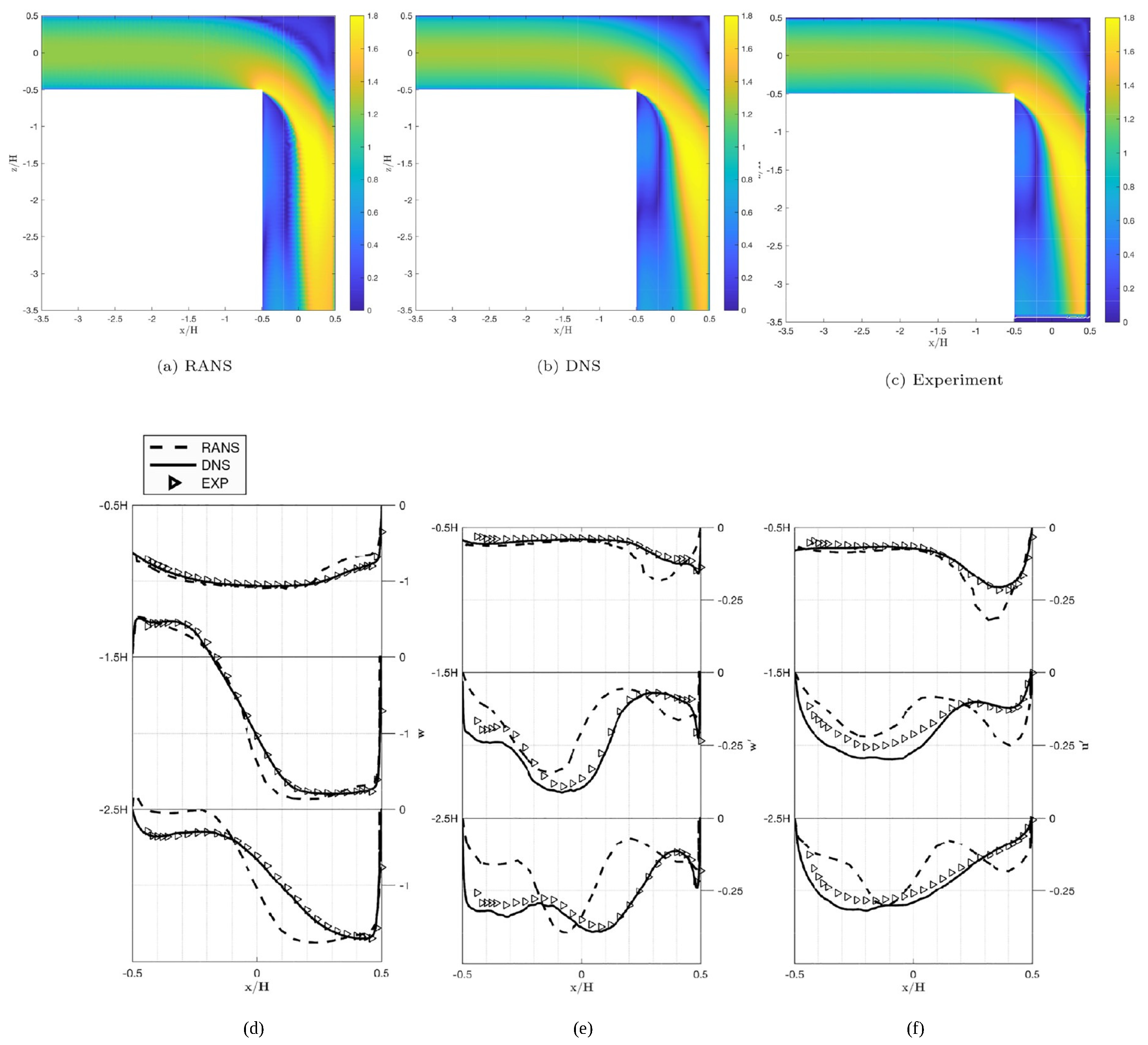

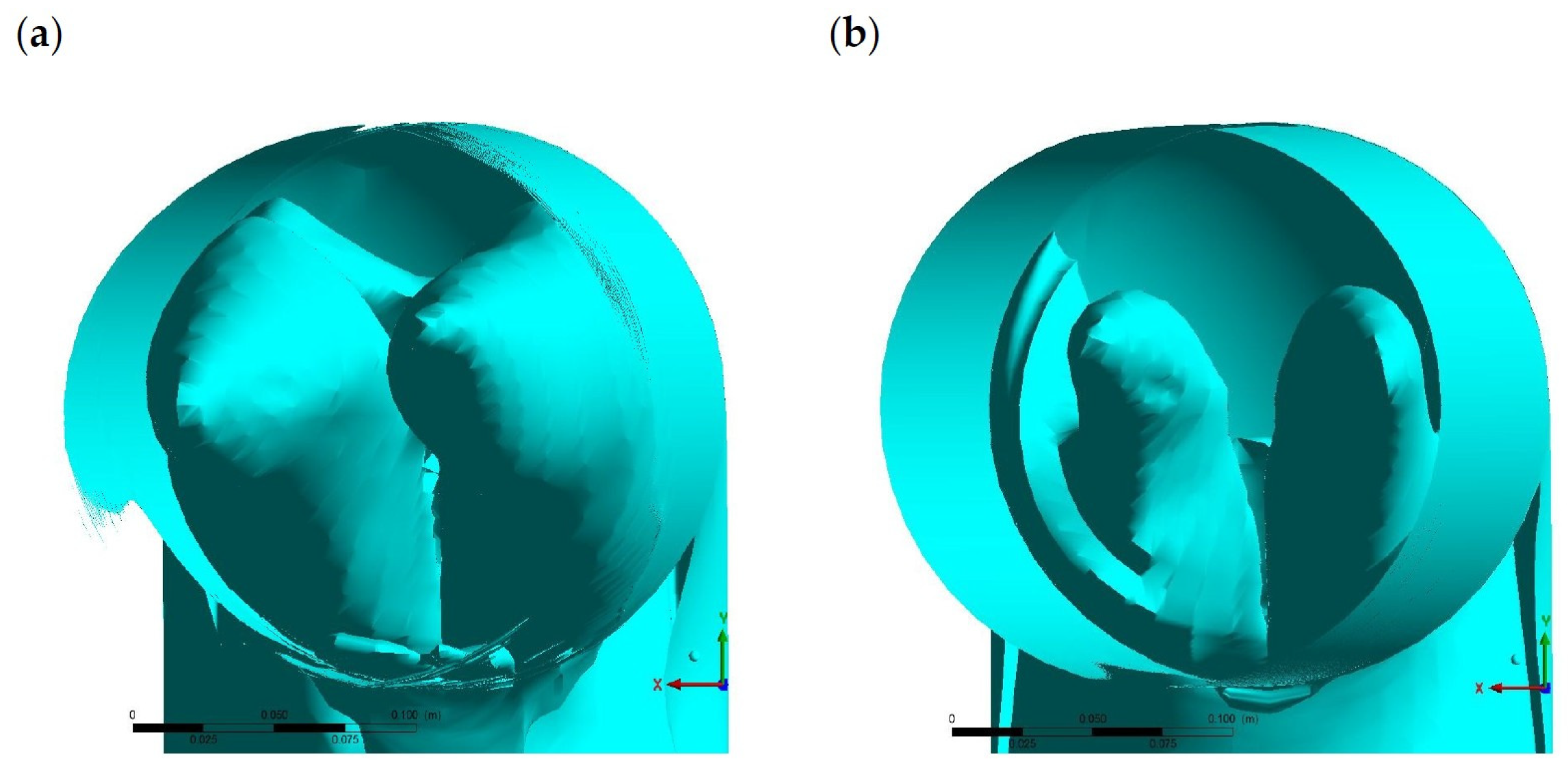

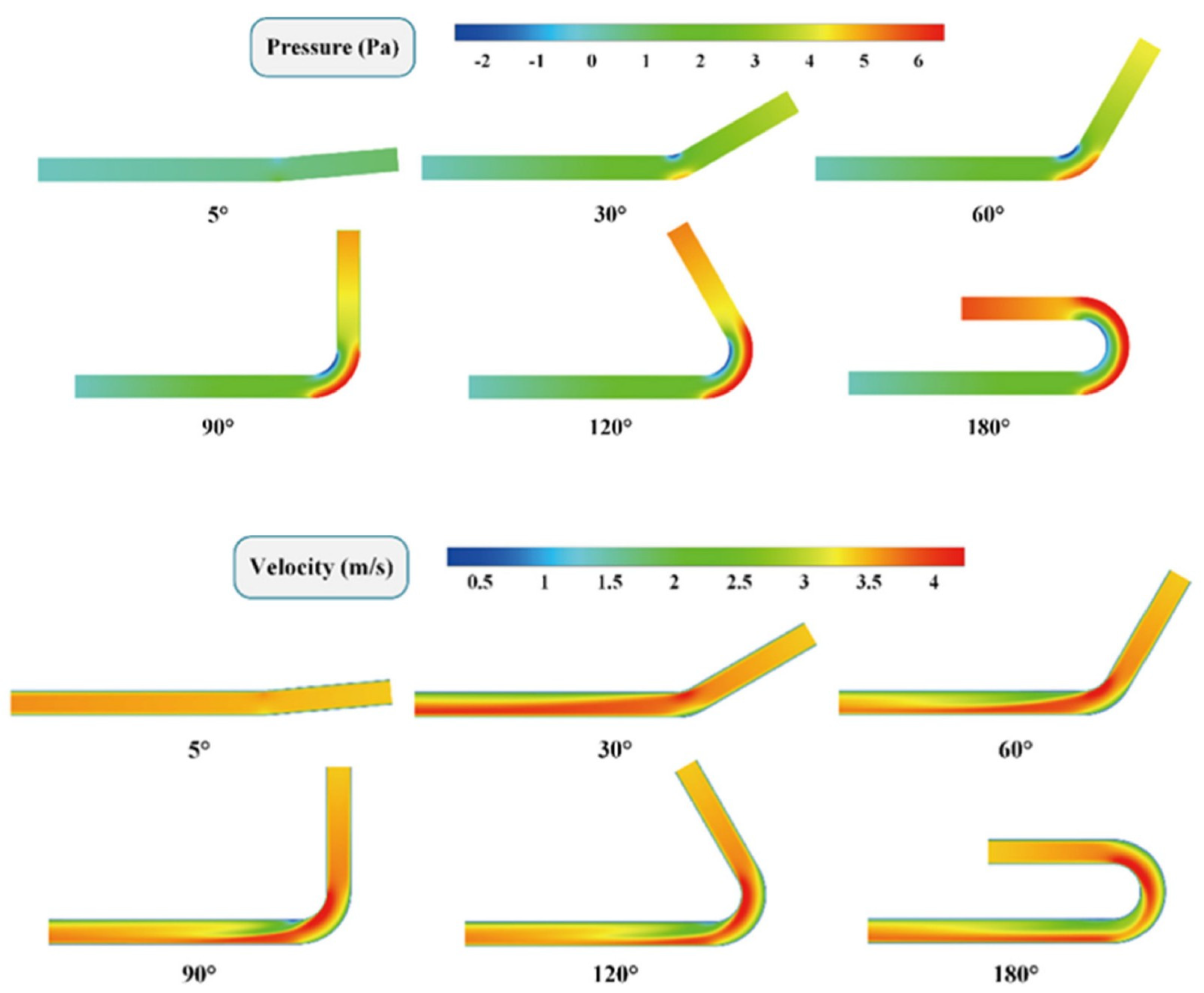

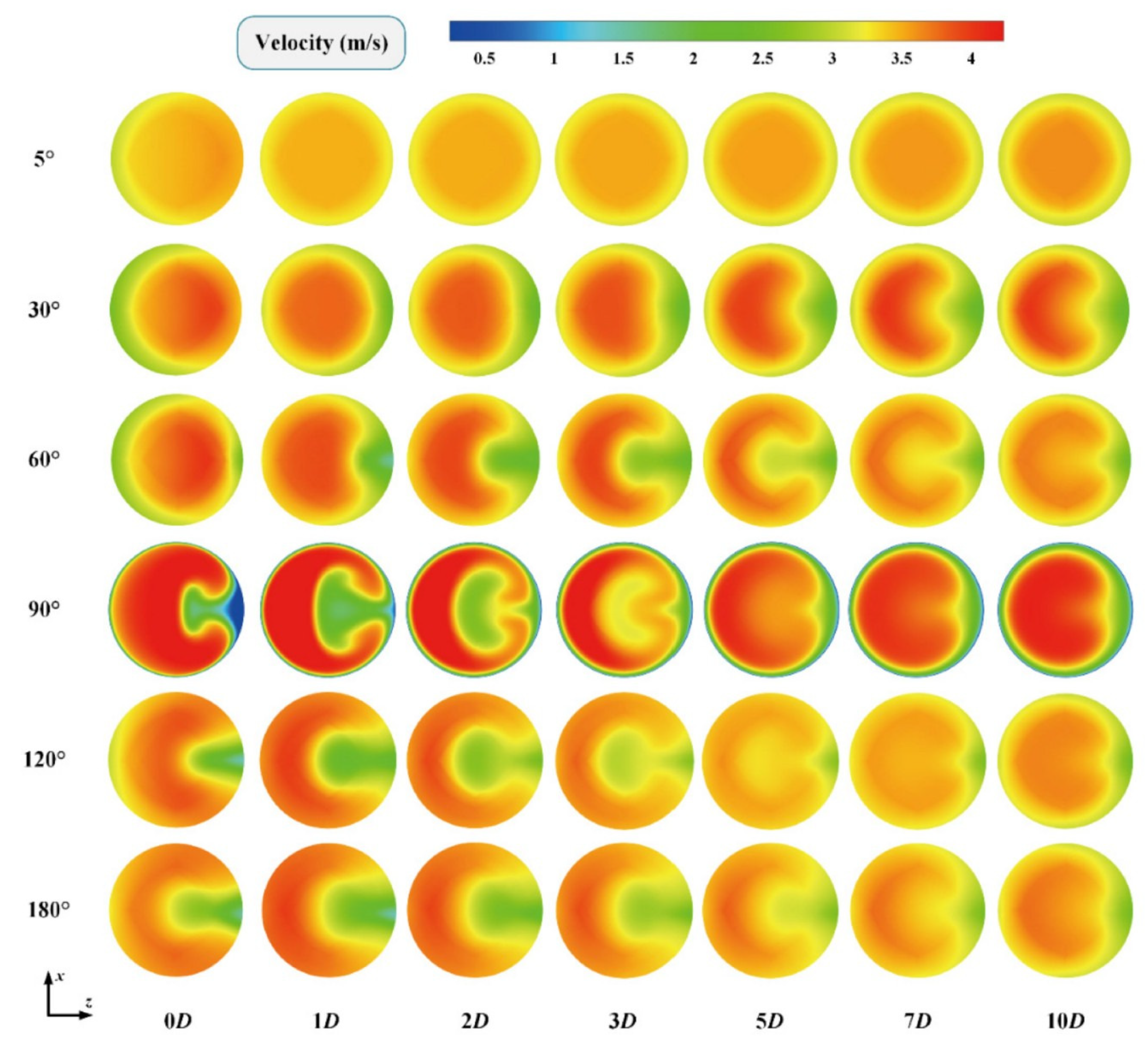

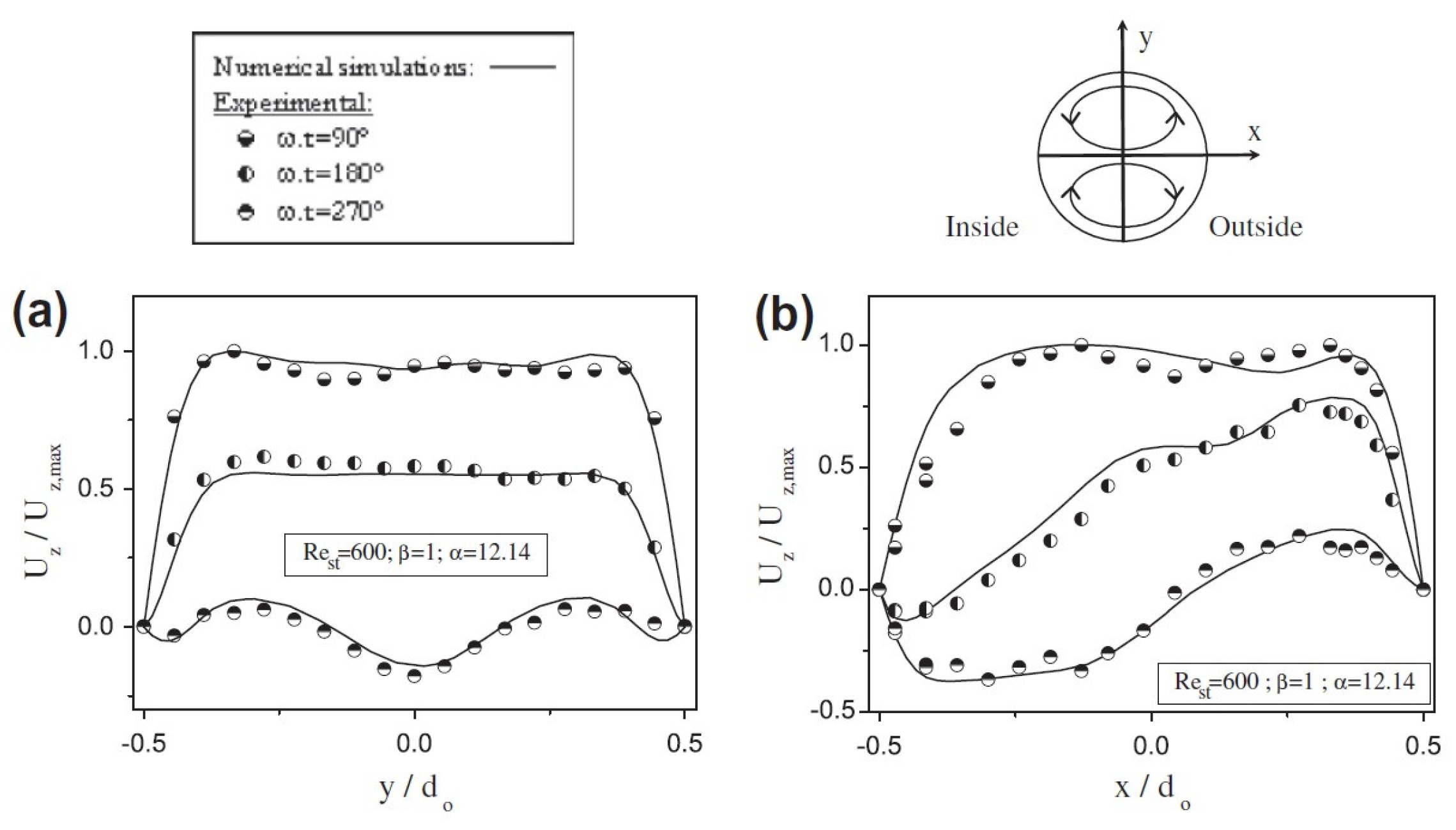

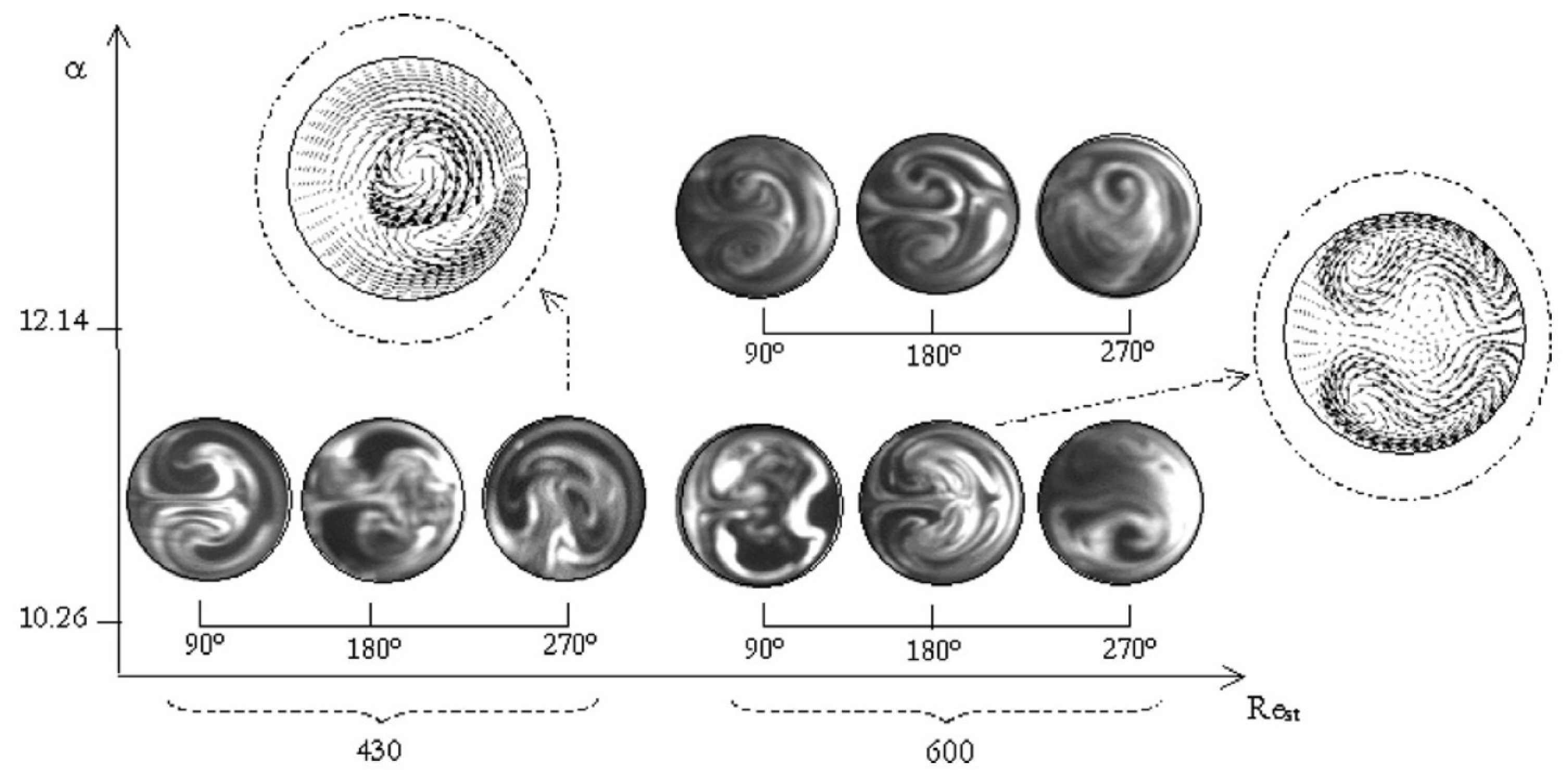

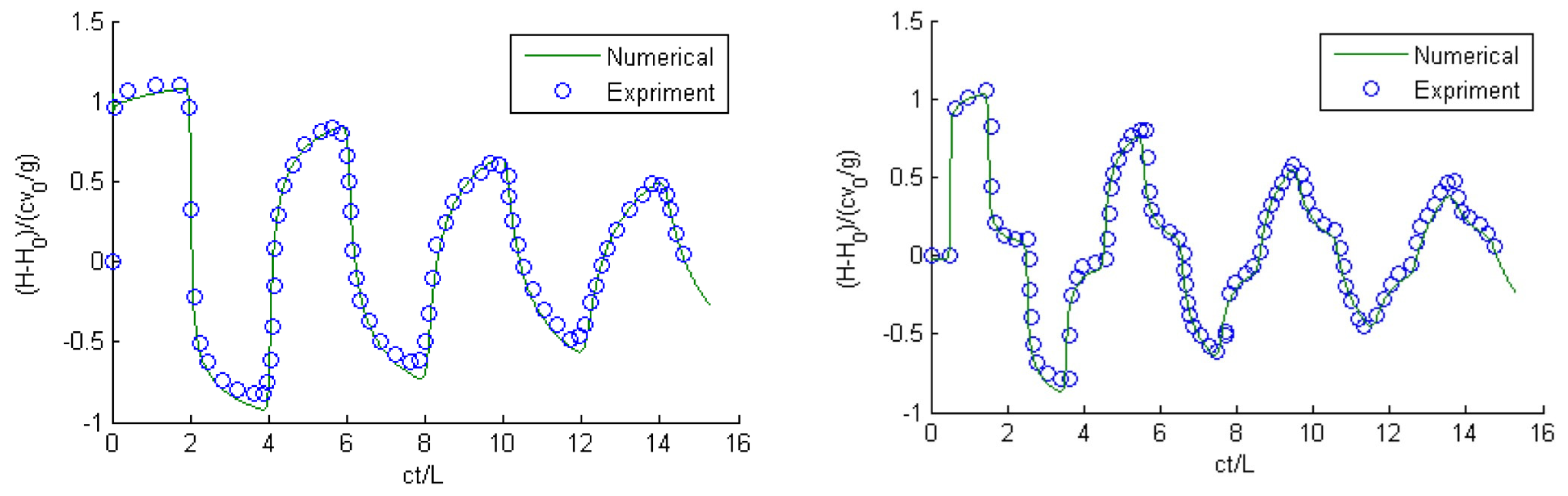

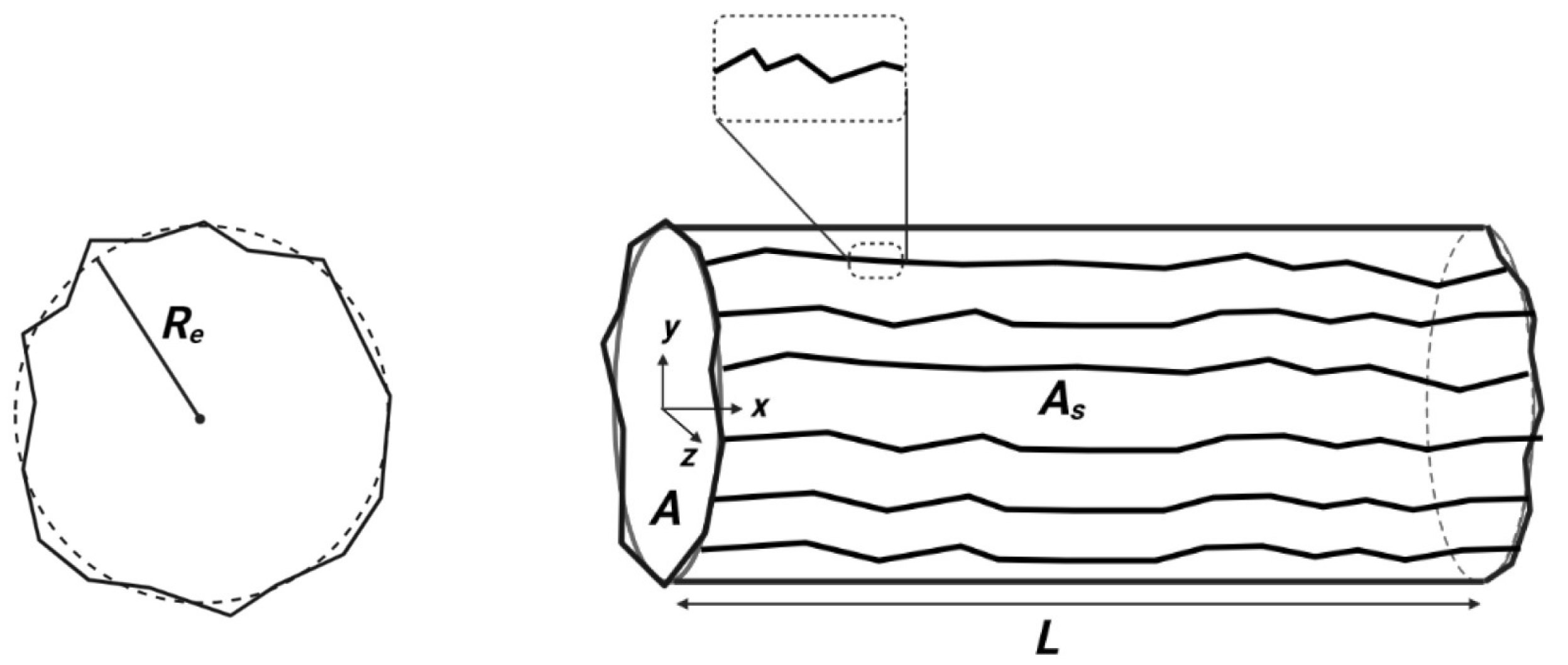

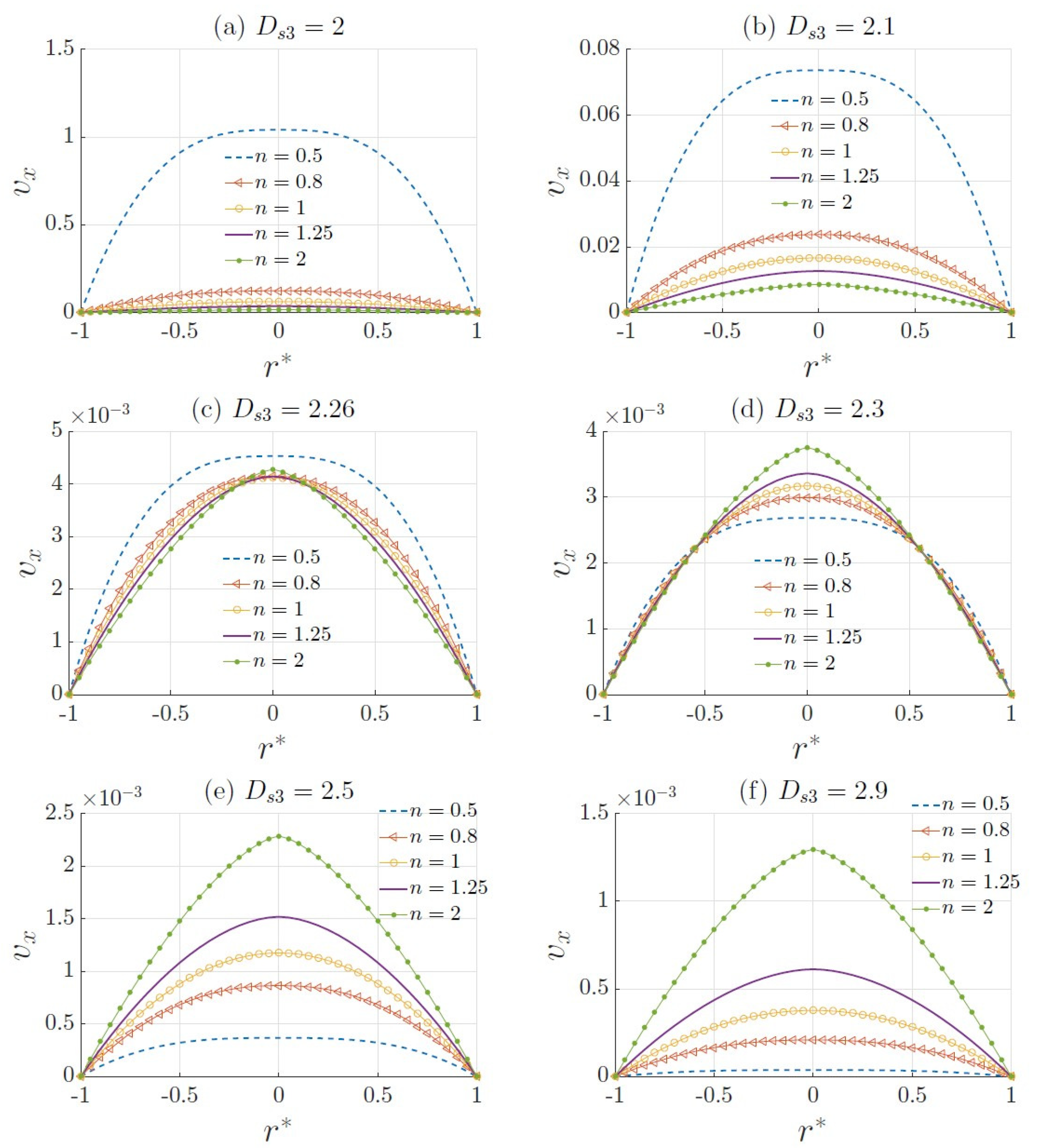

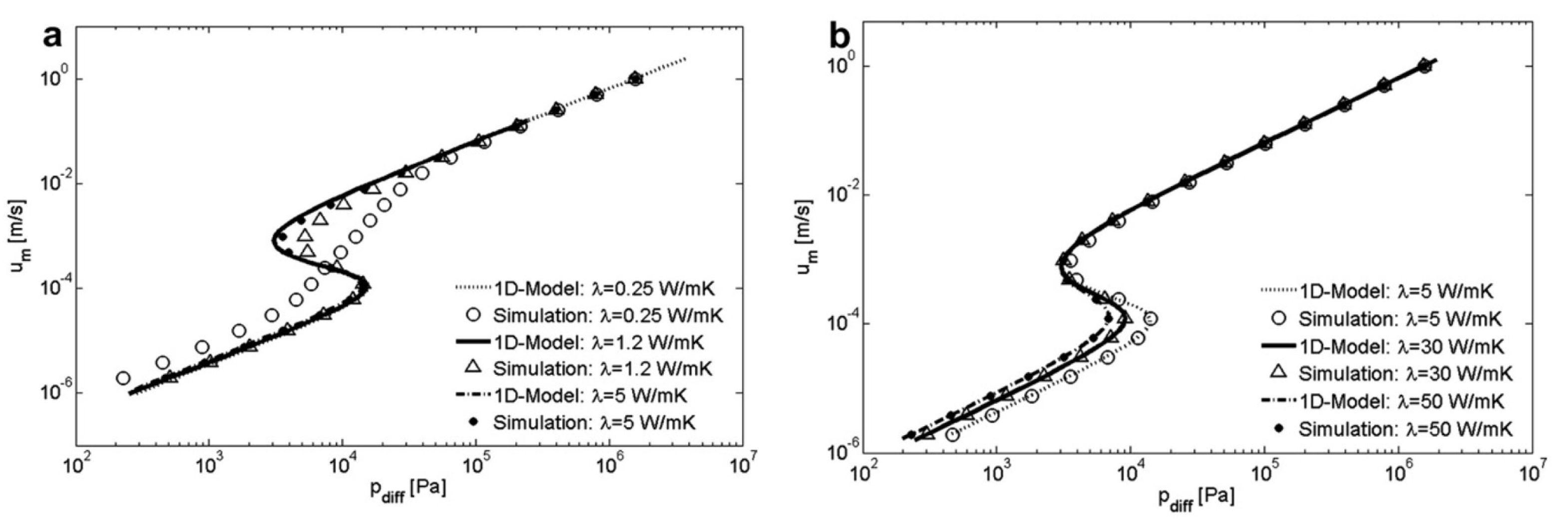

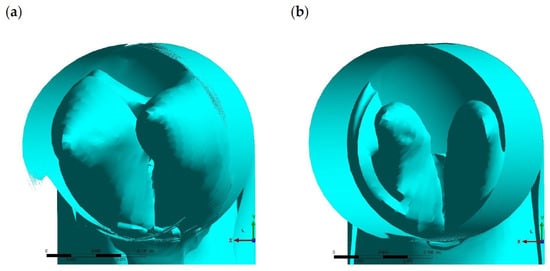

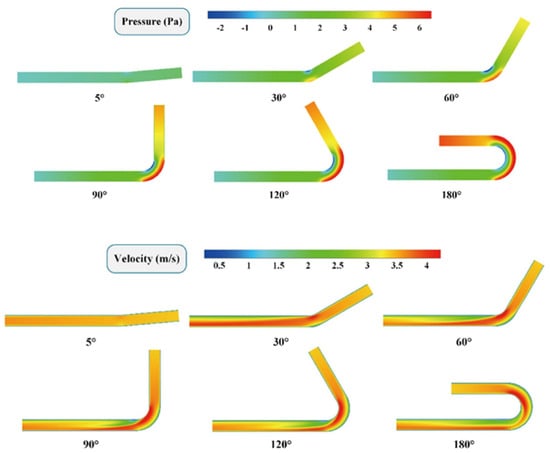

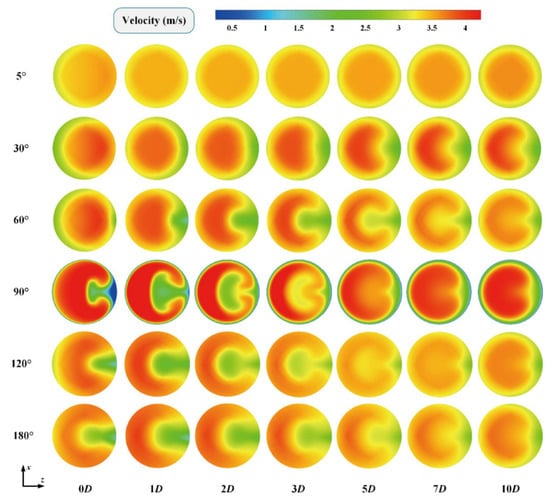

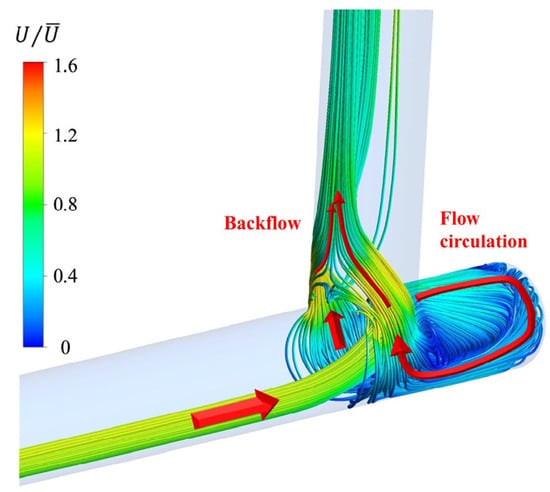

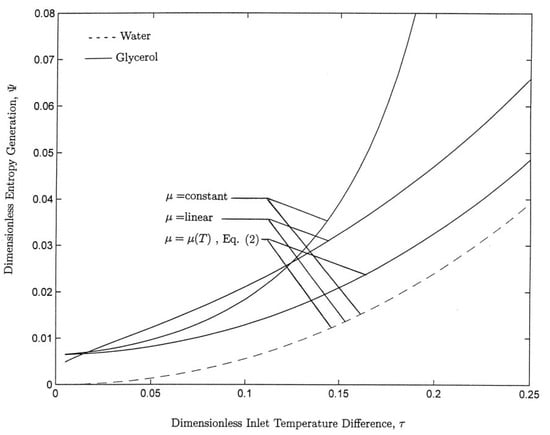

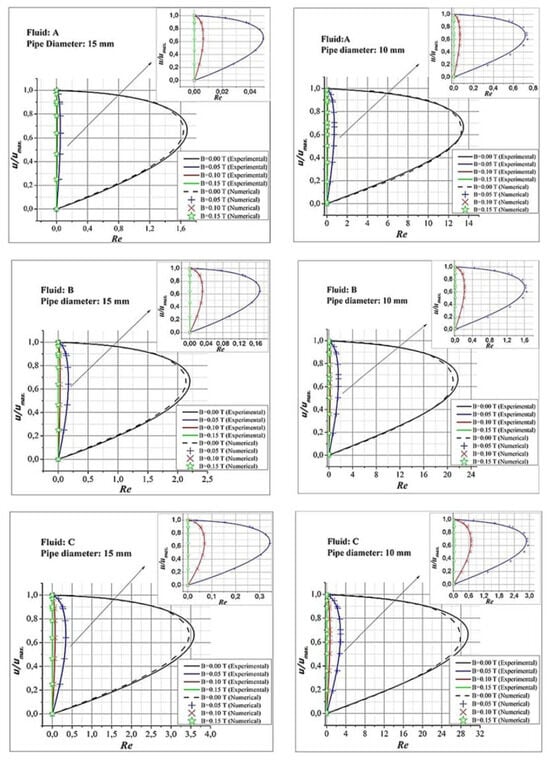

Contour maps of the scour depth for and W-Weir installation at (a) 30°, (b) and (c) 90° within the test bend. All numbers on the outer bend side are in meters. Figure taken from Atashi et al. [154].