Hysteresis-Induced Onset and Progressive Decay of Periodic and Metastable Sheet Cavitation in a Chamfered Circular Orifice

Abstract

1. Introduction

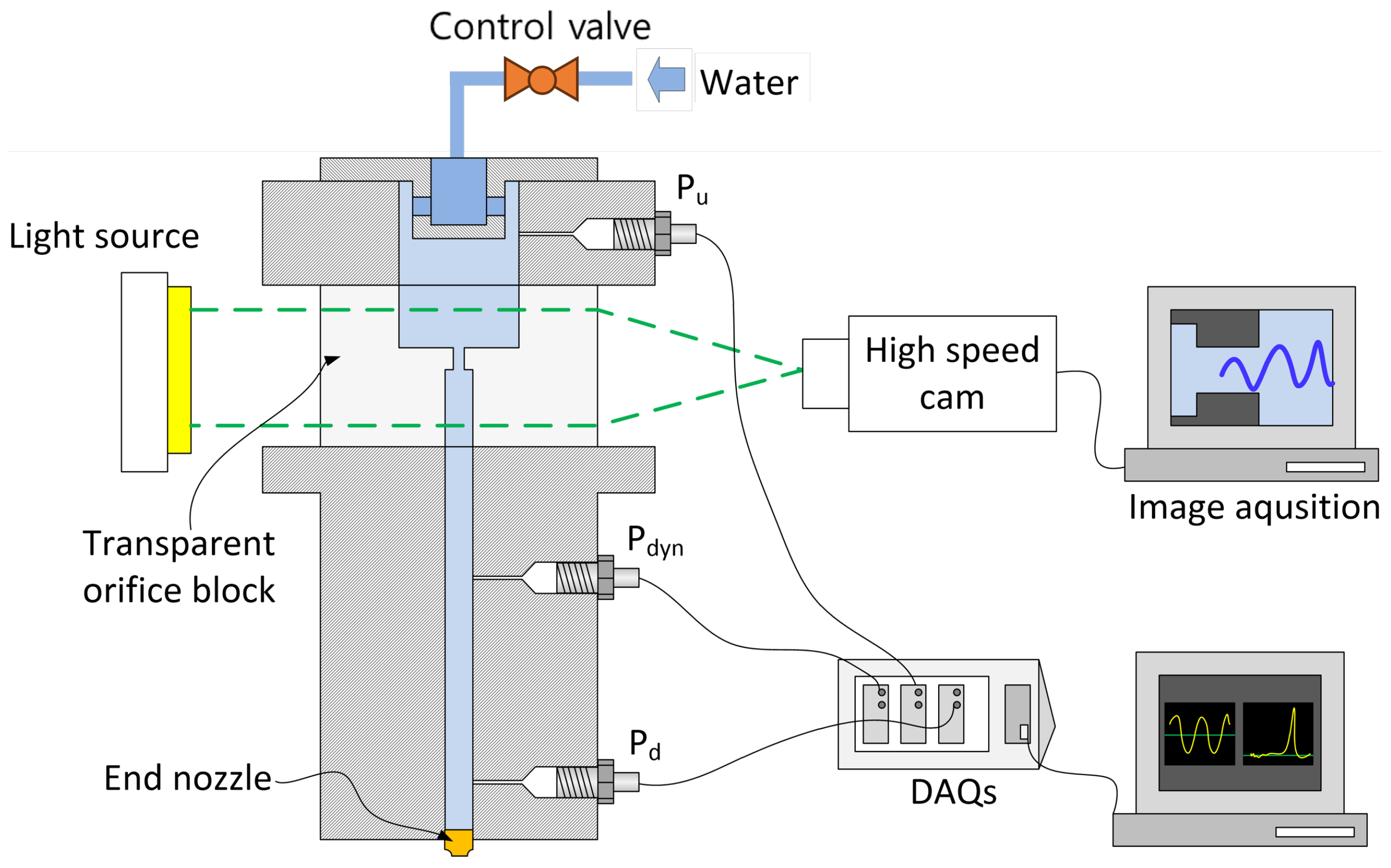

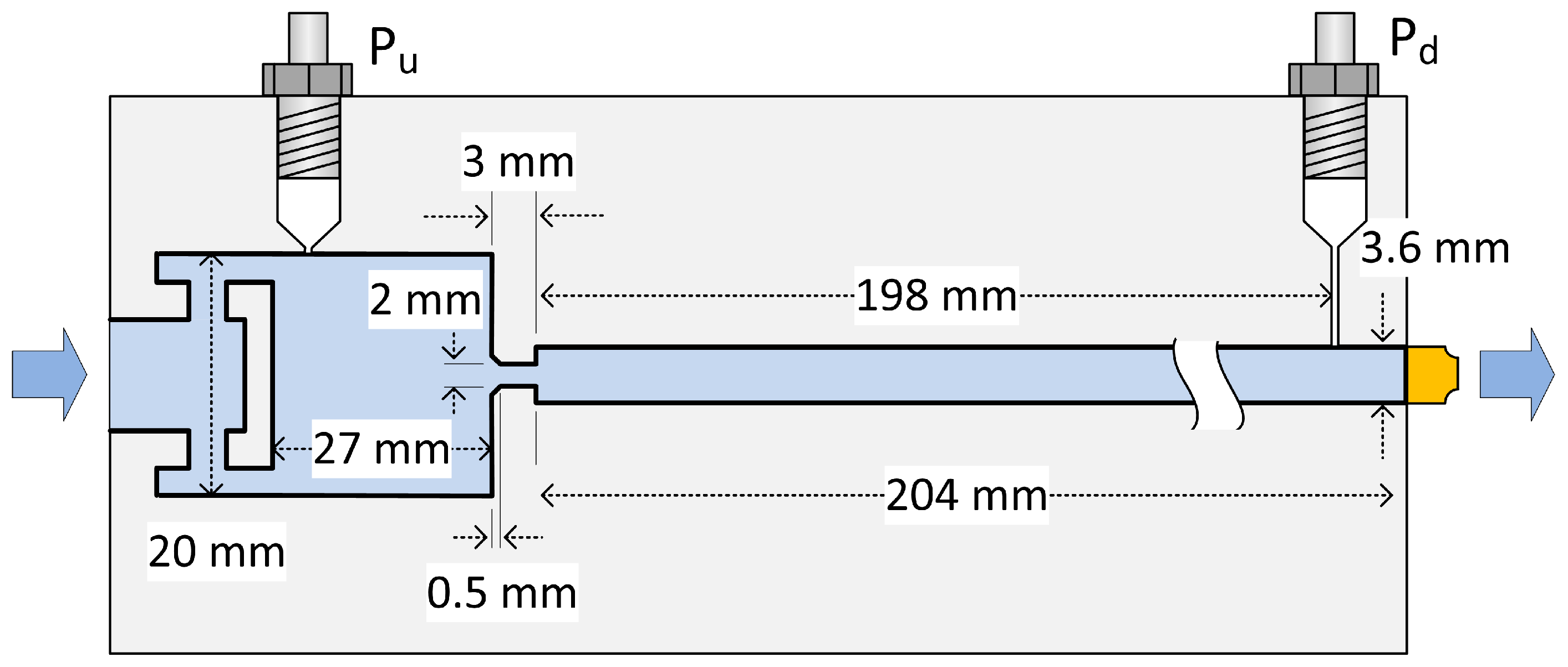

2. Experimental Setup and Methods

2.1. Experimental Setup

2.2. Experimental Conditions

3. Results and Discussion

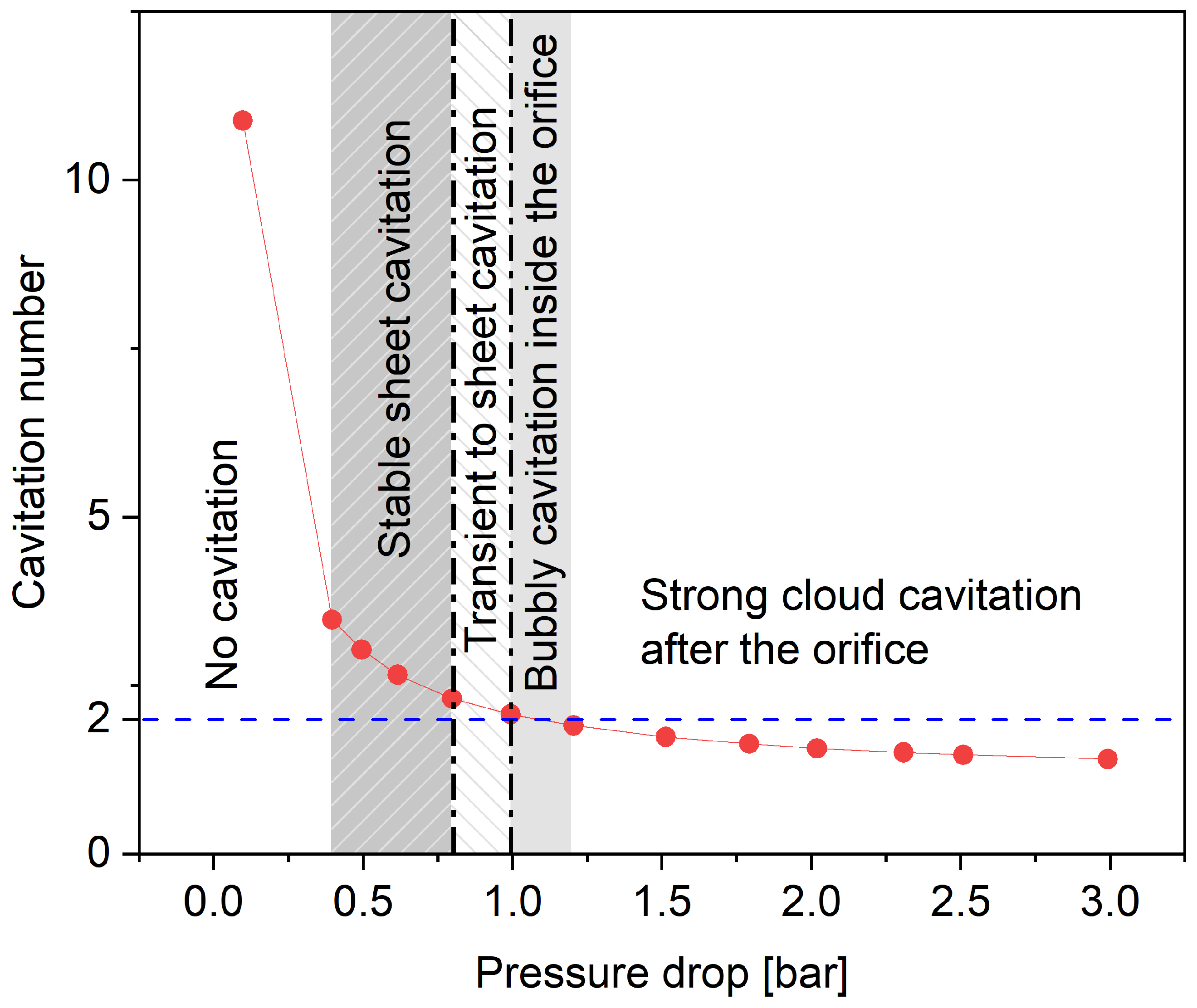

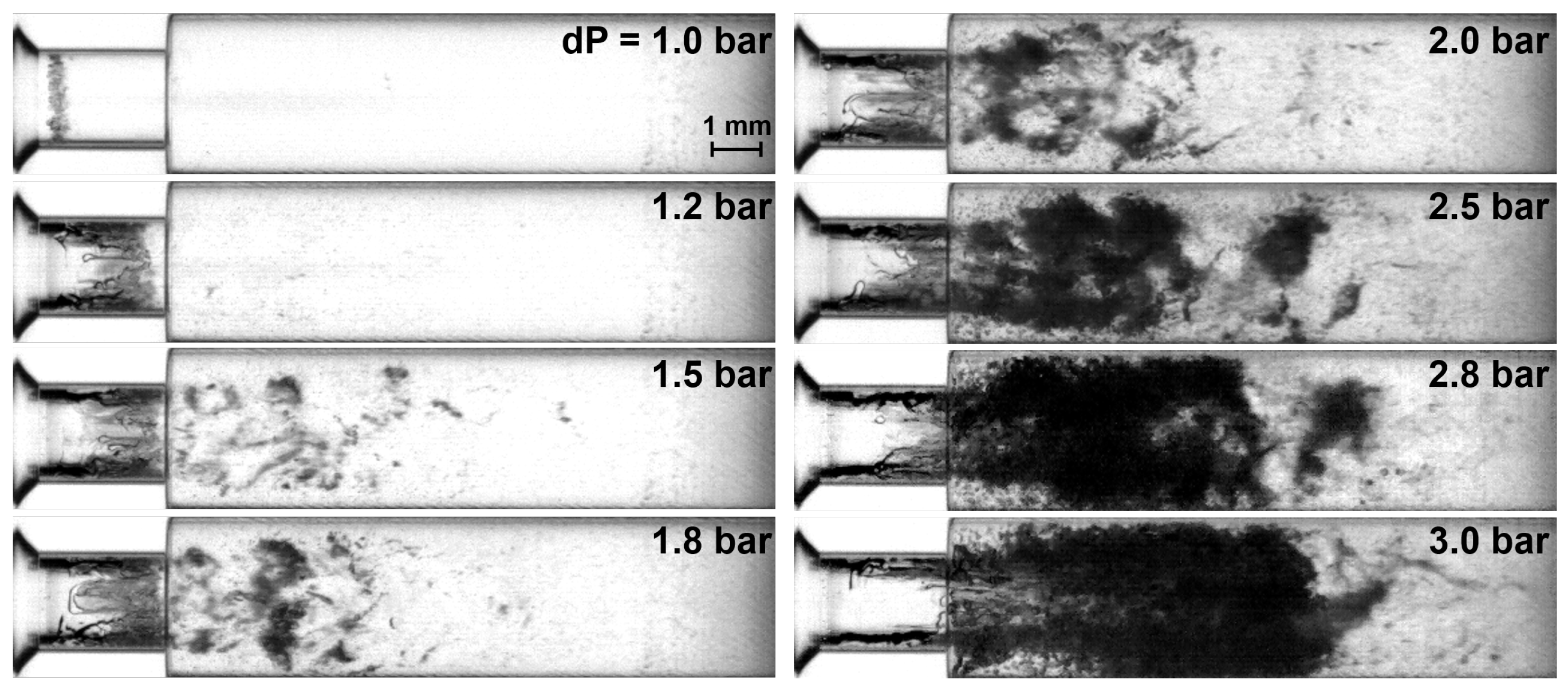

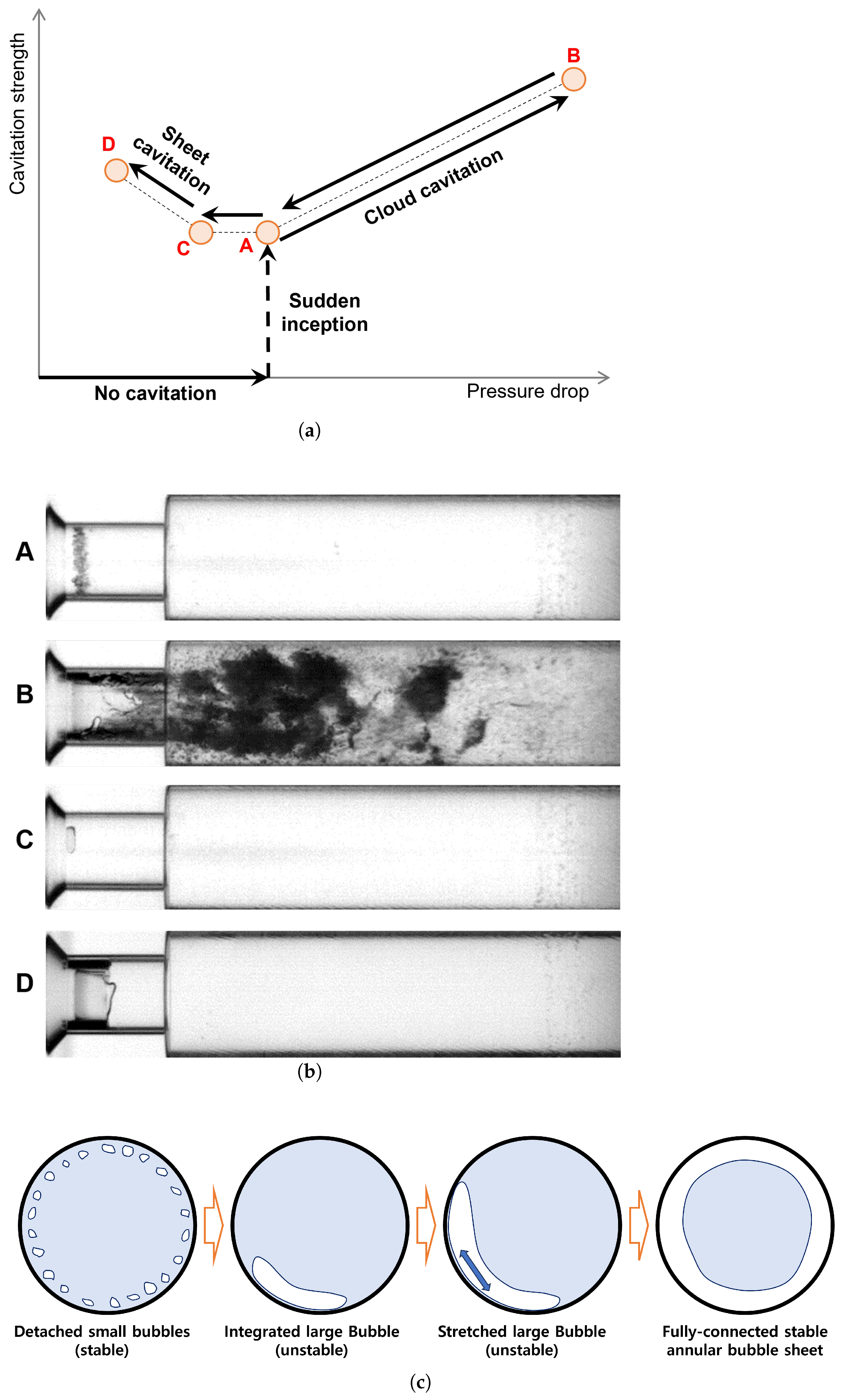

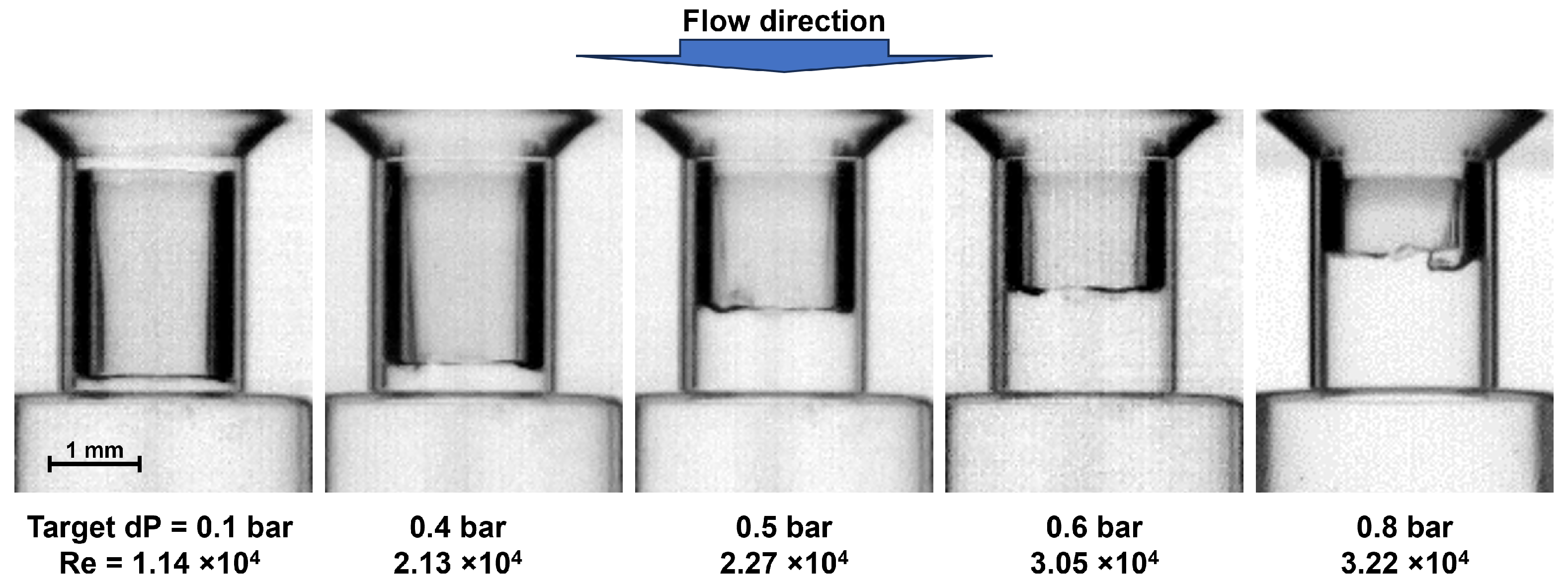

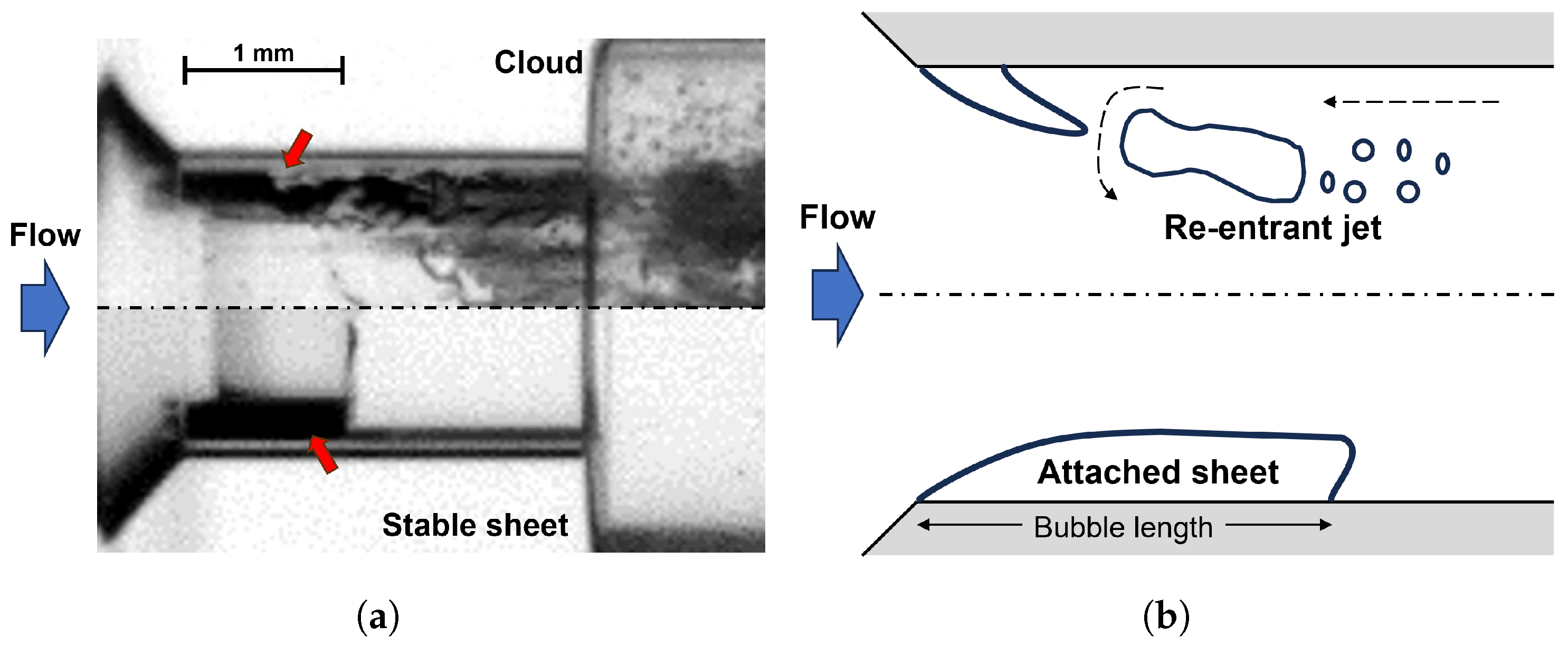

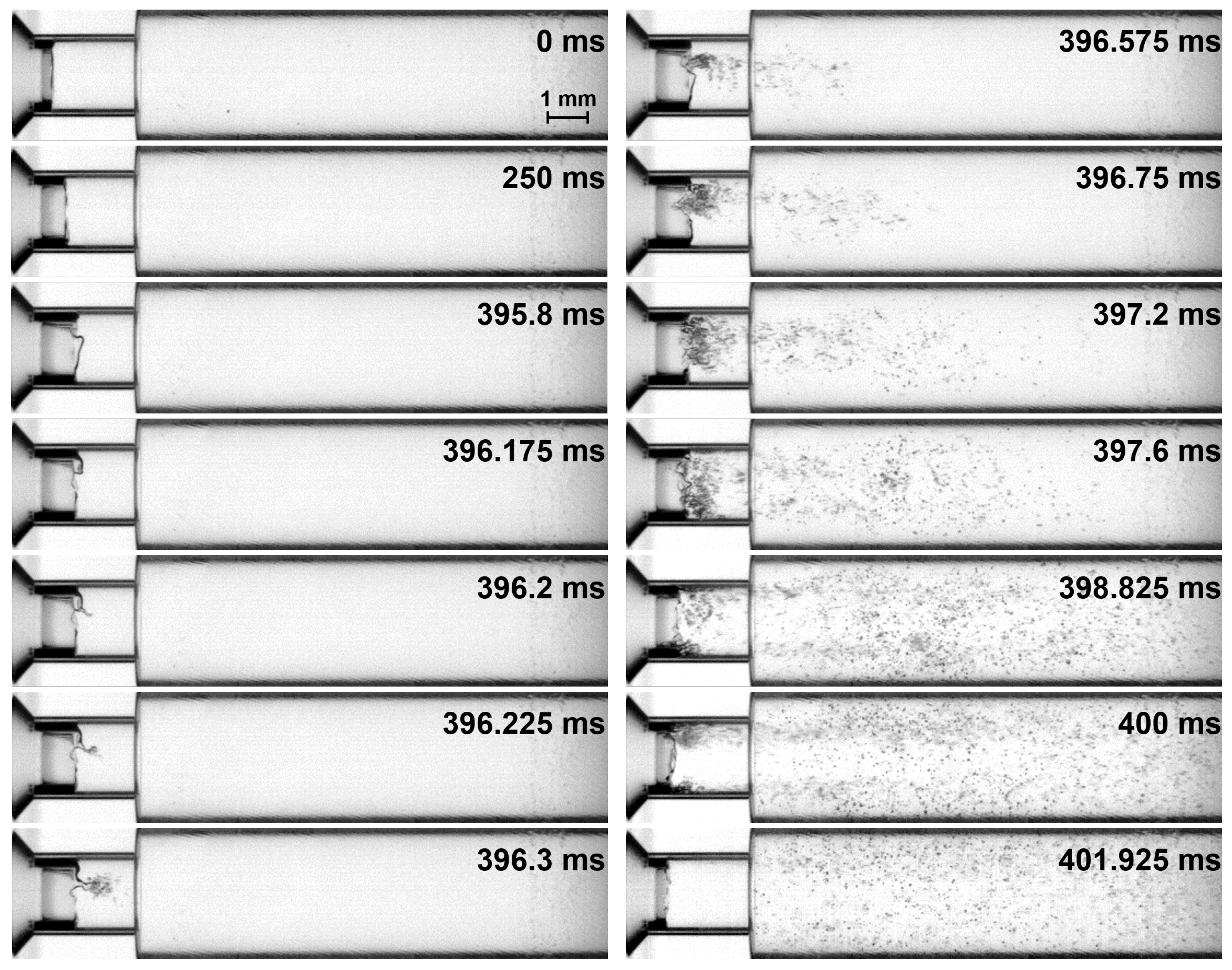

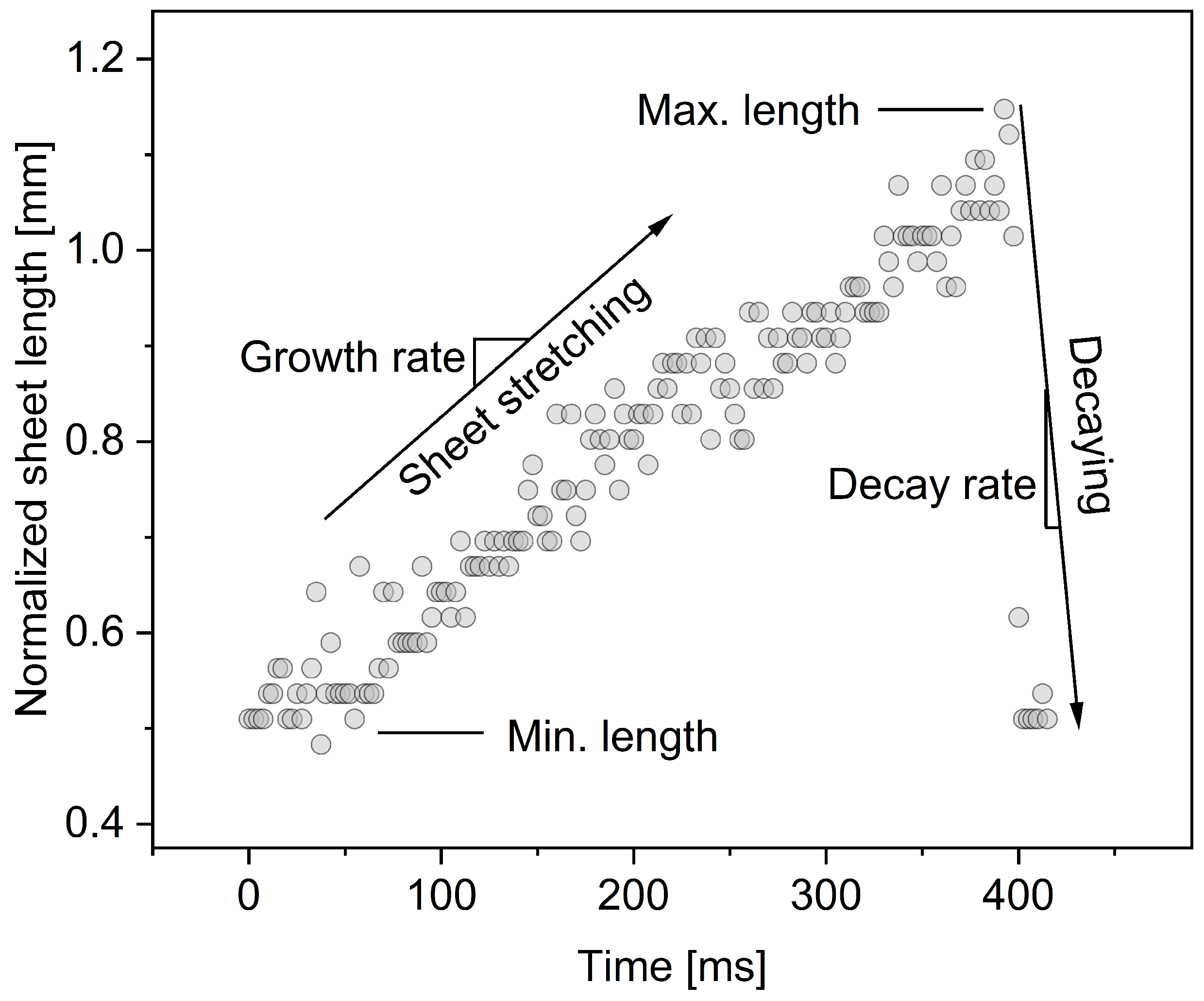

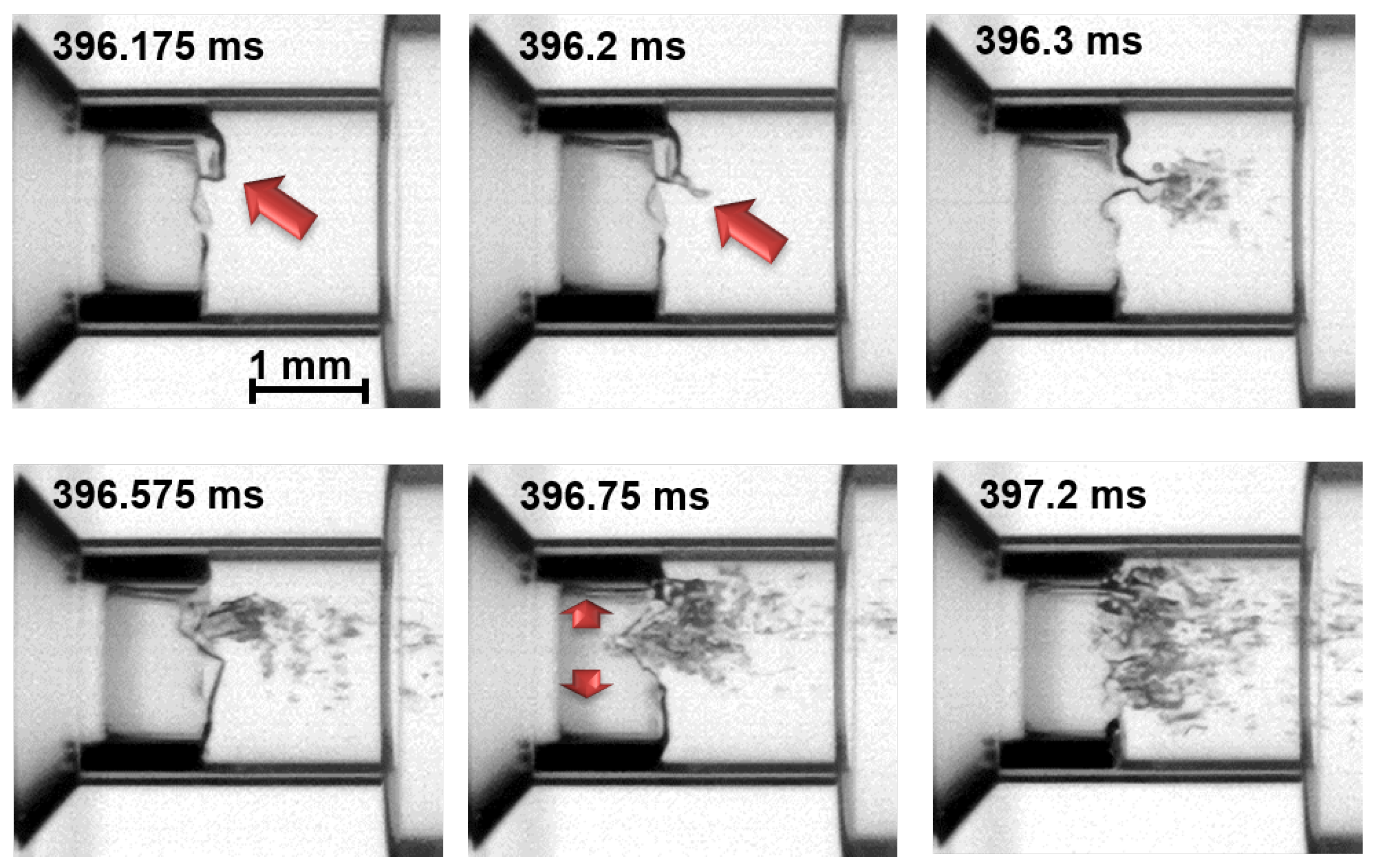

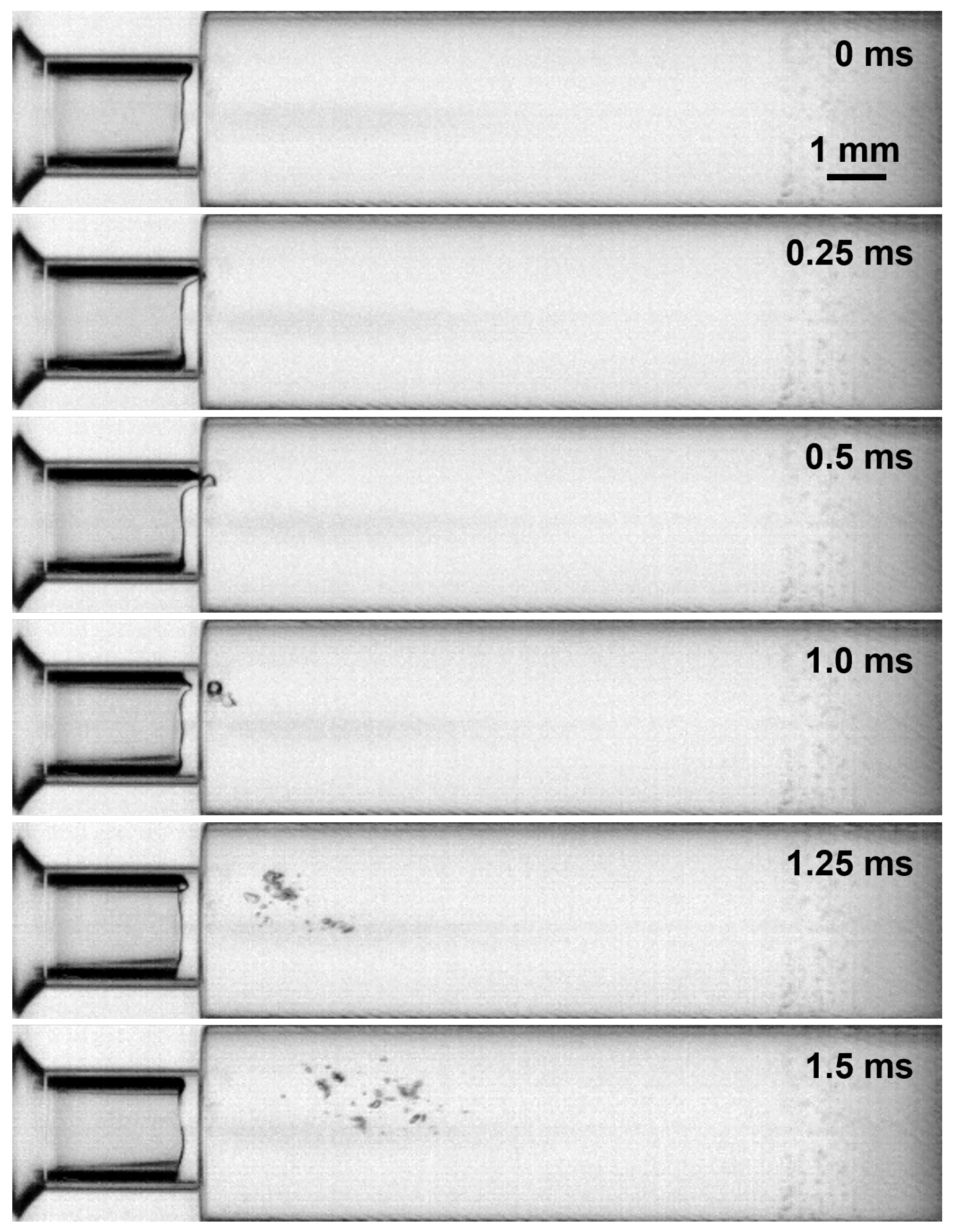

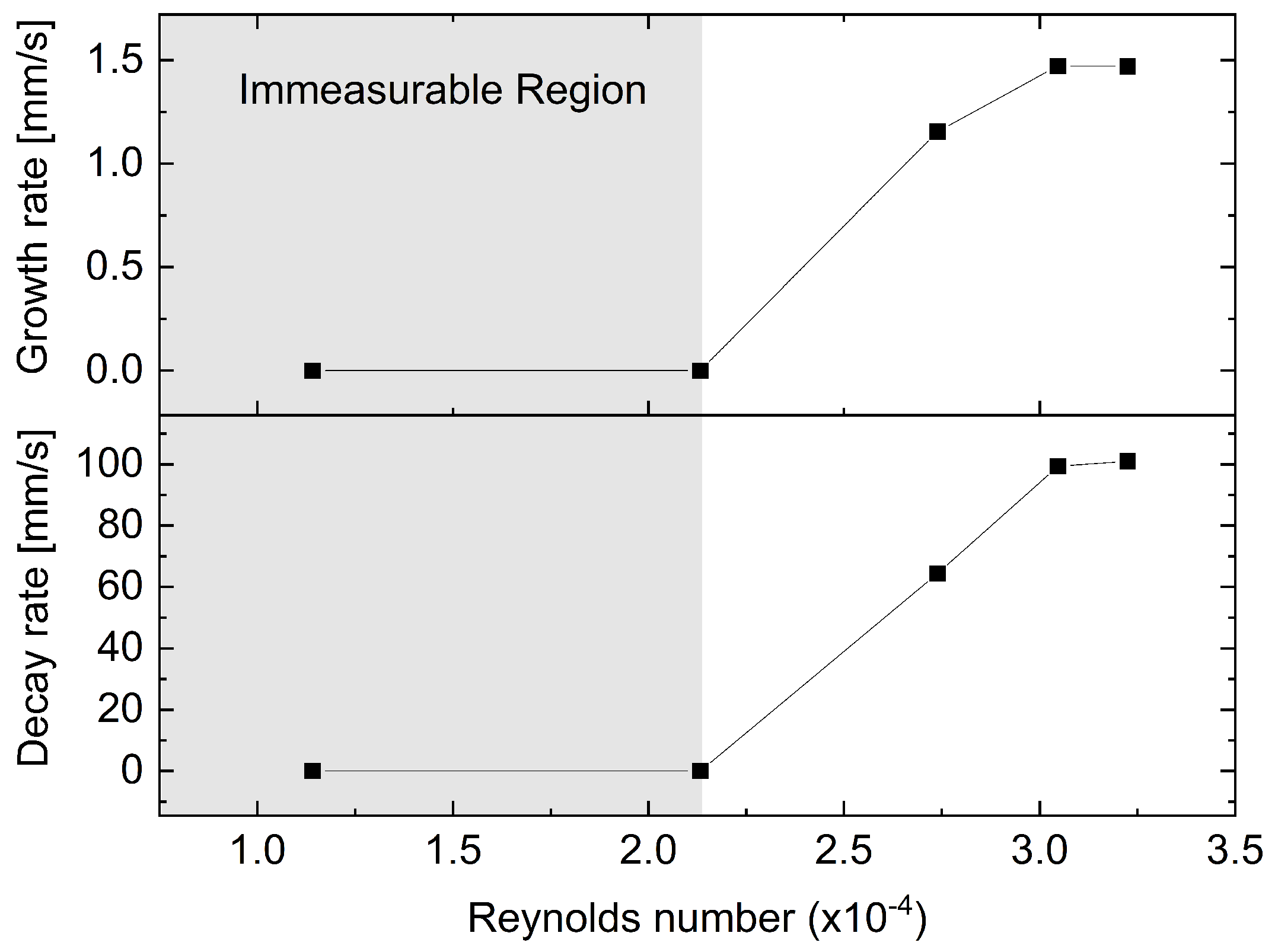

3.1. Onset and Decay Characteristics of Sheet Cavitation

3.2. Discussion

4. Conclusions

- The new sheet cavitation regime appears at high cavitation numbers where cavitation inception is typically unexpected, presenting a distinct hysteresis effect governed by path-dependent energy barriers. This suggests a potential risk to hydraulic systems with control valves, particularly in transient operations like rocket engine throttling.

- The behavior of sheet cavitation, particularly its linear growth and rapid collapse driven by tip instabilities and microjet penetration, provides insights into the dynamic stability of cavitation bubbles and their interactions with flow conditions.

- Because the metastable sheet cavitation regime can be intentionally initiated and controlled through the manipulation of pressure drop across the orifice, it reveals new possibilities for utilizing the new cavitation regime in various research fields through controlled and dispersed bubble generation.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Brennen, C.E. Cavitation and Bubble Dynamics; Cambridge University Press: Cambridge, UK, 2014. [Google Scholar]

- Kumar, P.; Saini, R. Study of cavitation in hydro turbines—A review. Renew. Sustain. Energy Rev. 2010, 14, 374–383. [Google Scholar] [CrossRef]

- Binama, M.; Muhirwa, A.; Bisengimana, E. Cavitation effects in centrifugal pumps-A review. Int. J. Eng. Res. Appl. 2016, 6, 52–63. [Google Scholar]

- Garcia, R.; Hammitt, F.G. Cavitation damage and correlations with material and fluid properties. J. Basic Eng. 1967, 89, 753–763. [Google Scholar] [CrossRef]

- Testud, P.; Moussou, P.; Hirschberg, A.; Aurégan, Y. Noise generated by cavitating single-hole and multi-hole orifices in a water pipe. J. Fluids Struct. 2007, 23, 163–189. [Google Scholar] [CrossRef]

- Asi, O. Failure of a diesel engine injector nozzle by cavitation damage. Eng. Fail. Anal. 2006, 13, 1126–1133. [Google Scholar] [CrossRef]

- Abderrezzak, B.; Huang, Y. Investigation of the effect of cavitation in nozzles with different length to diameter ratios on atomization of a liquid jet. J. Therm. Sci. Eng. Appl. 2017, 9, 031014. [Google Scholar] [CrossRef]

- Hashimoto, T.; Yoshida, M.; Watanabe, M.; Kamijo, K.; Tsujimoto, Y. Experimental study on rotating cavitation of rocket propellant pump inducers. J. Propuls. Power 1997, 13, 488–494. [Google Scholar] [CrossRef]

- Hardi, J.; Martin, J.; Son, M.; Armbruster, W.; Deeken, J.C.; Suslov, D.; Oschwald, M. Combustion Stability Characteristics of a sub-scale LOX/LNG Rocket Thrust Chamber. In Proceedings of the Aerospace Europe Conference 2020, Bordeaux, France, 25–28 February 2020. [Google Scholar]

- Kumar, K.S.; Moholkar, V.S. Conceptual design of a novel hydrodynamic cavitation reactor. Chem. Eng. Sci. 2007, 62, 2698–2711. [Google Scholar] [CrossRef]

- Zheng, H.; Zheng, Y.; Zhu, J. Recent developments in hydrodynamic cavitation reactors: Cavitation mechanism, reactor design, and applications. Engineering 2022, 19, 180–198. [Google Scholar] [CrossRef]

- Tao, Y.; Cai, J.; Huai, X.; Liu, B.; Guo, Z. Application of hydrodynamic cavitation to wastewater treatment. Chem. Eng. Technol. 2016, 39, 1363–1376. [Google Scholar] [CrossRef]

- Abdrashitov, A.; Gavrilov, A.; Marfin, E.; Panchenko, V.; Kovalev, A.; Bolshev, V.; Karaeva, J. Cavitation Reactor for Pretreatment of Liquid Agricultural Waste. Agriculture 2023, 13, 1218. [Google Scholar] [CrossRef]

- Asaithambi, N.; Singha, P.; Dwivedi, M.; Singh, S.K. Hydrodynamic cavitation and its application in food and beverage industry: A review. J. Food Process Eng. 2019, 42, e13144. [Google Scholar] [CrossRef]

- Xiong, Y.; Peng, F. Optimization of cavitation venturi tube design for pico and nano bubbles generation. Int. J. Min. Sci. Technol. 2015, 25, 523–529. [Google Scholar] [CrossRef]

- Son, M.; Börner, M.; Armbruster, W.; Hardi, J.S. Orifice Flow Dynamics in a Rocket Injector as an Excitation Source of Injector-Driven Combustion Instabilities. Aerospace 2023, 10, 452. [Google Scholar] [CrossRef]

- Gröning, S.; Hardi, J.S.; Suslov, D.; Oschwald, M. Injector-driven combustion instabilities in a hydrogen/oxygen rocket combustor. J. Propuls. Power 2016, 32, 560–573. [Google Scholar] [CrossRef]

- Armbruster, W.; Hardi, J.S.; Suslov, D.; Oschwald, M. Injector-Driven Flame Dynamics in a High-Pressure Multi-Element Oxygen–Hydrogen Rocket Thrust Chamber. J. Propuls. Power 2019, 35, 632–644. [Google Scholar] [CrossRef]

- Esposito, C.; Steelant, J.; Vetrano, M.R. Impact of Cryogenics on Cavitation through an Orifice: A Review. Energies 2021, 14, 8319. [Google Scholar] [CrossRef]

- Croci, K.; Ravelet, F.; Danlos, A.; Robinet, J.C.; Barast, L. Attached cavitation in laminar separations within a transition to unsteadiness. Phys. Fluids 2019, 31, 063605. [Google Scholar] [CrossRef]

- Pelz, P.; Keil, T.; Groß, T. The transition from sheet to cloud cavitation. J. Fluid Mech. 2017, 817, 439–454. [Google Scholar] [CrossRef]

- Ge, M.; Sun, C.; Zhang, G.; Coutier-Delgosha, O.; Fan, D. Combined suppression effects on hydrodynamic cavitation performance in Venturi-type reactor for process intensification. Ultrason. Sonochem. 2022, 86, 106035. [Google Scholar] [CrossRef] [PubMed]

- Amini, A.; Reclari, M.; Sano, T.; Iino, M.; Dreyer, M.; Farhat, M. On the physical mechanism of tip vortex cavitation hysteresis. Exp. Fluids 2019, 60, 118. [Google Scholar] [CrossRef]

- Khoo, M.; Venning, J.; Pearce, B.; Brandner, P. Statistical aspects of tip vortex cavitation inception and desinence in a nuclei deplete flow. Exp. Fluids 2020, 61, 145. [Google Scholar] [CrossRef]

- McCloy, D.; Beck, A. Some cavitation effects in spool valve orifices. Proc. Inst. Mech. Eng. 1967, 182, 163–174. [Google Scholar] [CrossRef]

- Esposito, C.; Mendez, M.; Steelant, J.; Vetrano, M.R. Spectral and modal analysis of a cavitating flow through an orifice. Exp. Therm. Fluid Sci. 2021, 121, 110251. [Google Scholar] [CrossRef]

- Callenaere, M.; Franc, J.P.; Michel, J.M.; Riondet, M. The cavitation instability induced by the development of a re-entrant jet. J. Fluid Mech. 2001, 444, 223–256. [Google Scholar] [CrossRef]

- Trummler, T.; Schmidt, S.J.; Adams, N.A. Investigation of condensation shocks and re-entrant jet dynamics in a cavitating nozzle flow by Large-Eddy Simulation. Int. J. Multiph. Flow 2020, 125, 103215. [Google Scholar] [CrossRef]

- Sarkar, P.; Ghigliotti, G.; Franc, J.P.; Fivel, M. Mechanism of material deformation during cavitation bubble collapse. J. Fluids Struct. 2021, 105, 103327. [Google Scholar] [CrossRef]

- Obreschkow, D.; Tinguely, M.; Dorsaz, N.; Kobel, P.; De Bosset, A.; Farhat, M. Universal scaling law for jets of collapsing bubbles. Phys. Rev. Lett. 2011, 107, 204501. [Google Scholar] [CrossRef]

- Sherry, M.; Jacono, D.L.; Sheridan, J. An experimental investigation of the recirculation zone formed downstream of a forward facing step. J. Wind Eng. Ind. Aerodyn. 2010, 98, 888–894. [Google Scholar] [CrossRef]

- Rodríguez-Rodríguez, J.; Sevilla, A.; Martínez-Bazán, C.; Gordillo, J.M. Generation of microbubbles with applications to industry and medicine. Annu. Rev. Fluid Mech. 2015, 47, 405–429. [Google Scholar] [CrossRef]

- Liu, Z.; Zheng, Y.; Jia, L.; Zhang, Q. Study of bubble induced flow structure using PIV. Chem. Eng. Sci. 2005, 60, 3537–3552. [Google Scholar] [CrossRef]

- Li, B.; Gu, Y.; Chen, M. An experimental study on the cavitation of water with dissolved gases. Exp. Fluids 2017, 58, 164. [Google Scholar] [CrossRef]

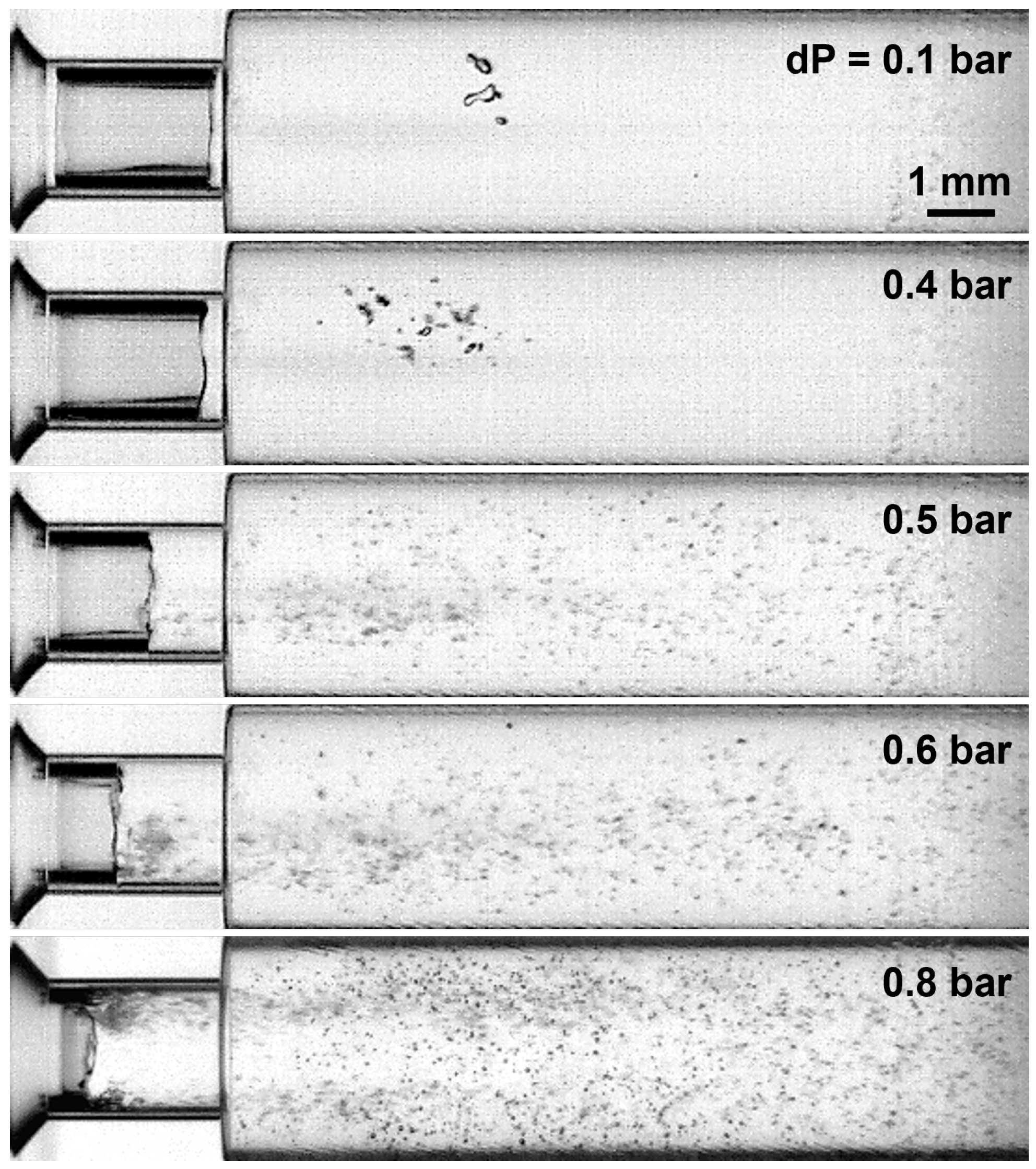

| Target [bar] | Measured [bar] | [g/s] | K | ||

|---|---|---|---|---|---|

| 0.1 | 0.097 | 15.3 | 10.88 | 1.14 × | 0.74 |

| 0.4 | 0.396 | 28.6 | 3.48 | 2.13 × | 0.81 |

| 0.5 | 0.496 | 36.7 | 3.03 | 2.74 × | 0.93 |

| 0.6 | 0.616 | 40.9 | 2.66 | 3.05 × | 0.95 |

| 0.8 | 0.798 | 44.6 | 2.31 | 3.22 × | 0.94 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Son, M.; Börner, M.; Armbruster, W.; Hardi, J.S. Hysteresis-Induced Onset and Progressive Decay of Periodic and Metastable Sheet Cavitation in a Chamfered Circular Orifice. Fluids 2025, 10, 59. https://doi.org/10.3390/fluids10030059

Son M, Börner M, Armbruster W, Hardi JS. Hysteresis-Induced Onset and Progressive Decay of Periodic and Metastable Sheet Cavitation in a Chamfered Circular Orifice. Fluids. 2025; 10(3):59. https://doi.org/10.3390/fluids10030059

Chicago/Turabian StyleSon, Min, Michael Börner, Wolfgang Armbruster, and Justin S. Hardi. 2025. "Hysteresis-Induced Onset and Progressive Decay of Periodic and Metastable Sheet Cavitation in a Chamfered Circular Orifice" Fluids 10, no. 3: 59. https://doi.org/10.3390/fluids10030059

APA StyleSon, M., Börner, M., Armbruster, W., & Hardi, J. S. (2025). Hysteresis-Induced Onset and Progressive Decay of Periodic and Metastable Sheet Cavitation in a Chamfered Circular Orifice. Fluids, 10(3), 59. https://doi.org/10.3390/fluids10030059