Effects of the Orifice and Absorber Grid Designs on Coolant Mixing at the Inlet of an RITM-Type SMR Fuel Assembly

Abstract

1. Introduction

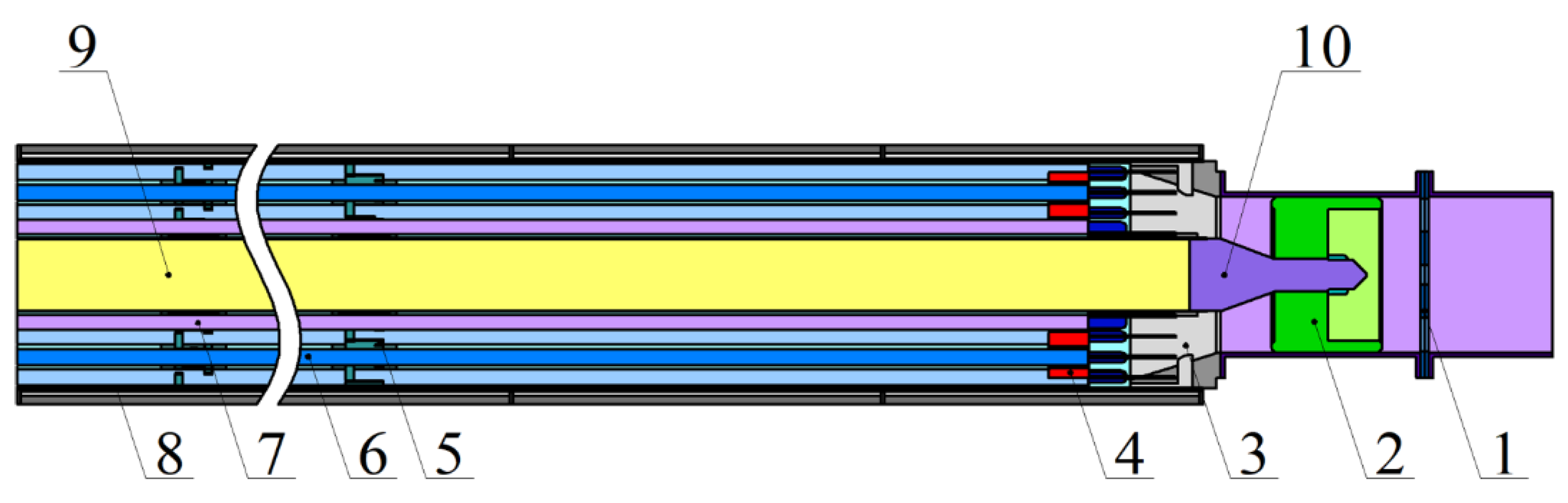

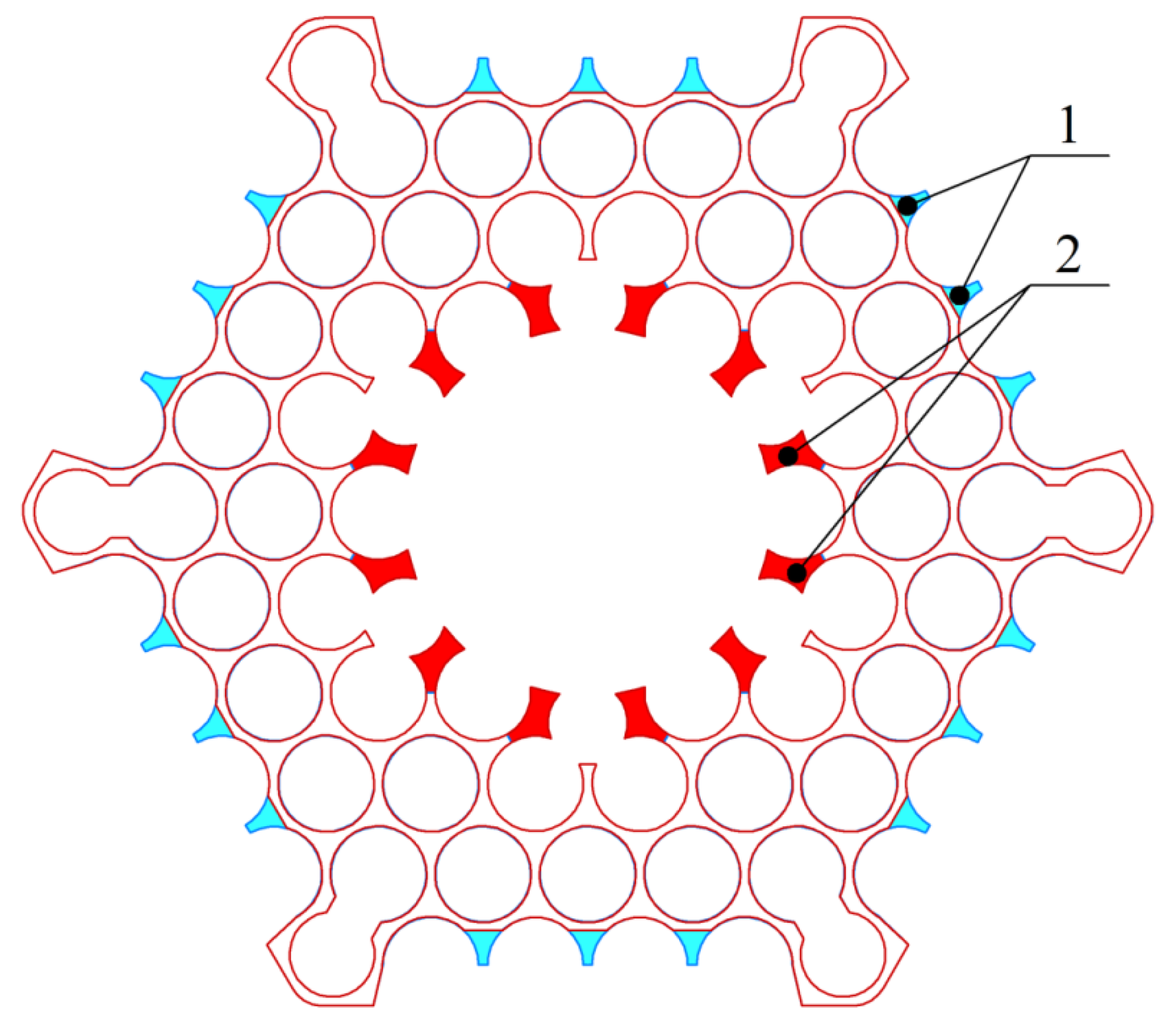

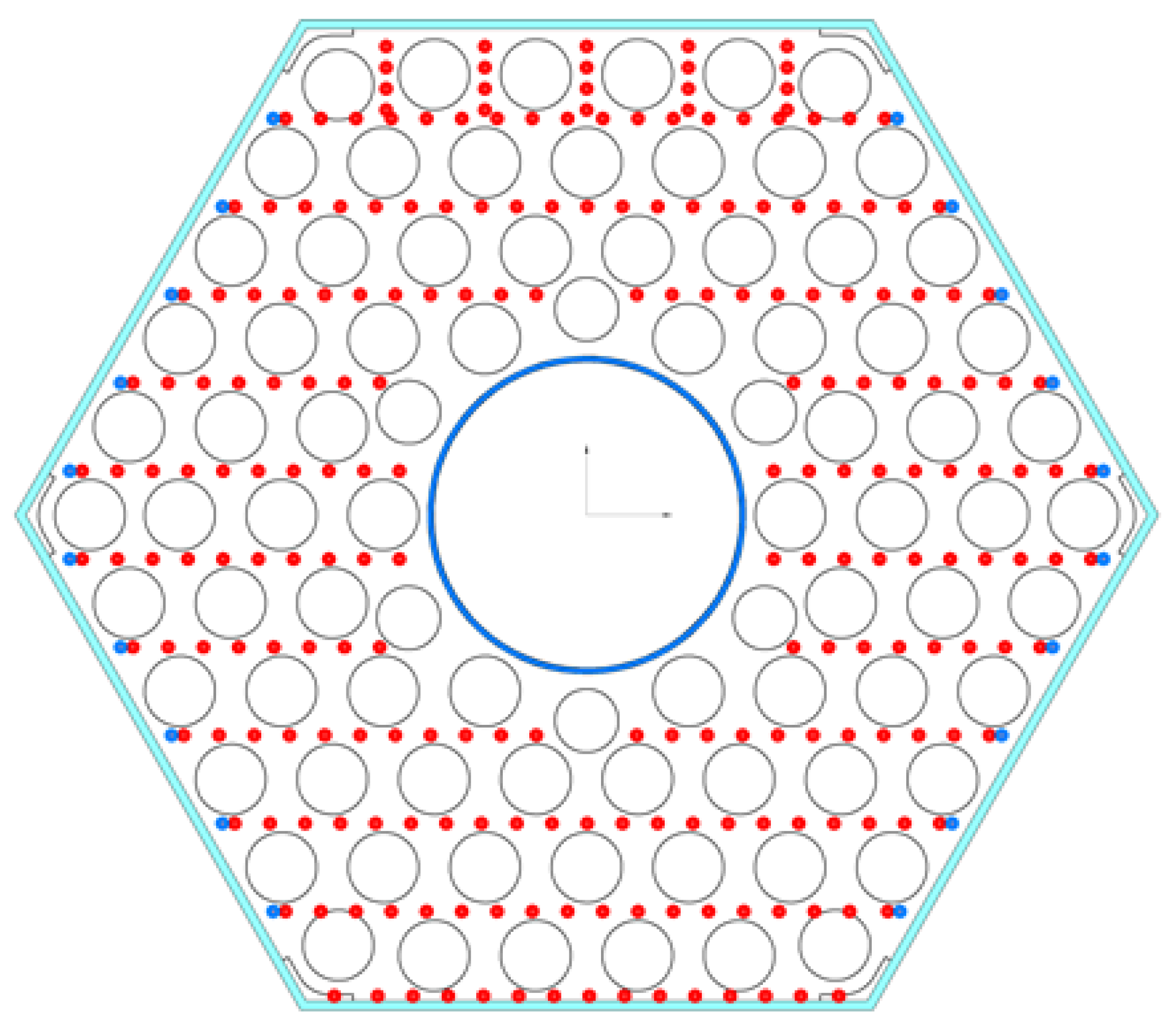

2. Research Facility and Experimental Technique

- A large hydraulic diameter (dh) of the experimental model allows for high Reynolds numbers to be achieved.

- Minimizing the influence of measurement instruments on the airflow within the model ensures accurate results.

3. Results

3.1. Dynamic Pressure Probe Measurements

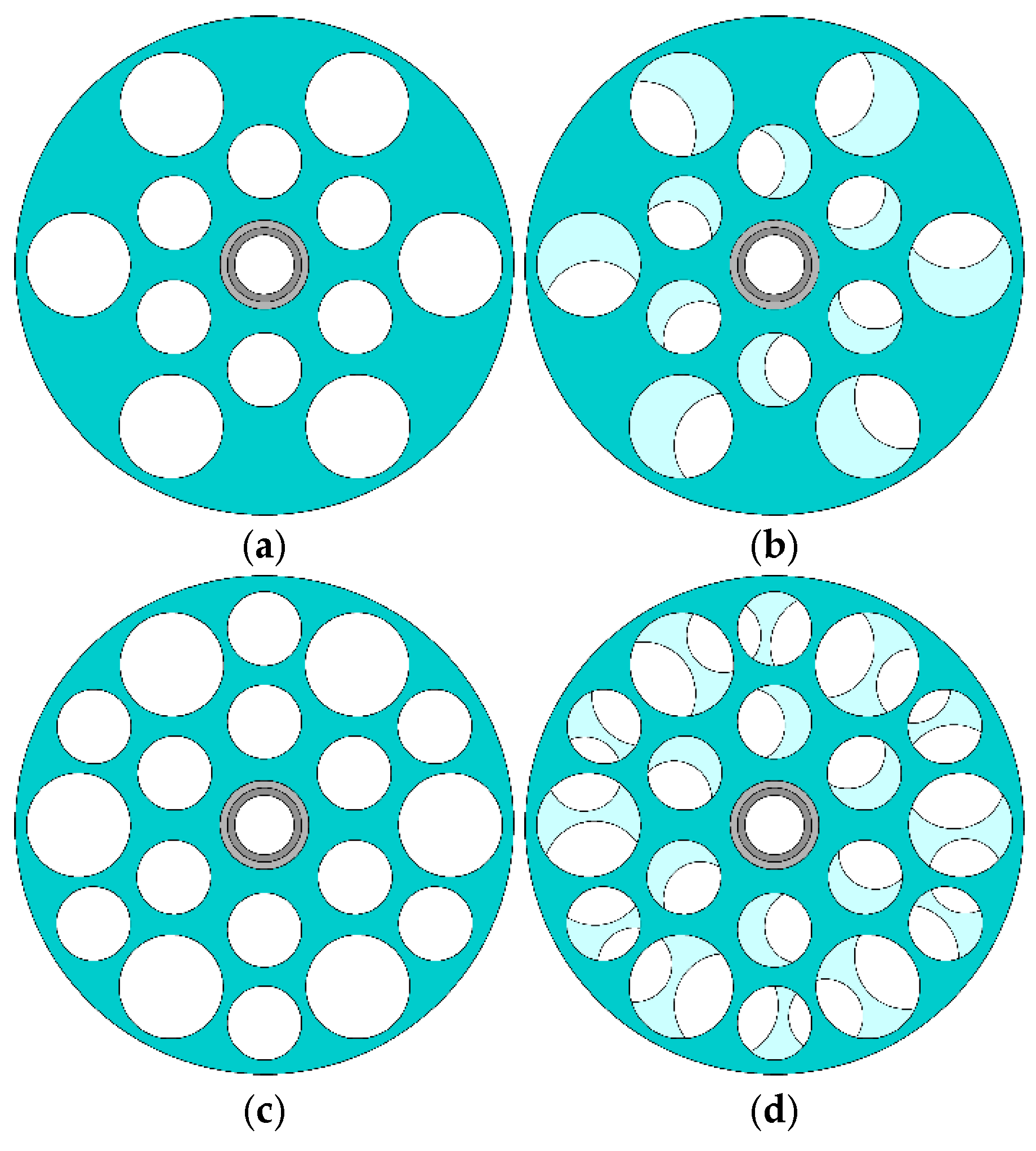

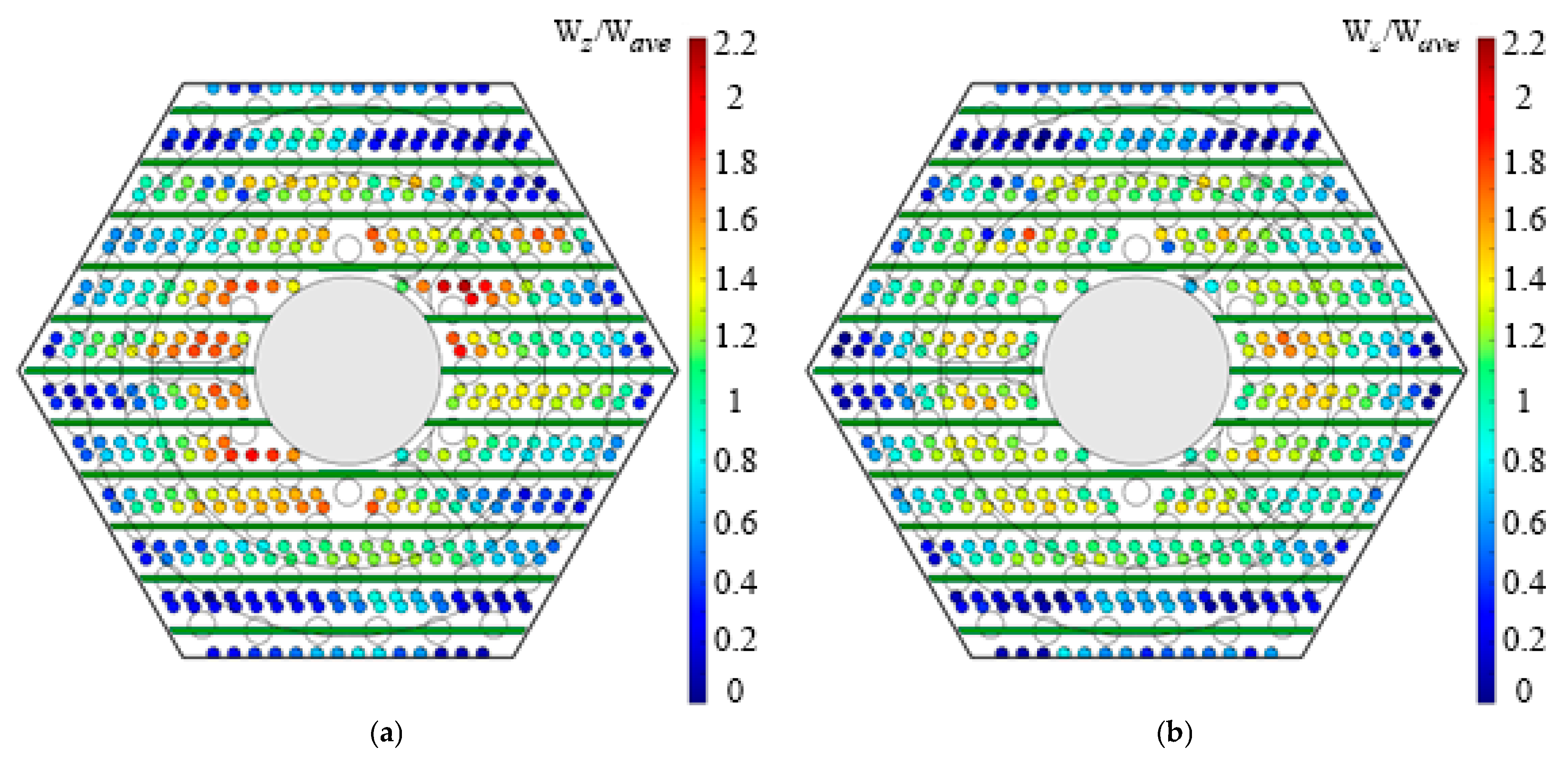

3.1.1. Integrated Grid Absorber with Peripheral Flow Restriction

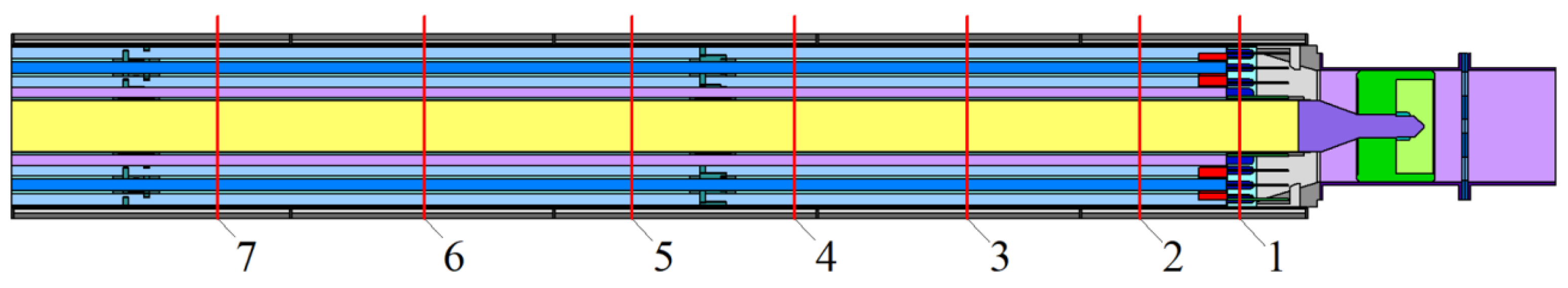

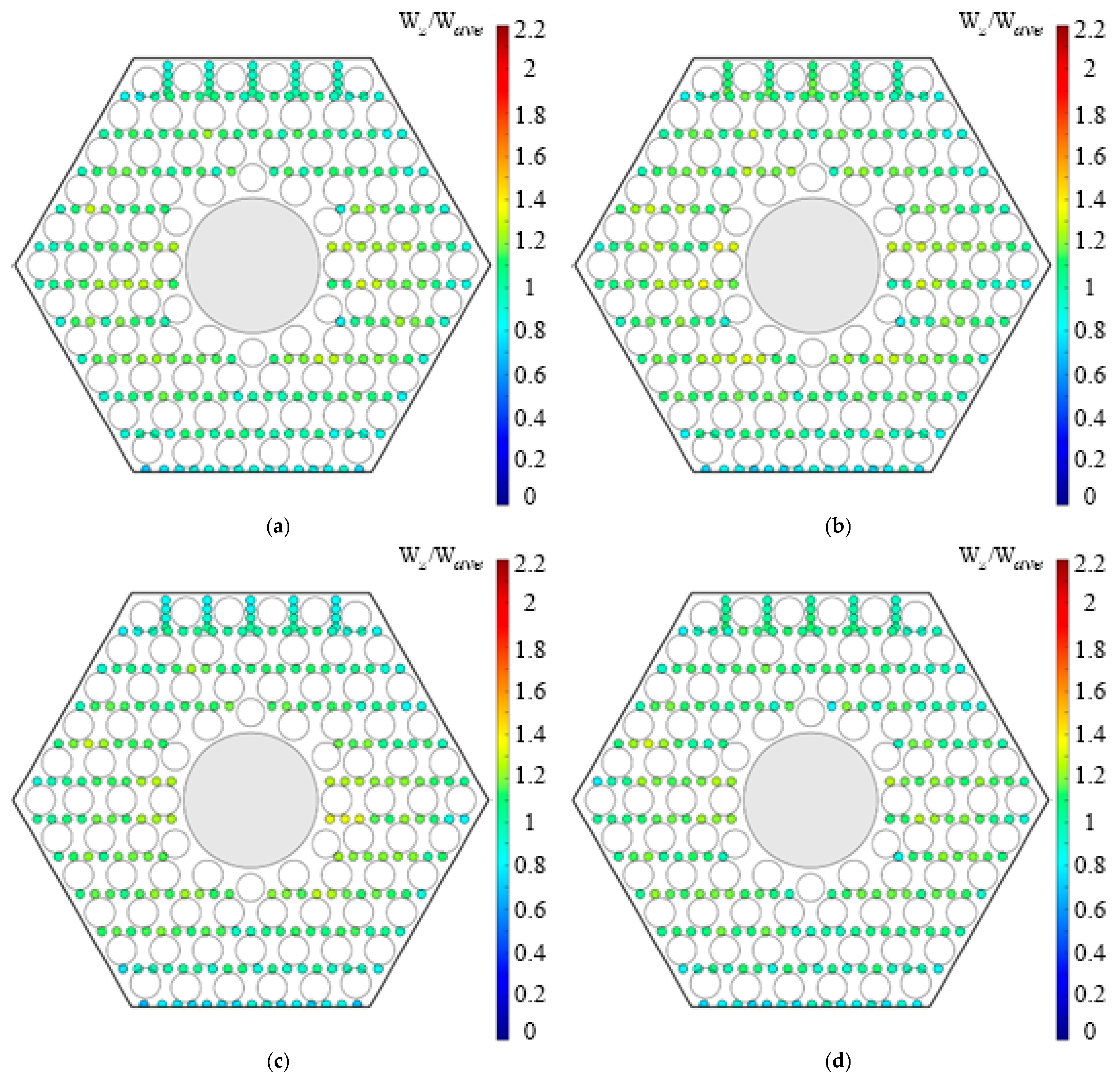

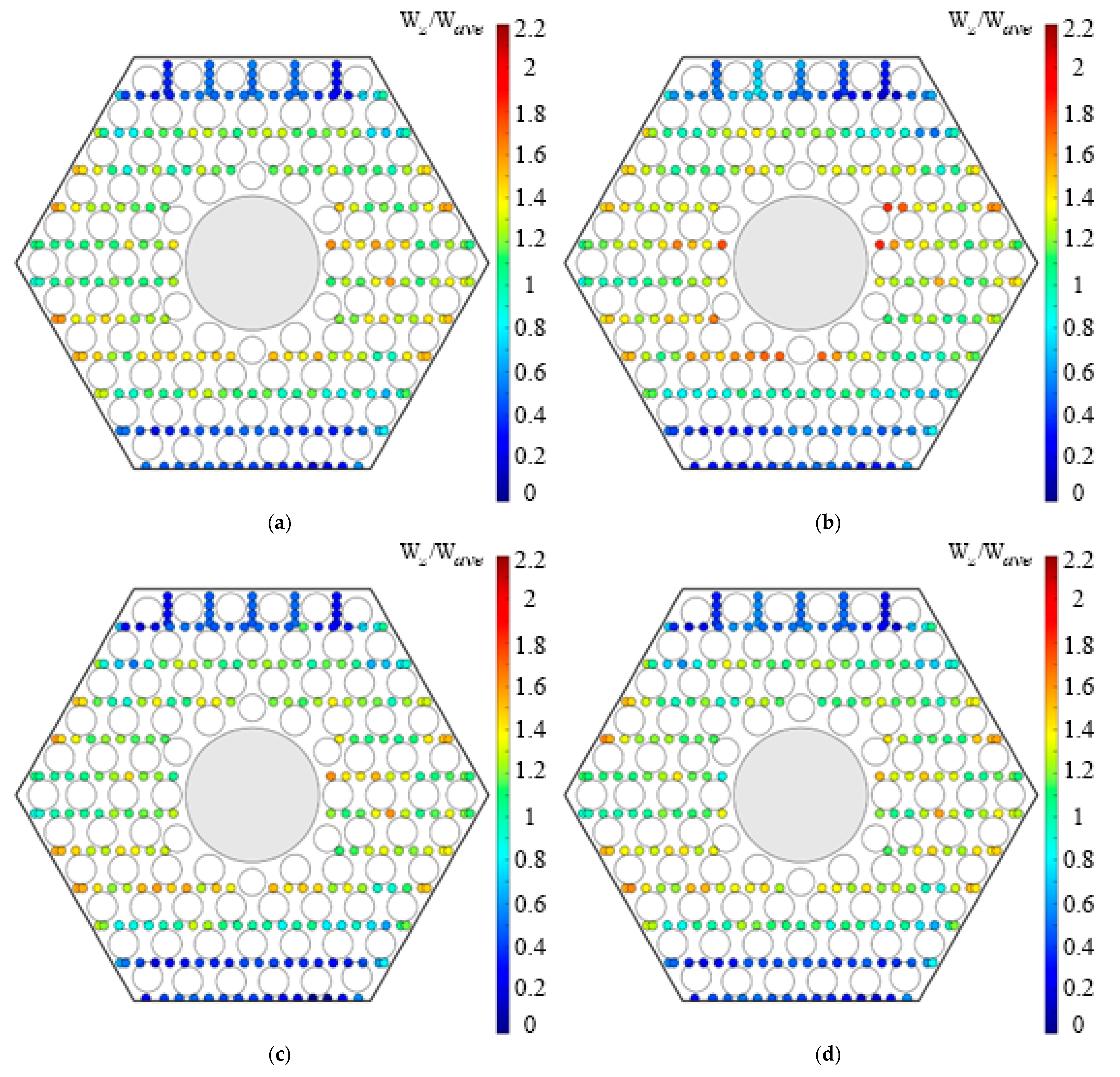

- In the fuel rod attachment area to the diffuser (L/dh = 1.2), with both types of orifice inlet devices installed in the open position, the axial flow velocity distributions exhibit a similar pattern (Figure 8). The minimum dimensionless axial flow velocity was localized near the model wrapper (within two rows of fuel rods near the wrapper faces parallel to the fuel rod attachment plates and within one row near the other wrapper faces) and amounted to 0.05–0.60 in the region of the stiffness corners and 0.3–0.8 at the centers of the wrapper faces. This location of the low-velocity region is likely caused by the combined influence of the structural elements within the inlet section from the orifice inlet device to the integrated grid absorber. The expansion of the low-velocity area near the wrapper faces parallel to the attachment plates could arise from the configuration of the attachment plates themselves and the diffuser, which restrict the flow area such that coolant cross-flow into the peripheral cells is practically absent. In the region of the stiffness corners, the axial velocity may be additionally affected by flow deceleration upstream of the integrated grid absorber, which significantly restricts the flow area in the corner region. The region of high axial flow velocity was located in the central part of the cross-section, where the dimensionless velocity ranged from 1.4 to 1.8. Its localization can be attributed to the formation of high-velocity jets downstream of the orifice inlet device holes. Closing the orifice inlet device with additional holes did not lead to a significant change in the axial velocity distribution; only near the centers of the wrapper faces did the velocity increase from 0.3–0.8 to 0.7–1.0 (Figure 9).

- 2.

- Downstream of the integrated grid absorber (L/dh = 9.6) displacing the peripheral region, with both types of orifice inlet devices installed in the open position, the preservation of the low axial velocity region near the wrapper faces parallel to the fuel rod attachment plates is characteristic, where the velocity was 0.1–0.6 (Figure 10a,c). When the flow area of the orifice inlet device without additional holes was closed, a local increase in the dimensionless axial flow velocity in the central part of the cross-section was observed (Figure 10b). Asymmetry in the axial velocity distributions is observed regardless of the type of installed orifice inlet device or the degree of its closure, which could be due to the persistent influence of the configuration of the fuel rod attachment plates to the diffuser, preventing cross-flow in the direction perpendicular to these plates.

- 3.

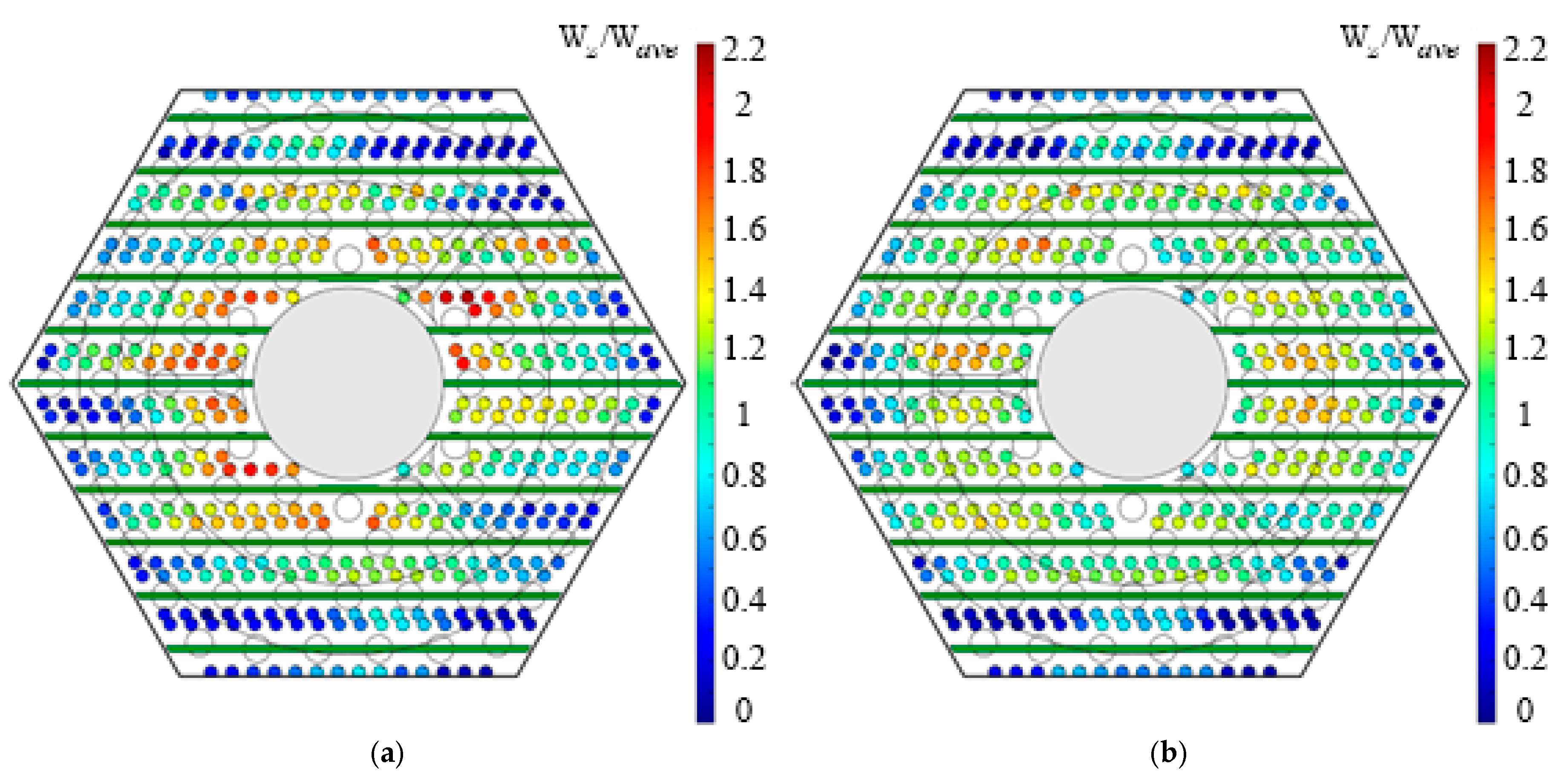

- With increasing distance downstream of the integrated grid absorber into the depth of the fuel rod bundle, a gradual equalization of the axial flow velocity across the cross-section occurred. The influence of the inlet section structural elements was practically absent in the cross-section located at the mid-span of the fuel rod bundle between the first and second spacer grids (L/dh = 70.2). This is characteristic for the case of installing the orifice inlet device with additional holes in the assembly, regardless of the degree of its flow area closure, as well as for installing the orifice inlet device without additional holes with a fully open flow area (Figure 11a,c,d). For these configurations, regions of low axial flow velocity (0.5–0.8) are observed adjacent to the surfaces of the hexagonal wrapper and the central displacer, which could have occurred due to flow deceleration near these surfaces. When the flow area of the orifice inlet device without additional holes was closed, equalization of the dimensionless axial flow velocity occurred only upstream of the second spacer grid (L/dh = 87.7) (Figure 11b).

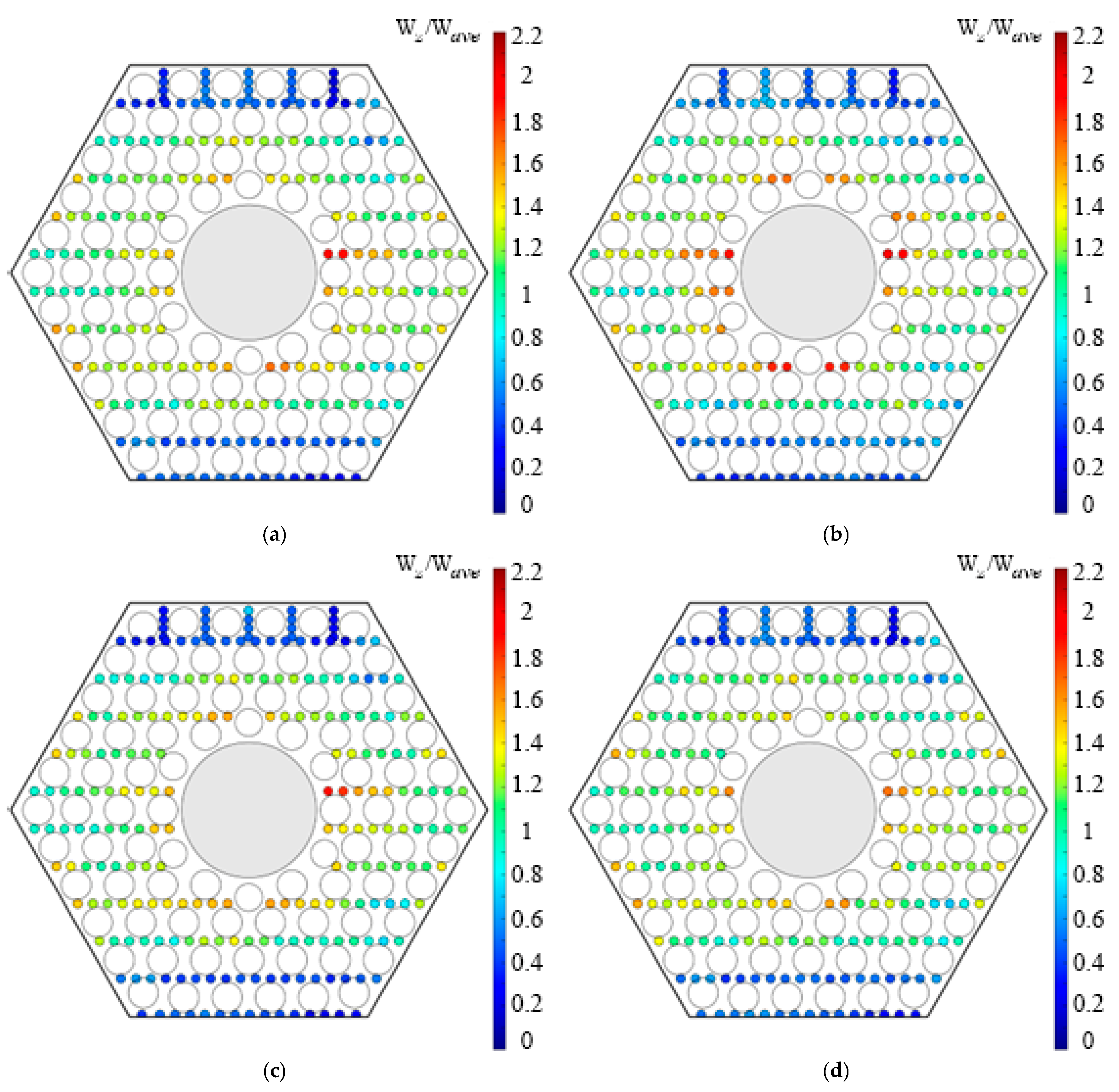

3.1.2. Integrated Grid Absorber with Central Flow Restriction

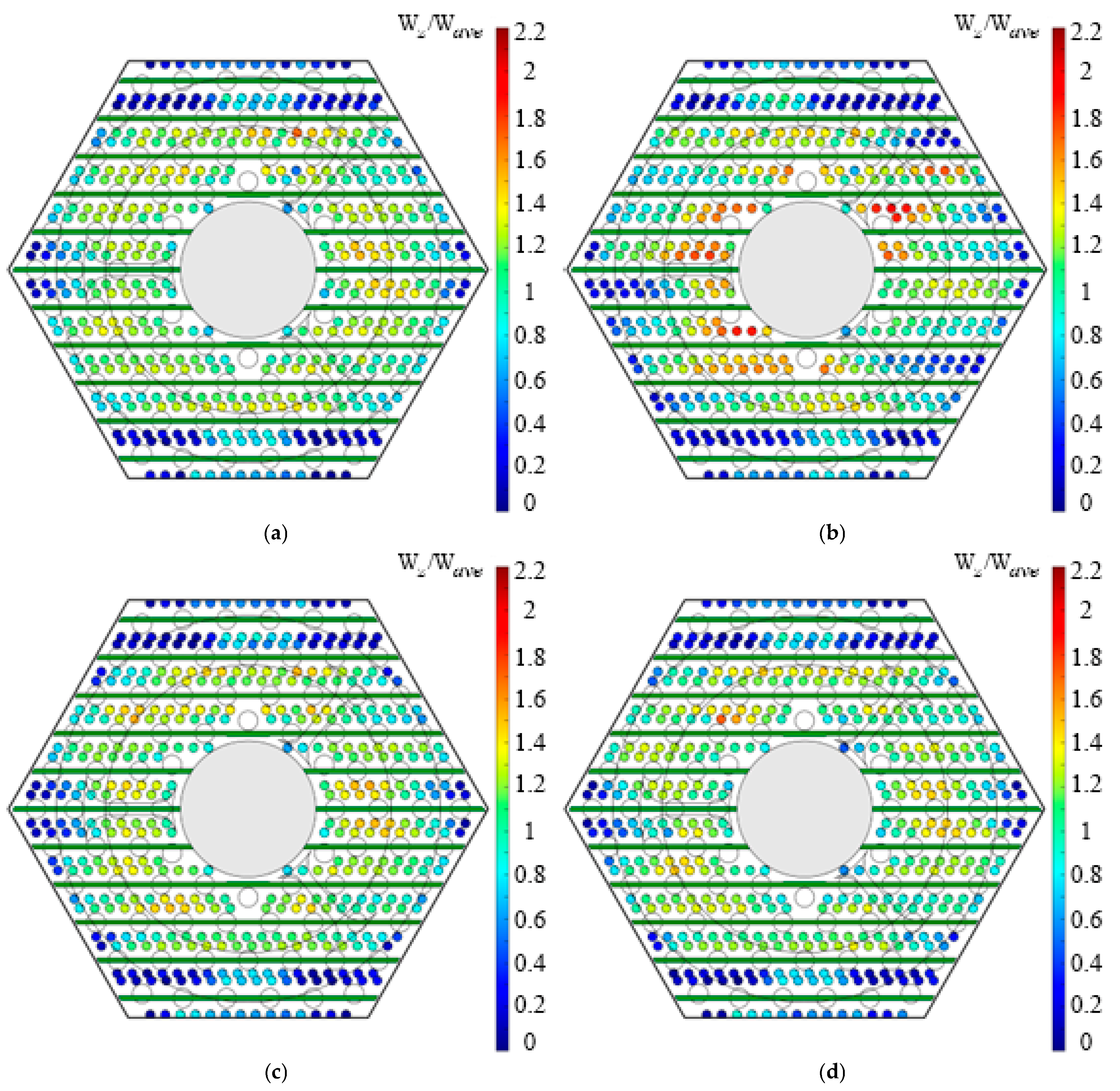

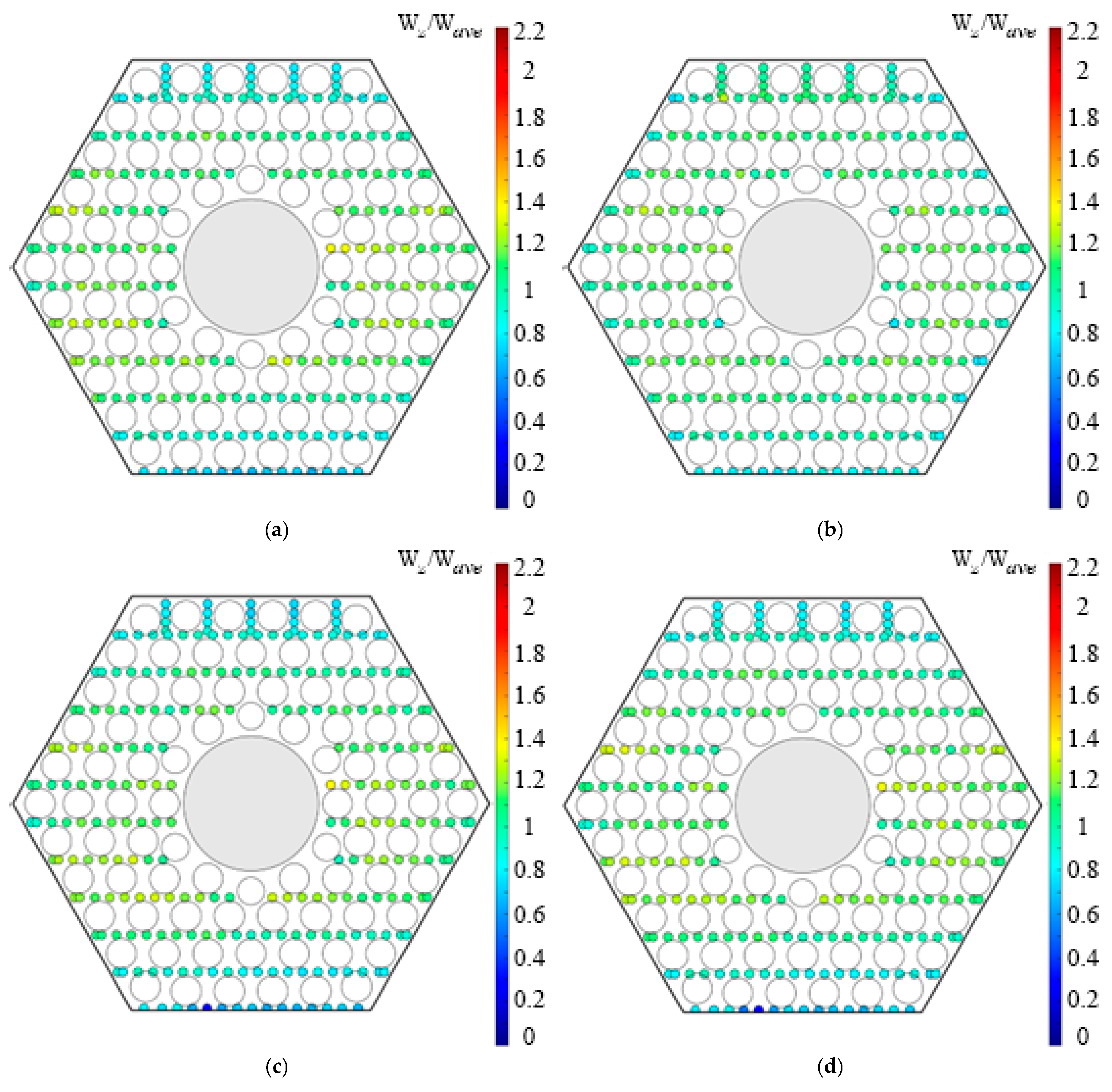

- At the cross-section located at the fuel rod attachment point to the diffuser (L/dh = 1.2), with the orifice inlet device without additional holes in the open position and with the orifice inlet device with additional holes regardless of its flow area reduction, the location of the low axial velocity region changed. This region became localized near the corner ribs, as the dimensionless axial velocity along the face centers increased from 0.05–0.60 to 0.50–1.00 (Figure 12). When the orifice inlet device without additional holes was installed in the model in the fully restricted position, no changes in the axial velocity distribution were observed.

- Downstream of the integrated grid absorber with central flow restriction (L/dh = 9.6), regardless of the type of installed orifice inlet device or its restriction level, an increase in axial flow velocity was observed at the periphery of the fuel rod bundle, except in the region of the reinforcing corner ribs where it reached 17% (Figure 13). In the region of the central displacer, local maxima of axial velocity showed a decrease in flow velocity magnitude compared to this parameter when a model with an integrated grid absorber featuring peripheral flow restriction was installed. When orifice inlet devices with an open flow area were installed, the maximum axial velocity decreased by 20%, and when the flow area of the orifice inlet devices was restricted, it decreased by 10%. The asymmetry in axial velocity distributions persisted, which the installation of an integrated grid absorber of a different design had practically no influence on.

- The design of the fuel assembly inlet section had practically no effect on the axial velocity distribution by the cross-section located midway between the spacer grids (L/dh = 70.2) in the case of installing the orifice inlet device without additional holes with a restricted flow area (Figure 14). In all other cases, the influence of the elements (orifice inlet device, diffuser, and integrated grid absorber) diminished upstream of the first spacer grid (L/dh = 38.8).

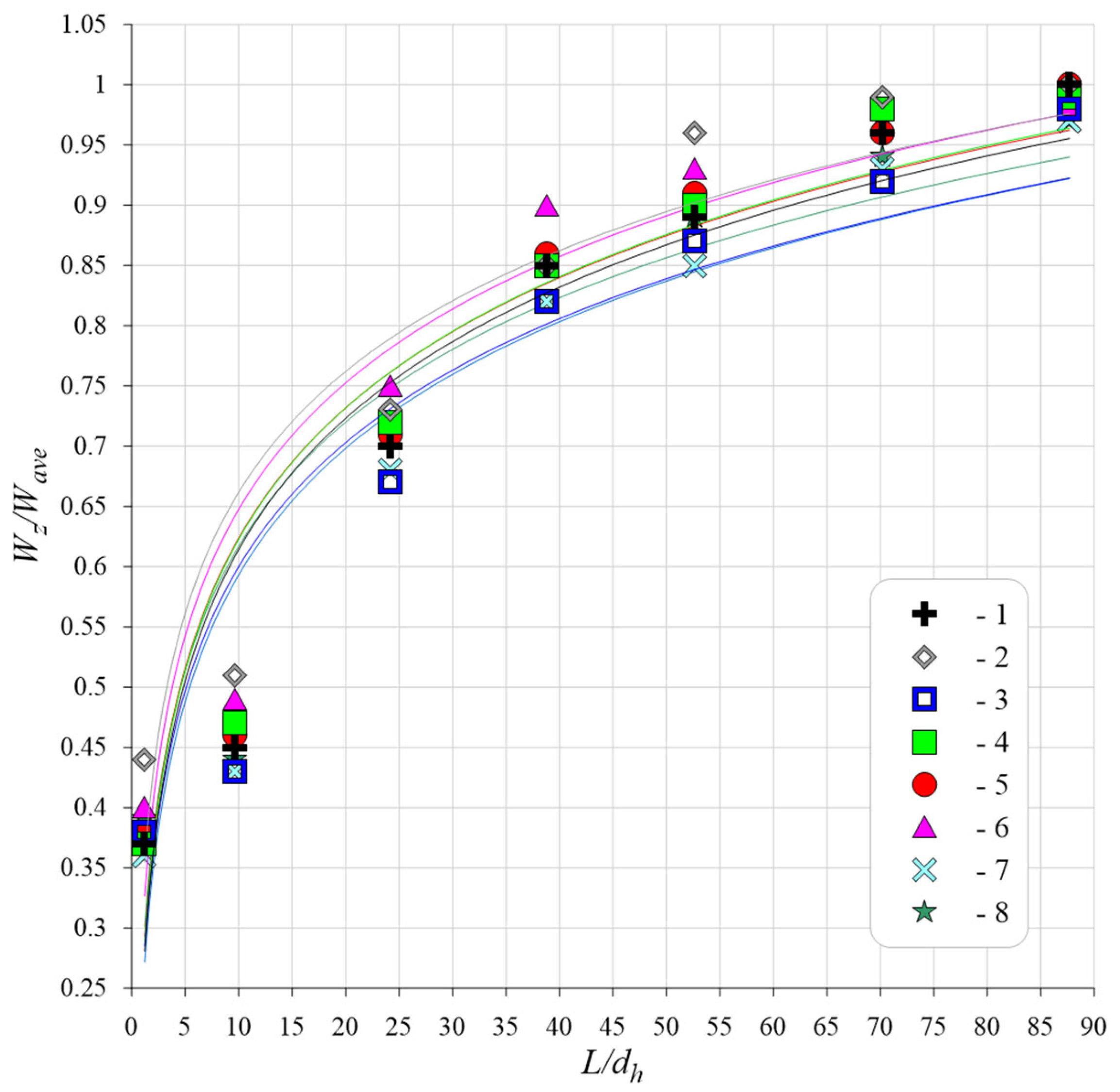

- The axial velocity at the entrance to the fuel element bundle near the sides of the cover is low (0.36–0.43) when the dimensionless parameter L/dh is 1.2. In front of the first spacer grid, the velocity increases by a factor of 2 to (0.81–0.89) at L/dh = 52.6. Complete alignment with the average outgoing velocity occurs before the second spacer grid at L/dh = 87.7 (Figure 15). Changing the design of the absorbing grid did not affect the process of equalization of the axial velocity in this area.

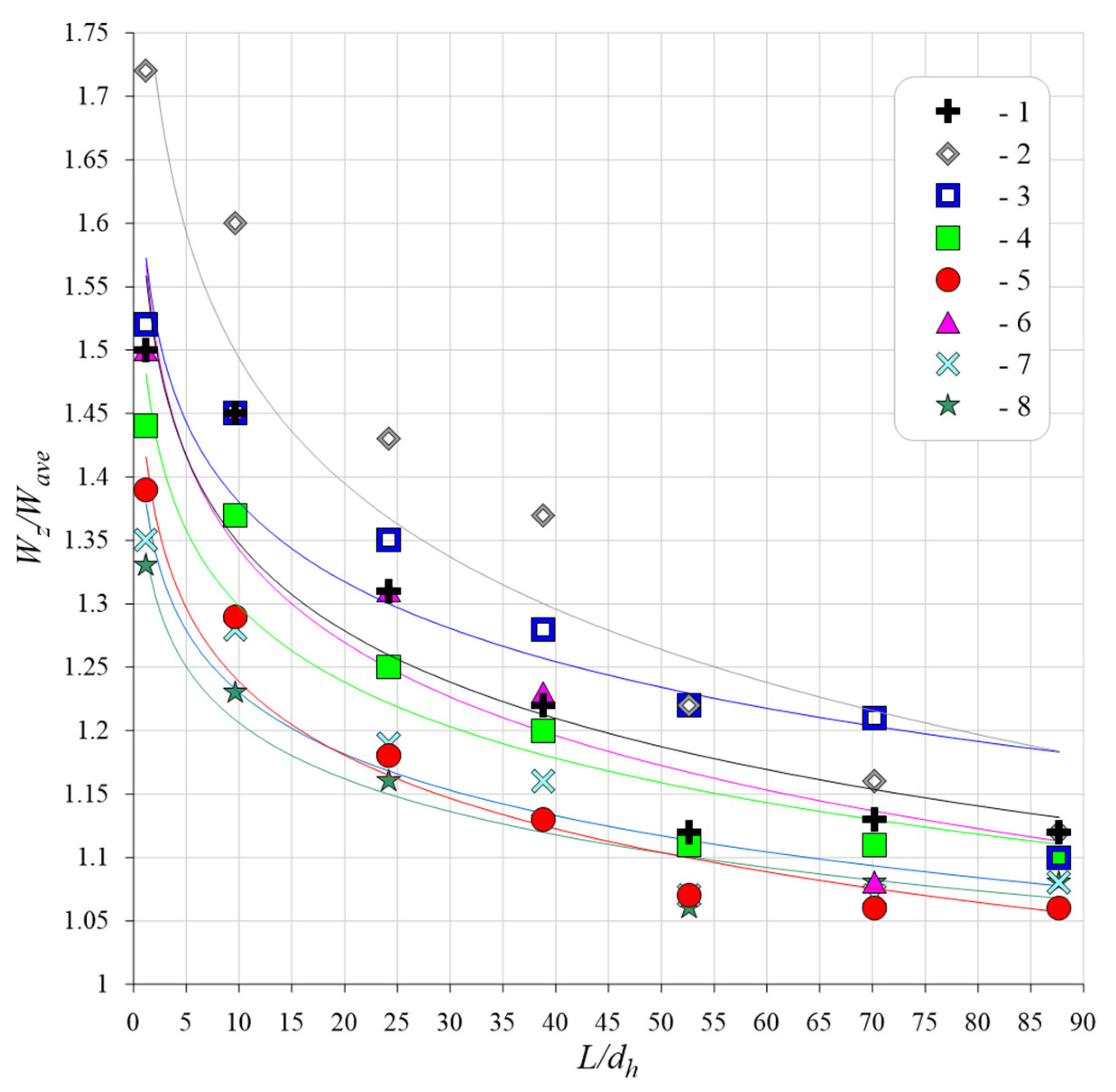

- Near the central tube, the axial velocity at L/dh = 1.2 was (1.33–1.72) at the entrance to the fuel bundle. Before the second spacer grid, the axial velocity did not equalize with the average outlet velocity and was (1.06–1.12) at L/dh of 87.7. A change in the absorbing grid design reduced the axial velocity near the center by 15% (Figure 16).

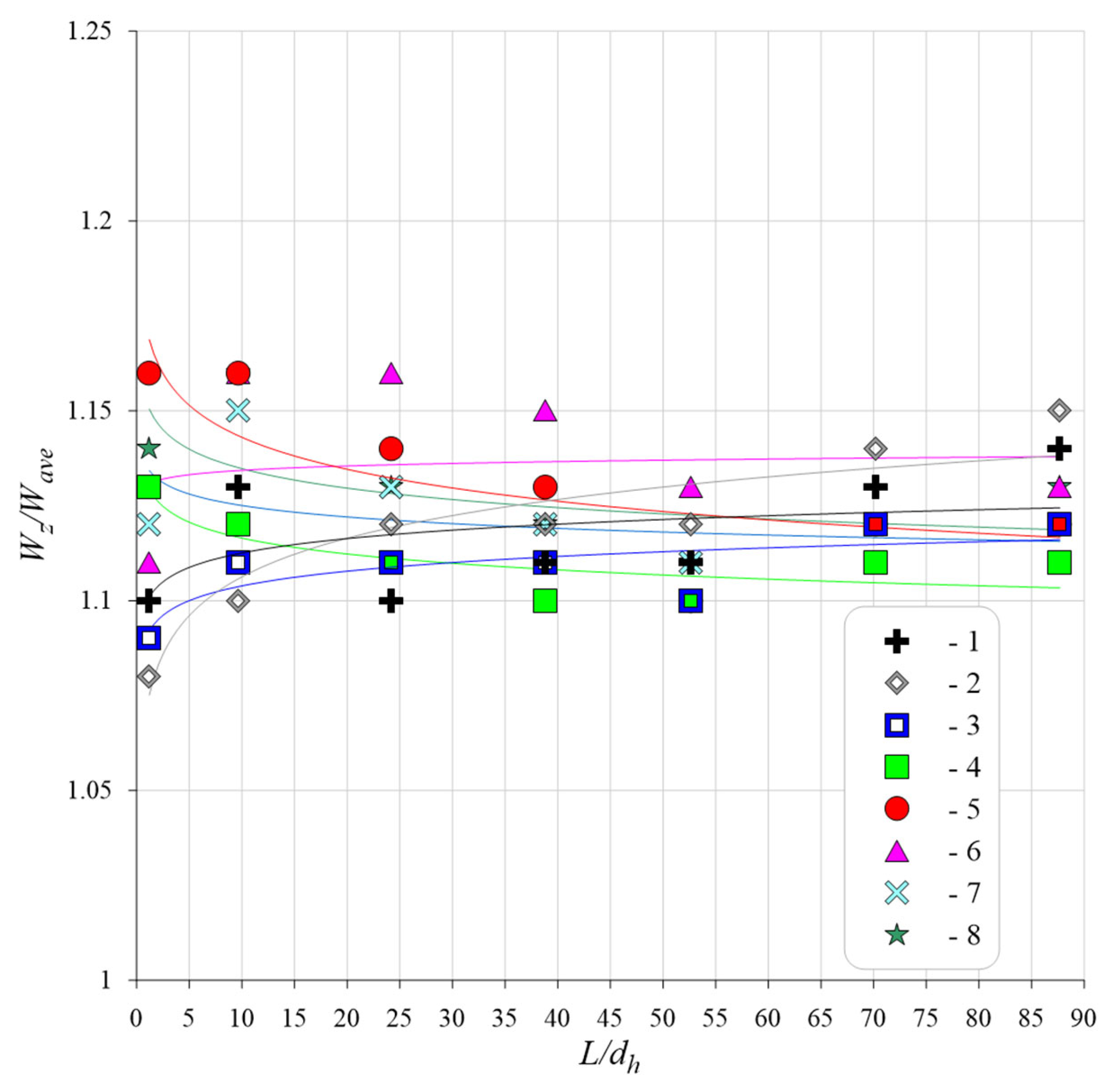

- The axial velocity in the regular cells at the entrance to the fuel element beam (L/dh = 1.2) was between 1.07 and 1.16. In front of the second spacer grating (L/dh = 87.7), the axial velocity ranged from 1.11 to 1.15. The change in the design of the absorbing grating did not have a significant effect on the value of the axial flow velocity in regular cells (see Figure 17).

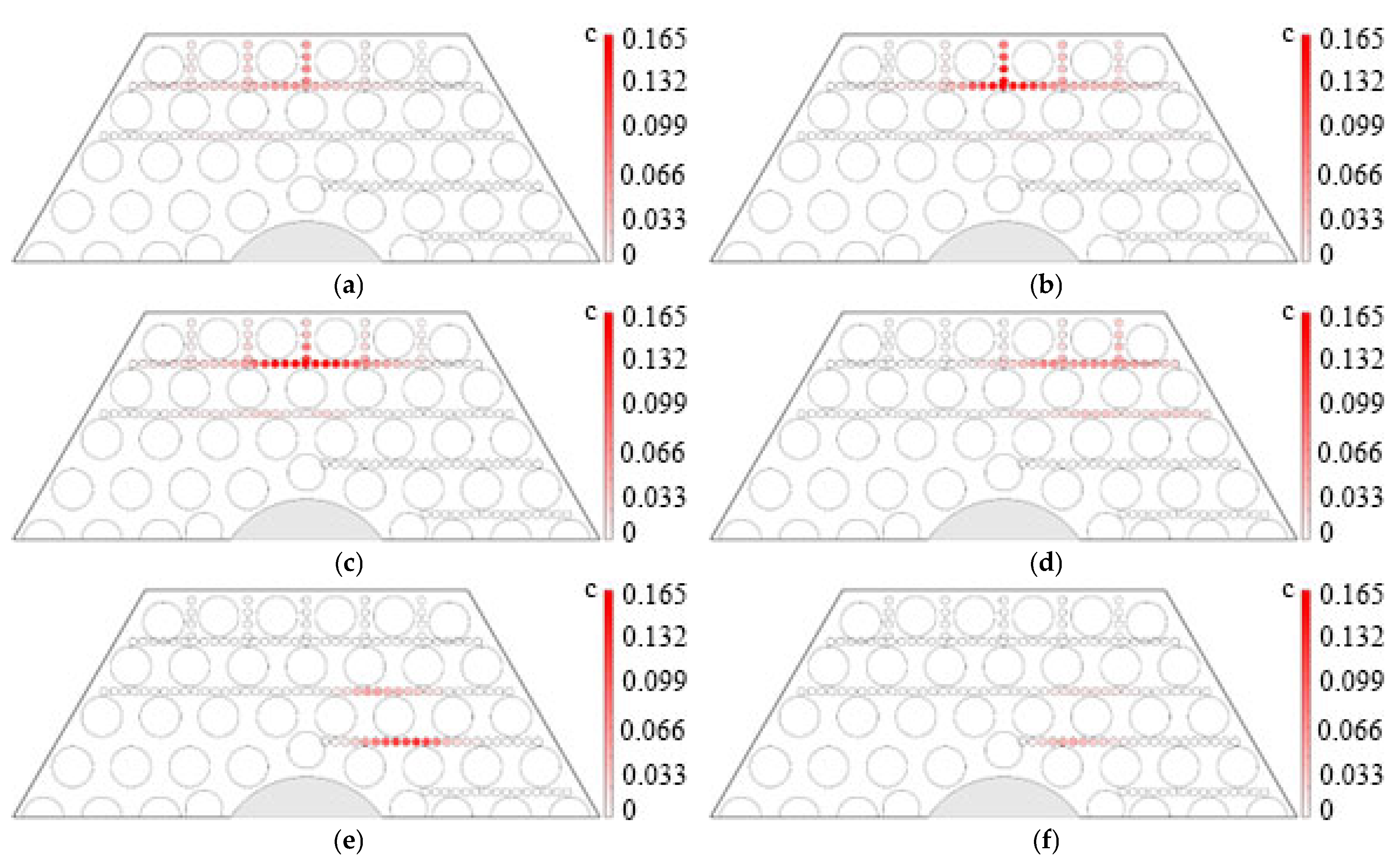

3.2. Tracer Injection Technique

4. Conclusions

- Regardless of the type or position of the installed orifice inlet device, the use of an integrated grid absorber featuring central flow restriction intensifies the process of axial flow velocity equalization across the fuel rod bundle cross-section compared to using an integrated grid absorber featuring peripheral flow restriction. When the orifice inlet device without additional holes is installed in the restricted position, the influence of the inlet section design diminishes at a distance 17.5 L/dh earlier. In all other cases of orifice inlet device installation, this influence diminishes 31.4 L/dh earlier compared to the case with the integrated grid absorber featuring peripheral flow restriction.

- The orifice inlet device without additional holes offers a wider range for regulating its loss coefficient (8.9–49.9). However, the orifice inlet device with additional holes in the open position provides a loss coefficient (2.5) lower than that of the device without additional holes.

- When designing new reactor cores, the combined use of both device designs is recommended. Combined use of orifice inlet devices implies installing devices with additional holes in the highest-power fuel assemblies (FAs), and devices without additional holes in the remaining assemblies.

- The use of an integrated grid absorber featuring central flow restriction will accelerate the process of axial flow velocity equalization across the fuel rod bundle cross-section.

- The obtained experimental data can be used not only to optimize the hydraulic profiling scheme for new small-sized nuclear plant cores and substantiate their safety but also as an empirical database for validating the CFD codes.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| CFD | Computational Fluid Dynamics |

| FA | Fuel Assemblies |

| NNSTU | Nizhniy Novgorod State Technical University |

| SMR | Small Modular Reactor |

References

- Samoylov, O.B.; Romanov, A.I.; Galitskikh, V.Y.; Zakharychev, A.A.; Morozov, O.A.; Mitrofanov, A.V.; Silaev, V.Y. Analysis of the Operating Experience of the Cores of First-Generation Nuclear Icebreakers. Database to Substantiate and Develop New Nuclear Icebreakers and Floating Power Units. Tekhnologii Obespecheniya Zhiznennogo Tsikla Yad. Energeticheskikh Ustanov. [Technol. Ensuring Life Cycle Nucl. Power Plants] 2023, 3, 16–24. (In Russian) [Google Scholar]

- Zverev, D.L.; Samoilov, O.B.; Morozov, O.A.; Zakharychev, A.A.; Silaev, V.Y.; Matyash, P.B.; Vishnev, A.Y.; Kashka, M.M.; Darbinyan, O.E. Cores of Operating Nuclear Icebreakers. Sudostroenie [Shipbuilding] 2020, 1, 13–16. (In Russian) [Google Scholar]

- Petrunin, V.V.; Sheshina, N.V.; Fateev, S.A.; Kurachenkov, A.V.; Shchekin, D.V.; Brykalov, S.M.; Bezrukov, A.A. Scientific and Technical Aspects of Creating the Innovative RITM-200N Reactor Unit for a Small Nuclear Power Plant. At. Energy 2023, 134, 1–10. [Google Scholar] [CrossRef]

- Romanov, A.I. Development of Cores for SMRs and FPUs. Current Status and Development Directions. Bull. At. Sci. Technol. Mater. Sci. New Mater. [Vestnik atomnoi nauki I techniki Seria Materialovedenie I Novie Materiali] 2023, 5, 86–111. (In Russian) [Google Scholar]

- Liu, Y.; Wang, C.; Tian, W.; Su, G.; Qiu, S. Experimental study of cross flow and lateral pressure drop in a 5 × 5 rod bundle with mixing vane spacer grid. Nucl. Eng. Des. 2019, 351, 9–19. [Google Scholar] [CrossRef]

- Liu, Y.; Li, Y.; Wang, C.; Tian, W.; Su, G.; Qiu, S. Investigation on cross-flow characteristics of two different mixing vane grid in a 5 × 5 rod bundle. Ann. Nucl. Energy 2024, 202, 110934. [Google Scholar] [CrossRef]

- Wang, C.; Tian, W.; Zhang, D.; Su, G.; Qiu, S. Experimental investigation of the turbulent flow in a rod bundle channel with spacer grids. Ann. Nucl. Energy 2019, 128, 295–306. [Google Scholar] [CrossRef]

- Caraghiaur, D.; Anglart, H. Experimental investigation of turbulent flow through spacer grids in fuel rod bundles. Nucl. Eng. Des. 2009, 239, 2013–2021. [Google Scholar] [CrossRef]

- Matyukhin, N.M.; Ushakov, P.A.; Yudina, E.V. Experimental study of the effect of spacer grid on the flow structure in fuel assemblies of the AES 2006 reactor. Therm. Eng. 2012, 59, 518–525. [Google Scholar] [CrossRef]

- Dmitriev, S.; Demkina, T.; Dobrov, A.; Doronkov, D.; Kuritsin, D.; Nikolaev, D.; Pronin, A.; Riazanov, A.; Solntsev, D. Modeling and Visualization of Coolant Flow in a Fuel Rod Bundle of a Small Modular Reactor. Fluids 2024, 9, 235. [Google Scholar] [CrossRef]

- Dmitriev, S.M.; Demkina, T.D.; Dobrov, A.A.; Doronkov, D.V.; Doronkova, D.S.; Pronin, A.N.; Ryazanov, A.V. Coolant Hydrodynamics at the Inlet to the Reactor Core of a RITM-Type Reactor at a Small Nuclear Power Plant. Therm. Eng. 2024, 71, 375–390. [Google Scholar] [CrossRef]

- Dmitriev, S.M.; Ivanov, A.S.; Simonenko, V.A.; Frolov, D.V.; Nikiforov, M.V.; Pasyukov, S.D.; Kotlovanov, I.P.; Sharapov, I.K.; Yurkov, S.I.; Dolgorukova, A.G. Study of Coolant Flow Characteristics at the Inlet to the Reactor Core of the RITM Icebreaker Reactor. At. Energy 2024, 136, 113–117. [Google Scholar] [CrossRef]

- Dragunov, Y.G.; Solonin, V.I.; Perevezentsev, V.V.; Petrov, I.V. Vibrations of fuel-element bundles in VVER fuel assemblies excited by turbulent coolant flow. At. Energy 2013, 113, 153–162. [Google Scholar] [CrossRef]

- Dragunov, Y.G.; Solonin, V.I.; Perevezentsev, V.V.; Petrov, I.V. Experimental studies of the dynamical characteristics of fuel-element bundles of VVER fuel assemblies in turbulent coolant flow. At. Energy 2013, 113, 295–299. [Google Scholar] [CrossRef]

- Solonin, V.I.; Perevezentsev, V.V. Studying the vibration and random hydrodynamic loads on the fuel rods bundles in the fuel assemblies of the reactor installations used at nuclear power stations equipped with VVER reactors. Therm. Eng. 2012, 59, 384–389. [Google Scholar] [CrossRef]

- Dmitriev, S.M.; Demkina, T.D.; Dobrov, A.A.; Doronkov, D.V.; Pronin, A.N.; Ryazanov, A.V. A study of the coolant flow at the inlet to the fuel assembly of the RITM nuclear icebreaker reactor. At. Energy 2024, 136, 141–145. [Google Scholar] [CrossRef]

- Dmitriev, S.M.; Demkina, T.D.; Dobrov, A.A.; Doronkov, D.V.; Doronkova, D.S.; Legchanov, M.A.; Pronin, A.N.; Ryazanov, A.V.; Solntsev, D.N. Features of forming a coolant flow in the inlet section of the fuel cartridge for a RITM small nuclear power plant. Thermophys. Aeromech. 2024, 31, 631–644. [Google Scholar] [CrossRef]

- Dmitriev, S.M.; Barinov, A.A.; Varentsov, A.V.; Doronkov, D.V.; Solntsev, D.N.; Khrobostov, A.E. Experimental studies of local coolant hydrodynamics using a scaled model of cassette-type fuel assembly of a KLT-40S reactor. Therm. Eng. 2016, 63, 567–574. [Google Scholar] [CrossRef]

- Dmitriev, S.M.; Demkina, T.D.; Dobrov, A.A.; Doronkov, D.V.; Doronkova, D.S.; Pronin, A.N.; Ryazanov, A.V.; Solntsev, D.N.; Khrobostov, A.E. Hydrodynamics of a Coolant in the Outlet Section of a Cassette Type Fuel Assembly. J. Eng. Phys. Thermophys. 2024, 97, 195–203. [Google Scholar] [CrossRef]

- Dmitriev, S.M.; Demkina, T.D.; Dobrov, A.A.; Doronkov, D.V.; Doronkova, D.S.; Kuritsin, D.D.; Pronin, A.N.; Ryazanov, A.V. Experimental Determination of the Hydrodynamic Characteristics of the Coolant Flow at the Outlet from the Reactor Core of the RITM Icebreaker Reactor. At. Energy 2024, 136, 57–61. [Google Scholar] [CrossRef]

- Gukhman, A.A. Vvedenie v Teoriyu Podobiya [Introduction to the Theory of Similarity]; Vysshaya Shkola: Moscow, Russia, 1973; 480p. (In Russian) [Google Scholar]

- GOST 12.3.018-79; Occupational Safety Standards System (OSSS). Ventilation Systems. Methods of Aerodynamic Testing. Standartinform: Moscow, Russia, 2004. (In Russian)

| Type of the Inlet Orifice Device | Loss Coefficient | |

|---|---|---|

| Without extra holes | fully open position | 8.9 |

| maximally restricted position | 49.9 | |

| With extra holes | fully open position | 2.5 |

| maximally restricted position | 9.9 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Riazanov, A.; Dmitriev, S.; Doronkov, D.; Dobrov, A.; Pronin, A.; Solntsev, D.; Demkina, T.; Kuritsin, D.; Nikolaev, D. Effects of the Orifice and Absorber Grid Designs on Coolant Mixing at the Inlet of an RITM-Type SMR Fuel Assembly. Fluids 2025, 10, 278. https://doi.org/10.3390/fluids10110278

Riazanov A, Dmitriev S, Doronkov D, Dobrov A, Pronin A, Solntsev D, Demkina T, Kuritsin D, Nikolaev D. Effects of the Orifice and Absorber Grid Designs on Coolant Mixing at the Inlet of an RITM-Type SMR Fuel Assembly. Fluids. 2025; 10(11):278. https://doi.org/10.3390/fluids10110278

Chicago/Turabian StyleRiazanov, Anton, Sergei Dmitriev, Denis Doronkov, Aleksandr Dobrov, Aleksey Pronin, Dmitriy Solntsev, Tatiana Demkina, Daniil Kuritsin, and Danil Nikolaev. 2025. "Effects of the Orifice and Absorber Grid Designs on Coolant Mixing at the Inlet of an RITM-Type SMR Fuel Assembly" Fluids 10, no. 11: 278. https://doi.org/10.3390/fluids10110278

APA StyleRiazanov, A., Dmitriev, S., Doronkov, D., Dobrov, A., Pronin, A., Solntsev, D., Demkina, T., Kuritsin, D., & Nikolaev, D. (2025). Effects of the Orifice and Absorber Grid Designs on Coolant Mixing at the Inlet of an RITM-Type SMR Fuel Assembly. Fluids, 10(11), 278. https://doi.org/10.3390/fluids10110278