Valorization of River Sediments in Sustainable Cementitious Gel Materials: A Review of Characteristics, Activation, and Performance

Abstract

1. Introduction

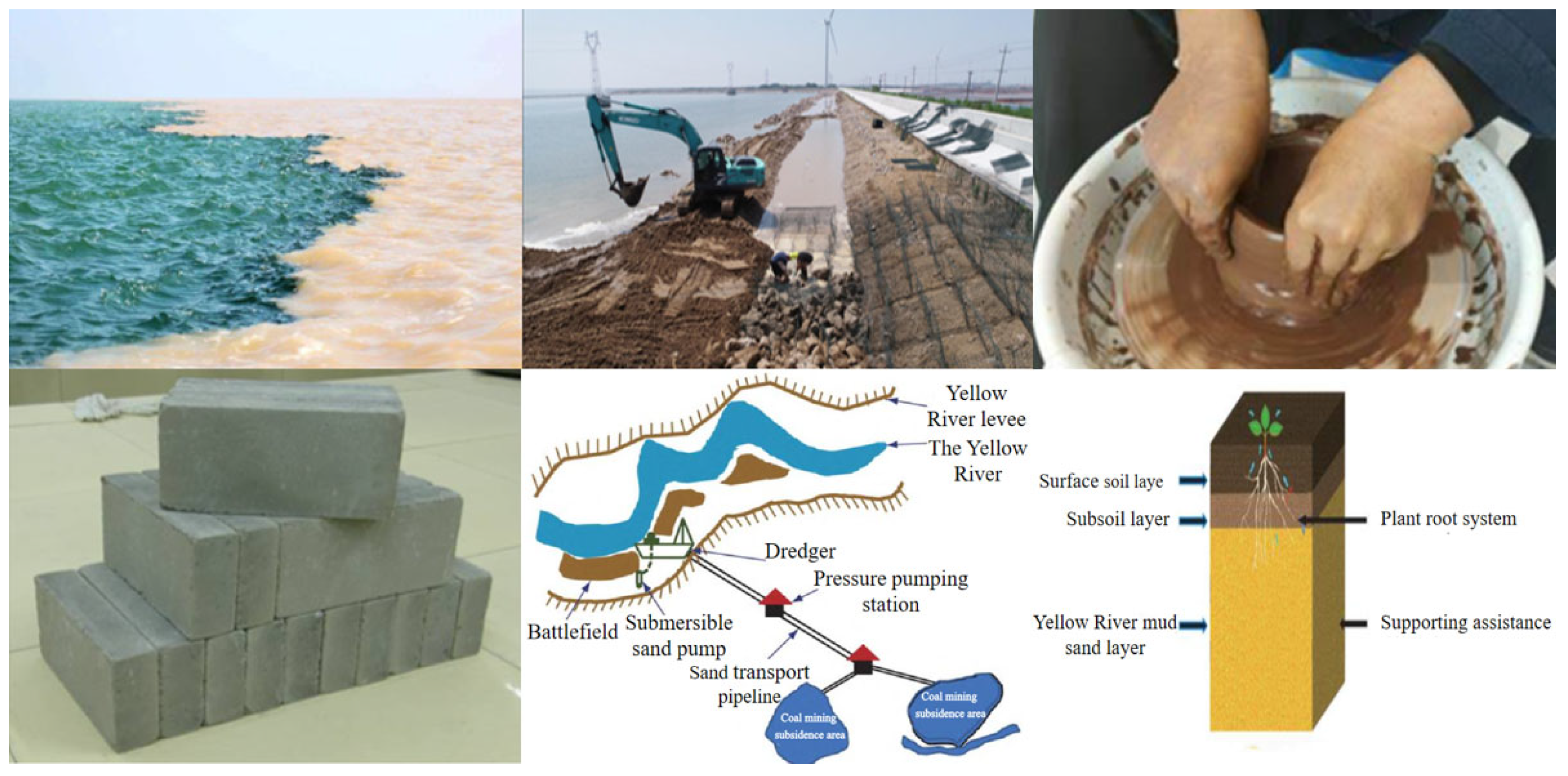

1.1. Research Background

1.2. Methodology

2. Physical Characteristics and Activation Measures of River Sediments

2.1. Fundamental Characteristics

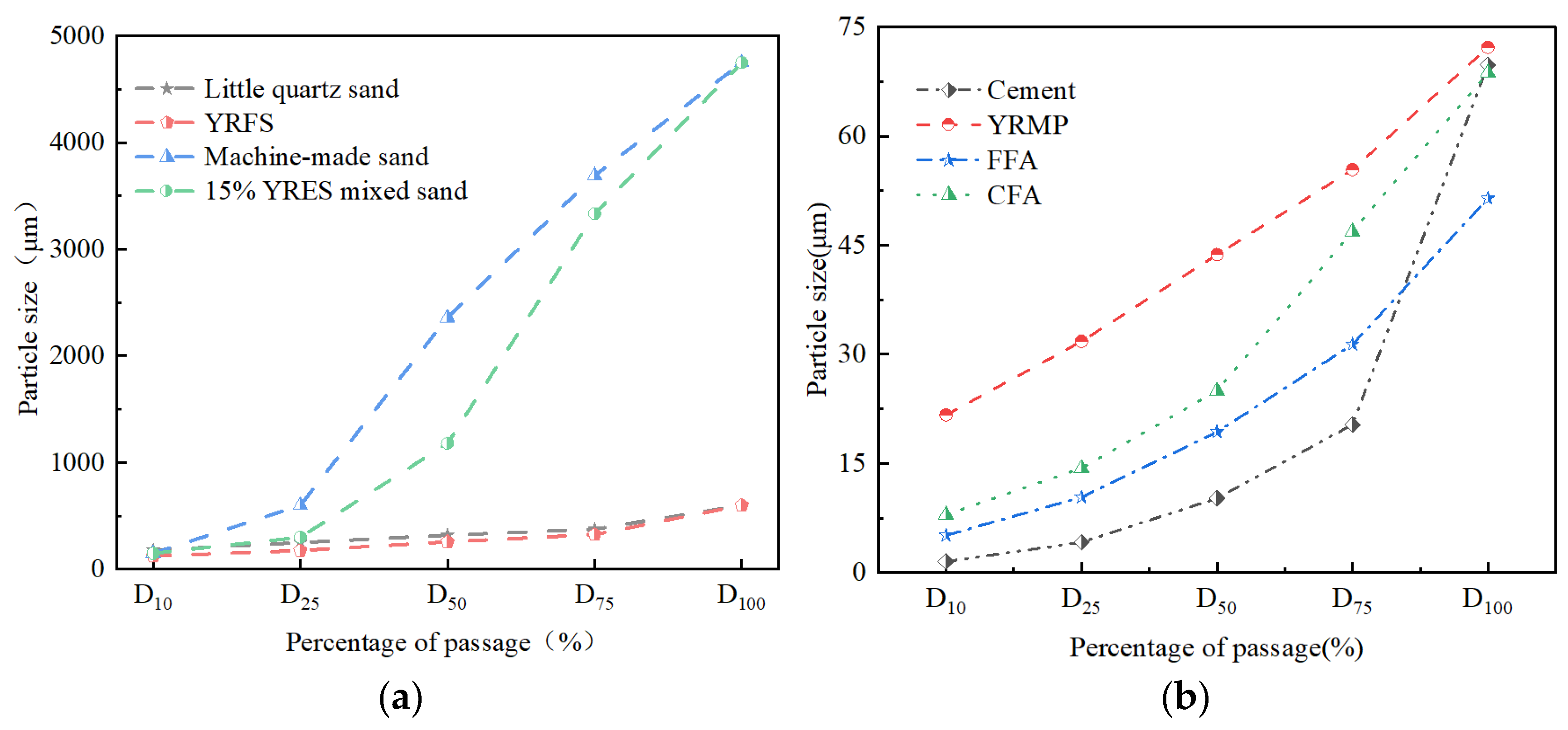

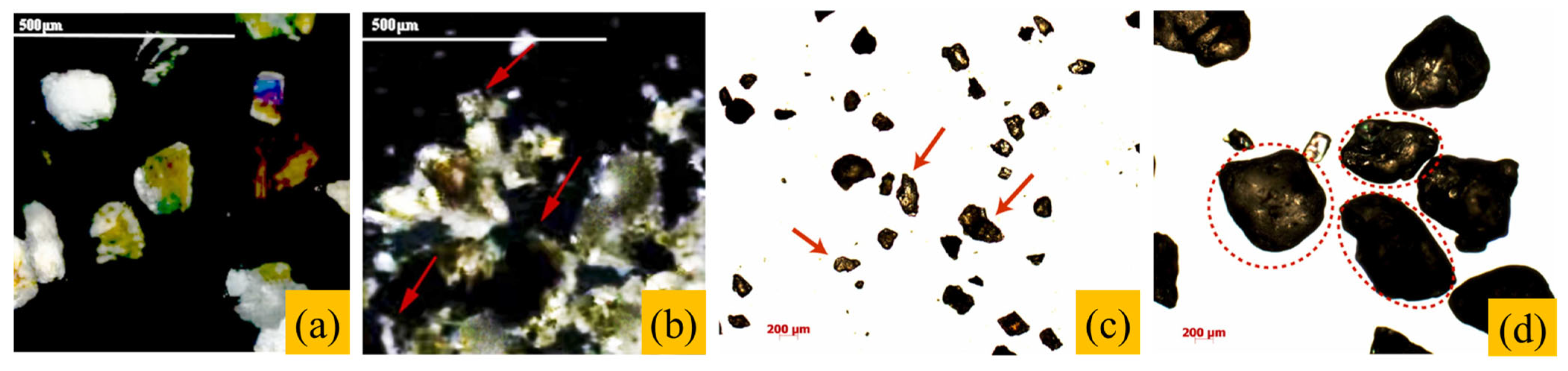

2.1.1. Physical Characteristics

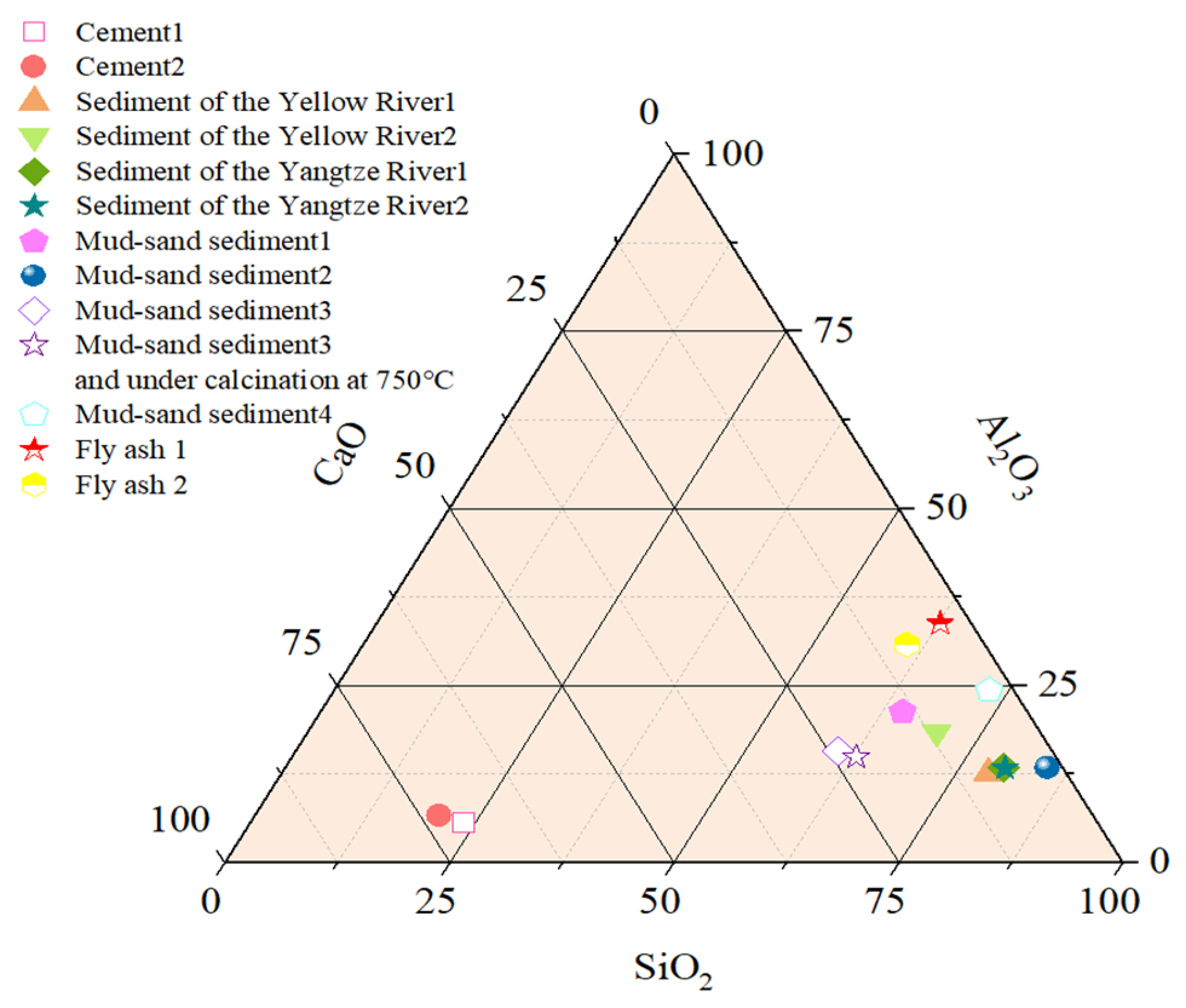

2.1.2. Chemical Composition

2.1.3. Mineral Composition

2.2. Activation Measures for Fine-Grained River Sediments

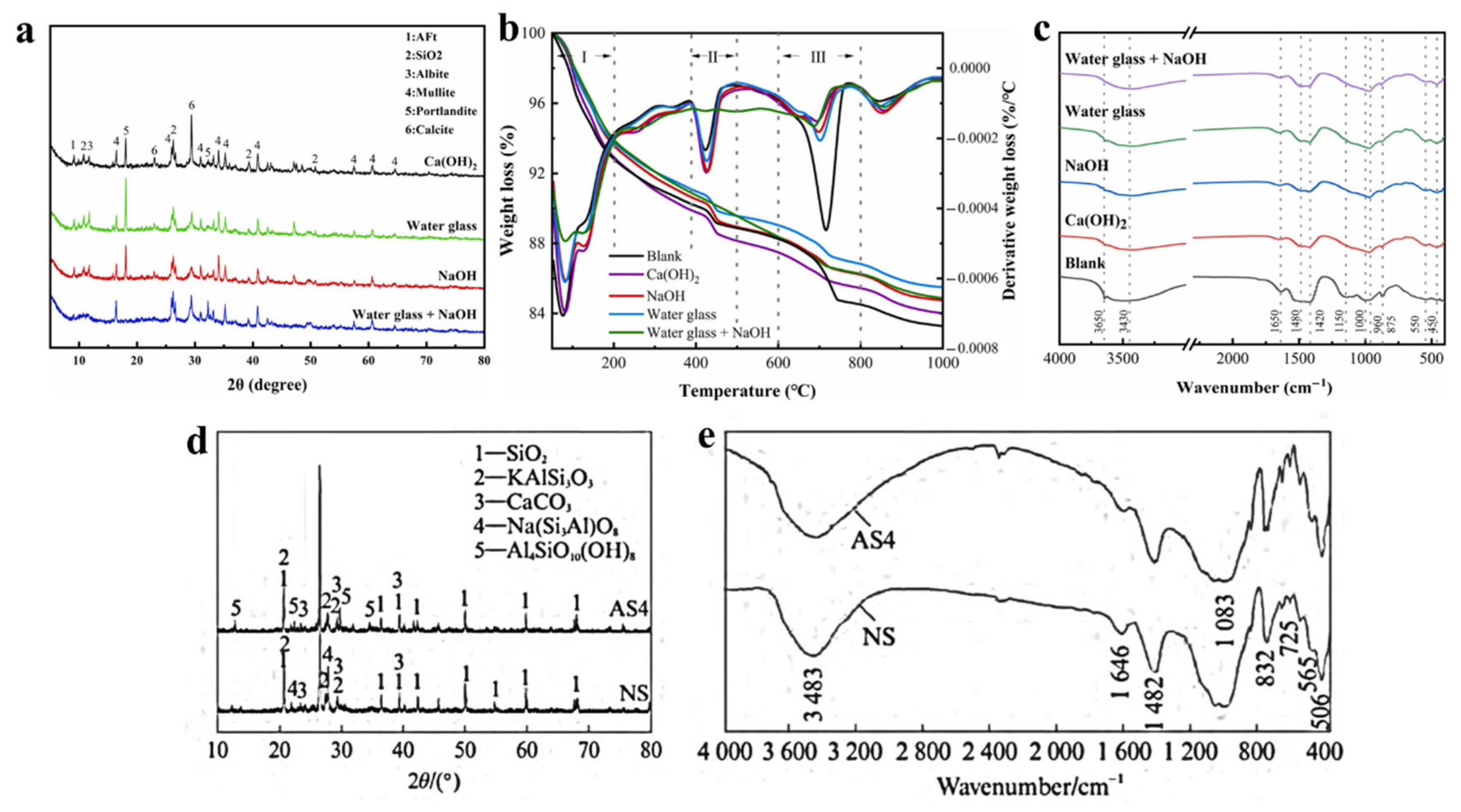

2.2.1. Chemical Excitation Activation

- (1)

- Categories of chemical excitants

- (2)

- Activation reaction mechanisms

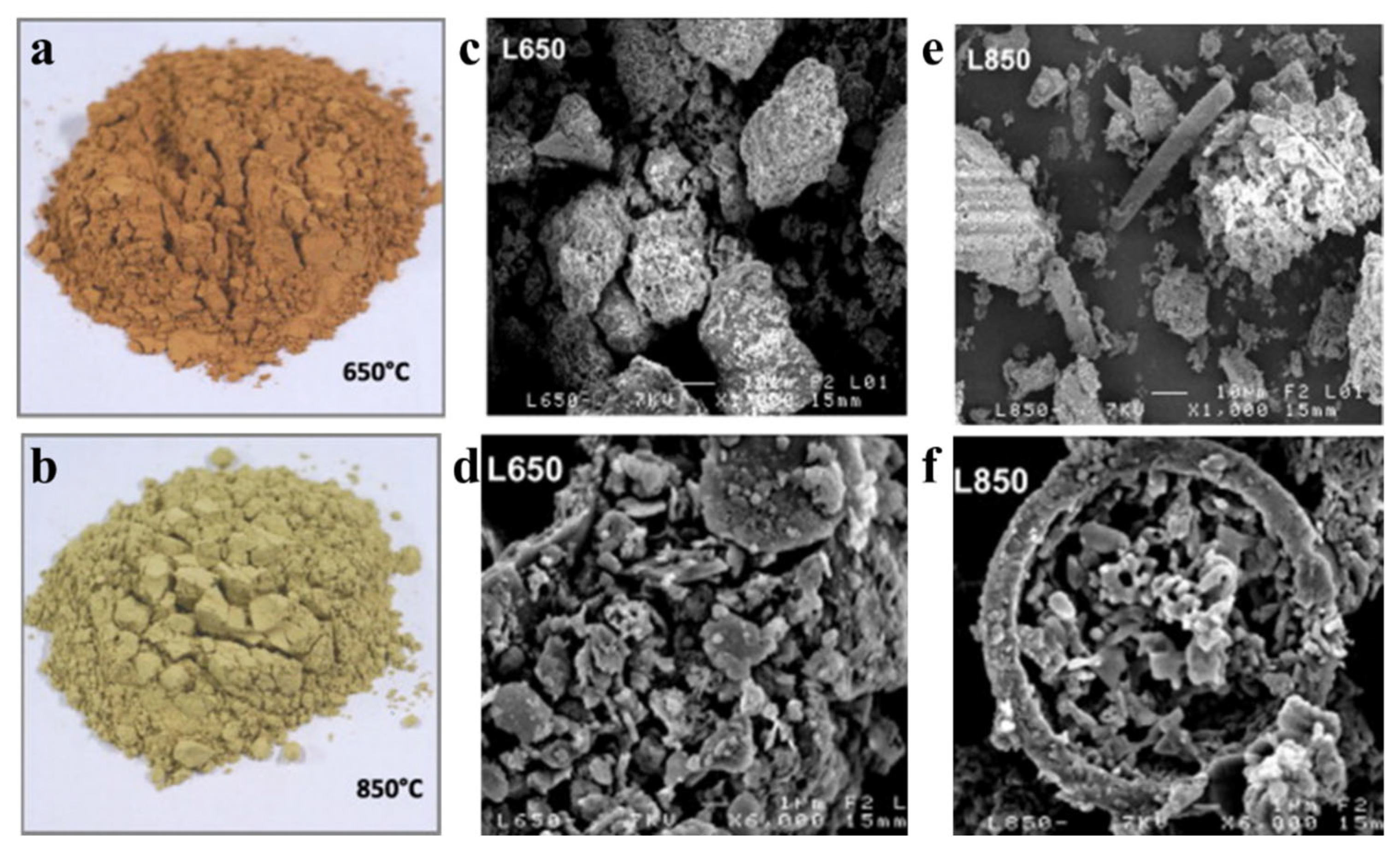

2.2.2. Thermal Activation

2.2.3. Mechanical Milling

2.2.4. Pozzolanic Reactivity Assessment Methods

- (1)

- A rapid evaluation method for the activity of pozzolanic materials was used, and the activity rate (Kα) of pozzolanic materials was defined as the ratio of the total reactive SiO2 and Al2O3 (reacted with saturated limewater) to the total amount of SiO2 and Al2O3, as shown in Equation (1) [91].

- (2)

- The Fratini test assesses pozzolanic reactivity by monitoring changes in OH− and Ca2+ concentrations in a system comprising 20% mineral admixture and 80% CEM I cement. After sealing at 40 °C for 8–15 days, ion concentrations are compared with the Ca2+ solubility curve to determine activity [92].

- (3)

- The strength activity index method evaluates mechanical performance by comparing the compressive strength of cement paste containing supplementary cementitious material with that of control paste made from ordinary Portland cement [87].

- (4)

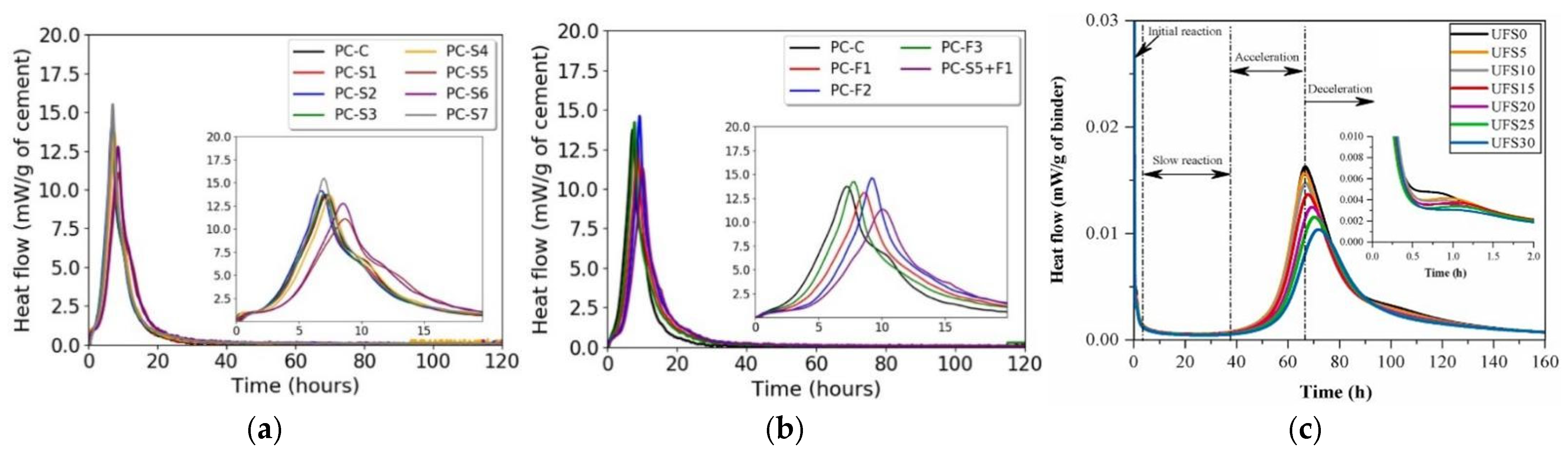

- Calorimetry is used to assess the effect of activated sedimentary pozzolanic material on cement hydration rate, thereby indirectly evaluating pozzolanic activity [87].

3. Performance-Enhancement Design for Sediment-Based Concrete

3.1. Mix Proportioning Methodology

3.2. Performance Enhancement in Sediment-Functionalized Concrete

3.2.1. Sediment as Partial Aggregate Replacement

3.2.2. Sediment as Partial Cementitious Material Replacement

- (1)

- Chemical activation

- (2)

- Performance-enhancing additives

4. Comprehensive Performance Analysis of River-Sediment Concrete

4.1. Hydration Heat Release

4.2. Rheological Behavior

4.3. Shrinkage Behavior

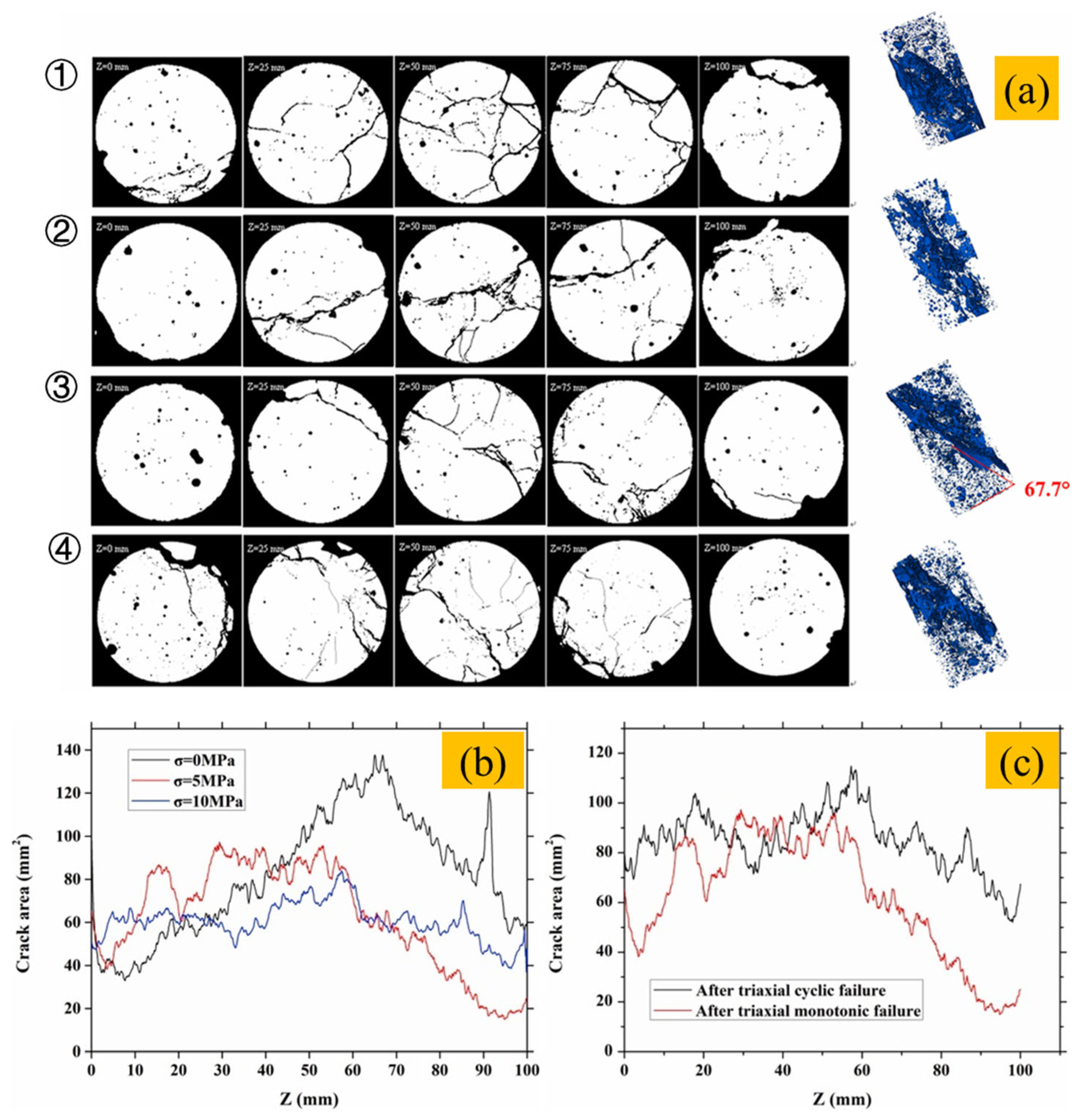

4.4. Fundamental Mechanical Properties

- (1)

- Fine aggregate substitution: Ultrafine dredged sand can increase strength by 3–10% at a 20–50% replacement ratio; above 60%, insufficient paste coating causes a sharp strength reduction.

- (2)

- Cementitious material substitution: Flash-calcined or alkali-activated sediments exhibit significantly enhanced pozzolanic activity, and at a 10–20% replacement of OPC or GGBS, compressive strength can increase by up to 17%, showing a “low dosage, high efficiency” effect.

- (3)

- Synergistic additives: Sediments combined with red mud, slag, or similar materials can achieve strength gains through “activation and densification” mechanisms; some systems (e.g., YRS-GGBS-RM ground polymer) show strength improvements over 20%.

4.5. Durability Performance

- (1)

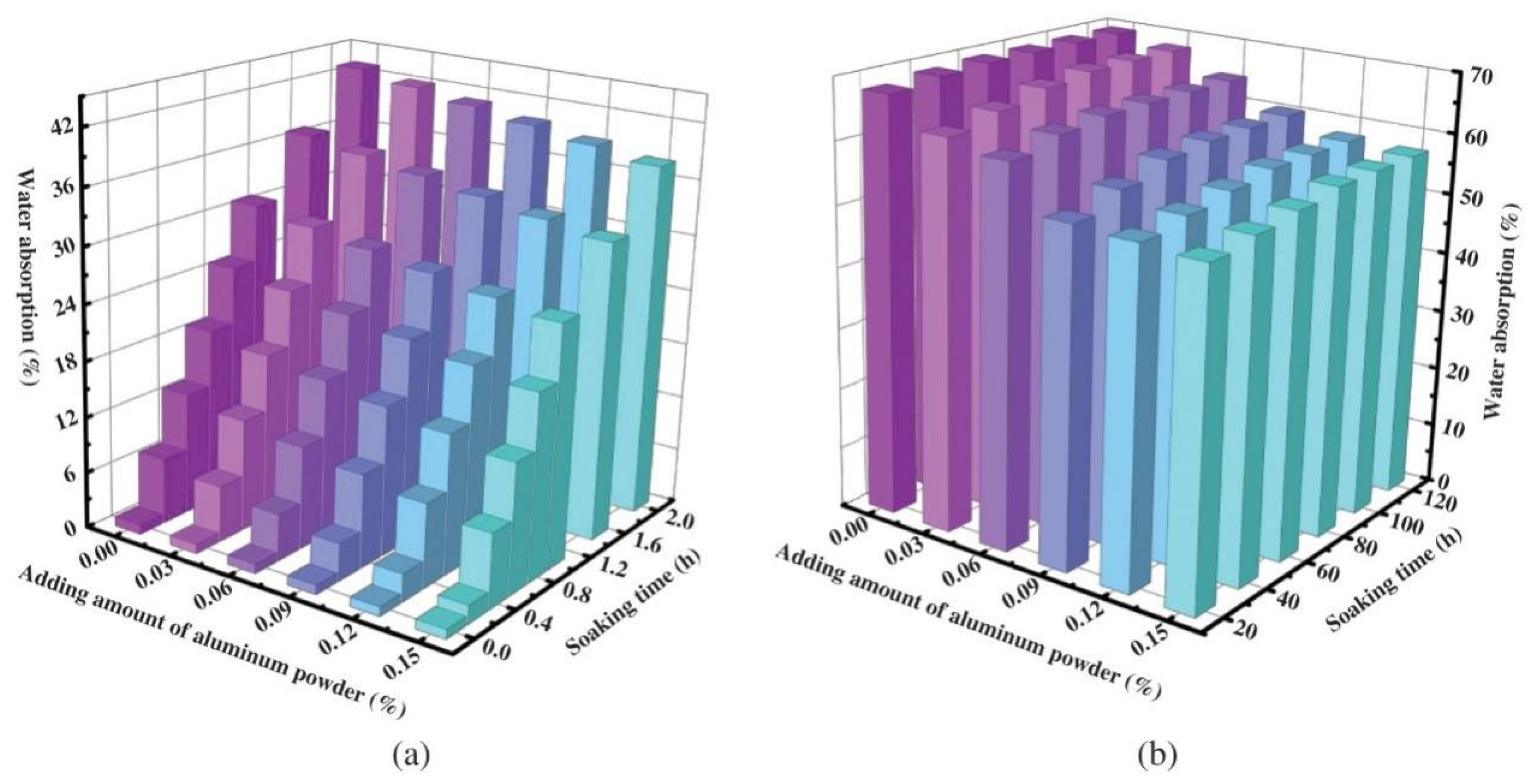

- Early-stage water absorption/pore structure regulation

- (2)

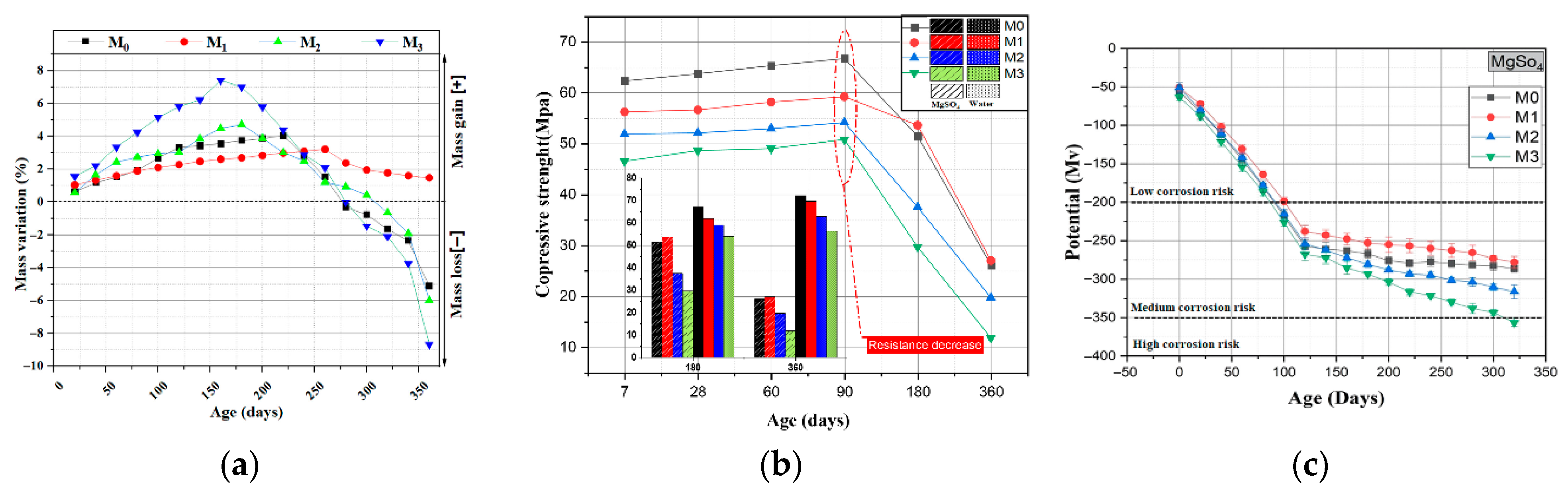

- Sulfate attack resistance

- (3)

- Freeze–thaw durability

- (4)

- Chloride ingress resistance

4.6. Hydration Kinetics and Microstructural Evolution

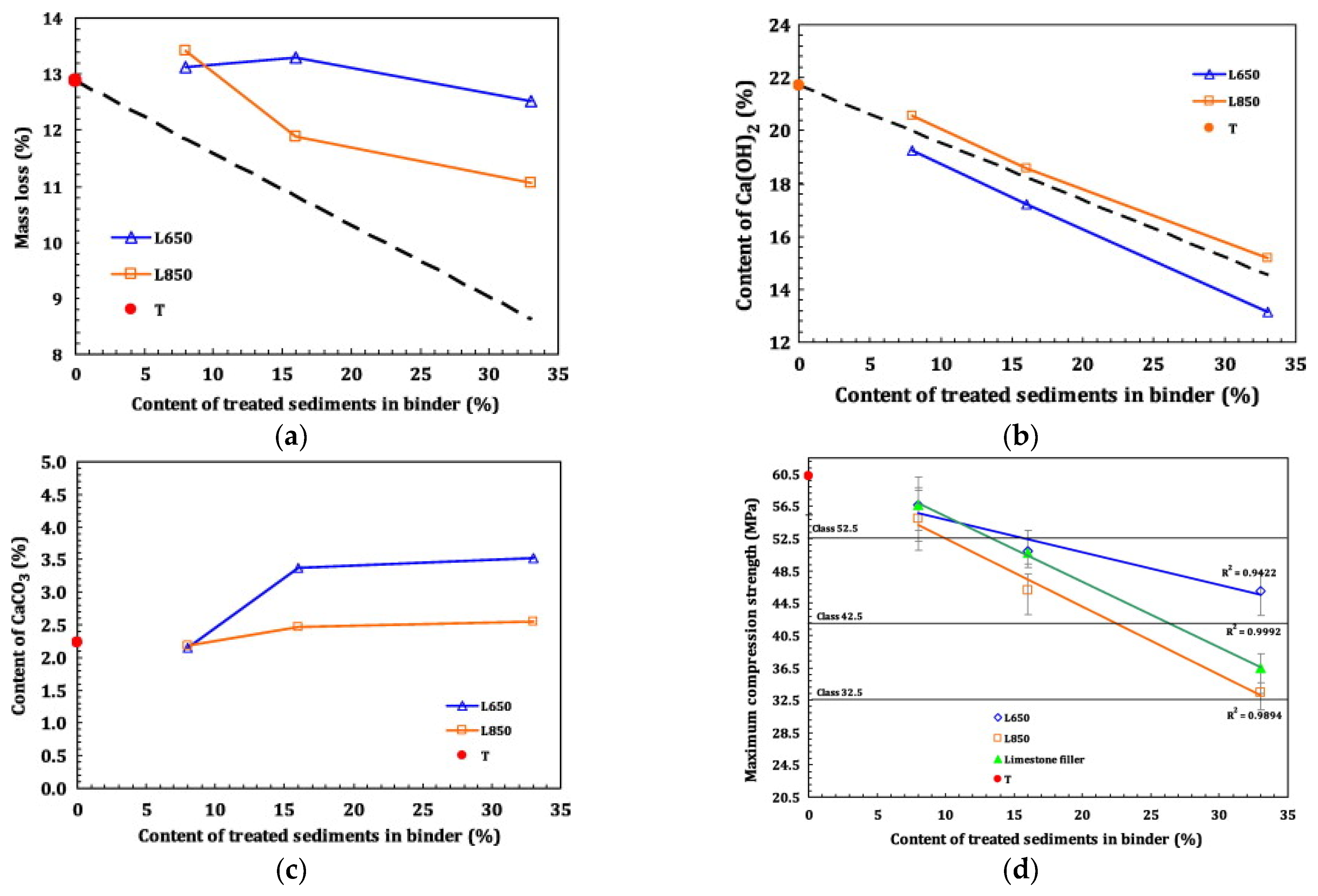

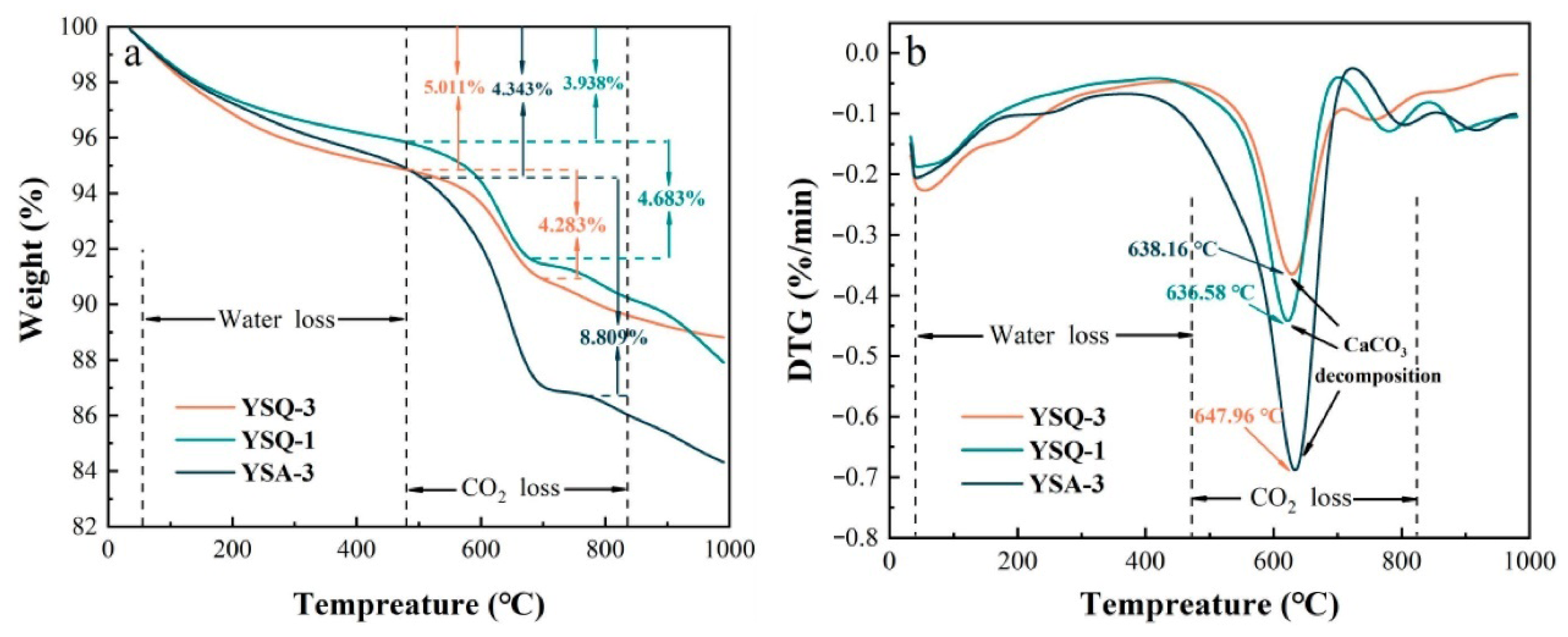

4.6.1. Thermogravimetric Analysis

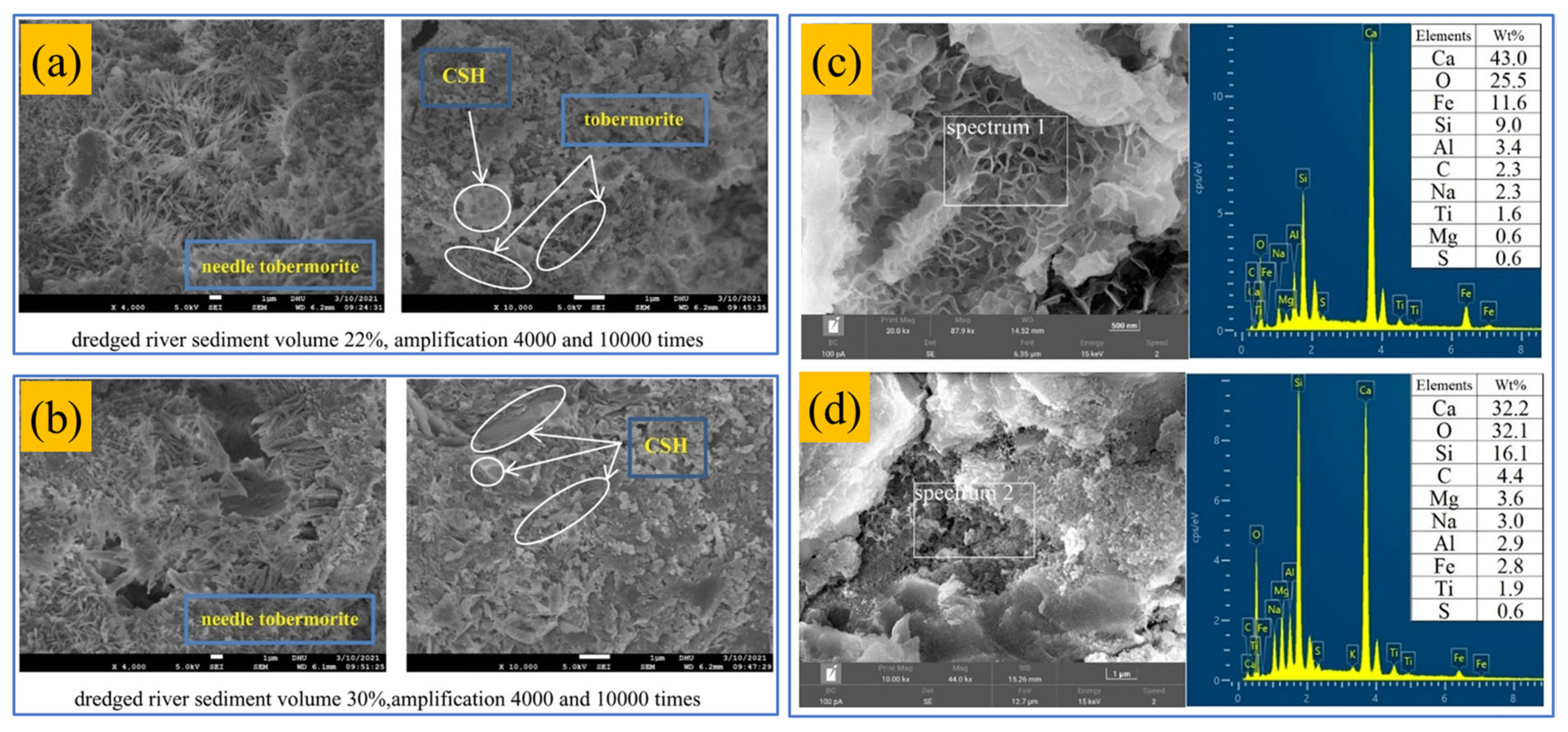

4.6.2. Microscopic Properties

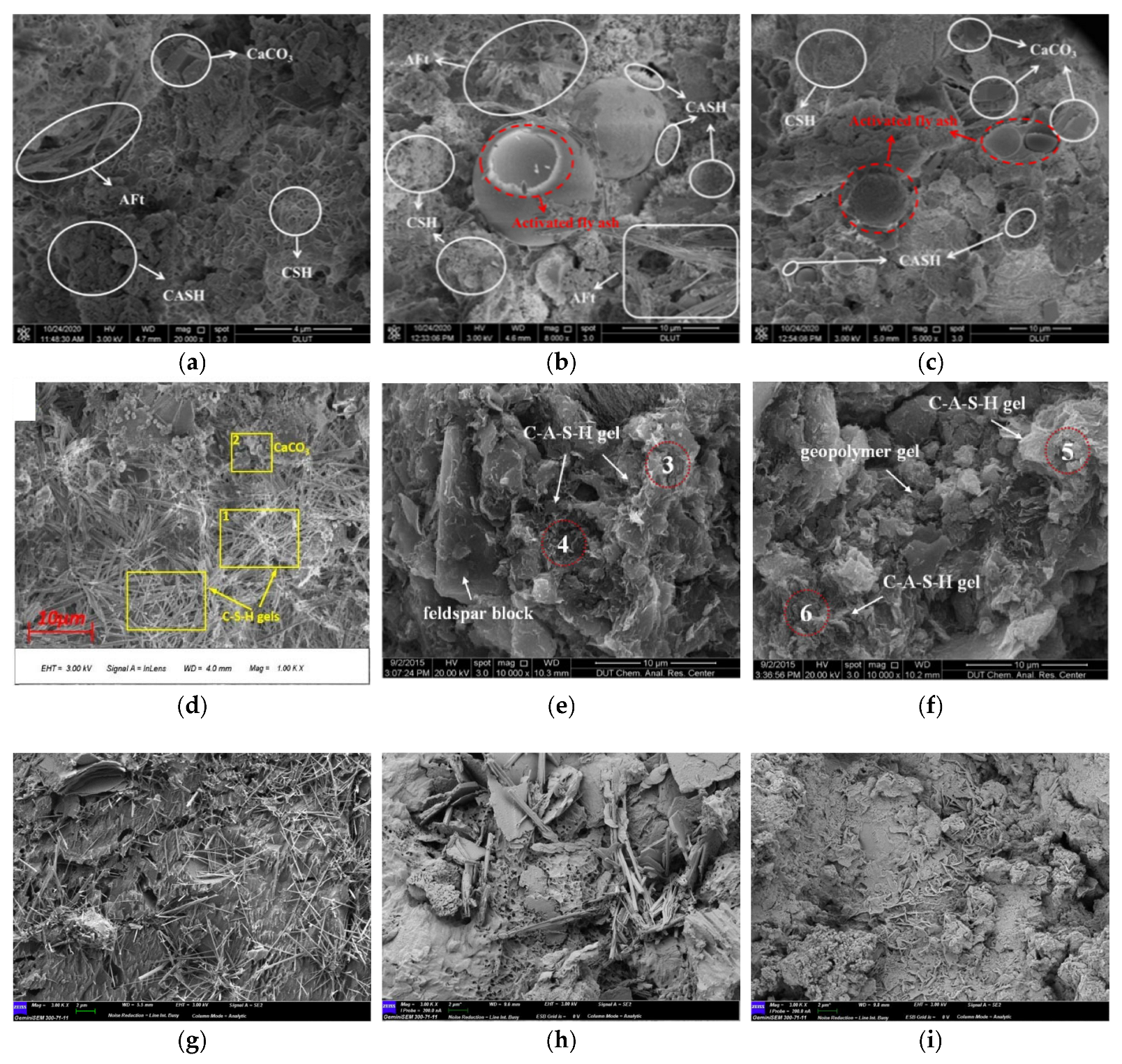

- (1)

- Scanning electron microscope

- (2)

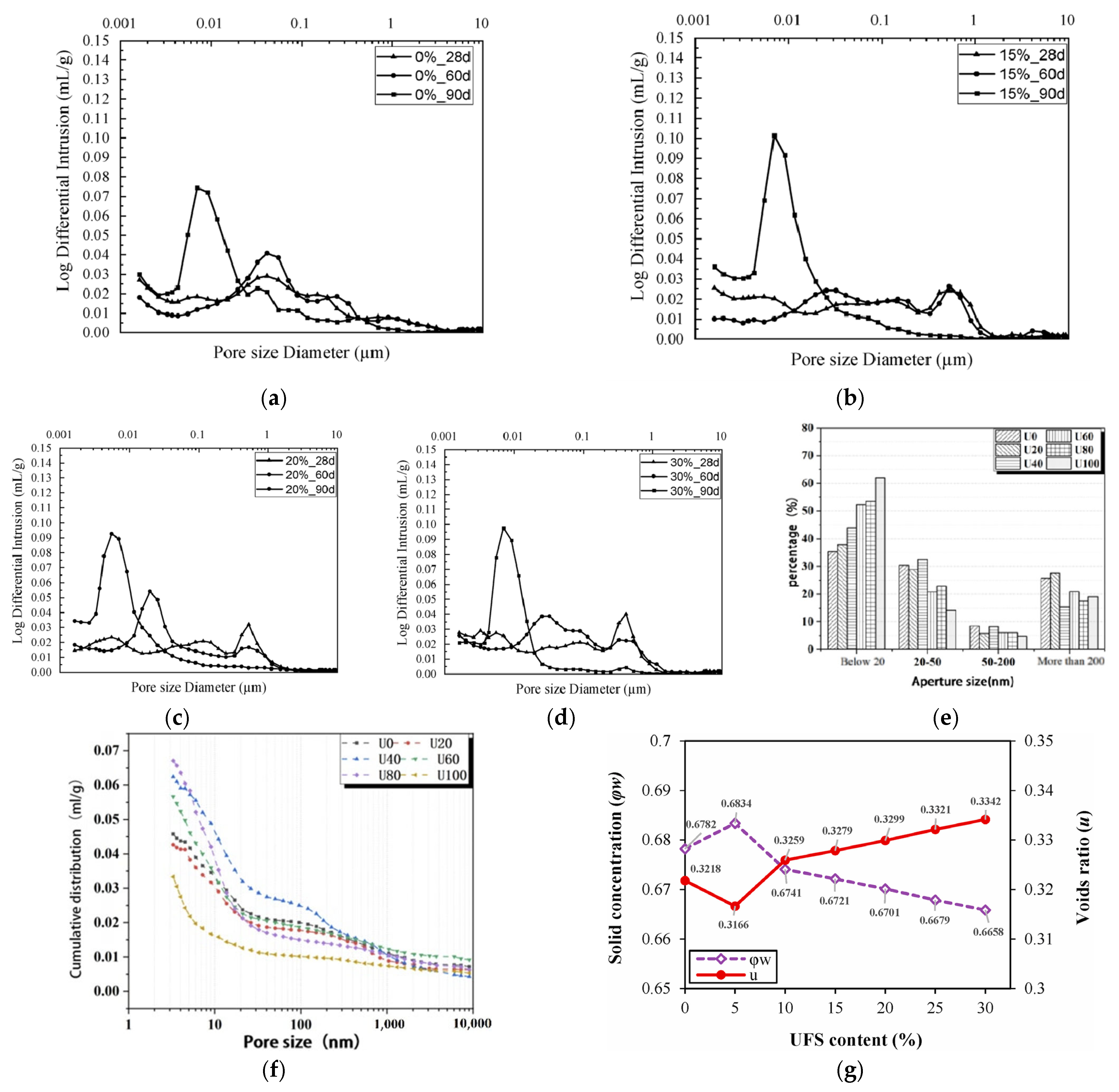

- Pore structure characterization

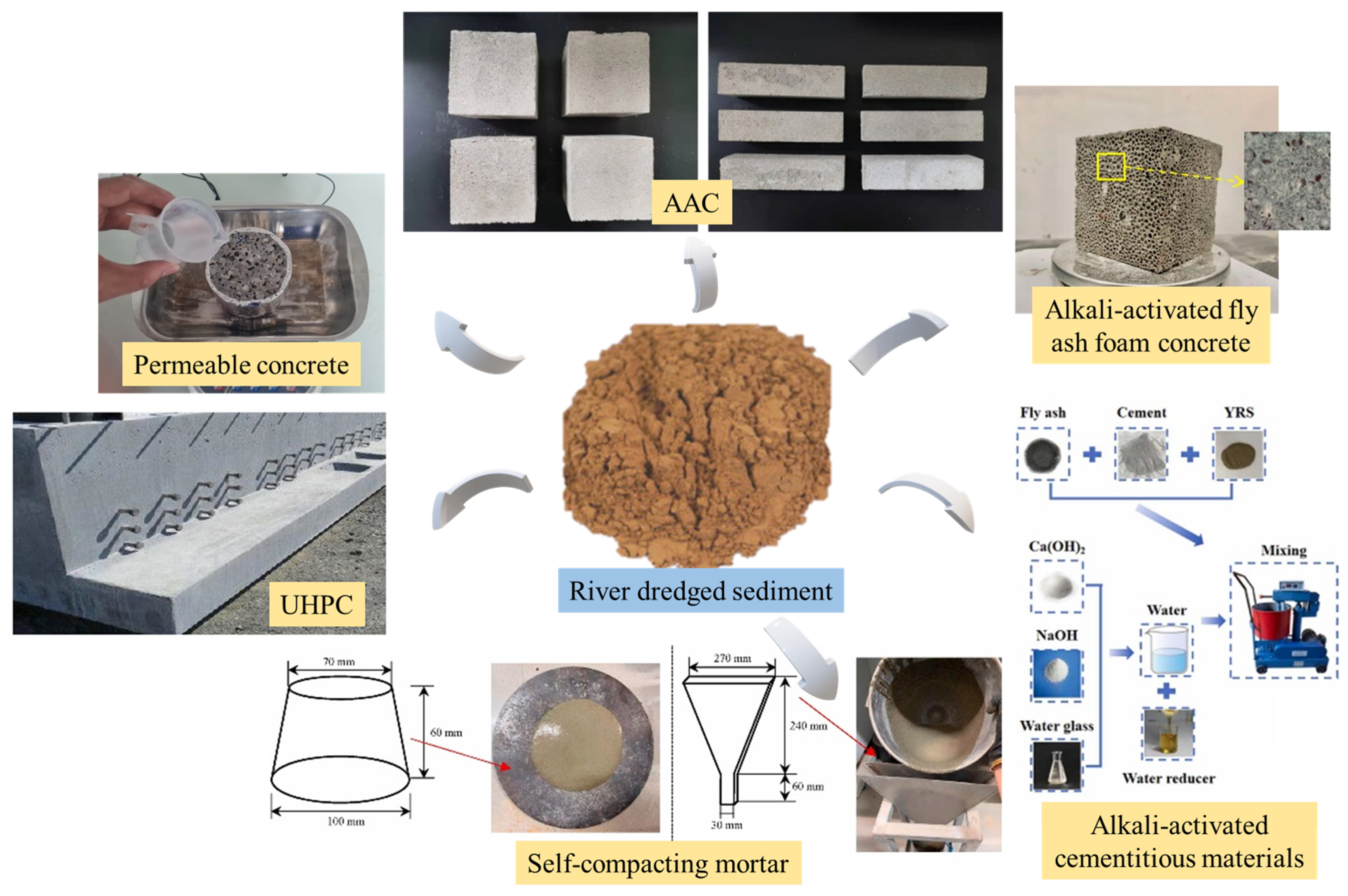

5. Taxonomy and Application Scenarios of Sediment-Tailored Multifunctional Concrete

5.1. Deposited Fine Sand as Partial Sand Replacement

- (1)

- Pervious concrete: Compared to conventional concrete, pervious concrete has lower thermal conductivity and heat capacity, helping to mitigate urban heat island effects [24]. Beddaa et al. [39] found that finer dredged sediments, used to fully replace sand, produced denser concrete with reduced porosity and permeability and improved compressive strength.

- (2)

- Lightweight and thermal-insulating concrete: A porous ceramic masonry mortar using Yellow River sediment and coal dust fully replaced standard sand and offered lightweight properties [23]. Zhang et al. [113] further improved the performance by incorporating biochar, enhancing water retention, water resistance, and insulation, making it suitable for green building applications.

- (3)

- Polymer-based mortar: Maherzi et al. [101] developed a polymer mortar by replacing traditional sand with sediment. The resulting material showed enhanced chemical resistance and thermal stability, with superior durability under corrosive and thermal conditions.

- (4)

- Autoclaved aerated concrete (AAC) and non-AAC blocks: AAC blocks made with 30–34% dredged silt, 24% cement, 10% quicklime, 30% fly ash, 2% gypsum, 0.09% aluminum powder, and a 0.5 water-to-material ratio, cured under 2.2 MPa for 6 h, achieved 4.5 MPa strength and 716.56 kg/m3 dry density [25]. Non-AAC blocks using 15% sediment, 48% cement, 20% lime, and the same water ratio reached 3.1 MPa and 924.19 kg/m3. Both met national standards.

- (5)

- High-performance structural concrete: Ultrafine Yellow River sand enabled high-strength UHPC with a refined pore structure even at high substitution levels [26]. Yuan et al. [139] applied it to ECC, achieving full quartz sand replacement. At 75% substitution, the material showed optimal ductility, crack control, and mechanical performance, supported by finite element modeling.

5.2. Fine-Grained Sediment as Binder Replacement

- (1)

- Foam concrete for sound insulation and air purification: Foam concrete combines sound insulation, low thermal conductivity, and photocatalytic performance. However, sediment addition lowers pH, weakening the foaming effect. At 40% cement replacement, the mixture achieves optimal performance: best sound insulation (1767 m/s, 9% foaming agent), lowest thermal conductivity (0.2831 W/m·K, 6% foaming agent), and excellent photocatalytic efficiency (14.1%, Bi4Ti3O12). Under optimized sediment and foaming agent ratios, it shows strong multifunctionality, making it suitable for green building applications [5]. Heavy metals in the sediment are well encapsulated, with low leaching even in acidic conditions. Silica fume can also be added as a pore-refining agent [38]. Jiang et al. [27] used Yellow River silt in alkali-activated fly ash foam concrete and studied the effects of sediment and alkali content on fluidity, mechanical properties, pore structure, and thermal performance, confirming its feasibility as a supplementary material.

- (2)

- Self-compacting and high-flow mortar: Mehdizadeh et al. [28] prepared self-compacting mortar by replacing 5–15% of cement with ultrafine Yangtze River sediment. The resulting mortar maintained good flowability and mechanical strength, meeting construction needs for complex structures.

- (3)

- Alkali-activated cementitious materials (AAMs) concrete: Li et al. [45,106] used sediment from the lower Yangtze River to prepare AAMs concrete and found that a 25% replacement rate improved strength, microstructure, and shrinkage resistance, offering good durability for green infrastructure. Yu et al. [29] combined Yellow River silt with fly ash and cement to develop alkali-activated materials for coal mine backfilling. They studied the effects of Ca(OH)2, NaOH, and water glass, revealing that the formation of C–(A)–S–H gel enhanced hydration, pore structure, strength, and workability, achieving both resource utilization and environmental benefits.

- (4)

- Application of Sediments in Ternary Cementitious Systems: Literature confirms sediments are a promising component in ternary systems. Some studies show sediments as key ternary blend components, enhancing mechanical properties and refining microstructure. First, explorations have focused on ternary systems with calcined sediment, limestone filler, and cement. Bellara, Zeraoui, Hadj Sadok, and others [13,14,140,141] prepared low-carbon binders by combining GGBS and cement with clay dam, flash-burned, or canal sediments. By optimizing the sediment/GGBS/cement ratio and moisture content, they enhanced fluidity and strength, developing an eco-friendly hydraulic road binder (HRB). The hydration mechanism was clarified: flash-burned sediment provides activity, GGBS adds strength, and cement supplies alkalinity synergy. Furlan et al. [142] studied fly ash reinforcement in lime–cement stabilized dredged sediment. They detailed the pozzolanic and micro-filling effects of fly ash on pore structure and products, linking them to improved strength and water resistance. Second, other ternary systems combined sediments with different mineral admixtures. Zhang et al. [143] showed that mixtures of sediment, slag, and fly ash achieved good compactness and mechanical performance. Yu [29] and Wang [75] focused on Yellow River sediment, formulating alkali-activated or cementitious ternary systems (sediment–fly ash–cement) for backfill and mortar. These studies achieved high strength and workability while controlling efflorescence by lowering alkaline ion concentrations. Collectively, these works confirm the strong potential and practicality of using sediments in ternary cementitious systems.

6. Exploring the Classification and Application Scenarios of Sediment-Based Multifunctional

7. Conclusions and Outlook

7.1. Conclusions

- (1)

- The resource properties and application potential of river sediments were evaluated. With wide particle size distribution, high SiO2 content, and cementitious potential, sediments can replace natural sand, gravel, and partial cement as fine aggregates, lightweight aggregates, or pozzolanic materials after proper grading and decontamination.

- (2)

- The activation mechanisms and property enhancement strategies were summarized. Synergistic activation with alkali (NaOH or Ca(OH)2) and water glass promotes full consumption of Ca(OH)2 and formation of dense C–S–H/C–A–S–H networks. Thermal treatment above 650 °C enhances the activity of clay minerals like kaolinite and chlorite, though activity declines beyond 900 °C. Mechanical milling and incorporation of additives such as biochar and fibers form a “micro-cement + filler” composite structure, improving 28-day compressive strength by 10–20%.

- (3)

- Optimized mix design strategies were established. Combining minimum paste theory with packing density optimization reduces paste volume by 8–12% while maintaining a slump ≥ 180 mm. Optimal mechanical and durability performance is achieved when the sediment replacement rate is controlled at 25% ± 5%.

- (4)

- The environmental and economic benefits of sediment reuse were confirmed. Life cycle assessment shows that replacing 30% of cement with sediment can reduce CO2 emissions by approximately 180 kg/m3 and material costs by 10–15%, offering substantial ecological and economic advantages.

7.2. Outlook

- (1)

- A unified evaluation system for sediment grading, activation level, and application classification is urgently needed to support large-scale engineering deployment.

- (2)

- Multi-scale coupling mechanisms should be explored using in situ neutron/X-ray techniques and molecular dynamics to uncover sediment–cement interface reactions and long-term degradation behavior.

- (3)

- Future work should study the durability of mud–sand concrete under coupled degradation, focusing on synergistic effects between carbonation and other stresses such as chloride intrusion, dry–wet cycling, or mechanical loading.

- (4)

- Low-energy activation processes such as microwave–alkali synergy should be developed to reduce energy use and secondary emissions.

- (5)

- Future research should focus on intelligent functionalization, including sediment-based materials with temperature control, phase-change energy storage, and photocatalytic functions to achieve multifunctionality and high-value applications.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chen, W.; Yang, S.; Zhang, X.; Jordan, N.D.; Huang, J. Embodied energy and carbon emissions of building materials in China. Build. Environ. 2022, 207 Pt A, 108434. [Google Scholar] [CrossRef]

- Liu, T.; Zhao, R.; Xie, Z.; Xiao, L.; Chen, A.; Feng, W.; You, Z.; Feng, M.; Li, R. Carbon emissions from accumulated stock of building materials in China. Build. Environ. 2023, 240, 110451. [Google Scholar] [CrossRef]

- Sousa, V.; Bogas, J.; Real, S.; Meireles, I.; Carriço, A. Recycled cement production energy consumption optimization. Sustain. Chem. Pharm. 2023, 32 (Suppl. C), 101010. [Google Scholar] [CrossRef]

- Ma, M.; Huang, Z.; Wang, J.; Niu, L.; Zhang, W.; Xu, X.; Xi, F.; Liu, Z. Carbon uptake by cement in China: Estimation and contribution to carbon neutrality goals. Sci. China Earth Sci. 2024, 67, 2056–2067. [Google Scholar] [CrossRef]

- Kou, R.; Guo, M.Z.; Shi, Y.; Mei, M.; Jiang, L.; Chu, H.; Zhang, Y.; Shen, H.; Xue, L. Sound-insulation and photocatalytic foamed concrete prepared with dredged sediment. J. Clean. Prod. 2022, 356, 131902. [Google Scholar] [CrossRef]

- Wang, J.; Yang, Y.; Zhang, M.; Zhu, L.; Li, S.; Wen, Y. Critical threshold of periodic point bar scour and sediment body transport path in tidal reaches: A case study of Fujiangsha reach, Yangtze River. J. Geogr. Sci. 2023, 33, 1334–1358. [Google Scholar] [CrossRef]

- Tian, X.; Tian, P.; Zhao, G.; Gómez, J.; Guo, J.; Mu, X.; Gao, P.; Sun, W. Sediment source tracing during flood events in the Huangfu River basin in the northern Loess Plateau, China. J. Hydrol. 2023, 620 Pt B, 129540. [Google Scholar] [CrossRef]

- Xue, C.; Yang, Y.; Xu, C.; Wang, M.; Gao, J.; Han, X.; Jia, J. Sedimentary records reveal two stages of evolution of the Abandoned Yellow River Delta from AD1128 to AD1855: Vertical accretion and land-forming. Anthr. Coasts 2023, 6, 1–14. [Google Scholar] [CrossRef]

- Sun, Z.; Zhou, W.; Yuan, J.; Yang, Z.; Chen, L. Hydrological and sediment-transport characteristics of the middle and lower Yangtze River: Analysis from a magnitude-frequency perspective. CATENA 2023, 231 (Suppl. C), 107293. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, Z.; Chen, Y.; Cao, T.; Yu, X.; Rui, P. Experimental study on bio-treatment effect of the dredged Yellow River silt based on soybean urease induced calcium carbonate precipitation. J. Build. Eng. 2023, 75 (Suppl. C), 106943. [Google Scholar] [CrossRef]

- Ni, Z.; Wang, S.; Zheng, X.; Qi, C. Application of geopolymer in synchronous grouting for reusing of the shield muck in silty clay layer. Constr. Build. Mater. 2024, 419, 135345. [Google Scholar] [CrossRef]

- Duan, D.; Song, H.; Wei, F.; Feng, Z.; Cheng, H.; Cheng, F. Mechanical properties of solid waste-based composite cementitious system enhanced by CO2 modification. Constr. Build. Mater. 2024, 426, 136187. [Google Scholar] [CrossRef]

- Bellara, S.; Hidjeb, M.; Maherzi, W.; Mezazigh, S.; Senouci, A. Optimization of an Eco-Friendly Hydraulic Road Binders Comprising Clayey Dam Sediments and Ground Granulated Blast-Furnace Slag. Buildings 2021, 11, 443. [Google Scholar] [CrossRef]

- Zeraoui, A.; Maherzi, W.; Benzerzour, M.; Abriak, N. Optimization of Ternary Binders Based on Flash-Calcined Sediments and Ground Granulated Blast Furnace slag Using a Mixture Design. Preprints 2021. [Google Scholar] [CrossRef]

- Wang, B.; Li, G.; Han, J.; Zheng, Y.; Liu, H.; Song, W. Study on the properties of artificial flood-prevention stone made by Yellow River silt. Constr. Build. Mater. 2017, 144, 484–492. [Google Scholar] [CrossRef]

- Siham, K.; Fabrice, B.; Edine, A.; Patrick, D. Marine dredged sediments as new materials resource for road construction. Waste Manag. 2008, 28, 919–928. [Google Scholar] [CrossRef]

- He, H.; Yue, Q.; Su, Y.; Gao, B.; Gao, Y.; Wang, J.; Yu, H. Preparation and mechanism of the sintered bricks produced from Yellow River silt and red mud. J. Hazard. Mater. 2012, 203–204, 53–61. [Google Scholar] [CrossRef]

- Wang, H.; Guo, J.; Liu, W.; Song, H.; Yan, T.; Fu, D. Use of COVID-19 personal protective equipment pollutants to improve physical properties of silty sand in Yellow River flooded area. Front. Environ. Sci. 2022, 10, 1011685. [Google Scholar] [CrossRef]

- Wu, Y.; Wan, Y.; He, X.; Cai, Y.; Xu, W.; Zhao, B.; Shen, Y. Improving the impermeability and mechanical properties of the Yellow River sediment with polymer gels. Case Stud. Constr. Mater. 2024, 20, e03246. [Google Scholar] [CrossRef]

- Yang, J.; Xu, L.; Hao, H.; Yang, S. Effect of TiO2 on the thermal conductivity of eco-friendly silica bricks fabricated by yellow river silt(Conference Paper). Mater. Sci. Forum 2009, 610–613 Pt 1, 206–210. [Google Scholar] [CrossRef]

- Liu, J.; Hai, R.; Zhang, L.; Bolf, N. Modification of Yellow River Sediment Based Stabilized Earth Bricks. Kem. u Ind. 2016, 65, 613–618. [Google Scholar] [CrossRef][Green Version]

- Tang, C. Producing synthetic lightweight aggregates by treating waste TFT-LCD glass powder and reservoir sediments. Comput. Concr. 2014, 13, 325–342. [Google Scholar] [CrossRef]

- Wang, S.; Yang, L.; Ma, X.; Mei, R.; Li, C.; Sun, Z. The formation of porous light ceramsite using Yellow River sediment and its application in concrete masonry production. Case Stud. Constr. Mater. 2022, 17 (Suppl. C), e01340. [Google Scholar] [CrossRef]

- Beddaa, H.; Tchiotsop, J.; Fraj, A.B.; Somé, C. Reuse of river sediments in pervious concrete: Towards an adaptation of concrete to the circular economy and climate change challenges. Constr. Build. Mater. 2023, 368 (Suppl. C), 130443. [Google Scholar] [CrossRef]

- Zhang, K.; Wei, Q.; Jiang, S.; Shen, Z.; Zhang, Y.; Tang, R.; Yang, A.; Chow, C. Utilization of Dredged River Sediment in Preparing Autoclaved Aerated Concrete Blocks. J. Renew. Mater. 2022, 10, 2989–3008. [Google Scholar] [CrossRef]

- Yan, J.; Zhong, S.; Chen, S.; Lv, Y.; Yang, L.; Peng, G.; Deng, A. Study on the Application of Sediment-Based Embankment Building and Ultra-High-Performance Concrete (UHPC) Preparation in the Resource Utilization of Yellow River Sediment. Materials 2022, 15, 5668. [Google Scholar] [CrossRef]

- Jiang, S.; Xu, J.; Song, Y.; Xu, Y. Alkali-activated fly ash foam concrete with Yellow River silt: Physico-mechanical and structural properties. Constr. Build. Mater. 2023, 373 (Suppl. C), 130879. [Google Scholar] [CrossRef]

- Mehdizadeh, H.; Guo, M.; Ling, T. Ultra-fine sediment of Changjiang estuary as binder replacement in self-compacting mortar: Rheological, hydration and hardened properties. J. Build. Eng. 2021, 44 (Suppl. C), 103251. [Google Scholar] [CrossRef]

- Yu, Z.; Wang, B.; Li, T.; Fan, C.; Yu, H. Effect and mechanism of activators on the properties of Yellow River sediment/fly ash/cement-based alkali-activated cementitious materials used for coal mine filling. Constr. Build. Mater. 2024, 445, 137955. [Google Scholar] [CrossRef]

- Guo, Y.; Gong, H.; Shi, W.; Fang, N.; Tan, Y.; Zhou, W.; Huang, J.; Dai, L.; Dai, X.; Guo, Y. Insights into multisource sludge distributed in the Yangtze River basin, China: Characteristics, correlation, treatment and disposal. J. Environ. Sci. 2023, 126, 321–332. [Google Scholar] [CrossRef] [PubMed]

- Huang, Z.; Liu, X.; Wen, J.; Fang, H.; Lin, S.; Li, W.; Wang, J.; Zeng, F.; Du, H.; Shi, L. Characteristics and fractionations of sediment oxygen demand in a complex tidal river network area. J. Environ. Manag. 2024, 354, 120352. [Google Scholar] [CrossRef]

- Rahman, M.; Ali, M. Properties of dredged material and potential scope of its beneficial use: A case study of the Pussur River in Bangladesh. Water Sci. Eng. 2024, 17, 336–343. [Google Scholar] [CrossRef]

- Marzouki, M.; Samet, B.; Tounsi, H. Application of Plackett–Burman and Box-Behnken designs for the optimization of Tunisian dam sediment-based geopolymers. J. Build. Eng. 2022, 50 (Suppl. C), 104162. [Google Scholar] [CrossRef]

- Slimanou, H.; Bouziane, A.; Bouzidi, N.; Bouzidi, M.; Quesada, D. Marine dredged sediment based cementitious matrix: Thermal treatment, physical properties and prediction using response surface methodology. Environ. Sci. Pollut. Res. Int. 2025, 32, 8284–8306. [Google Scholar] [CrossRef]

- Zhang, J.; Kang, S.; Shen, Y.; Song, C.; Lei, H.; Xie, W.; Chen, X.; Wang, J.; Wu, W.; Wang, X. Effects of Sand Type and Alkali Equivalent on Drying Shrinkage and Microstructure of Seawater–Sea Sand Alkali-Activated Slag Concrete. Materials 2025, 18, 1005. [Google Scholar] [CrossRef]

- Fernandes, I.; Lima, V.; Nascimento, C.; Carvalho, H.; Santos, C.; Neto, A. Valorization of textile sludge for use as supplementary cementitious material–Benefiting processes, pozzolanic activity, and application in no-slump concrete. Constr. Build. Mater. 2025, 458, 139619. [Google Scholar] [CrossRef]

- Hazarika, A.; Huang, L.; Erlingsson, S.; Weerdt, K.; Löfgren, I.; Iftikhar, S.; Babaahmadi, A. Characterization, activation and reactivity—A case study of Nordic volcanic materials for application as Supplementary Cementitious Materials. Case Stud. Constr. Mater. 2025, 22, e04096. [Google Scholar] [CrossRef]

- Yang, X.; Zhao, L.; Haque, M.; Chen, B.; Ren, Z.; Cao, X.; Shen, Z. Sustainable conversion of contaminated dredged river sediment into eco-friendly foamed concrete. J. Clean. Prod. 2020, 252, 119799. [Google Scholar] [CrossRef]

- Beddaa, H.; Fraj, A.; Ducléroir, S. Experimental study on river sediment incorporation in concrete as a full aggregate replacement: Technical feasibility and economic viability. Constr. Build. Mater. 2021, 313 (Suppl. C), 125425. [Google Scholar] [CrossRef]

- Yang, L. Research on the Preparation of High-Performance Concrete Using Yellow River Sand. Master’s Thesis, North China University of Water Resources and Electric Power, Zhengzhou, China, 2022. (In Chinese). [Google Scholar]

- Zhao, M.; Dai, M.; Li, J.; Li, C. Case study on performance of pumping concrete with super-fine river-sand and manufactured-sand. Case Stud. Constr. Mater. 2023, 18 (Suppl. C), e01850. [Google Scholar] [CrossRef]

- Zajac, M.; Bremeier, R.; Deja, J.; Król, M.; Haha, M.B. Carbonation hardening of Portland cement with recycled supplementary cementitious materials. Cem. Concr. Compos. 2025, 157, 105904. [Google Scholar] [CrossRef]

- Zhou, Y.; Yu, P.; Yang, H.; Xia, X.; He, S.; Huang, X. Utilization of municipal solid waste incinerator fly ash under high temperature sintering and alkali excitation for use in cementitious material. J. Build. Eng. 2024, 94, 110005. [Google Scholar] [CrossRef]

- Rong, X.; Zhang, X.; Zhang, J.; Xu, W.; Zhang, Z. Study on mechanical and thermal properties of alkali-excited fly ash aerogel foam concrete. Constr. Build. Mater. 2023, 408 (Suppl. C), 133770. [Google Scholar] [CrossRef]

- Li, S.; Chen, X.; Zhang, W.; Ning, Y.; Casas, J. Utilization of ultra-fine dredged sand from the Yangtze River in alkali-activated slag/fly ash mortars: Mechanical properties, drying shrinkage and microstructure. Case Stud. Constr. Mater. 2023, 107, e02264. [Google Scholar] [CrossRef]

- Ferone, C.; Liguori, B.; Capasso, I.; Colangelo, F.; Cioffi, R.; Cappelletto, E.; Di Maggio, R. Thermally treated clay sediments as geopolymer source material. Appl. Clay Sci. 2015, 107, 195–204. [Google Scholar] [CrossRef]

- Huang, W.; Chen, X.; Luan, J.; Ning, Y.; Ji, T.; Shi, Z. Deep insight into mechanical behaviour and microstructure mechanism of dredged sand in the lower reaches of the Yangtze River and manufactured sand concrete. J. Build. Eng. 2023, 68 (Suppl. C), 106105. [Google Scholar] [CrossRef]

- Benkabouche, A.; Amar, M.; Benzerzour, M.; Abriak, N.; T’kint, M.; Mouli, M. The Influence of External Sulfate Attack on the Durability of Reinforced Mortars in the Presence of Calcined River Sediments. Materials 2023, 16, 6684. [Google Scholar] [CrossRef]

- Shen, W.; Yang, Z.; Cao, L.; Cao, L.; Liu, Y.; Yang, H.; Lu, Z.; Bai, J. Corrigendum to: Characterization of manufactured sand: Particle shape, surface texture and behavior in concrete [Constr. Build. Mater. 114 (2016) 595–601]. Constr. Build. Mater. 2016, 119, 385. [Google Scholar] [CrossRef]

- He, H.; Wang, Y.; Wang, J. Compactness and hardened properties of machine-made sand mortar with aggregate micro fines. Constr. Build. Mater. 2020, 250, 118828. [Google Scholar] [CrossRef]

- Bayesteh, H.; Sharifi, M.; Haghshenas, A. Effect of stone powder on the rheological and mechanical performance of cement-stabilized marine clay/sand. Constr. Build. Mater. 2020, 262 Pt 2, 120792. [Google Scholar] [CrossRef]

- Tomasz, Z.; Tomasz, T.; Marcin, A. Effect of the amount of river sediment on the basic properties of cement mortars. MATEC Web Conf. 2020, 322, 1032. [Google Scholar] [CrossRef]

- Nakayenga, J.; Cikmit, A.; Tsuchida, T.; Hata, T. Influence of stone powder content and particle size on the strength of cement-treated clay. Constr. Build. Mater. 2021, 305 (Suppl. C), 124710. [Google Scholar] [CrossRef]

- Tian, E.; Ren, W.; Zhuang, Y.; Zeng, W. Effect of steel slag powder and stone powder by-product from manufactured sand on the mechanical properties and microstructure of cementitious materials. J. Clean. Prod. 2024, 452, 142128. [Google Scholar] [CrossRef]

- Tittarelli, F.; Carsana, M.; Ruello, M. Effect of hydrophobic admixture and recycled aggregate on physical–mechanical properties and durability aspects of no-fines concrete. Constr. Build. Mater. 2014, 66, 30–37. [Google Scholar] [CrossRef]

- Zaetang, Y.; Sata, V.; Wongsa, A.; Chindaprasirt, P. Properties of pervious concrete containing recycled concrete block aggregate and recycled concrete aggregate. Constr. Build. Mater. 2016, 111, 15–21. [Google Scholar] [CrossRef]

- Hai, R.; Liu, J.; Zhang, L.; Yang, J. The Effect and Mechanism of CaCl2 Composite Activation of Yellow River Sediment. J. Build. Mater. 2016, 19, 654–658. (In Chinese) [Google Scholar]

- Zhao, Z.; Benzerzour, M.; Abriak, N.; Damidot, D.; Courard, L.; Wang, D. Use of uncontaminated marine sediments in mortar and concrete by partial substitution of cement. Cem. Concr. Compos. 2018, 93, 155–162. [Google Scholar] [CrossRef]

- Jha, P.K.; Vaithiyanathan, P.; Subramanian, V. Mineralogical characteristics of the sediments of a Himalayan river: Yamuna River—A tributary of the Ganges. Environ. Geol. 1993, 22, 13. [Google Scholar] [CrossRef]

- Elsayed, H.; Beusen, A.; Bouwman, A.F. Nutrient transport from the Ganga–Brahmaputra–Meghna River system to the Bay of Bengal: Past and future trends. Environ. Res. Lett. 2025, 20, 024054. [Google Scholar] [CrossRef]

- Li, C.; Shi, X.; Gao, S.; Chen, M.; Liu, Y.; Fang, X.; Lv, H.; Zou, J.; Liu, S.; Qiao, S. Composition Characteristics and Material Sources of Clay Minerals in River Sediments in Taiwan. Chin. Sci. Bull. 2012, 57, 169–177. [Google Scholar]

- Singh, P.; Rajamani, V. Geochemistry of the Floodplain Sediments of the Kaveri River, Southern India. J. Sediment. Res. 2001, 71, 50–60. [Google Scholar] [CrossRef]

- Siddique, R.; Klaus, J. Influence of metakaolin on the properties of mortar and concrete: A review. Appl. Clay Sci. 2008, 43, 392–400. [Google Scholar] [CrossRef]

- Snellings, R.; Suraneni, P.; Skibsted, J. Future and emerging supplementary cementitious materials. Cem. Concr. Res. 2023, 171 (Suppl. C), 107199. [Google Scholar] [CrossRef]

- Nofalah, M.; Ghadir, P.; Hasanzadehshooiili, H.; Aminpour, M.; Javadi, A.; Nazem, M. Effects of binder proportion and curing condition on the mechanical characteristics of volcanic ash- and slag-based geopolymer mortars; machine learning integrated experimental study. Constr. Build. Mater. 2023, 395 (Suppl. C), 132330. [Google Scholar] [CrossRef]

- Shi, C.; Jimenez, A.F.; Palomo, A. New cements for the 21st century: The pursuit of an alternative to Portland cement. Cem. Concr. Res. 2011, 41, 750–763. [Google Scholar] [CrossRef]

- Scrivener, K.; Ouzia, A.; Juilland, P.; Mohamed, A. Advances in understanding cement hydration mechanisms. Cem. Concr. Res. 2019, 124, 105823. [Google Scholar] [CrossRef]

- Tan, H.; Yuan, P.; Sun, D.; Fan, X.; Wang, C.; Liu, J. Ratio of water to cement and supplementary cementitious materials on mechanical and impact resistance properties of reactive powder concrete. Sci. Rep. 2025, 15, 7480. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Zhang, T.; Wang, L. Mechanical properties and microstructure of alkali activated Pisha sandstone geopolymer composites. Constr. Build. Mater. 2014, 68, 233–239. [Google Scholar] [CrossRef]

- Rabehi, B.; Ghernouti, Y.; Driss, M. Potential Use of Calcined Silt of Dam as a Pozzolan in Blended Portland Cement. Int. J. Concr. Struct. Mater. 2014, 8, 259–268. [Google Scholar] [CrossRef][Green Version]

- Zhang, B.; Peng, Z.; Fahimizadeh, M.; Yu, T.; Faheem, M.; Belaroui, L.; Hamada, B.; Yuan, P. Recycling of an ion-adsorption type rare earth tailing in a low-carbon construction material: Performance modulation and life cycle assessment. Constr. Build. Mater. 2025, 475, 141167. [Google Scholar] [CrossRef]

- Jing, X.; Li, G.; Zhang, Y.; Han, J.; Wang, B. Experimental Research on the Modification of the Yellow River Sediment. Iran. J. Sci. Technol. Trans. Civ. Eng. 2021, 45, 1031–1037. [Google Scholar] [CrossRef]

- Junakova, N.; Junak, J. Sustainable Use of Reservoir Sediment through Partial Application in Building Material. Sustainability 2017, 9, 852. [Google Scholar] [CrossRef]

- Martinez-Ramirez, S.; Palomo, A. Microstructure studies on Portland cement pastes obtained in highly alkaline environments. Cem. Concr. Res. 2001, 31, 1581–1585. [Google Scholar] [CrossRef]

- Wang, Z. Research on the Activation and Application of Multi-Grain-Size Yellow River Sediment. Master’s Thesis, North China University of Water Resources and Electric Power, Zhengzhou, China, 2023. (In Chinese). [Google Scholar]

- Buchwald, A.; Hohmann, M.; Posern, K.; Brendler, E. The suitability of thermally activated illite/smectite clay as raw material for geopolymer binders. Appl. Clay Sci. 2009, 46, 300–304. [Google Scholar] [CrossRef]

- Li, C.; Dong, J.; Zhao, S.; Liu, H.; Yao, W.; Wang, L. Development of low cost supplementary cementitious materials utilizing thermally activated Pisha sandstone. Constr. Build. Mater. 2018, 174, 484–495. [Google Scholar] [CrossRef]

- Snellings, R.; Horckmans, L.; Van Bunderen, C.; Vandewalle, L.; Cizer, Ö. Flash-calcined dredging sediment blended cements: Effect on cement hydration and properties. Mater. Struct. 2017, 50, 241. [Google Scholar] [CrossRef]

- Chu, D.; Amar, M.; Kleib, J.; Benzerzour, M.; Betrancourt, D.; Abriak, N.; Nadah, J. The Pozzolanic Activity of Sediments Treated by the Flash Calcination Method. Waste Biomass Valorization 2022, 13, 4963–4982. [Google Scholar] [CrossRef]

- Dang, T.; Kamali-Bernard, S.; Prince, W. Design of new blended cement based on marine dredged sediment. Constr. Build. Mater. 2013, 41, 602–611. [Google Scholar] [CrossRef]

- He, C.; Makovicky, E.; Osbaeck, B. Thermal stability and pozzolanic activity of calcined kaolin. Appl. Clay Sci. 1994, 9, 165–187. [Google Scholar] [CrossRef]

- Földvári, M. Handbook of Thermogravimetric System of Minerals and Its Use in Geological Practice; Geological Institute of Hungary Budapest: Budapest, Hungary, 2011; Volume 213. [Google Scholar]

- García, R.; de la Villa, R.; Vegas, I.; Frías, M.; de Rojas, M.S. The pozzolanic properties of paper sludge waste. Constr. Build. Mater. 2008, 22, 1484–1490. [Google Scholar] [CrossRef]

- Cook, D. Calcinated clay, shale and other soils. Cem. Replace. Mater. 1985, 40–72. [Google Scholar]

- He, C.; Makovicky, E.; Øsbæck, B. Thermal stability and pozzolanic activity of calcined illite. Appl. Clay Sci. 1995, 9, 337–354. [Google Scholar] [CrossRef]

- Bonavetti, V.; Rahhal, V.; Irassar, E. Studies on the carboaluminate formation in limestone filler-blended cements. Cem. Concr. Res. 2001, 31, 853–859. [Google Scholar] [CrossRef]

- Faure, A.; Smith, A.; Coudray, C.; Anger, B.; Colina, H.; Moulin, I.; Thery, F. Ability of Two Dam Fine-Grained Sediments to be Used in Cement Industry as Raw Material for Clinker Production and as Pozzolanic Additional Constituent of Portland-Composite Cement. Waste Biomass Valorization 2017, 8, 2141–2163. [Google Scholar] [CrossRef]

- Benzerzour, M.; Maherzi, W.; Amar, M.; Abriak, N.; Damidot, D. Formulation of mortars based on thermally treated sediments. J. Mater. Cycles Waste Manag. 2018, 20, 592–603. [Google Scholar] [CrossRef]

- Junakova, N.; Junak, J. Recycling of reservoir sediment material as a binder in concrete. Procedia Eng. 2017, 180, 1292–1297. [Google Scholar] [CrossRef]

- Zhang, H.; Cao, M.; Xing, Z. Early-age properties of cement paste with mechanically ground Yellow River sediment. Constr. Build. Mater. 2024, 411, 134635. [Google Scholar] [CrossRef]

- Lian, H.-Z.; Zhang, Z.-L.; Wang, Y.-H. Rapid evaluation on activity of pozzolanic materials. J. Build. Mater. 2001, 4, 299–304. [Google Scholar]

- Deboucha, W.; Leklou, N.; Khelidj, A.; Oudjit, M. Hydration development of mineral additives blended cement using thermogravimetric analysis (TGA): Methodology of calculating the degree of hydration. Constr. Build. Mater. 2017, 146, 687–701. [Google Scholar] [CrossRef]

- Taylor, M.; Lydon, F.; Barr, B. Mix proportions for high strength concrete. Constr. Build. Mater. 1996, 10, 445–450. [Google Scholar] [CrossRef]

- Liu, G.; Cheng, W.; Chen, L. Investigating and optimizing the mix proportion of pumping wet-mix shotcrete with polypropylene fiber. Constr. Build. Mater. 2017, 150, 14–23. [Google Scholar] [CrossRef]

- Arora, A.; Almujaddidi, A.; Kianmofrad, F.; Mobasher, B.; Neithalath, N. Material design of economical ultra-high performance concrete (UHPC) and evaluation of their properties. Cem. Concr. Compos. 2019, 104, 103346. [Google Scholar] [CrossRef]

- Wang, J.; Yu, R.; Ji, D.; Tang, L.; Yang, S.; Fan, D.; Shui, Z.; Leng, Y.; Liu, K. Effect of distribution modulus (q) on the properties and microstructure development of a sustainable Ultra-High Performance Concrete (UHPC). Cem. Concr. Compos. 2022, 125, 104335. [Google Scholar] [CrossRef]

- Zhang, W.; Zheng, M.; Zhu, L.; Lv, Y. Mix design and characteristics evaluation of high-performance concrete with full aeolian sand based on the packing density theory. Constr. Build. Mater. 2022, 349 (Suppl. C), 128814. [Google Scholar] [CrossRef]

- Xue, Z.; Qi, P.; Yan, Z.; Pei, Q.; Zhong, J.; Zhan, Q. Mechanical Properties and Crack Resistance of Basalt Fiber Self-Compacting High Strength Concrete: An Experimental Study. Materials 2023, 16, 4374. [Google Scholar] [CrossRef]

- Akhtar, M.; Albatayneh, O.; Bani-Hani, K.; Malkawi, A. Performance of modified desert sand concrete: An experimental case study. Case Stud. Constr. Mater. 2024, 21, e03465. [Google Scholar] [CrossRef]

- Murtaza, M.; Zhang, J.; Yang, C.; Cui, X.; Su, C.; Ramadan, A. Performance analysis of self compacting concrete by incorporating fly ash, coal gangue powder, cement kiln dust and recycled concrete powder by absolute volume method. Constr. Build. Mater. 2024, 431, 136601. [Google Scholar] [CrossRef]

- Maherzi, W.; Ennahal, I.; Benzerzour, M.; Mammindy-Pajany, Y.; Abriak, N. Study of the polymer mortar based on dredged sediments and epoxy resin: Effect of the sediments on the behavior of the polymer mortar. Powder Technol. 2020, 361, 968–982. [Google Scholar] [CrossRef]

- Ji, T.; Chen, C.; Zhuang, Y.; Chen, J. A mix proportion design method of manufactured sand concrete based on minimum paste theory. Constr. Build. Mater. 2013, 44, 422–426. [Google Scholar] [CrossRef]

- Ennahal, I.; Maherzi, W.; Mamindy-Pajany, Y.; Benzerzour, M.; Abriak, N. Eco-friendly polymers mortar for floor covering based on dredged sediments of the north of France. J. Mater. Cycles Waste Manag. 2019, 21, 861–871. [Google Scholar] [CrossRef]

- Mehdipour, I.; Khayat, K.H. Effect of particle-size distribution and specific surface area of different binder systems on packing density and flow characteristics of cement paste. Cem. Concr. Compos. 2017, 78, 120–131. [Google Scholar] [CrossRef]

- Luan, J.; Chen, X.; Ning, Y.; Shi, Z. Beneficial utilization of ultra-fine dredged sand from Yangtze River channel as a concrete material based on the minimum paste theory. Case Stud. Constr. Mater. 2022, 16 (Suppl. C), e01098. [Google Scholar] [CrossRef]

- Li, S.; Chen, X.; Zhang, W.; Ning, Y.; Casas, J.R. Mechanical properties of alkali activated slag concrete with ultra fine dredged sand from Yangtze River. Fuhe Cailiao Xuebao/Acta Mater. Compos. Sin. 2022, 39, 335–343. [Google Scholar]

- Van Bunderen, C.; Benboudjema, F.; Snellings, R.; Vandewalle, L.; Cizer, Ö. Experimental analysis and modelling of mechanical properties and shrinkage of concrete recycling flash calcined dredging sediments. Cem. Concr. Compos. 2021, 115, 103787. [Google Scholar] [CrossRef]

- Altuki, R.; Ley, M.; Cook, D.; Gudimettla, M.; Praul, M. Increasing sustainable aggregate usage in concrete by quantifying the shape and gradation of manufactured sand. Constr. Build. Mater. 2022, 321 (Suppl. C), 125593. [Google Scholar] [CrossRef]

- Junakova, N.; Junak, J.; Balintova, M. Reservoir sediment as a secondary raw material in concrete production. Clean Technol. Environ. Policy 2015, 17, 1161–1169. [Google Scholar] [CrossRef]

- Her-Yung, W. Durability Of Self-consolidating Lightweight Aggregate Concrete Using Dredged Silt. Constr. Build. Mater. 2009, 23, 2332–2337. [Google Scholar] [CrossRef]

- Jin, W.; Chen, Y.; Lv, Y.; Jiang, L.; Bai, W.; Zhang, K.; Song, C.; Zhang, X. Mechanical Properties and Mechanism of Geopolymer Cementitious Materials Synergistically Prepared Using Red Mud and Yellow River Sand. Materials 2024, 17, 3810. [Google Scholar] [CrossRef]

- Lv, Y.; Chen, Y.; Dai, W.; Yang, H.; Jiang, L.; Li, K.; Jin, W. Preparation and Properties of Porous Concrete Based on Geopolymer of Red Mud and Yellow River Sediment. Materials 2024, 17, 923. [Google Scholar] [CrossRef]

- Zhang, Y.; Xu, H.; Fang, S.; Li, D.; Xue, W.; Chen, B.; Zhao, L. Biochar as additive for improved building performances and heavy metals solidification of sediment-based lightweight concrete. Environ. Sci. Pollut. Res. Int. 2022, 30, 4137–4150. [Google Scholar] [CrossRef] [PubMed]

- Lang, L.; Li, J.; Chen, X.; Han, L.; Wang, P. Tensile strength behavior of cement-stabilized dredged sediment reinforced by polypropylene fiber. Front. Struct. Civ. Eng. 2024, 18, 380–392. [Google Scholar] [CrossRef]

- Luo, D.; Lang, L.; Zhang, B. Splitting tensile strength behavior of dredged sediment with cement stabilization and straw fiber reinforcement. J. Mater. Cycles Waste Manag. 2025, 27, 1379–1393. [Google Scholar] [CrossRef]

- Lang, L.; Chen, B. Strength Properties of Cement-Stabilized Dredged Sludge Incorporating Nano-SiO2 and Straw Fiber. Int. J. Geomech. 2021, 21, 4021119. [Google Scholar] [CrossRef]

- Lang, L.; Chen, B.; Li, D. Effect of nano-modification and fiber-reinforcement on mechanical behavior of cement-stabilized dredged sediment. Mar. Georesources Geotechnol. 2021, 40, 1–17. [Google Scholar] [CrossRef]

- Leite, M.; Filho, J.; Lima, P. Workability study of concretes made with recycled mortar aggregate. Mater. Struct./Mater. et Constr. 2013, 46, 1765–1778. [Google Scholar] [CrossRef]

- Luan, J.; Chen, X.; Ning, Y.; Zhang, W. Mechanical characteristics and energy dissipation characteristics of dredged sand concrete during triaxial loading. J. Build. Eng. 2022, 55 (Suppl. C), 104700. [Google Scholar] [CrossRef]

- Rozière, E.; Granger, S.; Turcry, P.; Loukili, A. Influence of paste volume on shrinkage cracking and fracture properties of self-compacting concrete. Cem. Concr. Compos. 2007, 29, 626–636. [Google Scholar] [CrossRef]

- Mohammadi, M.; Wu, Y. Modified plastic-damage model for passively confined concrete based on triaxial tests. Compos. Part B-Eng. 2019, 159, 211–223. [Google Scholar] [CrossRef]

- Zhang, T.; Xu, W.; Wang, R.; Yan, L.; He, M. Deformation characteristics of cement mortar under triaxial cyclic loading: An experimental investigation. Int. J. Fatigue 2021, 150 (Suppl. C), 106305. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, J.; Lin, G.; Yu, T.; Fernando, D. Stress-strain models for ultra-high performance concrete (UHPC) and ultra-high performance fiber-reinforced concrete (UHPFRC) under triaxial compression. Constr. Build. Mater. 2023, 370 (Suppl. C), 130658. [Google Scholar] [CrossRef]

- Falade, F. An investigation of periwinkle shells as coarse aggregate in concrete. Build. Environ. 1995, 30, 573–577. [Google Scholar] [CrossRef]

- Martínez-García, C.; González-Fonteboa, B.; Martínez-Abella, F.; Carro-López, D. Performance of mussel shell as aggregate in plain concrete. Constr. Build. Mater. 2017, 139, 570–583. [Google Scholar] [CrossRef]

- Zivica, V.; Bajza, A. Acidic attack of cement-based materials—A review Part 2. Factors of rate of acidic attack and protective measures. Constr. Build. Mater. 2002, 16, 215. [Google Scholar] [CrossRef]

- Ghrici, M.; Kenai, S.; Said-Mansour, M. Mechanical properties and durability of mortar and concrete containing natural pozzolana and limestone blended cements. Cem. Concr. Compos. 2007, 29, 542–549. [Google Scholar] [CrossRef]

- Felekoğlu, B.; Selçuk, T.; Bülent, B. Effect of water/cement ratio on the fresh and hardened properties of self-compacting concrete. Build. Environ. 2007, 42, 1795–1802. [Google Scholar] [CrossRef]

- Ibrahim, I.A.; ElSersy, H.H.; Abadir, M.F. The use of thermal analysis in the approximate determination of the cement content in concrete. J. Therm. Anal. Calorim. 2004, 76, 713–718. [Google Scholar] [CrossRef]

- Singh, M.; Garg, M. Refereed paper Activation of gypsum anhydrite-slag mixtures. Cem. Concr. Res. 1995, 25, 332–338. [Google Scholar] [CrossRef]

- Ma, X.; Zhang, C.; Li, R.; Zheng, L.; Xu, J. Effect of temperature and humidity environment on the microstructure and physicochemical properties of SBS modified asphalt. Case Stud. Constr. Mater. 2025, 22, e04192. [Google Scholar] [CrossRef]

- Chang, J. A study on the setting characteristics of sodium silicate-activated slag pastes. Cem. Concr. Res. 2003, 33, 1005–1011. [Google Scholar] [CrossRef]

- Lilkov, V.; Petrov, O.; Tzvetanova, Y.; Savov, P. Mossbauer, DTA and XRD study of Portland cement blended with fly ash and silica fume. Constr. Build. Mater. 2012, 29, 33–41. [Google Scholar] [CrossRef]

- Safhi, A.; Rivard, P.; Yahia, A.; Benzerzour, M.; Khayat, K. Valorization of dredged sediments in self-consolidating concrete: Fresh, hardened, and microstructural properties. J. Clean. Prod. 2020, 263, 121472. [Google Scholar] [CrossRef]

- Gong, J.; Zhang, W. The effects of pozzolanic powder on foam concrete pore structure and frost resistance. Constr. Build. Mater. 2019, 208, 135–143. [Google Scholar] [CrossRef]

- Achour, R.; Zentar, R.; Abriak, N.; Rivard, P.; Gregoire, P. Durability study of concrete incorporating dredged sediments. Case Stud. Constr. Mater. 2019, 11, e00244. [Google Scholar] [CrossRef]

- Silva, L.; Nehring, V.; de Paiva, F.; Tamashiro, J.; Galvin, A.; Lopez-Uceda, A.; Kinoshita, A. Use of blast furnace slag in cementitious materials for pavements-Systematic literature review and eco-efficiency. Sustain. Chem. Pharm. 2023, 33 (Suppl. C), 101030. [Google Scholar] [CrossRef]

- Sim, S.; Her, S.; Suh, H.; Cho, S.; Im, S.; Li, P.; Bae, S. Influences of alumina type and sulfate content on hydration and physicochemical changes in Portland–limestone cement. Constr. Build. Mater. 2024, 426, 135989. [Google Scholar] [CrossRef]

- Yuan, C.; Raza, A.; Manan, A.; Ahmad, S.; Chao, W.; Umar, M. Numerical and experimental study of Yellow River sand in engineered cementitious composite. Proc. Inst. Civ. Eng.-Eng. Sustain. 2025, 178, 3–20. [Google Scholar]

- Hadj Sadok, R.; Maherzi, W.; Benzerzour, M.; Lord, R.; Torrance, K.; Zambon, A.; Abriak, N. Mechanical Properties and Microstructure of Low Carbon Binders Manufactured from Calcined Canal Sediments and Ground Granulated Blast Furnace Slag (GGBS). Sustainability 2021, 13, 9057. [Google Scholar] [CrossRef]

- Zeraoui, A.; Maherzi, W.; Benzerzour, M.; Abriak, N.; Aouad, G. Development of Flash-Calcined Sediment and Blast Furnace Slag Ternary Binders. Buildings 2023, 13, 333. [Google Scholar] [CrossRef]

- Furlan, A.; Razakamanantsoa, A.; Ranaivomanana, H.; Amiri, O.; Levacher, D.; Deneele, D. Effect of fly ash on microstructural and resistance characteristics of dredged sediment stabilized with lime and cement. Constr. Build. Mater. 2021, 272, 121637. [Google Scholar] [CrossRef]

- Zhang, G.; Li, K.; Shi, H.; Chen, C.; Yuan, C. Study on the Effects and Mechanisms of Fly Ash, Silica Fume, and Metakaolin on the Properties of Slag-Yellow River Sediment-Based Geopolymers. Materials 2025, 18, 1845. [Google Scholar] [CrossRef] [PubMed]

- Mostafaei, H.; Bahmani, H. Sustainable High-Performance Concrete Using Zeolite Powder: Mechanical and Carbon Footprint Analyses. Buildings 2024, 14, 3660. [Google Scholar] [CrossRef]

- DIN EN ISO 14040:2006+A1:2020; Environmental Management—Life Cycle Assessment—Principles and Framework. Deutsches Institut für Normung (DIN): Berlin, Germany, 2020.

- ISO 14075:2024; Environmental Management—Principles and Framework for Social Life Cycle Assessment. International Organization for Standardization (ISO): Geneva, Switzerland, 2024.

- Zhu, S.; Lu, Y.; Wang, S.; Liu, W.; Tang, K.; Li, N. Characteristics and reduction potential of carbon dioxide emission in China’s cement industry from 2020 to 2050. Huanjing Kexue Xuebao/Acta Sci. Circumstantiae 2024, 44, 453–463. [Google Scholar]

- Nian, T.; Li, Y.; Jin, X.; Wang, Z.; Wang, M.; Wang, Y.; Moacir, K. Toward Carbon Balance in Life Cycle: The Carbon Emission Assessment for the Recycled Coarse Aggregate Concrete. Adv. Civ. Eng. 2025, 2025, 9184976. [Google Scholar] [CrossRef]

| Water Content (%) | Absorption (%) | Density (g/cm3) | ||

|---|---|---|---|---|

| Conventional aggregates [39] | Sand | 0.081 | 4.7 | 2.41 |

| Gravel | 0.065 | 2.3 | 2.53 | |

| Neuilly raw sediment [39] | Sand | N.D. | 3.0 | 2.45 |

| Gravel | 10.69 | 1.8 | 2.53 | |

| Puteaux raw sediment [39] | Sand | N.D. | 3.6 | 2.46 |

| Gravel | 6.43 | 2.6 | 2.47 | |

| Preparation of lightweight aggregates [22] | Gravel | N.D. | 5.5–9.5 | 1.01–1.38 |

| Preparation of ceramic granules [23] | Gravel | N.D. | 5.9 | 0.879 |

| Seine Basin [24] | Sand | N.D. | N.D. | 2.24–2.41 |

| Gravel | N.D. | 3.7–17.2 | 2.05–2.41 | |

| Yangtze River ultra-fine dredged sand [45] | Sand | N.D. | 4.5 | 2.69 |

| Sports Event | SiO2 (%) | Al2O3 (%) | CaO (%) | Fe2O3 (%) | Na2O (%) | K2O (%) | MgO | LOI |

|---|---|---|---|---|---|---|---|---|

| Cement 1 [29] | 21.49 | 5.24 | 64.16 | 2.89 | 0.76 | 0.42 | 2.12 | 1.0 |

| Cement 2 [5] | 18.093 | 5.882 | 64.394 | 3.904 | N.D. | 1.219 | 1.944 | N.D. |

| Yellow River sediment 1 [29] | 68.73 | 11.08 | 7.56 | 3.64 | 1.76 | 3.21 | 2.11 | 2.85 |

| Yellow River sediment 2 [23] | 60.5 | 15.9 | 9.96 | 4.77 | 1.56 | 2.81 | 3.18 | N.D. |

| Yangtze River sediment 1 [47] | 68.2 | 11.4 | 5.66 | 3.22 | 1.88 | 2.31 | 2.46 | N.D. |

| Yangtze River sediment 2 [45] | 68.74 | 11.4 | 5.56 | 3.20 | 1.84 | 2.3 | 2.42 | N.D. |

| Mud and sand sediment 1 [46] | 47.50 | 15.60 | 10.20 | 6.70 | 0.30 | 1.90 | 2.40 | 15.1 |

| Mud and sand sediment 2 [47] | 75.717 | 11.988 | 1.59 | 4.971 | 0.029 | 1.857 | 0.951 | N.D. |

| Mud and sand sediment 3 [48] | 33.25 | 8.65 | 13.1 | 3.89 | 0.45 | 149 | 0.75 | N.D. |

| Mud and sand sediment 3 calcined at 750 °C [48] | 43.45 | 10.30 | 15.4 | 4.95 | 0.63 | 1.84 | 0.91 | N.D. |

| Mud and sand sediment 4 [25] | 56.93 | 18.98 | 2.14 | 12.05 | 0.70 | 4.07 | 2.07 | 4.13 |

| Fly ash 1 [18] | 50.6 | 27.2 | 2.8 | 7.0 | 0.5 | 2.6 | 0.97 | 1.14 |

| Fly ash 2 [25] | 53.7 | 27.3 | 7.7 | 5.70 | 0.7 | 0.12 | 1.8 | 0.40 |

| Method | Name | Principle | Features |

|---|---|---|---|

| Aggregate-based method | Compressive Packing Model (CPM) [95] | This approach uses virtual packing density to model particle combinations and improve packing efficiency. | It requires full particle size distribution data. |

| Andreasen and Andersen model [26,96,97] | This method determines component ratios by optimizing a continuous particle size distribution curve. | It provides more precise control than the traditional residual fitting method. | |

| Absolute Volume Method [98,99,100] | This theory derives component ratios from aggregate volume. | It is complex and requires separate volume data for each material. | |

| Packing Density Modeling (PDM) [101] | This model predicts mixture density using energy input, material densities, and particle sizes. | It avoids the separate calculation of packing parameters and achieves relatively high accuracy. | |

| Slurry-based method | The minimum paste theory [102]. | This theory considers concrete as an aggregate skeleton coated with the minimum paste. | Reducing paste volume improves volumetric stability and crack resistance while maintaining workability and strength. |

| Setup and Level | Sediment Sources/Treatment | Range of Replacement Rates (%) | Optimal Substitution Rate (%) | Change in Compressive Strength | Change in Bending/Splitting Strength | Remarks/Key Conditions | |

|---|---|---|---|---|---|---|---|

| Sediment as Fine Aggregate Replacement Systems | |||||||

| [28] | Self-compacting mortar | Ultrafine sediments (unactivated) in the Yangtze River Estuary | 5–30 | 5 | 45.88 → 43.51 MPa ↓ 5% | 8.02 → 8.84 MPa ↑ 10% | Rapid decrease in strength after >15% |

| [45] | Alkali-inspired system mortar | Ultrafine sediments in the Yangtze River + Ground Granulated Blastfurnace Slag: Fly Ash = 3:7 | 25–100 | 25 | 25.67 → 26.36 MPa ↑ 3% | 4.50 → 5.08 MPa ↑ 13% | Activation system, >50% significant decrease |

| [45] | Alkali-inspired system mortar | Ultrafine sediments in the Yangtze River + Ground Granulated Blastfurnace Slag: Fly Ash = 7:3 | 0–100 | 25 | 59.18 → 61.2 4 MPa ↑ 3% | 9.09 → 9.34 MPa ↑ 3% | — |

| [26] | Ultra high-performance concrete | Ultrafine sediments of the Yellow River + Fine sand | 0–100 | 80 | 100.3 → 104.3 MPa ↑ 4% | 15.5 → 16.9 MPa ↑ 9% | Optimum 80% sand mixing ratio |

| [106] | Alkali-inspired concrete | Ultrafine sediments in the Yangtze River | 0–100 | 50 | 49.89 → 54.60 MPa ↑ 9% | — | — |

| [39] | Ordinary concrete | Seine River sediments (completely replacing coarse and fine aggregates) | 100 | — | Requires ↑ 5% cement to reach C30 grade strength | — | Technical feasibility, economic assessment |

| [47] | Ordinary concrete | Yangtze River dredged sand and machine-made sand concrete | 0–50 | 25 | 41.48 → 65.50 MPa ↑ 57.9% | — | — |

| Sediment–Cement Binder Systems | |||||||

| [107] | OPC mortar | (Flash calcination) calcined dredging sediments | 20–40 | 20 | 64.74 → 71.46 MPa ↑ 10% | — | Flash calcination activation is significant |

| [27] | Foam Concrete | Yellow River sludge (Ca(OH)2 activation) | 5–20 | 5 | 4.32 → 3.82 MPa ↓ 11% | — | High substitution rate intensity falls |

| [112] | Ground polymer mortar | Yellow River Silt Replacement Ground Granulated Blastfurnace Slag + Red mud | 10–40 | Standard maintenance: 10; High temperature water bath maintenance: 20 | 68.10 → 80.00 MPa ↑ 17% (Standard maintenance); 22.06 → 65.43 MPa ↑ 17.47 (High temperature water bath maintenance) | — | Standard maintenance; High temperature water bath maintenance, same trend |

| [112] | Porous ground-polymerized concrete | Yellow River Silt Replacement Ground Granulated Blastfurnace Slag + Red mud | 10–40 | 10 | 24.35 → 26.25 MPa ↑ 8% | — | — |

| [111] | Alkali-inspired system mortar | Yellow River sediment + Red mud | 20–80 | 40 | 16.80 → 26.52 MPa ↑ 57.86 (Natural Curing); 39.87 → 48.67 MPa ↑ 22.07% (Standard Curing) | — | The compressive strength of 28 d under standard curing can be increased by 82~132% to that under natural curing |

| Temperature Range(°C) | Main Causes of Quality Loss | Note |

|---|---|---|

| 50–100 | Free water evaporation | Corresponds to the weight loss peak at ~100 °C in the DTG curve, initial physical weight loss, which is present in all samples [129]. |

| 100–200 | C–S–H and C–A–S–H initial dewatering; AFt, AFm dewatering | The appearance of a distinct weight loss peak indicates the formation of reaction products that enhance structural strength [130,131]. |

| 200–500 | C–S–H and C–A–S–H continuous dewatering | The process continues and affects the mechanical strength of the samples. From this stage, it is possible to determine the promotion or inhibition of gel generation by the addition of river sediments [27]. |

| 400–500 | Ca(OH)2 dehydroxylation reaction (chemistry) | Ca(OH)2 is involved in the reaction or consumed by carbonation [29]. It is possible to determine whether river sediments promote CH production based on the amount of CH consumed at this stage of the process. Furthermore, this densification inhibits penetration of aggressive agents, directly enhancing concrete durability. |

| ~630 | CaCO3 decomposition | Related to the carbonation reaction, increased carbonation products enhance strength and densification [132,133,134]. |

| 500–850 | Decomposition of heat-stabilized components such as calcium carbonate | The degree of overall mass loss indicates the extent to which sediment affects cement hydration. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, Y.; Xie, Y.; Zhang, Y.; Wan, C.; Miao, L.; Zhang, P. Valorization of River Sediments in Sustainable Cementitious Gel Materials: A Review of Characteristics, Activation, and Performance. Gels 2025, 11, 755. https://doi.org/10.3390/gels11090755

Zheng Y, Xie Y, Zhang Y, Wan C, Miao L, Zhang P. Valorization of River Sediments in Sustainable Cementitious Gel Materials: A Review of Characteristics, Activation, and Performance. Gels. 2025; 11(9):755. https://doi.org/10.3390/gels11090755

Chicago/Turabian StyleZheng, Yuanxun, Yuxiao Xie, Yu Zhang, Cong Wan, Li Miao, and Peng Zhang. 2025. "Valorization of River Sediments in Sustainable Cementitious Gel Materials: A Review of Characteristics, Activation, and Performance" Gels 11, no. 9: 755. https://doi.org/10.3390/gels11090755

APA StyleZheng, Y., Xie, Y., Zhang, Y., Wan, C., Miao, L., & Zhang, P. (2025). Valorization of River Sediments in Sustainable Cementitious Gel Materials: A Review of Characteristics, Activation, and Performance. Gels, 11(9), 755. https://doi.org/10.3390/gels11090755