Emulgels as Fat-Replacing Systems in Biscuits Developed with Ternary Mixtures of Pea and Soy Protein Isolates and Gums

Abstract

1. Introduction

2. Results

2.1. Turbidity of the Hydrogels

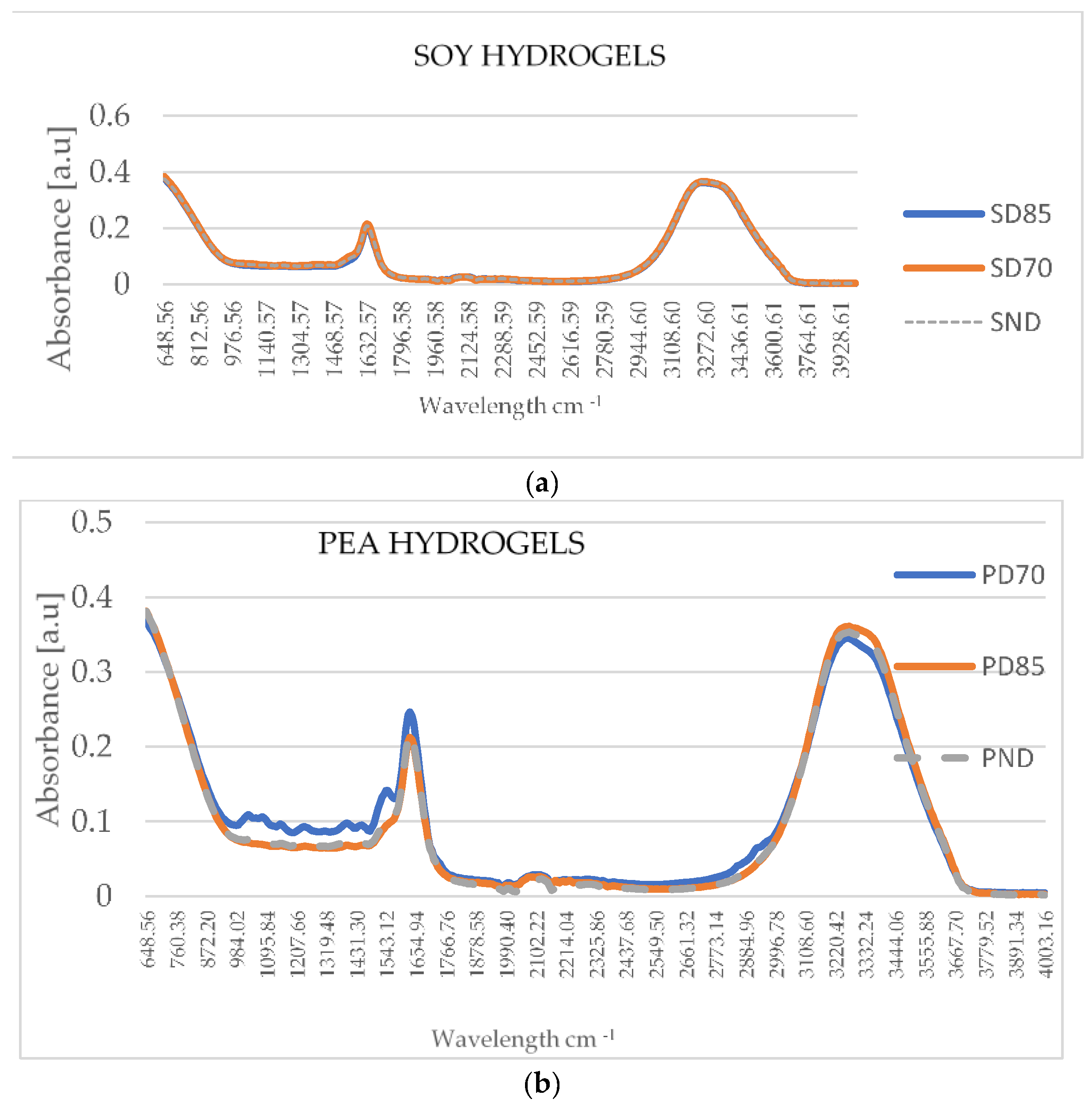

2.2. FTIR Spectral Data Analysis

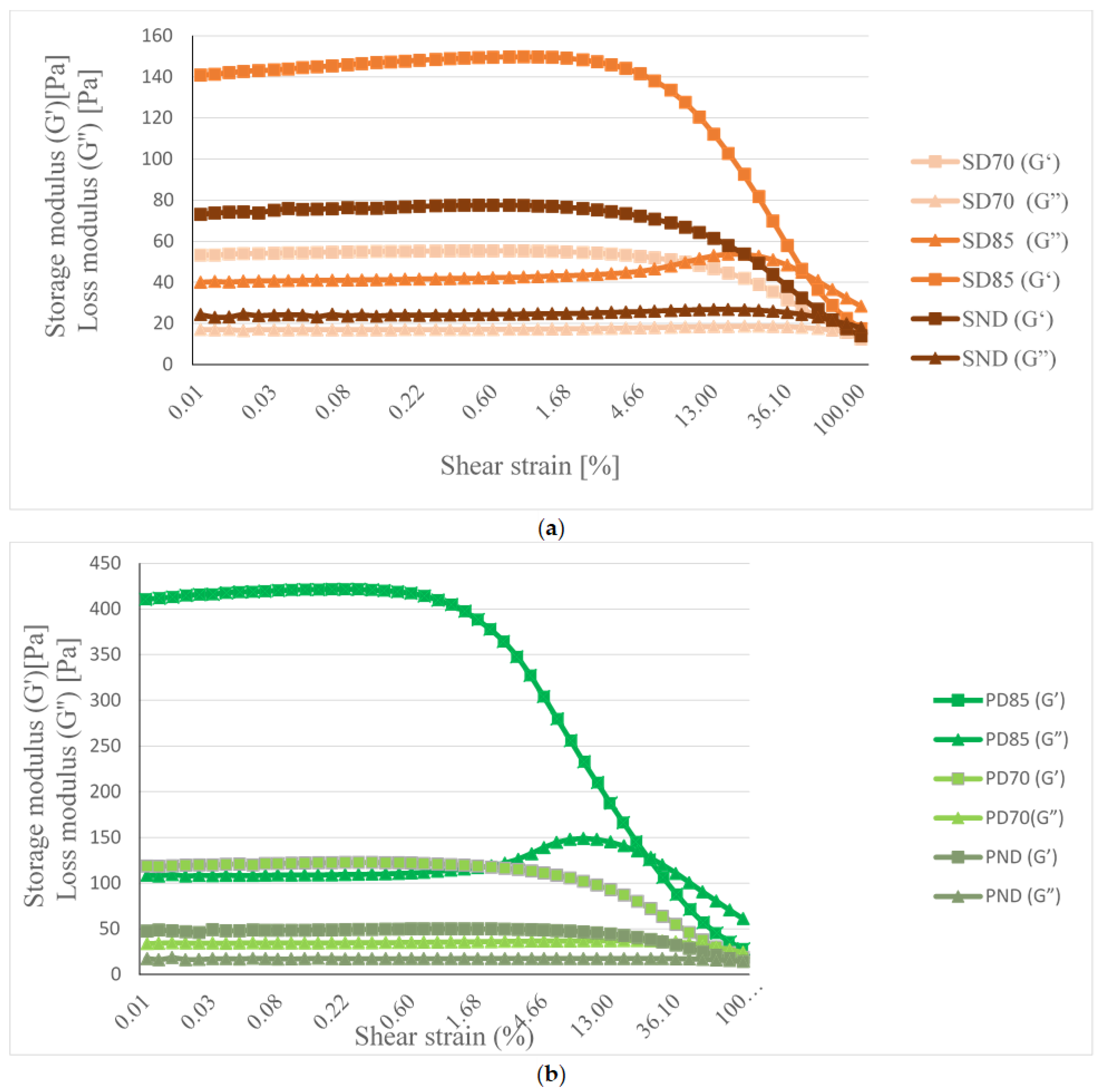

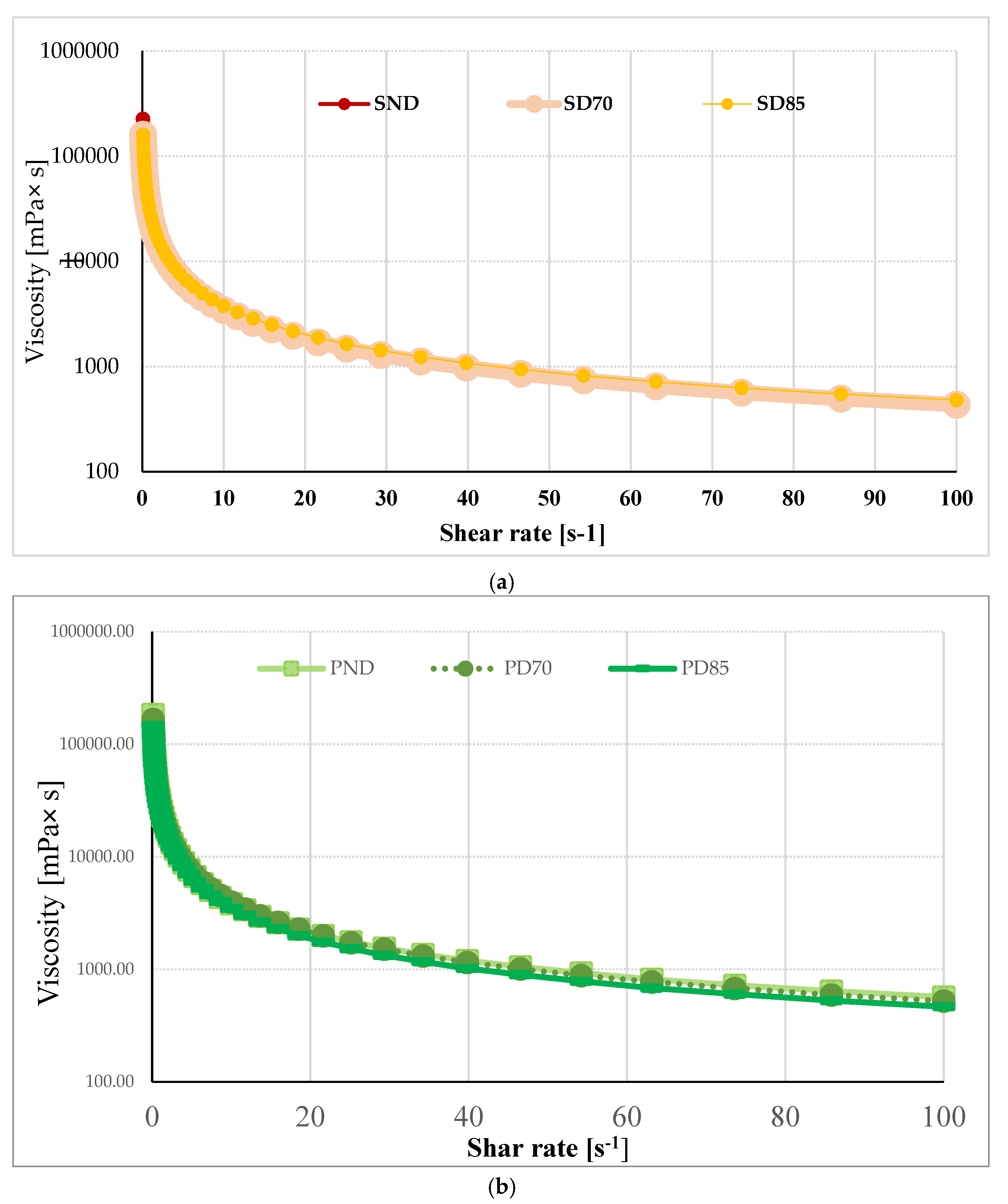

2.3. Hydrogel Rheological Properties

2.4. Emulgel Textural Analysis

2.5. Biscuit Properties

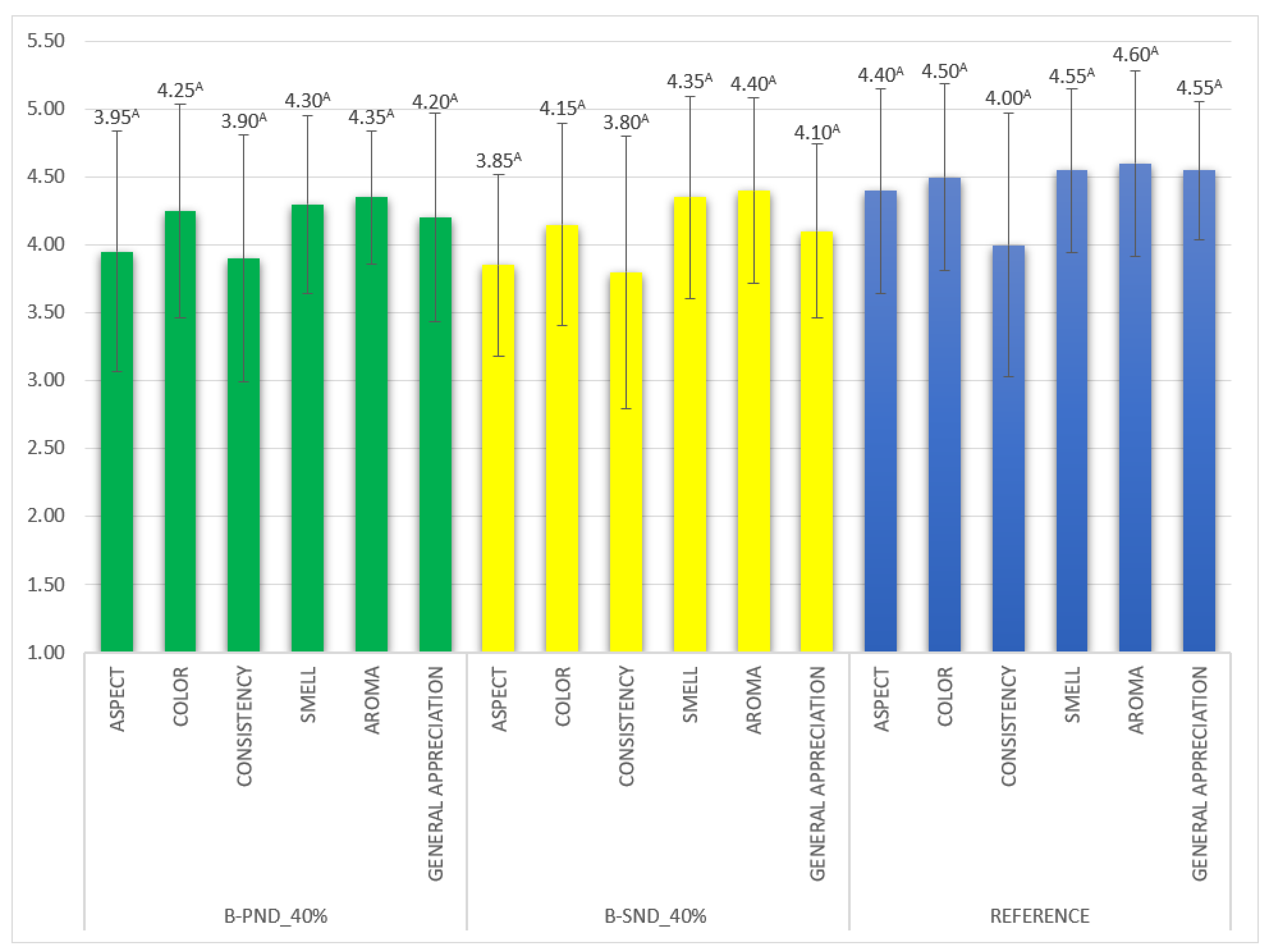

2.6. Results Regarding Sensory Analysis

3. Conclusions

4. Material and Methods

4.1. Materials

4.2. Samples Preparation

4.2.1. Ultrasound-Assisted Hydrogel Formation

4.2.2. Emulgel Formation

4.3. Obtaining Biscuits

4.4. Characterization of Hydrogels

4.5. Emulgels’ Structural Characterization

4.6. Biscuits’ Characterization

4.6.1. Textural, Color, and Stability Attributes

4.6.2. Sensory Analysis

4.7. Statistical Analysis

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Light, K.; Karboune, S. Emulsion, hydrogel and emulgel systems and novel applications in cannabinoid delivery: A review. Nutrition 2022, 62, 8199–8229. [Google Scholar] [CrossRef] [PubMed]

- Lee, K.Z.; Jeon, J.; Jiang, B.; Subramani, S.V.; Li, J.; Zhang, F. Protein-Based Hydrogels and Their Biomedical Applications. Molecules 2023, 28, 4988. [Google Scholar] [CrossRef]

- Nath, P.C.; Debnath, S.; Sridhar, K.; Inbaraj, B.S.; Nayak, P.K.; Sharma, M. A Comprehensive Review of Food Hydrogels: Principles, Formation Mechanisms, Microstructure, and Its Applications. Gels 2023, 9, 1. [Google Scholar] [CrossRef]

- Feichtinger, A.; Nibbelink, D.G.; Poppe, S.; Bozzo, L.; Landman, J.; Scholten, E. Protein oleogels prepared by solvent transfer method with varying protein sources. Food Hydrocoll. 2022, 132, 107821. [Google Scholar] [CrossRef]

- Babu, A.; Shams, R.; Dash, K.K.; Shaikh, A.M.; Kovács, B. Protein-polysaccharide complexes and conjugates: Structural modifications and interactions under diverse treatments. J. Agric. Food Res. 2024, 18, 101510. [Google Scholar] [CrossRef]

- Aljewicz, M.; Keklik, M.; Recio, I.; Martínez-Sanz, M. Effect of polysaccharide-protein interactions on the multi-scale structure of hybrid micellar casein-xanthan gum systems. Food Hydrocoll. 2024, 151, 109833. [Google Scholar] [CrossRef]

- Nooshkam, M.; Varidi, M. Whey protein isolate-low acyl gellan gum Maillard-based conjugates with tailored technological functionality and antioxidant activity. Int. Dairy J. 2020, 109, 104783. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, K.; Qin, Y.; Zhu, S.; Gao, Q.; Liu, D. The synthesis, biological activities and applications of protein–polysaccharide conjugates in food system: A review. Food Qual. Saf. 2023, 7, fyad006. [Google Scholar] [CrossRef]

- Li, J.; Yang, Y.; Su, Y.; Gu, L.; Chang, C.; Yang, Y. Phase separation in ternary composite cold-set gel of egg yolk/κ-carrageenan/xanthan: Study on rheological and proton mobility properties. LWT 2019, 116, 108497. [Google Scholar] [CrossRef]

- Liu, K.; Chen, Y.-Y.; Zha, X.-Q.; Li, Q.-M.; Pan, L.-H.; Luo, J.-P. Research progress on polysaccharide/protein hydrogels: Preparation method, functional property and application as delivery systems for bioactive ingredients. Food Res. Int. 2021, 147, 110542. [Google Scholar] [CrossRef]

- Chityala, P.K.; Khouryieh, H.; Williams, K.; Conte, E. Effect of xanthan/enzyme-modified guar gum mixtures on the stability of whey protein isolate stabilized fish oil-in-water emulsions. Food Chem. 2016, 212, 332–340. [Google Scholar] [CrossRef]

- Chassenieux, C.; Nicolai, T. Mechanical properties and microstructure of (emul) gels formed by mixtures of proteins and polysaccharides. Curr. Opin. Colloid Interface Sci. 2024, 70, 101781. [Google Scholar] [CrossRef]

- De Berardinis, L.; Plazzotta, S.; Manzocco, L. Optimising Soy and Pea Protein Gelation to Obtain Hydrogels Intended as Precursors of Food-Grade Dried Porous Materials. Gels 2023, 9, 62. [Google Scholar] [CrossRef] [PubMed]

- Ge, A.; Iqbal, S.; Chen, X.D. Alteration in rheology and microstructure of O/W emulsions using controlled soy protein isolate-polysaccharide aggregation in aqueous phases. J. Food Eng. 2022, 317, 110872. [Google Scholar] [CrossRef]

- Tahmouzi, S.; Meftahizadeh, H.; Eyshi, S.; Mahmoudzadeh, A.; Alizadeh, B.; Mollakhalili-Meybodi, N.; Hatami, M. Application of guar (Cyamopsis tetragonoloba L.) gum in food technologies: A review of properties and mechanisms of action. Food Sci. Nutr. 2023, 11, 4869–4897. [Google Scholar] [CrossRef]

- Kaur, G.; Thakur, B.; Gill, R.; Kaur, R.; Kaur, S. Biopolymeric conjugation with food additives. Phys. Sci. Rev. 2023, 9, 2899–2923. [Google Scholar]

- Martins, A.J.; Silva, P.; Maciel, F.; Pastrana, L.M.; Cunha, R.L.; Cerqueira, M.A.; Vicente, A.A. Hybrid gels: Influence of oleogel/hydrogel ratio on rheological and textural properties. Food Res. Int. 2019, 116, 1298–1305. [Google Scholar] [CrossRef]

- Cittadini, A.; Domínguez, R.; Munekata, P.E.S.; Pateiro, M.; Sarriés, M.V.; Lorenzo, J.M. Use of oil mixture emulsion hydrogels as partial animal fat replacers in dry-fermented foal sausages. Food Res. Int. 2022, 161, 111881. [Google Scholar] [CrossRef]

- Câmara, A.K.F.I.; Ozaki, M.M.; Santos, M.; Vidal, V.A.S.; Ribeiro, W.O.; Paglarini, C.d.S.; Bernardinelli, O.D.; Sabadini, E.; Pollonio, M.A.R. Olive oil-based emulsion gels containing chia (Salvia hispanica L.) mucilage delivering healthy claims to low-saturated fat Bologna sausages. Food Struct. 2021, 28, 100187. [Google Scholar] [CrossRef]

- Zhang, H.; Wei, A.; Zhou, S.; Zhang, H.; Xia, N.; Wang, J.; Ma, Y.; Fan, M. Effect of the substitution of butter by double cross-linked egg yolk granules/sodium alginate emulsion gel on properties of baking dough during frozen storage. Food Chem. 2024, 438, 137965. [Google Scholar] [CrossRef]

- Onacik-Gür, S.; Żbikowska, A. Effect of high-oleic rapeseed oil oleogels on the quality of short-dough biscuits and fat migration. J. Food Sci. Technol. 2020, 57, 1609–1618. [Google Scholar] [CrossRef] [PubMed]

- Gutiérrez-Luna, K.; Ansorena, D.; Astiasarán, I. Use of hydrocolloids and vegetable oils for the formulation of a butter replacer: Optimization and oxidative stability. LWT 2022, 153, 112538. [Google Scholar] [CrossRef]

- Pradhan, A.; Anis, A.; Alam, M.A.; Al-Zahrani, S.M.; Jarzebski, M.; Pal, K. Effect of Soy Wax/Rice Bran Oil Oleogel Replacement on the Properties of Whole Wheat Cookie Dough and Cookies. Foods 2023, 12, 3650. [Google Scholar] [CrossRef]

- Zulfiqar, A.; Shabbir, M.A.; Tahir, F.; Khan, M.R.; Ahmed, W.; Yıkmış, S.; Manzoor, M.F.; Abdi, G.; Aadil, R.M. Development of oleogel by structuring the blend of corn oil and sunflower oil with beeswax to replace margarine in cookies. Food Chem. X 2024, 23, 101676. [Google Scholar] [CrossRef] [PubMed]

- Sereti, V.; Kotsiou, K.; Biliaderis, C.G.; Lazaridou, A. Emulsion gel enriched with a barley β-glucan concentrate for reducing saturated fat in biscuits. Food Hydrocoll. 2023, 145, 109163. [Google Scholar] [CrossRef]

- Boukid, F.; Carini, E.; Curti, E.; Diantom, A.; Corte, R.; Vittadini, E. Can a structured emulsion (fat in water-fibre system) substitute saturated fat in cookies without hampering their quality? Int. J. Food Sci. Technol. 2021, 56, 5071–5079. [Google Scholar] [CrossRef]

- Giarnetti, M.; Paradiso, V.M.; Caponio, F.; Summo, C.; Pasqualone, A. Fat replacement in shortbread cookies using an emulsion filled gel based on inulin and extra virgin olive oil. LWT 2015, 63, 339–345. [Google Scholar] [CrossRef]

- Quilaqueo, M.; Iturra, N.; Contardo, I.; Millao, S.; Morales, E.; Rubilar, M. Food-Grade Bigels with Potential to Replace Saturated and Trans Fats in Cookies. Gels 2022, 8, 445. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.-H.; Tai, Z.-J.; Song, X.-J.; Li, Z.-J.; Zhang, D.-J. Effects of Germination on the Structure, Functional Properties, and In Vitro Digestibility of a Black Bean (Glycine max (L.) Merr.) Protein Isolate. Foods 2024, 13, 488. [Google Scholar] [CrossRef]

- Jiang, S.; Ding, J.; Andrade, J.; Rababah, T.M.; Almajwal, A.; Abulmeaty, M.M.; Feng, H. Modifying the physicochemical properties of pea protein by pH-shifting and ultrasound combined treatments. Ultrason. Sonochem. 2017, 38, 835–842. [Google Scholar] [CrossRef]

- Nasrabadi, M.N.; Doost, A.S.; Mezzenga, R. Modification approaches of plant-based proteins to improve their techno-functionality and use in food products. Food Hydrocoll. 2021, 118, 106789. [Google Scholar] [CrossRef]

- Hong, T.; Yin, J.-Y.; Nie, S.-P.; Xie, M.-Y. Applications of infrared spectroscopy in polysaccharide structural analysis: Progress, challenge and perspective. Food Chem. X 2021, 12, 100168. [Google Scholar] [CrossRef]

- Guerrero, P.; Kerry, J.P.; de la Caba, K. FTIR characterization of protein–polysaccharide interactions in extruded blends. Carbohydr. Polym. 2014, 111, 598–605. [Google Scholar] [CrossRef] [PubMed]

- Ghosh, A.K.; Bandyopadhyay, P. Polysaccharide-protein interactions and their relevance in food colloids. In The Complex World of Polysaccharides; IntechOpen Limited: London, UK, 2012; Chapter 14; pp. 395–406. [Google Scholar]

- Zhu, P.; Huang, W.; Guo, X.; Chen, L. Strong and elastic pea protein hydrogels formed through pH-shifting method. Food Hydrocoll. 2021, 117, 106705. [Google Scholar] [CrossRef]

- Benichou, A.; Aserin, A.; Garti, N. Protein-Polysaccharide Interactions for Stabilization of Food Emulsions. J. Dispers. Sci. Technol. 2002, 23, 93–123. [Google Scholar] [CrossRef]

- Warji, W.; Mardjan, S.S.; Yuliani, S.; Schroën, K.; Purwanti, N. Flow Behavior of Isolate Protein from Soybeans var. Grobogan and Whey Protein Isolate at Acidic Condition under Various Heating Times. J. Keteknikan Pertan. 2018, 6, 171–178. [Google Scholar] [CrossRef][Green Version]

- Said dos Santos, R.; Bassi da Silva, J.; Rosseto, H.C.; Vecchi, C.F.; Campanholi, K.d.S.S.; Caetano, W.; Bruschi, M.L. Emulgels Containing Propolis and Curcumin: The Effect of Type of Vegetable Oil, Poly(Acrylic Acid) and Bioactive Agent on Physicochemical Stability, Mechanical and Rheological Properties. Gels 2021, 7, 120. [Google Scholar] [CrossRef]

- Zhao, J.; Xu, S.; Gu, L.; Yang, F.; Fang, X.; Gao, S. High internal phase emulsions gels stabilized by soy protein isolate and rutin complexes: Encapsulation, interfacial properties and in vitro digestibility. LWT 2024, 203, 116317. [Google Scholar] [CrossRef]

- Tanislav, A.E.; Pușcaș, A.; Păucean, A.; Mureșan, A.E.; Semeniuc, C.A.; Mureșan, V.; Mudura, E. Evaluation of Structural Behavior in the Process Dynamics of Oleogel-Based Tender Dough Products. Gels 2022, 8, 317. [Google Scholar] [CrossRef]

- Gutiérrez-Luna, K.; Astiasaran, I.; Ansorena, D. Fat reduced cookies using an olive oil-alginate gelled emulsion: Sensory properties, storage stability and in vitro digestion. Food Res. Int. 2023, 167, 112714. [Google Scholar] [CrossRef]

- Ansorena, D.; Cartagena, L.; Astiasaran, I. A Cake Made with No Animal Origin Ingredients: Physical Properties and Nutritional and Sensory Quality. Foods 2023, 12, 54. [Google Scholar] [CrossRef] [PubMed]

| Samples | Absorbance 600 nm | Samples | Absorbance 600 nm |

|---|---|---|---|

| SND | 0.15 ± 0.00 Bb | PND | 0.09 ± 0.00 Ac |

| SD70 | 0.17 ± 0.07 Ba | PD70 | 0.22 ± 0.07 Ab |

| SD85 | 0.13 ± 0.00 Bc | PD85 | 0.24 ± 0.01 Aa |

| Biscuit Sample | Hardness [g] | Fracturability [g] | L* | a* | b* | ΔE | Oil Loss (%) |

|---|---|---|---|---|---|---|---|

| B_SND_40% | 371 ± 31.11 a | 260 ± 48.08 a | 58.66 ± 0.85 a b | 13.76 ± 2.16 b | 30.77 ± 3.11 a | 4.05 ± 0.56 a | 0.22 ± 0.0 a |

| B_SD70_40% | 612 ± 55.15 a | 350 ± 50.00 a | 55.19 ± 1.43 c | 17.35 ± 0.66 a | 30.69 ± 0.48 a | 5.49 ± 1.19 a | 0.22 ± 0.0 a |

| B_PND_40% | 310 ± 65.05 a | 216.5 ± 16.26 a | 59.61 ± 0.11 a | 12.99 ± 1.33 b | 31.73 ± 1.91 a | 3.53 ± 0.85 a | 0.21 ± 0/01 a |

| B_PD70_40% | 338.5 ± 24.74 a | 231 ± 22.62 a | 59.65 ± 0.81 a | 12.67 ± 0.53 b | 30.87 ± 0.59 a | 3.36 ± 0.78 a | 0.19 ± 0.01 a |

| Reference | 180 ± 11.31 b | 39 ± 7.07 b | 56.34 ± 0.70 bc | 12.28 ± 0.57 b | 30.87 ± 0.59 a | - | - |

| Hydrogel Codification (97% Water) Based on the Ternary Mixture Composition/THERMAL Treatment | Denaturated at 85 °C for 15 min | Denaturated at 70 °C for 20 min | Not Denaturated |

|---|---|---|---|

| 2% pea isolate, 0.5% guar gum, 0.5% xanthan gum. | PD85 | PD70 | PND |

| 2% soy isolate, 0.5% guar gum, 0.5% xanthan gum. | SD85 | SD70 | SND |

| Emulgel Codification Composition/Thermal Treatment | Pea Protein + 40%OIL | Pea Protein + 60%OIL | Soy Protein + 40%OIL | Soy Protein + 60%OIL |

|---|---|---|---|---|

| 70 °C for 20 min | P70_60% | P70_40% | S70_60% | S70_40% |

| 85 °C for 15 min | P85_60% | PND85_40% | S85_60% | S85_40% |

| No thermal treatment | PND_60% | PND_40% | SND_60% | SND40% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pușcaș, A.; Tanislav, A.E.; Mureșan, A.E.; Mureșan, V. Emulgels as Fat-Replacing Systems in Biscuits Developed with Ternary Mixtures of Pea and Soy Protein Isolates and Gums. Gels 2025, 11, 478. https://doi.org/10.3390/gels11070478

Pușcaș A, Tanislav AE, Mureșan AE, Mureșan V. Emulgels as Fat-Replacing Systems in Biscuits Developed with Ternary Mixtures of Pea and Soy Protein Isolates and Gums. Gels. 2025; 11(7):478. https://doi.org/10.3390/gels11070478

Chicago/Turabian StylePușcaș, Andreea, Anda Elena Tanislav, Andruța Elena Mureșan, and Vlad Mureșan. 2025. "Emulgels as Fat-Replacing Systems in Biscuits Developed with Ternary Mixtures of Pea and Soy Protein Isolates and Gums" Gels 11, no. 7: 478. https://doi.org/10.3390/gels11070478

APA StylePușcaș, A., Tanislav, A. E., Mureșan, A. E., & Mureșan, V. (2025). Emulgels as Fat-Replacing Systems in Biscuits Developed with Ternary Mixtures of Pea and Soy Protein Isolates and Gums. Gels, 11(7), 478. https://doi.org/10.3390/gels11070478