Gel-Based Approaches to Vegan Leather: Opportunities and Challenges in Mimicking Leather Properties

Abstract

1. Introduction

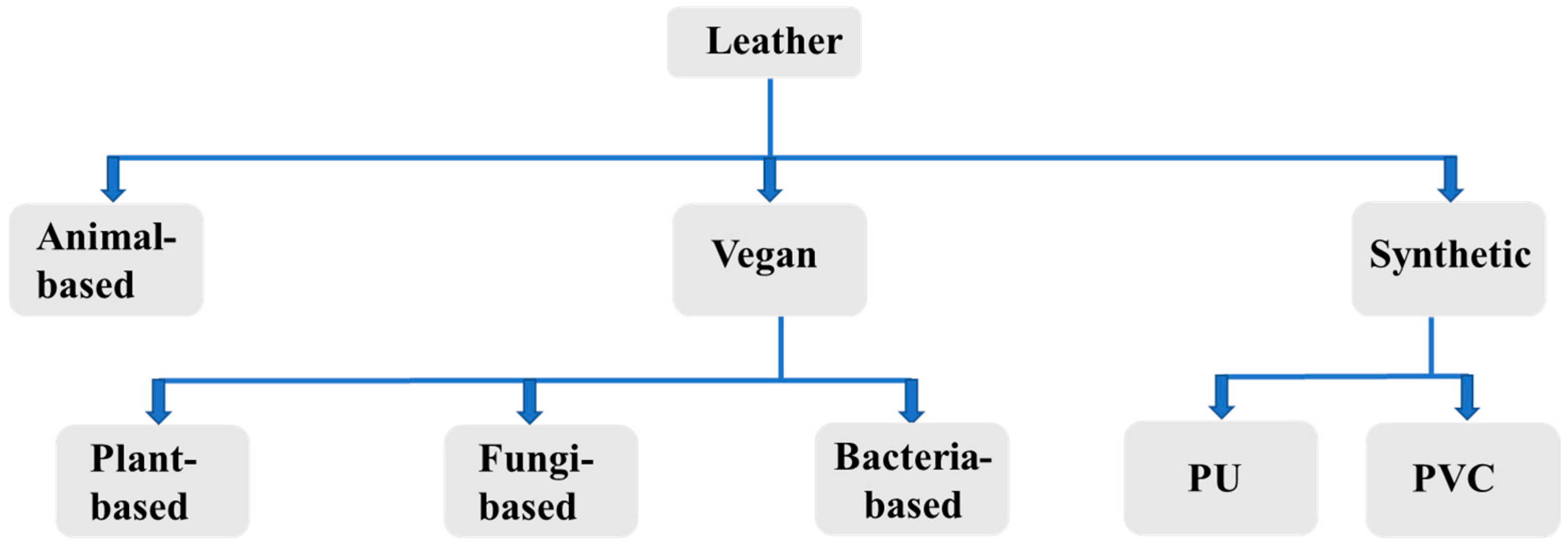

2. Requirements for Leather Alternatives

3. Alternatives to Animal-Based Leather

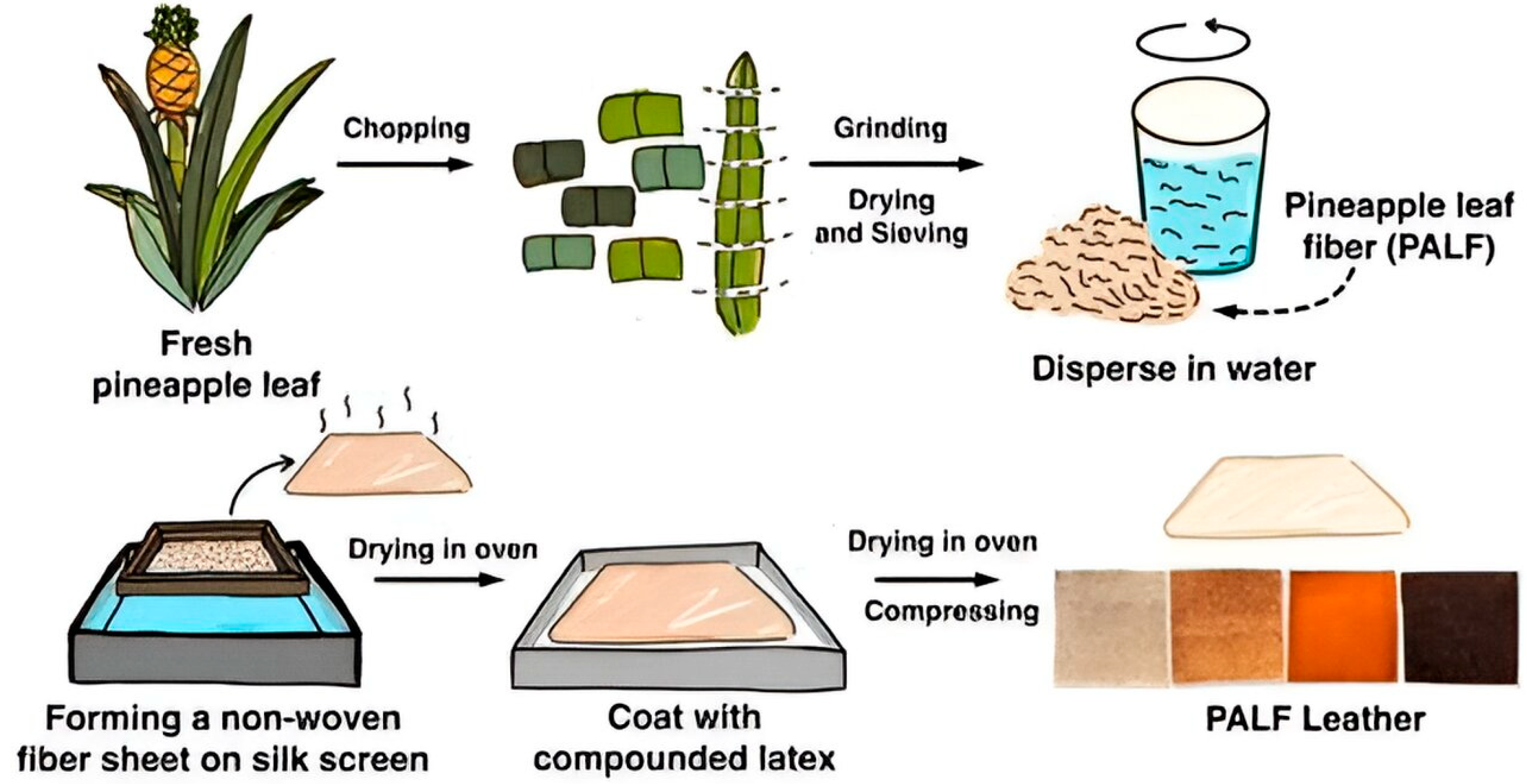

3.1. Plant-Based Leather

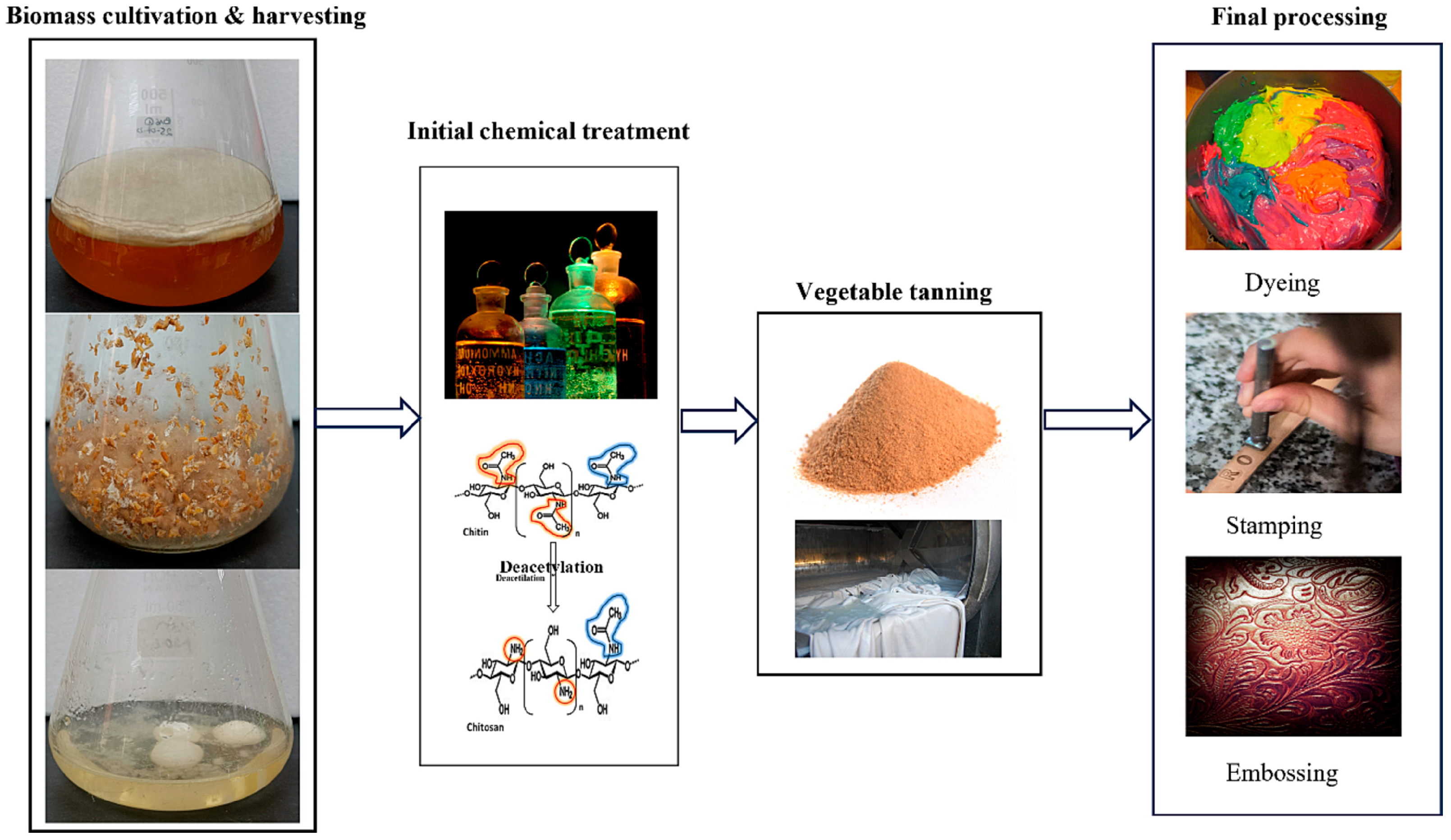

3.2. Fungi-Based Leather

3.3. Bacterial Cellulose (BC)-Based Leather

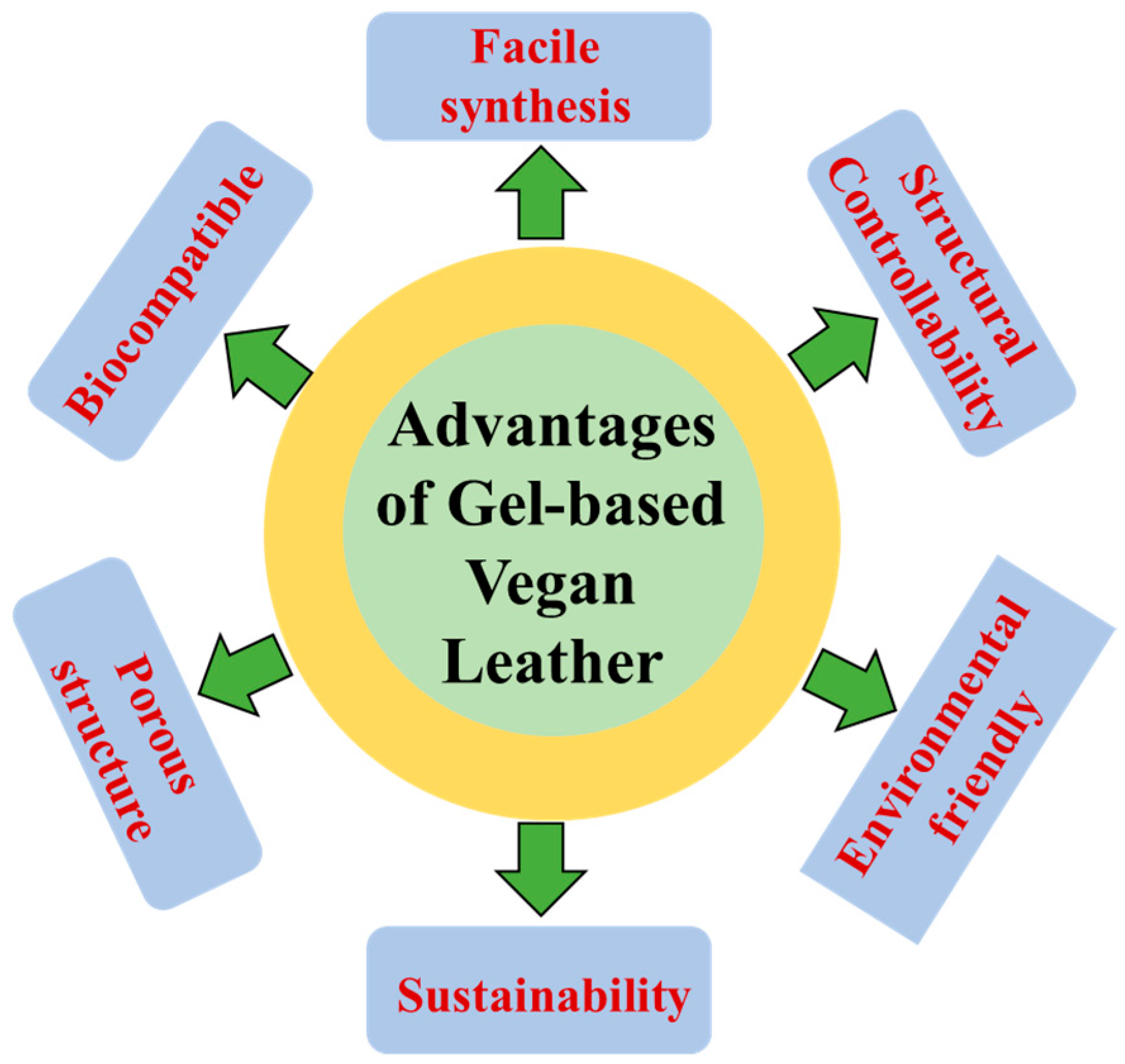

4. Opportunities for Gel-Based Materials as Leather Alternatives

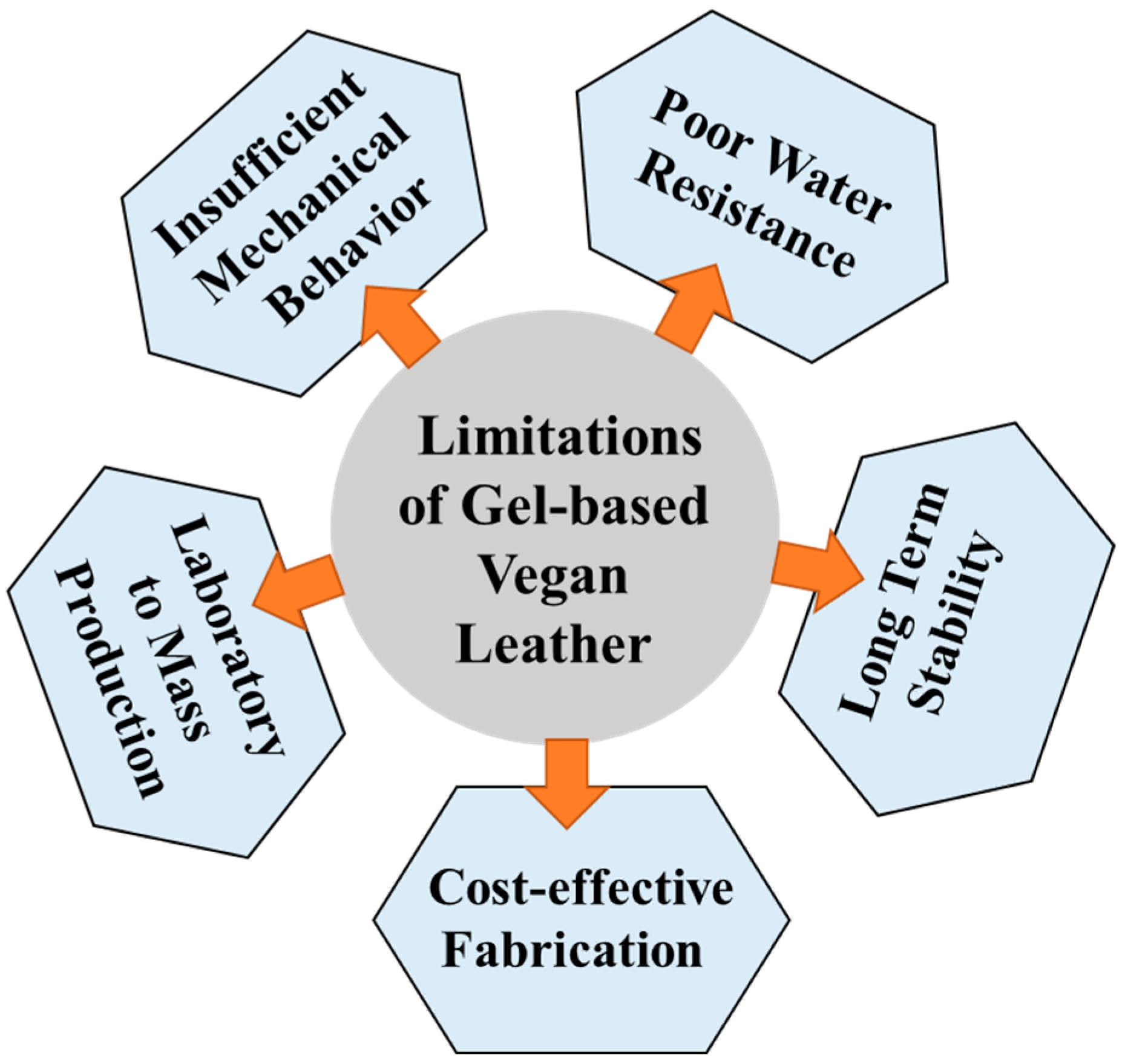

5. Challenges and Limitations of Gel-Based Materials for Leather Alternatives

6. Future Strategies for the Development of Gel-Based Vegan Leather

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, P.; Guo, Z.; Ullah, S.; Melagraki, G.; Afantitis, A.; Lynch, I. Nanotechnology and artificial intelligence to enable sustainable and precision agriculture. Nat. Plants 2021, 7, 864–876. [Google Scholar] [CrossRef] [PubMed]

- Babbitt, C.W.; Moore, E.A. Sustainable nanomaterials by design. Nat. Nanotechnol. 2018, 13, 621–623. [Google Scholar] [CrossRef] [PubMed]

- Yang, C.; Li, P.; Wei, C.; Prominski, A.; Ma, J.; Sun, C.; Yue, J.; Cheng, Z.; Zhang, J.; Ashwood, B.; et al. A bioinspired permeable junction approach for sustainable device microfabrication. Nat. Sustain. 2024, 7, 1190–1203. [Google Scholar] [CrossRef]

- Popescu, C.; Dissanayake, H.; Mansi, E.; Stancu, A. Eco Breakthroughs: Sustainable Materials Transforming the Future of our Planet. Sustainability 2024, 16, 10790. [Google Scholar] [CrossRef]

- Arman, S.M.; Mark-Herbert, C. Ethical Consumption: A Review and Research Agenda. Int. J. Consum. Stud. 2024, 48, e13079. [Google Scholar] [CrossRef]

- Li, M.; Choe, Y.-H.; Gu, C. How perceived sustainability influences consumers’ clothing preferences. Sci. Rep. 2024, 14, 28672. [Google Scholar] [CrossRef]

- Kefale, G.Y.; Kebede, Z.T.; Birlie, A.A. A Systematic Review on Potential Bio Leather Substitute for Natural Leather. J. Eng. 2023, 2023, 1629174. [Google Scholar] [CrossRef]

- Wills, B. The tanning of sheep and goat skins in North Africa. Newsletter 1987, 20, 84–90. [Google Scholar]

- Van Driel-Murray, C. Leatherwork and skin products. In Ancient Egyptian Materials and Technology; Nicholson, P.T., Shaw, I., Eds.; Cambridge University Press: Cambridge, UK, 2000; pp. 299–319. [Google Scholar]

- Xu, X.; Sharma, P.; Shu, S.; Lin, T.-S.; Ciais, P.; Tubiello, F.N.; Smith, P.; Campbell, N.; Jain, A.K. Global greenhouse gas emissions from animal-based foods are twice those of plant-based foods. Nat. Food 2021, 2, 724–732. [Google Scholar] [CrossRef]

- Zhang, X.; Gong, Z.; Allinson, G.; Xiao, M.; Li, X.; Jia, C.; Ni, Z. Environmental risks caused by livestock and poultry farms to the soils: Comparison of swine, chicken, and cattle farms. J. Environ. Manag. 2022, 317, 115320. [Google Scholar] [CrossRef]

- Arti; Mehra, R. Analysis of heavy metals and toxicity level in the tannery effluent and the environs. Environ. Monit. Assess. 2023, 195, 554. [Google Scholar] [CrossRef] [PubMed]

- Bielak, E.; Marcinkowska, E. Heavy metals in leathers, artificial leathers, and textiles in the context of quality and safety of use. Sci. Rep. 2022, 12, 5061. [Google Scholar] [CrossRef] [PubMed]

- Ahmadi, S.S.; Maysami, M.; Abdi, R.; Zarei, M.; Dröge, S. Environmental and energy analysis of chromium recovery from residual tanned leather using alkaline thermal hydrolysis. Sci. Rep. 2025, 15, 11202. [Google Scholar] [CrossRef]

- Alemu, L.G.; Kefale, G.Y.; Hailu, R.; Tilahun, A.; Minbale, E.; Eyasu, A. Toward Sustainable Leather Processing: A Comprehensive Review of Cleaner Production Strategies and Environmental Impacts. Adv. Mater. Sci. Eng. 2024, 2024, 8117915. [Google Scholar] [CrossRef]

- Daddi, T.; Ahmad, S.; Albano, F. Fostering environmental sustainability of leather industry: Environmental impact assessment and improvement prospects for leather-tanning technologies. Environ. Sci. Pollut. Res. 2024, 31. [Google Scholar] [CrossRef]

- Akhter, S.; Jahan, M.S.; Rahman, M.L.; Ruhane, T.A.; Ahmed, M.; Khan, M.A. Revolutionizing Sustainable Fashion: Jute–Mycelium Vegan Leather Reinforced with Polyhydroxyalkanoate Biopolymer Crosslinking from Novel Bacteria. Adv. Polym. Technol. 2024, 2024, 1304800. [Google Scholar] [CrossRef]

- Tewari, S.; Reshamwala, S.M.S.; Bhatt, L.; Kale, R.D. Vegan leather: A sustainable reality or a marketing gimmick? Environ. Sci. Pollut. Res. 2024, 31, 3361–3375. [Google Scholar] [CrossRef]

- Meyer, M.; Dietrich, S.; Schulz, H.; Mondschein, A. Comparison of the technical performance of leather, artificial leather, and trendy alternatives. Coatings 2021, 11, 226. [Google Scholar] [CrossRef]

- Wang, H. Advantages of animal leather over alternatives and its medical applications. Eur. Polym. J. 2024, 214, 113153. [Google Scholar] [CrossRef]

- Vijeandran, K.; Vu Thanh, T.A. Synthesis of Vegan Leather Using Plant-Based Substrates: A Preliminary Study. Defect Diffus. Forum 2021, 411, 57–66. [Google Scholar] [CrossRef]

- Minh, N.T.; Ngan, H.N. Vegan leather: An Eco-Friendly Material for Sustainable Fashion Towards Environmental Awareness. In Proceedings of the AIP Conference Proceedings, Ho Chi Minh City, Vietnam, 20 September 2021. [Google Scholar]

- Cao, H.; Duan, L.; Zhang, Y.; Cao, J.; Zhang, K. Current hydrogel advances in physicochemical and biological response-driven biomedical application diversity. Signal Transduct. Target. Ther. 2021, 6, 426. [Google Scholar] [CrossRef] [PubMed]

- Zhao, L.; Zhou, Y.; Zhang, J.; Liang, H.; Chen, X.; Tan, H. Natural Polymer-Based Hydrogels: From Polymer to Biomedical Applications. Pharmaceutics 2023, 15, 2514. [Google Scholar] [CrossRef] [PubMed]

- Yarahmadi, A.; Dousti, B.; Karami-Khorramabadi, M.; Afkhami, H. Materials based on biodegradable polymers chitosan/gelatin: A review of potential applications. Front. Bioeng. Biotechnol. 2024, 12, 2024. [Google Scholar] [CrossRef]

- Nanda, D.; Behera, D.; Pattnaik, S.S.; Behera, A.K. Advances in natural polymer-based hydrogels: Synthesis, applications, and future directions in biomedical and environmental fields. Discov. Polym. 2025, 2, 6. [Google Scholar] [CrossRef]

- China, C.R.; Maguta, M.M.; Nyandoro, S.S.; Hilonga, A.; Kanth, S.V.; Njau, K.N. Alternative tanning technologies and their suitability in curbing environmental pollution from the leather industry: A comprehensive review. Chemosphere 2020, 254, 126804. [Google Scholar] [CrossRef]

- Amde, B. Major factors affecting hide and skin production, quality and the tanning industry in Ethiopia. Adv. Biol. Res. 2017, 11, 116–125. [Google Scholar]

- Haines, B.; Barlow, J. The anatomy of leather. J. Mater. Sci. 1975, 10, 525–538. [Google Scholar] [CrossRef]

- Choi, Y.-H.; Lee, K.-H. Ethical consumers’ awareness of vegan materials: Focused on fake fur and fake leather. Sustainability 2021, 13, 436. [Google Scholar] [CrossRef]

- Duangsuwan, S.; Junkong, P.; Phinyocheep, P.; Thanawan, S.; Amornsakchai, T. Development of Green Leather Alternative from Natural Rubber and Pineapple Leaf Fiber. Sustainability 2023, 15, 15400. [Google Scholar] [CrossRef]

- Baur, X.; Marek, W.; Ammon, J.; Czuppon, A.; Marczynski, B.; Raulf-Heimsoth, M.; Roemmelt, H.; Fruhmann, G. Respiratory and other hazards of isocyanates. Int. Arch. Occup. Environ. Health 1994, 66, 141–152. [Google Scholar] [CrossRef]

- Otake, Y.; Kobayashi, T.; Asabe, H.; Murakami, N.; Ono, K. Biodegradation of low-density polyethylene, polystyrene, polyvinyl chloride, and urea formaldehyde resin buried under soil for over 32 years. J. Appl. Polym. Sci. 1995, 56, 1789–1796. [Google Scholar] [CrossRef]

- Duo, Y.; Qian, X.; Zhao, B.; Qian, Y.; Xu, P.; Qi, J. Micro/nano microfiber synthetic leather base with different nanofiber diameters. J. Ind. Text. 2021, 50, 1127–1142. [Google Scholar] [CrossRef]

- Singaraj, S.P.; Chengamchetty, M.R.; Ambika, K.; Gunasekaran, B. Characteristic Analysis of Sisal Fabric and Cow Nubuck Leather for Developing Leather Lifestyle Accessories. J. Nat. Fibers 2023, 20, 2218120. [Google Scholar] [CrossRef]

- He, X.; Wang, Y.-N.; Zhou, J.; Wang, H.; Ding, W.; Shi, B. Suitability of Pore Measurement Methods for Characterizing the Hierarchical Pore Structure of Leather. J. Am. Leather Chem. Assoc. 2019, 114, 41–47. [Google Scholar]

- Smiechowski, K.; Zarlok, J.; Kowalska, M. The Relationship Between Water Vapour Permeability and Softness for Leathers Produced in Poland. J. Soc. Leather Technol. Chem. 2014, 98, 259–263. [Google Scholar]

- Adıgüzel Zengin, A.C.; Oğlakcıoğlu, N.; Bitlisli, B.O. Effect of finishing techniques on some physical characteristics of shoe upper leathers. Text. Appar. 2017, 27, 198–203. [Google Scholar]

- Mesa, J.W.; Onyancha, D.O.; Magut, P.K.S. Assessment of the Quality of Leather Footwear for School Children Made by SMEs in Kariokor Kenya. Int. J. Sci. Res. Publ. 2019, 9, 908–916. [Google Scholar] [CrossRef]

- Mihai, A.; Seul, A.; Curteza, A.; Costea, M. Mechanical Parameters of Leather in Relation to Technological Processing of the Footwear Uppers. Materials 2022, 15, 5107. [Google Scholar] [CrossRef]

- Ding, W.; Pang, X.; Zhiwen, D.; Tsang, D.C.W.; Jiang, Z.; Shi, B. Constructing a robust chrome-free leather tanned by biomass-derived polyaldehyde via crosslinking with chitosan derivatives. J. Hazard. Mater. 2020, 396, 122771. [Google Scholar] [CrossRef]

- Sundar, V.; Muralidharan, C. A Study on Water Vapour Permeability with Increased Functional Properties of Upper Leathers. Leather Footwear J. 2017, 17, 155–162. [Google Scholar] [CrossRef]

- Locker, C.R.; Theregowda, R. Life-cycle assessment of Bioleather. Clean. Circ. Bioecon. 2022, 1, 100003. [Google Scholar] [CrossRef]

- Kellen, C.; Zhafirah, L.; Kasih, T.P. Transforming Fast Fashion: Exploring Bio-Leather as a Sustainable Alternative. IOP Conf. Ser. Earth Environ. Sci. 2025, 1488, 012039. [Google Scholar] [CrossRef]

- Polko, J.K.; Kieber, J.J. The Regulation of Cellulose Biosynthesis in Plants. Plant Cell 2019, 31, 282–296. [Google Scholar] [CrossRef]

- Amobonye, A.; Lalung, J.; Awasthi, M.K.; Pillai, S. Fungal mycelium as leather alternative: A sustainable biogenic material for the fashion industry. Sustain. Mater. Technol. 2023, 38, e00724. [Google Scholar] [CrossRef]

- Cerimi, K.; Akkaya, K.C.; Pohl, C.; Schmidt, B.; Neubauer, P. Fungi as source for new bio-based materials: A patent review. Fungal Biol. Biotechnol. 2019, 6, 17. [Google Scholar] [CrossRef]

- Angelova, G.V.; Brazkova, M.S.; Krastanov, A.I. Renewable mycelium based composite—Sustainable approach for lignocellulose waste recovery and alternative to synthetic materials—A review. Z. Naturforschung. 2021, 76, 431–442. [Google Scholar] [CrossRef]

- Bustillos, J.; Loganathan, A.; Agrawal, R.; Gonzalez, B.A.; Perez, M.G.; Ramaswamy, S.; Boesl, B.; Agarwal, A. Uncovering the Mechanical, Thermal, and Chemical Characteristics of Biodegradable Mushroom Leather with Intrinsic Antifungal and Antibacterial Properties. ACS Appl. Bio Mater. 2020, 3, 3145–3156. [Google Scholar] [CrossRef]

- Williams, E.; Cenian, K.; Golsteijn, L.; Morris, B.; Scullin, M.L. Life cycle assessment of MycoWorks’ Reishi™: The first low-carbon and biodegradable alternative leather. Environ. Sci. Eur. 2022, 34, 120. [Google Scholar] [CrossRef]

- Fazli Wan Nawawi, W.M.; Lee, K.-Y.; Kontturi, E.; Murphy, R.J.; Bismarck, A. Chitin Nanopaper from Mushroom Extract: Natural Composite of Nanofibers and Glucan from a Single Biobased Source. ACS Sustain. Chem. Eng. 2019, 7, 6492–6496. [Google Scholar] [CrossRef]

- Chen, H.; Abdullayev, A.; Bekheet, M.F.; Schmidt, B.; Regler, I.; Pohl, C.; Vakifahmetoglu, C.; Czasny, M.; Kamm, P.H.; Meyer, V.; et al. Extrusion-based additive manufacturing of fungal-based composite materials using the tinder fungus Fomes fomentarius. Fungal Biol. Biotechnol. 2021, 8, 21. [Google Scholar] [CrossRef]

- Susel, G.D.E.; Domínguez, E.M.H.; Fernández, A.G.E.; Cervantes, J.Á.; Medellín, L.D.R.; Mendoza, B.M. Biomaterial obtenido a partir de micelio de hongo (Ganoderma lucidum) y residuos agrícolas: Biomaterial obtained from fungus micellium (Ganoderma lucidum) and agricultural wastes. South Fla. J. Dev. 2021, 2, 4663–4681. [Google Scholar] [CrossRef]

- García, C.; Prieto, M.A. Bacterial cellulose as a potential bioleather substitute for the footwear industry. Microb. Biotechnol. 2019, 12, 582–585. [Google Scholar] [CrossRef] [PubMed]

- Sun, S.; Mitchell, J.R.; Macnaughtan, W.; Foster, T.J.; Harabagiu, V.; Song, Y.; Zheng, Q. Comparison of the mechanical properties of cellulose and starch films. Biomacromolecules 2010, 11, 126–132. [Google Scholar] [CrossRef]

- Portela, R.; Leal, C.R.; Almeida, P.L.; Sobral, R.G. Bacterial cellulose: A versatile biopolymer for wound dressing applications. Microb. Biotechnol. 2019, 12, 586–610. [Google Scholar] [CrossRef]

- Pasaribu, K.M.; Ilyas, S.; Tamrin, T.; Radecka, I.; Swingler, S.; Gupta, A.; Stamboulis, A.G.; Gea, S. Bioactive bacterial cellulose wound dressings for burns with collagen in-situ and chitosan ex-situ impregnation. Int. J. Biol. Macromol. 2023, 230, 123118. [Google Scholar] [CrossRef]

- Mehrotra, N.; Bhuvana, T.; Tiwari, A.; Chandraprakash, C. Aerogel-like biodegradable acoustic foams of bacterial cellulose. J. Appl. Polym. Sci. 2024, 141, e55881. [Google Scholar] [CrossRef]

- Walker, K.T.; Li, I.S.; Keane, J.; Goosens, V.J.; Song, W.; Lee, K.-Y.; Ellis, T. Self-pigmenting textiles grown from cellulose-producing bacteria with engineered tyrosinase expression. Nat. Biotechnol. 2025, 43, 345–354. [Google Scholar] [CrossRef]

- Kubiak, K.; Kurzawa, M.; Jędrzejczak-Krzepkowska, M.; Ludwicka, K.; Krawczyk, M.; Migdalski, A.; Kacprzak, M.M.; Loska, D.; Krystynowicz, A.; Bielecki, S. Complete Genome Sequence of Gluconacetobacter Xylinus E25 Strain-Valuable and Effective Producer of Bacterial Nanocellulose. J. Biotechnol. 2014, 176, 18–19. [Google Scholar] [CrossRef]

- Kumar, A.; Won, S.-Y.; Sood, A.; Choi, S.-Y.; Singhmar, R.; Bhaskar, R.; Kumar, V.; Zo, S.M.; Han, S.-S. Triple-Networked Hybrid Hydrogels Reinforced with Montmorillonite Clay and Graphene Nanoplatelets for Soft and Hard Tissue Regeneration. Int. J. Mol. Sci. 2022, 23, 14158. [Google Scholar] [CrossRef]

- Kumar, A.; Sood, A.; Agrawal, G.; Thakur, S.; Thakur, V.K.; Tanaka, M.; Mishra, Y.K.; Christie, G.; Mostafavi, E.; Boukherroub, R.; et al. Polysaccharides, proteins, and synthetic polymers based multimodal hydrogels for various biomedical applications: A review. Int. J. Biol. Macromol. 2023, 247, 125606. [Google Scholar] [CrossRef]

- Zöller, K.; To, D.; Bernkop-Schnürch, A. Biomedical applications of functional hydrogels: Innovative developments, relevant clinical trials and advanced products. Biomaterials 2025, 312, 122718. [Google Scholar] [CrossRef] [PubMed]

- Kuang, X.; Arıcan, M.O.; Zhou, T.; Zhao, X.; Zhang, Y.S. Functional Tough Hydrogels: Design, Processing, and Biomedical Applications. Acc. Mater. Res. 2023, 4, 101–114. [Google Scholar] [CrossRef]

- Kebede, Z.T.; Tadesse, M.G.; Chane, T.E.; Mengistie, D.A. Application of PEDOT:PSS Conductive Polymer to Enhance the Conductivity of Natural Leather: Retanning Process. J. Nanomater. 2023, 2023, 3026487. [Google Scholar] [CrossRef]

- Fan, Q.; Ma, J.; Xu, Q. Insights into functional polymer-based organic-inorganic nanocomposites as leather finishes. J. Leather Sci. Eng. 2019, 1, 3. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, F.; An, Z.; Shi, W.; Li, H. Novel bio-based filler: Hyperbranched polymer modified leather buffing dust and its influence on the porous structure and mechanical properties of polyurethane film. RSC Adv. 2021, 11, 27183–27192. [Google Scholar] [CrossRef]

- Pringle, T.; Barwood, M.; Rahimifard, S. The Challenges in Achieving a Circular Economy Within Leather Recycling. Procedia CIRP 2016, 48, 544–549. [Google Scholar] [CrossRef]

- Alven, S.; Aderibigbe, B.A. Chitosan-Based Scaffolds Incorporated with Silver Nanoparticles for the Treatment of Infected Wounds. Pharmaceutics 2024, 16, 327. [Google Scholar] [CrossRef]

- Pérez-Díaz, M.; Alvarado-Gomez, E.; Magaña-Aquino, M.; Sánchez-Sánchez, R.; Velasquillo, C.; Gonzalez, C.; Ganem-Rondero, A.; Martínez-Castañon, G.; Zavala-Alonso, N.; Martinez-Gutierrez, F. Anti-biofilm activity of chitosan gels formulated with silver nanoparticles and their cytotoxic effect on human fibroblasts. Mater. Sci. Eng. 2016, 60, 317–323. [Google Scholar] [CrossRef]

- Cirillo, C.; Iuliano, M.; Fierro, F.; Florio, C.; Maffei, G.; Loi, A.; Batakliev, T.; Sarno, M. Silver Nanoparticle-Based Finishing for Leather Antimicrobial and UV Protection. Micromachines 2025, 16, 376. [Google Scholar] [CrossRef]

- Liu, G.; Li, K.; Luo, Q.; Wang, H.; Zhang, Z. PEGylated chitosan protected silver nanoparticles as water-borne coating for leather with antibacterial property. J. Colloid Interface Sci. 2017, 490, 642–651. [Google Scholar] [CrossRef]

- Cirillo, C.; Iuliano, M.; Scarpa, D.; Gallucci, L.; Florio, C.; Maffei, G.; Loi, A.; Sarno, M. Nanoparticle Usage in Leather Processing: Worker Safety and Health. ACS Chem. Health Saf. 2024, 31, 276–290. [Google Scholar] [CrossRef]

- Ignat, M.; Miu, L.; Hadîmbu, E.; Sendrea, C.; Micu, M.-C.; Paunescu, S.; Caniola, I.; Badea, E. The influence of TiO2 and N-TiO2 Nanopowders in Natural Leather Finishing for Heritage or Modern Binding. In Proceedings of the 8th International Conference on Advanced Materials and Systems, Bucharest, Romania, 1–3 October 2020; pp. 501–506. [Google Scholar]

- Samprovalaki, K.; Robbins, P.T.; Fryer, P.J. Investigation of the diffusion of dyes in agar gels. J. Food Eng. 2012, 111, 537–545. [Google Scholar] [CrossRef]

- Xu, Y.; Gilbert, E.P.; Sokolova, A.; Stokes, J.R. Phase transition and gelation in cellulose nanocrystal-based aqueous suspensions studied by SANS. J. Colloid Interface Sci. 2024, 658, 660–670. [Google Scholar] [CrossRef]

- da Câmara, P.C.F.; de Morais, S.C.; do Nascimento Marques, N.; de Souza, E.A.; de Carvalho Balaban, R. Cellulose nanocrystals reinforcement for glycerol-based gels: Effects on gelation behavior and thermal insulation performance. J. Mol. Liq. 2025, 428, 127562. [Google Scholar] [CrossRef]

- Liu, W.; Zhao, X.; Ye, X.; Zheng, X.; Zhang, Y.; Wang, M.; Lin, X.; Liu, B.; Han, L.; Ning, Y.; et al. Graphene Oxide Nanoribbon-Based Composite Gel Polymer Electrolytes: Enhancing Mechanical Strength and Ionic Conductivity for Long Cycling Lifetime of Flexible Zinc–Air Batteries. Energy Fuels 2024, 38, 6508–6517. [Google Scholar] [CrossRef]

- Qin, D.; Gao, W.; Zhang, S.; Cui, X.; Chen, H.; Yang, P.; Zheng, X. In situ composite of graphene oxide in polyacrylamide to enhance strength of hydrogel with polyethyleneimine as crosslinker. Geoenergy Sci. Eng. 2023, 231, 212304. [Google Scholar] [CrossRef]

- Mei, X.; Ouyang, J. Gels of carbon nanotubes and a nonionic surfactant prepared by mechanical grinding. Carbon 2010, 48, 293–299. [Google Scholar] [CrossRef]

- Li, D.; Xu, S.; Wang, F.; Li, L.; Li, J. Multifunctional carbon nanotubes based hydrogel integrates photothermal water desalination, photothermal power generation, sensing, and flame retardancy, with a multi purpose and adjustable thermoelectric effect. J. Colloid Interface Sci. 2025, 690, 137344. [Google Scholar] [CrossRef]

- Zhu, L.; Qiu, J.; Sakai, E. A high modulus hydrogel obtained from hydrogen bond reconstruction and its application in vibration damper. RSC Adv. 2017, 7, 43755–43763. [Google Scholar] [CrossRef]

- Costa, A.M.S.; Mano, J.F. Extremely strong and tough hydrogels as prospective candidates for tissue repair—A review. Eur. Polym. J. 2015, 72, 344–364. [Google Scholar] [CrossRef]

- Farajifard, M.; Yeganeh, J.K.; Zare, Y.; Munir, M.T.; Rhee, K.Y. Simulation of tensile strength for polymer hydroxyapatite nanocomposites by interphase and nanofiller dimensions. Polym. Compos. 2024, 45, 10234–10245. [Google Scholar] [CrossRef]

- Ji, D.; Kim, J. Recent Strategies for Strengthening and Stiffening Tough Hydrogels. Adv. NanoBiomed Res. 2021, 1, 2100026. [Google Scholar] [CrossRef]

- Li, Z.; Soto, M.A.; Drummond, J.G.; Martinez, D.M.; Hamad, W.Y.; MacLachlan, M.J. Cellulose Nanocrystal Gels with Tunable Mechanical Properties from Hybrid Thermal Strategies. ACS Appl. Mater. Interfaces 2023, 15, 8406–8414. [Google Scholar] [CrossRef]

- Lu, S.; Bo, Q.; Zhao, G.; Shaikh, A.; Dai, C. Recent advances in enhanced polymer gels for profile control and water shutoff: A review. Front. Chem. 2023, 11, 1067094. [Google Scholar] [CrossRef]

- Tang, G.; Gong, Z.; Liu, M.; Hou, Y.; Tao, K.; Dai, K.; Zhang, S. Enhancing flame resistance properties and water resistance of rigid polyurethane foam using microencapsulation. Case Stud. Therm. Eng. 2025, 66, 105738. [Google Scholar] [CrossRef]

- Shi, S.; Chen, Y.; Li, W.; Liu, L.; Guo, H.; Xie, L.; Chai, X.; Xu, K.; Du, G.; Lei, H.; et al. Preparation of high water resistance full biomass adhesive by ultrastrong crosslinking with gelatin, citric acid and sucrose. Polymer 2024, 308, 127414. [Google Scholar] [CrossRef]

- Yang, H.; Li, L.; Dong, G.; Wei, Q.; Zhang, J.; Wang, X.; Wang, Z.; Xu, C.; Zhang, Z. High-Temperature-Resistant and Gelation-Controllable Silica-Based Gel for Water Management. Energy Fuels 2024, 38, 23398–23406. [Google Scholar] [CrossRef]

| Property | Range | Reference |

|---|---|---|

| Diameter of collagen fibers | 2–8 µm | [34] |

| Tensile strength | 10–40 MPa | [35] |

| Pore size | 10–300 µm | [36] |

| Water vapor permeability | 1.5–16.7 mg/cm2 h | [37] |

| Elongation at break | 30–80% | [19] |

| Moisture absorption capacities | 7–12% | [42] |

| Fungal Species | Young’s Modulus | Strain at Break (%) | Tensile Strength (MPa) | Ref. |

|---|---|---|---|---|

| Agaricus bisporus | 7 GPa | - | 100–200 | [51] |

| Fomes fomentarius | 22.21 ± 3.38 kPa | - | 0.51 ± 0.12 | [52] |

| Ganoderma lucidum | - | 26 | 0.392 | [53] |

| Phellinus ellipsoideus | - | 101 | 1.2 | [49] |

| Animal Leather | Synthetic Leather | Fungi-Based Leather | Bacterial Cellulose-Based Leather | Plant-Based Leather | |

|---|---|---|---|---|---|

| Biodegradability | Limited | Limited | Highly | Highly | Highly |

| Cost of production | High | Moderate | Moderate | Moderate | Less |

| Mechanical attributes | Good | Moderate | Less | Less | Less |

| Environmental impact | High | Moderate | Less | Less | Less |

| Advantage | Durable | Ease in bulk production | Environmentally friendly | Ease in bulk production | Economically viable |

| Disadvantage | Environmental hazard | Batch-to-batch variations | Species-dependent processing | Requirement of specific conditions | Less yield |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, S.M.; Lee, D.H.; Zo, S.M.; Sood, A.; Han, S.S. Gel-Based Approaches to Vegan Leather: Opportunities and Challenges in Mimicking Leather Properties. Gels 2025, 11, 395. https://doi.org/10.3390/gels11060395

Choi SM, Lee DH, Zo SM, Sood A, Han SS. Gel-Based Approaches to Vegan Leather: Opportunities and Challenges in Mimicking Leather Properties. Gels. 2025; 11(6):395. https://doi.org/10.3390/gels11060395

Chicago/Turabian StyleChoi, Soon Mo, Do Hyun Lee, Sun Mi Zo, Ankur Sood, and Sung Soo Han. 2025. "Gel-Based Approaches to Vegan Leather: Opportunities and Challenges in Mimicking Leather Properties" Gels 11, no. 6: 395. https://doi.org/10.3390/gels11060395

APA StyleChoi, S. M., Lee, D. H., Zo, S. M., Sood, A., & Han, S. S. (2025). Gel-Based Approaches to Vegan Leather: Opportunities and Challenges in Mimicking Leather Properties. Gels, 11(6), 395. https://doi.org/10.3390/gels11060395