Optimization of Film-Dressings Containing Herbal Extracts for Wound Care—A Quality by Design Approach

Abstract

1. Introduction

2. Results and Discussion

2.1. Preparation of the CHE-Loaded Film-Dressings

2.2. The QbD Approach

2.3. Establishment of the QTPP and CQAs of the Film-Dressings

| QTPP | |||

|---|---|---|---|

| Parameter | Importance | CQAs | Target |

| Appearance | Visual inspection of the wound | - | Transparent and homogenous, CHE-colored [14] |

| Application | Appropriate topical application to the wound | - | Intimate contact of the film with the wound site [14] |

| Uniformity of mass (g) | Homogenous quantity of phytocompounds from CHE applied to the skin | - | Average weight ±10% [34] |

| Thickness (mm) | Application ease, flexibility, and film aesthetics | - | 0.10–0.20 [14,24,35] |

| Swelling degree (%) | Absorbance of the exudate from the wound and jellification | Yes | Maximized [7,29] |

| WCA (°) * | Jellification of a hydrophilic surface | - | <90° [36] |

| pH * | Skin compatibility, wound healing promotion | - | 4.1–5.8 [37,38] |

| WVTR (g/m2/day) * | Appropriate permeation of gases and water | - | 2000–2500 g/m2/day [36] |

| Folding endurance | Flexibility during storage and usage to avoid cracks or breakage | - | Resistance to >300 folds without visible cracks [9,39] |

| Hardness (g) | Resistance during storage and application to avoid cracks or breakage | Yes | Maximized >2500 g [24] |

| Rigidity at 5 mm (g) (hardness at 5 mm) | Resistance during storage and application to avoid cracks or breakage | - | High values [40] |

| Deformation at target (mm) | Conformability to irregular or moving surfaces of the skin, comfortable during usage | Yes | Maximized [31] |

| Adhesiveness (mJ) | Appropriate adhesion and covering to protect the wound side, contact with wound site, and the release of the CHE active ingredients | Yes | Maximized [7] |

| Adhesive force (g) | Appropriate adhesion and covering to protect the wound side | Yes | Maximized [7] |

| Tensile strength (MPa) | Resistance during storage and application to avoid cracks or breakage | - | 1–32 MPa [41,42] |

| Elongation at break (%) | Flexibility during storage and usage to avoid cracks or breakage, comfortability during usage | Yes | Maximized [31] |

| Young’s modulus (MPa) | Conformability to irregular or moving surfaces of the skin, comfortability during usage | - | 0.4–20 MPa [42,43] |

| In vitro active substances release | Effectiveness of the treatment, reduced frequency of dressing changing | - | Sustained release for at least 6 h [24] |

2.4. Risk Analysis

2.5. Development of the DoE

2.6. Statistical Analysis

2.7. Characterization of the CHE-Loaded Film-Dressings

2.7.1. Organoleptic Analysis

2.7.2. Uniformity of Mass

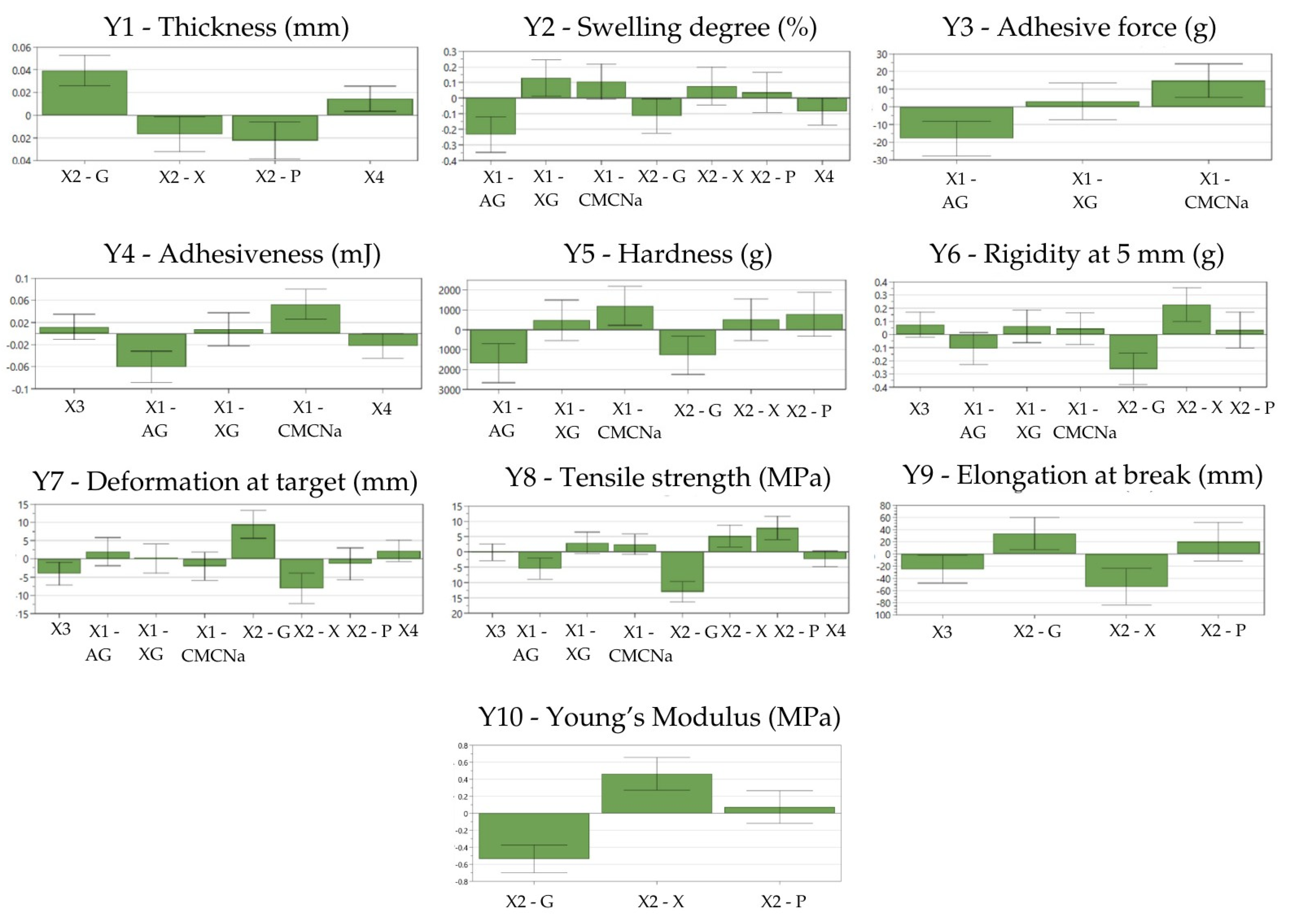

2.7.3. Characterization of the CHE-Loaded Film-Dressings: Results from DoE

2.7.4. Folding Endurance

2.8. Optimization of CHE-Loaded Film-Dressing Formulation

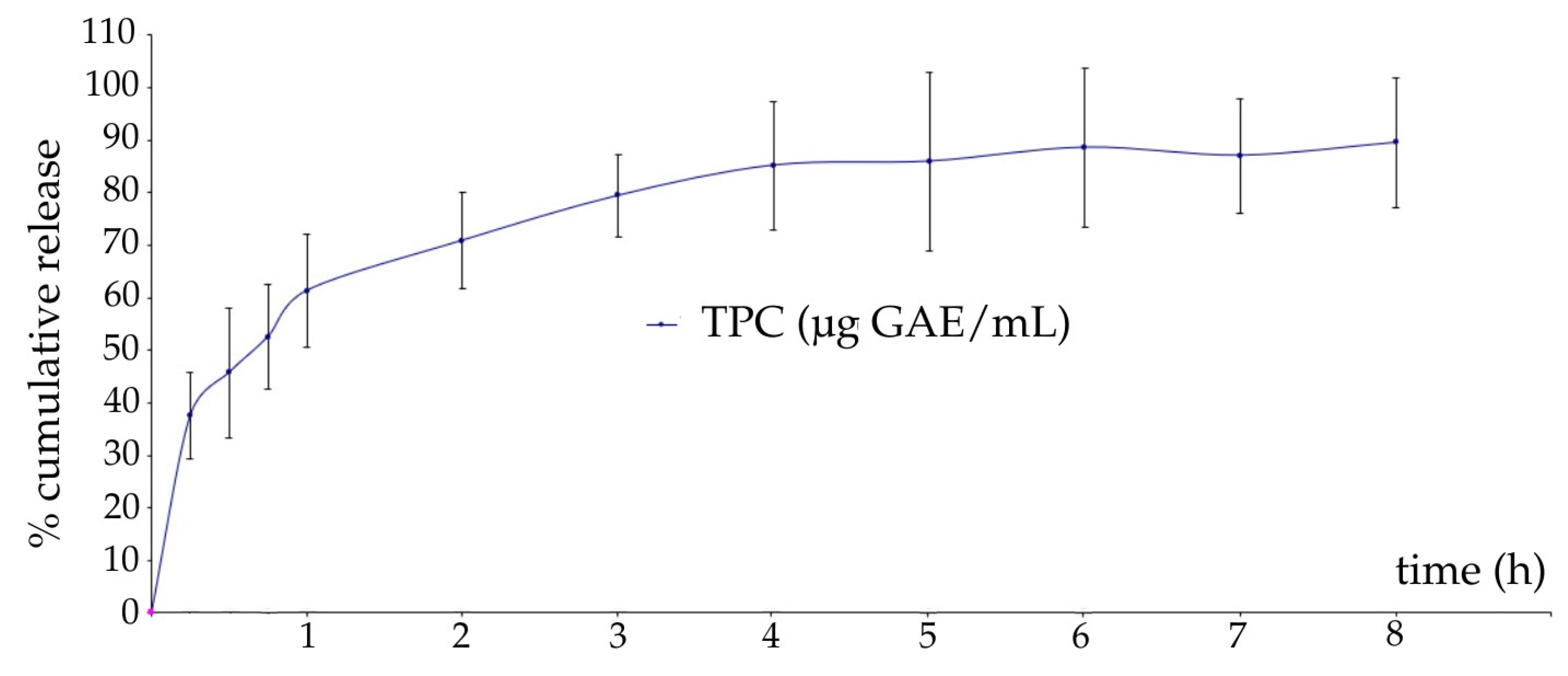

2.9. In Vitro CHE Release from the Optimized CHE-Loaded Film-Dressing

3. Conclusions

4. Materials and Methods

4.1. Chemicals and Reagents

4.2. The QbD Approach

4.2.1. Establishment of the QTPP and CQAs of the CHE-Loaded Film-Dressings

4.2.2. Risk Analysis

4.2.3. Development of the DoE

4.3. Preparation of the CHE-Loaded Film-Dressings

4.4. Characterization of the CHE-Loaded Film-Dressings

4.4.1. Organoleptic Evaluation

4.4.2. Uniformity of Mass

4.4.3. Film Thickness

4.4.4. Swelling Degree

4.4.5. Mechanical Properties—Puncture Test

4.4.6. Mechanical Properties—Tensile Test

4.4.7. Adhesive Properties

4.4.8. Folding Endurance

4.5. Optimization of CHE-Loaded Film-Dressing Formulation

4.6. In Vitro CHE Release from the Optimized CHE-Loaded Film-Dressing

4.7. Statistical Analysis

4.8. Study Limitations

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| CHE | Complex Herbal Extract |

| QbD | Quality by Design |

| DoE | Design of Experiments |

| WVTR | Water Vapor Transmission Rate |

| WCA | Water Contact Angle |

| QTPP | Quality Target Profile Product |

| CQAs | Critical Quality Attributes |

References

- Queen, D.; Harding, K. Estimating the cost of wounds both nationally and regionally within the top 10 highest spenders. Int. Wound J. 2024, 21, e14709. [Google Scholar] [CrossRef] [PubMed]

- Safta, D.A.; Bogdan, C.; Moldovan, M.L. Vesicular Nanocarriers for Phytocompounds in Wound Care: Preparation and Characterization. Pharmaceutics 2022, 14, 991. [Google Scholar] [CrossRef]

- Sen, C.K. Human Wound and Its Burden: Updated 2020 Compendium of Estimates. Adv. Wound Care 2021, 10, 281–292. [Google Scholar] [CrossRef] [PubMed]

- Tejiram, S.; Kavalukas, S.L.; Shupp, J.W.; Barbul, A. Wound healing. In Wound Healing Biomaterials; Ågren, M.S., Ed.; Volume 1: Therapies and Regeneration; Woodhead Publishing Series in Biomaterials; Elsevier: Amsterdam, The Netherlands, 2016; pp. 3–39. [Google Scholar]

- Mouro, C.; Dunne, C.P.; Gouveia, I.C. Designing New Antibacterial Wound Dressings: Development of a Dual Layer Cotton Material Coated with Poly(Vinyl Alcohol)_Chitosan Nanofibers Incorporating Agrimonia eupatoria L. Extract. Molecules 2020, 26, 83. [Google Scholar] [CrossRef] [PubMed]

- Patel, S.; Srivastava, S.; Singh, M.R.; Singh, D. Preparation and optimization of chitosan-gelatin films for sustained delivery of lupeol for wound healing. Int. J. Biol. Macromol. 2018, 107, 1888–1897. [Google Scholar] [CrossRef]

- Schoukens, G. Bioactive dressings to promote wound healing. In Advanced Textiles for Wound Care, 2nd ed.; Rajendran, S., Ed.; Woodhead Publishing: Sawston, UK; Elsevier: Amsterdam, The Netherlands, 2019; pp. 135–167. [Google Scholar]

- Mirhaj, M.; Labbaf, S.; Tavakoli, M.; Seifalian, A. An Overview on the Recent Advances in the Treatment of Infected Wounds: Antibacterial Wound Dressings. Macromol. Biosci. 2022, 22, e2200014. [Google Scholar] [CrossRef]

- Karki, S.; Kim, H.; Na, S.-J.; Shin, D.; Jo, K.; Lee, J. Thin films as an emerging platform for drug delivery. Asian J. Pharm. Sci. 2016, 11, 559–574. [Google Scholar] [CrossRef]

- Alven, S.; Peter, S.; Mbese, Z.; Aderibigbe, B.A. Polymer-Based Wound Dressing Materials Loaded with Bioactive Agents: Potential Materials for the Treatment of Diabetic Wounds. Polymers 2022, 14, 724. [Google Scholar] [CrossRef]

- Saghazadeh, S.; Rinoldi, C.; Schot, M.; Kashaf, S.S.; Sharifi, F.; Jalilian, E.; Nuutila, K.; Giatsidis, G.; Mostafalu, P.; Derakhshandeh, H.; et al. Drug delivery systems and materials for wound healing applications. Adv. Drug Deliv. Rev. 2018, 127, 138–166. [Google Scholar] [CrossRef]

- Safta, D.A.; Bogdan, C.; Moldovan, M.-L. SLNs and NLCs for Skin Applications: Enhancing the Bioavailability of Natural Bioactives. Pharmaceutics 2024, 16, 1270. [Google Scholar] [CrossRef]

- Colobatiu, L.; Gavan, A.; Potarniche, A.-V.; Rus, V.; Diaconeasa, Z.; Mocan, A.; Tomuta, I.; Mirel, S.; Mihaiu, M. Evaluation of bioactive compounds-loaded chitosan films as a novel and potential diabetic wound dressing material. React. Funct. Polym. 2019, 145, 104369. [Google Scholar] [CrossRef]

- Colobatiu, L.; Gavan, A.; Mocan, A.; Bogdan, C.; Mirel, S.; Tomuta, I. Development of bioactive compounds-loaded chitosan films by using a QbD approach—A novel and potential wound dressing material. React. Funct. Polym. 2019, 138, 46–54. [Google Scholar] [CrossRef]

- Jridi, M.; Sellimi, S.; Ben Lassoued, K.; Beltaief, S.; Souissi, N.; Mora, L.; Toldra, F.; Elfeki, A.; Nasri, M.; Nasri, R. Wound healing activity of cuttlefish gelatin gels and films enriched by henna (Lawsonia inermis) extract. Colloids Surf. A Physicochem. Eng. Asp. 2017, 512, 71–79. [Google Scholar] [CrossRef]

- Chin, C.-Y.; Jalil, J.; Ng, P.Y.; Ng, S.-F. Development and formulation of Moringa oleifera standardised leaf extract film dressing for wound healing application. J. Ethnopharmacol. 2018, 212, 188–199. [Google Scholar] [CrossRef]

- Luo, A.; Chen, J.; Hu, B. Preparation, Characterization, and Release Kinetics of Zanthoxylum bungeanum Leaf Polyphenol–Chitosan Films. Coatings 2023, 13, 1138. [Google Scholar] [CrossRef]

- Silva, G.C.; Rodrigues, R.A.F.; Bottoli, C.B.G. In vitro diffusion of plant phenolics through the skin: A review update. Int. J. Cosmet. Sci. 2023, 46, 239–261. [Google Scholar] [CrossRef]

- Carrasco-Sandoval, J.; Aranda-Bustos, M.; Henríquez-Aedo, K.; López-Rubio, A.; Fabra, M.J. Bioaccessibility of different types of phenolic compounds co-encapsulated in alginate/chitosan-coated zein nanoparticles. LWT 2021, 149, 112024. [Google Scholar] [CrossRef]

- Safta, D.A.; Vlase, A.M.; Pop, A.; Cherfan, J.; Carpa, R.; Iurian, S.; Bogdan, C.; Vlase, L.; Moldovan, M.L. Optimized Sambucus nigra, Epilobium hirsutum, and Lythrum salicaria Extracts: Biological Effects Supporting Their Potential in Wound Care (accepted). Antioxidants 2025, 14. in press. [Google Scholar]

- ICH Q8 (R2) Pharmaceutical Development—Scientific Guideline|European Medicines Agency (EMA). Available online: https://www.ema.europa.eu/en/ich-q8-r2-pharmaceutical-development-scientific-guideline (accessed on 27 January 2025).

- Quality by Design|European Medicines Agency (EMA). Available online: https://www.ema.europa.eu/en/human-regulatory-overview/research-development/quality-design (accessed on 27 January 2025).

- Mykhailenko, O.; Ivanauskas, L.; Bezruk, I.; Petrikaitė, V.; Georgiyants, V. Application of Quality by Design Approach to the Pharmaceutical Development of Anticancer Crude Extracts of Crocus sativus Perianth. Sci. Pharm. 2022, 90, 19. [Google Scholar] [CrossRef]

- Savencu, I.; Iurian, S.; Bogdan, C.; Spînu, N.; Suciu, M.; Pop, A.; Țoc, A.; Tomuță, I. Design, optimization and pharmaceutical characterization of wound healing film dressings with chloramphenicol and ibuprofen. Drug Dev. Ind. Pharm. 2024, 50, 446–459. [Google Scholar] [CrossRef]

- Bogdan, C.; Safta, D.A.; Iurian, S.; Petrușcă, D.R.; Moldovan, M.-L. QbD Approach in Cosmetic Cleansers Research: The Development of a Moisturizing Cleansing Foam Focusing on Thickener, Surfactants, and Polyols Content. Gels 2024, 10, 484. [Google Scholar] [CrossRef] [PubMed]

- Safta, D.A.; Ielciu, I.; Șuștic, R.; Hanganu, D.; Niculae, M.; Cenariu, M.; Pall, E.; Moldovan, M.L.; Achim, M.; Bogdan, C.; et al. Chemical Profile and Biological Effects of an Herbal Mixture for the Development of an Oil-in-Water Cream. Plants 2023, 12, 248. [Google Scholar] [CrossRef] [PubMed]

- Taheri, P.; Jahanmardi, R.; Koosha, M.; Abdi, S. Physical, mechanical and wound healing properties of chitosan/gelatin blend films containing tannic acid and/or bacterial nanocellulose. Int. J. Biol. Macromol. 2020, 154, 421–432. [Google Scholar] [CrossRef] [PubMed]

- Cesar, P.H.S.; Natarelli, C.V.L.; de Oliveira, J.E.; Andrade, P.A.; dos Santos, T.L.; Marcussi, S. Development and characterization of a poly (vinyl alcohol) and sodium alginate blend foam for wound dressing loaded with propolis and all-trans retinoic acid. J. Appl. Polym. Sci. 2021, 138, 50480. [Google Scholar] [CrossRef]

- Ng, S.-F.; Leow, H.-L. Development of biofilm-targeted antimicrobial wound dressing for the treatment of chronic wound infections. Drug Dev. Ind. Pharm. 2015, 41, 1902–1909. [Google Scholar] [CrossRef]

- Naeem, A.; Yu, C.; Wang, X.; Peng, M.; Liu, Y.; Liu, Y. Hydroxyethyl Cellulose-Based Hydrogels as Controlled Release Carriers for Amorphous Solid Dispersion of Bioactive Components of Radix Paeonia Alba. Molecules 2023, 28, 7320. [Google Scholar] [CrossRef]

- Cazón, P.; Vázquez, M.; Velazquez, G. Environmentally Friendly Films Combining Bacterial Cellulose, Chitosan, and Polyvinyl Alcohol: Effect of Water Activity on Barrier, Mechanical, and Optical Properties. Biomacromolecules 2019, 21, 753–760. [Google Scholar] [CrossRef]

- Jantrawut, P.; Bunrueangtha, J.; Suerthong, J.; Kantrong, N. Fabrication and Characterization of Low Methoxyl Pectin/Gelatin/Carboxymethyl Cellulose Absorbent Hydrogel Film for Wound Dressing Applications. Materials 2019, 12, 1628. [Google Scholar] [CrossRef]

- Singh, B.; Sharma, S.; Dhiman, A. Acacia gum polysaccharide based hydrogel wound dressings: Synthesis, characterization, drug delivery and biomedical properties. Carbohydr. Polym. 2017, 165, 294–303. [Google Scholar] [CrossRef]

- European Pharmacopeia (Ed.) 11.5. 2024. Available online: https://pheur.edqm.eu/home (accessed on 27 January 2025).

- Hoffmann, E.M.; Breitenbach, A.; Breitkreutz, J. Advances in orodispersible films for drug delivery. Expert Opin. Drug Deliv. 2011, 8, 299–316. [Google Scholar] [CrossRef]

- Savencu, I.; Iurian, S.; Porfire, A.; Bogdan, C.; Tomuță, I. Review of advances in polymeric wound dressing films. React. Funct. Polym. 2021, 168, 105059. [Google Scholar] [CrossRef]

- Proksch, E. pH in nature, humans and skin. J. Dermatol. 2018, 45, 1044–1052. [Google Scholar] [CrossRef] [PubMed]

- Percival, S.L.; McCarty, S.; Hunt, J.A.; Woods, E.J. The effects of pH on wound healing, biofilms, and antimicrobial efficacy. Wound Repair Regen. 2014, 22, 174–186. [Google Scholar] [CrossRef] [PubMed]

- Antonoaea, P.; Todoran, N.; Rédai, E.; Ciurba, A.; Bogdan, C.; Moldovan, M.; Muntean, D.L. Evaluation of Mechanical Properties of Nonsteroidal Anti-Inflammatory Matrix Type Transdermal Therapeutic Systems. Acta Medica Marisiensis 2017, 63, 56–61. [Google Scholar] [CrossRef]

- Iurian, S.M.; Adespei, D.-R.; Pop, A.; Fizeșan, I.; Carpa, R.; Moldovan, M.L.; Loghin, F.; Achim, M.; Bogdan, C. Development of a Mouthwash Using Freeze-Drying Technique: An Optimization Study. Appl. Sci. 2021, 11, 9609. [Google Scholar] [CrossRef]

- Farshi, P.; Salarian, R.; Rabiee, M.; Alizadeh, S.; Gholipourmalekabadi, M.; Ahmadi, S.; Rabiee, N. Design, preparation, and characterization of silk fibroin/carboxymethyl cellulose wound dressing for skin tissue regeneration applications. Polym. Eng. Sci. 2022, 62, 2741–2749. [Google Scholar] [CrossRef]

- Annaidh, A.N.; Bruyère-Garnier, K.; Destrade, M.; Gilchrist, M.D.; Otténio, M. Characterization of the anisotropic mechanical properties of excised human skin. J. Mech. Behav. Biomed. Mater. 2012, 5, 139–148. [Google Scholar] [CrossRef]

- dos Santos, D.M.; Leite, I.S.; Bukzem, A.d.L.; Santos, R.P.d.O.; Frollini, E.; Inada, N.M.; Campana-Filho, S.P. Nanostructured electrospun nonwovens of poly(ε-caprolactone)/quaternized chitosan for potential biomedical applications. Carbohydr. Polym. 2018, 186, 110–121. [Google Scholar] [CrossRef]

- Panova, T.V.; Efimova, A.A.; Berkovich, A.K.; Efimov, A.V. Plasticity control of poly(vinyl alcohol)–graphene oxide nanocomposites. RSC Adv. 2020, 10, 24027–24036. [Google Scholar] [CrossRef]

- Singh, S.; Nwabor, O.F.; Sukri, D.M.; Wunnoo, S.; Dumjun, K.; Lethongkam, S.; Kusolphat, P.; Hemtanon, N.; Klinprathum, K.; Sunghan, J.; et al. Poly (vinyl alcohol) copolymerized with xanthan gum/hypromellose/sodium carboxymethyl cellulose dermal dressings functionalized with biogenic nanostructured materials for antibacterial and wound healing application. Int. J. Biol. Macromol. 2022, 216, 235–250. [Google Scholar] [CrossRef]

- Couți, N.; Porfire, A.; Iovanov, R.; Crișan, A.G.; Iurian, S.; Casian, T.; Tomuță, I. Polyvinyl Alcohol, a Versatile Excipient for Pharmaceutical 3D Printing. Polymers 2024, 16, 517. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Taguchi, T. Enhanced Skin Adhesive Property of Hydrophobically Modified Poly(vinyl alcohol) Films. ACS Omega 2020, 5, 1519–1527. [Google Scholar] [CrossRef]

- Amalraj, A.; Haponiuk, J.T.; Thomas, S.; Gopi, S. Preparation, characterization and antimicrobial activity of polyvinyl alcohol/gum arabic/chitosan composite films incorporated with black pepper essential oil and ginger essential oil. Int. J. Biol. Macromol. 2020, 151, 366–375. [Google Scholar] [CrossRef] [PubMed]

- Voss, G.T.; Gularte, M.S.; Vogt, A.G.; Giongo, J.L.; Vaucher, R.A.; Echenique, J.V.; Soares, M.P.; Luchese, C.; Wilhelm, E.A.; Fajardo, A.R. Polysaccharide-based film loaded with vitamin C and propolis: A promising device to accelerate diabetic wound healing. Int. J. Pharm. 2018, 552, 340–351. [Google Scholar] [CrossRef] [PubMed]

- Kaczmarek-Szczepańska, B.; Zasada, L.; Wekwejt, M.; Brzezinska, M.S.; Michno, A.; Ronowska, A.; Ciesielska, M.; Kovtun, G.; Cuberes, M.T. PVA-Based Films with Strontium Titanate Nanoparticles Dedicated to Wound Dressing Application. Polymers 2024, 16, 484. [Google Scholar] [CrossRef]

- Hajian, M.; Mahmoodi, M.; Imani, R. In Vitro Assessment of Poly (Vinyl Alcohol) Film Incorporating Aloe Vera for Potential Application as a Wound Dressing. J. Macromol. Sci. Part B 2017, 56, 435–450. [Google Scholar] [CrossRef]

- Kanikireddy, V.; Varaprasad, K.; Jayaramudu, T.; Karthikeyan, C.; Sadiku, R. Carboxymethyl cellulose-based materials for infection control and wound healing: A review. Int. J. Biol. Macromol. 2020, 164, 963–975. [Google Scholar] [CrossRef]

- Wong, T.W.; Ramli, N.A. Carboxymethylcellulose film for bacterial wound infection control and healing. Carbohydr. Polym. 2014, 112, 367–375. [Google Scholar] [CrossRef]

- SUNTOUCH Soluble Hemostatic Gauze. Available online: http://www.sassanico.com/en-US/Product/143 (accessed on 27 January 2025).

- Wang, H.; Liu, Y.; Cai, K.; Zhang, B.; Tang, S.; Zhang, W.; Liu, W. Antibacterial polysaccharide-based hydrogel dressing containing plant essential oil for burn wound healing. Burn. Trauma 2021, 9, tkab041. [Google Scholar] [CrossRef]

- Eghbalifam, N.; Shojaosadati, S.A.; Hashemi-Najafabadi, S.; Khorasani, A.C. Synthesis and characterization of antimicrobial wound dressing material based on silver nanoparticles loaded gum Arabic nanofibers. Int. J. Biol. Macromol. 2020, 155, 119–130. [Google Scholar] [CrossRef]

- Alves, A.; Miguel, S.P.; Araujo, A.R.; de Jesús Valle, M.J.; Sánchez Navarro, A.; Correia, I.J.; Ribeiro, M.P.; Coutinho, P. Xanthan gum-konjac glucomannan blend hy-drogel for wound healing. Polymers 2020, 12, 99. [Google Scholar] [CrossRef] [PubMed]

- Tang, S.; Gong, Z.; Wang, Z.; Gao, X.; Zhang, X. Multifunctional hydrogels for wound dressings using xanthan gum and poly-acrylamide. Int. J. Biol. Macromol. 2022, 217, 944–955. [Google Scholar] [CrossRef] [PubMed]

- Saravanakumar, K.; Sathiyaseelan, A.; Zhang, X.; Choi, M.; Wang, M.-H. Bimetallic (Ag and MgO) nanoparticles, Aloe vera extracts loaded xanthan gum nanocomposite for enhanced antibacterial and in-vitro wound healing activity. Int. J. Biol. Macromol. 2023, 242, 124813. [Google Scholar] [CrossRef] [PubMed]

- Song, Z.; Zhang, Y.; Shao, H.; Ying, Y.; Chen, X.; Mei, L.; Ma, X.; Chen, L.; Ling, P.; Liu, F. Effect of xanthan gum on the prevention of intra-abdominal adhesion in rats. Int. J. Biol. Macromol. 2019, 126, 531–538. [Google Scholar] [CrossRef]

- Farooq, M.; Sagbas, S.; Sahiner, M.; Siddiq, M.; Turk, M.; Aktas, N.; Sahiner, N. Synthesis, characterization and modification of Gum Arabic microgels for hemocompatibility and antimicrobial studies. Carbohydr. Polym. 2017, 156, 380–389. [Google Scholar] [CrossRef]

- Manuja, A.; Raguvaran, R.; Kumar, B.; Kalia, A.; Tripathi, B. Accelerated healing of full thickness excised skin wound in rabbits using single application of alginate/acacia based nanocomposites of ZnO nanoparticles. Int. J. Biol. Macromol. 2020, 155, 823–833. [Google Scholar] [CrossRef]

- Zhang, X.; Kang, X.; Jin, L.; Bai, J.; Liu, W.; Wang, Z. Stimulation of wound healing using bioinspired hydrogels with basic fibroblast growth factor (bFGF). Int. J. Nanomed. 2018, 13, 3897–3906. [Google Scholar] [CrossRef]

- Acacia Gum Uses, Benefits & Dosage—Drugs.com Herbal Database. Available online: https://www.drugs.com/npp/acacia-gum.html (accessed on 27 January 2025).

- Ngece, K.; Aderibigbe, B.; Ndinteh, D.; Fonkui, Y.; Kumar, P. Alginate-gum acacia based sponges as potential wound dressings for exuding and bleeding wounds. Int. J. Biol. Macromol. 2021, 172, 350–359. [Google Scholar] [CrossRef]

- Bilck, A.P.; Müller, C.M.O.; Olivato, J.B.; Mali, S.; Grossmann, M.V.E.; Yamashita, F. Using glycerol produced from biodiesel as a plasticiser in extruded biodegradable films. Polim. E Tecnol. 2015, 25, 331–335. [Google Scholar] [CrossRef]

- Eslami, Z.; Elkoun, S.; Robert, M.; Adjallé, K. A Review of the Effect of Plasticizers on the Physical and Mechanical Properties of Alginate-Based Films. Molecules 2023, 28, 6637. [Google Scholar] [CrossRef]

- Jouki, M.; Khazaei, N.; Ghasemlou, M.; HadiNezhad, M. Effect of glycerol concentration on edible film production from cress seed carbohydrate gum. Carbohydr. Polym. 2013, 96, 39–46. [Google Scholar] [CrossRef] [PubMed]

- Xie, M. Phospholipids. In Encyclopedia of Food Chemistry; Varelis, P., Melton, L., Shahidi, F., Eds.; Academic Press: Oxford, UK, 2019; pp. 214–217. [Google Scholar]

- Lyons, A.; Herrmann, J.; Moy, R. Topical glycerol improved psoriasiform lesions and inhibited epidermal hyperplasia in an in vivo mouse model of psoriasis. J. Am. Acad. Dermatol. 2018, 79, AB298. [Google Scholar] [CrossRef]

- Stout, E.I.; McKessor, A. Glycerin-Based Hydrogel for Infection Control. Adv. Wound Care 2012, 1, 48–51. [Google Scholar] [CrossRef]

- Alee, M.; Fu, J.; Duan, Q.; Yang, M.; Liu, H.; Zhu, J.; Xianyang, B.; Chen, L.; Yu, L. Plasticizing Effectiveness and Characteristics of Different Mono-Alcohols, Di-Alcohols, and Polyols for Starch-Based Materials. Starch 2023, 75, 2300059. [Google Scholar] [CrossRef]

- Kim, D.W.; Kim, K.S.; Seo, Y.G.; Lee, B.-J.; Park, Y.J.; Youn, Y.S.; Kim, J.O.; Yong, C.S.; Jin, S.G.; Choi, H.-G. Novel sodium fusidate-loaded film-forming hydrogel with easy application and excellent wound healing. Int. J. Pharm. 2015, 495, 67–74. [Google Scholar] [CrossRef]

- Pemberton, M.A.; Kimber, I. Propylene glycol, skin sensitisation and allergic contact dermatitis: A scientific and regulatory co-nundrum. Regul. Toxicol. Pharmacol. 2023, 138, 105341. [Google Scholar] [CrossRef]

- Meza-Valle, K.Z.; Saucedo-Acuña, R.A.; Tovar-Carrillo, K.L.; Cuevas-González, J.C.; Zaragoza-Contreras, E.A.; Melgoza-Lozano, J. Characterization and Topical Study of Aloe Vera Hydrogel on Wound-Healing Process. Polymers 2021, 13, 3958. [Google Scholar] [CrossRef]

- Meng, Y.; Cao, Y.; Ji, H.; Chen, J.; He, Z.; Long, Z.; Dong, C. Fabrication of environmental humidity-responsive iridescent films with cel-lulose nanocrystal/polyols. Carbohydr. Polym. 2020, 240, 116281. [Google Scholar] [CrossRef]

- Yun, Y.-H.; Lee, C.-M.; Kim, Y.-S.; Yoon, S.-D. Preparation of chitosan/polyvinyl alcohol blended films containing sulfosuccinic acid as the crosslinking agent using UV curing process. Food Res. Int. 2017, 100, 377–386. [Google Scholar] [CrossRef]

- Faust, S.; Foerster, J.; Lindner, M.; Schmid, M. Effect of glycerol and sorbitol on the mechanical and barrier properties of films based on pea protein isolate produced by high-moisture extrusion processing. Polym. Eng. Sci. 2021, 62, 95–102. [Google Scholar] [CrossRef]

- Pagano, C.; Puglia, D.; Luzi, F.; Di Michele, A.; Scuota, S.; Primavilla, S.; Ceccarini, M.R.; Beccari, T.; Iborra, C.A.V.; Ramella, D.; et al. Development and Characterization of Xanthan Gum and Alginate Based Bioadhesive Film for Pycnogenol Topical Use in Wound Treatment. Pharmaceutics 2021, 13, 324. [Google Scholar] [CrossRef] [PubMed]

- Helmiyati, H.; Hidayat, Z.S.Z.; Sitanggang, I.F.R.; Liftyawati, D. Antimicrobial packaging of ZnO–Nps infused into CMC–PVA nanocomposite films effectively enhances the physicochemical properties. Polym. Test. 2021, 104, 107412. [Google Scholar] [CrossRef]

- Chang, G.; Dang, Q.; Liu, C.; Wang, X.; Song, H.; Gao, H.; Sun, H.; Zhang, B.; Cha, D. Carboxymethyl chitosan and carboxymethyl cellulose based self-healing hydrogel for accelerating diabetic wound healing. Carbohydr. Polym. 2022, 292, 119687. [Google Scholar] [CrossRef]

- Soliman, T.S. Effects of SiO2 Nanoparticles on Polyvinyl Alcohol/Carboxymethyl Cellulose Polymer Blend Films’ Structural, Wettability, Surface Roughness, and Optical Characteristics. Adv. Polym. Technol. 2024, 2024, 3623198. [Google Scholar] [CrossRef]

- Isotton, F.; Bernardo, G.; Baldasso, C.; Rosa, L.; Zeni, M. The plasticizer effect on preparation and properties of etherified corn starchs films. Ind. Crop. Prod. 2015, 76, 717–724. [Google Scholar] [CrossRef]

- Heikkinen, S.; Mikkonen, K.; Koivisto, P.; Heikkilä, M.; Pirkkalainen, K.; Liljeström, V.; Serimaa, R.; Tenkanen, M. Long-term physical stability of plas-ticized hemicellulose films. Bioresources 2014, 9, 906–921. [Google Scholar]

- Kraskouski, A.; Hileuskaya, K.; Kulikouskaya, V.; Kabanava, V.; Agabekov, V.; Pinchuk, S.; Vasilevich, I.; Volotovski, I.; Kuznetsova, T.; Lapitskaya, V. Polyvinyl alcohol and pectin blended films: Preparation, characterization, and mesenchymal stem cells attachment. J. Biomed. Mater. Res. Part A 2020, 109, 1379–1392. [Google Scholar] [CrossRef]

- Li, C.; Wang, Z.Y.; He, Z.J.; Li, Y.J.; Mao, J.; Dai, K.H.; Yan, C.; Zheng, J.C. An advance review of solid-state battery: Challenges, progress and prospects. Sustain. Mater. Technol. 2021, 29, e00297. [Google Scholar] [CrossRef]

- Vivek, N.; Gopalan, N.; Das, S.; Sasikumar, K.; Sindhu, R.; Nampoothiri, K.M.; Pandey, A.; Binod, P. Synthesis and Characterization of Transparent Biodegradable Chitosan: Exopolysaccharide Composite Films Plasticized by Bio-Derived 1,3-Propanediol. Sustain. Chem. 2021, 2, 49–62. [Google Scholar] [CrossRef]

- Mitrea, L.; Călinoiu, L.-F.; Martău, G.-A.; Szabo, K.; Teleky, B.-E.; Mureșan, V.; Rusu, A.-V.; Socol, C.-T.; Vodnar, D.-C. Poly(vinyl alcohol)-Based Biofilms Plasticized with Polyols and Colored with Pigments Extracted from Tomato By-Products. Polymers 2020, 12, 532. [Google Scholar] [CrossRef]

- Masti, S.; Kasai, D. Effect of Gum Acacia (GA) on Tensile Properties of Biodegradable Chitosan (CS)/Poly (vinyl alcohol) (PVA) Polymer Blend Films. Res. J. Mater. Sci. 2016, 4, 5–8. [Google Scholar]

- McKee, C.T.; Last, J.A.; Russell, P.; Murphy, C.J. Indentation Versus Tensile Measurements of Young’s Modulus for Soft Biological Tissues. Tissue Eng. Part B Rev. 2011, 17, 155–164. [Google Scholar] [CrossRef] [PubMed]

- Tijani, A.T.; Ayodele, T.; Liadi, M.; Sarker, N.C.; Hammed, A. Mechanical and Thermal Characteristics of Films from Glycerol Mixed Emulsified Carnauba Wax/Polyvinyl Alcohol. Polymers 2024, 16, 3024. [Google Scholar] [CrossRef] [PubMed]

- Zanela, J.; Olivato, J.B.; Dias, A.P.; Grossmann, M.V.E.; Yamashita, F. Mixture design applied for the development of films based on starch, polyvinyl alcohol, and glycerol. J. Appl. Polym. Sci. 2015, 132, 42697. [Google Scholar] [CrossRef]

- Sato, N.; Murata, A.; Fujie, T.; Takeoka, S. Stretchable, adhesive and ultra-conformable elastomer thin films. Soft Matter 2016, 12, 9202–9209. [Google Scholar] [CrossRef]

- Pelin, I.M.; Silion, M.; Popescu, I.; Rîmbu, C.M.; Fundueanu, G.; Constantin, M. Pullulan/Poly(vinyl alcohol) Hydrogels Loaded with Calendula officinalis Extract: Design and In Vitro Evaluation for Wound Healing Applications. Pharmaceutics 2023, 15, 1674. [Google Scholar] [CrossRef]

- Khan, B.A.; Ullah, S.; Khan, M.K.; Uzair, B.; Menaa, F.; Braga, V.A. Fabrication, Physical Characterizations, and In Vitro, In Vivo Evaluation of Ginger Extract-Loaded Gelatin/Poly(Vinyl Alcohol) Hydrogel Films Against Burn Wound Healing in Animal Model. Aaps Pharmscitech 2020, 21, 323. [Google Scholar] [CrossRef]

- Ahmad, N.; Tayyeb, D.; Ali, I.; KAlruwaili, N.; Ahmad, W.; ur Rehman, A.; Khan, A.H.; Iqbal, M.S. Development and Characterization of Hemicellu-lose-Based Films for Antibacterial Wound-Dressing Application. Polymers 2020, 12, 548. [Google Scholar] [CrossRef]

- Pechová, V.; Gajdziok, J.; Muselík, J.; Vetchý, D. Development of Orodispersible Films Containing Benzydamine Hydrochloride Using a Modified Solvent Casting Method. Aaps Pharmscitech 2018, 19, 2509–2518. [Google Scholar] [CrossRef]

- Garcia-Carrasco, M.; Picos-Corrales, L.A.; Gutiérrez-Grijalva, E.P.; Angulo-Escalante, M.A.; Licea-Claverie, A.; Heredia, J.B. Loading and Release of Phenolic Compounds Present in Mexican Oregano (Lippia graveolens) in Different Chitosan Bio-Polymeric Cationic Matrixes. Polymers 2022, 14, 3609. [Google Scholar] [CrossRef]

- Hosseini, S.F.; Zandi, M.; Rezaei, M.; Farahmandghavi, F. Two-step method for encapsulation of oregano essential oil in chitosan nanoparticles: Preparation, characterization and in vitro release study. Carbohydr. Polym. 2013, 95, 50–56. [Google Scholar] [CrossRef] [PubMed]

- Ijaola, A.O.; Akamo, D.O.; Damiri, F.; Akisin, C.J.; Bamidele, E.A.; Ajiboye, E.G.; Berrada, M.; Onyenokwe, V.O.; Yang, S.Y.; Asmatulu, E. Polymeric biomaterials for wound healing ap-plications: A comprehensive review. J. Biomater. Sci. Polym. Ed. 2022, 33, 1998–2050. [Google Scholar] [CrossRef]

- Gethin, G.; Ivory, J.D.; Sezgin, D.; Muller, H.; O’Connor, G.; Vellinga, A. What is the “normal” wound bed temperature? A scoping review and new hypothesis. Wound Repair Regen. 2021, 29, 843–847. [Google Scholar] [CrossRef]

- Baccarin, T.; Lemos-Senna, E. Potential Application of Nanoemulsions for Skin Delivery of Pomegranate Peel Polyphenols. Aaps Pharmscitech 2017, 18, 3307–3314. [Google Scholar] [CrossRef]

- Gomaa, M.; Hifney, A.F.; Fawzy, M.A.; Abdel-Gawad, K.M. Use of seaweed and filamentous fungus derived polysaccharides in the development of alginate-chitosan edible films containing fucoidan: Study of moisture sorption, polyphenol release and antioxidant properties. Food Hydrocoll. 2018, 82, 239–247. [Google Scholar] [CrossRef]

- Talón, E.; Trifkovic, K.T.; Vargas, M.; Chiralt, A.; González-Martínez, C. Release of polyphenols from starch-chitosan based films containing thyme extract. Carbohydr. Polym. 2017, 175, 122–130. [Google Scholar] [CrossRef]

- Esmaeili, J.; Barati, A.; Salehi, E.; Ai, J. Reliable Kinetics for Drug Delivery with a Microfluidic Device Integrated with the Dialysis Bag. Mol. Pharm. 2023, 20, 1129–1137. [Google Scholar] [CrossRef]

- Ojsteršek, T.; Vrečer, F.; Hudovornik, G. Comparative Fitting of Mathematical Models to Carvedilol Release Profiles Obtained from Hypromellose Matrix Tablets. Pharmaceutics 2024, 16, 498. [Google Scholar] [CrossRef]

- Siddiqui, M.N.; Garg, G.; Sharma, P.K. A Short Review on “A Novel Approach in Oral Fast Dissolving Drug Delivery System and Their Patents”. Adv. Biol. Res. 2011, 5, 291–303. [Google Scholar]

- ISO 175:2010; Plastics—Methods of Test for the Determination of the Effects of Immersion in Liquid Chemicals. Available online: https://www.iso.org/standard/55483.html (accessed on 27 January 2025).

- Schmid, M.; Pröls, S.; Kainz, D.M.; Hammann, F.; Stäbler, A. Impact of Hydrolyzed Whey Protein on the Molecular Interactions and Cross-Linking Density in Whey Protein Isolate-Based Films. Int. J. Polym. Sci. 2016, 2016, 3723758. [Google Scholar] [CrossRef]

- Koga, A.Y.; Felix, J.C.; Silvestre, R.G.M.; Lipinski, L.C.; Carletto, B.; Kawahara, F.A.; Pereira, A.V. Evaluation of wound healing effect of alginate film containing Aloe vera gel and cross-linked with zinc chloride. Acta Cir. Bras. 2020, 35, e202000507. [Google Scholar] [CrossRef] [PubMed]

- Brookfield Ametek I and SCD. CT3 Texture Analyzer Operating Instructions Manual. pp. 1–64. Available online: https://www.brookfieldengineering.com/-/media/ametekbrookfield/manuals/texture/ct3%20manual%20m08-372-f1116.pdf (accessed on 27 January 2025).

- Baranauskaite, J.; Ockun, M.A.; Uner, B.; Gungor, B.; Duman, G.; Tas, C.; Yesilada, E. Development and In vitro characterization of pullulan fast dissolving films loaded with Panax ginseng extract, antioxidant properties and cytotoxic efficiency on lung and breast cancer cell lines. J. Drug Deliv. Sci. Technol. 2022, 76, 103701. [Google Scholar] [CrossRef]

- Momoh, F.U.; Boateng, J.S.; Richardson, S.C.; Chowdhry, B.Z.; Mitchell, J.C. Development and functional characterization of alginate dressing as potential protein delivery system for wound healing. Int. J. Biol. Macromol. 2015, 81, 137–150. [Google Scholar] [CrossRef] [PubMed]

- Vlase, A.-M.; Toiu, A.; Tomuță, I.; Vlase, L.; Muntean, D.; Casian, T.; Fizeșan, I.; Nadăș, G.C.; Novac, C.Ș.; Tămaș, M.; et al. Epilobium Species: From Optimization of the Extraction Process to Evaluation of Biological Properties. Antioxidants 2022, 12, 91. [Google Scholar] [CrossRef]

- Paşcalău, V.; Bogdan, C.; Pall, E.; Matroş, L.; Pandrea, S.-L.; Suciu, M.; Borodi, G.; Iuga, C.A.; Ştiufiuc, R.; Topală, T.; et al. Development of BSA gel/Pectin/Chitosan polyelectrolyte complex microcapsules for Berberine delivery and evaluation of their inhibitory effect on Cutibacterium acnes. React. Funct. Polym. 2019, 147, 104457. [Google Scholar] [CrossRef]

| Response | R2 | Q2 | p-Value | Lack of Fit | Model Validity | Reproducibility |

|---|---|---|---|---|---|---|

| Y1 | 0.778 | 0.732 | 0.000 | 0.107 | 0.440 | 0.964 |

| Y2 | 0.710 | 0.531 | 0.006 | 0.067 | 0.322 | 0.966 |

| Y3 | 0.549 | 0.397 | 0.003 | 0.070 | 0.336 | 0.957 |

| Y4 | 0.712 | 0.482 | 0.002 | 0.323 | 0.717 | 0.832 |

| Y5 | 0.579 | 0.313 | 0.017 | 0.427 | 0.787 | 0.655 |

| Y6 | 0.703 | 0.419 | 0.006 | 0.028 | 0.109 | 0.985 |

| Y7 | 0.781 | 0.661 | 0.004 | 0.440 | 0.794 | 0.775 |

| Y8 | 0.885 | 0.697 | 0.000 | 0.086 | 0.385 | 0.980 |

| Y9 | 0.525 | 0.327 | 0.013 | 0.248 | 0.651 | 0.812 |

| Y10 | 0.785 | 0.753 | 0.000 | 0.194 | 0.589 | 0.940 |

| Exp. | Average Mass (g) | Exp. | Average Mass (g) |

|---|---|---|---|

| N1 | 0.0540 ± 0.0070 | N10 | 0.0746 ± 0.0191 |

| N2 | 0.1456 ± 0.0327 | N11 | 0.0693 ± 0.0155 |

| N3 | 0.0720 ± 0.0173 | N12 | 0.0543 ± 0.0095 |

| N4 | 0.1183 ± 0.0143 | N13 | 0.9039 ± 0.0097 |

| N5 | 0.1286 ± 0.0372 | N14 | 0.0423 ± 0.0025 |

| N6 | 0.0770 ± 0.0108 | N15 | 0.1263 ± 0.0120 |

| N7 | 0.0646 ± 0.0108 | N16 | 0.1120 ± 0.0401 |

| N8 | 0.0906 ± 0.0253 | N17 | 0.1193 ± 0.0217 |

| N9 | 0.0792 ± 0.0233 | N18 | 0.0983 ± 0.0140 |

| Exp. | X1 | X2 | X3 | X4 | Y1 (mm) | Y2 (%) | Y3 (g) | Y4 (mJ) | Y5 (g) | Y6 (g) | Y7 (mm) | Y8 (MPa) | Y9 (%) | Y10 (MPa) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| N1 | AG | G | −1 | −1 | 0.13 ± 0.01 | 907.86 ± 66.60 | 62.20 ± 5.00 | 0.27 ± 0.03 | 4219.00 ± 315.00 | 1111.00 ± 278.00 | 30.49 ± 9.25 | 8.24 ± 2.26 | 70.44 ± 11.01 | 76.20 ± 31.84 |

| N2 | AG | G | 1 | 1 | 0.20 ± 0.03 | 446.61 ± 17.68 | 36.00 ± 1.70 | 0.18 ± 0.01 | 2485.00 ± 115.00 | 669.00 ± 97.00 | 29.89 ± 3.38 | 4.58 ± 0.33 | 115.12 ± 36.39 | 13.11 ± 4.01 |

| N3 | XG | G | 1 | −1 | 0.19 ± 0.05 | 2932.04 ± 1444.75 | 62.50 ± 22.40 | 0.30 ± 0.05 | 6946.00 ± 872.00 | 1823.00 ± 471.00 | 19.19 ± 4.66 | 13.84 ± 2.46 | 93.30 ± 25.62 | 35.59 ± 10.46 |

| N4 | XG | G | −1 | 1 | 0.17 ± 0.04 | 555.26 ± 41.74 | 40.70 ± 7.80 | 0.25 ± 0.03 | 4273.00 ± 613.00 | 788.00 ± 116.00 | 36.70 ± 6.18 | 9.41 ± 1.08 | 176.56 ± 20.32 | 24.22 ± 4.50 |

| N5 | CMC-Na | G | −1 | 1 | 0.20 ± 0.07 | 1126.05 ± 81.61 | 84.80 ± 3.70 | 0.25 ± 0.04 | 3523.00 ± 291.00 | 697.00 ± 60.00 | 35.99 ± 7.19 | 6.88 ± 0.66 | 169.92 ± 20.62 | 16.09 ± 5.40 |

| N6 | CMC-Na | G | 1 | −1 | 0.12 ± 0.04 | 1653.08 ± 82.24 | 52.10 ± 22.30 | 0.32 ± 0.11 | 8019.00 ± 1533.00 | 2890.00 ± 819.00 | 11.21 ± 2.52 | 22.71 ± 1.83 | 11.26 ± 3.45 | 196.19 ± 93.21 |

| N7 | AG | X | −1 | −1 | 0.10 ± 0.04 | 970.69 ± 74.64 | 13.00 ± 2.60 | 0.15 ± 0.02 | 3948.00 ± 257.00 | 1882.00 ± 496.00 | 13.66 ± 2.33 | 23.75 ± 1.56 | 66.77 ± 17.57 | 361.14 ± 73.84 |

| N8 | AG | X | 1 | 1 | 0.11 ± 0.05 | 889.29 ± 35.17 | 25.30 ± 6.70 | 0.20 ± 0.06 | 5621.00 ± 1892.00 | 2750.00 ± 574.00 | 12.53 ± 2.98 | 16.25 ± 2.85 | 23.27 ± 18.95 | 352.76 ± 25.54 |

| N9 | XG | X | 1 | −1 | 0.12 ± 0.02 | 3560.62 ± 1095.17 | 69.00 ± 8.50 | 0.32 ± 0.01 | 6771.00 ± 964.00 | 3203.00 ± 450.00 | 9.87 ± 0.46 | 36.30 ± 11.43 | 4.73 ± 4.62 | 796.25 ± 260.43 |

| N10 | XG | X | −1 | 1 | 0.13 ± 0.05 | 2398.01 ± 498.766 | 37.80 ± 7.70 | 0.18 ± 0.10 | 6650.00 ± 926.00 | 5051.00 ± 374.00 | 7.80 ± 1.77 | 33.54 ± 4.93 | 2.45 ± 1.26 | 704.89 ± 36.74 |

| N11 | CMC-Na | X | −1 | −1 | 0.12 ± 0.03 | 1721.66 ± 232.28 | 52.20 ± 13.70 | 0.34 ± 0.07 | 8543.00 ± 1476.00 | 3096.00 ± 494.00 | 12.01 ± 1.78 | 34.18 ± 6.81 | 48.99 ± 7.58 | 412.93 ± 135.39 |

| N12 | AG | P | 1 | −1 | 0.10 ± 0.04 | 951.20 ± 126.18 | 22.80 ± 3.80 | 0.16 ± 0.02 | 3985.00 ± 376.00 | 1926.00 ± 293.00 | 12.93 ± 1.35 | 24.72 ± 1.78 | 89.36 ± 24.57 | 183.27 ± 21.400 |

| N13 | AG | P | −1 | 1 | 0.15 ± 0.03 | 897.19 ± 111.37 | 31.50 ± 11.00 | 0.18 ± 0.04 | 5856.00 ± 1267.00 | 1456.00 ± 208.00 | 23.00 ± 6.26 | 31.49 ± 14.66 | 143.90 ± 60.70 | 246.19 ± 35.27 |

| N14 | XG | P | −1 | −1 | 0.10 ± 0.03 | 1907.52 ± 318.88 | 53.80 ± 16.30 | 0.25 ± 0.07 | 7166.00 ± 1054.00 | 1710.00 ± 334.00 | 22.32 ± 3.79 | 34.4 ± 7.24 | 130.85 ± 64.30 | 108.63 ± 8.91 |

| N15 | CMC-Na | P | 0 | 1 | 0.11 ± 0.05 | 1928.64 ± 65.72 | 72.80 ± 13.80 | 0.29 ± 0.06 | 8556.00 ± 984.00 | 2456.00 ± 201.00 | 16.11 ± 1.83 | 29.71 ± 3.91 | 51.86 ± 17.95 | 213.88 ± 37.67 |

| N16 | CMC-Na | G | 0 | 0 | 0.19 ± 0.04 | 1532.19 ± 37.66 | 64.70 ± 17.20 | 0.31 ± 0.01 | 4547.00 ± 1687.00 | 896.00 ± 459.00 | 23.21 ± 7.15 | 13.11 ± 0.88 | 142.36 ± 25.24 | 33.41 ± 1.05 |

| N17 | CMC-Na | G | 0 | 0 | 0.18 ± 0.05 | 1608.00 ± 114.15 | 60.20 ± 10.80 | 0.30 ± 0.02 | 6658.00 ± 618.00 | 1027.00 ± 296.00 | 31.93 ± 5.69 | 10.76 ± 3.97 | 98.03 ± 38.41 | 22.81 ± 11.28 |

| N18 | CMC-Na | G | 0 | 0 | 0.19 ± 0.03 | 1327.00 ± 93.27 | 56.7 ± 10.30 | 0.26 ± 0.04 | 5609.00 ± 1260.00 | 996.00 ± 107.00 | 26.13 ± 3.36 | 13.58 ± 1.87 | 124.05 ± 26.27 | 43.57 ± 11.5 |

| Composition of Optimized CHE-Loaded Film-Dressing | |

|---|---|

| Ingredient | Concentration (%) |

| Polyvinyl alcohol | 5.00 |

| Xanthan gum | 0.25 |

| Glycerol | 10.00 |

| CHE | 20.00 |

| Distilled water | Qs ad 100 |

| Y1 (mm) | Y2 (%) | Y3 (g) | Y4 (mJ) | Y5 (g) | Y6 (g) | Y7 (%) | Y8 (MPa) | Y9 (%) | Y10 (MPa) | |

|---|---|---|---|---|---|---|---|---|---|---|

| Predicted values | 0.19 | 1223.33 | 52.76 | 0.22 | 5293.70 | 1104.32 | 32.89 | 12.86 | 135.17 | 35.52 |

| Experimental values | 0.19 ±0.04 | 627.28 ±85.23 | 28.00 ±6.00 | 0.20 ±0.00 | 2616.00 ±409.00 | 593.00 ±100.00 | 29.80 ±4.75 | 5.41 ±0.93 | 106.90 ±9.76 | 11.22 ±3.90 |

| Residual | 0 | −596.05 | −24.76 | −0.02 | −2677.7 | −511.32 | −3.09 | −7.45 | −28.27 | −24.3 |

| Independent Variables (Formulation Factors) | Dependent Variables (Responses) | |||||

|---|---|---|---|---|---|---|

| Qualitative Variables | Quantitative Variables | |||||

| X1—Type of co-film-forming agent | XG | X3—Concentration of co-film-forming agent | Variation levels (%) | Y1—Film thickness (mm), Y2—Swelling degree (%), Y3—Adhesive force (g), Y4—Adhesiveness (mJ), Y5—Hardness (g), Y6—Rigidity la 5 mm (g), Y7—Deformation at target (mm), Y8—Tensile strength (MPa), Y9—Elongation at break (%), Y10—Young’s modulus (MPa). | ||

| −1 | 0 | 1 | ||||

| 0.25 | 0.375 | 0.5 | ||||

| AG | 0.5 | 0.75 | 1.5 | |||

| CMC-Na | 1 | 1.5 | 2 | |||

| X2—Type of plasticizer | G | X4—Concentration of plasticizer | 3 | 6.5 | 10 | |

| X | 3 | 4 | 5 | |||

| P | 3 | 4 | 5 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Safta, D.A.; Bogdan, C.; Iurian, S.; Moldovan, M.-L. Optimization of Film-Dressings Containing Herbal Extracts for Wound Care—A Quality by Design Approach. Gels 2025, 11, 322. https://doi.org/10.3390/gels11050322

Safta DA, Bogdan C, Iurian S, Moldovan M-L. Optimization of Film-Dressings Containing Herbal Extracts for Wound Care—A Quality by Design Approach. Gels. 2025; 11(5):322. https://doi.org/10.3390/gels11050322

Chicago/Turabian StyleSafta, Diana Antonia, Cătălina Bogdan, Sonia Iurian, and Mirela-Liliana Moldovan. 2025. "Optimization of Film-Dressings Containing Herbal Extracts for Wound Care—A Quality by Design Approach" Gels 11, no. 5: 322. https://doi.org/10.3390/gels11050322

APA StyleSafta, D. A., Bogdan, C., Iurian, S., & Moldovan, M.-L. (2025). Optimization of Film-Dressings Containing Herbal Extracts for Wound Care—A Quality by Design Approach. Gels, 11(5), 322. https://doi.org/10.3390/gels11050322