Construction of a ‘Simple, Fast and Accurate’ Evaluation Method for Profile Control and Plugging Effect of Gel Plugging Agent Based on Simulations

Abstract

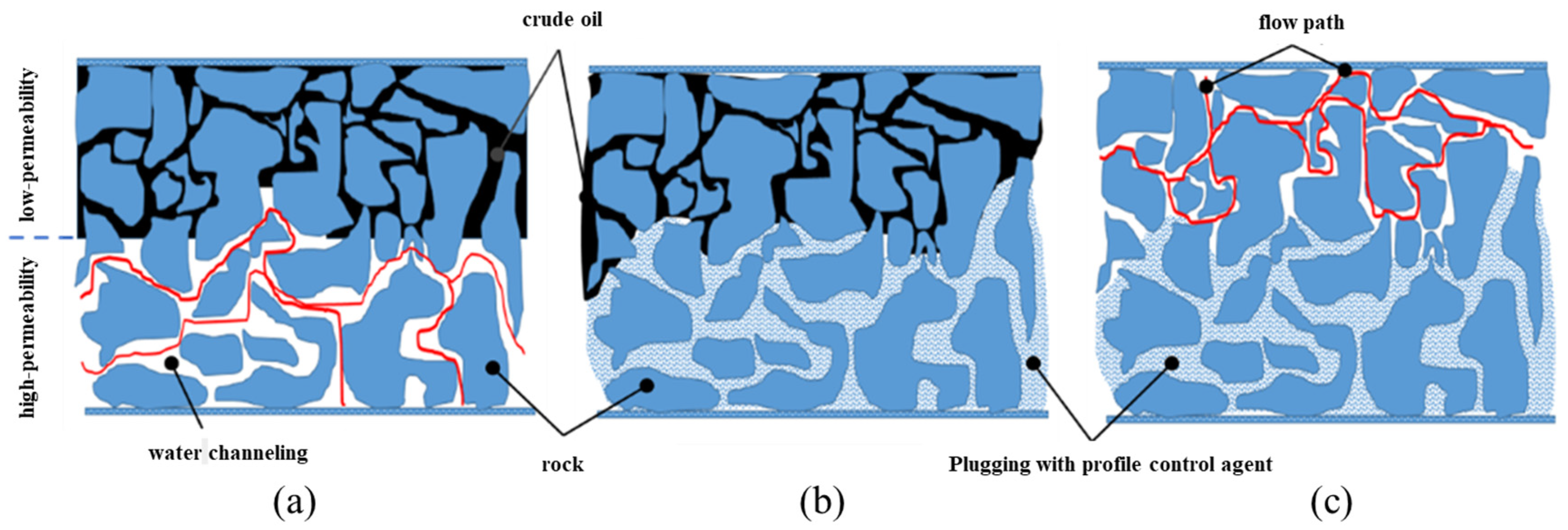

1. Introduction

2. Results and Discussion

2.1. Screening Using Conventional Test Methods

| Gel System | Composition of Gel System | The Gel Strength Level Obtained by Visual Code Method | Breakthrough Vacuum Degree, MPa | Remark |

|---|---|---|---|---|

| Gel system 1 | 3000 mg/L HPAM + 0.3% phenolic resin + 0.3% organic chromium crosslinking agent + 0.15% crosslinking accelerator | H | −0.094 | The system used before the mine |

| Gel system 2 | 3000 mg/L HPAM + 0.3% phenolic resin + 0.15% Resorcinol + 0.3% hexamethylenetetramine + 0.15% crosslinking accelerator | H | −0.066 | The present system of ore field |

| Gel system 3 | 3000 mg/L HPAM + 0.3% amino resin + 0.15% crosslinking accelerator | H * | −0.063 | Comparison system |

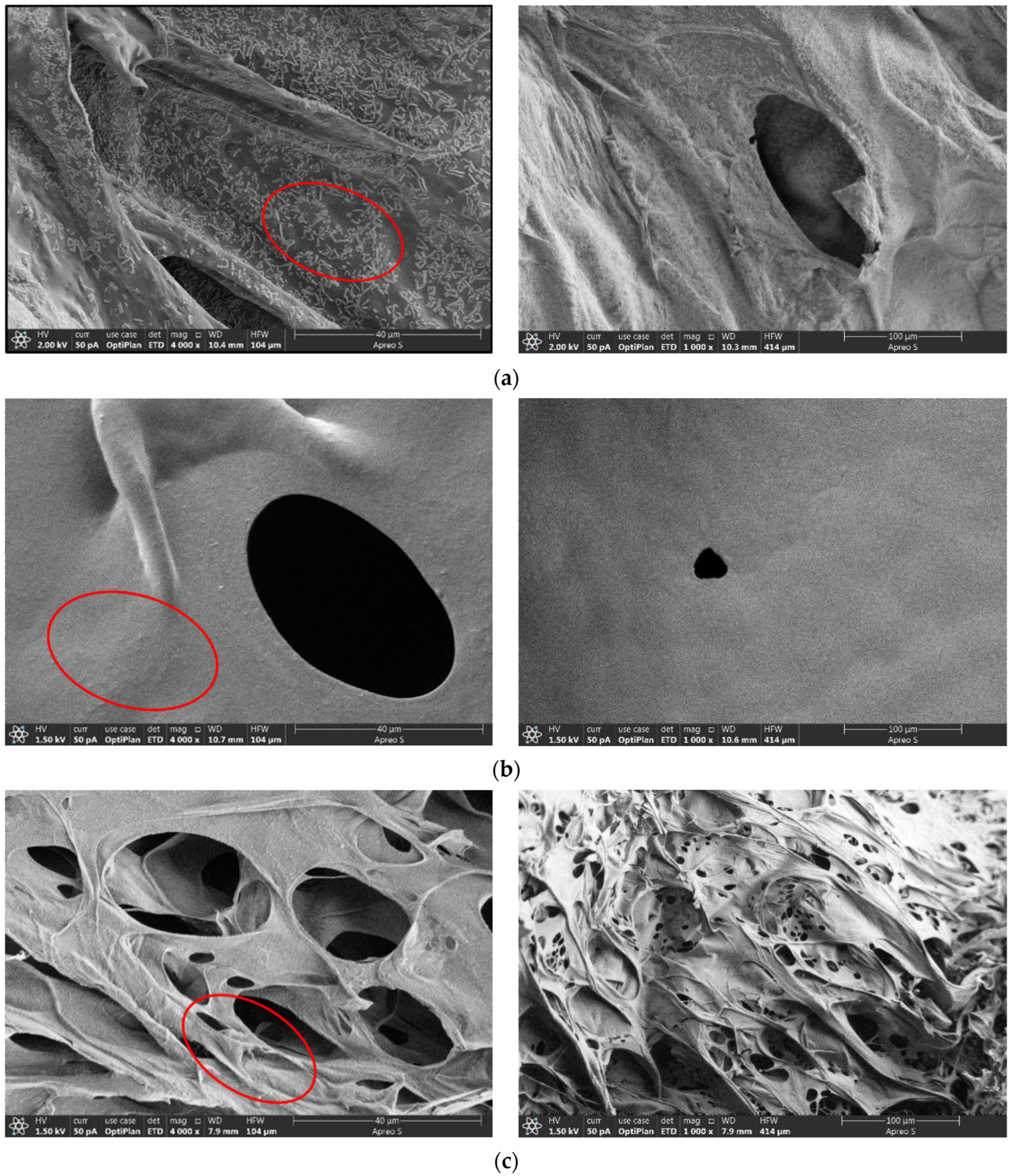

2.2. Comparison of Actual Plugging Capability of Gel System

2.3. Optimization of the Plugging Capacity of Gel Plugging Agent by Evaluation Index Method

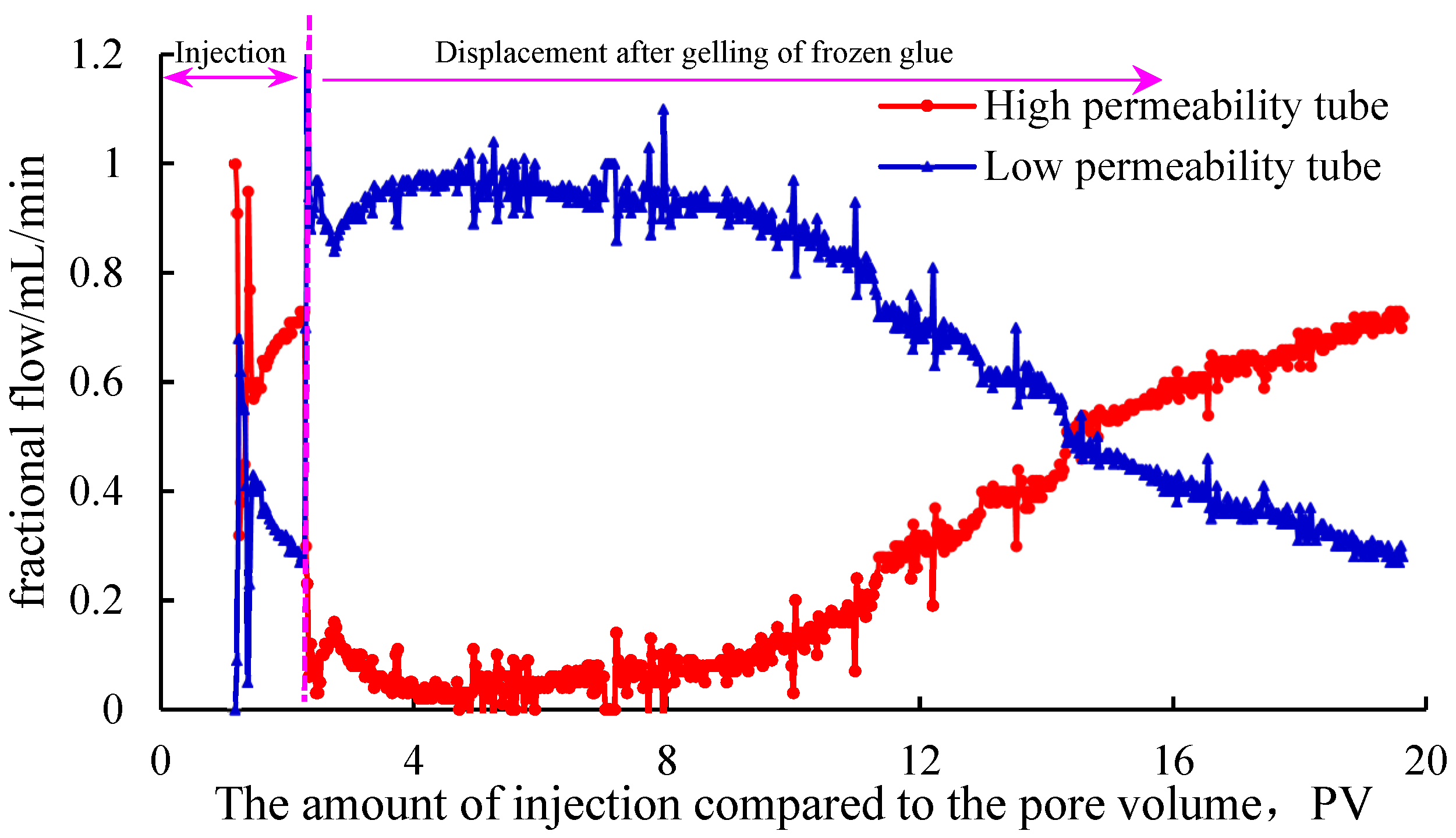

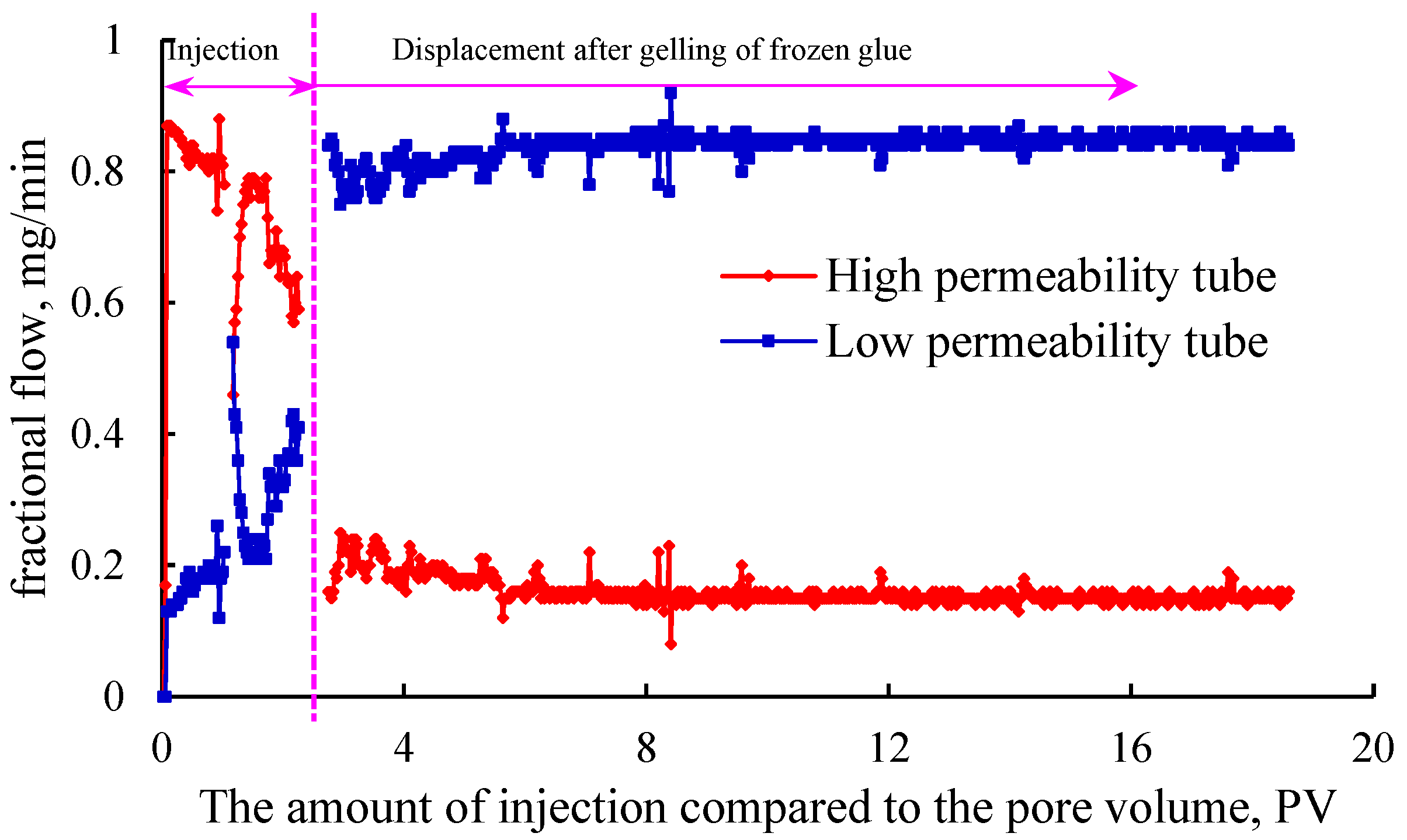

2.4. Comparison of Profile Control Capability of the Gel Plugging Agent

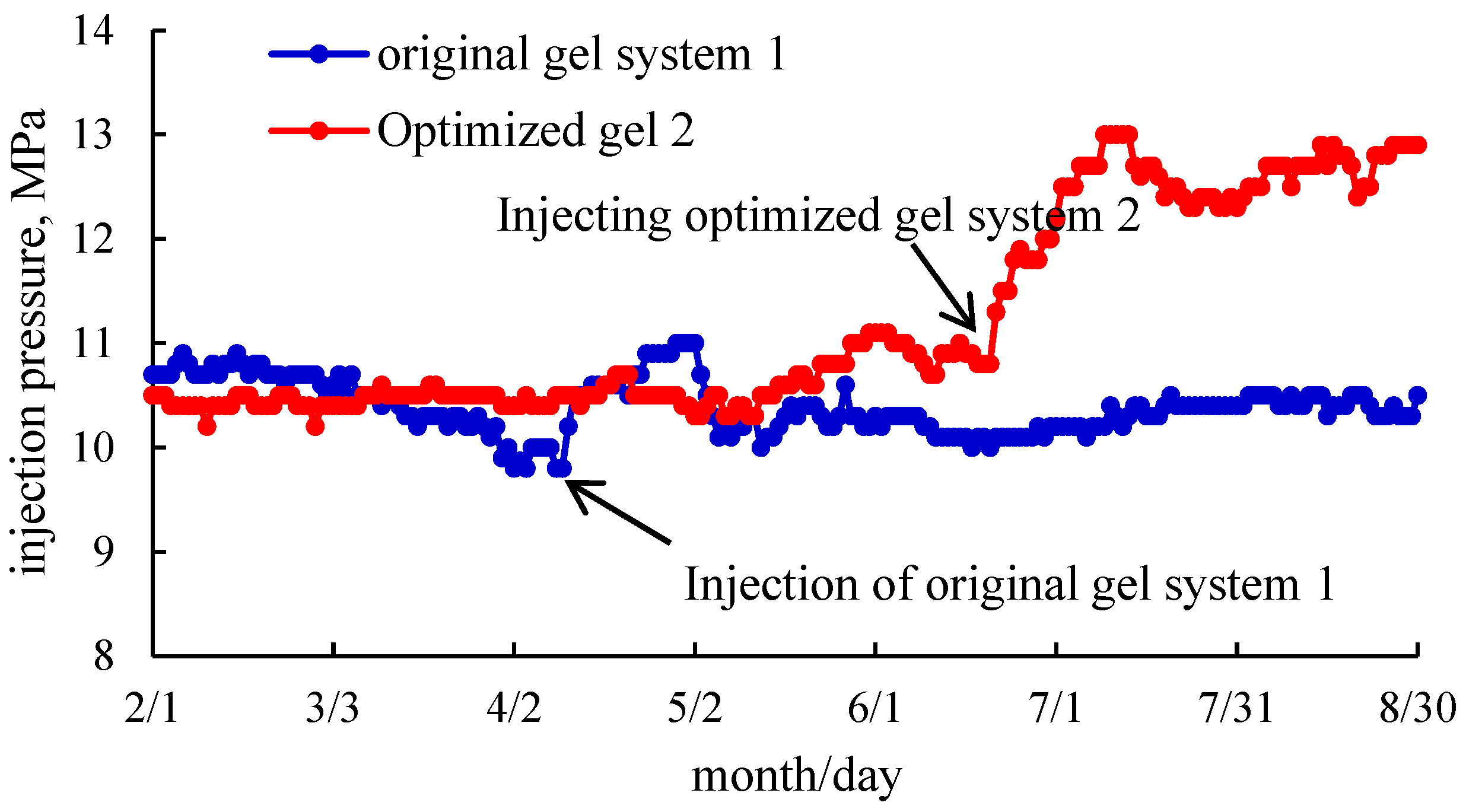

2.5. Field Tests

3. Conclusions

- In the present work, gel system 1 (3000 mg/L HPAM + 0.3% phenolic resin + 0.3% organic chromium crosslinking agent + 0.15% crosslinking accelerator) was screened from three different systems using the conventional breakthrough vacuum method and visual code method. Based on field tests and profile-controlling displacement plugging experiments, the screened gel was easy to separate from the reservoir, resulting in poor plugging capacity. The evaluation effect (strength code: H, degree of breakthrough vacuum: 0.094 MPa, indicating favorable gel performance) was different from the actual plugging capacity (after plugging, the permeability was 2.23 × 103 μm2, and the breakthrough pressure gradient was 14.77 MPa/m, indicating poor gel performance). The results showed that the adhesive capability and erosion resistance of the gel to the reservoir pore throat were neglected in the conventional method, and the evaluation angle was found not to be comprehensive enough. The plugging capacity test of the gel plugging agent is cumbersome and not suitable for on-site rapid detection.

- After analyzing the current laboratory evaluation procedure and summarizing the controlling factors of the plugging capacity of the gel plugging agent, a new evaluation method for the plugging effect of the gel plugging agent was established. Based on this, the gel plugging capability evaluation index method (with the correlation of ) was constructed, which comprehensively considered the gel strength, gel adhesion capability, shear resistance, and long-term anti-dehydration performance. The experimental results showed that the evaluation results of the proposed method were consistent with the experimental results of profile control and displacement plugging.

- A new gel system (3000 mg/L HPAM + 0.3% phenolic resin + 0.15% Resorcinol + 0.3% hexamethylenetetramine + 0.15% crosslinking accelerator) was selected by the newly established method, and its comprehensive evaluation index was found to be 8.97 Pa2. Compared with the old system, the failure of profile control gradually occurred when 8 PV was displaced. The new system could achieve a 1:9 ratio of high and low permeability tubes, and the effective period was more than 20 PV. Moreover, the profile control and the plugging capability were obviously improved.

- A field in the Shengli oilfield was selected for the verification of the experimental results. The gel system optimized by the evaluation method achieved an injection pressure of up to 13 MPa, with a plugging duration exceeding 60 days. The injection pressure of the new system was 2.5 times that before the optimization. The effective plugging period was prolonged to more than two times that of the original system. The field test results were consistent with the plugging capacity evaluation index. To sum up, the newly established method is more scientific and practical, and can provide a reference for screening and evaluating batches of gel plugging agent systems under actual reservoir conditions.

4. Materials and Methods

4.1. Materials

4.2. The Traditional Test Method of Gel Performance

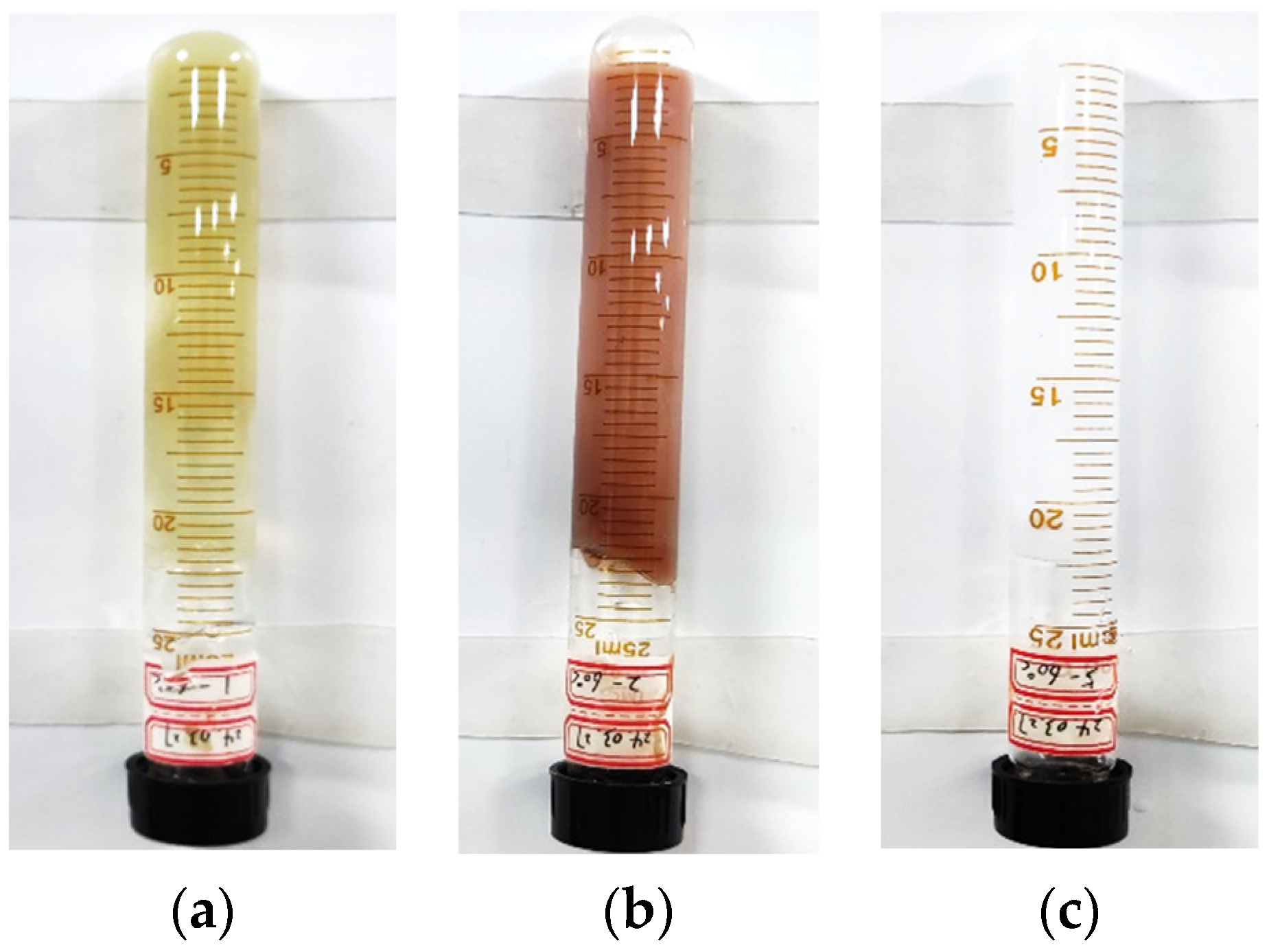

4.2.1. Visual Code Method [33]

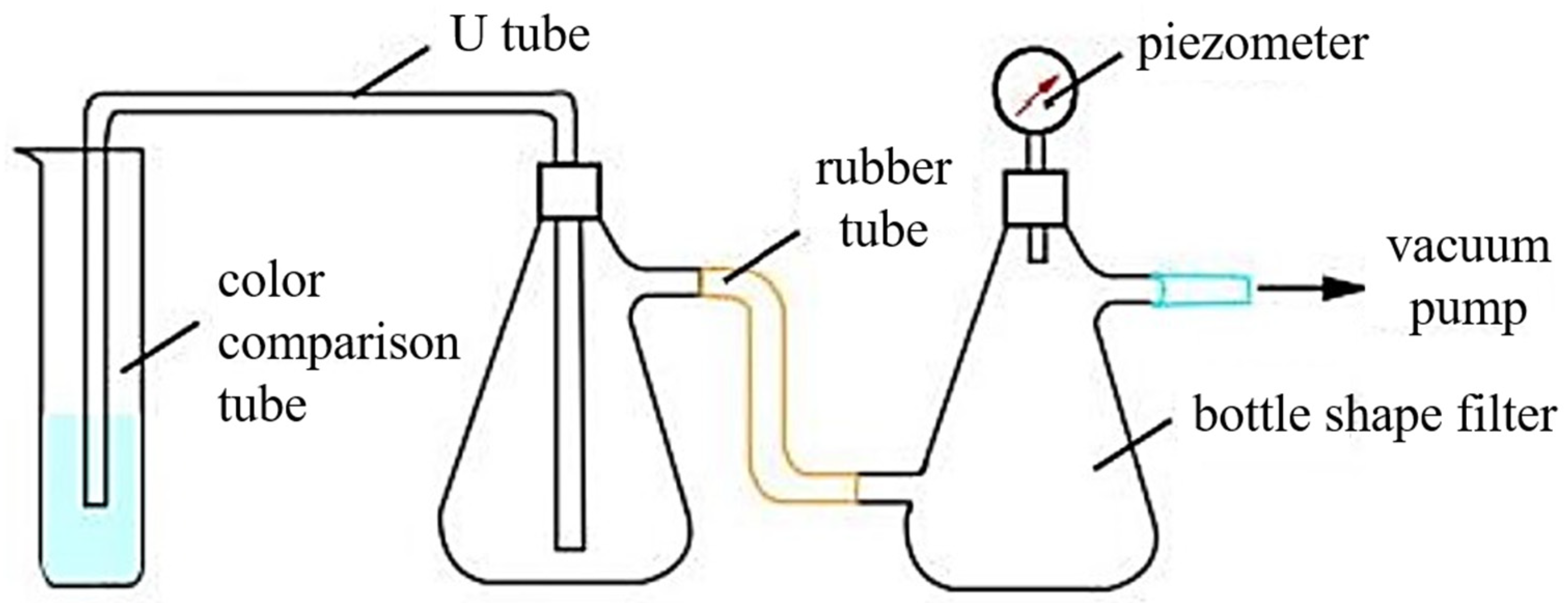

4.2.2. Vacuum Breakthrough Method

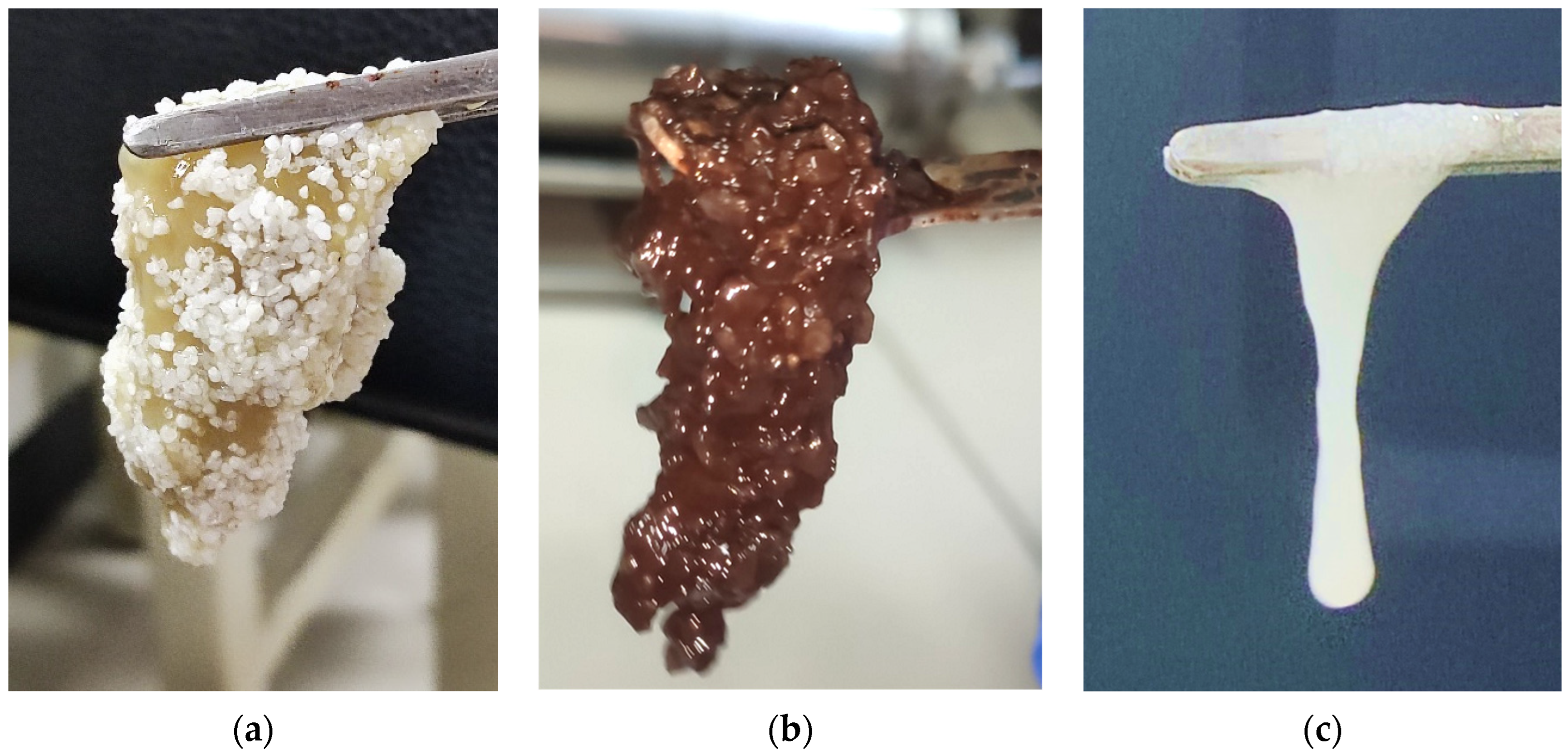

4.2.3. Adhesion Sand Test

4.2.4. Cryo-SEM Test of Gel

4.3. Experimental Method of Profile Control Plugging Displacement of Gel Plugging Agent

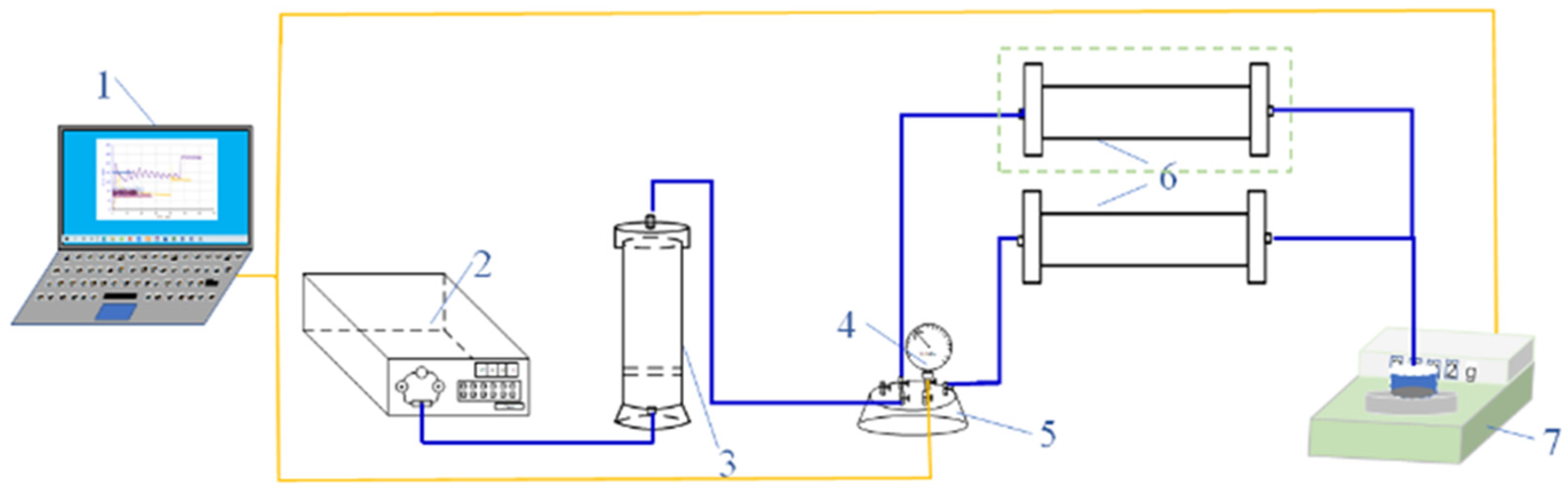

4.3.1. Plugging Capacity Test of the Gel Plugging Agent

4.3.2. Profile-Controlling Capacity Test of Gel Plugging Agent

4.4. Construction of the Evaluation Method for Plugging Effect of Gel Plugging Agent

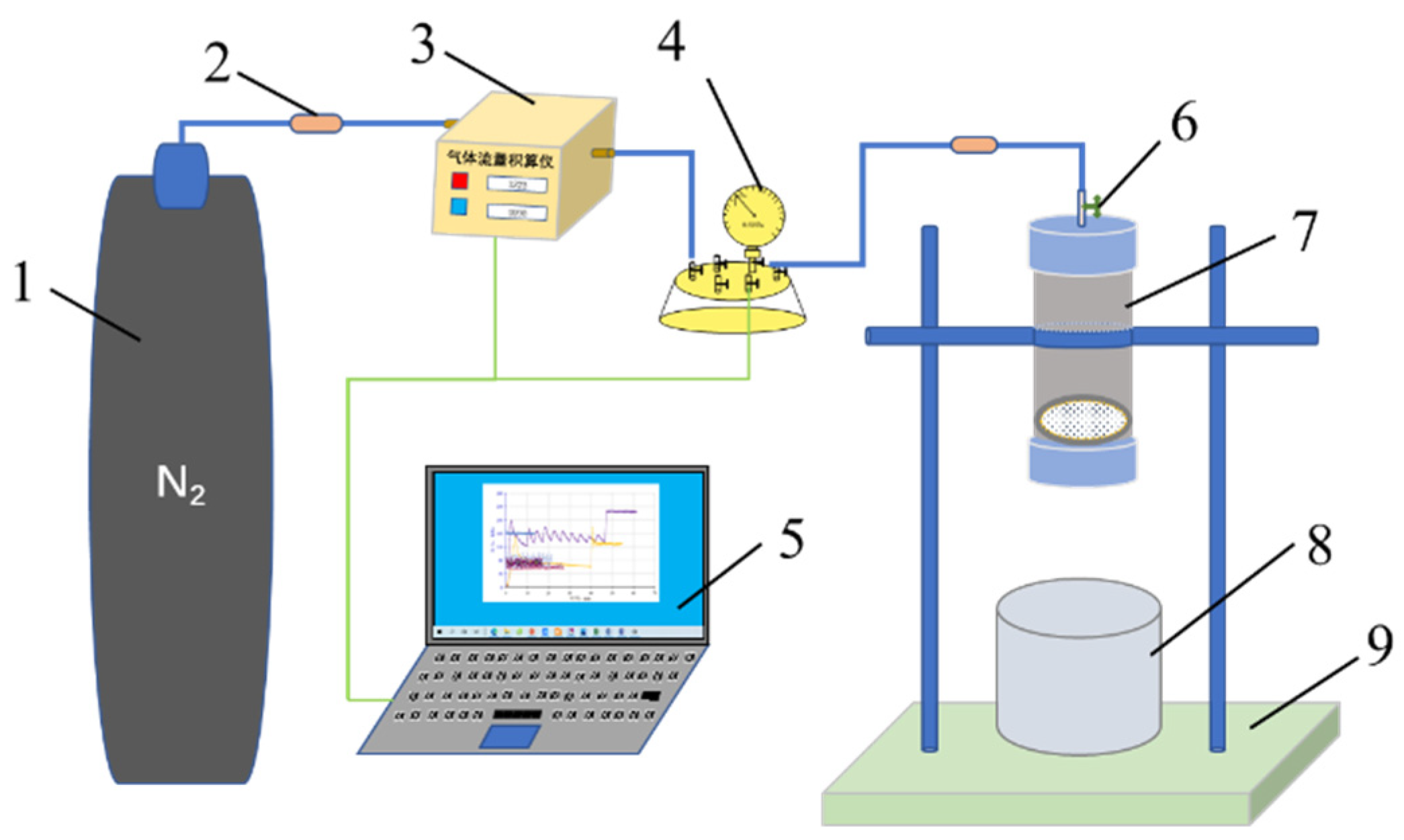

4.4.1. Body Strength Test Method

- The solution of the gel system was poured into the container used to measure the strength of the gel. The liquid level was 2 cm higher than the porous mesh.

- The container was sealed and placed in the thermostat box, which was set to the gelling temperature.

- After the gel system was gelled, the container was taken out. The upper cover valve was opened, emptied, and fixed on the bracket table. The experimental device was connected as shown in Figure 11.

- The lower cover of the container was opened. The gas flow rate was set to be 20 mL/min. The pressure reading was recorded. The maximum pressure value was collected when the gel broke through, which was the body strength of the gel plugging agent.

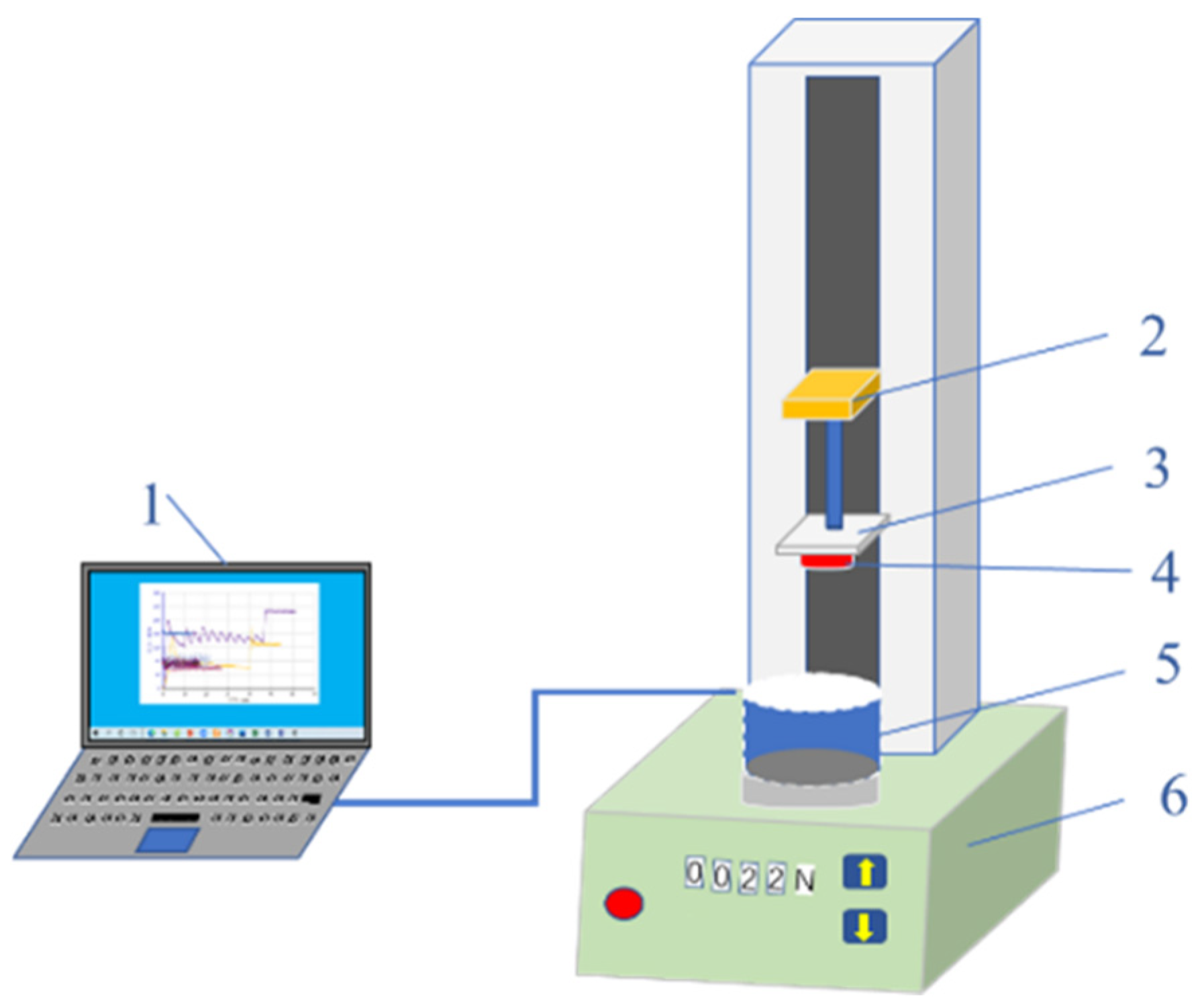

4.4.2. Adhesion Strength Test Method

- The gel system solution was poured into a transparent sample cup to a height of 4–6 cm. The cup was sealed and placed in a constant-temperature box that was set to the gelling temperature.

- After the gel system was gelled, the sample cup was taken out. The cover of the sample cup was removed and placed on the sample table of the precision tensile testing machine.

- The cutting flat core piece was bonded to the lifting platform plate, and the experimental device was connected as shown in Figure 13.

- The lifting platform was controlled to drop lower until the lower end of the core slice was in close contact with the gel and maintained for a period of 5–10 min.

- The lifting speed of the lifting platform was set to 2 mm/min. The value of the tension was collected when it started to rise. The maximum tension value (F) was collected, and the adhesion strength of the gel plugging agent was calculated by Equation (4).

4.4.3. Method for Measuring the Degree of Damage

- After the strength test of the gel body, the gel sheared by the porous mesh was taken. The mass of the gel was m1 (g). The gel was placed in a suitable cover screw glass test tube and sealed.

- The sealed gel was placed in the constant-temperature box for 48 h, which was set to the reservoir temperature.

- The screw glass test tube was removed. The amount of water from the gel was noted down, and the mass was observed as m2 (g). The gel damage index is calculated using the expression .

4.5. Construction of the Comprehensive Evaluation Index of Plugging Effect

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| GSR | gel strength rank index method |

| BV | breakthrough vacuum |

| HPAM | partially hydrolyzed polyacrylamide |

| PV | pore volume |

References

- Deng, R.; Dong, J.; Dang, L. Numerical Simulation and Evaluation of Residual Oil Saturation in Waterflooded Reservoirs. Fuel 2025, 384, 134018. [Google Scholar] [CrossRef]

- Wang, Z.; Zhai, D.; Zhao, X. The Evaluation Method of Residual Oil Distribution Based on Three-Distribution Visible Model. Res. Explor. Lab. 2016, 35, 13–16. [Google Scholar]

- Yin, H.; Zhang, G.; Wu, Q.; Cui, F.; Yan, B.; Yin, S.; Soltanian, M.R.; Thanh, H.V.; Dai, Z. Unraveling Overlying Rock Fracturing Evolvement for Mining Water Inflow Channel Prediction: A Spatiotemporal Analysis Using ConvLSTM Image Reconstruction. IEEE Trans. Geosci. Remote Sens. 2024, 62, 4510417. [Google Scholar] [CrossRef]

- Pu, W.; Wen, C.; Liu, R.; Jin, F.; Wang, C.; Liao, Z. Evaluation of a Novel Profile Control Agent for Enhancing an Oil-Recovery Application. J. Appl. Polym. Sci. 2016, 133, 43756. [Google Scholar] [CrossRef]

- Singh, V.; Ruwali, N.; Pandey, R.K.; Vaferi, B.; Wood, D.A. Applying a Deep-Learning Surrogate Model to Simulate and Compare Achievable Oil Recovery by Different Waterflood Scenarios. Pet. Sci. Technol. 2024, 42, 4405–4423. [Google Scholar] [CrossRef]

- Zhu, D.; Bai, B.; Hou, J. Polymer Gel Systems for Water Management in High-Temperature Petroleum Reservoirs: A Chemical Review. Energy Fuels 2017, 31, 13063–13087. [Google Scholar] [CrossRef]

- Lu, S.; Bo, Q.; Zhao, G.; Shaikh, A.; Dai, C. Recent Advances in Enhanced Polymer Gels for Profile Control and Water Shutoff: A Review. Front. Chem. 2023, 11, 1067094. [Google Scholar] [CrossRef]

- Cao, B.; Xie, K.; Lu, X.; Cao, W.; He, X.; Xiao, Z.; Zhang, Y.; Wang, X.; Su, C. Effect and Mechanism of Combined Operation of Profile Modification and Water Shutoff with In-Depth Displacement in High-Heterogeneity Oil Reservoirs. Colloids Surf. A Physicochem. Eng. Asp. 2021, 631, 127673. [Google Scholar] [CrossRef]

- Li, Y.; Xiao, C.; Wang, L. Research and Application of Profile Control Technology for Improving the Recovery Factor of Medium and High Permeability Reservoirs. In Proceedings of the International Field Exploration and Development Conference 2023, Wuhan, China, 20–22 September 2023; pp. 453–459. [Google Scholar]

- Li, Y.; Shi, H.; Chen, H.; Wang, L.; Wang, S. Water analysis and chemical plugging technology of oil wells in oilfields of western water injection development. Oil-Gasfield Surf. Eng. 2010, 29, 23–25. [Google Scholar]

- Wang, Y.; Seright, R.; Huang, B.; Fu, C.; Zeng, Y. Describing Flow Behavior of Polymer Gel in Fracture Using Rheology. J. Pet. Sci. Eng. 2017, 157, 1209–1219. [Google Scholar] [CrossRef]

- Sun, Z.; Li, Z.; Qu, K.; Zhang, Z.; Niu, Y.; Xu, W.; Ren, C. A Review on Recent Advances in Gel Adhesion and Their Potential Applications. J. Mol. Liq. 2021, 325, 115254. [Google Scholar] [CrossRef]

- Dai, C.; Zhang, G.; Zhao, F. Study on the factors affecting the freezing of aldehyde gel. Oilfield Chem. 2001, 24–26, 47. [Google Scholar] [CrossRef]

- Hubbard, S.; Roberts, L.J.; Sorbie, K.S. Experimental and Theoretical Investigation of Time-Setting Polymer Gels in Porous Media. SPE Reserv. Eng. 1988, 3, 1257–1267. [Google Scholar] [CrossRef]

- Seno, N.N.; Zheng, H. Chemical glue water plugging design and field application in oil wells of natural fractured carbonate reservoirs. Oil Recovery Process Inf. 1990, 3, 11–25. [Google Scholar]

- Southard, M.Z.; Green, D.W.; Willhite, G.P. Kinetics of the Chromium(VI) Thiourea Reaction in the Presence of Polyacrylamide; SPE: Tulsa, OK, USA, 1984; p. SPE-12715-MS. [Google Scholar]

- Sydansk, R.D. A New Conformance-Improvement-Treatment Chromium(III) Gel Technology; Society of Petroleum Engineers: Tulsa, OK, USA, 1988. [Google Scholar]

- Weisser, D.F.; Shakeel, A.; Mayer, D.; Schmid, J.; Heienbrock, S.J.; Deckert, M.H.; Rapp, B.E. Gel Point Investigation of Liquid Silicone Rubber Using Rheological Approaches. Polymer 2023, 283, 126286. [Google Scholar] [CrossRef]

- Zhou, H.; Jia, H.; Cao, J.; Liu, X.; Zhu, Y.; Jiang, K. Quick Measurement of Gel Strength by Breakthrough Vacuum Value Method through Viscosity Quantification. Oil Drill. Prod. Technol. 2015, 37, 116–119. [Google Scholar] [CrossRef]

- Zhu, H.; Yu, C.; Zhao, F. Zirconium Gelling System for Water Shutoff. Oilfield Chem. 1989, 1, 27–31. [Google Scholar] [CrossRef]

- Zhao, Q. Studies on Behavior Evaluation Methods and Suitable Conditions of Polymer Gels. Master’s Thesis, Daqing Petroluem Institute, Daqing, China, 2004. [Google Scholar]

- Ai, W. Laboratory Study on Low Temperature Chrome Gel. Master’s Thesis, Daqing Petroluem Institute, Daqing, China, 2001. [Google Scholar]

- Purkaple, J.D.; Summers, L.E. Evaluation of Commercial Crosslinked Polyacrylamide Gel Systems for Injection Profile Modification. In SPE Enhanced Oil Recovery Symposium; SPE: Tulsa, OK, USA, 1988. [Google Scholar]

- Aldhaheri, M.; Wei, M.; Zhang, N.; Bai, B. A Review of Field Oil-Production Response of Injection-Well Gel Treatments. SPE Reserv. Eval. Eng. 2019, 22, 597–611. [Google Scholar] [CrossRef]

- Kang, C.; Guo, J.; Sun, X.; Fei, D. Progress in Evaluation Methods of Gel Plugging Agent. Appl. Chem. Ind. 2022, 10, 2952–2955. [Google Scholar] [CrossRef]

- Tang, X.; Liu, Y.; Xiang, W.; Liu, G.; Lin, Y.; Hu, P. Performance Evaluation on Indexes and Measures of Cross—Linked Polymer Gel for Water Shutoff and Profile Control. Oil Drill. Prod. Technol. 2004, 49–53, 84. [Google Scholar] [CrossRef]

- Seright, R.; Brattekas, B. Water Shutoff and Conformance Improvement: An Introduction. Pet. Sci. 2021, 18, 450–478. [Google Scholar] [CrossRef]

- Lai, N.; Yuan, L.; Li, W.; Xiong, W.; Yu, G.; Du, Z.; Song, Z.; Wen, Y. Research on the Properties of Natural Gas Foamed Gel as a Profile Control and an Oil Displacement Agent in Strong Heterogeneous Reservoirs. Energy Fuels 2021, 35, 7738–7755. [Google Scholar] [CrossRef]

- Konoplin, A.Y.; Pushkarev, A.V.; Shakurov, A.V.; Baurova, N.I. Evaluation of Frost Resistance of Organosilicon Sealant at Ultralow Temperatures. Polym. Sci. Ser. D 2021, 14, 335–339. [Google Scholar] [CrossRef]

- Li, X.; Fu, M.; Hu, J. Preparation and Performance Evaluation of Temperature-Resistant and Salt-Resistant Gels. Gels 2024, 10, 337. [Google Scholar] [CrossRef] [PubMed]

- Singh, W.P.; Singh, R.S. Gelation-Based Visual Detection of Analytes. Soft Mater. 2019, 17, 93–118. [Google Scholar] [CrossRef]

- Wang, Z.; Zhao, X.; Bai, Y.; Gao, Y. Study of a Double Cross-Linked HPAM Gel for in-Depth Profile Control. J. Dispers. Sci. Technol. 2016, 37, 1010–1018. [Google Scholar] [CrossRef]

- Liu, Y.; Bai, B.; Wang, Y. Applied Technologies and Prospects of Conformance Control Treatments in China. Oil Gas Sci. Technol.—Rev. IFP Energ. Nouv. 2010, 65, 859–878. [Google Scholar] [CrossRef]

- Liu, P.; Li, W.; Wei, F.; Hu, F.; Zhu, X.; Jia, Z. Preparation of a Fluid Diversion Agent for Profile Control in Elevated Temperature and High Salinity Reservoirs. J. Appl. Polym. Sci. 2021, 138, 50875. [Google Scholar] [CrossRef]

- Ge, J.; Guo, H.; Zhang, T.; Zhou, D.; Xu, Y.; Lü, Q. Development of Temperature and Salinity Resistant Phenolic Gel and Its Performance Regulation Mechanism. Acta Pet. Sin. 2022, 43, 1145–1157. [Google Scholar] [CrossRef]

- Farasat, A.; Younesian-Farid, H.; Sadeghnejad, S. Conformance Control Study of Preformed Particle Gels (PPGs) in Mature Waterflooded Reservoirs: Numerical and Experimental Investigations. J. Pet. Sci. Eng. 2021, 203, 108575. [Google Scholar] [CrossRef]

- Wang, Z.; Bai, B.; Sun, X.; Wang, J. Effect of Multiple Factors on Preformed Particle Gel Placement, Dehydration, and Plugging Performance in Partially Open Fractures. Fuel 2019, 251, 73–81. [Google Scholar] [CrossRef]

- Leng, J.; Wei, M.; Bai, B. Review of Transport Mechanisms and Numerical Simulation Studies of Preformed Particle Gel for Conformance Control. J. Pet. Sci. Eng. 2021, 206, 109051. [Google Scholar] [CrossRef]

- Xie, K.; Su, C.; Liu, C.; Cao, W.; He, X.; Ding, H.; Mei, J.; Yan, K.; Cheng, Q.; Lu, X. Synthesis and Performance Evaluation of an Organic/Inorganic Composite Gel Plugging System for Offshore Oilfields. ACS Omega 2022, 7, 12870–12878. [Google Scholar] [CrossRef] [PubMed]

- Yang, S.; Shu, Z.; Zhang, Q.; Zhao, Y.; Chen, Z.; Zhang, L. Experimental Study on Compatibility of Reservoir and Polymer Gel Profile Control Agent. Front. Earth Sci. 2022, 10, 1029309. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, L.; Xi, R.; Geng, Z.; Zhang, Q.; Ma, X. CO2-H2O Two-Phase Displacement Characteristics of Low Permeability Core Using Nuclear Magnetic Resonance and Magnetic Resonance Imaging Techniques. RockandSoilMechanics 2023, 44, 1636–1644. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, Z. Chemical Profile Control Water Plugging Technology; Petroleum Industry press: Beijing, China, 1999; ISBN 978-7-5021-2740-4. [Google Scholar]

- Wu, W.; Hou, J.; Li, G.; Chen, L. Effect of Temperature and Inorganic Salts Concentration on Syneresis Rate of AM/DAC Hydrogel. Colloids Surf. A Physicochem. Eng. Asp. 2022, 641, 128561. [Google Scholar] [CrossRef]

| Gel System | Permeability Before Plugging × 103, μm2 | Permeability After Plugging × 103, μm2 | Permeability After Displacement of 16 PV × 103, μm2 | Plugging Rate, % | Plugging Rate After Displacement of 16 PV, % | Breakthrough Pressure Gradient, MPa/m |

|---|---|---|---|---|---|---|

| Gel system 1 | 8493.6 | 2.23 | 1.98 | 99.97 | 99.98 | 14.77 |

| Gel system 2 | 8495.8 | 0.90 | 1.45 | 99.99 | 99.98 | 36.57 |

| Gel system 3 | 8542.1 | 6.41 | 46.3 | 99.92 | 99.45 | 4.70 |

| Gel System | Body Strength δ, KPa | Adhesion Strength η, N/m2 | Degree of Injury λ, Dimensionless | Plugging Capacity Evaluation Index Γ, Pa2 | ||

|---|---|---|---|---|---|---|

| Adhesive Force, mN | Core Slice Diameter, cm | η, N/m2 | ||||

| Gel system 1 | 90 | 190 | 2.5 | 387.3 | 6.4 | 5.45 |

| Gel system 2 | 66 | 140 | 2.5 | 285.4 | 2.1 | 8.97 |

| Gel system 3 | 63 | 60 | 2.5 | 122.3 | 2.3 | 3.35 |

| Ionic Types | Ca2+ | Na+ | Mg2+ | Cl− | SO42− | HCO3− |

|---|---|---|---|---|---|---|

| ion concentration, mg/L | 1022 | 6422 | 259 | 12,326 | 31 | 202 |

| Grade | Strength Classification Standard |

|---|---|

| A | No continuous gel formation was detected: the viscosity of the gelling system was the same as that of the same concentration of polymer solution without a crosslinking agent, but sometimes there might be some unconnected gel blocks with great viscosity in the system. |

| B | Highly flowable gel: The viscosity of the gel system is slightly higher than that of a polymer solution of the same concentration without a crosslinking agent. |

| C | Flowing gel: When the sample bottle is inverted, most of the gel flows to the cap. |

| D | Medium flow gel: Only a small portion (10~15%) when the vial is inverted vertically. The gel does not easily flow to the cap (typically described as long tongue type gel). |

| E | Difficult to flow gel: When the sample bottle is vertically inverted, the gel flows very slowly to the cap or a large part (>15%) does not flow to the cap. |

| F | Highly Deformed No Flow Gel: Gel does not flow to the cap when the vial is inverted vertically. |

| G | Moderate deformation non-flowing gel: When the sample bottle is vertically inverted, the gel is deformed downward to about half of the position. |

| H | Slight deformation does not flow gel: When the sample bottle is vertically inverted, only the surface of the gel is slightly deformed. |

| I | Rigid gel: When the sample bottle is inverted vertically, the surface of the gel does not deform. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Jiang, J.; Huang, W.; Gan, Y.; Bai, Y. Construction of a ‘Simple, Fast and Accurate’ Evaluation Method for Profile Control and Plugging Effect of Gel Plugging Agent Based on Simulations. Gels 2025, 11, 115. https://doi.org/10.3390/gels11020115

Wang Z, Jiang J, Huang W, Gan Y, Bai Y. Construction of a ‘Simple, Fast and Accurate’ Evaluation Method for Profile Control and Plugging Effect of Gel Plugging Agent Based on Simulations. Gels. 2025; 11(2):115. https://doi.org/10.3390/gels11020115

Chicago/Turabian StyleWang, Zengbao, Junjie Jiang, Weian Huang, Yuwei Gan, and Yingrui Bai. 2025. "Construction of a ‘Simple, Fast and Accurate’ Evaluation Method for Profile Control and Plugging Effect of Gel Plugging Agent Based on Simulations" Gels 11, no. 2: 115. https://doi.org/10.3390/gels11020115

APA StyleWang, Z., Jiang, J., Huang, W., Gan, Y., & Bai, Y. (2025). Construction of a ‘Simple, Fast and Accurate’ Evaluation Method for Profile Control and Plugging Effect of Gel Plugging Agent Based on Simulations. Gels, 11(2), 115. https://doi.org/10.3390/gels11020115