Advances and Future Prospects of Temperature and Salt-Resistant Gel Materials for Downhole Plugging Applications

Abstract

1. Introduction

2. Results and Discussion

2.1. Preparation and Performance Analysis of Polymer Materials

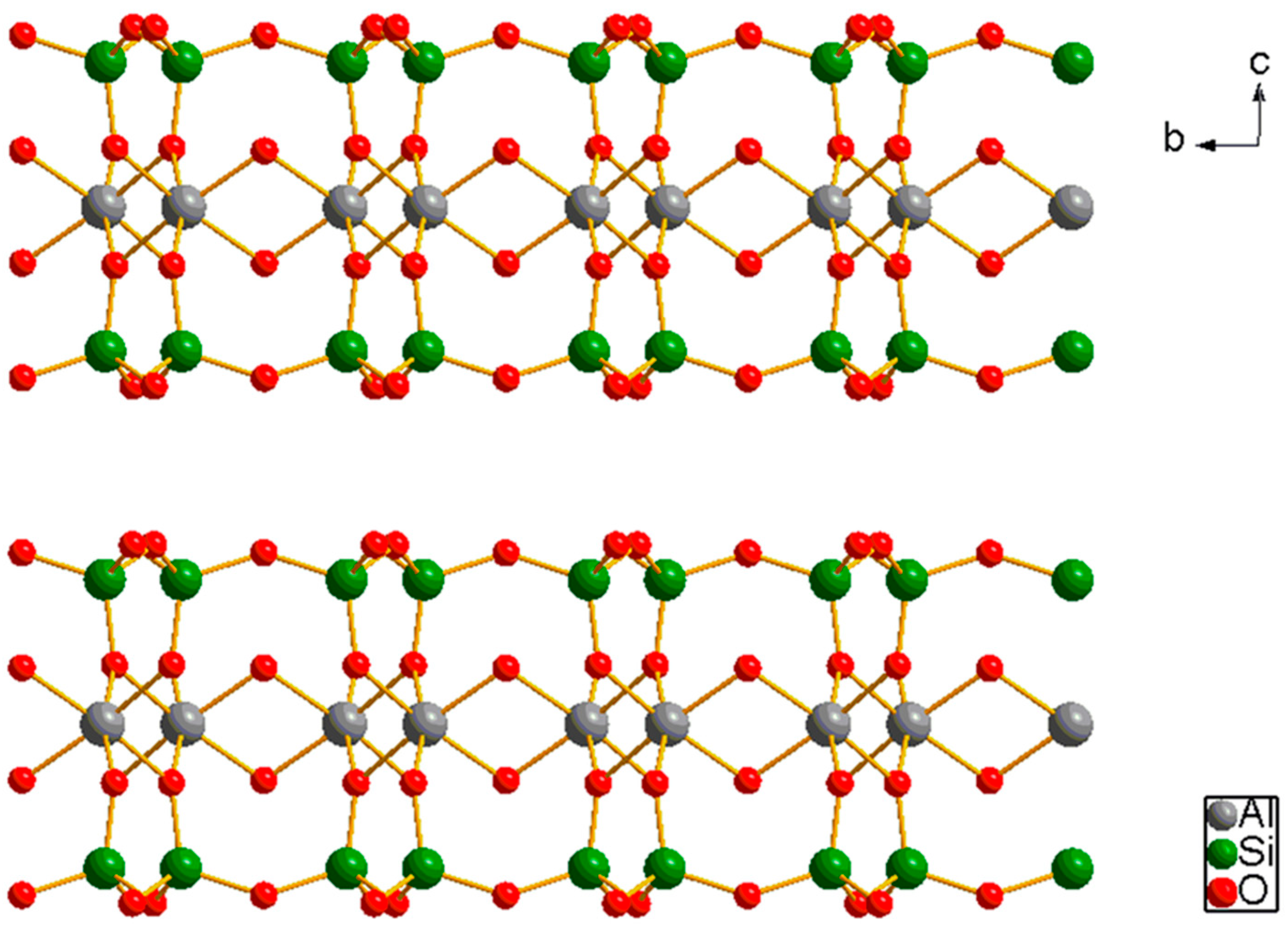

2.2. Structure Design and Application Research of Inorganic Composite Materials

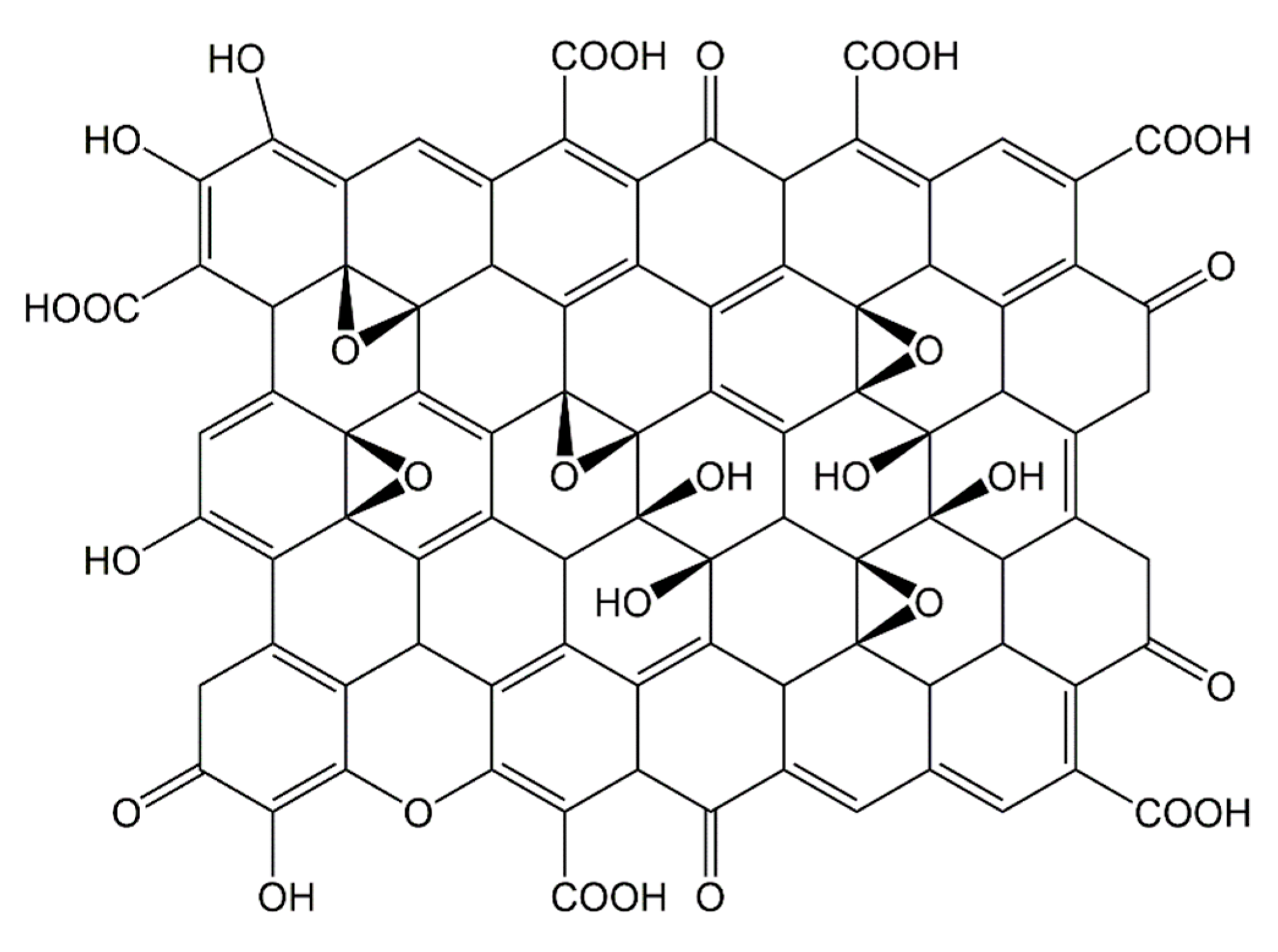

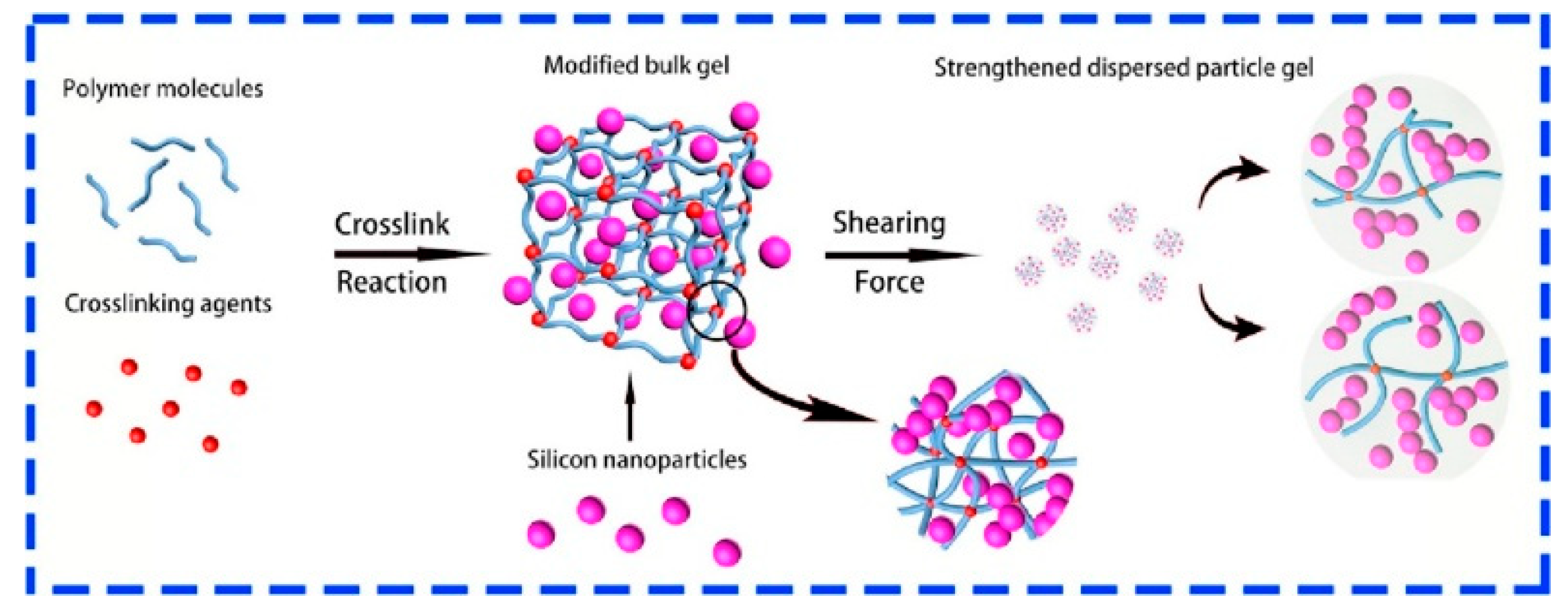

2.3. Synthesis Methods and Property Characterization of Nano-Materials

2.4. Key Properties Comparison of Plugging Materials

3. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Shen, Z.; Wang, M.; Gao, Y.; Wu, W.; Cheng, X.; Feng, X.; Deng, S. A Review of Water Detection Method and Plugging Technology for Horizontal Wells. Spec. Oil Gas Reserv. 2023, 30, 10. [Google Scholar] [CrossRef]

- Sun, J.; Lei, S.; Bai, Y.; Wang, X.; Lv, K.; Liu, B.; Wang, J.; Dai, C.; Liu, J. Research progress and application prospects of smart materials in lost circulation control of drilling fluids. J. China Univ. Pet. 2020, 4, 100–110. [Google Scholar]

- Xiang, C.; He, B.; Li, H.; Chen, X.; Gao, L. Oil and gas blocking technology with high temperature resistant curable gel slug. Nat. Gas Explor. Dev. 2022, 45, 70–77. [Google Scholar] [CrossRef]

- Aslani, F.; Zhang, Y.; Manning, D.; Valdez, L.C.; Manning, N. Additive and alternative materials to cement for well plugging and abandonment: A state-of-the-art review. J. Pet. Sci. Eng. 2022, 215, 110728. [Google Scholar] [CrossRef]

- Yuan, C.-D.; Pu, W.-F.; Jin, F.-Y.; Zhang, Y.-C.; Jia, H.; Zhao, T.-h. Performance of oil-based cement slurry as a selective water-plugging agent in high-temperature and high-salinity cave-fractured carbonate reservoirs. Ind. Eng. Chem. Res. 2014, 53, 6137–6149. [Google Scholar] [CrossRef]

- Xia, X.; Guo, J.; Feng, Y.; Chen, D.; Yu, Y.; Jin, J.; Liu, S. Hydrophobic associated polymer “grafted onto” nanosilica as a multi-functional fluid loss agent for oil well cement under ultrahigh temperature. RSC Adv. 2016, 6, 91728–91740. [Google Scholar] [CrossRef]

- Yao, Y.; Fan, H.; Gao, S.; Zhang, Y. Study on the adaptability of the general technical conditions and evaluation standards of the chemical agents used for oil recovery. Oil Gas Chem. 2016, 45, 82–87. [Google Scholar]

- Lu, X.; Li, X.; Zhang, Y. Experimental Study on Solid Particle Plugging System in Fractured Reservoir. J. Oil Gas Technol. 2023, 45, 37–43. [Google Scholar] [CrossRef]

- Zhao, F.; Li, Z.; Wu, J.; Hou, J.; Qu, S. New type plugging particle system with high temperature & high salinity resistance. J. Pet. Sci. Eng. 2017, 152, 317–329. [Google Scholar] [CrossRef]

- Shan, W.; Tao, S.; Jiang, R.; Li, Y. Technology and Progress in High Temperature Resistant Drilling Fluid for Hot Dry Rock. Prospect. Eng. (Geotech. Drill.) 2018, 45, 52–56. [Google Scholar]

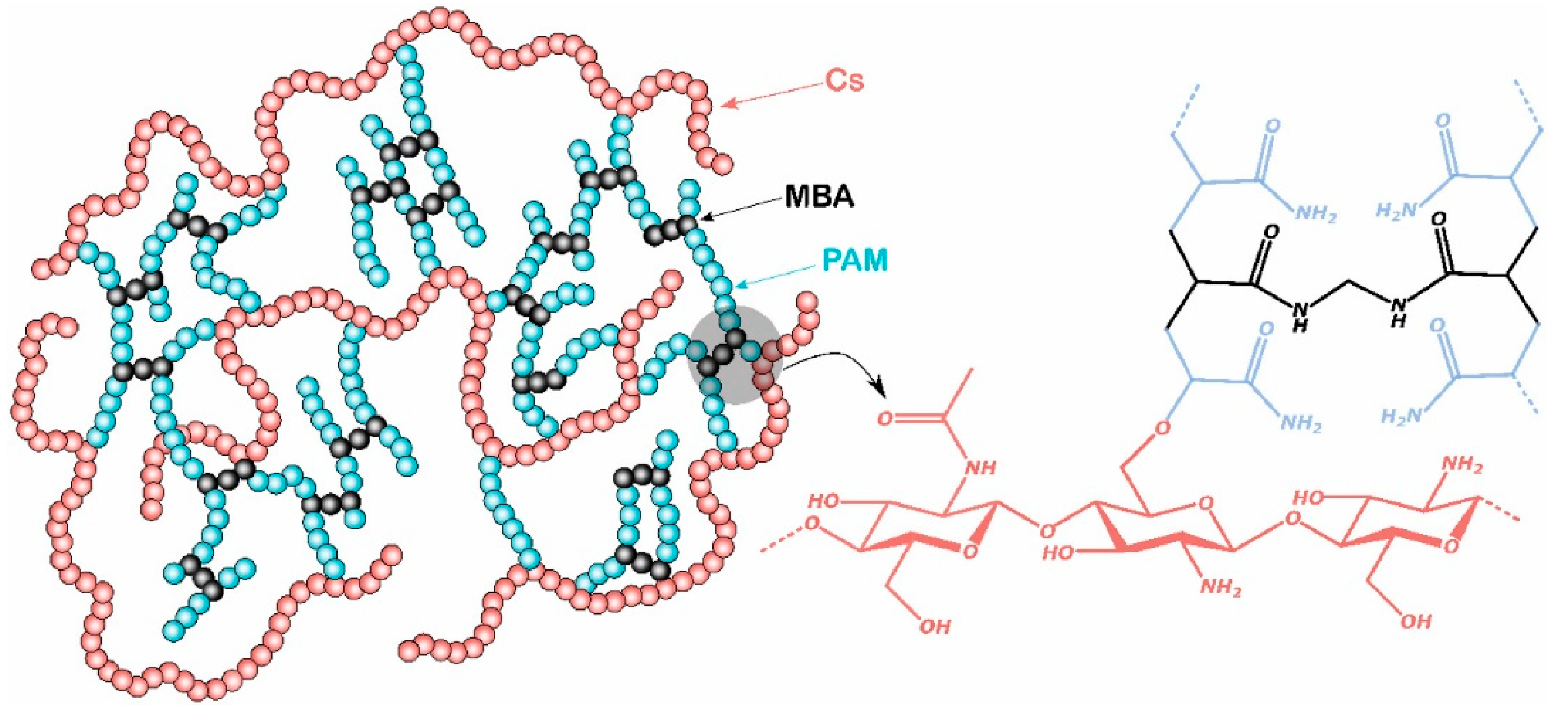

- Elaf, R.; Ben Ali, A.; Saad, M.; Hussein, I.A.; Bai, B. Development of eco-friendly chitosan-g-polyacrylamide preformed particle gel for conformance control in high-temperature and high-salinity reservoirs. Geoenergy Sci. Eng. 2023, 230, 212136. [Google Scholar] [CrossRef]

- Ge, X.; Alotibi, A.; Al-Hlaichi, A.; Liu, Y.; Song, T.; Liu, J.; Bai, B.; Schuman, T. Novel Re-Crosslinkable Preformed Particle Gels (RPPG) for Parent- and Infill-Well-Fracture Interactions Mitigation. In Proceedings of the SPE Eastern Regional Meeting, Wheeling, WV, USA, 8–10 October 2024. [Google Scholar] [CrossRef]

- Cui, Y.; Tan, Z.; An, C. Research and application of multi-functional acrylic resin grouting material. Constr. Build. Mater. 2022, 359, 129381. [Google Scholar] [CrossRef]

- Chen, C.; Zhou, P.; Huang, C.; Zeng, R.; Yang, L.; Han, Z.; Qu, Y.; Zhang, C. Photothermal-promoted multi-functional dual network polysaccharide hydrogel adhesive for infected and susceptible wound healing. Carbohydr. Polym. 2021, 273, 118557. [Google Scholar] [CrossRef]

- Sun, J.; Lei, S.; Bai, Y.; Lü, K.; Zhang, S.; Han, J.; Cheng, R.; Liu, F. Mechanical transformation mechanism of polymer materials and its application prospects in the field of drilling fluids. Acta Pet. Sin. 2021, 42, 1382–1394. [Google Scholar]

- Yang, K.; Bai, Y.; Ma, J.; Sun, J.; Liu, Y.; Lang, Y. Functional Gels and Chemicals Used in Oil and Gas Drilling Engineering: A Status and Prospective. Gels 2024, 10, 47. [Google Scholar] [CrossRef] [PubMed]

- Bai, Y.; Pu, W.; Jin, X.; Shen, C.; Ren, H. Review of the micro and Macro mechanisms of gel-based plugging agents for enhancing oil recovery of unconventional water flooding oil reservoirs. J. Mol. Liq. 2024, 399, 124318. [Google Scholar] [CrossRef]

- Li, X.; Fu, M.; Liu, J.; Xiao, Q.; Tang, W.; Yang, G. Synthesis and Performance Evaluation of a Novel Heat and Salt-Resistant Gel Plugging Agent. Polymers 2022, 14, 3894. [Google Scholar] [CrossRef] [PubMed]

- Jiang, G.; Deng, Z.; He, Y.; Li, Z.; Ni, X. Cross-linked polyacrylamide gel as loss circulation materials for combating lost circulation in high temperature well drilling operation. J. Pet. Sci. Eng. 2019, 181, 106250. [Google Scholar] [CrossRef]

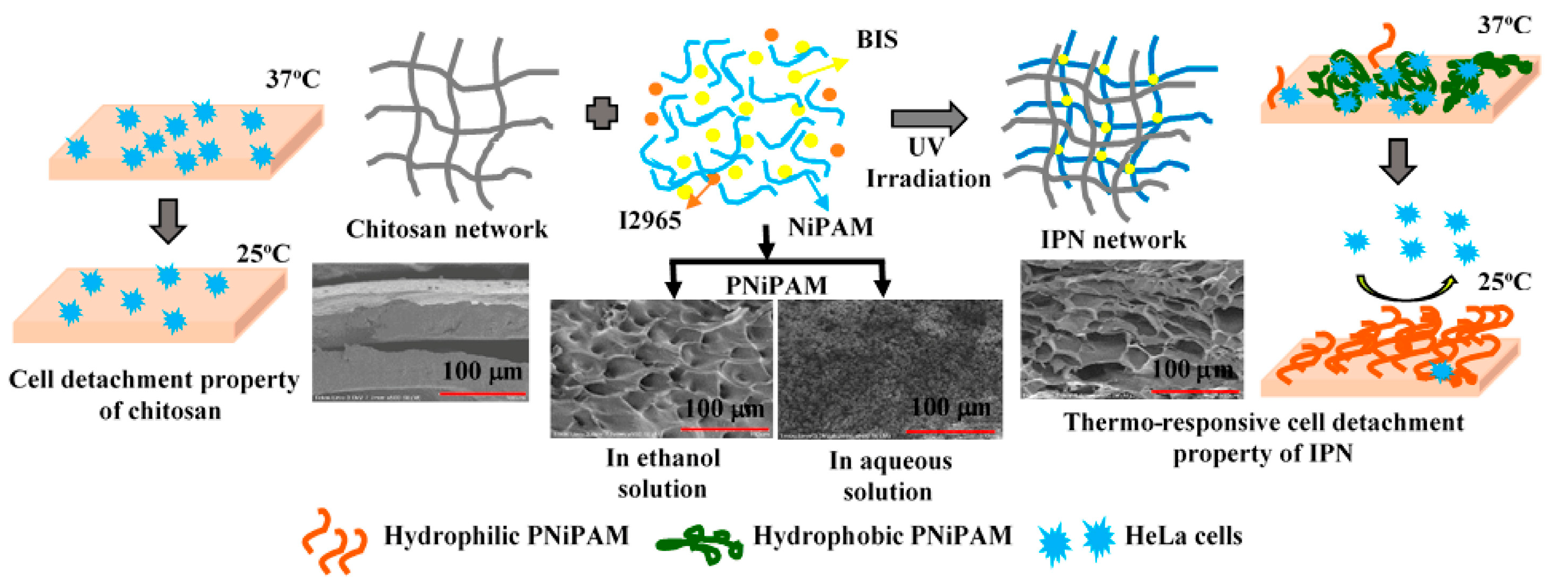

- Dueramae, I.; Tanaka, F.; Shinyashiki, N.; Yagihara, S.; Kita, R. UV-Crosslinked Poly(N-isopropylacrylamide) Interpenetrated into Chitosan Structure with Enhancement of Mechanical Properties Implemented as Anti-Fouling Materials. Gels 2024, 10, 20. [Google Scholar] [CrossRef]

- Fang, J.; Zhang, X.; Li, L.; Zhang, J.; Shi, X.; Hu, G. Research Progress of High-Temperature Resistant Functional Gel Materials and Their Application in Oil and Gas Drilling. Gels 2023, 9, 34. [Google Scholar] [CrossRef]

- Li, X.; Fu, M.; Hu, J. Preparation and Performance Evaluation of Temperature-Resistant and Salt-Resistant Gels. Gels 2024, 10, 337. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, J.; Sun, J.; Lv, K.; Wang, Z.; Xu, Z.; Sun, Y. Novel Modified Styrene-Based Microspheres for Enhancing the Performance of Drilling Fluids at High Temperatures. Gels 2023, 9, 763. [Google Scholar] [CrossRef]

- Wang, B.; Sun, J.; Lv, K.; Shen, F.; Bai, Y. Effects of a crosslinking agent on a supramolecular gel to control lost circulation. New J. Chem. 2021, 45, 7089–7095. [Google Scholar] [CrossRef]

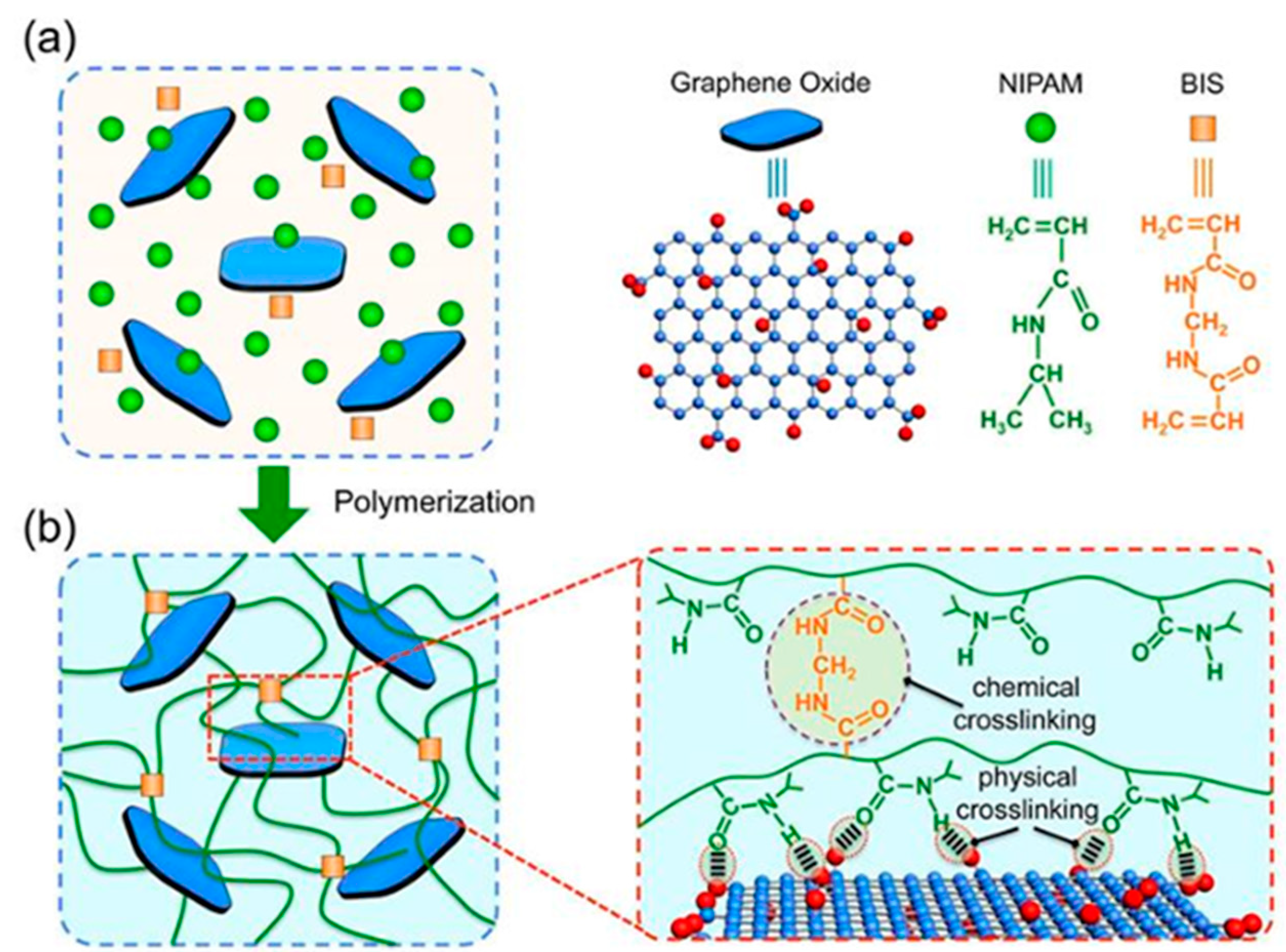

- Shi, K.; Liu, Z.; Wei, Y.-Y.; Wang, W.; Ju, X.-J.; Xie, R.; Chu, L.-Y. Near-infrared light-responsive poly (N-isopropylacrylamide)/graphene oxide nanocomposite hydrogels with ultrahigh tensibility. ACS Appl. Mater. Interfaces 2015, 7, 27289–27298. [Google Scholar] [CrossRef]

- Ma, R.; Dai, L.; Sun, D.; Yang, Y.; Tang, C.; Li, L.; He, Z.; Ni, Y. Nanocellulose/scleroglucan-enhanced robust, heat-resistant composite hydrogels for oilfield water plugging. Carbohydr. Polym. 2024, 341, 122320. [Google Scholar] [CrossRef]

- Lei, S.; Sun, J.; Lv, K.; Zhang, Q.; Yang, J. Types and Performances of Polymer Gels for Oil-Gas Drilling and Production: A Review. Gels 2022, 8, 386. [Google Scholar] [CrossRef]

- Liu, H.Z.; Zhou, M.; Wu, J.; Lu, H.; Zheng, J.; Peng, T. Performance evaluation and application of modified urea–formaldehyde resin water shutoff agent. J. Pet. Explor. Prod. Technol. 2017, 7, 155–160. [Google Scholar] [CrossRef]

- Pan, Y.; Zhang, C.; Yang, S.; Li, Z.; Xu, M.; Yan, G. Research progress of environmentally sensitive materials in oil and gas drilling and exploitation field. Chem. Ind. Eng. Prog. 2021, 40, 6121–6134. [Google Scholar] [CrossRef]

- Lu, Y.; Liu, D.; Wei, X.; Xiao, Q.; Song, J.; Yu, Y. Study and Validation of a Novel Grouting Clamp Type Deepwater Oilfield Pipeline Repair Method Based on Computational Fluid Dynamics. Processes 2023, 11, 1142. [Google Scholar] [CrossRef]

- Liu, Y.; Li, Z.; Pan, M. A high-temperature plugging system for offshore heavy oil thermal recovery. PLoS ONE 2018, 13, e0199709. [Google Scholar] [CrossRef] [PubMed]

- Yu, L.; Dong, M.; Ding, B.; Yuan, Y. Emulsification of heavy crude oil in brine and its plugging performance in porous media. Chem. Eng. Sci. 2018, 178, 335–347. [Google Scholar] [CrossRef]

- Han, J.; Sun, J.; Lv, K.; Yang, J.; Li, Y. Polymer Gels Used in Oil–Gas Drilling and Production Engineering. Gels 2022, 8, 637. [Google Scholar] [CrossRef] [PubMed]

- Luo, Z.; Li, J.; Zhang, N.; Fu, H.; Huang, J.; Zhang, Q.; Li, H.; Sun, H. Performance evaluation and field verification of a selective water pluggingagent. J. Dispers. Sci. Technol. 2024, 45, 2302–2314. [Google Scholar] [CrossRef]

- Zhou, S.; Gao, S.; Jin, F.; Qi, N. Development and evaluation of deep water plugging system in high temperature and high salt fracture-vuggy reservoir. Appl. Chem. 2023, 52, 2048–2052+2058. [Google Scholar] [CrossRef]

- Yang, J.; Bai, Y.; Sun, J.; Lv, K. High-Temperature, Salt-Resistant, and High-Strength-Controlled Consolidated Resin Slurry for Fracture Plugging during Oil and Gas Well Drilling. SPE J. 2024, 29, 4619–4632. [Google Scholar] [CrossRef]

- Zhang, J.; Li, G. Current status of research on chemical dissection and water plugging technology. Daqing Pet. Geol. Dev. 2006, 3, 85–87+109. [Google Scholar]

- Wang, H.; Zhang, Y.; Xing, Z.; Tian, Y. Research progress of chemical plugging agents for oil wells. Chem. Eng. Equip. 2019, 9, 219–220. [Google Scholar] [CrossRef]

- Bao, D.; Qiu, Z.; Qiu, W.; Wang, B.; Guo, B.; Wang, X.; Liu, J.; Chen, J. Experiments on the properties of drilling and plugging materials for high-temperature formations. Pet. J. 2019, 40, 846–857. [Google Scholar]

- Liu, J.; Ma, C.; Yang, C.; Zhong, F.; Luo, G. Status and Prospect of Research on Drilling Fluid Plugging Materials for Well Leakage Formations. Oilfield Chem. 2023, 40, 729–735. [Google Scholar] [CrossRef]

- Du, J.; Wang, Q.; Liu, P.; Xiong, G.; Chen, P.; Chen, X.; Liu, J. Nanocomposite gels for water shut-off and temporary plugging in the petroleum industry: A review. Pet. Sci. Technol. 2023, 41, 2204–2239. [Google Scholar] [CrossRef]

- Razzaq, W.; Elkatatny, S.; Gowida, A.; Samsuri, A. Application of Silicomanganese Fume as a Novel Bridging Material for Water-Based Drilling Fluids. ACS Omega 2023, 8, 509–518. [Google Scholar] [CrossRef] [PubMed]

- Krishnan, M.R.; Omar, H.; Almohsin, A.; Alsharaeh, E.H. An overview on nanosilica–polymer composites as high-performance functional materials in oil fields. Polym. Bull. 2024, 81, 3883–3933. [Google Scholar] [CrossRef]

- Asad, M.S.; Jaafar, M.T.; Rashid, F.L.; Togun, H.; Rasheed, M.K.; Al-Obaidi, M.A.; Al-Amir, Q.R.; Mohammed, H.I.; Sarris, I.E. Sustainable Drilling Fluids: A Review of Nano-Additives for Improved Performance and Reduced Environmental Impact. Processes 2024, 12, 2180. [Google Scholar] [CrossRef]

- Shu, Z.; Qi, Y.; Luo, P. Research and performance evaluation of modified nano-silica gel plugging agent. J. Appl. Polym. Sci. 2023, 140, e53873. [Google Scholar] [CrossRef]

- Sergeev, V.; Tanimoto, K.; Abe, M. The Water-blocking Agent with Improved Properties for IOR Implementation. Eur. Assoc. Geosci. Eng. 2019, 2019, 1–11. [Google Scholar] [CrossRef]

- Jeong, S.; Lee, H.; Cho, C.; Yoo, S. Characterization of multi-functional, biodegradable sodium metabisulfite-incorporated films based on polycarprolactone for active food packaging applications. Food Packag. Shelf Life 2020, 25, 100512. [Google Scholar] [CrossRef]

- Wu, X. High-temperature-resistant multilayer intercalated expanded graphite materials and their applications. Drill. Proj. 2023, 50, 66–73. [Google Scholar]

- Zhao, G.; Dai, C.; Gu, C.; You, Q.; Sun, Y. Expandable graphite particles as a novel in-depth steam channeling control agent in heavy oil reservoirs. Chem. Eng. J. 2019, 368, 668–677. [Google Scholar] [CrossRef]

- Sun, J.; Yang, J.; Bai, Y.; Lu, K.; Wang, J.; Wang, L. Review and Prospect of the Development of Bridging Plugging Technology for Fissured Formations. Pet. Sci. Bull. 2023, 8, 415–431. [Google Scholar]

- Han, S.; Tan, H.; Wei, J.; Yuan, H.; Li, S.; Yang, P.; Mi, H.; Liu, C.; Shen, C. Surface Modification of Super Arborized Silica for Flexible and Wearable Ultrafast-Response Strain Sensors with Low Hysteresis. Adv. Sci. 2023, 10, 2301713. [Google Scholar] [CrossRef]

- Lin, S. Research on Water-Expansion System for Low-Permeability Reservoirs. Master’s Thesis, Liaoning Petrochemical University, Fushun, China, 2020. [Google Scholar] [CrossRef]

- Wang, H.; Pu, X. Structure and inhibition properties of a new amine-terminated hyperbranched oligomer shale inhibitor. J. Appl. Polym. Sci. 2019, 136, 47573. [Google Scholar] [CrossRef]

- Chen, H. Study on the Development and Mechanism of Temporary Plugging Pill for High-Temperature Resistance Solidify Elastic Nanocomposite Gel. Master’s Thesis, Southwest Petro University, Chengdu, China, 2018. Available online: https://kns.cnki.net/kcms2/article/abstract?v=LYi8dJWcB0U-mDW6vJH9ORVobcPjoFSXmi6hhJrUEk4IVI0TKroVVB9aMycMgzlZPgc6ZCMToBdsEH9PnYLoKRpD_hYOC76Vxdcz7sdHoTebjON_N9Ne-cnimXrxW2G2qnq0X__97m-EmMgeytXe1IFAlrzJVKF4vLqVDqd9xwtCOP7vgn1XynVfFeaWU_ZO&uniplatform=NZKPT&language=CHS (accessed on 21 September 2025).

- Wang, J. Research on Adaptive Plugging Technology of Functional Composite Gel. Ph.D. Thesis, Sichuan University, Chengdu, China, 2007. Available online: https://kns.cnki.net/kcms2/article/abstract?v=uXGtp3S0eCCxVlfSxWn9IFFix3fxhwYzgBefBj6Y_I0aV0qET3YFsek9aNqucnz6eOojyTHsxwwaYmhQvURBCvojM937VRRnlPOlj4TG6-I-iiE2IZbqhdnTocLxZooNP2fHLE6NpwEhAJkSVwbnk_N3GDRhwmiSHwN9BKD0_nTdc9io1j4yemuKr0qlVkNj0aVYg9trf38=&uniplatform=NZKPT&language=CHS (accessed on 21 September 2025).

- Yuan, Z.; Liu, P.; Gao, Y.; Wang, C. Experimental study on blocking mechanism of nitrogen foam for enhancing oil recovery in heavy oil reservoirs. Energy Sources Part A Recovery Util. Environ. Eff. 2018, 40, 1947–1955. [Google Scholar] [CrossRef]

- Tang, X.; Yang, L.; Liu, Y.; Li, Z.; Li, Y.; Wei, F. A new in-depth fluid diverting agent of inorganic gel coating. Pet. Explor. Dev. 2012, 39, 82–87. [Google Scholar] [CrossRef]

- He, Y.; Li, X.; Shao, Y.; Du, M. Application of Hybrid Polymer Containing POSS as High-Temperature-and High-Salt-Resistant Fluid Loss Additive in Water-Based Drilling Fluids. Energy Fuels 2024, 38, 10019–10031. [Google Scholar] [CrossRef]

- Wu, Y.; Hou, S.; You, F. Research progress of polymer nanocomposites in water-based drilling fluids. Oilfield Chem. 2024, 41, 543–552. [Google Scholar] [CrossRef]

- Luo, Y.; Lin, L.; Guo, C.; Yang, Y.; Xiong, G.; Ren, R.; Qu, Y. Advances in the application of nanomaterials in high temperature resistant drilling fluids. Chem. Prog. 2022, 41, 4895–4906. [Google Scholar] [CrossRef]

- Gautam, S.; Guria, C.; Rajak, V.K. A state of the art review on the performance of high-pressure and high-temperature drilling fluids: Towards understanding the structure-property relationship of drilling fluid additives. J. Pet. Sci. Eng. 2022, 213, 110318. [Google Scholar] [CrossRef]

- Sun, J.; Bai, Y.; Cheng, R.; Lu, K.; Liu, F.; Feng, J.; Lei, S.; Zhang, J.; Hao, H. Progress and Prospect of Research on Plugging Technology for Fractured Malignant Well Leakage Formation. Oil Explor. Dev. 2021, 48, 630–638. [Google Scholar]

- Xu, Z.; Sun, J.; Li, L.; Lv, K.; Liu, J.; Dai, Z.; Zhang, X.; Wang, Z. Development and performance evaluation of a high temperature resistant, internal rigid, and external flexible plugging agent for water-based drilling fluids. Petroleum 2023, 9, 33–40. [Google Scholar] [CrossRef]

- Huang, X.; Meng, X.; Lv, K.; Zhang, Z.; Cao, L.; Wang, R.; Feng, J.; Wu, Y.; Sheng, W. Development of a high temperature resistant nano-plugging agent and the plugging performance of multi-scale micropores. Colloids Surf. A Physicochem. Eng. Asp. 2022, 639, 128275. [Google Scholar] [CrossRef]

- Qassem, A.; Zainab, A.; Abdullah, A.-S.; Abdullah, A. Innovative Nanotechnology for Enhancing Bridging System Supports Stabilizing Drilling Deep Formations. In Proceedings of the Mediterranean Offshore Conference, Alexandria, Egypt, 20–22 October 2024. [Google Scholar] [CrossRef]

- Dai, C.; Chen, W.; You, Q.; Wang, H.; Yang, Z.; He, L.; Jiao, B.; Wu, Y. A novel strengthened dispersed particle gel for enhanced oil recovery application. J. Ind. Eng. Chem. 2016, 41, 175–182. [Google Scholar] [CrossRef]

- Bai, Y.; Pu, W.; Jin, X.; Ren, H. Synthesis and characterization of in-situ self-growth mineralization-responsive dispersed gel nanoparticles. J. Mol. Liq. 2024, 394, 123767. [Google Scholar] [CrossRef]

- Park, Y.; Huh, C.; Ok, J.; Cho, H. One-Step Synthesis and Functionalization of High-Salinity-Tolerant Magnetite Nanoparticles with Sulfonated Phenolic Resin. Langmuir 2019, 35, 8769–8775. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Wang, K.; Xian, L.; Su, Y. Carboxylated cellulose nanocrystals as environmental-friendly and multi-functional additives for bentonite water-based drilling fluids under high-temperature conditions. Cellulose 2022, 29, 6659–6675. [Google Scholar] [CrossRef]

- Xu, B.; Lv, D.; Zhou, D.; Sun, N.; Lu, S.; Dai, C.; Zhao, G.; Shi, M. Potential application of wet-phase modified expandable graphite particles as a novel in-depth profile control agent in carbonate reservoirs. Pet. Sci. 2024, 21, 4153–4164. [Google Scholar] [CrossRef]

- Liu, H.; Wang, Y.; Zheng, A.; Sun, X.; Dong, X.; Li, D.; Zhang, Q. Experimental investigation on improving steam sweep efficiency by novel particles in heavy oil reservoirs. J. Pet. Sci. Eng. 2020, 193, 107429. [Google Scholar] [CrossRef]

- Wang, D.; Qin, H.; Wang, Y.; Hu, J.; Sun, D.; Yu, B. Experimental study of the temporary plugging capability of diverters to block hydraulic fractures in high-temperature geothermal reservoirs. Pet. Sci. 2023, 20, 3687–3699. [Google Scholar] [CrossRef]

- Hou, J.; Wen, Y.; Qu, M.; Wu, W.; Zhang, W.; Ding, Y. Research and Application of Nanomaterials for Enhanced Oil and Gas Recovery Technology. Spec. Reserv. 2020, 27, 47–53. [Google Scholar]

- Liu, D.; Kang, Y.; Lei, M.; Li, D.; Liu, Y. Advances in shielding and temporary plugging technology for protecting carbonate reservoirs. Drill. Complet. Fluids 2008, 5, 57–61+88. [Google Scholar]

- Mao, H. Research on well leakage and plugging materials in geological drilling. Northwest Geol. 2010, 43, 141–146. [Google Scholar]

- Persiani, S.G.; Persiani, S.G. Materials of Autoreaction. In Design of Autoreaction: A Framework for Kinetic Reaction at Zero Energy; Springer Nature: Berlin/Heidelberg, Germany, 2020; pp. 115–155. [Google Scholar]

- Tu, H.; Aviles, I.; Dardis, M. Degradable Materials for Multi-Stage Stimulation. In Proceedings of the Offshore Technology Conference (OTC), Houston, TX, USA, 6 March 2019; p. D021S021R007. [Google Scholar]

- Lyu, S.; Wang, S.; Chen, X.; Shah, S.M.; Li, R.; Xiao, Y.; Dong, Q.; Gu, Y. Experimental study of a degradable polymer drilling fluid system for coalbed methane well. J. Pet. Sci. Eng. 2019, 178, 678–690. [Google Scholar] [CrossRef]

- Hassan, A.M.; Al-Shalabi, E.W.; Ayoub, M.A. Updated perceptions on polymer-based enhanced oil recovery toward high-temperature high-salinity tolerance for successful field applications in carbonate reservoirs. Polymers 2022, 14, 2001. [Google Scholar] [CrossRef]

- Pan, Y.; Cui, X.; Wang, H.; Lou, X.; Yang, S.; Oluwabusuyi, F.F. Research Progress of Intelligent Polymer Plugging Materials. Molecules 2023, 28, 2975. [Google Scholar] [CrossRef]

- Zhu, D.; Fang, X.; Sun, R.; Xu, Z.; Liu, Y.; Liu, J. Development of degradable pre-formed particle gel (DPPG) as temporary plugging agent for petroleum drilling and production. Pet. Sci. 2021, 18, 479–494. [Google Scholar] [CrossRef]

- Yang, S.; Wang, H.; Wang, Y. Temperature-sensitive materials for oil and gas drilling applications. Molecules 2024, 29, 1471. [Google Scholar] [CrossRef]

- Liu, C.; Zou, H.; Wang, Y.; Zhu, M.; Su, G.; Huang, Z.; Yu, X.; Yang, H. Degradation behavior and mechanism of P (AM/AA/AMPS)@ PLA core-shell self-degrading temporary plugging agent. J. Mol. Liq. 2024, 393, 123656. [Google Scholar] [CrossRef]

- Yang, F.; Liu, J.; Ji, R.; Yu, X.; Yang, H.; Su, G. Degradable Gel for Temporary Plugging in High Temperature Reservoir and Its Properties. Gels 2024, 10, 445. [Google Scholar] [CrossRef] [PubMed]

- Cai, J.; Wu, X.; Gu, S. Research on Environmentally Safe Temporary Plugging Drilling Fluid in Water Well Drilling. In Proceedings of the SPE Asia Pacific Health, Safety, Security, Environment and Social Responsibility Symposium, Jakarta, Indonesia, 4–6 August 2009; p. SPE-122437. [Google Scholar]

- Zhang, Z.; Sun, L.; Huo, X.; Liu, X. Bioinspired Self-Assembly Polymer Based on Nucleobase for Enhanced Oil Recovery. J. Polym. Environ. 2024, 32, 5406–5421. [Google Scholar] [CrossRef]

- Ruginescu, R.; Purcarea, C. Plastic-Degrading Enzymes from Marine Microorganisms and Their Potential Value in Recycling Technologies. Mar. Drugs 2024, 22, 441. [Google Scholar] [CrossRef]

- Guo, Y.; Yan, G.; Huang, Y.; LI, L.; Jiang, G.; Deng, Z. Development and evaluation of high-temperature gel-forming degradable polymer gel plugging agent. Drill. Complet. Fluids 2019, 36, 293–297. [Google Scholar]

- Ye, C.; Qiu, Z.; Chen, X.; Zhong, H.; Zhao, X.; Stormy, D. Evaluation of new self-degradable plugging agent for sealing cracks and protecting reservoir properties. Drill. Complet. Fluids 2020, 37, 731–736. [Google Scholar]

- Luo, M.; Feng, Y.; Gui, Y.; Deng, J.; Han, C. Development Status and Prospect of High Temperature and High Pressure Drilling Key Technology. Pet. Sci. Bull. 2021, 6, 228–244. [Google Scholar]

- Wang, H.; Huang, H.; JI, G.; Chen, C.; LU, Z.; Chen, W.; BI, W.; Liu, L. Progress and Challenges of Drilling and Completion Technologies for Deep, Ultra-Deep and Horizontal Wells in China’s Petroleum Industry. China Oil Explor. 2023, 28, 1–11. [Google Scholar]

- Lu, B. New Progress and Development Suggestions for Petroleum Engineering Technology in Sinopec. Oil Drill. Technol. 2021, 49, 1–10. [Google Scholar]

- Lei, Q.; Xu, Y.; Yang, Z.; Cai, B.; Wang, X.; Zhou, L.; Liu, H.; Xu, M.; Wang, L.; Li, S. Progress and Development Direction of Ultra-deep Oil and Gas Reservoir Rehabilitation Technology. Oil Explor. Dev. 2021, 48, 193–201. [Google Scholar]

- Liu, Y.; Chen, R.; Liu, J.; Yu, Y.; Zhu, K. Development and field application of strongly resilient temporary plugging diversion agent for fracturing. J. Pet. Explor. Prod. Technol. 2024, 14, 2073–2088. [Google Scholar] [CrossRef]

- Xiong, C.; Shi, Y.; Zhou, F.; Liu, X.; Yang, X.; Yang, X. High efficiency reservoir stimulation based on temporary plugging and diverting for deep reservoirs. Pet. Explor. Dev. 2018, 45, 948–954. [Google Scholar] [CrossRef]

- Pu, L.; Xu, P.; Xu, M.; Song, J.; He, M. Lost circulation materials for deep and ultra-deep wells: A review. J. Pet. Sci. Eng. 2022, 214, 110404. [Google Scholar] [CrossRef]

- Ma, C.; Song, B.; Xu, T.; Peng, F.; Song, T.; Liu, Z. Research Progress of Nano Blocking Agent for Drilling Fluids. Drill. Complet. Fluids 2017, 34, 1–8. [Google Scholar]

- Chen, F.; Tian, F.; Li, B.; Wang, Y.; Hao, G. Nanoscale blocking agents and their applications. Drill. Complet. Fluids 2014, 31, 71–74+100–101. [Google Scholar]

- Liu, H.; Li, L.; Zheng, J.; Sun, G. Silicate chemical water plugging technology research status and outlook. Oilfield Chem. 2015, 32, 146–150. [Google Scholar] [CrossRef]

- Han, C.; Huang, K.; Luo, M.; Liu, X.; Deng, W. Plugging Technology for High Temperature and High Pressure Wells in Yingqiong Basin, South China Sea. Oil Drill. Technol. 2019, 47, 15–20. [Google Scholar]

- Liu, Y.; Ren, Y.; Dong, H.; Chen, C.; Liu, X.; Lei, Y.; Xiao, X.; Wang, L. High-Strength Thermally Activated Shape-Adaptive Plugging Hydrogels with Plastic Semicrystalline Metallosupramolecular Polymer Networks. ACS Appl. Polym. Mater. 2024, 6, 10478–10487. [Google Scholar] [CrossRef]

- Kashfipour, M.; Mehra, N.; Zhu, J. A review on the role of interface in mechanical, thermal, and electrical properties of polymer composites. Adv. Compos. Hybrid Mater. 2018, 1, 415–439. [Google Scholar] [CrossRef]

- Han, J.; Wang, J.; Yang, W.; Wang, X.; Wang, R.; Zhu, S.; Li, T. Experimental study on the properties of a polymer-modified superfine cementitious composite material for waterproofing and plugging. Case Stud. Constr. Mater. 2023, 19, e02552. [Google Scholar] [CrossRef]

- Khan, A.; Sapuan, S.; Zainudin, E.; Zuhri, M. Physical, Mechanical and Thermal Properties of Novel Bamboo/Kenaf Fiber-Reinforced Polylactic Acid (PLA) Hybrid Composites. Compos. Commun. 2024, 51, 102103. [Google Scholar] [CrossRef]

- Leong, G.W.; Mo, K.; Loh, Z.P.; Ibrahim, Z. Mechanical properties and drying shrinkage of lightweight cementitious composite incorporating perlite microspheres and polypropylene fibers. Constr. Build. Mater. 2020, 246, 118410. [Google Scholar] [CrossRef]

- Gonçalves, F.; Kawano, Y.; Braga, R.R. Contraction stress related to composite inorganic content. Dent. Mater. Off. Publ. Acad. Dent. Mater. 2010, 26, 704–709. [Google Scholar] [CrossRef]

- Sassoni, E.; Manzi, S.; Motori, A.; Montecchi, M.; Canti, M. Novel sustainable hemp-based composites for application in the building industry: Physical, thermal and mechanical characterization. Energy Build. 2014, 77, 219–226. [Google Scholar] [CrossRef]

- Wang, Z.; Liu, Y.; Huang, W.; Yang, X.; Liu, Z.; Zhang, X. Preparation and Performance Evaluation of a Plugging Agent with an Interpenetrating Polymer Network. Gels 2023, 9, 205. [Google Scholar] [CrossRef]

- Patra, S.C.; Swain, S.; Senapati, P.; Sahu, H.; Murmu, R.; Sutar, H. Polypropylene and Graphene Nanocomposites: Effects of Selected 2D-Nanofiller’s Plate Sizes on Fundamental Physicochemical Properties. Inventions 2022, 8, 8. [Google Scholar] [CrossRef]

- Feng, D.; He, X.; Dong, S.; Yang, Z.; Zhang, L.; Zhu, S. Study on the polymerization shrinkage and mechanical-physical properties of dental resin composite modified by polyurethane dimechacrylate and glass flake fillers: Short title: Aging resistance for dental resin composites with low shrinkage. J. Dent. 2024, 151, 105426. [Google Scholar] [CrossRef]

- Leprince, J.; Palin, W.; Mullier, T.; Devaux, J.; Vreven, J.; Leloup, G. Investigating filler morphology and mechanical properties of new low-shrinkage resin composite types. J. Oral Rehabil. 2010, 37, 364–376. [Google Scholar] [CrossRef]

- Tang, L.; Wang, T.; Song, H.; Xu, M.; Xu, Y.; Wang, Y. A temperature-sensitive plugging material composed of shape memory polymer and self-made gel. Mater. Res. Express 2023, 10, 065701. [Google Scholar] [CrossRef]

- Barbaros, I.; Yang, Y.-M.; Safaei, B.; Yang, Z.; Qin, Z.-Y.; Asmael, M.B.A. State-of-the-art review of fabrication, application, and mechanical properties of functionally graded porous nanocomposite materials. Nanotechnol. Rev. 2022, 11, 321–371. [Google Scholar] [CrossRef]

- Shibasaki, S.; Takamizawa, T.; Nojiri, K.; Imai, A.; Tsujimoto, A.; Endo, H.; Suzuki, S.; Suda, S.; Barkmeier, W.; Latta, M.; et al. Polymerization Behavior and Mechanical Properties of High-Viscosity Bulk Fill and Low Shrinkage Resin Composites. Oper. Dent. 2017, 42, E177–E187. [Google Scholar] [CrossRef] [PubMed]

- Dijvejin, Z.A.; Ghaffarkhah, A.; Sadeghnejad, S.; Sefti, M.V. Effect of silica nanoparticle size on the mechanical strength and wellbore plugging performance of SPAM/chromium (III) acetate nanocomposite gels. Polym. J. 2019, 51, 693–707. [Google Scholar] [CrossRef]

- Cazan, C.; Enesca, A.; Andronic, L. Synergic Effect of TiO2 Filler on the Mechanical Properties of Polymer Nanocomposites. Polymers 2021, 13, 2017. [Google Scholar] [CrossRef] [PubMed]

- Ibrahim, A.; Klopocinska, A.; Horvat, K.; Hamid, A. Graphene-Based Nanocomposites: Synthesis, Mechanical Properties, and Characterizations. Polymers 2021, 13, 2869. [Google Scholar] [CrossRef] [PubMed]

- Malashin, I.; Tynchenko, V.; Nelyub, V.; Borodulin, A.; Gantimurov, A. Estimation and Prediction of the Polymers’ Physical Characteristics Using the Machine Learning Models. Polymers 2023, 16, 115. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, E. Study on the Gelation Process and Mechanical Properties of Organic Polymer Grouting Materials Applied to Fissure Sealing in Underground Mines. Polymers 2024, 16, 446. [Google Scholar] [CrossRef]

- Papageorgiou, D.; Kinloch, I.; Young, R. Mechanical properties of graphene and graphene-based nanocomposites. Prog. Mater. Sci. 2017, 90, 75–127. [Google Scholar] [CrossRef]

- Abdeltawab, H.; Svirskis, D.; Sharma, M. Formulation strategies to modulate drug release from poloxamer based in situ gelling systems. Expert Opin. Drug Deliv. 2020, 17, 495–509. [Google Scholar] [CrossRef] [PubMed]

- Douglas, J. Weak and Strong Gels and the Emergence of the Amorphous Solid State. Gels 2018, 4, 19. [Google Scholar] [CrossRef] [PubMed]

- Taylor, M.; Tomlins, P.; Sahota, T. Thermoresponsive Gels. Gels 2017, 3, 4. [Google Scholar] [CrossRef]

| Property | Polymer Materials [101,102,103,104,105] | Inorganic Composite Materials [106,107,108] | Nanocomposite Materials [109,110,111,112,113,114,115,116,117,118,119,120] |

|---|---|---|---|

| Density (g/cm3) | 1.0–1.2 | 1.5–2.2 | 1.1–1.8 |

| Mechanical Strength | Elastic Modulus: 102–104 Pa Compressive Strength: 10–60 MPa | Compressive Strength: 20–80 MPa | Compressive Strength: 30–100 MPa Storage Modulus (G’): 102–105 Pa |

| Shrinkage/Coefficient of Expansion | ~70–200 × 10−6/K | ~5–15 × 10−6/K | ~20–100 × 10−6/K |

| Heat Capacity (J/g·K) | ~1.5–2.5 | ~0.8–1.2 | ~1.0–2.0 |

| Max. Service Temperature (°C) | 120–200 | 200–400+ | 150–300+ |

| Salinity Tolerance (TDS) | Moderate to High | Very High | Very High |

| Degradability/Removability | Good to Excellent | Poor | Good |

| Material Type | Advantages | Disadvantages |

|---|---|---|

| Gel Materials | Tunable properties, Self-healing, Enhanced by hybrid systems, multifunctional [121] | Limited robustness, Sensitive to stress |

| Non-Gel Materials | Strong, durable, stable for structure [122] | Not self-healing, lacks adaptability, Limited biocompatibility |

| (Resins, Cements) | Good for long-term sealing [123] | Fewer functions, not responsive |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fang, J.; Xue, P.; Wang, B.; Sun, J.; Bai, Y.; Lv, K.; Zhang, Y. Advances and Future Prospects of Temperature and Salt-Resistant Gel Materials for Downhole Plugging Applications. Gels 2025, 11, 955. https://doi.org/10.3390/gels11120955

Fang J, Xue P, Wang B, Sun J, Bai Y, Lv K, Zhang Y. Advances and Future Prospects of Temperature and Salt-Resistant Gel Materials for Downhole Plugging Applications. Gels. 2025; 11(12):955. https://doi.org/10.3390/gels11120955

Chicago/Turabian StyleFang, Junwei, Peng Xue, Biao Wang, Jinsheng Sun, Yingrui Bai, Kaihe Lv, and Yi Zhang. 2025. "Advances and Future Prospects of Temperature and Salt-Resistant Gel Materials for Downhole Plugging Applications" Gels 11, no. 12: 955. https://doi.org/10.3390/gels11120955

APA StyleFang, J., Xue, P., Wang, B., Sun, J., Bai, Y., Lv, K., & Zhang, Y. (2025). Advances and Future Prospects of Temperature and Salt-Resistant Gel Materials for Downhole Plugging Applications. Gels, 11(12), 955. https://doi.org/10.3390/gels11120955