Direct Ink Writing Additive Manufacturing of Polyimide Aerogels

Abstract

1. Introduction

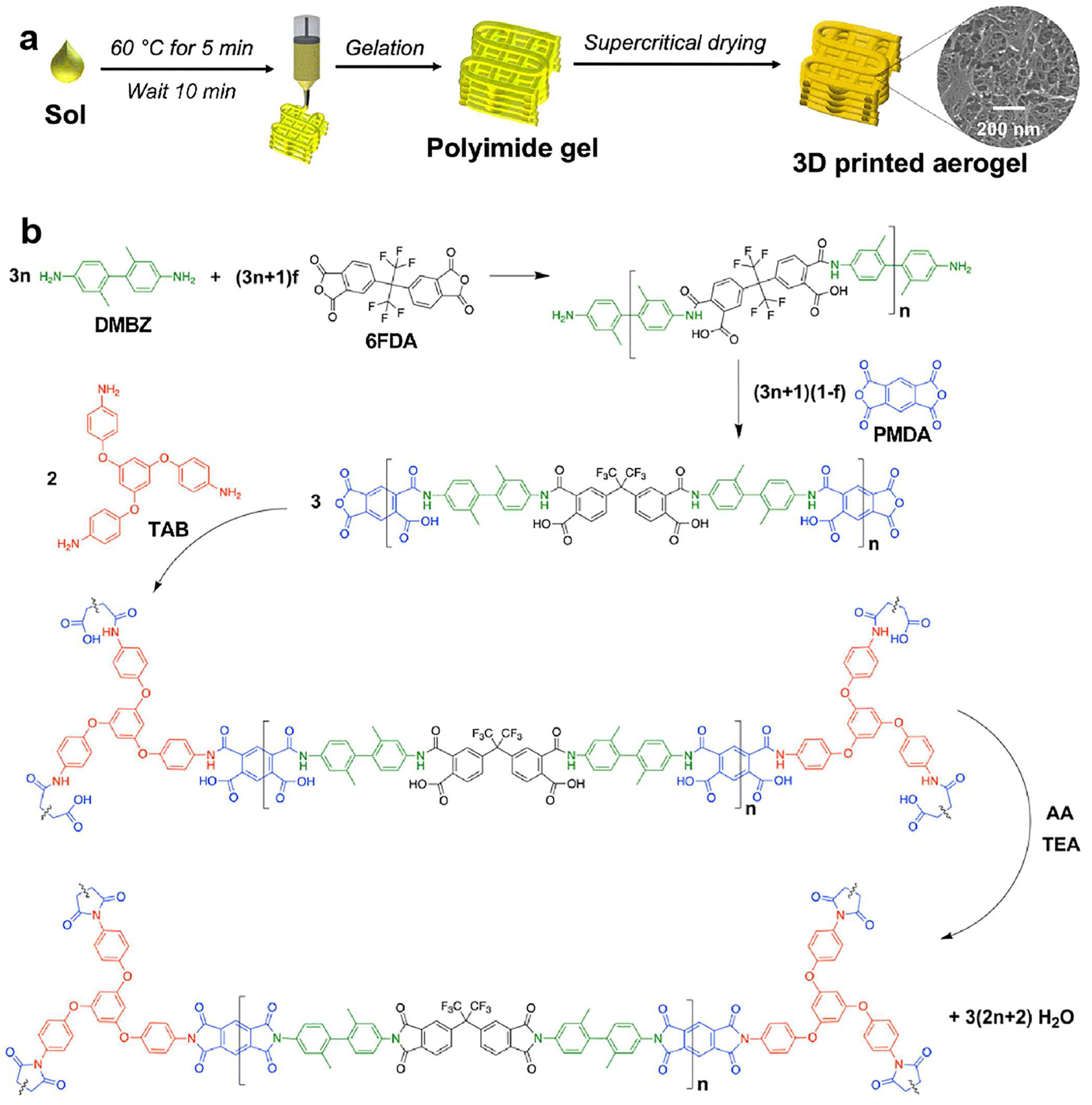

2. DIW 3D Printing of PAs

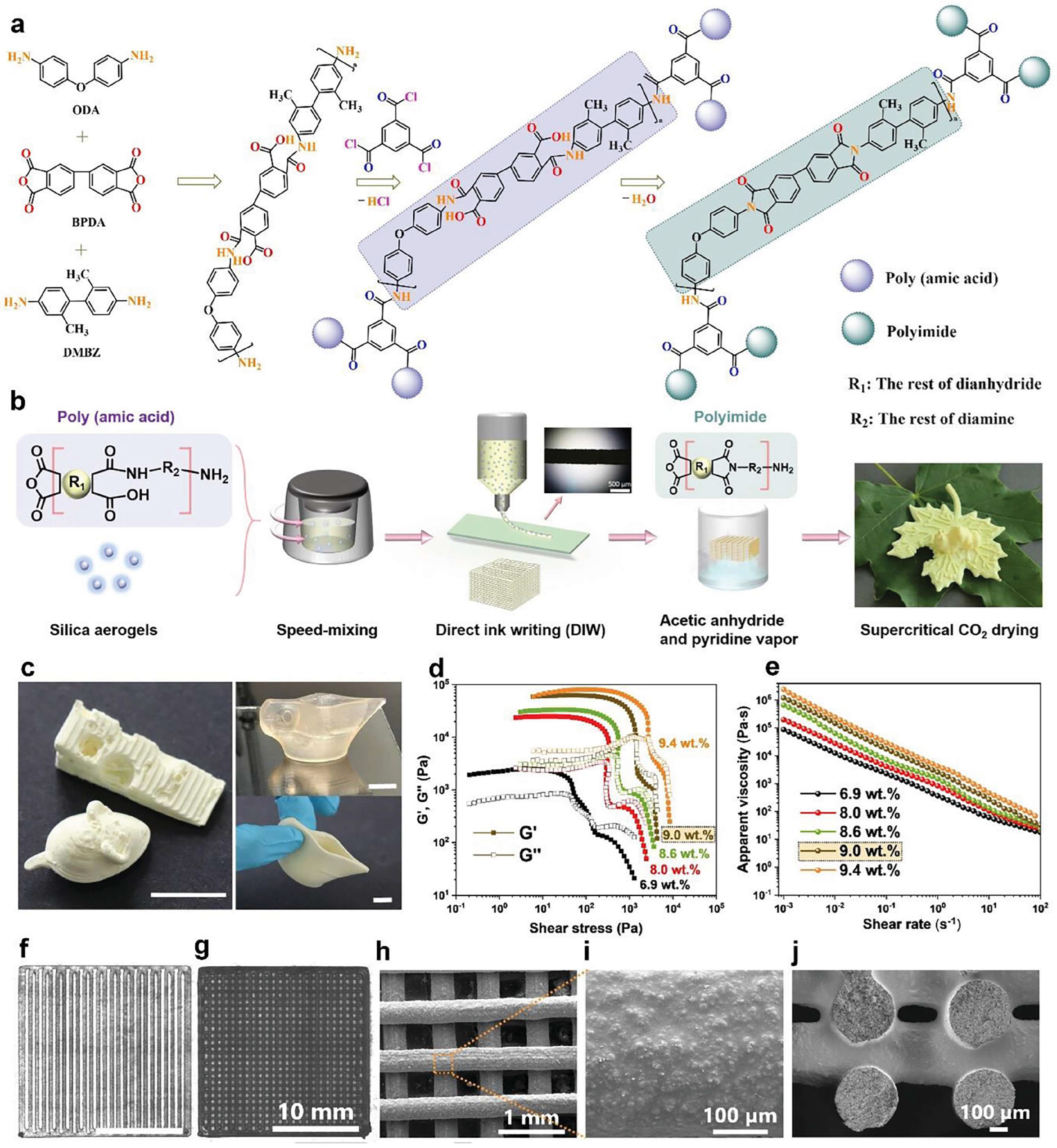

2.1. Preparation and Composition of PAs Ink Formulations

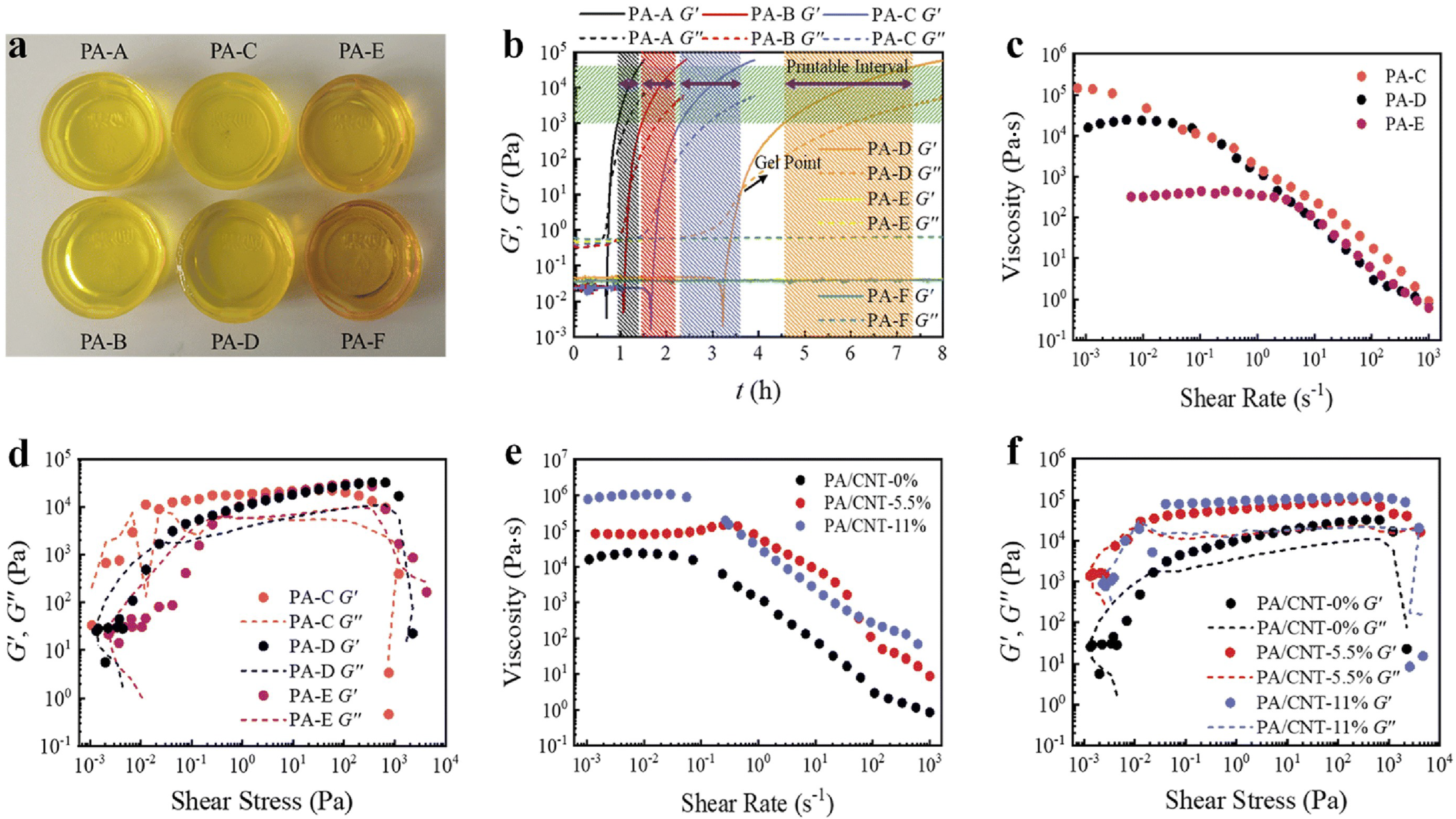

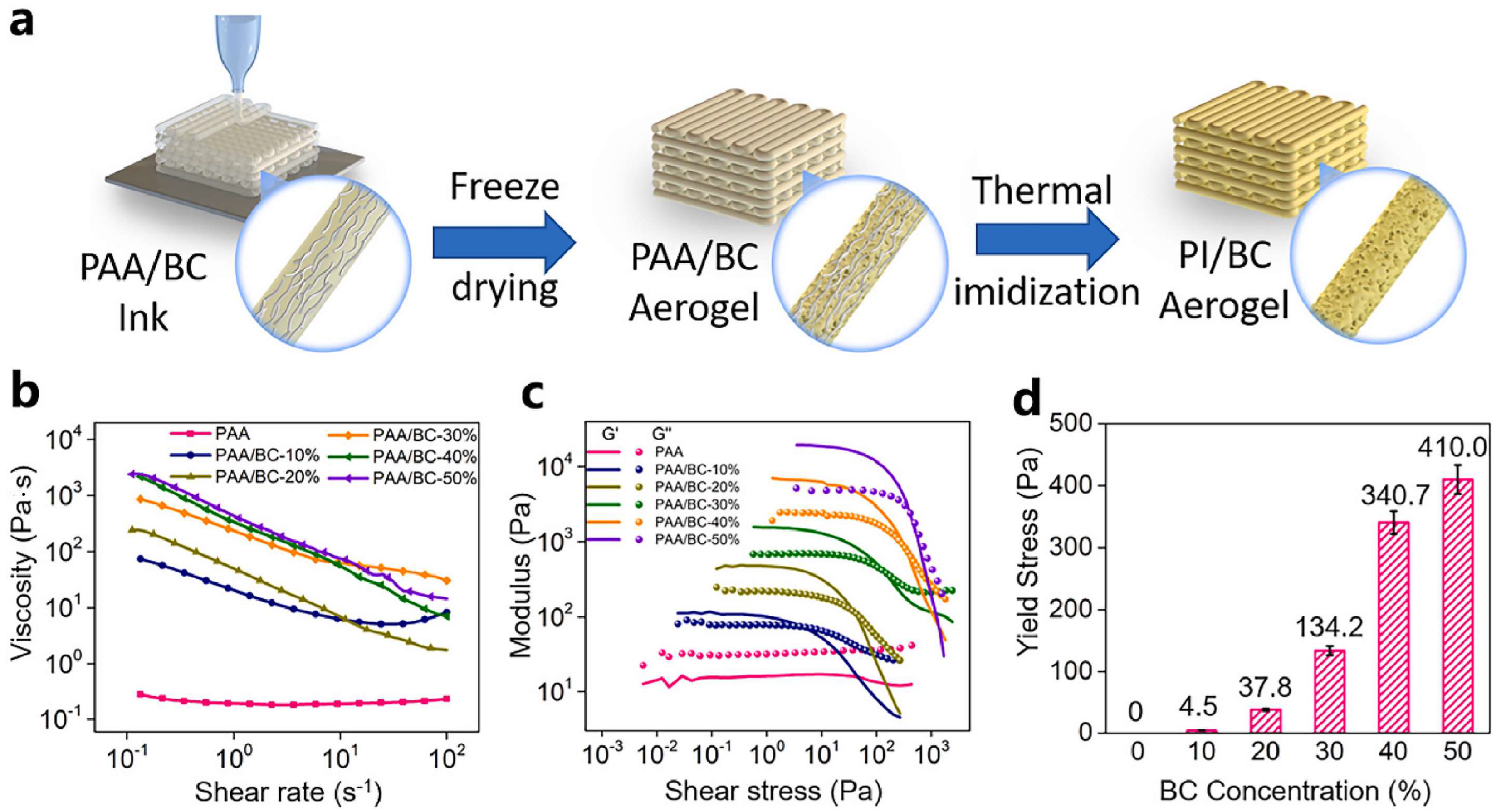

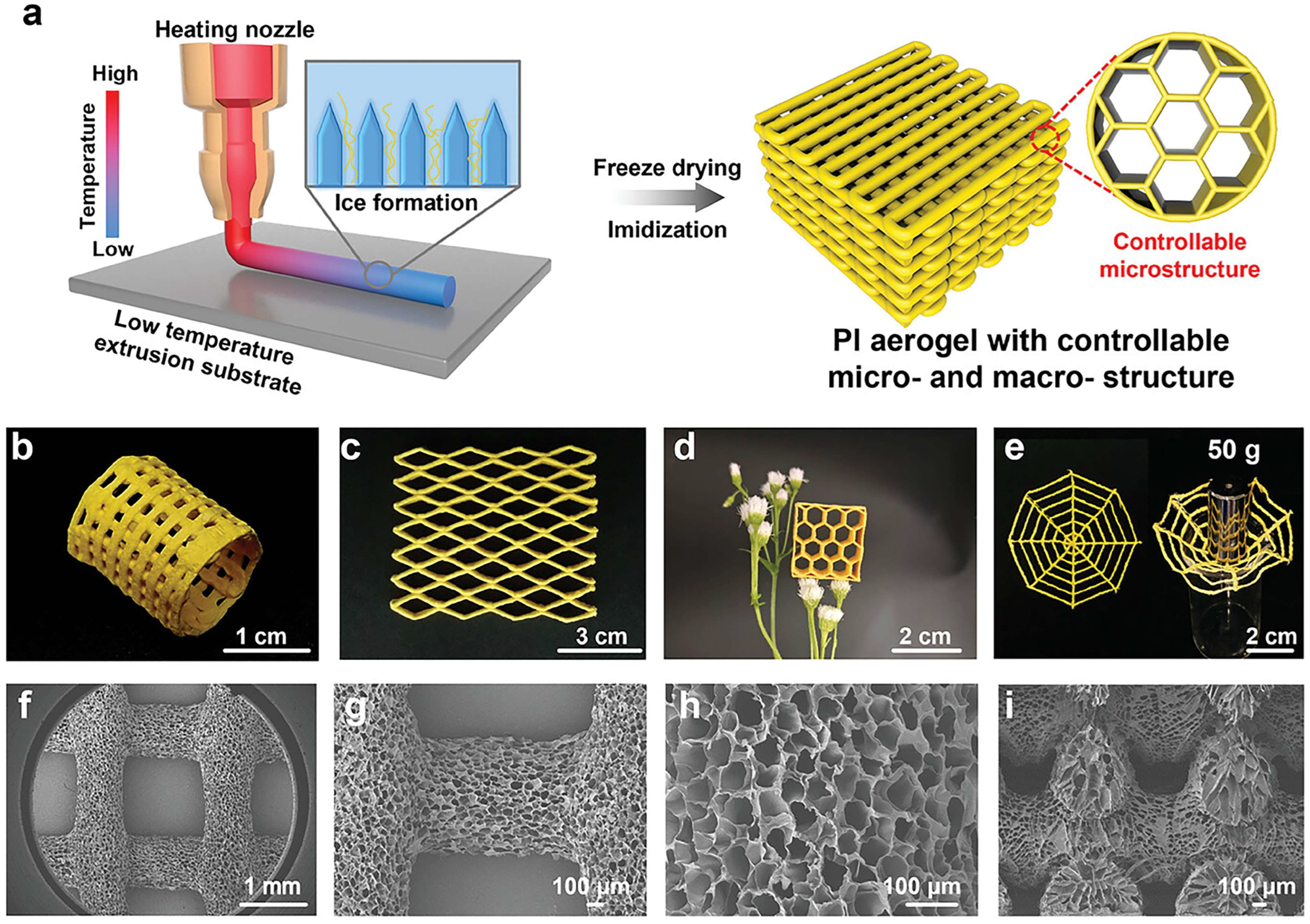

2.2. Requirements for the Rheological Properties of Inks

2.3. Ink Preparation Processes for Printed PAs

3. Applications of DIW 3D-Printed PAs

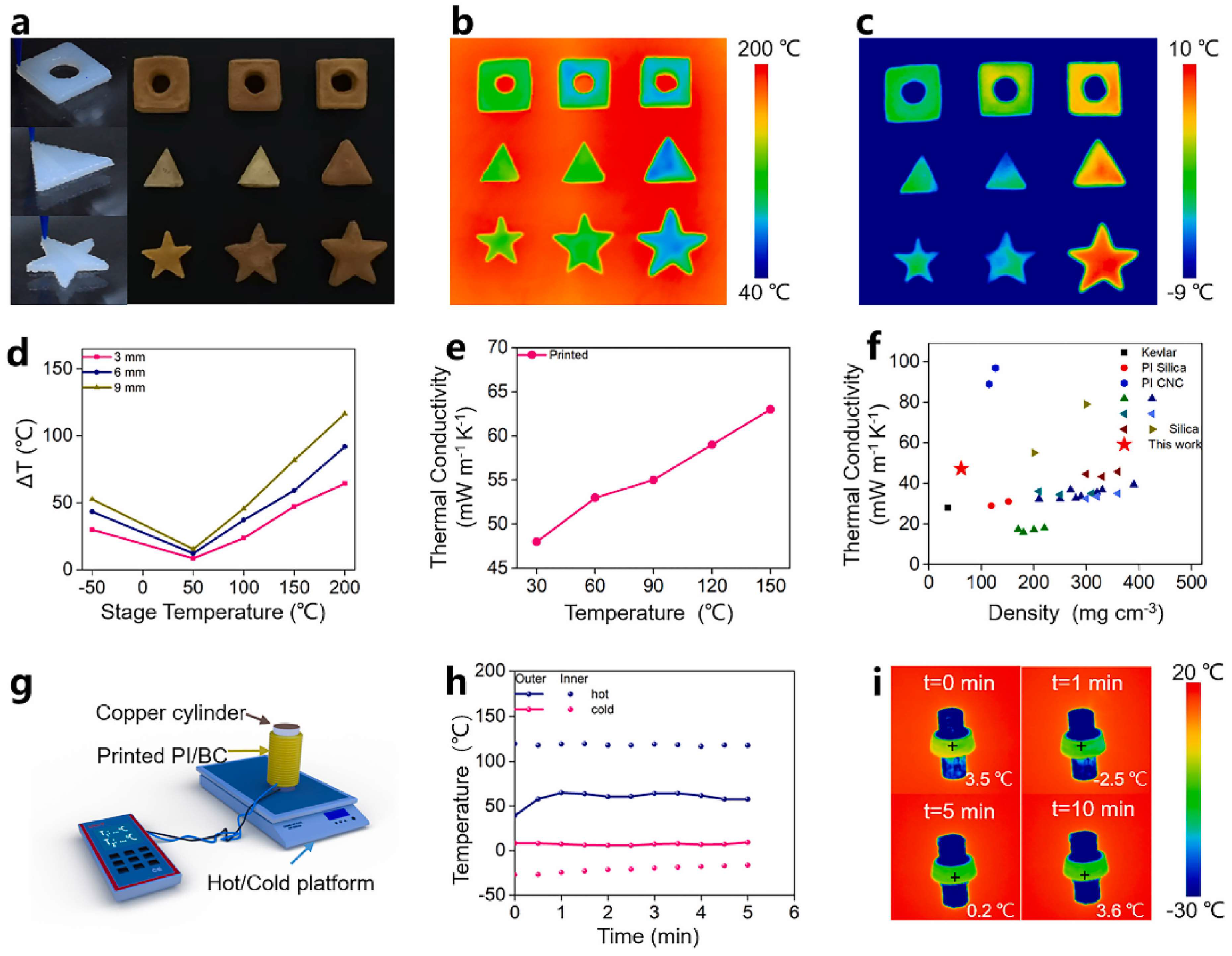

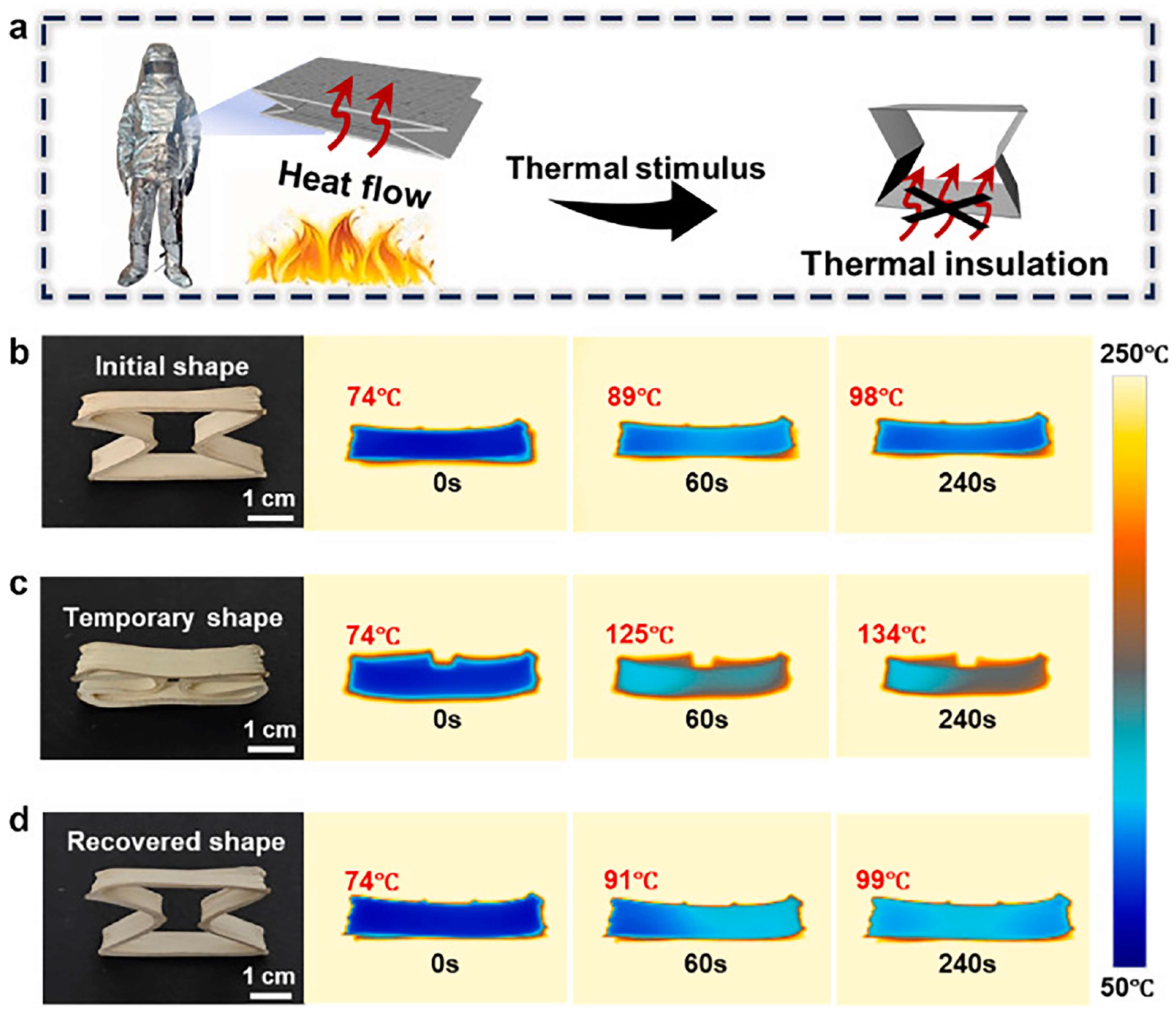

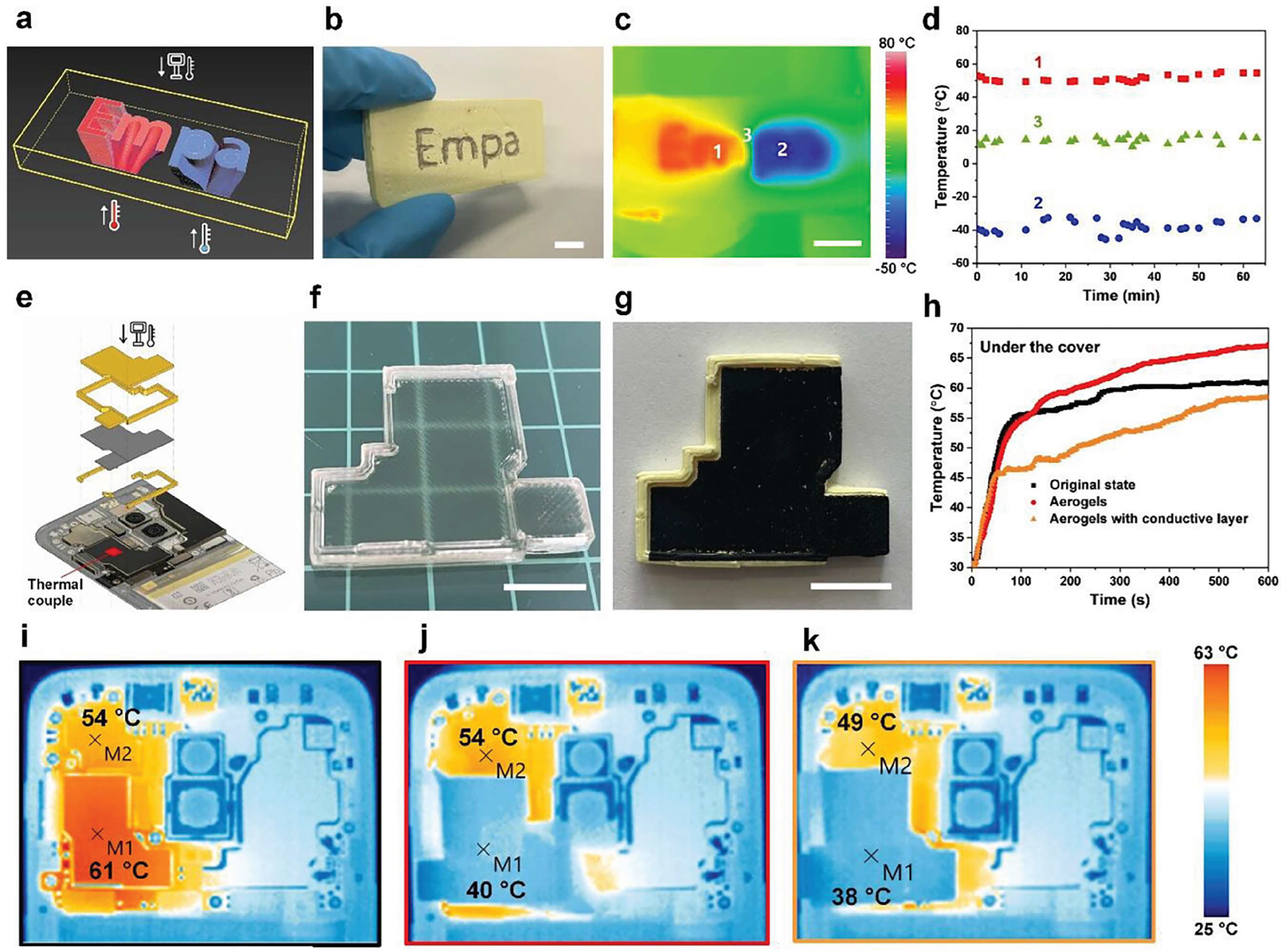

3.1. Thermal Management

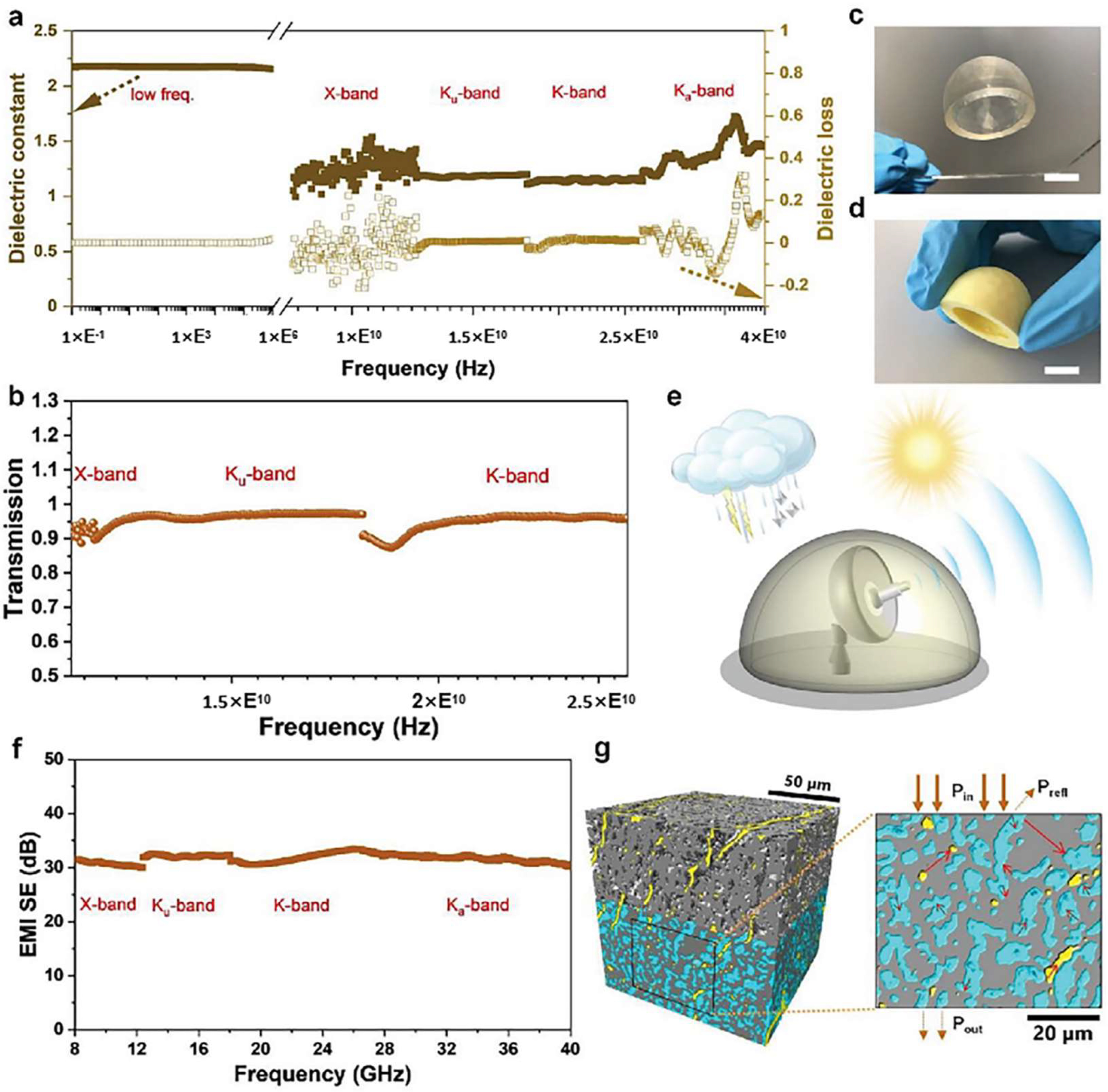

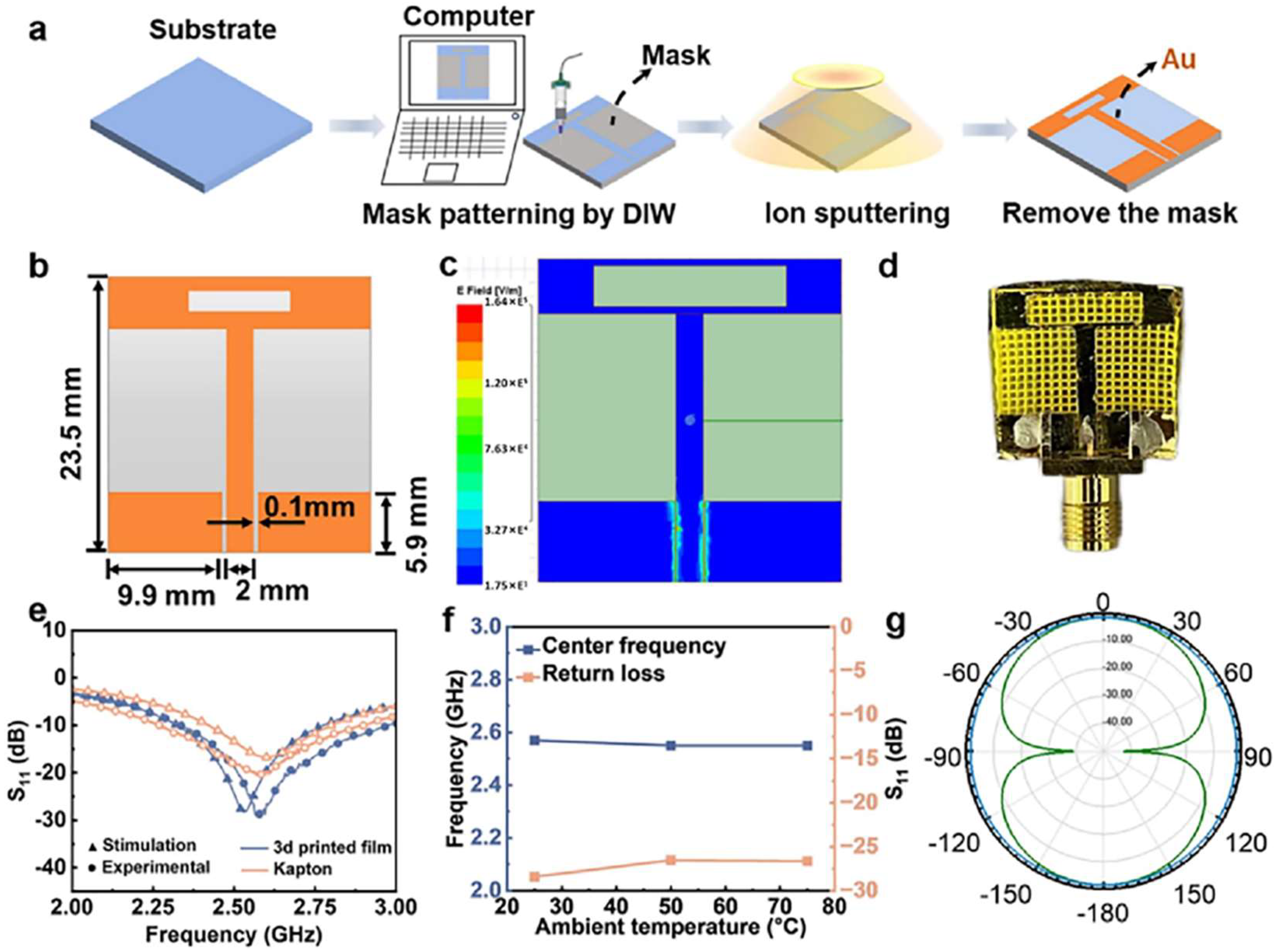

3.2. EMI Shielding and Dielectric Substrates

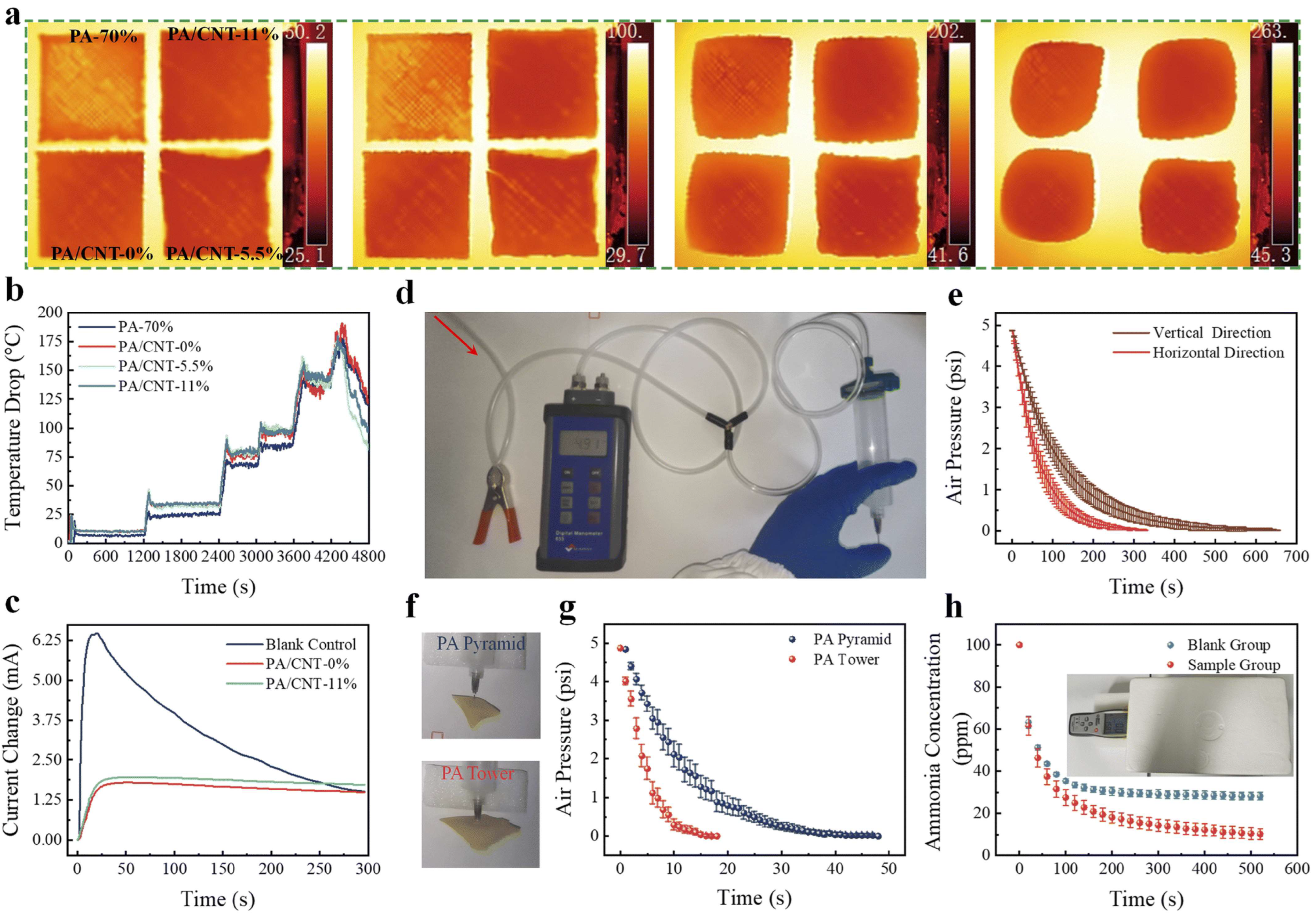

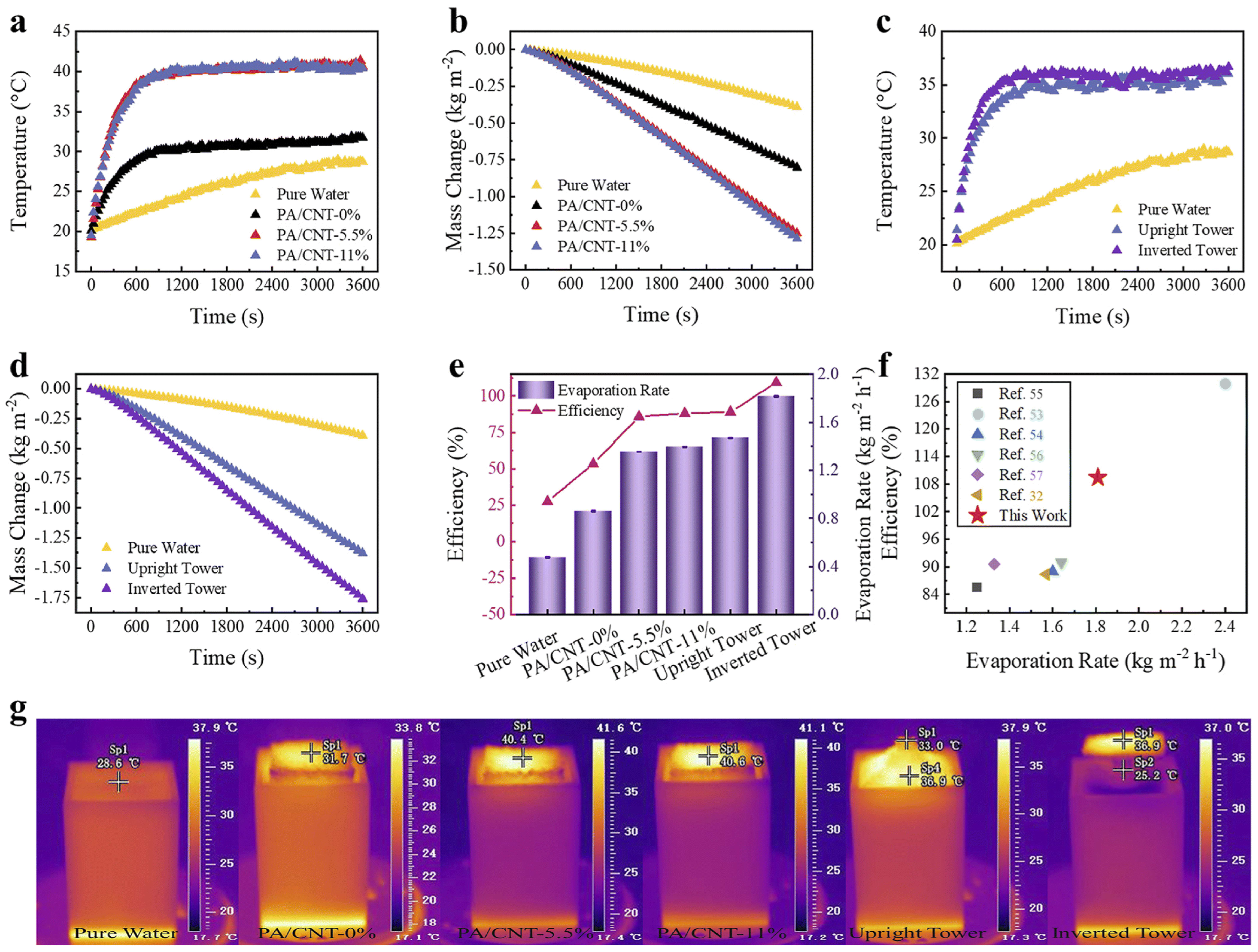

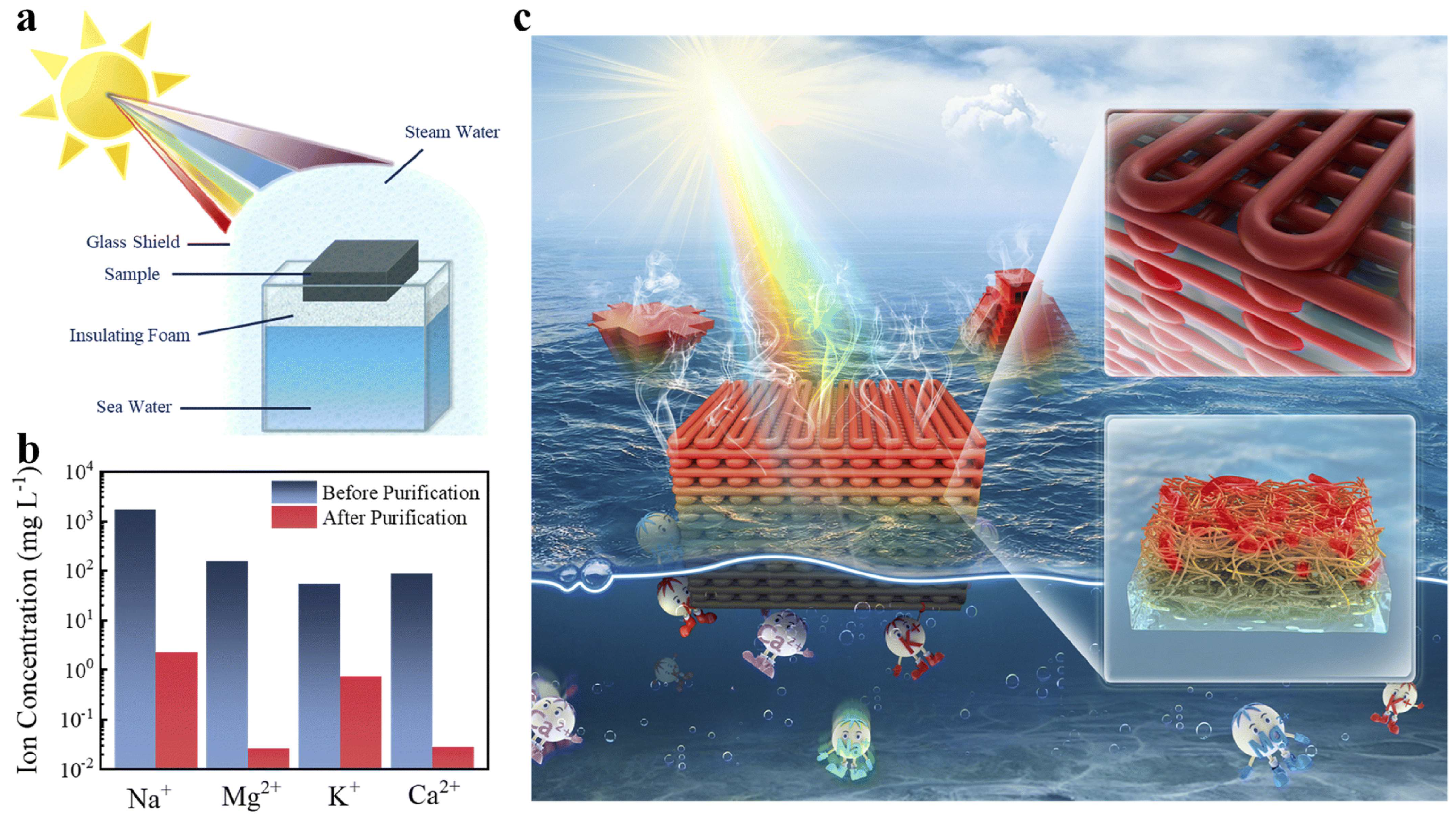

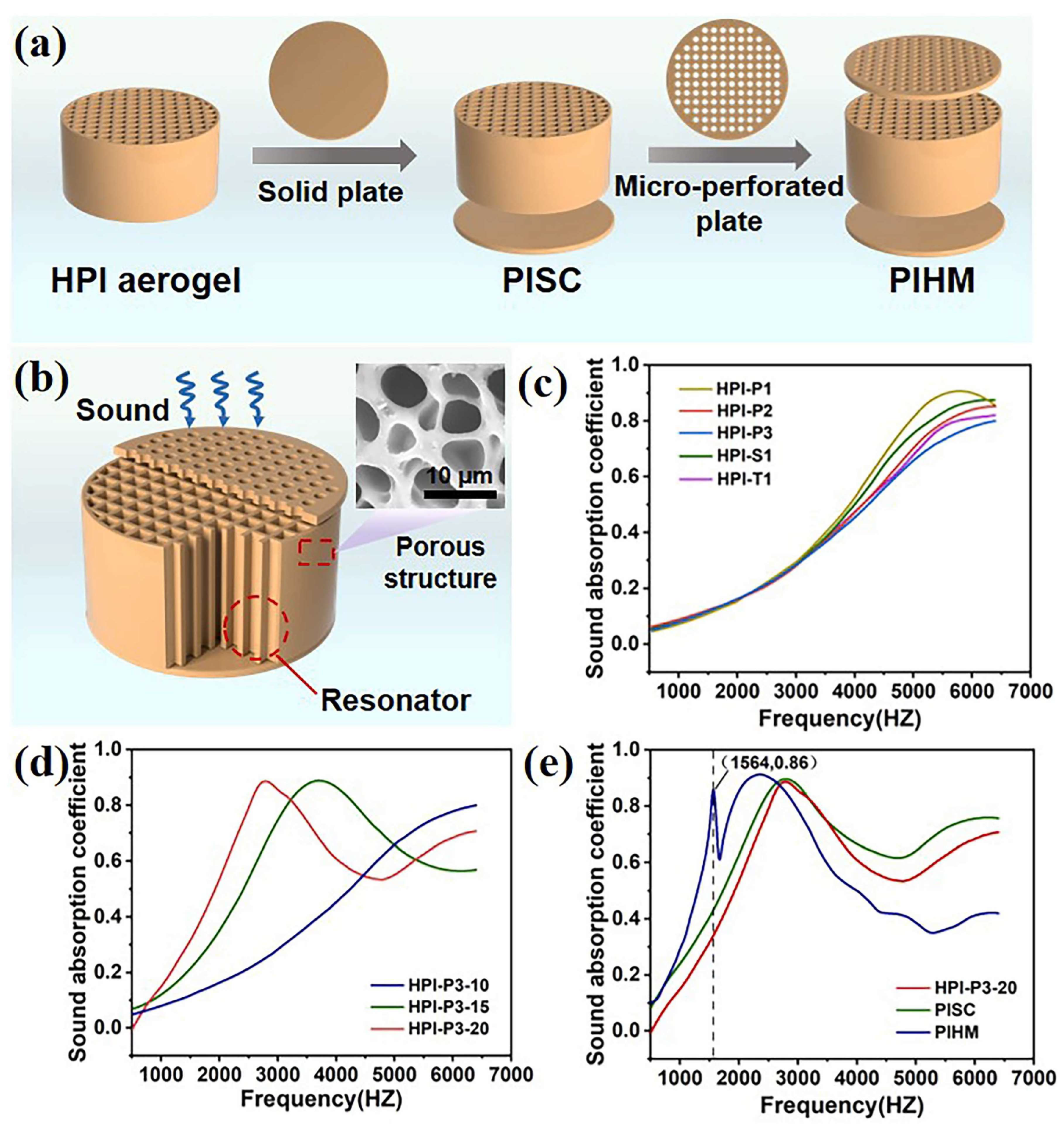

3.3. Gas Permeability, Photothermal Conversion, Adsorption and Acoustic

4. Summary and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kistler, S.S. Coherent expanded aerogels and jellies. Nature 1931, 127, 741. [Google Scholar] [CrossRef]

- Fricke, J. Aerogels—A fascinating class of high-performance porous solids. In Proceedings of the Aerogels: Proceedings of the First International Symposium, Würzburg, Germany, 23–25 September 1985; Springer: Berlin/Heidelberg, Germany, 1986; pp. 2–19. [Google Scholar]

- Büttner, D.; Hümmer, E.; Fricke, J. Thermal conductivity of granular SiO2 aerogel. In Proceedings of the Aerogels: Proceedings of the First International Symposium, Würzburg, Germany, 23–25 September 1985; Springer: Berlin/Heidelberg, Germany, 1986; pp. 116–120. [Google Scholar]

- POLJAK, V. Poliimidni aerogelovi. Polim. časopis Za Plast. I Gumu 2013, 34, 63–66. [Google Scholar]

- Liu, T.; Liu, Y.; Wang, X.-D.; Shen, J.; Zhang, Z.; Xi, S.; Liu, Q. Preparation and application of polyimide aerogel materials. Chin. J. Eng. 2020, 42, 39–47. [Google Scholar] [CrossRef]

- Pierre, A.C.; Pajonk, G.M. Chemistry of Aerogels and Their Applications. Chem. Rev. 2002, 102, 4243–4266. [Google Scholar] [CrossRef]

- Norris, P.M.; Shrinivasan, S. Aerogels: Unique material, fascinating properties and unlimited applications. Annu. Rev. Heat Transf. 2005, 14, 385–408. [Google Scholar] [CrossRef]

- Li, X.; Guo, Z.; Yang, P.; Zhao, B.; Li, J.; Yin, M.; Liu, W.; Luo, C.; Zhang, L. Regulating porous microstructure of polyimide aerogels toward efficient shape memory performance. Polymer 2024, 307, 127224. [Google Scholar] [CrossRef]

- Zhang, L.; Sun, L.; Nie, H.; Zhang, R.; Wang, B.; Zhang, H. Effect of porosity and pore heterogeneity on heat transfer performance of polyimide aerogels. Mater. Today Commun. 2024, 40, 110105. [Google Scholar] [CrossRef]

- Chen, Z.; Chen, J.; Hou, X.; Chen, L. Mechanically robust and thermal-insulated polyimide aerogel films by polymerization-regulated strategy for flexible thermal protection. Chem. Eng. J. 2024, 496, 154251. [Google Scholar] [CrossRef]

- Liu, C.; Wang, M.; Zhao, X.; Yang, C.; Wei, R.; Zeng, W.; Ding, F.; Zhang, S.; Lei, Y. High-Temperature Resistant Polyimide Aerogels with Extreme Condition Tolerance Constructed by In Situ Skeleton Encapsulation Growth. Adv. Funct. Mater. 2025, 35, 2500881. [Google Scholar] [CrossRef]

- Chen, J.; Hou, X.; Chen, Z.; Chen, L.; Nie, S.; Zhu, S.; Liu, T.; Chen, L.; Zhang, R. Double-Crosslinked Organic–Inorganic Hybrid Polyimide Aerogel Composites with Ultra-Robust Toughness for Foldable Mechanical-Thermal-Coupled Protection. Adv. Funct. Mater. 2025, 35, 2420717. [Google Scholar] [CrossRef]

- Meng, Y.; Xue, J.; Huang, W.; Liu, L.; Ding, Y.; Yang, X.; Chen, Z.; Yang, Y. Aramid nanofibers/polyimide aerogel with multi-dimensional structure for noise reduction and thermal insulation. Compos. Sci. Technol. 2025, 266, 111181. [Google Scholar] [CrossRef]

- Bheekhun, N.; Abu Talib, A.R.; Hassan, M.R. Aerogels in aerospace: An overview. Adv. Mater. Sci. Eng. 2013, 2013, 406065. [Google Scholar] [CrossRef]

- Randall, J.P.; Meador, M.A.B.; Jana, S.C. Tailoring mechanical properties of aerogels for aerospace applications. ACS Appl. Mater. Interfaces 2011, 3, 613–626. [Google Scholar] [CrossRef]

- García-González, C.A.; Budtova, T.; Durães, L.; Erkey, C.; Del Gaudio, P.; Gurikov, P.; Koebel, M.; Liebner, F.; Neagu, M.; Smirnova, I. An Opinion Paper on Aerogels for Biomedical and Environmental Applications. Molecules 2019, 24, 1815. [Google Scholar] [CrossRef]

- Maleki, H.; Durães, L.; García-González, C.A.; del Gaudio, P.; Portugal, A.; Mahmoudi, M. Synthesis and biomedical applications of aerogels: Possibilities and challenges. Adv. Colloid Interface Sci. 2016, 236, 1–27. [Google Scholar] [CrossRef] [PubMed]

- Zhao, J.; Yang, X.; Yang, Y.; Liu, L.; Lin, Y.; Xie, L.; Chai, X.; Xu, K.; Du, G.; Zhang, L. Biomass polyamine-functionalized nanocellulose-loaded covalent organic framework to construct composite aerogels for highly efficient removal of Cr (VI) and methyl orange. Chem. Eng. J. 2024, 486, 150282. [Google Scholar] [CrossRef]

- Guo, J.; Fu, S.; Deng, Y.; Xu, X.; Laima, S.; Liu, D.; Zhang, P.; Zhou, J.; Zhao, H.; Yu, H. Hypocrystalline ceramic aerogels for thermal insulation at extreme conditions. Nature 2022, 606, 909–916. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Huang, Z.; Wang, Y.; Hai, G.; Huang, W.-H.; Chang, C.-C.; Yeh, M.-H.; Lai, F.; Zhang, N.; Liu, T. High-Entropy Metallene Aerogels: A New Balancer for* H Production and Consumption in Nitrate Reduction Reaction. Angew. Chem. Int. Ed. 2025, 64, e202505156. [Google Scholar] [CrossRef]

- Cao, M.; Liu, B.-W.; Zhang, L.; Peng, Z.-C.; Zhang, Y.-Y.; Wang, H.; Zhao, H.-B.; Wang, Y.-Z. Fully biomass-based aerogels with ultrahigh mechanical modulus, enhanced flame retardancy, and great thermal insulation applications. Compos. Part B Eng. 2021, 225, 109309. [Google Scholar] [CrossRef]

- Qin, B.; Yu, Z.-L.; Huang, J.; Meng, Y.-F.; Chen, R.; Chen, Z.; Yu, S.-H. A Petrochemical-Free Route to Superelastic Hierarchical Cellulose Aerogel. Angew. Chem. Int. Ed. 2023, 62, e202214809. [Google Scholar] [CrossRef]

- Chang, X.; Wu, F.; Cheng, X.; Zhang, H.; He, L.; Li, W.; Yin, X.; Yu, J.; Liu, Y.T.; Ding, B. Multiscale interpenetrated/interconnected network design confers all-carbon aerogels with unprecedented thermomechanical properties for thermal insulation under extreme environments. Adv. Mater. 2024, 36, 2308519. [Google Scholar] [CrossRef]

- Luo, B.; Cai, C.; Liu, T.; Meng, X.; Zhuang, X.; Liu, Y.; Gao, C.; Chi, M.; Zhang, S.; Wang, J. Multiscale structural nanocellulosic triboelectric aerogels induced by hofmeister effect. Adv. Funct. Mater. 2023, 33, 2306810. [Google Scholar] [CrossRef]

- Niu, Z.; Qu, F.; Chen, F.; Ma, X.; Chen, B.; Wang, L.; Xu, M.; Wang, S.; Jin, L.; Zhang, C.; et al. Multifunctional Integrated Organic–Inorganic-Metal Hybrid Aerogel for Excellent Thermal Insulation and Electromagnetic Shielding Performance. Nano-Micro Lett. 2024, 16, 200. [Google Scholar] [CrossRef]

- Ma, J.-W.; Zeng, F.-R.; Lin, X.-C.; Wang, Y.-Q.; Ma, Y.-H.; Jia, X.-X.; Zhang, J.-C.; Liu, B.-W.; Wang, Y.-Z.; Zhao, H.-B. A photoluminescent hydrogen-bonded biomass aerogel for sustainable radiative cooling. Science 2024, 385, 68–74. [Google Scholar] [CrossRef]

- Aghabararpour, M.; Mohsenpour, M.; Motahari, S. Effect of crosslinker molecular structure on mechanical and thermal properties of resorcinol formaldehyde aerogel. Mater. Res. Express 2019, 6, 075059. [Google Scholar] [CrossRef]

- Pekala, R.W. Organic aerogels from the polycondensation of resorcinol with formaldehyde. J. Mater. Sci. 1989, 24, 3221–3227. [Google Scholar] [CrossRef]

- Wang, L.; Feng, J.; Jiang, Y.; Zhang, S.; Li, L.; Feng, J. Facile fabrication of hydrophobic polyvinylpolysilsesquioxane aerogels with improved optical properties. J. Sol-Gel Sci. Technol. 2020, 94, 88–97. [Google Scholar] [CrossRef]

- Bi, H.; Chen, I.-W.; Lin, T.; Huang, F. A New Tubular Graphene Form of a Tetrahedrally Connected Cellular Structure. Adv. Mater. 2015, 27, 5943–5949. [Google Scholar] [CrossRef]

- Bryning, M.B.; Milkie, D.E.; Islam, M.F.; Hough, L.A.; Kikkawa, J.M.; Yodh, A.G. Carbon Nanotube Aerogels. Adv. Mater. 2007, 19, 661–664. [Google Scholar] [CrossRef]

- Worsley, M.A.; Kucheyev, S.O.; Satcher, J.H., Jr.; Hamza, A.V.; Baumann, T.F. Mechanically robust and electrically conductive carbon nanotube foams. Appl. Phys. Lett. 2009, 94, 073115. [Google Scholar] [CrossRef]

- Zhao, X.; Yao, W.; Gao, W.; Chen, H.; Gao, C. Wet-Spun Superelastic Graphene Aerogel Millispheres with Group Effect. Adv. Mater. 2017, 29, 1701482. [Google Scholar] [CrossRef]

- Tseng, P.; Napier, B.; Zhao, S.; Mitropoulos, A.N.; Applegate, M.B.; Marelli, B.; Kaplan, D.L.; Omenetto, F.G. Directed assembly of bio-inspired hierarchical materials with controlled nanofibrillar architectures. Nat. Nanotechnol. 2017, 12, 474–480. [Google Scholar] [CrossRef]

- Rodríguez-Dorado, R.; López-Iglesias, C.; García-González, C.A.; Auriemma, G.; Aquino, R.P.; Del Gaudio, P. Design of Aerogels, Cryogels and Xerogels of Alginate: Effect of Molecular Weight, Gelation Conditions and Drying Method on Particles’ Micromeritics. Molecules 2019, 24, 1049. [Google Scholar] [CrossRef]

- Takeshita, S.; Sadeghpour, A.; Malfait, W.J.; Konishi, A.; Otake, K.; Yoda, S. Formation of Nanofibrous Structure in Biopolymer Aerogel during Supercritical CO2 Processing: The Case of Chitosan Aerogel. Biomacromolecules 2019, 20, 2051–2057. [Google Scholar] [CrossRef]

- Li, Z.; Zhong, L.; Zhang, T.; Qiu, F.; Yue, X.; Yang, D. Sustainable, Flexible, and Superhydrophobic Functionalized Cellulose Aerogel for Selective and Versatile Oil/Water Separation. ACS Sustain. Chem. Eng. 2019, 7, 9984–9994. [Google Scholar] [CrossRef]

- Wang, S.; Ding, R.; Liang, G.; Zhang, W.; Yang, F.; Tian, Y.; Yu, J.; Zhang, S.; Ding, B. Direct synthesis of polyimide curly nanofibrous aerogels for high-performance thermal insulation under extreme temperature. Adv. Mater. 2024, 36, 2313444. [Google Scholar] [CrossRef]

- Yao, K.; Jiang, S.; Li, S.; Zhang, C.; Hou, H. Solvothermal imidization to polyimide composite aerogels by vacuum drying. Compos. Commun. 2023, 38, 101503. [Google Scholar] [CrossRef]

- Xu, X.; Zhang, Q.; Hao, M.; Hu, Y.; Lin, Z.; Peng, L.; Wang, T.; Ren, X.; Wang, C.; Zhao, Z. Double-negative-index ceramic aerogels for thermal superinsulation. Science 2019, 363, 723–727. [Google Scholar] [CrossRef] [PubMed]

- Su, L.; Jia, S.; Ren, J.; Lu, X.; Guo, S.-W.; Guo, P.; Cai, Z.; Lu, D.; Niu, M.; Zhuang, L. Strong yet flexible ceramic aerogel. Nat. Commun. 2023, 14, 7057. [Google Scholar] [CrossRef] [PubMed]

- Xu, X.; Fu, S.; Guo, J.; Li, H.; Huang, Y.; Duan, X. Elastic ceramic aerogels for thermal superinsulation under extreme conditions. Mater. Today 2021, 42, 162–177. [Google Scholar] [CrossRef]

- Cheng, X.; Liu, Y.-T.; Si, Y.; Yu, J.; Ding, B. Direct synthesis of highly stretchable ceramic nanofibrous aerogels via 3D reaction electrospinning. Nat. Commun. 2022, 13, 2637. [Google Scholar] [CrossRef] [PubMed]

- Tan, C.; Fung, B.M.; Newman, J.K.; Vu, C. Organic aerogels with very high impact strength. Adv. Mater. 2001, 13, 644–646. [Google Scholar] [CrossRef]

- Lu, X.; Arduini-Schuster, M.; Kuhn, J.; Nilsson, O.; Fricke, J.; Pekala, R. Thermal conductivity of monolithic organic aerogels. Science 1992, 255, 971–972. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Xiang, S.; Cao, S.; Zhang, J.; Ouyang, G.; Chen, L.; Su, C.-Y. A synthetic route to ultralight hierarchically micro/mesoporous Al (III)-carboxylate metal-organic aerogels. Nat. Commun. 2013, 4, 1774. [Google Scholar] [CrossRef]

- Wang, C.; Eisenreich, F.; Tomović, Ž. Aerogel-To-Sol-To-Aerogel (ASA) Process for Recycling, Repairing, Reprogramming of High-Performance Organic Aerogels. Adv. Funct. Mater. 2024, 34, 2314447. [Google Scholar] [CrossRef]

- Hu, H.; Wang, J.; Li, C.; Xu, J.; Li, L. Enhanced thermal insulation of polyimide aerogels in extreme environments tailored by rigid-flexible coupling synergy. Compos. Commun. 2025, 53, 102225. [Google Scholar] [CrossRef]

- Ram, G.; Bachhar, N. Overview of organic–inorganic hybrid aerogels. In Hybrid Aerogels: Energy and Environmental Applications; De Gruyter Brill: Berlin, Germany, 2024; p. 67. [Google Scholar]

- Li, D.; Ye, Q.; Zhao, D.; Li, H.; Chen, C.; Qian, G.; Yang, J. Lightweight and strong toughness of polyimide/SiO2 composite aerogels with super-high working temperature for high-performance thermal insulation and flame-resistant application. J. Mater. Sci. 2024, 59, 15283–15297. [Google Scholar] [CrossRef]

- Yu, D.; Xue, T.; Ma, Z.; Hu, Z.; Long, L.; Miao, Y.-E.; Fan, W.; Liu, T. 3D printed polyimide/silica composite aerogels for customizable thermal insulation from −50 °C to 1300 °C. Chin. J. Polym. Sci. 2024, 42, 936–945. [Google Scholar] [CrossRef]

- Yang, J.; Qian, X.; Yang, J.; Lu, J.; Han, D.; Fan, C.; Shi, T.; Jiang, Z.; Zhang, Z.; Qin, L. Additive-Free Aerogel 3D Printing Using Ultra-Low Storage Modulus Inks. Adv. Funct. Mater. 2025, 35, 2423739. [Google Scholar] [CrossRef]

- Gui, Y.; Fei, Z.; Zhao, S.; Zhang, Z.; Shao, H.; Chen, J.; Li, K.; Du, H.; Yang, Z. High-strength and multifunctional honeycomb polyimide aerogel fabricated by a freeze casting-assisted extrusion printing and building block-assembly strategy for sound absorbing metamaterials. Addit. Manuf. 2023, 77, 103799. [Google Scholar] [CrossRef]

- Cheng, Q.; Sheng, Z.; Ding, Y.; Li, Y.; Zhang, X. 3D printed colloidal aerogels: Principle, process, performance, and perspective. Prog. Mater. Sci. 2025, 152, 101456. [Google Scholar] [CrossRef]

- Feng, J.; Su, B.-L.; Xia, H.; Zhao, S.; Gao, C.; Wang, L.; Ogbeide, O.; Feng, J.; Hasan, T. Printed aerogels: Chemistry, processing, and applications. Chem. Soc. Rev. 2021, 50, 3842–3888. [Google Scholar] [CrossRef] [PubMed]

- Gibson, I.; Rosen, D.; Stucker, B.; Khorasani, M.; Rosen, D.; Stucker, B.; Khorasani, M. Additive Manufacturing Technologies; Springer: Berlin/Heidelberg, Germany, 2021; Volume 17. [Google Scholar]

- Daghigh, V.; Daghigh, H.; Harrison, R. High-Temperature Polyimide Composites—A Review on Polyimide Types, Manufacturing, and Mechanical and Thermal Behavior. J. Compos. Sci. 2025, 9, 526. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, F.; Medarametla, S.P.; Li, H.; Zhou, C.; Lin, D. 3D printing of graphene aerogels. Small 2016, 12, 1702–1708. [Google Scholar] [CrossRef] [PubMed]

- Li, V.C.-F.; Dunn, C.K.; Zhang, Z.; Deng, Y.; Qi, H.-J. Direct ink write (DIW) 3D printed cellulose nanocrystal aerogel structures. Sci. Rep. 2017, 7, 8018. [Google Scholar] [CrossRef]

- Chandrasekaran, S.; Lin, D.; Li, Y.; Worsley, M.A. Aerogels, additive manufacturing, and energy storage. Joule 2023, 7, 866–883. [Google Scholar] [CrossRef]

- Sivaraman, D.; Nagel, Y.; Siqueira, G.; Chansoria, P.; Avaro, J.; Neels, A.; Nyström, G.; Sun, Z.; Wang, J.; Pan, Z. Additive Manufacturing of Nanocellulose Aerogels with Structure-Oriented Thermal, Mechanical, and Biological Properties. Adv. Sci. 2024, 11, 2307921. [Google Scholar] [CrossRef]

- Barrulas, R.V.; Corvo, M.C. Rheology in product development: An insight into 3D printing of hydrogels and aerogels. Gels 2023, 9, 986. [Google Scholar] [CrossRef]

- Zhu, C.; Han, T.Y.-J.; Duoss, E.B.; Golobic, A.M.; Kuntz, J.D.; Spadaccini, C.M.; Worsley, M.A. Highly compressible 3D periodic graphene aerogel microlattices. Nat. Commun. 2015, 6, 6962. [Google Scholar] [CrossRef]

- Lewis, J.A. Direct ink writing of 3D functional materials. Adv. Funct. Mater. 2006, 16, 2193–2204. [Google Scholar] [CrossRef]

- Lewis, J.A.; Smay, J.E.; Stuecker, J.; Cesarano, J. Direct ink writing of three-dimensional ceramic structures. J. Am. Ceram. Soc. 2006, 89, 3599–3609. [Google Scholar] [CrossRef]

- Nguyen, B.N.; Meador, M.A.B.; Scheiman, D.; McCorkle, L. Polyimide aerogels using triisocyanate as cross-linker. ACS Appl. Mater. Interfaces 2017, 9, 27313–27321. [Google Scholar] [CrossRef] [PubMed]

- Meador, M.A.B.; Malow, E.J.; Silva, R.; Wright, S.; Quade, D.; Vivod, S.L.; Guo, H.; Guo, J.; Cakmak, M. Mechanically strong, flexible polyimide aerogels cross-linked with aromatic triamine. ACS Appl. Mater. Interfaces 2012, 4, 536–544. [Google Scholar] [CrossRef] [PubMed]

- Meador, M.A.B.; Alemán, C.R.; Hanson, K.; Ramirez, N.; Vivod, S.L.; Wilmoth, N.; McCorkle, L. Polyimide aerogels with amide cross-links: A low cost alternative for mechanically strong polymer aerogels. ACS Appl. Mater. Interfaces 2015, 7, 1240–1249. [Google Scholar] [CrossRef] [PubMed]

- Vivod, S.L.; Meador, M.A.B.; Pugh, C.; Wilkosz, M.; Calomino, K.; McCorkle, L. Toward improved optical transparency of polyimide aerogels. ACS Appl. Mater. Interfaces 2020, 12, 8622–8633. [Google Scholar] [CrossRef]

- Meador, M.A.B.; McMillon, E.; Sandberg, A.; Barrios, E.; Wilmoth, N.G.; Mueller, C.H.; Miranda, F.A. Dielectric and other properties of polyimide aerogels containing fluorinated blocks. ACS Appl. Mater. Interfaces 2014, 6, 6062–6068. [Google Scholar] [CrossRef]

- Guo, H.; Meador, M.A.B.; McCorkle, L.; Quade, D.J.; Guo, J.; Hamilton, B.; Cakmak, M.; Sprowl, G. Polyimide aerogels cross-linked through amine functionalized polyoligomeric silsesquioxane. ACS Appl. Mater. Interfaces 2011, 3, 546–552. [Google Scholar] [CrossRef]

- Yuan, R.; Zhou, Y.; Lu, X.; Dong, Z.; Lu, Q. Rigid and flexible polyimide aerogels with less fatigue for use in harsh conditions. Chem. Eng. J. 2022, 428, 131193. [Google Scholar] [CrossRef]

- Feng, C.; Yu, S.-S. 3D Printing of Thermal Insulating Polyimide/Cellulose Nanocrystal Composite Aerogels with Low Dimensional Shrinkage. Polymers 2021, 13, 3614. [Google Scholar] [CrossRef]

- Cipriani, C.E.; Dornbusch, D.A.; Vivod, S.L.; Pentzer, E.B. Direct ink writing of polyimide aerogels for battery thermal mitigation. RSC Appl. Polym. 2024, 2, 71–86. [Google Scholar] [CrossRef]

- Saadi, M.; Maguire, A.; Pottackal, N.T.; Thakur, M.S.H.; Ikram, M.M.; Hart, A.J.; Ajayan, P.M.; Rahman, M.M. Direct ink writing: A 3D printing technology for diverse materials. Adv. Mater. 2022, 34, 2108855. [Google Scholar] [CrossRef] [PubMed]

- Das, A.; Gilmer, E.L.; Biria, S.; Bortner, M.J. Importance of polymer rheology on material extrusion additive manufacturing: Correlating process physics to print properties. ACS Appl. Polym. Mater. 2021, 3, 1218–1249. [Google Scholar] [CrossRef]

- Li, L.; Lin, Q.; Tang, M.; Duncan, A.J.; Ke, C. Advanced polymer designs for direct-ink-write 3D printing. Chem. A Eur. J. 2019, 25, 10768–10781. [Google Scholar] [CrossRef]

- Bean, R.H.; Rau, D.A.; Williams, C.B.; Long, T.E. Rheology guiding the design and printability of aqueous colloidal composites for additive manufacturing. J. Vinyl Addit. Technol. 2023, 29, 607–616. [Google Scholar] [CrossRef]

- Elbadawi, M.; Rivera-Armenta, J.; Cruz, B. Polymeric additive manufacturing: The necessity and utility of rheology. In Polymer Rheology; Rivera-Armenta, J.L., Cruz, B.A.S., Eds.; IntechOpen: London, UK, 2018; Volume 10, pp. 43–64. [Google Scholar]

- del-Mazo-Barbara, L.; Ginebra, M.-P. Rheological characterisation of ceramic inks for 3D direct ink writing: A review. J. Eur. Ceram. Soc. 2021, 41, 18–33. [Google Scholar] [CrossRef]

- Wang, Z.; Smith, D.E. Rheology effects on predicted fiber orientation and elastic properties in large scale polymer composite additive manufacturing. J. Compos. Sci. 2018, 2, 10. [Google Scholar] [CrossRef]

- Rau, D.A.; Bortner, M.J.; Williams, C.B. A rheology roadmap for evaluating the printability of material extrusion inks. Addit. Manuf. 2023, 75, 103745. [Google Scholar] [CrossRef]

- Yang, J.; Lu, J.; Xi, S.; Wang, H.; Han, D.; Fan, C.; Zhang, Z.; Shen, J.; Zhou, B.; Du, A. Direct 3D print polyimide aerogels for synergy management of thermal insulation, gas permeability and light absorption. J. Mater. Chem. A 2023, 11, 21272–21284. [Google Scholar] [CrossRef]

- Fu, Z.; Yu, D.; Xue, T.; Zhang, X.; Fan, W. 3D printed polyimide-based composite aerogels with shape memory and thermal insulation properties. Compos. Commun. 2025, 56, 102335. [Google Scholar] [CrossRef]

- Li, M.; Wu, T.; Zhao, Z.; Li, L.; Shan, T.; Wu, H.; Zboray, R.; Bernasconi, F.; Cui, Y.; Hu, P.; et al. Multiscale Manufacturing of Recyclable Polyimide Composite Aerogels. Adv. Mater. 2025, 37, 2411599. [Google Scholar] [CrossRef]

- Xue, T.; Yuan, S.; Yang, Y.; Wan, X.; Yang, Y.; Mu, X.; Zhang, L.; Zhang, C.; Fan, W.; Liu, T. Freezing-Assisted Direct Ink Writing of Customized Polyimide Aerogels with Controllable Micro-and Macro-Structures for Thermal Insulation. Adv. Funct. Mater. 2025, 35, 2417734. [Google Scholar] [CrossRef]

- Geng, M.; Liu, T.; Zhang, X.; Xue, T.; Fan, W.; Liu, T. 4D Printed Shape Memory Polyimide Composite Aerogels with High Recovery Stress for Load Driving. ACS Appl. Mater. Interfaces 2025, 17, 14615–14622. [Google Scholar] [CrossRef]

- Guo, Y.; Qin, S.; Yao, X.; Liu, S.; Ji, Z.; Ma, Z.; Wang, X. Preparation of polyimide aerogels by freeze-extraction and chemical imidization for 3D printing. J. Appl. Polym. Sci. 2022, 139, e52891. [Google Scholar] [CrossRef]

- Tafreshi, O.A.; Sheydaeian, E.; Dughaish, M.A.B.; Ghaffari-Mosanenzadeh, S.; Saadatnia, Z.; Naguib, H.E. Additive manufacturing of aerogels: Recent advancements and innovations. Appl. Mater. Today 2025, 45, 102800. [Google Scholar] [CrossRef]

- De France, K.; Zeng, Z.; Wu, T.; Nyström, G. Functional materials from nanocellulose: Utilizing structure–property relationships in bottom-up fabrication. Adv. Mater. 2021, 33, 2000657. [Google Scholar] [CrossRef]

- Kam, D.; Chasnitsky, M.; Nowogrodski, C.; Braslavsky, I.; Abitbol, T.; Magdassi, S.; Shoseyov, O. Direct CRYO writing of aerogels via 3D Printing of aligned cellulose nanocrystals inspired by the plant cell wall. Colloids Interfaces 2019, 3, 46. [Google Scholar] [CrossRef]

- Cheng, Q.; Liu, Y.; Lyu, J.; Lu, Q.; Zhang, X.; Song, W. 3D printing-directed auxetic Kevlar aerogel architectures with multiple functionalization options. J. Mater. Chem. A 2020, 8, 14243–14253. [Google Scholar] [CrossRef]

- Kam, D.; Layani, M.; BarkaiMinerbi, S.; Orbaum, D.; Abrahami BenHarush, S.; Shoseyov, O.; Magdassi, S. Additive manufacturing of 3D structures composed of wood materials. Adv. Mater. Technol. 2019, 4, 1900158. [Google Scholar] [CrossRef]

- Hua, T.; Guo, H.; Qin, J.; Wu, Q.; Li, L.; Qian, B. 3D printing lamellar Ti 3 C 2 T x MXene/graphene hybrid aerogels for enhanced electromagnetic interference shielding performance. RSC Adv. 2022, 12, 24980–24987. [Google Scholar] [CrossRef]

- Guo, H.; Hua, T.; Qin, J.; Wu, Q.; Wang, R.; Qian, B.; Li, L.; Shi, X. A new strategy of 3D printing lightweight lamellar graphene aerogels for electromagnetic interference shielding and piezoresistive sensor applications. Adv. Mater. Technol. 2022, 7, 2101699. [Google Scholar] [CrossRef]

- López-Iglesias, C.; Casielles, A.M.; Altay, A.; Bettini, R.; Alvarez-Lorenzo, C.; García-González, C.A. From the printer to the lungs: Inkjet-printed aerogel particles for pulmonary delivery. Chem. Eng. J. 2019, 357, 559–566. [Google Scholar] [CrossRef]

- Lübkemann, F.; Miethe, J.F.; Steinbach, F.; Rusch, P.; Schlosser, A.; Zámbó, D.; Heinemeyer, T.; Natke, D.; Zok, D.; Dorfs, D. Patterning of nanoparticle-based aerogels and xerogels by inkjet printing. Small 2019, 15, 1902186. [Google Scholar] [CrossRef]

- Põldsalu, I.; Harjo, M.; Tamm, T.; Uibu, M.; Peikolainen, A.-L.; Kiefer, R. Inkjet-printed hybrid conducting polymer-activated carbon aerogel linear actuators driven in an organic electrolyte. Sens. Actuators B Chem. 2017, 250, 44–51. [Google Scholar] [CrossRef]

- Koo, J.; Kim, J.W.; Kim, M.; Yoon, S.; Shim, J.H. Inkjet printing of silica aerogel for fabrication of 2-D patterned thermal insulation layers. Int. J. Precis. Eng. Manuf. Green Technol. 2021, 8, 445–451. [Google Scholar] [CrossRef]

- Remuiñán-Pose, P.; López-Iglesias, C.; Iglesias-Mejuto, A.; Mano, J.F.; García-González, C.A.; Rial-Hermida, M.I. Preparation of vancomycin-loaded aerogels implementing inkjet printing and superhydrophobic surfaces. Gels 2022, 8, 417. [Google Scholar] [CrossRef] [PubMed]

- García-Torres, B.; Aguilar-Elguezabal, A.; Román-Aguirre, M.; Álvarez-Contreras, L. Synthesis of silica aerogels microspheres prepared by ink jet printing and dried at ambient pressure without surface hydrophobization. Mater. Chem. Phys. 2016, 172, 32–38. [Google Scholar] [CrossRef]

- Tang, A.; Li, J.; Li, J.; Zhao, S.; Liu, W.; Liu, T.; Wang, J.; Liu, Y. Nanocellulose/PEGDA aerogel scaffolds with tunable modulus prepared by stereolithography for three-dimensional cell culture. J. Biomater. Sci. Polym. Ed. 2019, 30, 797–814. [Google Scholar] [CrossRef]

- Tetik, H.; Wang, Y.; Sun, X.; Cao, D.; Shah, N.; Zhu, H.; Qian, F.; Lin, D. Additive manufacturing of 3D aerogels and porous scaffolds: A review. Adv. Funct. Mater. 2021, 31, 2103410. [Google Scholar] [CrossRef]

- Farrell, E.S.; Ganonyan, N.; Cooperstein, I.; Moshkovitz, M.Y.; Amouyal, Y.; Avnir, D.; Magdassi, S. 3D-printing of ceramic aerogels by spatial photopolymerization. Appl. Mater. Today 2021, 24, 101083. [Google Scholar] [CrossRef]

- Maines, E.M.; Porwal, M.K.; Ellison, C.J.; Reineke, T.M. Sustainable advances in SLA/DLP 3D printing materials and processes. Green Chem. 2021, 23, 6863–6897. [Google Scholar] [CrossRef]

- Steyrer, B.; Busetti, B.; Harakály, G.; Liska, R.; Stampfl, J. Hot Lithography vs. room temperature DLP 3D-printing of a dimethacrylate. Addit. Manuf. 2018, 21, 209–214. [Google Scholar] [CrossRef]

- Borrello, J.; Nasser, P.; Iatridis, J.C.; Costa, K.D. 3D printing a mechanically-tunable acrylate resin on a commercial DLP-SLA printer. Addit. Manuf. 2018, 23, 374–380. [Google Scholar] [CrossRef]

- Kafle, A.; Luis, E.; Silwal, R.; Pan, H.M.; Shrestha, P.L.; Bastola, A.K. 3D/4D printing of polymers: Fused deposition modelling (FDM), selective laser sintering (SLS), and stereolithography (SLA). Polymers 2021, 13, 3101. [Google Scholar] [CrossRef]

- Ma, X.L. Research on application of SLA technology in the 3D printing technology. Appl. Mech. Mater. 2013, 401, 938–941. [Google Scholar] [CrossRef]

- Shahzad, A.; Lazoglu, I. Direct ink writing (DIW) of structural and functional ceramics: Recent achievements and future challenges. Compos. Part B Eng. 2021, 225, 109249. [Google Scholar] [CrossRef]

- Rau, D.A.; Williams, C.B.; Bortner, M.J. Rheology and printability: A survey of critical relationships for direct ink write materials design. Progress in Materials Science 2023, 140, 101188. [Google Scholar] [CrossRef]

- Sevcik, M.J.; Bjerke, G.; Wilson, F.; Kline, D.J.; Morales, R.C.; Fletcher, H.E.; Guan, K.; Grapes, M.D.; Seetharaman, S.; Sullivan, K.T. Extrusion parameter control optimization for DIW 3D printing using image analysis techniques. Prog. Addit. Manuf. 2024, 9, 517–528. [Google Scholar] [CrossRef]

- Dai, J.; Ogbeide, O.; Macadam, N.; Sun, Q.; Yu, W.; Li, Y.; Su, B.-L.; Hasan, T.; Huang, X.; Huang, W. Printed gas sensors. Chem. Soc. Rev. 2020, 49, 1756–1789. [Google Scholar] [CrossRef] [PubMed]

- Naficy, S.; Jalili, R.; Aboutalebi, S.H.; Gorkin Iii, R.A.; Konstantinov, K.; Innis, P.C.; Spinks, G.M.; Poulin, P.; Wallace, G.G. Graphene oxide dispersions: Tuning rheology to enable fabrication. Mater. Horiz. 2014, 1, 326–331. [Google Scholar] [CrossRef]

- Zhao, S.; Siqueira, G.; Drdova, S.; Norris, D.; Ubert, C.; Bonnin, A.; Galmarini, S.; Ganobjak, M.; Pan, Z.; Brunner, S.; et al. Additive manufacturing of silica aerogels. Nature 2020, 584, 387–392. [Google Scholar] [CrossRef]

- Li, V.C.; Mulyadi, A.; Dunn, C.K.; Deng, Y.; Qi, H.J. Direct ink write 3D printed cellulose nanofiber aerogel structures with highly deformable, shape recoverable, and functionalizable properties. ACS Sustain. Chem. Eng. 2018, 6, 2011–2022. [Google Scholar] [CrossRef]

- Iglesias-Mejuto, A.; Malandain, N.; Ferreira-Gonçalves, T.; Ardao, I.; Reis, C.P.; Laromaine, A.; Roig, A.; García-González, C.A. Cellulose-in-cellulose 3D-printed bioaerogels for bone tissue engineering. Cellulose 2024, 31, 515–534. [Google Scholar] [CrossRef]

- Guo, Y.; Shen, K.; Chen, Z.; Chen, S.; Wu, C.; Wu, Q.; Liu, A.; Yang, P.; Ma, Z.; Yang, L. 3D-printed fumed silica/sodium alginate aerogels for thermal insulation. Ceram. Int. 2025, 51, 17492–17502. [Google Scholar] [CrossRef]

- Han, D.; Yang, J.; Lu, J.; Yang, J.; Qian, X.; Shen, J.; Wu, G.; Zhang, Z.; Zhou, B.; Du, A. Direct Ink Writing of Multifunctional Silica-Reinforced Zirconia Aerogels via Electrostatic Attraction-Assisted Co-Gelation. Langmuir 2025, 41, 23519–23528. [Google Scholar] [CrossRef] [PubMed]

- Yang, Q.; Yu, H.; Wang, X.; Li, Y.; Li, D.; Guo, F. New 3D Ink Formulation Comprising a Nanocellulose Aerogel Based on Electrostatic Repulsion and Sol-Gel Transition. Polymers 2025, 17, 1065. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, N.T.T.; Nguyen, L.M.; Nguyen, T.T.T.; Nguyen, D.T.C.; Van Tran, T. Synthesis strategies, regeneration, cost analysis, challenges and future prospects of bacterial cellulose-based aerogels for water treatment: A review. Chemosphere 2024, 362, 142654. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Wang, B.; Qi, J.; Liu, T.; Feng, Y.; Liu, C.; Shen, C. Eco-friendly bacterial cellulose/MXene aerogel with excellent photothermal and electrothermal conversion capabilities for efficient separation of crude oil/seawater mixture. Carbohydr. Polym. 2024, 336, 122140. [Google Scholar] [CrossRef]

- Ruan, J.-Q.; Xie, K.-Y.; Wan, J.-N.; Chen, Q.-Y.; Zuo, X.; Li, X.; Wu, X.; Fei, C.; Yao, S. Effects of Freeze-Drying Processes on the Acoustic Absorption Performance of Sustainable Cellulose Nanocrystal Aerogels. Gels 2024, 10, 141. [Google Scholar] [CrossRef]

- Jiang, L.; Zhang, W.; Zhang, R.; Hu, Z.; Yang, J.; Ma, X.; Fan, J. High latent heat phase change materials composites based on MXene/biomass-derived cellulose nanocrystalline aerogel for solar-thermal energy conversion and storage. Ceram. Int. 2024, 50, 17428–17438. [Google Scholar] [CrossRef]

- Ramachandran, T.; Roy, N.; Hegazy, H.; Yahia, I.; Kumar, Y.A.; Moniruzzaman, M.; Joo, S.W. From graphene aerogels to efficient energy storage: Current developments and future prospects. J. Alloys Compd. 2025, 1010, 177248. [Google Scholar] [CrossRef]

- Liang, K.; Zhang, H.; Wang, Q.; Cheng, Z. PVA-assisted graphene aerogels composite phase change materials with anisotropic porous structure for thermal management. Carbon 2024, 230, 119639. [Google Scholar] [CrossRef]

- Guo, Y.; Duan, Y.; Liu, X.; Tian, J.; Wen, N.; Fan, Z.; Pan, L. Construction of rGO/MOF-derived CNTs aerogel with multiple losses for multi-functional efficient electromagnetic wave absorber. Carbon 2024, 230, 119591. [Google Scholar] [CrossRef]

- Cao, X.; Liu, Y.; Sun, Q.; Che, T.; Wu, C.; Yang, Y. CNTs/PVA composite aerogel for efficient microwave and acoustic absorption. Compos. Struct. 2024, 329, 117805. [Google Scholar] [CrossRef]

- Yang, T.; Xu, J.; Lv, S. HNTs Improve Flame Retardant and Thermal Insulation of the PVA/CA Composite Aerogel. ACS Omega 2024, 9, 40608–40617. [Google Scholar] [CrossRef]

- Wu, X.; Gu, X.; Tai, J.; Tang, J.; Yuan, K.; Liu, L.; Zheng, Y.; Altaf, A.; Shen, X.; Cui, S. Facile synthesis of the NiFe bimetallic alloy wrapped on the porous N-doped graphene aerogel via thermal reduction and electronic structure modulation for boosting oxygen evolution reaction. J. Power Sources 2025, 633, 236430. [Google Scholar] [CrossRef]

- Tao, Z.; He, W.; Xu, X.; Fan, J.; Zhang, Z.; Yang, Z.; Liu, Y.; Ma, H.; Qian, M.; Yang, M. Three-dimensional macroporous rGO-aerogel-based composite phase-change materials with high thermal storage capacity and enhanced thermal conductivity. Materials 2023, 16, 4878. [Google Scholar] [CrossRef] [PubMed]

- Wei, P.; Cipriani, C.; Hsieh, C.-M.; Kamani, K.; Rogers, S.; Pentzer, E. Go with the flow: Rheological requirements for direct ink write printability. J. Appl. Phys. 2023, 134, 100701. [Google Scholar] [CrossRef]

- Wu, S.; Du, A.; Xiang, Y.; Liu, M.; Li, T.; Shen, J.; Zhang, Z.; Li, C.; Zhou, B. Silica-aerogel-powders “jammed” polyimide aerogels with excellent hydrophobicity and conversion to ultra-light polyimide aerogel. RSC Adv. 2016, 6, 58268–58278. [Google Scholar] [CrossRef]

- Ma, Z.; Xue, T.; Wali, Q.; Miao, Y.-E.; Fan, W.; Liu, T. Direct ink writing of polyimide/bacterial cellulose composite aerogel for thermal insulation. Compos. Commun. 2023, 39, 101528. [Google Scholar] [CrossRef]

- Wu, T.; Ganobjak, M.; Siqueira, G.; Zeng, Z.; Li, M.; Filimonova, E.; Saghamanesh, S.; Bonnin, A.; Sivaraman, D.; Yip, J.; et al. 3D Printed Polyimide Nanocomposite Aerogels for Electromagnetic Interference Shielding and Thermal Management. Adv. Mater. Technol. 2023, 8, 2202155. [Google Scholar] [CrossRef]

- Wang, L.; Feng, J.; Jiang, Y.; Lu, D.; Men, J.; Luo, Y.; Wang, X.; Feng, J. Ultraviolet-assisted direct-write printing strategy towards polyorganosiloxane-based aerogels with freeform geometry and outstanding thermal insulation performance. Chem. Eng. J. 2023, 455, 140818. [Google Scholar] [CrossRef]

- Zeng, L.; Ling, S.; Du, D.; He, H.; Li, X.; Zhang, C. Direct Ink Writing 3D Printing for High-Performance Electrochemical Energy Storage Devices: A Minireview. Adv. Sci. 2023, 10, 2303716. [Google Scholar] [CrossRef] [PubMed]

- Kantaros, A.; Ganetsos, T.; Petrescu, F.I.T.; Ungureanu, L.M.; Munteanu, I.S. Post-production finishing processes utilized in 3D printing technologies. Processes 2024, 12, 595. [Google Scholar] [CrossRef]

- Yang, G.; Sun, Y.; Li, M.; Ou, K.; Fang, J.; Fu, Q. Direct-ink-writing (DIW) 3D printing functional composite materials based on supra-molecular interaction. Compos. Sci. Technol. 2021, 215, 109013. [Google Scholar] [CrossRef]

- Reiner, M. Rheology. In Elasticity and Plasticity/Elastizität und Plastizität; Springer: Berlin/Heidelberg, Germany, 1958; pp. 434–550. [Google Scholar]

- De Smedt, S.; Attaianese, B.; Cardinaels, R. Direct ink writing of particle-based multiphase materials: From rheology to functionality. Curr. Opin. Colloid Interface Sci. 2025, 75, 101889. [Google Scholar] [CrossRef]

- Agrawal, R.; García-Tuñón, E. Interplay between yielding,‘recovery’, and strength of yield stress fluids for direct ink writing: New insights from oscillatory rheology. Soft Matter 2024, 20, 7429–7447. [Google Scholar] [CrossRef] [PubMed]

- Krall, E.A.; Mettry, M.Y.; Fears, T.M. Formulation of PI Aerogels with 3-D Printing Applications; Lawrence Livermore National Lab.(LLNL): Livermore, CA, USA, 2022.

- Li, X.; Dong, G.; Liu, Z.; Zhang, X. Polyimide aerogel fibers with superior flame resistance, strength, hydrophobicity, and flexibility made via a universal sol–gel confined transition strategy. ACS Nano 2021, 15, 4759–4768. [Google Scholar] [CrossRef]

- Cui, Y.; Yang, K.; Zhang, F.; Lyu, Y.; Zhang, Q.; Zhang, B. Ultra-light MXene/CNTs/PI aerogel with neat arrangement for electromagnetic wave absorption and photothermal conversion. Compos. Part A Appl. Sci. Manuf. 2022, 158, 106986. [Google Scholar] [CrossRef]

- Faghri, A.; Zhang, Y. Fundamentals of Multiphase Heat Transfer and Flow; Springer: Berlin/Heidelberg, Germany, 2020. [Google Scholar]

- Venkataraman, M.; Sözcü, S.; Militký, J. Radiative Heat Transfer Properties of Fiber–Aerogel Composites for Thermal Insulation. Gels 2025, 11, 538. [Google Scholar] [CrossRef]

- Ma, J.; Lü, Y.; Wen, H.; Zhang, Y.; Wei, W.; Qin, G.; Zhao, Y.; Jiang, L.; Liu, L.; Liu, S. Facile synthesis of super-thermal insulating polyimide aerogel-like films. iScience 2022, 25, 105641. [Google Scholar] [CrossRef]

- Guo, L.; Deng, H.; Ma, T.; Chen, K.; Tian, C.; Qiang, X.; Liang, S.; Wang, J.; Song, N. Ultralight and robust polyimide aerogels with tunable porous structures based on cation-π interactions for superior thermal insulation. Chem. Eng. J. 2025, 503, 158267. [Google Scholar] [CrossRef]

- Garimella, S.V.; Persoons, T.; Weibel, J.A.; Gektin, V. Electronics thermal management in information and communications technologies: Challenges and future directions. IEEE Trans. Compon. Packag. Manuf. Technol. 2016, 7, 1191–1205. [Google Scholar] [CrossRef]

- Wang, L.; Yang, J.; Cheng, W.; Zou, J.; Zhao, D. Progress on polymer composites with low dielectric constant and low dielectric loss for high-frequency signal transmission. Front. Mater. 2021, 8, 774843. [Google Scholar] [CrossRef]

- Grill, A.; Gates, S.M.; Ryan, T.E.; Nguyen, S.V.; Priyadarshini, D. Progress in the development and understanding of advanced low k and ultralow k dielectrics for very large-scale integrated interconnects—State of the art. Appl. Phys. Rev. 2014, 1, 011306. [Google Scholar] [CrossRef]

- Wang, L.; Liu, C.; Shen, S.; Xu, M.; Liu, X. Low dielectric constant polymers for high speed communication network. Adv. Ind. Eng. Polym. Res. 2020, 3, 138–148. [Google Scholar] [CrossRef]

- Isari, A.A.; Ghaffarkhah, A.; Hashemi, S.A.; Wuttke, S.; Arjmand, M. Structural design for EMI shielding: From underlying mechanisms to common pitfalls. Adv. Mater. 2024, 36, 2310683. [Google Scholar] [CrossRef] [PubMed]

- Mao, Y.; Sheng, Y.; Fan, Z.; Yang, J.; Liu, J.; Tang, C.; Fu, S. Atmospheric Pressure Dried Discontinuous Pore Gradient Structured CNF-Based Aerogel for Ultra-Low Reflection, Broadband, and Super-High EMI Shielding. Adv. Funct. Mater. 2025, 35, 2421492. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, X.; Hao, S.; Qiao, J.; Wang, Z.; Wu, L.; Liu, J.; Wang, F. Nitrogen-doped magnetic-dielectric-carbon aerogel for high-efficiency electromagnetic wave absorption. Nano-Micro Lett. 2024, 16, 16. [Google Scholar] [CrossRef]

- Liu, H.; Shao, Y.; Wang, Z.; Jiang, L.; Mou, B.; Tian, N.; You, C.; Li, Y. Mechanically robust and multifunctional Ti3C2Tx MXene composite aerogel for broadband EMI shielding. Carbon 2024, 221, 118948. [Google Scholar] [CrossRef]

- Shen, M.; Li, X.; Qi, J.; Sun, J.; Cao, W.; Xiu, H.; Li, J.; Zhang, Z.; Zheng, X.; Shang, Z. Magnetic metal-loaded wood carbon aerogel composites for electromagnetic shielding and microwave absorption. Compos. Part A Appl. Sci. Manuf. 2025, 198, 109070. [Google Scholar] [CrossRef]

- Chen, M.; Zhu, J.; Zhang, K.; Zhou, H.; Gao, Y.; Fan, J.; Chen, R.; Wang, H.-L. Carbon nanofiber/polyaniline composite aerogel with excellent electromagnetic interference shielding, low thermal conductivity, and extremely low heat release. Nano-Micro Lett. 2025, 17, 80. [Google Scholar] [CrossRef]

- Guo, P.; Su, L.; Jia, S.; Ni, Z.; Dai, Z.; Guo, J.; Wang, X.; Peng, K.; Wang, H. Strong SiC@ Carbon nanowire aerogel metamaterials for efficient electromagnetic interference shielding. Carbon 2024, 229, 119492. [Google Scholar] [CrossRef]

- Wu, Q.; Zeng, Z.; Xiao, L. From 2D graphene and MXene nanolayers to 3D biomimetic porous composite aerogels for electromagnetic interference shielding. Compos. Part A Appl. Sci. Manuf. 2024, 177, 107939. [Google Scholar] [CrossRef]

- Li, S.; Sun, Y.; Meng, F.; Jiang, X.; Yu, H. Lightweight Fe3O4/Fe/C/rGO multifunctional aerogel for efficient microwave absorption, electromagnetic interference shielding, hydrophobicity and thermal insulation. Chem. Eng. J. 2024, 498, 155405. [Google Scholar] [CrossRef]

- Liu, Y.; Li, T.; Chen, Y.; Yi, S.; Li, X.; Qi, Q.; Meng, F. Biomimetic dictyophora-inspired RGO/MXene aerogel films for synergistically enhanced EMI shielding and photothermal conversion performance. Carbon 2025, 245, 120788. [Google Scholar] [CrossRef]

- Ji, D.; Wang, Y.; He, C.; Cui, K.; Han, P.; Sun, N.; Li, Y. High-efficiency electromagnetic shielding based on multipolar effect in RGO/MXene aerogels decorated with ordered Fe3O4 cluster. Carbon 2024, 226, 119189. [Google Scholar] [CrossRef]

- Volksen, W.; Miller, R.D.; Dubois, G. Low dielectric constant materials. Chem. Rev. 2010, 110, 56–110. [Google Scholar] [CrossRef] [PubMed]

- Sole-Gras, M.; Ren, B.; Ryder, B.J.; Ge, J.; Huang, J.; Chai, W.; Yin, J.; Fuchs, G.E.; Wang, G.; Jiang, X. Vapor-induced phase-separation-enabled versatile direct ink writing. Nat. Commun. 2024, 15, 3058. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Wang, S.; Kong, X.; Li, M.; Zhang, L.; Gong, M.; Lin, X.; Wang, D. Room-temperature 3D printing of recyclable polyimide dielectrics for high-frequency antenna applications. Sustain. Mater. Technol. 2025, 45, e01431. [Google Scholar] [CrossRef]

- Zheng, Z.; Liu, H.; Wu, D.; Wang, X. Polyimide/MXene hybrid aerogel-based phase-change composites for solar-driven seawater desalination. Chem. Eng. J. 2022, 440, 135862. [Google Scholar] [CrossRef]

- Franco, P.; Cardea, S.; Tabernero, A.; De Marco, I. Porous aerogels and adsorption of pollutants from water and air: A review. Molecules 2021, 26, 4440. [Google Scholar] [CrossRef]

- Hou, Y.; Gao, M.; Bai, X.; Zhao, L.; Du, H.; Zhou, K. 3D printing of bio-inspired porous polymeric solar steam generators for efficient and sustainable desalination. Appl. Phys. Rev. 2024, 11, 031407. [Google Scholar] [CrossRef]

- Hu, E.; Zhu, Y.; Cheng, X.; Liu, Q.; Zhu, M. Recent progress on organic aerogels for sound absorption. Mater. Today Commun. 2024, 39, 109243. [Google Scholar] [CrossRef]

- Budtova, T.; Lokki, T.; Malakooti, S.; Rege, A.; Lu, H.; Milow, B.; Vapaavuori, J.; Vivod, S.L. Acoustic properties of aerogels: Current status and prospects. Adv. Eng. Mater. 2023, 25, 2201137. [Google Scholar] [CrossRef]

- Mazrouei-Sebdani, Z.; Begum, H.; Schoenwald, S.; Horoshenkov, K.V.; Malfait, W.J. A review on silica aerogel-based materials for acoustic applications. J. Non-Cryst. Solids 2021, 562, 120770. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, X.; Chen, F.; Tong, W.-S.; Zhang, Y.-H. A review on recent progress of research and applications for polyimide aerogels. In Polyimides: Synthesis, Applications and Research; Nova: Hauppauge, NY, USA, 2017; pp. 105–130. [Google Scholar]

- Muringayil Joseph, T.; Azat, S.; Kianfar, E.; Joshy, K.S.; Moini Jazani, O.; Esmaeili, A.; Ahmadi, Z.; Haponiuk, J.; Thomas, S. Identifying gaps in practical use of epoxy foam/aerogels: Review-solutions and prospects. Rev. Chem. Eng. 2025, 41, 269–308. [Google Scholar] [CrossRef]

- Arenas, J.P.; Crocker, M.J. Recent trends in porous sound-absorbing materials. Sound Vib. 2010, 44, 12–18. [Google Scholar]

| Composition of Aerogel | Drying Method and Post-Treatment After Drying | Applications | Ref. | |

|---|---|---|---|---|

| Main Raw Material | Additive | |||

| ODA and triethylamine (TEA), PMDA | CNCs | Freeze drying, thermal imidization | Thermal insulation | [73] |

| BC | [134] | |||

| ODA, 4,4′-Diphenoxydianiline (ODPA), 2-Dimethylamino ethanol (DMAE), TEA | - | Freezing-extraction, chemical imidization and thermal treatment | Aerospace applications | [88] |

| 2,2′-Dimethylbenzidine (DMBZ), 4,4′-hexafluoroisopropylidene di(phthalic anhydride) (6FDA), PMDA, 1,3,5-Triaminophenoxybenzene (TAB), TEA | - | Drying under reduced pressure | Battery thermal mitigation | [74] |

| 2,2′-dimethyl-[1,1′-biphenyl]-4,4′-diamine (DMBZ), Pyridine (PD), benzophenone-3,3′, 4,4′-tetracarboxylic dianhydride (BTDA) | CNTs | One-step chemical imidization | Thermal insulation, gas permeability and light absorption | [83] |

| ODA, DMBZ, 3,3′,4,4′-biphenyl tetracar boxylic dianhydride (BPDA) | SA | Chemical imidization and supercritical CO2 drying | Electromagnetic interference shielding and thermal management | [135] |

| BPDA, ODA, NMP | SA | Chemical imidization and supercritical CO2 drying | Thermal insulation | [136] |

| BPDA, ODA, NMP, TEA | - | Freeze drying, thermal imidization | Sound absorbing metamaterials | [53] |

| 2,2-Bis [4-(4-aminophenoxy)phenyl]propane (BAPP), 2,2-bis [4-(3,4-dicarboxyphenoxy) phenyl]propanedianhydride (BPADA) | SA | Freeze drying, thermal imidization | Shape memory and thermal insulation materials | [84] |

| Composition of Aerogel | Viscosity (Pa·s) | Storage Modulus G′ (Pa) | Loss Modulus G″ (Pa) | Yield Stress(Pa) | Ref. |

|---|---|---|---|---|---|

| PA/CNCs nanocomposites | 228–18,134 | ~103–104 | ~300–600 | >200 | [73] |

| PAs | 6.03 ± 1.52–9.93 ± 3.75 | <103 | <103 | - | [74] |

| PAs | - | <7 × 104 | - | - | [135] |

| PAs | <1.4 × 104 | 4.6 × 102–1.4 × 105 | - | - | [136] |

| PAs | 20–328 | ~1 × 103–2 × 103 | ~4 × 102–5 × 102 | - | [53] |

| PAs | 4 × 101–6 × 107 | ~1 × 101–9 × 103 | ~1 × 101–7 × 103 | - | [86] |

| PAs | - | - | - | - | [85] |

| PAs | - | - | - | - | [53] |

| PAs | - | 4 × 104 | - | 2700 | [51] |

| PAs | - | 2.9 × 103–1.34 × 104 | - | 433–3594 | [84] |

| PAs | - | 5.01 × 102–1.82 × 103 | - | 27–46 | [87] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, B.; Jiang, Q.; Jiang, J. Direct Ink Writing Additive Manufacturing of Polyimide Aerogels. Gels 2025, 11, 940. https://doi.org/10.3390/gels11120940

Chen B, Jiang Q, Jiang J. Direct Ink Writing Additive Manufacturing of Polyimide Aerogels. Gels. 2025; 11(12):940. https://doi.org/10.3390/gels11120940

Chicago/Turabian StyleChen, Bo, Qiyang Jiang, and Jianhu Jiang. 2025. "Direct Ink Writing Additive Manufacturing of Polyimide Aerogels" Gels 11, no. 12: 940. https://doi.org/10.3390/gels11120940

APA StyleChen, B., Jiang, Q., & Jiang, J. (2025). Direct Ink Writing Additive Manufacturing of Polyimide Aerogels. Gels, 11(12), 940. https://doi.org/10.3390/gels11120940